Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good for roasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

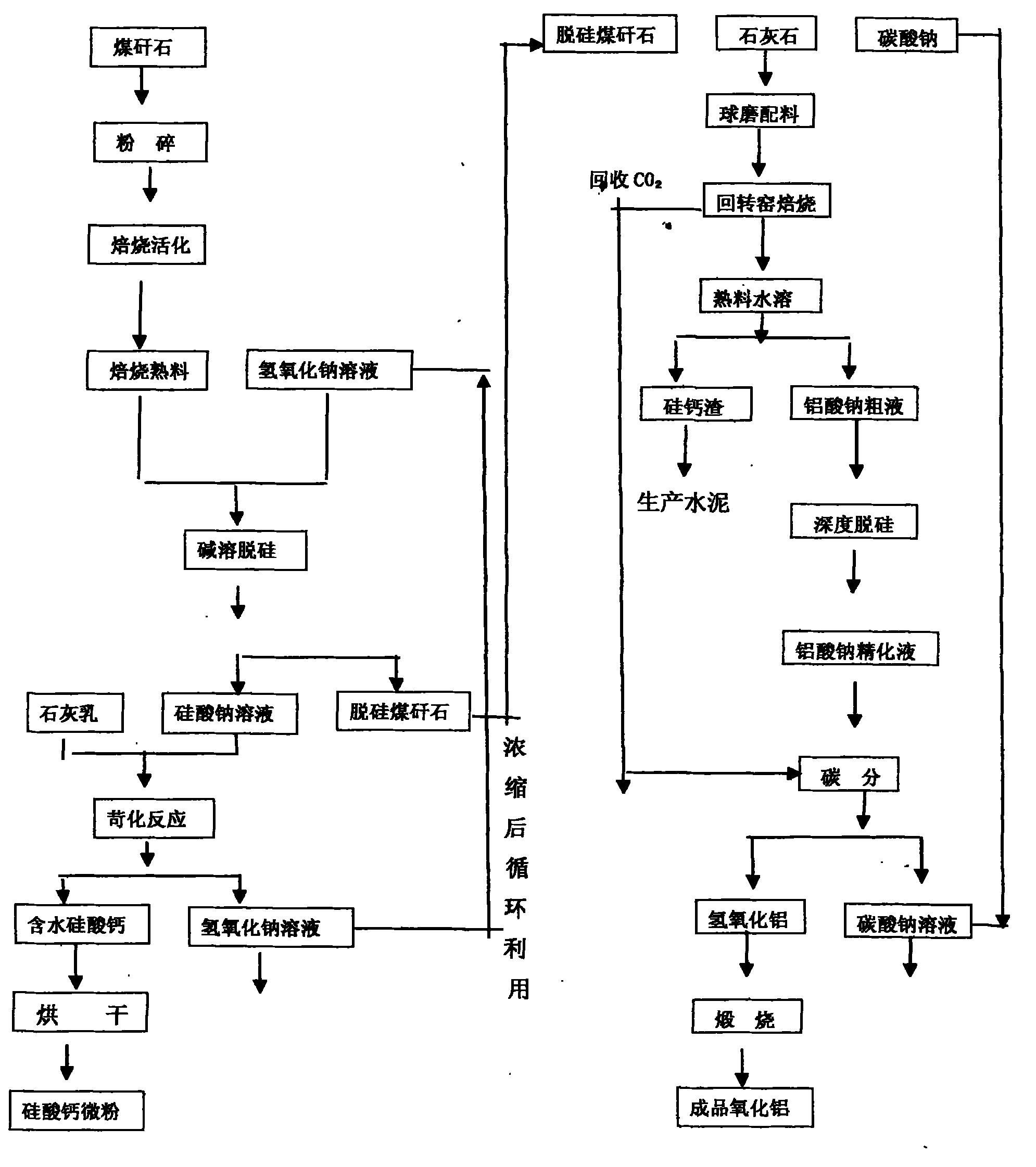

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

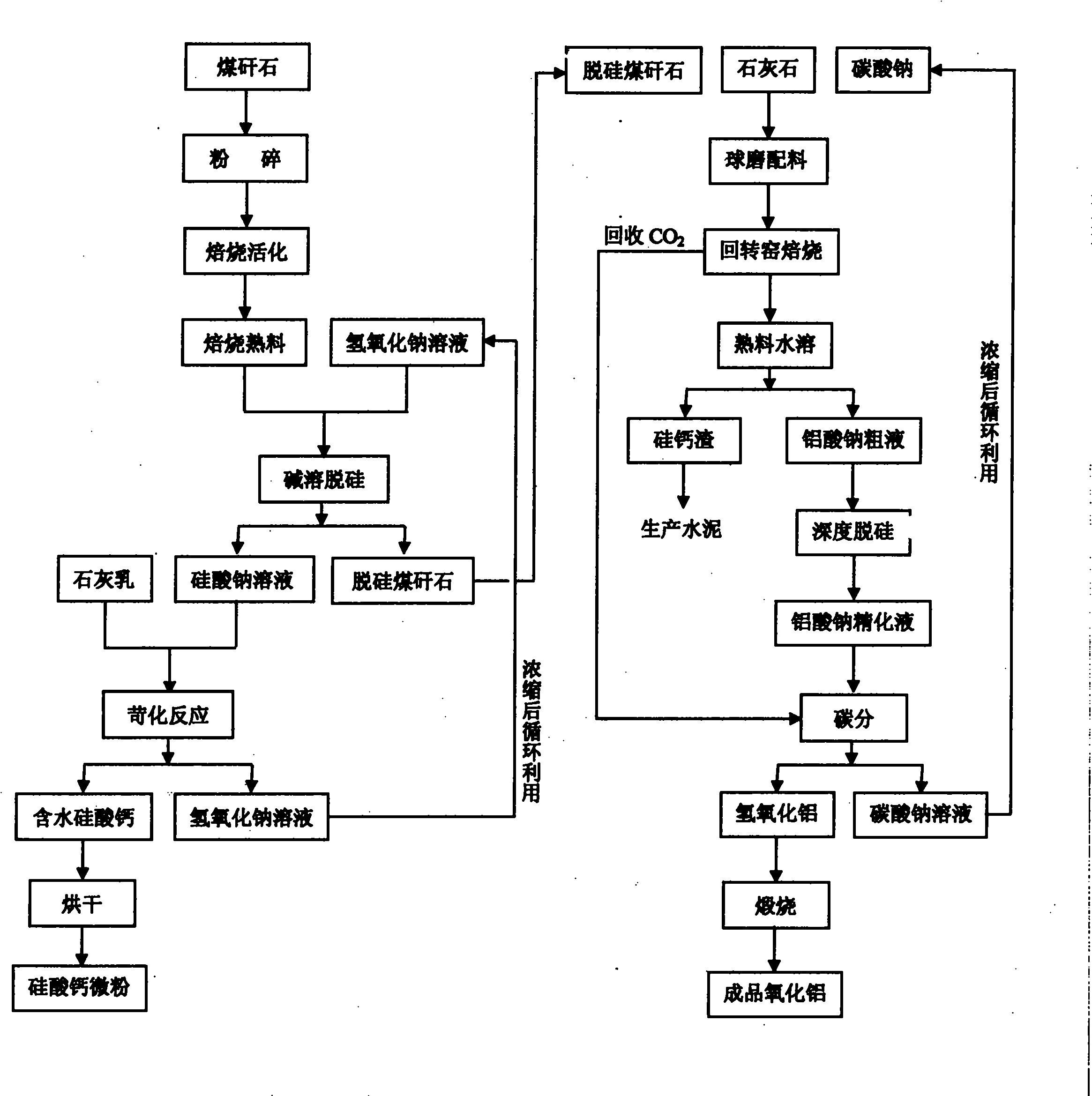

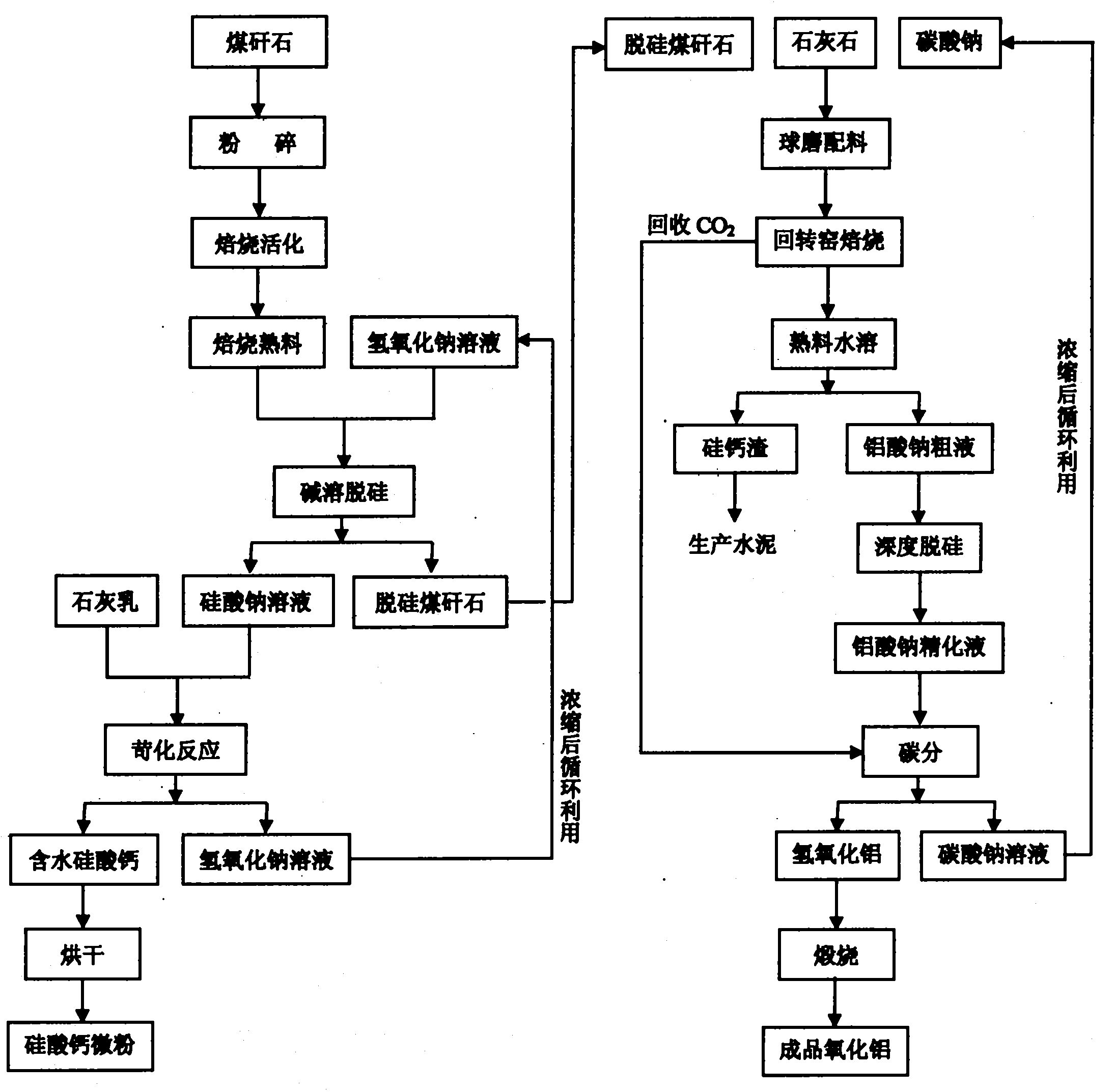

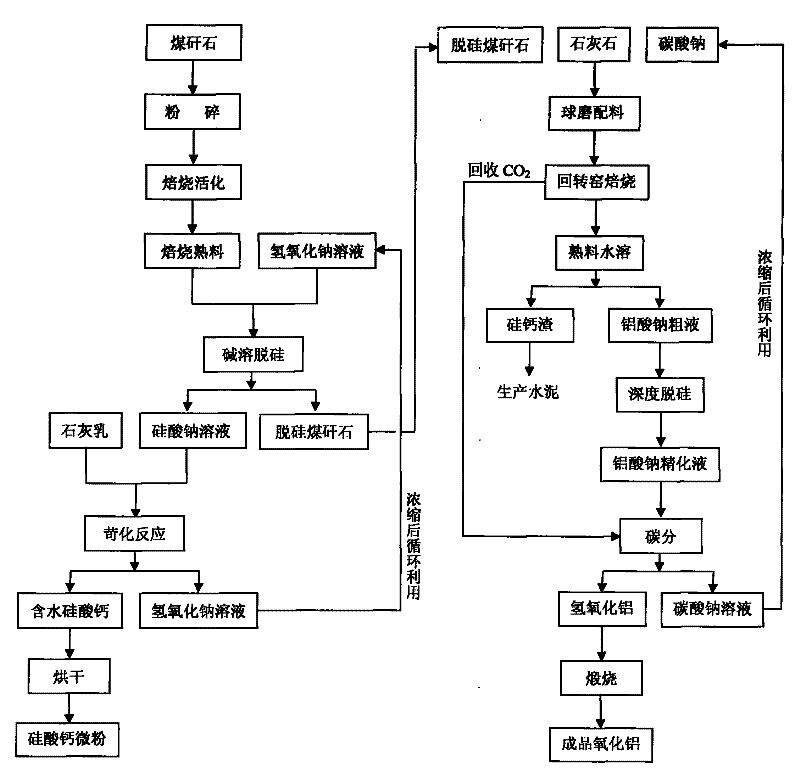

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

Light-weight ceramsites of riverway sludge and production method for same

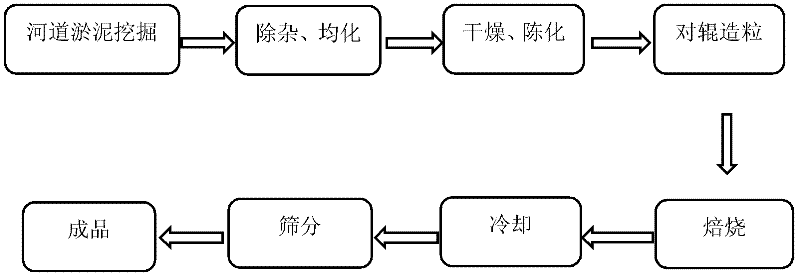

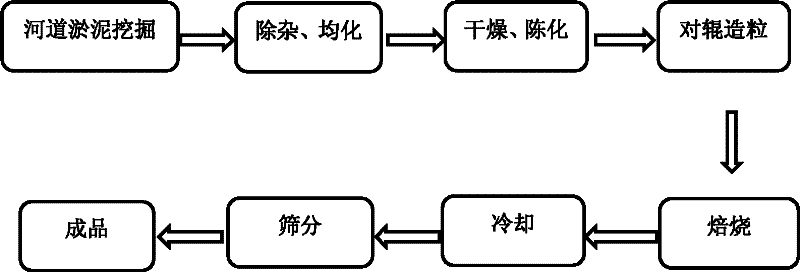

InactiveCN102515605AIncrease moisture contentReduce moisture contentSolid waste managementSocial benefitsSludge

The invention relates to a light-weight ceramsites of riverway sludge and a production method for the same. The light-weight ceramsites of riverway sludge disclosed by the invention are obtained by using riverway sludge as a main raw material, and then performing impurity removal and homogenization, drying and ageing, granulation, roasting and screening to prepare a finished product. The light-weight ceramsites of riverway sludge prepared by 100% of urban riverway sludge have a bulk density of 300-500 kg / m<3>, wherein a part of the riverway sludge can be replaced by other kinds of clay raw materials such as lake sludge and marsh sludge. The various performance indexes of the ceramsites industrially produced from riverway sludge achieve the requirements of the national standard GB2839-81 of clay ceramsites. In the light-weight ceramsites of riverway sludge and the production method for the same disclosed by the invention, riverway sludge is used for replacing clay to realize development and utilization for waste, and to protect farmland, so that great social benefits, economic benefits and environmental benefits are obtained.

Owner:TONGJI UNIV

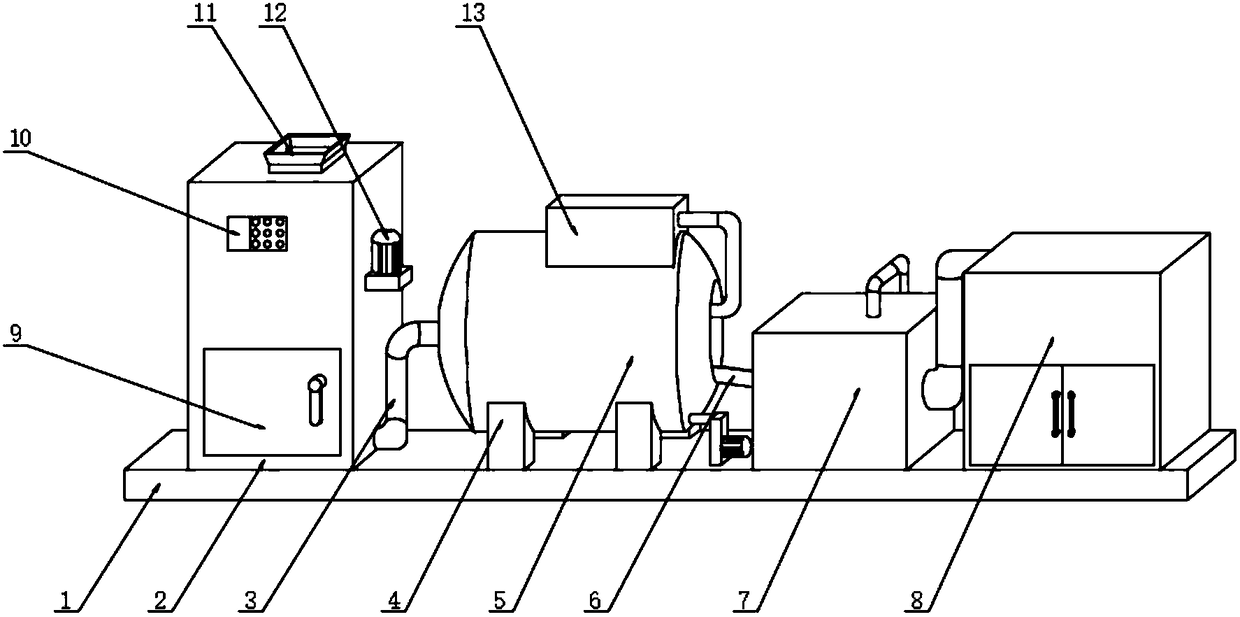

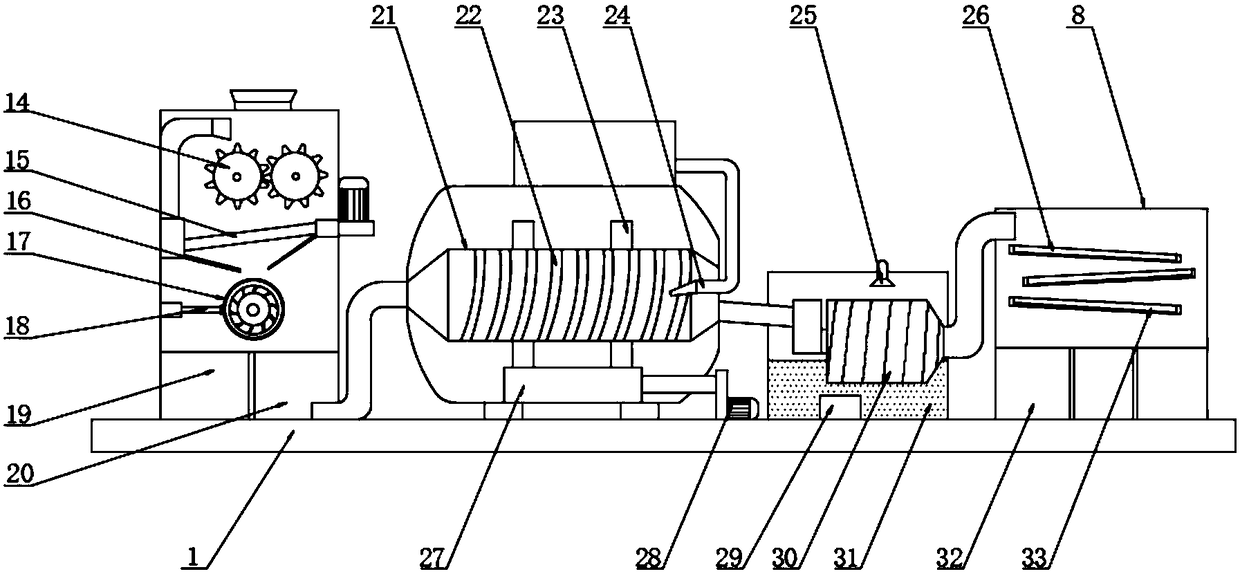

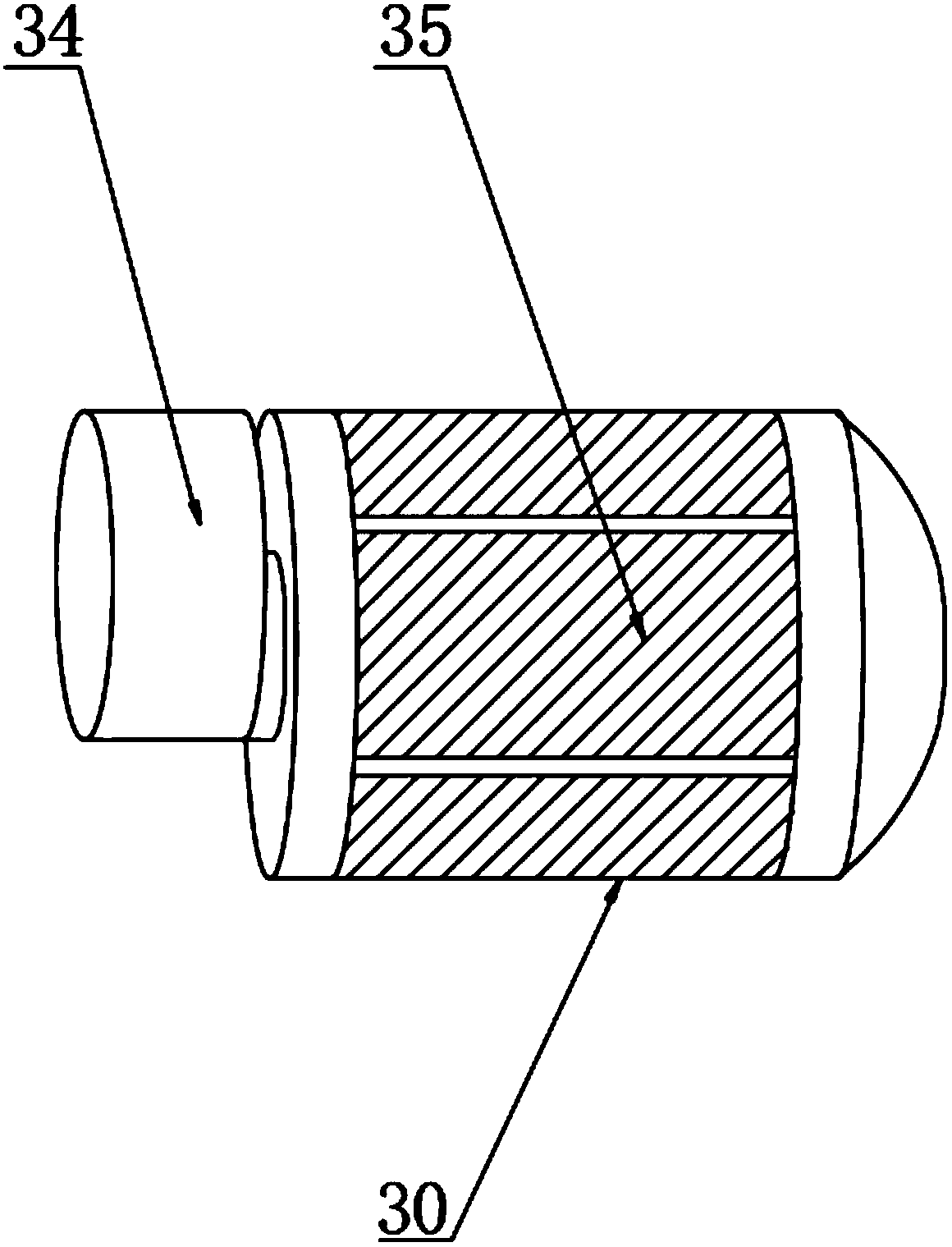

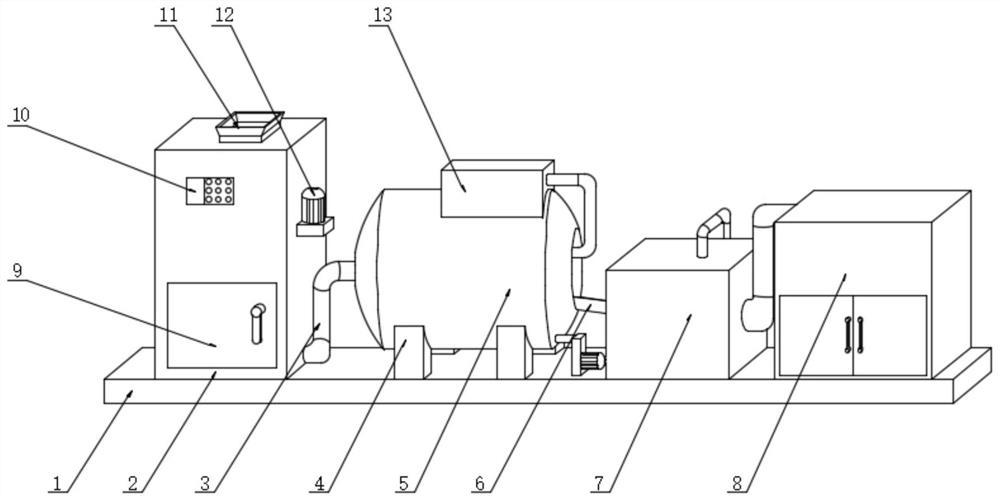

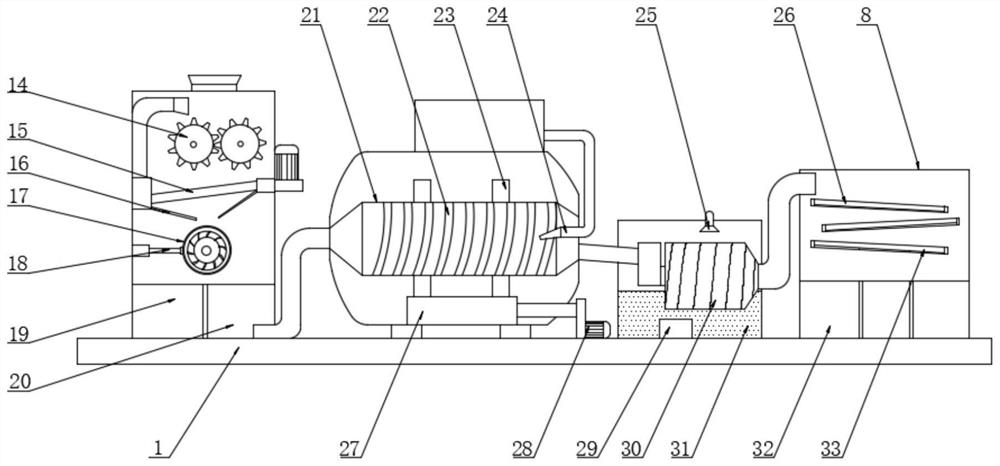

Industrial waste residue treatment equipment

ActiveCN108311207AEasy to crush and screenAvoid incomplete roastingSolid waste disposalTransportation and packagingHelical bladeToxic industrial waste

The invention discloses industrial waste residue treatment equipment, comprising a base, a crushing box, a packing auger delivery pipe, a supporting seat, a roasting drum, a delivery pipe, a washing box, a drying storage box, a box door, control buttons, a feed pipe, a first motor, a gas storage tank, a crushing roller, a vibrating screen plate, a blocking plate, a magnetic separation drum, a scraper blade, an iron-containing waste residue storage bin, a reject bin, a roasting roller, a helical blade, a transmission rack, a fire spray pipe, a nozzle, a vibration drying plate, a transmission case, a second motor, a water suction pump, a washing drum, cleaning fluid, a graded storage bin, a graded screening board, a material conveying bin, a washing net, an electromagnetic board, a smooth sleeve and a screen, wherein the crushing box is installed at one side of the top of the base, the feed pipe is arranged on the top of the crushing box, the control buttons are installed on the outer wall of one side of the crushing box, and the box door is connected under the control buttons by means of a hinge. The industrial waste residue treatment equipment has the advantages of being convenient for waste residue screening and uniform in waste residue roasting, and realizing graded screening and storing.

Owner:安徽中疆数字科技有限公司

Method for producing alkaline fertilizer from insoluble potassium-containing rock by kiln process

ActiveCN103086778AIncreased alkalinityReduce the temperatureFertilizer mixturesPotassiumPhosphogypsum

The invention discloses a method for producing an alkaline fertilizer from insoluble potassium-containing rock by a kiln process, belonging to the technical field of chemical production. The method comprises the following steps: mixing phosphate rock tailings or low-grade phosphate rock with the insoluble potassium-containing rock according to the weight ratio of 1:(0.4-0.9), further adding anthracite accounting for 3-8% of the total mixed weight, drying, grinding and further preparing a material block; and then placing into a kiln, roasting at the temperature of 1000-1200 DEG C for 30-150 minutes to prepare sintered clinker, finally performing water quenching, reducing the temperature of the sintered clinker to 400-700 DEG C, and draining, drying, crushing and grinding the sintered clinker after water quenching to prepare the alkaline fertilizer. According to the method disclosed by the invention, the roasting temperature is only 1000-1200 DEG C, the energy consumption is low, and the process is simple; and phosphogypsum is not used, SO2 gas causing serious pollution of air is not contained in tail gas, and the special treatment of the tail gas is not required.

Owner:KINGENTA NORSTERRA CHEM CO LTD

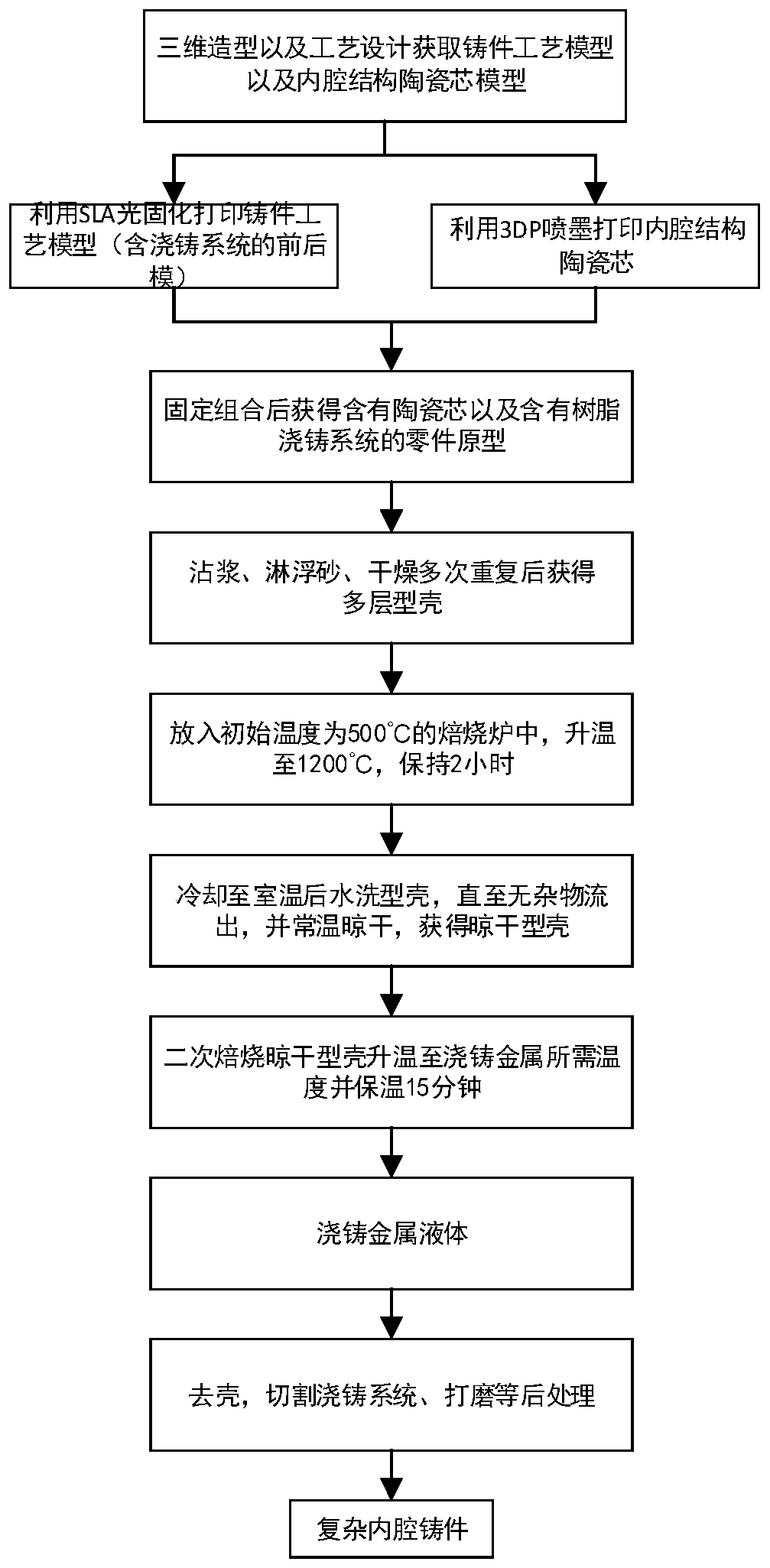

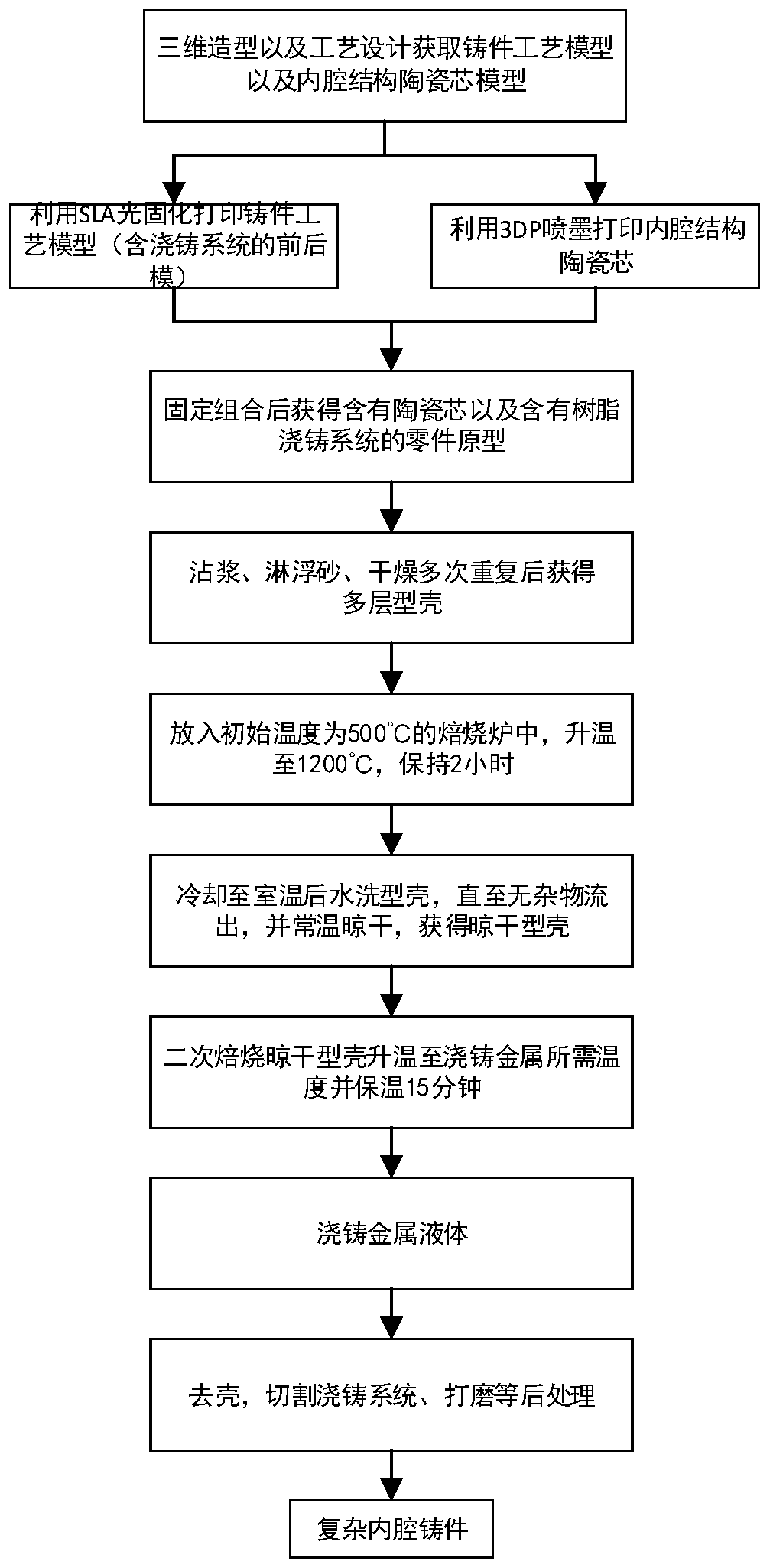

Precision casting forming method based on 3D printing technology

InactiveCN111112552AReduce mold costShort production cycleAdditive manufacturing apparatusFoundry mouldsBatch productionManufacturing engineering

The invention discloses a precision casting forming method based on a 3D printing technology. Three-dimensional modeling software is used for drawing a digital model of a casting piece and drawing ofa casting system, and then the core design is carried out according to an inner cavity, so that a model of a ceramic core with a positioning system is obtained. Parting is carried out according to thestructure of the ceramic core so that the ceramic core can be assembled and put in conveniently, and the process model is divided into a front model body and a rear model body. The front model body,the rear model body and the casting system are subjected to 3D printing by using an SLA photocuring process, and 3D printing of the ceramic core is carried out by using a 3DP ink jet process; a part prototype containing the ceramic core and the resin casting system is obtained after fixing and combination; and finally a metal part is obtained through shell making, roasting and casting of a traditional precision casting process. By the adoption of the precision casting forming method based on the 3D printing technology, casting of the casting piece with the complex inner cavity structure can beachieved without using a mold completely, and the precision casting forming method is very suitable for process verification and small-batch production of casting pieces with complex inner cavity structures.

Owner:无锡惠思特快速制造科技有限公司

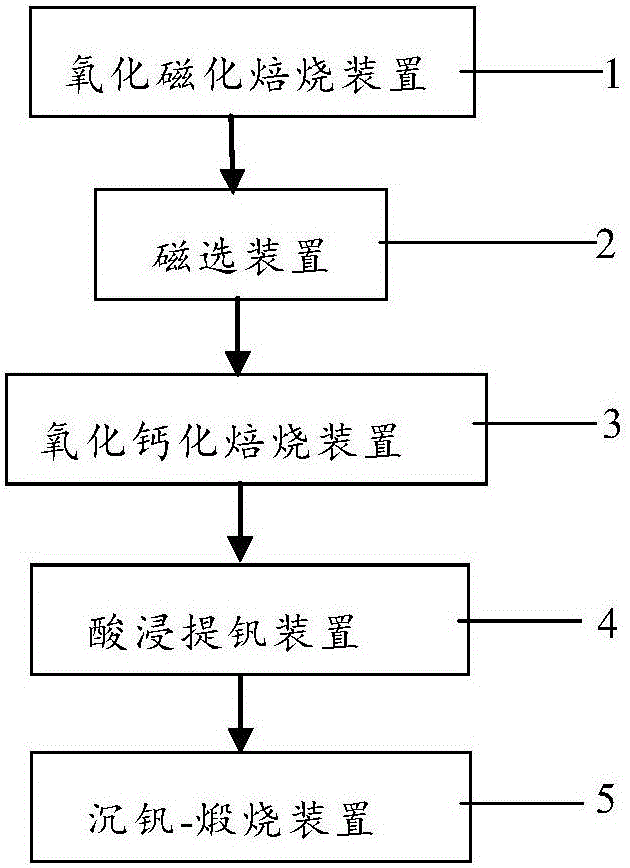

Method and system for treating vanadium slag

InactiveCN106065436AHigh recovery rateAchieve recyclingProcess efficiency improvementSlagCalcification

The invention discloses a method and system for treating vanadium slag and belongs to the field of extracting of valuable metal in the vanadium slag. The invention firstly discloses the method for treating the vanadium slag. The method includes the steps that the vanadium slag is subjected to oxidization magnetizing roasting firstly so that iron in the vanadium slag can be converted into magnetic ferroferric oxide to be subjected to magnetic separation recycling, vanadium can be enriched through the vanadium slag obtained after iron recycling, and non-magnetic vanadium-enriched slag is obtained; and calcium salt is mixed into the vanadium-enriched slag, then vanadium in the vanadium-enriched slag is recycled through an oxidization roasting-acid leaching vanadium extracting method, and therefore the iron and the vanadium in the vanadium slag can be extracted step by step. The invention further discloses the system for implementing the method for treating the vanadium slag. The system comprises an oxidization magnetizing roasting device, a magnetic separation device, an oxidization calcification roasting device, an acid leaching vanadium extracting device and a vanadium precipitation-roasting device. By means of the method and system for treating the vanadium slag, the recovery rate of the iron and the vanadium in the vanadium slag is high, the vanadium slag can be comprehensively utilized, and operation is simple.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for utilizing sulfate slag and red mud comprehensively

The invention discloses a method for utilizing sulfate slag and red mud comprehensively. The method comprises the steps that the sulfate slag and the red mud are mixed with a reducing agent so as to obtain a mixed material; roasting is carried out on the mixed material so as to obtain a reduced iron product; the reduced iron product is separated so as to obtain iron powder. By the utilization of the method, the two metallurgical solid waste resources, namely the red mud and the sulfate slag are utilized comprehensively, so that the iron product with good indexes is obtained.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

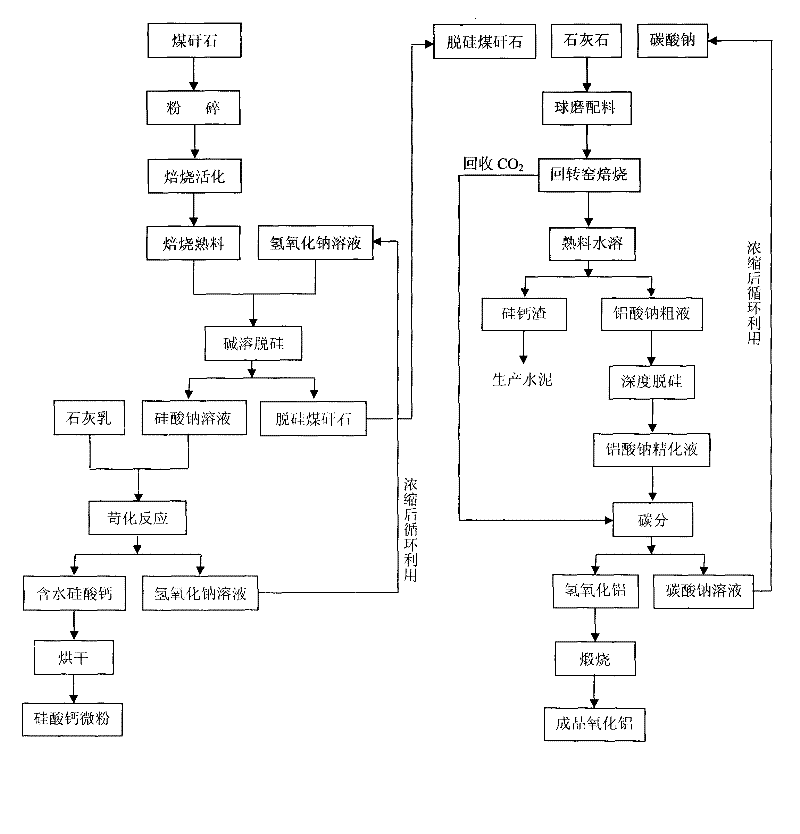

Process for combined production of alumina as well as active calcium silicate and cement from gangue

InactiveCN103754905AIncrease Al-Si RatioReasonable roasting temperatureWaste processingAlkaline-earth metal silicatesCalcium silicateAluminium hydroxide

The invention provides a process for combined production of alumina as well as active calcium silicate and cement from gangue, and relates to the technology field of combined production of alumina and active calcium silicon. The invention carries out a desilicication reaction by calcinating gangue, and preparing a sodium hydroxide solution and sodium carbonate solution by reaction and processing, and calcining aluminium hydroxide for preparing alumina product. The invention has the advantages of simple process, low production cost, low energy consumption and little material consumption, and simultaneously three products with silicon containing products are prepared without waste generation.

Owner:雷菊花

Preparation method of oxidized pellets with coarse-grain hematite as main raw material

The invention relates to a preparation method of oxidized pellets with coarse-grain hematite as a main raw material. The technical scheme of the invention is as follows: uniformly mixing 60-70 percent by weight of coarse-grain hematite, 20-30 percent by weight of fine-grain iron-containing raw material, 2-6 percent by weight of organic binding agent and 5-8 percent by weight of water, and carrying out pressure forming to obtain ellipsoidal green-balls; and roasting the ellipsoidal green-balls at 1150-1200 DEG C for 15-30min to obtain the oxidized pellets, wherein the coarse-grain hematite is ground hematite or pelletized return fines and has the grain diameter of being less than or equal to 6mm; the fine-grain iron-containing raw material is electric precipitation dust in the smelting process of iron ore concentrate or steel; the organic binding agent is prepared by mixing starch, inorganic sodium salt, borate and water according to a mass ratio of 1: (0.04-0.15): (0.02-0.10): (4.0-5.0); and forming equipment is a double-roll ball press machine, wherein the forming pressure is 10-30MPa. The preparation method disclosed by the invention has the advantages of strong adaptability to raw material granularity, simple process, low energy consumption, low production cost and high quality of oxidized pellets.

Owner:WUHAN UNIV OF SCI & TECH

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725BIncrease Al-Si RatioLow firing temperatureAlkaline-earth metal silicatesCement productionCalcium silicateAluminium hydroxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon andcalcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxideto obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

Vanadium-titanium alkaline pellet production method

The invention discloses a vanadium-titanium alkaline pellet production method. The vanadium-titanium alkaline pellet production method comprises the following steps: S1, mixing 80 parts by weight of limestone powder with 20 parts by weight of bentonite to prepare alkaline bentonite; S2, adding 4-6 parts by weight of magnesia bentonite into 100 parts by weight of iron ore powder, adding 1.3-1.5 part of bentonite, and adding 0.2 part by weight of magnesia bentonite as a material mixture; S3, uniformly mixing the material mixture through a mixer; S4, transporting alkaline bentonite into a circular disc pelletizer, adding the material mixture and water, and pelletizing to obtain fresh pellets, wherein the diameters of the fresh pellets are 1-20 mm; and S5, sequentially performing screening, drying, pre-heating, roasting, kiln head distributing, kiln head cooling and ring cooler cooling on the fresh pellets, thereby obtaining vanadium-titanium alkaline pellets. The vanadium-titanium alkaline pellet production method improves pelletizing and pellet-forming performance, is beneficial for green pellet roasting, improves a condition that powder is much and atmosphere is poor in a roasting process, can achieve the mass production target in a chain-grate machine-rotary kiln pellet production process, and only reduces yield ratio design ability by about 15%.

Owner:承德信通首承科技有限责任公司

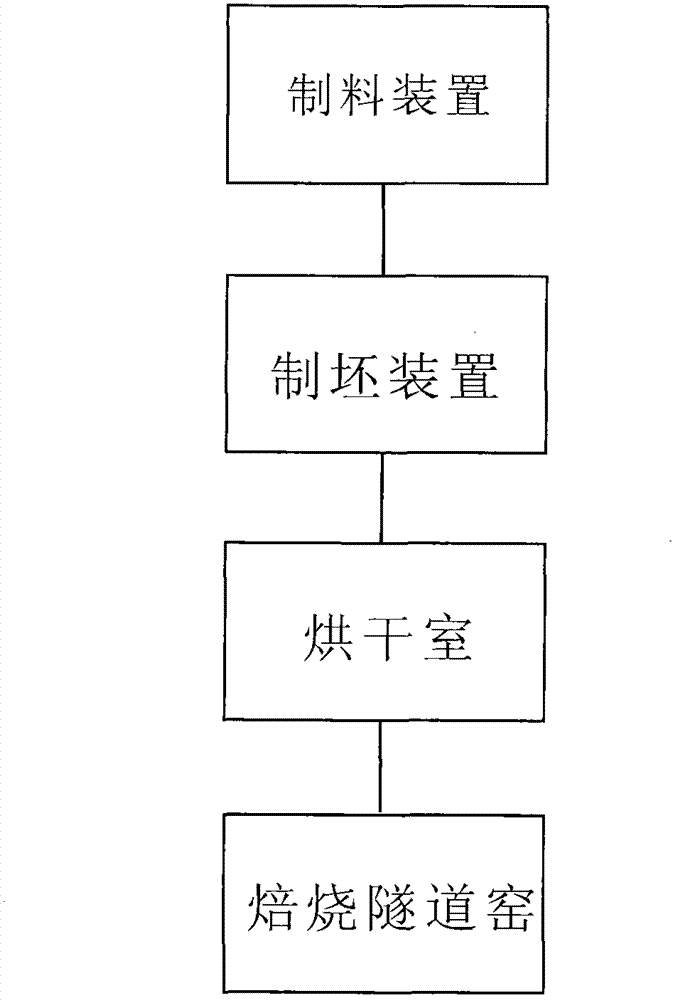

Wall brick roasting tunnel kiln and roasting method

The invention relates to a wall brick roasting tunnel kiln and a roasting method. The wall brick roasting tunnel kiln comprises a material preparing device, a blank preparing device, a drying chamber, a roasting tunnel kiln and a kiln vehicle for placing wall brick blanks. A kiln vehicle loading platform has the length of 3.85m, and the width of 5.1m. The roasting method has the following steps of: smashing raw materials, stirring, aging, re-stirring, preparing the blanks, staking the kiln vehicle, drying, roasting and the like. Wall bricks which are roasted by using the method are high in intensity, and are extremely low in blank brick rate. By utilizing the method provided by the invention, energy sources are saved, and the productivity is improved.

Owner:张崇云

Production method of magnetite and roasting furnace for magnetite

The invention discloses a production method of magnetite and a vertical roasting reduction furnace for the magnetite. The production method comprises the steps of with low-grade siderite, limonite, specularite, hematite and sulfuric acid residues as raw materials, controlling the pressure of the vertical roasting reduction furnace at 300-350Pa, adding a small amount of additives into mineral aggregates in proportion at reducing atmosphere, moving the mixture from a temperature layer of 1 DEG C to a temperature layer of 490-750 DEG C under the action of natural pressure, cooling, and magnetizing, so as to obtain the magnetite. The production method has the beneficial effects that the technical flow is simple, a product path for utilizing low-grade and difficultly-utilized siderite, limonite, specularite and hematite by virtue of a process technique with the advantages of energy conservation, environmental friendliness, high efficiency, low investment, land conservation, easiness in management and control, high handling capacity and high rate of certified products is utilized, and an excellent waste recycling effect is achieved.

Owner:闫鼎基

Y-type joint pouring technology

InactiveCN107866531ASolve compactSolve the problem of avoiding local shrinkageFoundry mouldsFoundry coresStress concentrationWax

The invention discloses a Y-type joint pouring technology which is implemented by a primary pouring system and an auxiliary system, wherein the primary pouring system comprises a casting head, a feeding area, a feeding channel, a product wax pattern and a semi-closed space; a feeding sprue is formed in the top outer wall of the feeding area; the casting head is welded on the inner wall of the feeding sprue; the casting head and the feeding sprue are arranged at main hot spots of a casting by a step of arranging the feeding sprue and the casting head are the main hot spots of the casting according to the casting structure; continuous feeding is facilitated in a cooling process; through vertical pouring and under the pressure formed by the weight of molten steel, enough feeding ability is guaranteed for the part cooled earlier, based on a rule that thin walls are cooled earlier and the thick and big walls are supplemented. According to the technology disclosed by the invention, enough feeding ability is guaranteed for the part cooled earlier, thus, heat crack caused by stress concentration in molten steel cooling resulting from non-uniform wall thickness can be prevented, air holes and roughness caused by overheating as well as consequent adverse outcomes are avoided, and the requirements on the product performance are completely met.

Owner:QINGDAO HONGXINTIAN MACHINERY CO LTD

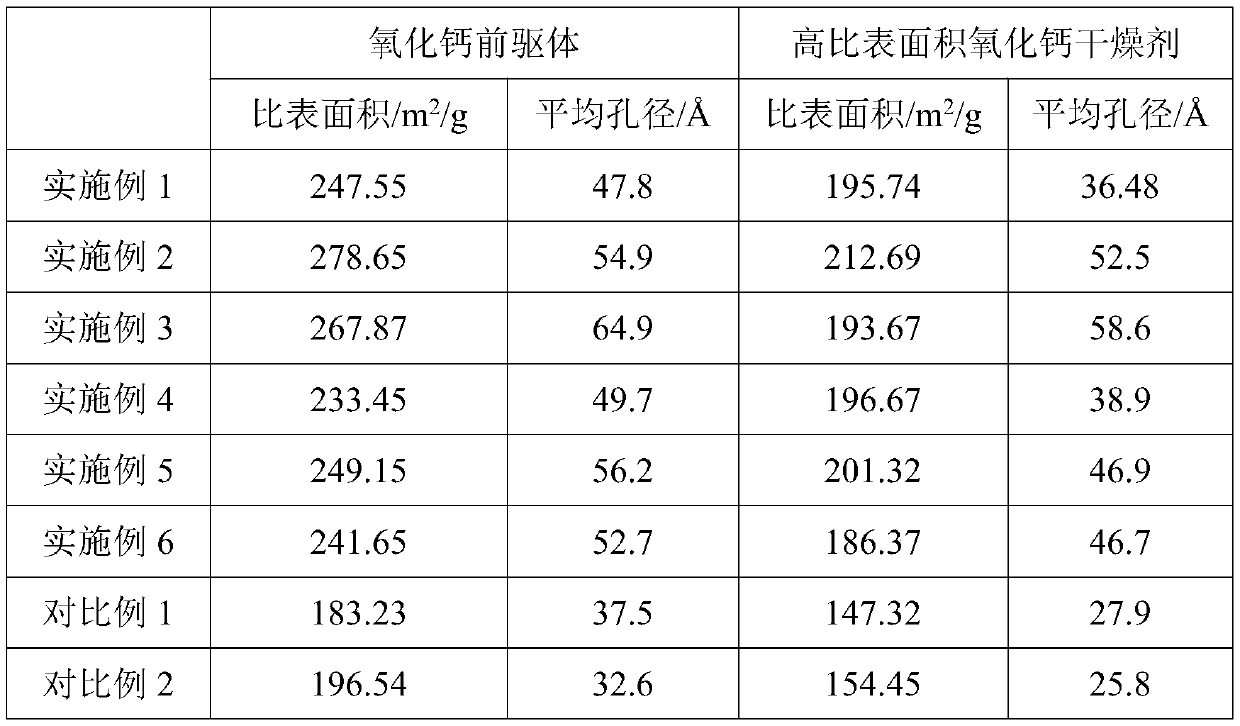

Preparation method of calcium oxide with high specific surface area

ActiveCN110773110ALarge specific surface areaGood hygroscopicityGas treatmentOther chemical processesDesiccantPhysical chemistry

The invention discloses a preparation method of calcium oxide with a high specific surface area, and relates to the technical field of drying agents. The preparation method comprises: (1) preparing amixed solution from a calcium salt and a chelating agent, and adjusting the pH value to 2-5; (2) evaporating and concentrating at a temperature of 60-100 DEG C; (3) drying at a temperature of 100-120DEG C; (4) roasting for 0.5-1 h at a temperature of 200-270 DEG C under the protection of nitrogen; (5) carrying out pressing molding; and (6) roasting at a temperature of 270-400 DEG C for 3-7 h. Theinvention further discloses a calcium oxide drying agent prepared by the method. According to the invention, the calcium oxide prepared by the method has characteristics of high specific surface areaand porosity, so that the calcium oxide has strong hygroscopicity.

Owner:JIUJIANG CSSC CHEM TECH

Full-washing coal gangue self-thermal insulation building block and manufacturing method thereof

The invention discloses a full-washing coal gangue self-thermal insulation building block and a manufacturing method thereof.The full-washing coal gangue self-thermal insulation building block is characterized by being prepared from, by mass, 10-15% of water, 80-88% of washing coal gangue and 2-5% of a pore-forming agent.The manufacturing method comprises the steps of smashing, water adding to achieving uniform stirring, normal-temperature aging, extrusion, slitting, low-temperature drying, high-temperature sintering and the like.The adopted raw materials are convenient to obtain, the burning consumption of the self-thermal insulation building block can be effectively lowered, the production cost is lowered, the mineral waste utilization rate is enlarged, and environmental protection is achieved.The building block is high in strength level and low in density level, water absorption rate and heat transfer coefficient, the requirement for that a public building in a hot summer and cold winter area saves energy by 65%, and the wall heat transfer coefficient is smaller than 1 W(m<2>.k) according to the national building energy-saving design standard can be met, the technology is simple, the production cost is low, popularization and application are easy.

Owner:HUAIBEI XINYU IND & TRADE

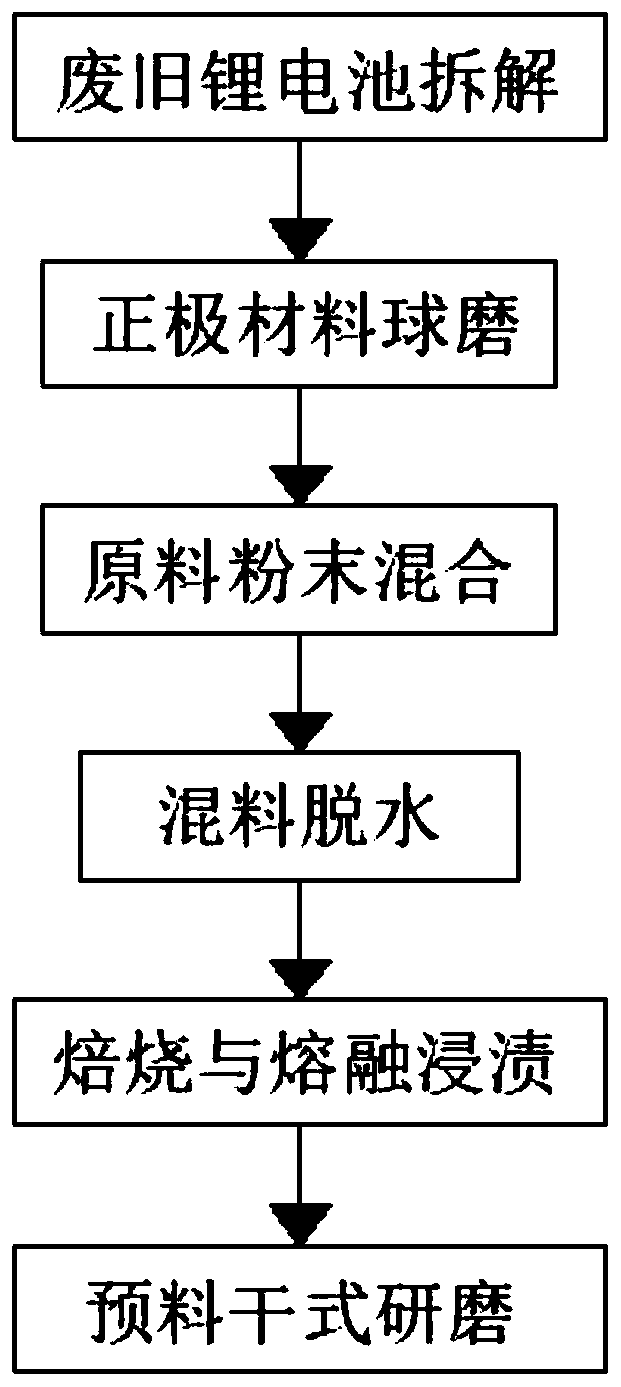

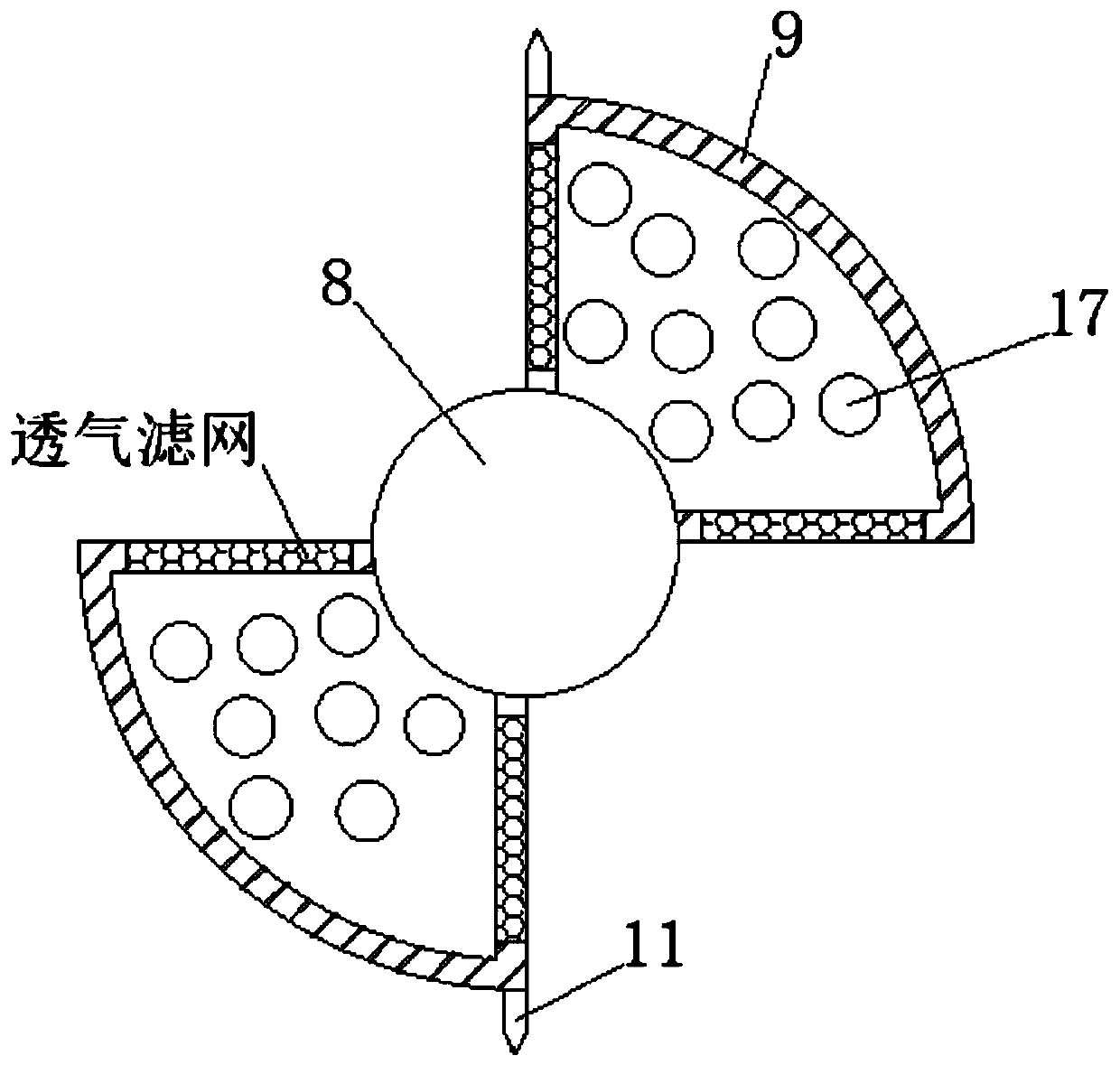

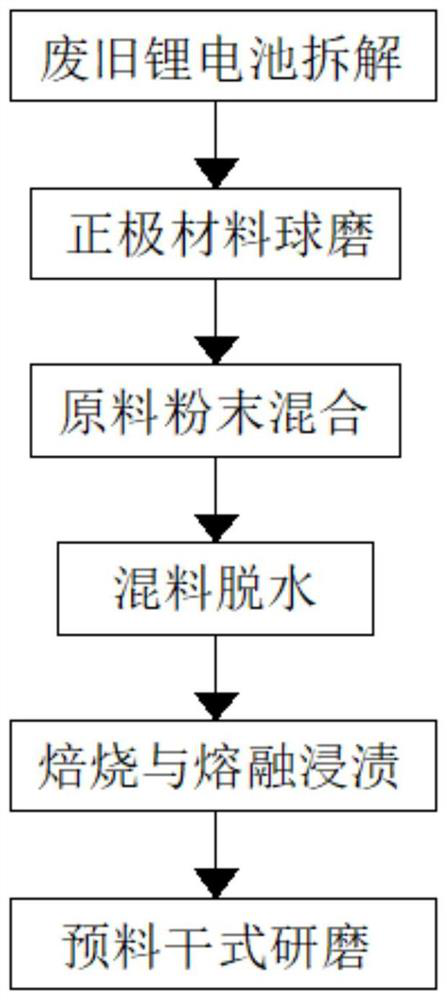

Complete set of energy-saving roasting technology for regenerated lithium iron phosphate

ActiveCN110562948AReduce consumption costQuality improvementCell electrodesChemical industryCarbon coatingLithium iron phosphate

Belonging to the technical field of new energy, the invention discloses a complete set of energy-saving roasting technology for regenerated lithium iron phosphate. The complete set of energy-saving roasting technology for regenerated lithium iron phosphate includes the steps of: waste lithium battery disassembly, anode material ball milling, raw material powder mixing, mixture dehydration, roasting and melt impregnation, and drying grinding of premix: putting the obtained lithium iron phosphate premix into a mill and carrying out dry grinding for a certain period of time so as to obtain a lithium iron phosphate material. The technology provided by the invention can realize carbon coating of the lithium iron phosphate material with carbon-based glucose, improves the diffusion coefficient oflithium ions between two phases, increases the discharge capacity of the lithium iron phosphate anode material, and then improves the quality of the recycled lithium iron phosphate material, at the same time, protective gas involved in the roasting process is collected through a special structure of the material itself, so that the protective gas in the lithium iron phosphate roasting process canbe recycled, and the cost consumption of lithium iron phosphate regeneration and recycling can be reduced.

Owner:内蒙古圣钒科技新能源有限责任公司

An industrial waste treatment equipment

ActiveCN108311207BEasy to crush and screenAvoid incomplete roastingTransportation and packagingSolid waste disposalElectric machineHelical blade

The invention discloses an industrial waste slag treatment equipment, which comprises a base, a crushing box, an auger conveying pipe, a support seat, a roasting cylinder, a conveying pipe, a water washing box, a drying storage box, a box door, a control button, a feeding pipe, a first 1. Motor, gas storage tank, crushing roller, vibrating sieve plate, baffle plate, magnetic separation cylinder, scraper, iron-containing waste slag storage bin, waste bin, roasting drum, spiral blade, transmission rack, flame spray pipe, nozzle, Vibrating drying plate, transmission box, second motor, water pump, washing drum, cleaning liquid, grading storage bin, grading screening plate, feeding bin, washing net, electromagnetic plate, smooth sleeve and screen, the base A crushing box is installed on one side of the top of the crushing box, a feeding pipe is arranged on the top of the crushing box, a control button is installed on one side of the outer wall of the crushing box, and a box door is connected to the bottom of the control button through a hinge. The processing equipment has the advantages of convenient waste residue screening, uniform waste residue roasting and graded screening storage.

Owner:安徽中疆数字科技有限公司

Steelmaking refractory material recycling technology

The invention relates to a steelmaking refractory material recycling technology. Waste steelmaking refractory materials are reasonably utilized to produce a usable amorphous refractory material, so environmental pollution is reduced, and the cost of the refractory material and the steelmaking cost are greatly reduced. The recycling technology is used to make the recycling rate of the steelmaking refractory material reach 96% or above, performs coarse crushing through a jaw crusher firstly, and then performs fine crushing through a hammer crusher, so the working efficiency is high; and three different specifications of waste steelmaking refractory material particles are roasted and rolled respectively, so that the roasting and rolling effects are good, the working efficiency is high, the time cost is saved, and the recycling rate of the waste steelmaking refractory materials is increased.

Owner:天津炜润达新材料科技有限公司

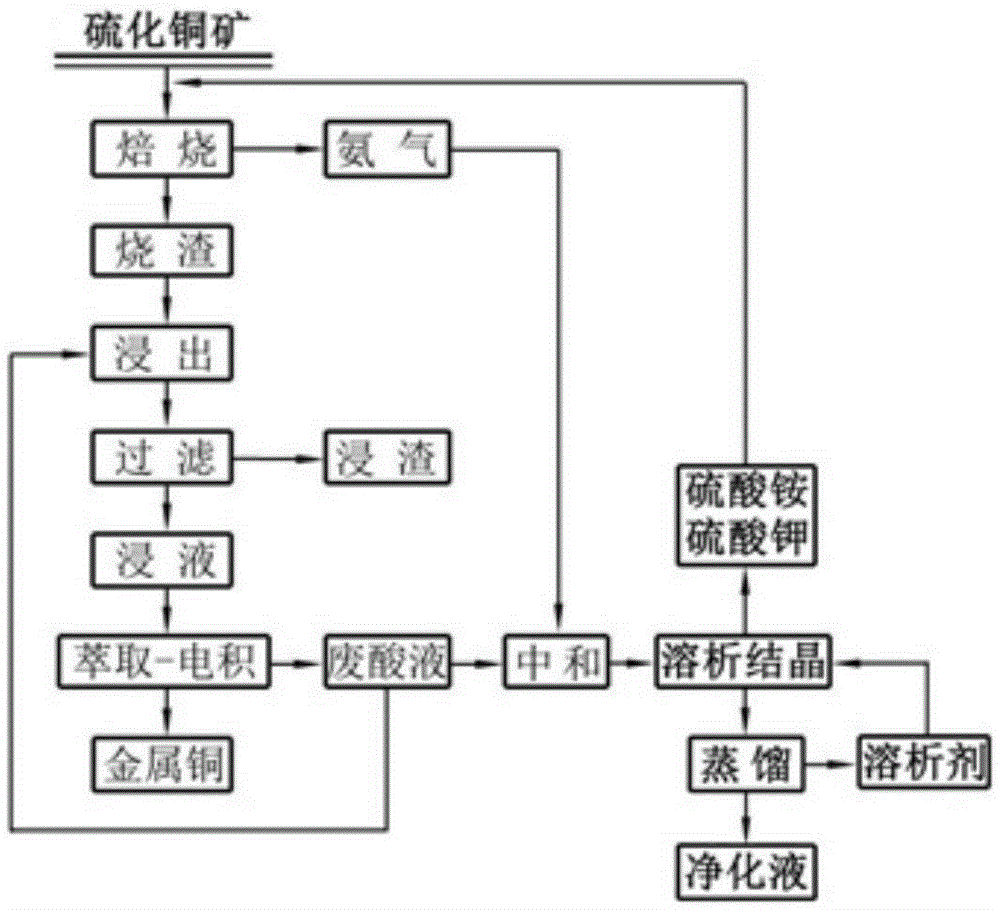

Technique for recycling ammonium sulfate to extract copper from copper sulphide minerals through wet process

InactiveCN105316490AReduce energy costsReduce manufacturing costProcess efficiency improvementSolventElectrowinning

The invention belongs to the field of wet process copper extraction, and particularly relates to a technique for recycling ammonium sulfate to extract copper from copper sulphide minerals through a wet process. The technique particularly comprises the following steps that the copper sulphide minerals and the ammonium sulfate are mixed and subjected to sulfating roasting; water or a sulfuric acid solution is added into roasted ore to be subjected to copper leaching treatment; metal copper is extracted from an immersion solution through an extraction and electrodeposition process, the generated waste acid pickle part returns to the leaching copper, surplus waste acid pickle is neutralized by ammonia gas decomposed by roasting to obtain ammonium sulfate, and the ammonium sulfate is crystallized out through a solvent-out crystallization method to be recycled. The sulfating roasting temperature is 400-500 DEG C, the copper minerals are mainly converted into freely soluble CuSO4 or CuO.CuSO4 by controlling the roasting temperature, iron minerals are mainly converted into difficultly soluble FeS, sulphur is left in the roasted ore mainly in a simple substance mode, SO2 gas is not generated, the environment is not polluted, and subsequent selective copper leaching is facilitated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Glass batch granulation and glass production method and fly ash and/or fly ash aluminum extraction residue to produce glass and glass products

ActiveCN107352796BGood for roastingWell mixedGlass furnace apparatusGlass productionSilicic acidSlag

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A complete roasting process for energy-saving regenerated lithium iron phosphate

ActiveCN110562948BReduce consumption costQuality improvementCell electrodesChemical industryLithium iron phosphateNew energy

The invention discloses a complete roasting process for energy-saving regenerated lithium iron phosphate, which belongs to the technical field of new energy. A complete roasting process for energy-saving regenerated lithium iron phosphate comprises the following steps: dismantling waste lithium batteries, ball milling positive electrode materials, Raw material powder mixing, mixing and dehydration, roasting and melt impregnation, dry grinding is expected, the obtained lithium iron phosphate is expected to be put into the mill, and dry grinding is carried out for a certain period of time to obtain lithium iron phosphate material, which can realize the utilization of carbon-based Glucose coats the lithium iron phosphate material with carbon, increases the diffusion coefficient of lithium ions between the two phases, increases the discharge capacity of the lithium iron phosphate cathode material, thereby improving the quality of the recovered lithium iron phosphate material, and at the same time through its own special The structure collects the protective gas during the roasting process, so that the protective gas during the roasting process of lithium iron phosphate can be recycled, and the cost consumption of regeneration and recovery of lithium iron phosphate is reduced.

Owner:内蒙古圣钒科技新能源有限责任公司

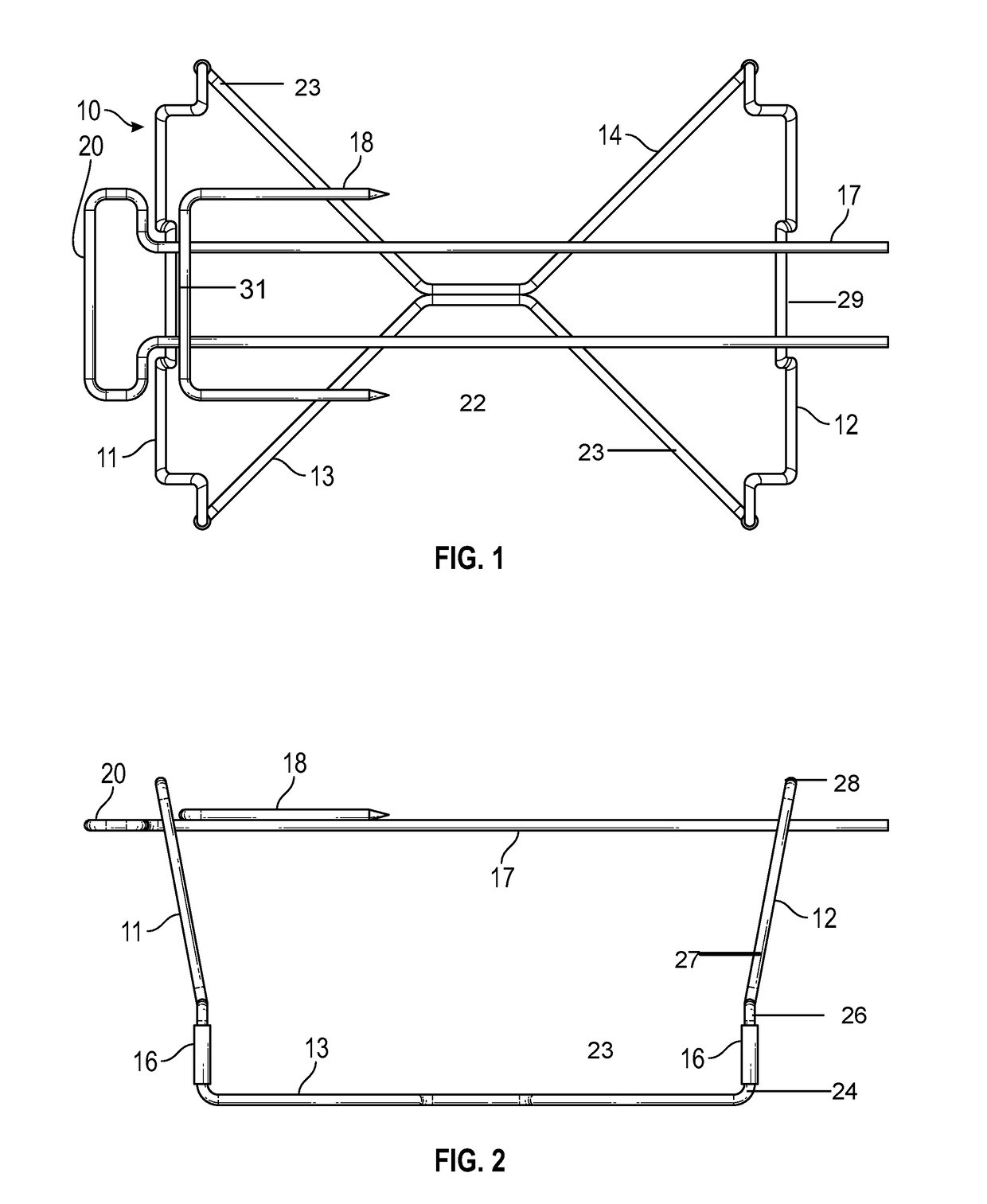

Oven Roasting Rack

ActiveUS20180249864A1Easy to moveEasy flipStoves/ranges shelves or racksRoasting apparatusMechanical engineering

Owner:MELLER BRUCE T

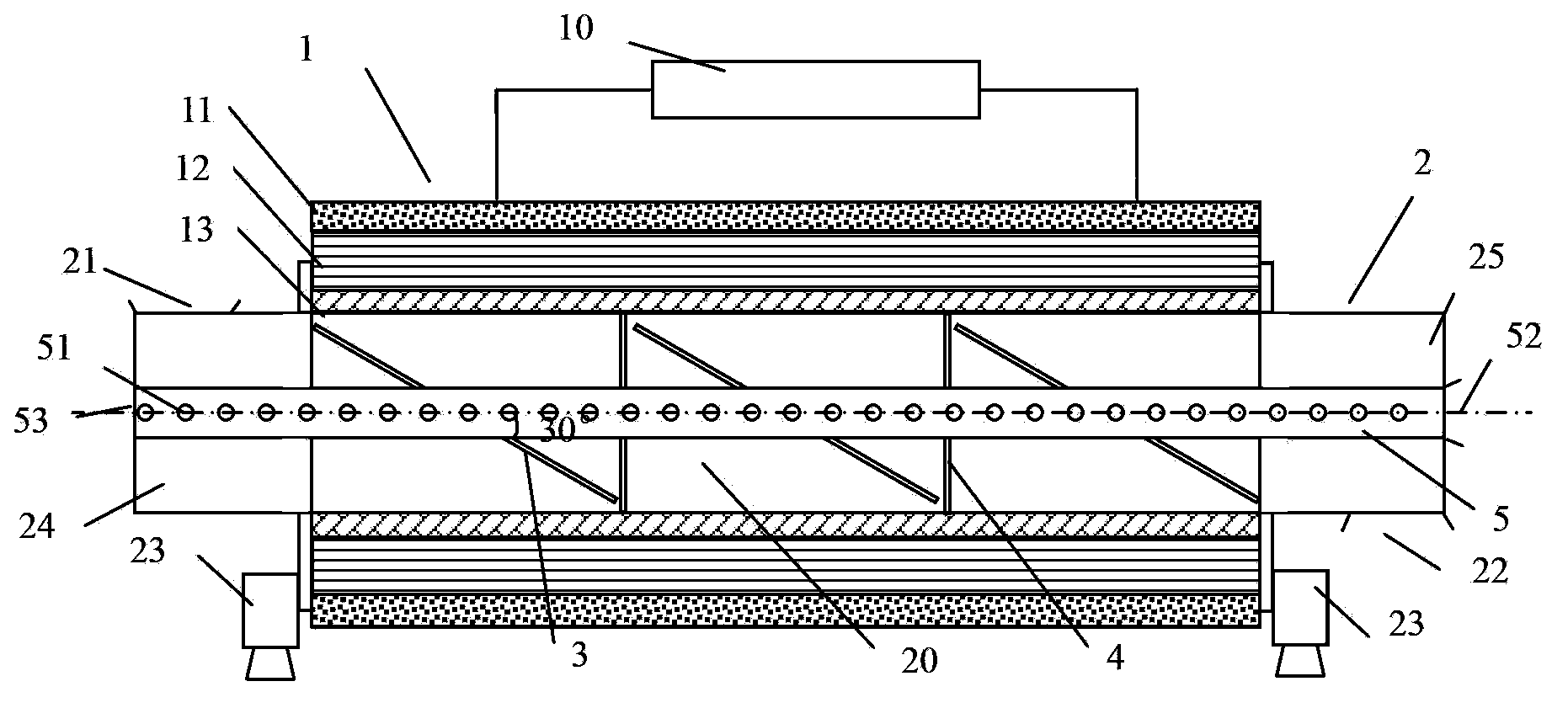

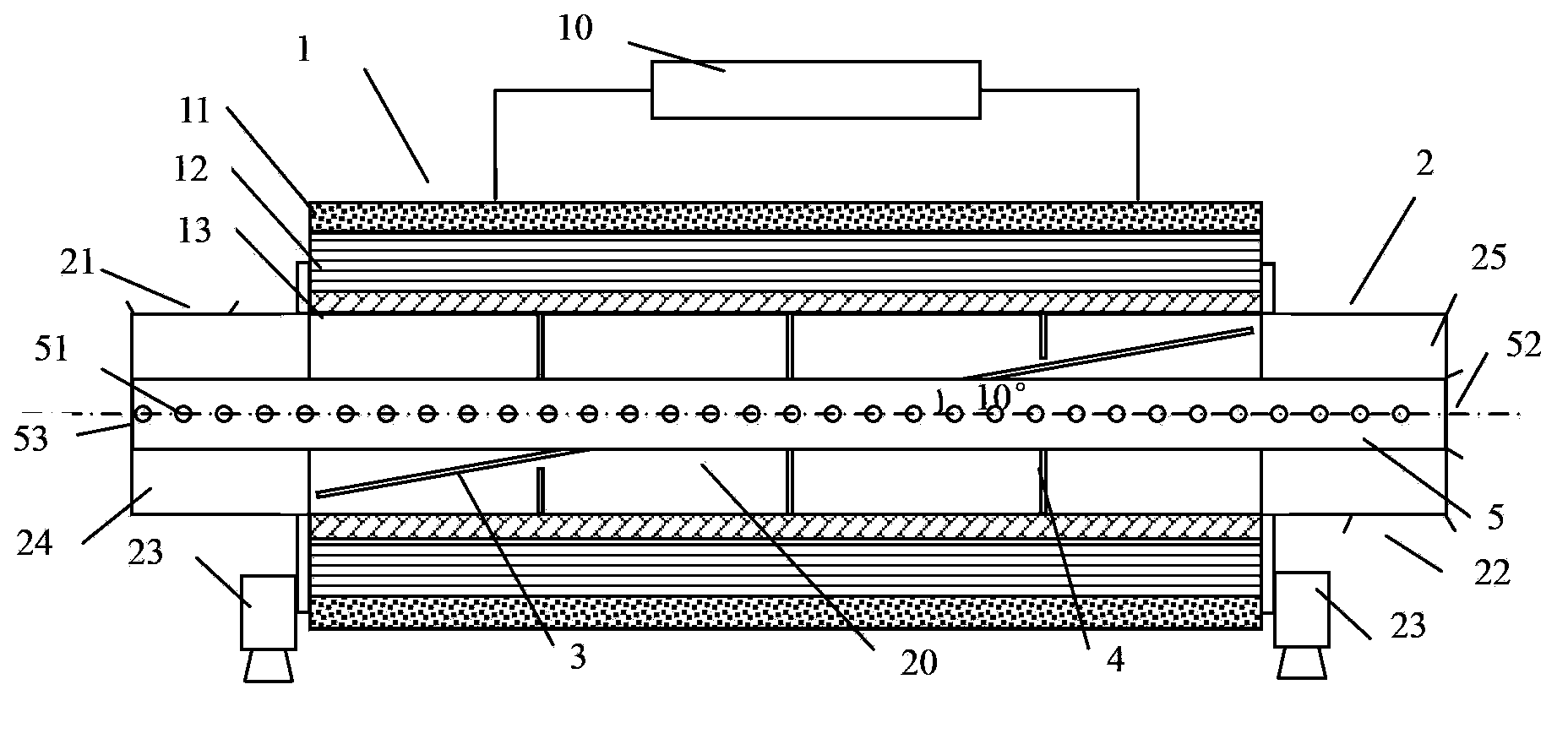

Y-type molecular sieve modification method and catalytic cracking catalyst preparation method

ActiveCN103771441AImprove structural stabilityImprove thermal stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

The invention discloses a Y-type molecular sieve modification method and a catalytic cracking catalyst preparation method. The Y-type molecular sieve modification method is characterized in that: a furnace having one or more water vapor distributors and shoveling plates is used, an angle between the extension direction of the shoveling plates and the axial direction of an intermediate cylindrical shell is an acute angle or obtuse angle, improved roasting conditions and secondary exchange conditions are adopted, and the roasting temperature of a Y-type molecular sieve is 400-500DEG C; and the secondary exchange is water washing or acidic solution washing, and the secondary exchange temperature is 20-70DEG C. The Y-type molecular sieve prepared through the modification method has a low Na2O content, and a catalytic cracking catalyst prepared by using the modified Y-type molecular sieve has a good catalysis performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

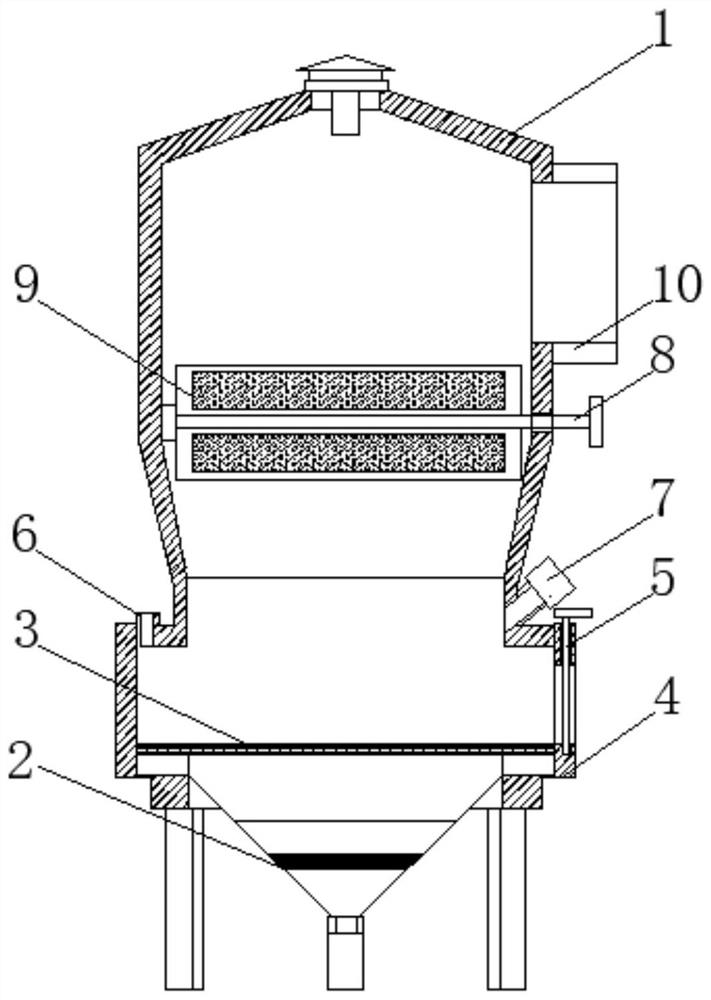

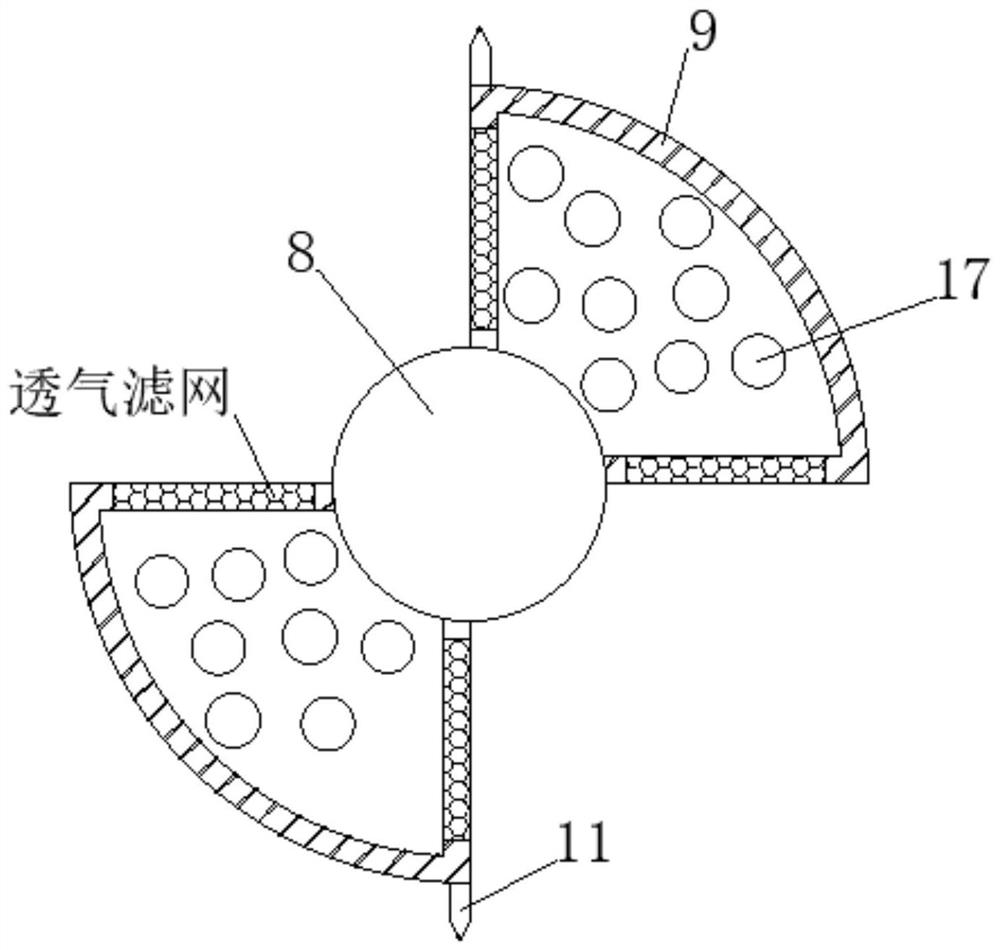

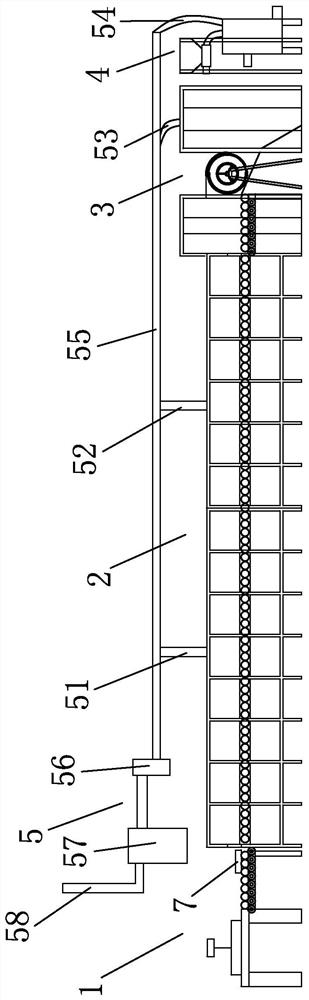

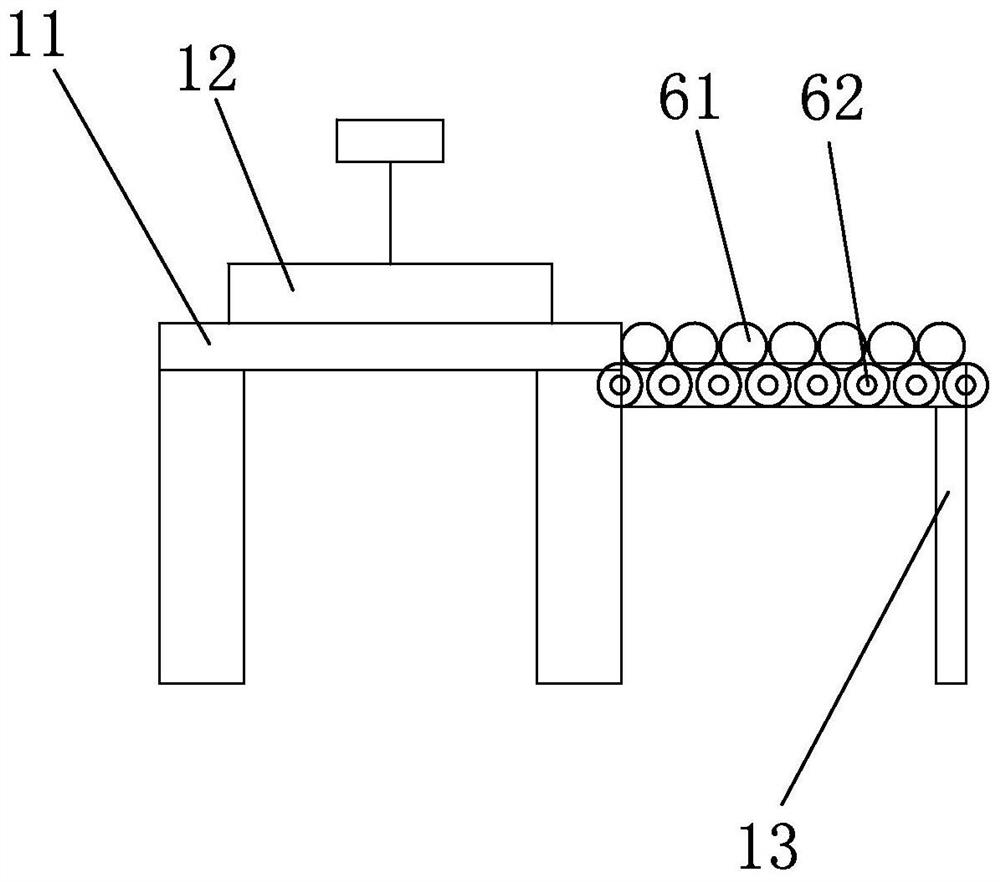

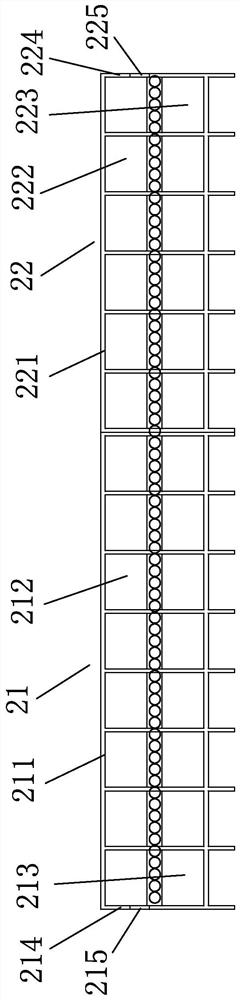

Activated powder production line device

PendingCN114053952AReasonable structural designEasy loadingGas current separationAluminium silicatesProcess engineeringManufacturing engineering

The invention discloses an activated powder production line device. The activated powder production line device structurally comprises a feeding mechanism, a roasting mechanism and a discharging and storing mechanism which are sequentially arranged, a finished product screening mechanism is further arranged on the rear side of the discharging and storing mechanism. The dust removal mechanism is connected with the roasting mechanism, the discharging and storing mechanism and the finished product screening mechanism. The charging tray is sequentially conveyed by the feeding mechanism to pass through the roasting mechanism and the discharging and storing mechanism. The production line device has the advantages that the structural design is reasonable, convenient feeding, roasting, cooling, discharging and storing of activated powder and screening of finished products are achieved, the production efficiency can be effectively improved, the product quality is guaranteed, and the production requirement is met.

Owner:无锡市三晓新材料有限公司

Methods of glass batch granulation and glass production, a method of producing glass by utilizing fly ash and/or fly ash aluminum-extraction slag and a glass product

ActiveCN107352796AReduce the presence of air bubblesImprove glass qualityGlass furnace apparatusGlass productionDecompositionSilicic acid

The invention relates to the field of granulation of a batch used for glass melting, and discloses methods of glass batch granulation and glass production, a method of producing glass by utilizing fly ash and / or fly ash aluminum-extraction slag and a glass product. The method of granulation includes (1) mixing a silicic acid precipitate, a sodium oxide source, a calcium oxide source and a water phase to form slurry; and (2) roasting the slurry under stirring to subject the silicic acid precipitate, the sodium oxide source and the calcium oxide source in the slurry to drying, pre-decomposition and granulation under the roasting condition to obtain glass batch granules. Glass batch granulation in a non-compression manner is achieved, and pre-decomposition and granulation of the glass batch can be completed simultaneously, thus simplifying a glass melting process, and increasing the melting amount of a glass kiln. Obtained molded glass has reduced air bubbles and improved quality.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of production method of high magnesium pellets

The invention discloses a production method of high-magnesium pellets. The specific steps are as follows: mix magnesium oxide powder into bentonite to make magnesia bentonite, mix magnesia bentonite into iron concentrate powder, and then add magnesia bentonite Bentonite is used as a mixture; the mixture is mixed with a mixer and transported to the pelletizing disc in the pelletizing chamber through a belt, and the above-mentioned mixture and water are added to the disc pelletizer to form pellets to obtain raw pellets; After the green balls are screened, dried, preheated, roasted and cooled, high-magnesium pellets are obtained. In the present invention, since bentonite and magnesium oxide powder are mixed and ground first, the affinity between bentonite and fine iron powder has been improved, which is beneficial to the roasting of green balls, and effectively improves the powder, poor atmosphere and cooling during the roasting process. In a bad situation, the output is not affected, the production process is easy to control, and the ringing of the rotary kiln is delayed, the production of high-magnesium pellets is normalized, and the quality index meets the index requirements of the steel plant.

Owner:承德信通首承科技有限责任公司

Production process of high-purity barium oxide

InactiveCN106698492AGuaranteed purityGood crystal formCalcium/strontium/barium oxides/hydroxidesChemistryBarium nitrate

The invention relates to a production process of high-purity barium oxide. The production process comprises the following steps: (1) adjusting the pH value of a barium nitrate saturated solution prepared from high-purity barium nitrate to be 8-9, adding high-purity hydrogen peroxide, and stirring for 5-10 minutes so as to generate a great deal of barium peroxide precipitate; (2) performing spin-dry on the precipitate, and washing for times with high-purity water till no NO3 exists; (3) performing spin-dry roasting. As the raw material of the production process of the high-purity barium oxide is purified in advance, a high-purity standard is met, the product purity is controlled from the raw material, introduction of later feeding reaction impurities can be avoided, and the purity of a final product can be ensured.

Owner:TIANJIN GUANGFU TECH DEV

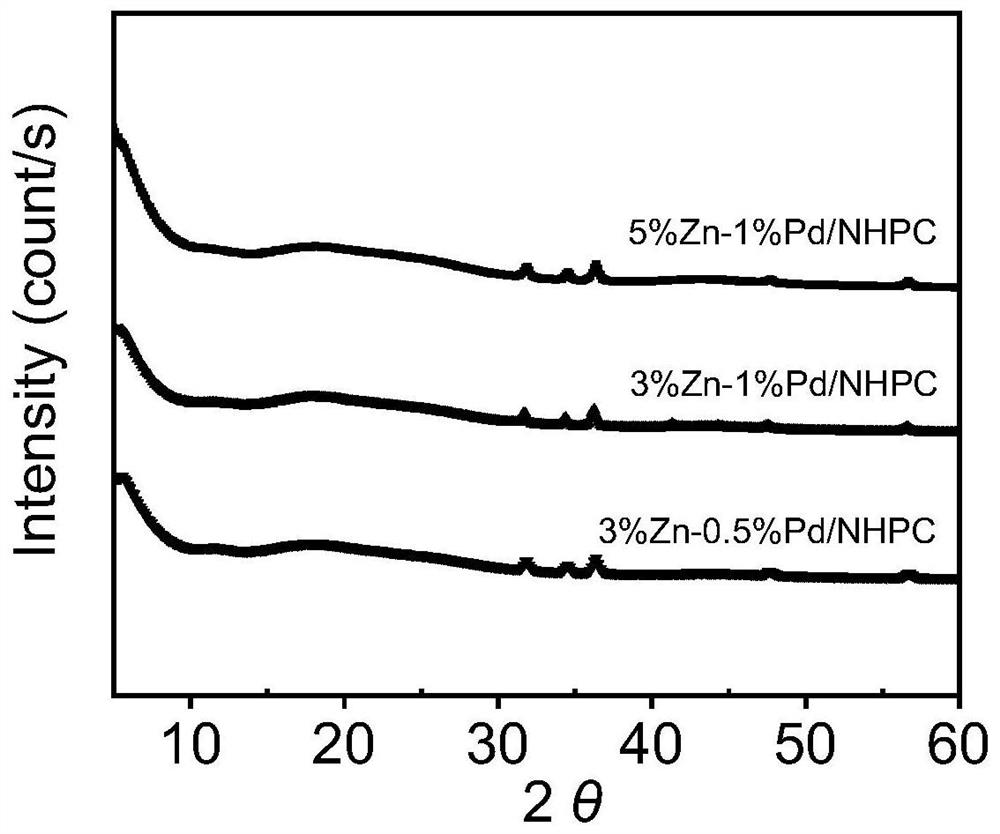

Maleic anhydride selective hydrogenation catalyst as well as preparation method and application method thereof

PendingCN113649049AHigh activityKeep aliveOrganic chemistryPhysical/chemical process catalystsPtru catalystSuccinic anhydride

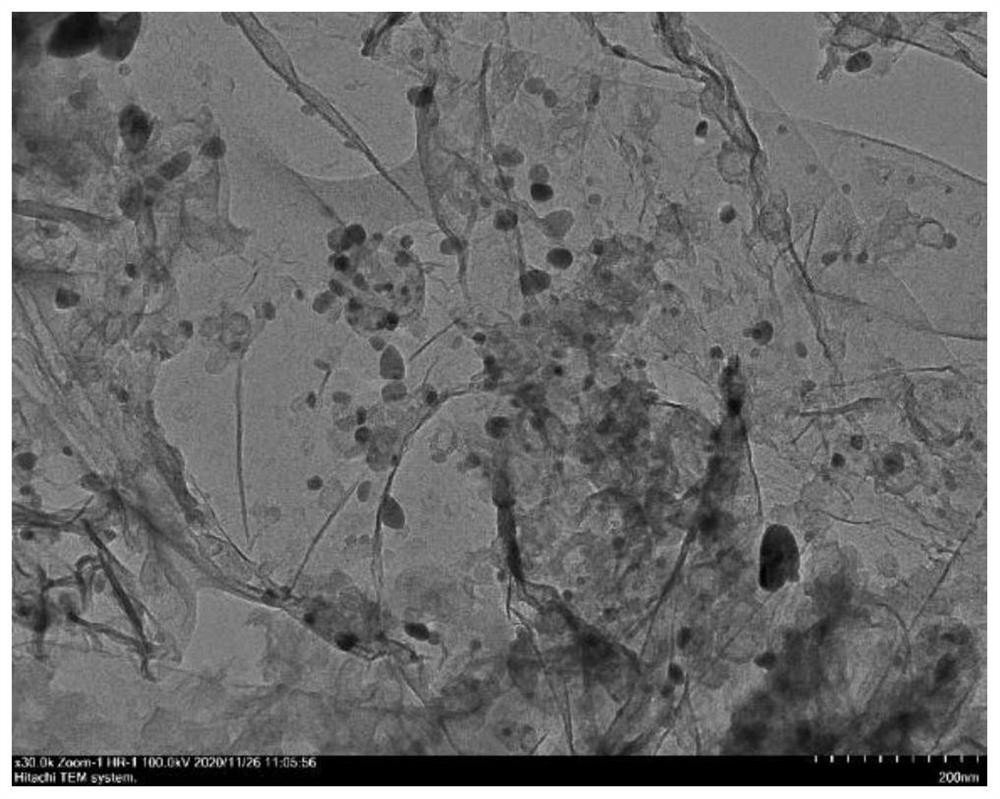

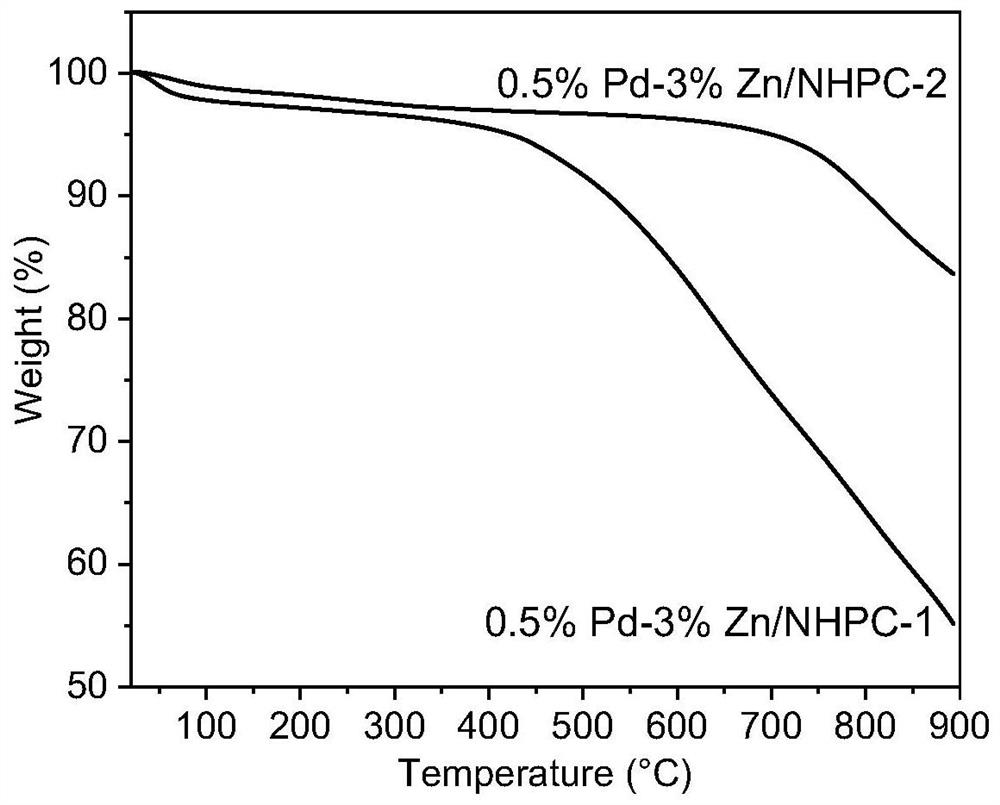

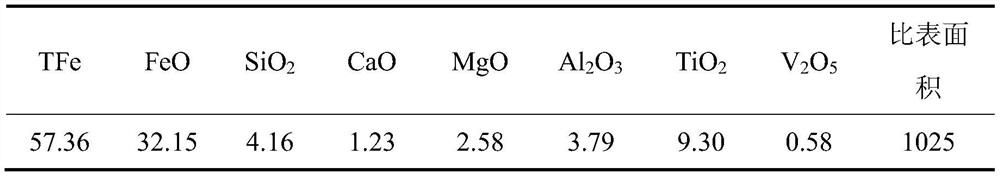

The invention relates to a maleic anhydride selective hydrogenation catalyst as well as a preparation method and an application method thereof. The catalyst is a Pd-M / NHPC catalyst which is prepared by taking a nitrogen-doped mesoporous carbon material NHPC as a carrier and loading Pd-M bimetallic by adopting an impregnation method, in the catalyst, the content of the active component metal Pd is 0.1-5wt%, the content of the metal M is 0.5-10.0 wt%, and the specific surface area is 80-1000m < 2 > / g; and the metal M is one or more of iron, cobalt, zinc and copper. The catalyst is low in cost, large in specific surface area, good in catalytic stability and high in activity and selectivity in reaction for catalyzing maleic anhydride hydrogenation to prepare succinic anhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

A preparation method of high-quality vanadium-titanium pellets with low energy consumption based on high-pressure roller mill pretreatment

The invention discloses a preparation method based on high-pressure roll-grinding pretreatment and used for low-energy-consumption and high-quality vanadium-titanium pellet ores. According to the method, the specific surface area and the particle size composition of vanadium-titanium magnetite are improved by controlling the conditions of high-pressure roll-grinding, and meanwhile, the compact structure of vanadium-titanium magnetite particles are broken by virtue of the high-pressure roll-grinding, so that favorable conditions are provided for pelletization and oxidation-solidification for the vanadium-titanium magnetite; pelletization and roasting methods suitable for the vanadium-titanium magnetite subjected to the high-pressure roll-grinding are developed according to the structure andsurface characteristics of the vanadium-titanium magnetite subjected to the high-pressure roll-grinding; and uniform oxidation and efficient solidification for the vanadium-titanium magnetite are realized through the coupling action of the high-pressure roll-grinding pretreatment, pellet particle size control, thermal process optimization and the like, so that the strength of the vanadium-titanium ore pellets is greatly increased, the energy consumption of the roasting process is reduced, and then the high-quality vanadium-titanium pellet ores are prepared.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com