Coal pitch quality-divided treatment method for preparing nuclear graphite material

A technology of quality separation treatment and coal tar pitch, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to reduce low value-added products, promote development, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

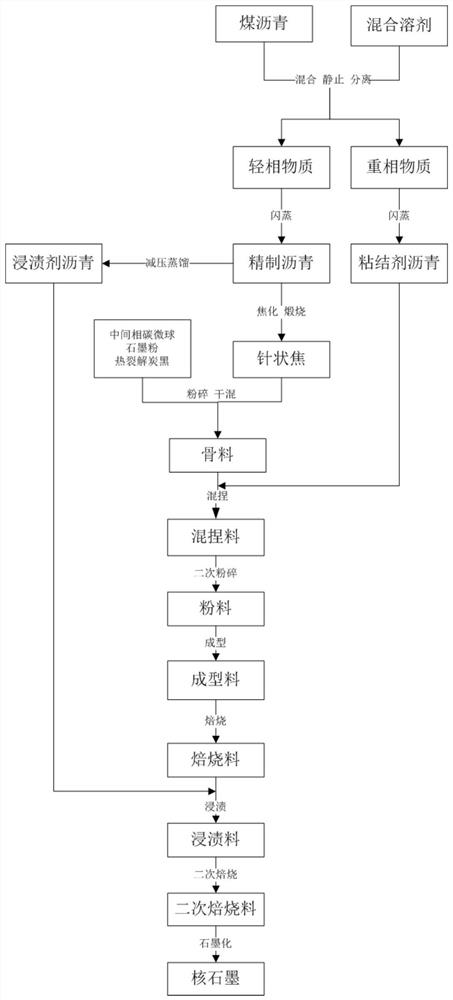

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below through specific examples, but the use and purpose of these exemplary embodiments are only used to exemplify the present invention, and do not constitute any form of any limitation to the actual protection scope of the present invention, nor will the present invention The scope of protection is limited to this.

[0033] 【Example】

[0034] A coal tar pitch separation treatment method for preparing nuclear graphite material, the method comprises the steps of:

[0035] (1) The mixture of kerosene and washing oil is used as mixed solvent and coal tar pitch to stir evenly in a mixing container, then left to stand and separated to obtain light phase material and heavy phase material;

[0036] (2) The light phase material is flashed at a vacuum degree of -0.07MPa and the tower top temperature is 110°C to obtain refined pitch; the heavy phase material is flashed at a vacuum degree of -0.09MPa and the tower top temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com