Process for combined production of alumina as well as active calcium silicate and cement from gangue

A technology of activated calcium silicate and coal gangue, which is applied in the production of alumina/hydroxide, silicate, cement, etc., can solve the problems of high limestone temperature, waste of resources, and high energy consumption, and achieve high whiteness, The effect of saving production costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

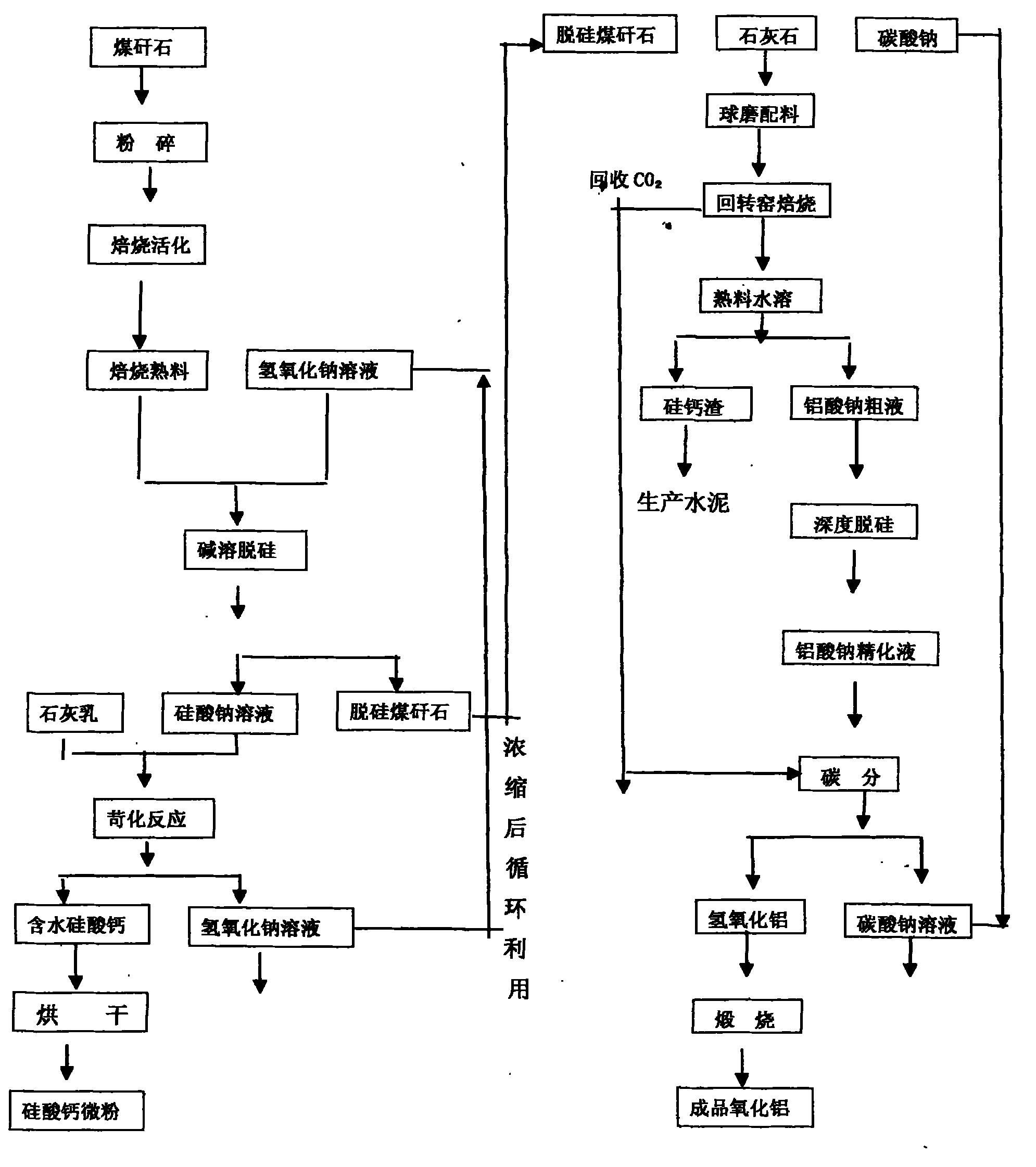

[0035] Referring to accompanying drawing, production step of the present invention is:

[0036] ①The selection of raw materials contains AI 2 o 3 42.93% / SiO2 2 51.92% coal gangue, after being ground to 200 meshes, is activated by high-temperature roasting, the roasting temperature is 650°C, and the holding time is 2 hours.

[0037] ②After the roasted clinker is naturally cooled, add 15% sodium hydroxide solution according to the mass ratio of coal gangue to NaOH of 1:1.5, and carry out desiliconization reaction at 110°C. The reaction time is 2h. After the reaction is finished, filter and separate to obtain the filtrate sodium silicate solution and filter cake desiliconized coal gangue.

[0038] ③ Add lime milk to the filtrate sodium silicate solution for causticization reaction, the amount of lime milk added is based on CaO and SiO 2 The molar ratio is 1.1, the reaction temperature is 90° C., and the reaction is separated by filtration after 1 h. The filtrate is sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com