A kind of nuclear graphite material preparation method

A technology of nuclear graphite and petroleum coke powder, which is applied in the field of nuclear graphite material preparation, can solve the problems of expensive purification costs, achieve the effects of reducing impurities and boron equivalents, facilitating popularization and application, and less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

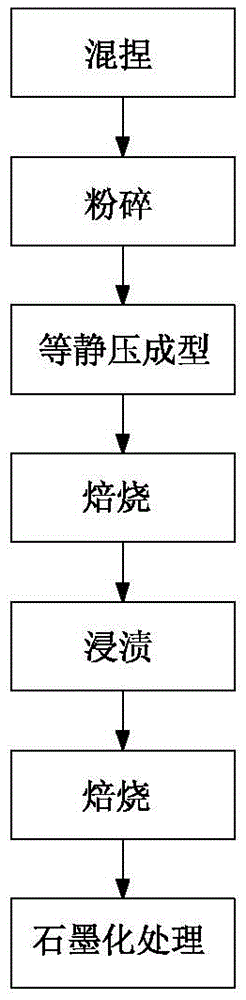

[0026] Please refer to figure 1 Shown, the present invention discloses a kind of nuclear graphite material preparation method, comprises the following steps:

[0027] (1) kneading

[0028] Put 30-70 parts by weight of petroleum coke powder and 70-30 parts by weight of asphalt powder into a kneader for 0.5-2 hours and knead at a temperature of 100-200 degrees. The particle size of the petroleum coke powder and asphalt powder is less than 20 um.

[0029] (2) Smash

[0030] The product obtained in step (1) is pulverized for the second time, and the particle size is not greater than 40 μm.

[0031] (3) Isostatic pressing

[0032] Put the product obtained in step (2) into a rubber mold, and then put it into an isostatic pressing molding machine for molding with a pressure of 100-300 MPa.

[0033] (4) Roasting

[0034] The product obtained in step (3) is roasted in an atmosphere furnace with halogens or halogenated hydrocarbons, the treatment temperature is 800-1100 ° C, and th...

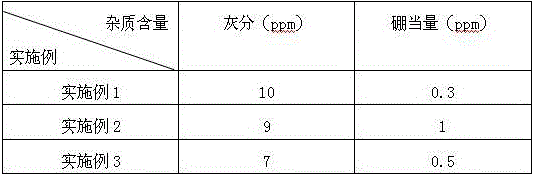

Embodiment 1

[0043] (1) kneading

[0044] Put 30 parts by weight of petroleum coke powder and 70 parts by weight of asphalt powder into a kneader for 0.5 h at a temperature of 100 degrees, and the particle diameters of the petroleum coke powder and asphalt powder are both less than 20 um.

[0045] (2) Smash

[0046] The product obtained in step (1) is pulverized for the second time, and the particle size is not greater than 40 μm.

[0047] (3) Isostatic pressing

[0048] Put the product obtained in step (2) into a rubber mold, and then put it into an isostatic molding machine for molding with a pressure of 100MPa.

[0049] (4) Roasting

[0050] The product obtained in step (3) is roasted in an atmosphere furnace with halogens or halogenated hydrocarbons at a temperature of 800°C. In this example, the halogens or halogenated hydrocarbons are F 2 .

[0051] (5) Dipping

[0052] The product obtained in step (4) is impregnated with pitch one or more times to deposit additional pitch coke...

Embodiment 2

[0058] (1) kneading

[0059] Put 35 parts by weight of petroleum coke powder and 65 parts by weight of asphalt powder into a kneader for 0.6 h at a temperature of 120 degrees. The particle size of the petroleum coke powder and asphalt powder are both less than 20 um.

[0060] (2) Smash

[0061] The product obtained in step (1) is pulverized for the second time, and the particle size is not greater than 40 μm.

[0062] (3) Isostatic pressing

[0063] Put the product obtained in step (2) into a rubber mold, and then put it into an isostatic molding machine for molding with a pressure of 150MPa.

[0064] (4) Roasting

[0065] The product obtained in step (3) is roasted in an atmosphere furnace with halogen or halogenated hydrocarbon at a temperature of 850°C. In this example, the halogen or halogenated hydrocarbon is Cl 2 .

[0066] (5) Dipping

[0067] The product obtained in step (4) is impregnated with pitch one or more times to deposit additional pitch coke into any ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com