Nuclear graphite based on microcrystalline graphite as raw material and preparation method thereof

A technology of microcrystalline graphite and nuclear graphite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of no report and research of aphanitic graphite, and achieve favorable roasting and low isotropy ratio, the effect of high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a method for preparing nuclear graphite based on microcrystalline graphite as a raw material, comprising the following steps:

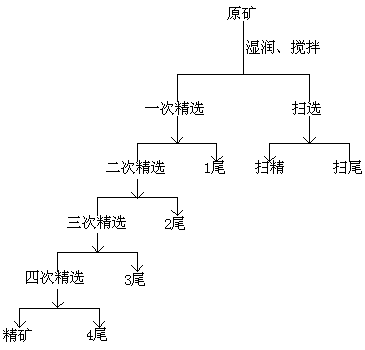

[0036] S1. Raw ore treatment: crush the microcrystalline graphite raw ore, and then carry out deep grinding on the microcrystalline graphite raw ore, and obtain the material with a fineness of -0.074mm through grinding, and the content of the material with a grinding fineness of -0.074mm accounts for 90% % of the raw ore samples are subjected to flotation, using a roughing process, four selections, and a sweeping process, followed by drying and magnetic separation to obtain microcrystalline graphite with a fixed carbon content of 90%;

[0037] In the raw ore treatment of this embodiment, the raw ore of microcrystalline graphite is Lutang graphite, wherein the moisture is 2.4%, the volatile matter is 2.99%, the ash content is 18.37%, and the carbon content is 78.64%;

[0038] S2. Purification by acid leaching:

...

Embodiment 2

[0053] The present embodiment provides a method for preparing nuclear graphite based on microcrystalline graphite as a raw material, comprising the following steps:

[0054] S1. Raw ore treatment: crush the microcrystalline graphite raw ore, and then carry out deep grinding on the microcrystalline graphite raw ore, and obtain the material with a fineness of -0.074mm through grinding, and the content of the material with a grinding fineness of -0.074mm accounts for 90% % of the raw ore samples are subjected to flotation, using a roughing process, four selections, and a sweeping process, followed by drying and magnetic separation to obtain microcrystalline graphite with a fixed carbon content of 90%;

[0055] In the raw ore treatment of this embodiment, the raw ore of microcrystalline graphite is Lutang graphite, wherein the moisture is 2.4%, the volatile matter is 2.99%, the ash content is 18.37%, and the carbon content is 78.64%;

[0056] S2. Purification by acid leaching:

...

Embodiment 3

[0068] The present embodiment provides a method for preparing nuclear graphite based on microcrystalline graphite as a raw material, comprising the following steps:

[0069] S1. Raw ore treatment: crush the microcrystalline graphite raw ore, and then carry out deep grinding on the microcrystalline graphite raw ore, and obtain the material with a fineness of -0.074mm through grinding, and the content of the material with a grinding fineness of -0.074mm accounts for 90% % of raw ore samples are subjected to flotation, such as figure 1 As shown, a roughing process is adopted for four times of selection and one sweeping process, followed by drying and magnetic separation to obtain microcrystalline graphite with a fixed carbon content of 90%;

[0070] In the raw ore treatment of this embodiment, the raw ore of microcrystalline graphite is Lutang graphite, wherein the moisture is 2.4%, the volatile matter is 2.99%, the ash content is 18.37%, and the carbon content is 78.64%;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com