Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Increase Al-Si Ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

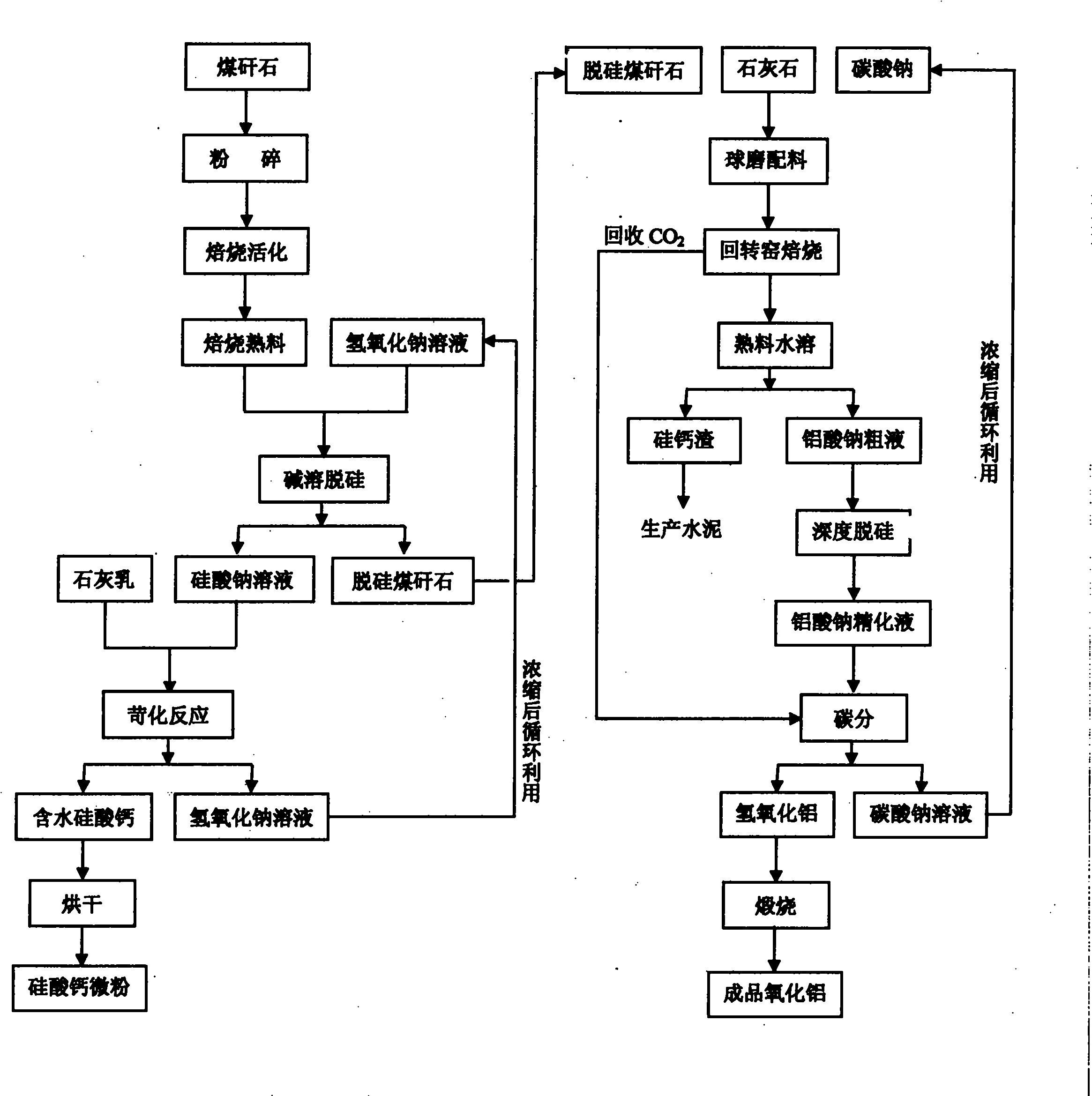

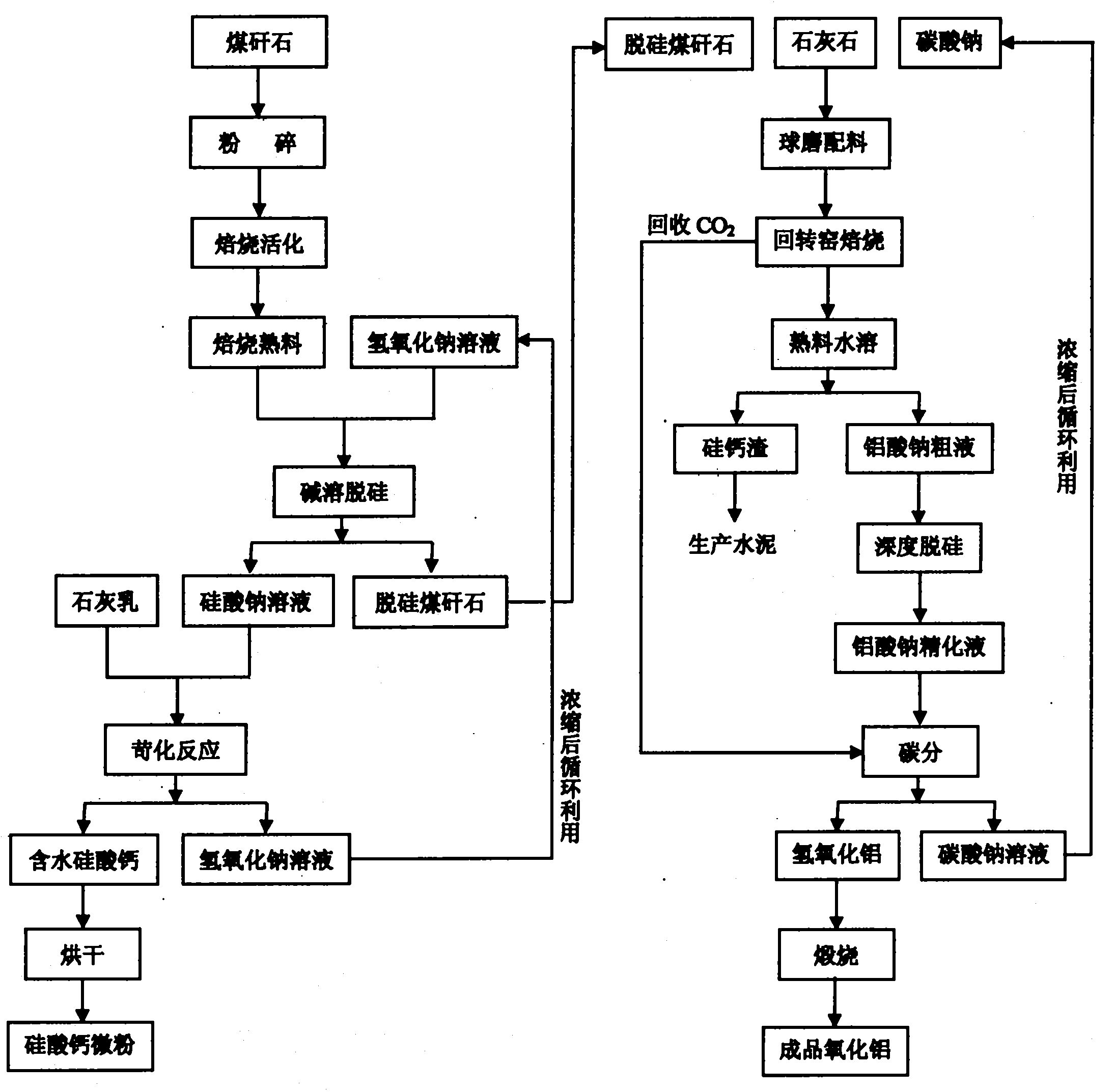

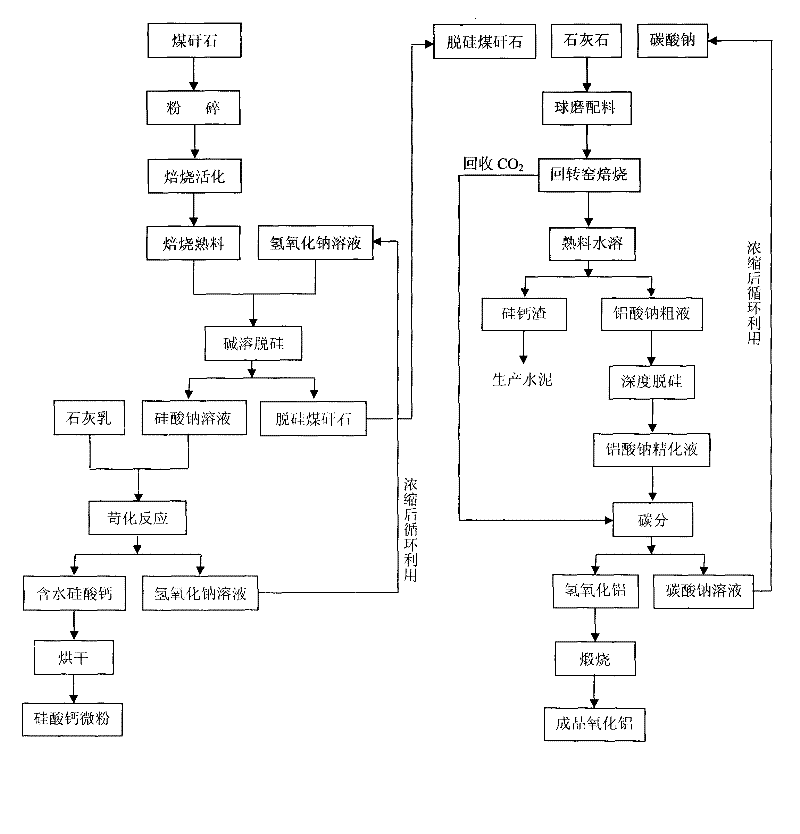

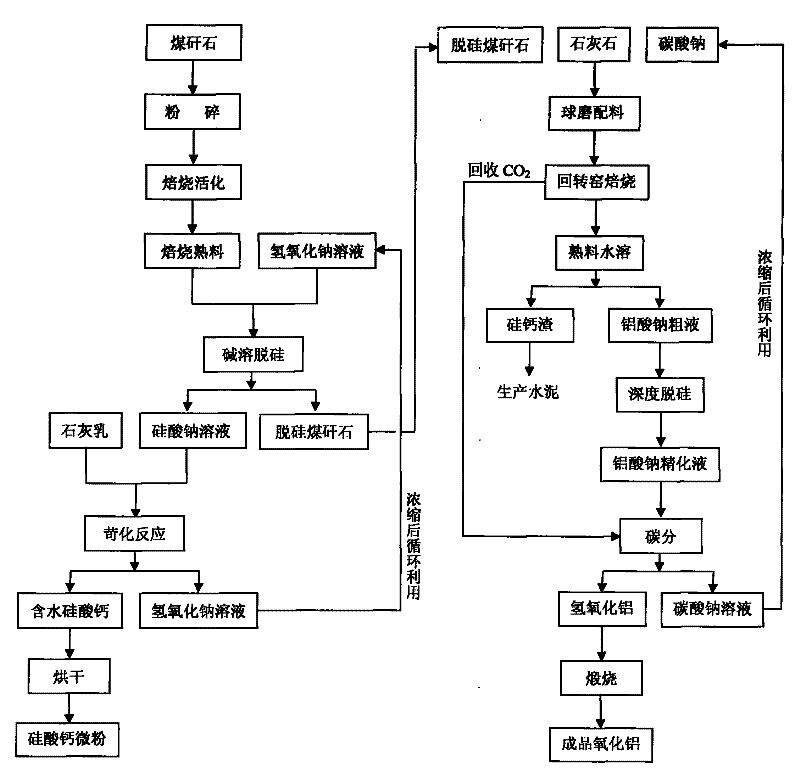

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

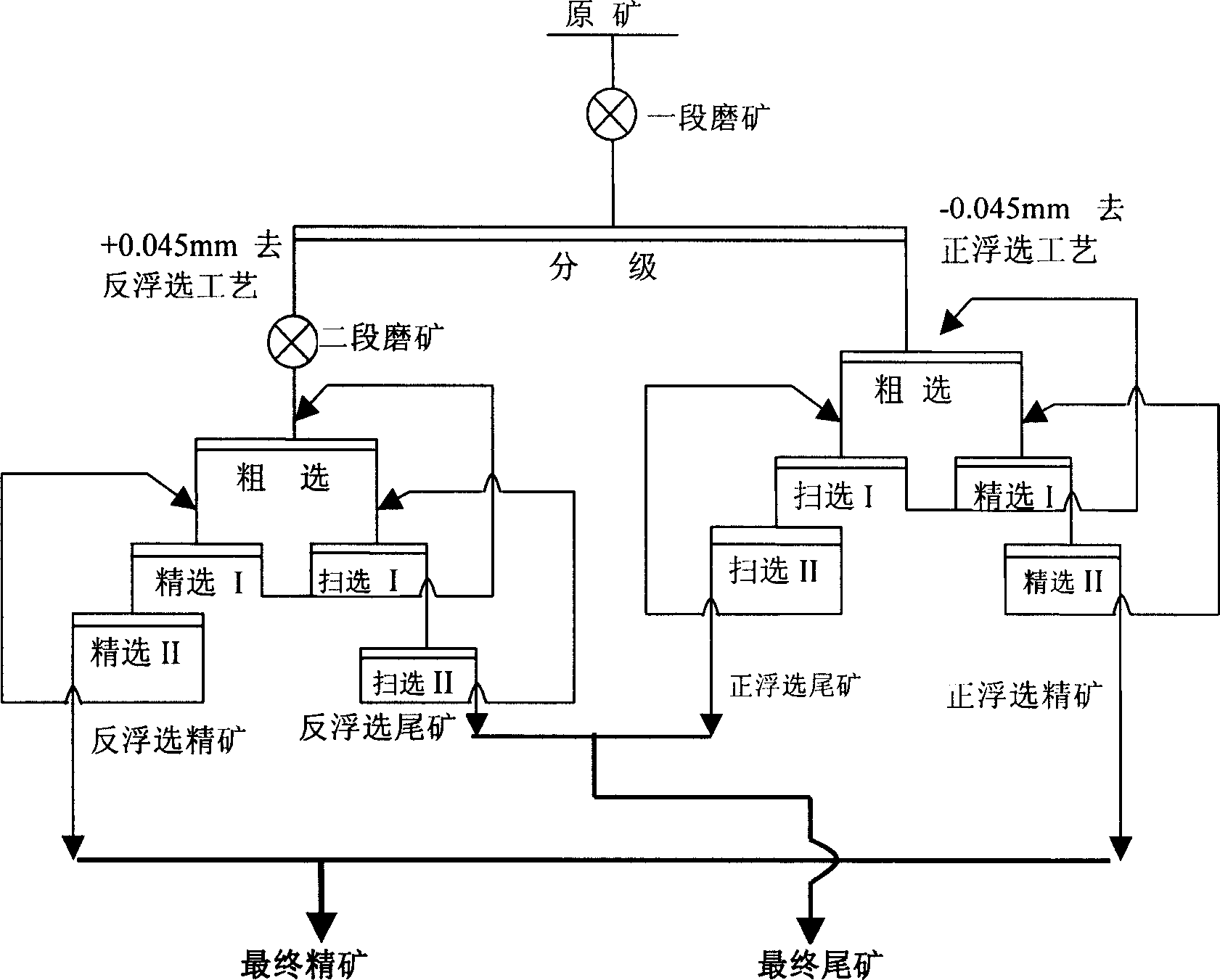

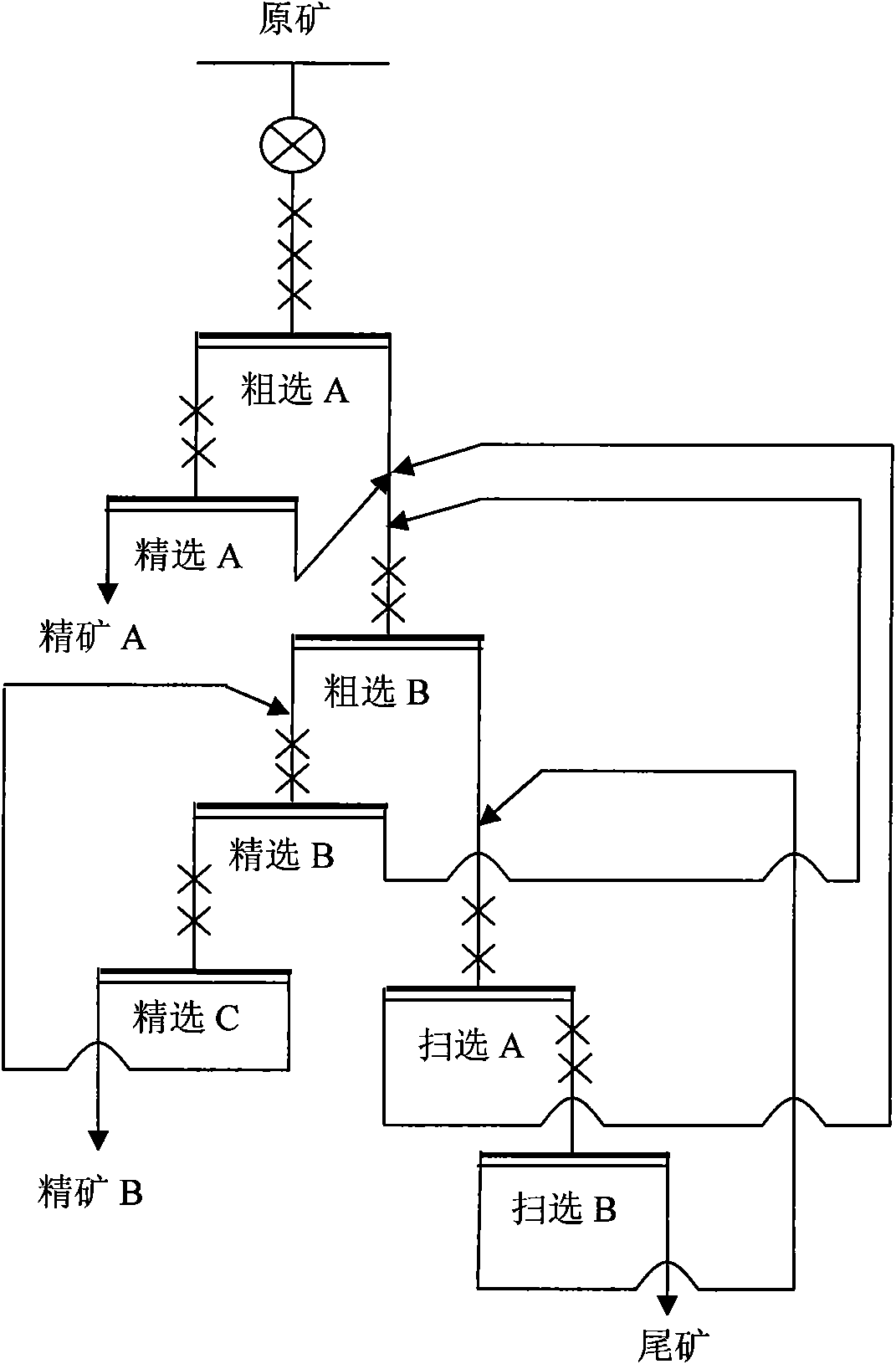

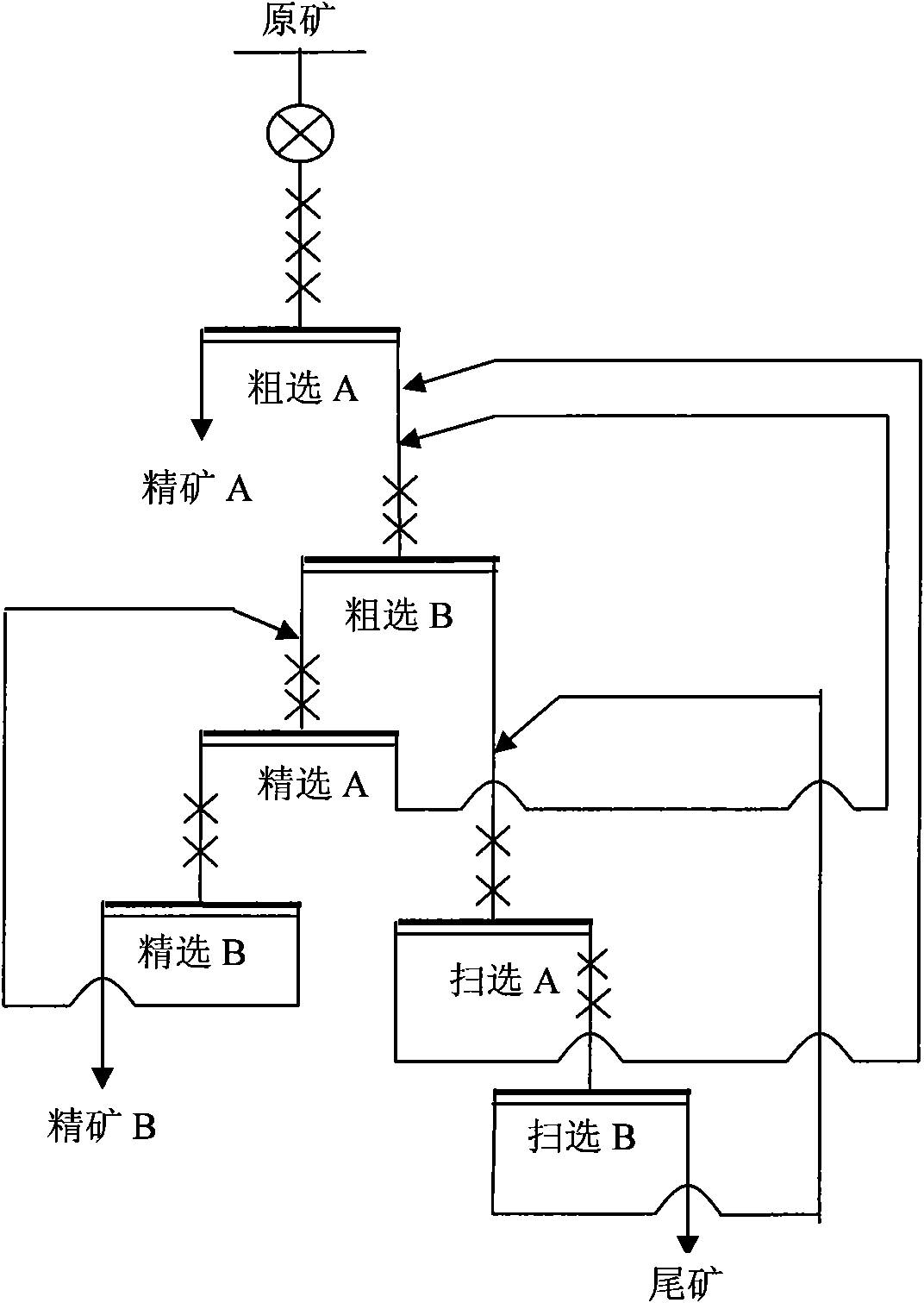

Parallel floatation process of desilionization for bauxite

InactiveCN1869258AEfficient separationIncrease production capacityFlotationProcess efficiency improvementEngineeringMaceral

The invention relates to a parallel floatation selecting method for bauxite desilication that adopts one section or two sections grinding technology to take classification to the bauxite pulp to gain raw and fine class product. The fine class product adopts positive floatation technology, and the raw class product adopts reverse floatation technology after taking or not taking second grinding. The positive floatation mine and the reverse floatation mine could be mixed to form final fine mine, and the positive floatation tail mine and the reverse floatation tail mine would be mixed to form final tail mine. The invention has great advantages and has wide application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

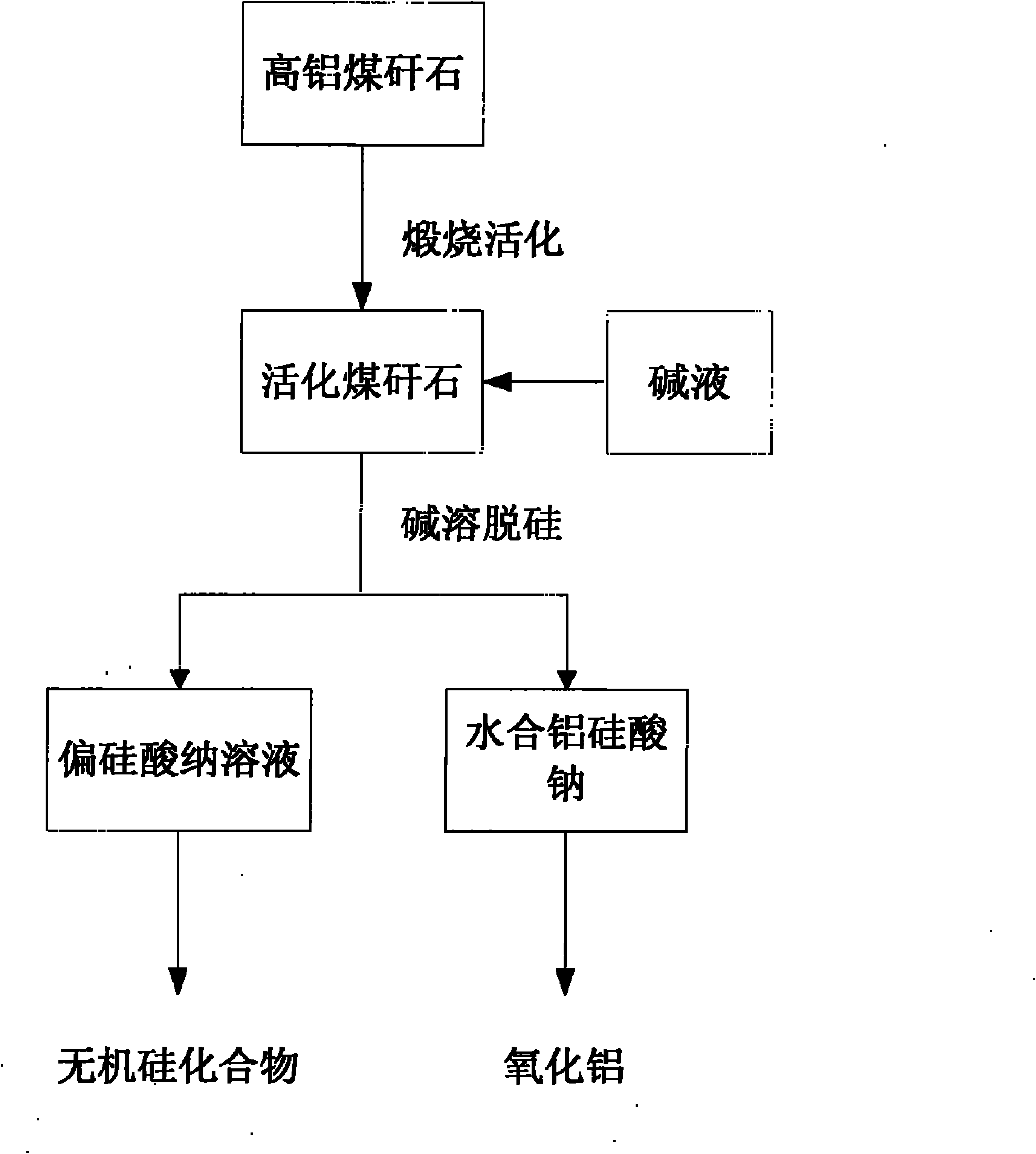

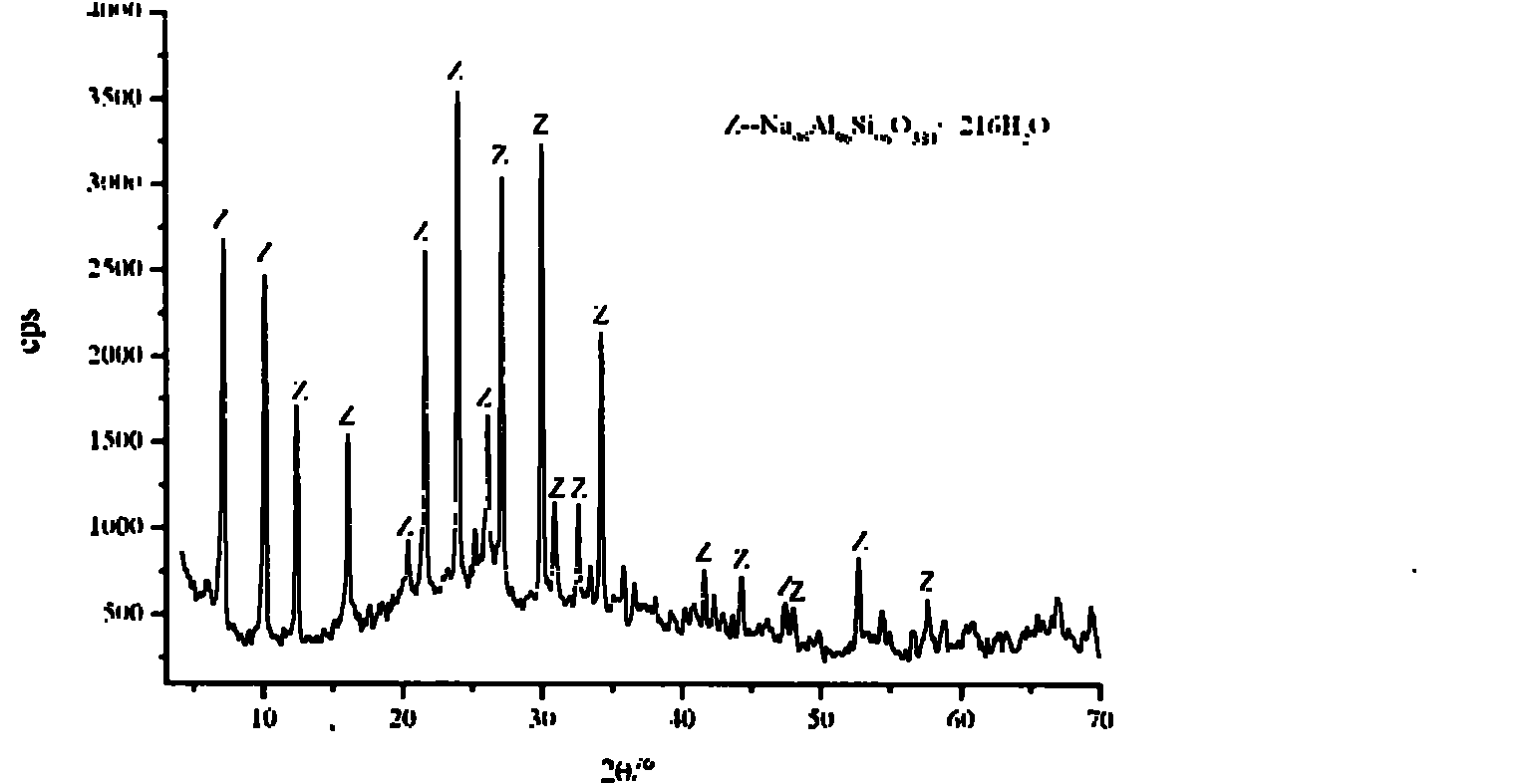

Technology for preparing hydrated sodium aluminosilicate by utilizing high-alumina coal gangue and fly ash alkali soluble desiliconization

InactiveCN102167338AIncrease Al-Si RatioEmission reductionAluminium silicatesSODIUM SILICATE SOLNSodium aluminosilicate

The invention discloses a technology for preparing hydrated sodium aluminosilicate by utilizing high-alumina coal gangue and fly ash alkali soluble desiliconization, and the technology provided by the invention comprises a high-alumina coal gangue alkali soluble desiliconization technology and a high-alumina fly ash alkali soluble desiliconization technology. The high-alumina coal gangue is activated in a roasting way and is leached by alkali liquor, solid-liquid separation is carried out, and the filter liquor is sodium silicate solution which can be used for preparing an inorganic silicon compound; and a filter cake is a hydrated sodium aluminosilicate material which can be used as a raw material for producing aluminum oxide. The high-alumina fly ash can be formed at a high temperature,the activating working procedure in a roasting way can be omitted, and the alkali soluble desiliconization can be directly performed. The technology is characterized in that the technical process is simple, the obtained hydrated sodium aluminosilicate material is taken as the raw material for producing the aluminum oxide, the hydrated sodium aluminosilicate is higher in aluminum-silicon mass ratio and higher in sodium oxide mass fraction, the alkali matching quantity and the silicon-calcium tailings discharging quantity of the process for preparing the aluminum oxide by utilizing the high-alumina coal gangue or the high-alumina fly ash can be obviously reduced, and the economic benefit of the technical process for preparing the aluminum oxide by utilizing the high-alumina coal gangue or the high-alumina fly ash can be improved.

Owner:昊青薪材(北京)技术有限公司

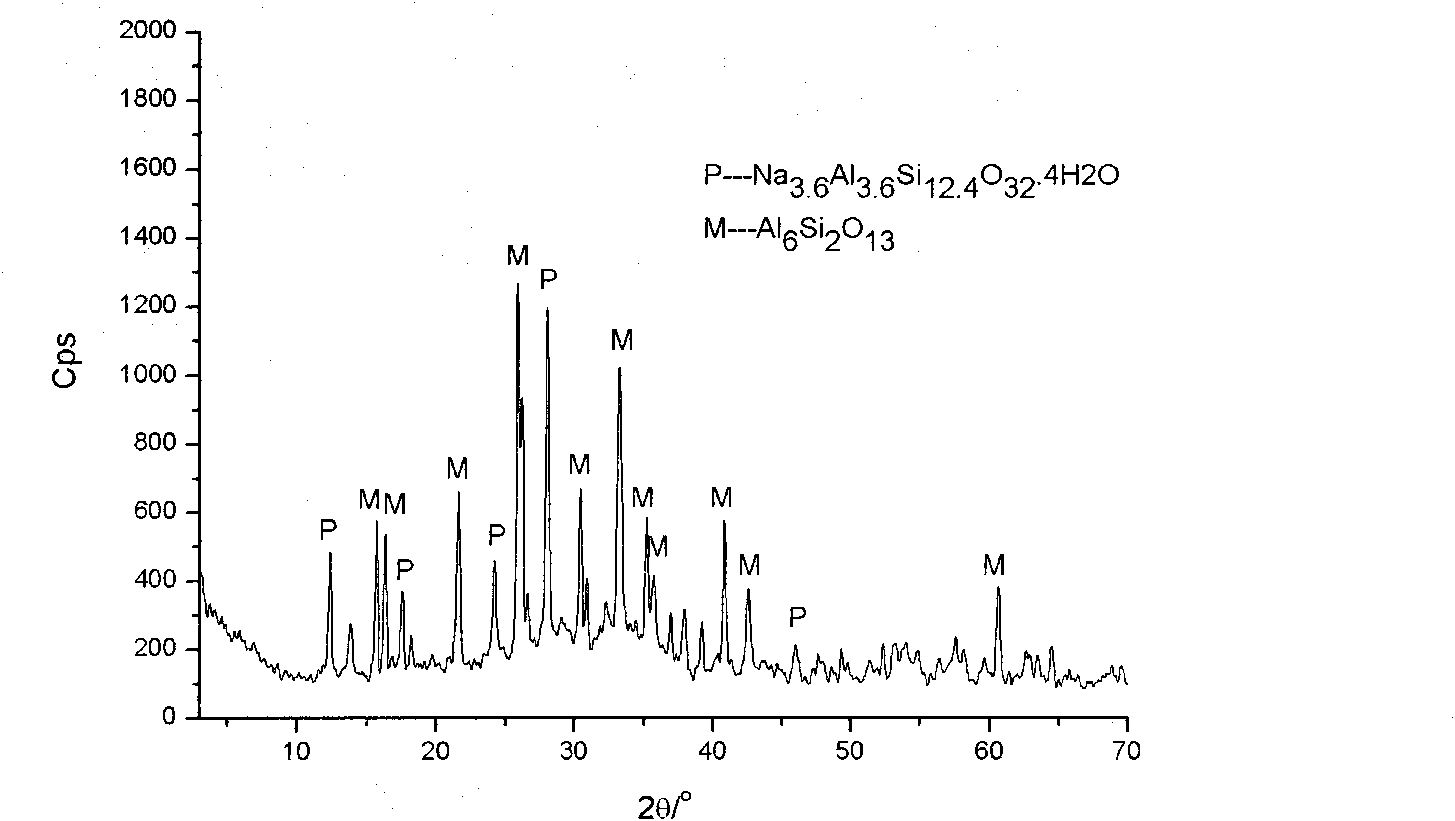

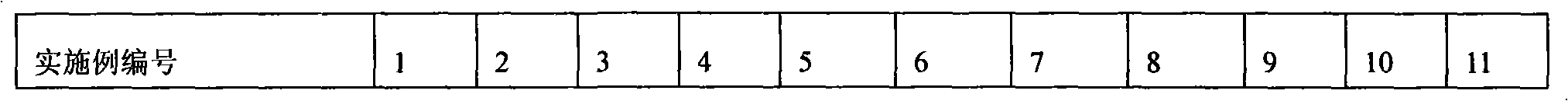

Process for abstracting floating air ball from fly ash or slag

The invention relates to a method for comprehensively utilizing fly ash and furnace cinder, in particularly to a method for extracting floating beads from the fly ash or the furnace cinder. The method comprises the following: a working procedure of screening refined iron sand from the fly ash or the furnace cinder; a working procedure of flotating floating beads; a working procedure of pre-desiliconization; a technological flow of producing white carbon black; a technological flow of producing aluminum oxide; and a technological flow of producing cement by utilization of waste residue. The method arranges a flotating device before pre-desiliconization technological reaction to extract the floating beads from the reacted mixture, and can obtain white floating bead products after decarbonization and secondary selection. Simultaneously, the white carbon black, the aluminum oxide and the joint cement can be organically, continuously and sequentially extracted from the fly ash or the furnace cinder after the floating beads are extracted, thereby the method realizes comprehensive utilization of the fly ash or the furnace cinder.

Owner:北京世纪地和控股有限公司

Method for producing aluminum oxide by utilizing high-alumina fly ash

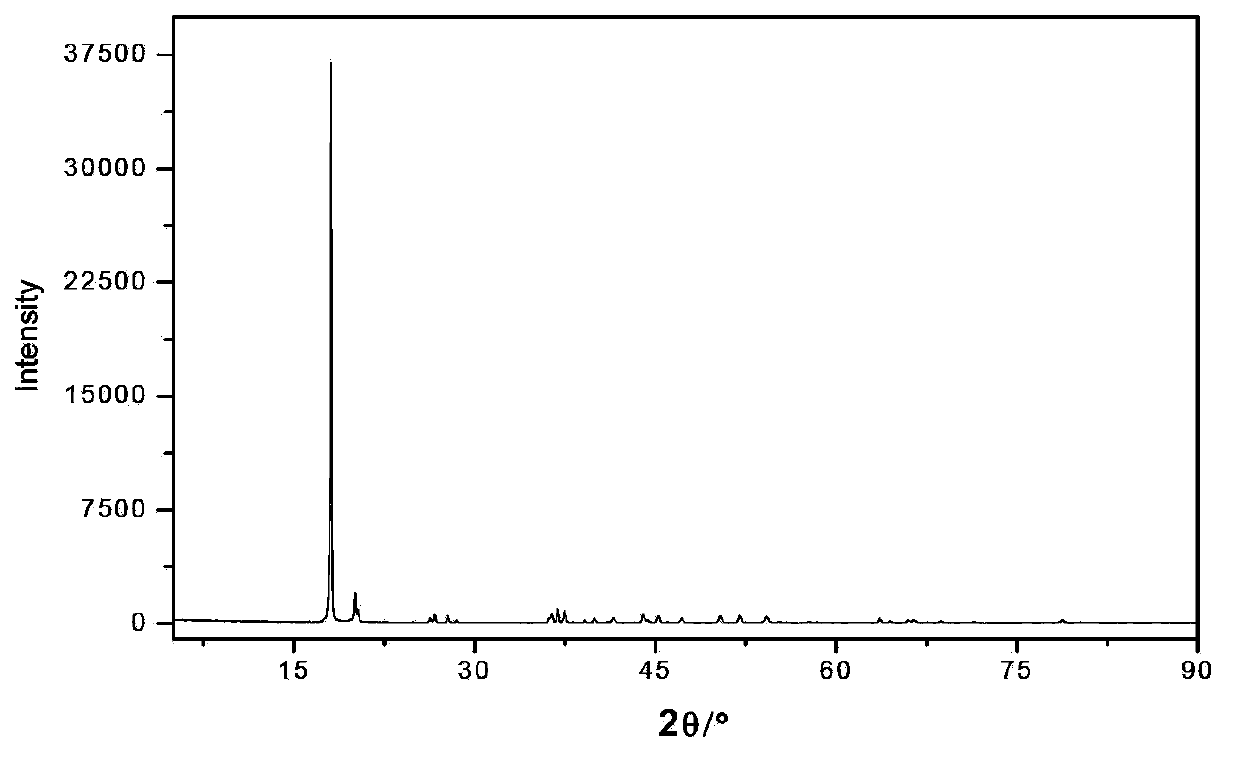

ActiveCN104030331AEmission reductionReduce production energy consumptionAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationState of artDecomposition

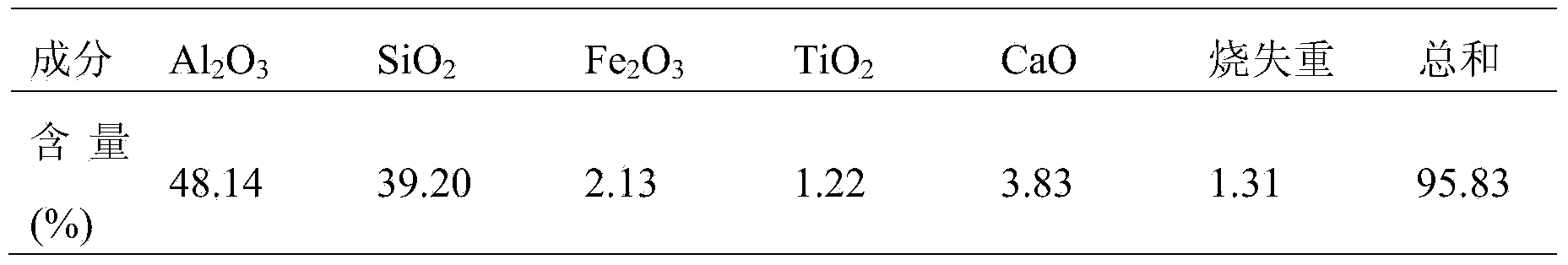

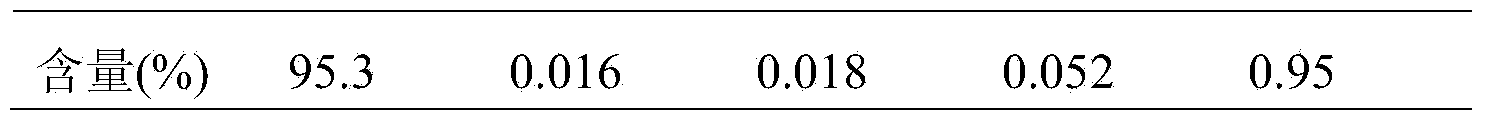

The invention provides a method for producing aluminum oxide by utilizing high-alumina fly ash. The method comprises the following steps: 1) pre-desilicification treatment; 2) primary alkali dissolution reaction; 3) secondary alkali dissolution reaction; 4) crystallization of sodium metaaluminate; 5) seed precipitation decomposition of aluminum hydroxide; and 6) aluminum oxide product. After the pre-desilicification treatment is carried out on high-alumina fly ash, the dissolution processes of the aluminum oxide are conducted by two steps, twice alkali dissolution adopts different alkali concentrations, so that the problem that the prior art only adopts alkali dissolution once and has high requirements on the reaction conditions of temperature and alkali concentration and the like can be effectively solved, the aluminum oxide in the high-alumina fly ash can be fully dissolved, and the dissolution rate can achieve more than 92%.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for preparing aluminum hydroxide by utilizing high-alumina coal ash

ActiveCN103663516AIncrease Al-Si RatioReduce productionAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

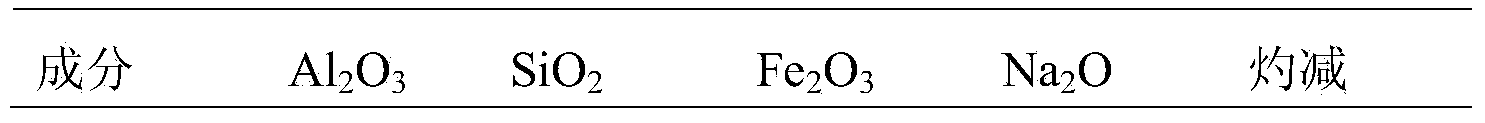

The invention relates to a method for preparing aluminum hydroxide by utilizing high-alumina coal ash. By adopting the deep desilicication process and the two-step sub-molten salt dissolution process, not only can the secondary enrichment of the silicon component be realized, but also the aluminum component can be adequately dissolved under the low temperature and low pressure, the operation condition is moderate, the silicon and aluminum can be adequately utilized, and the dissolution rate of the aluminum can reach more than 95 percent. The method comprises the following steps: pretreating the high-alumina coal ash in a deep desilicication way; primarily dissolving; secondarily dissolving; concentrating and crystallizing the dissolution liquid; dissolving hydrated sodium aluminate crystals; performing desilicication on the sodium aluminate coarse liquid; seed precipitating the aluminium hydroxide; and dealkalizing tailings. The obtained desilicication liquid can be used for preparing a liquid controlled process silicon-base product such as white carbon black, and the dealkalized tailings obtained in the process can be used for preparing a solid controlled silicon-base building material such as cement. The raw materials used in the method are wide in source, the price is low, the process is simple, the alkali circulation volume is small, the energy consumption and the water consumption are low, the utilization rate of raw materials is high, and the method is applicable to the industrialized popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

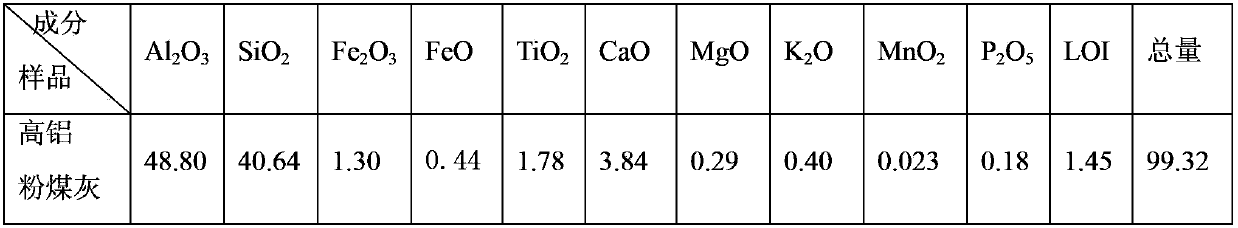

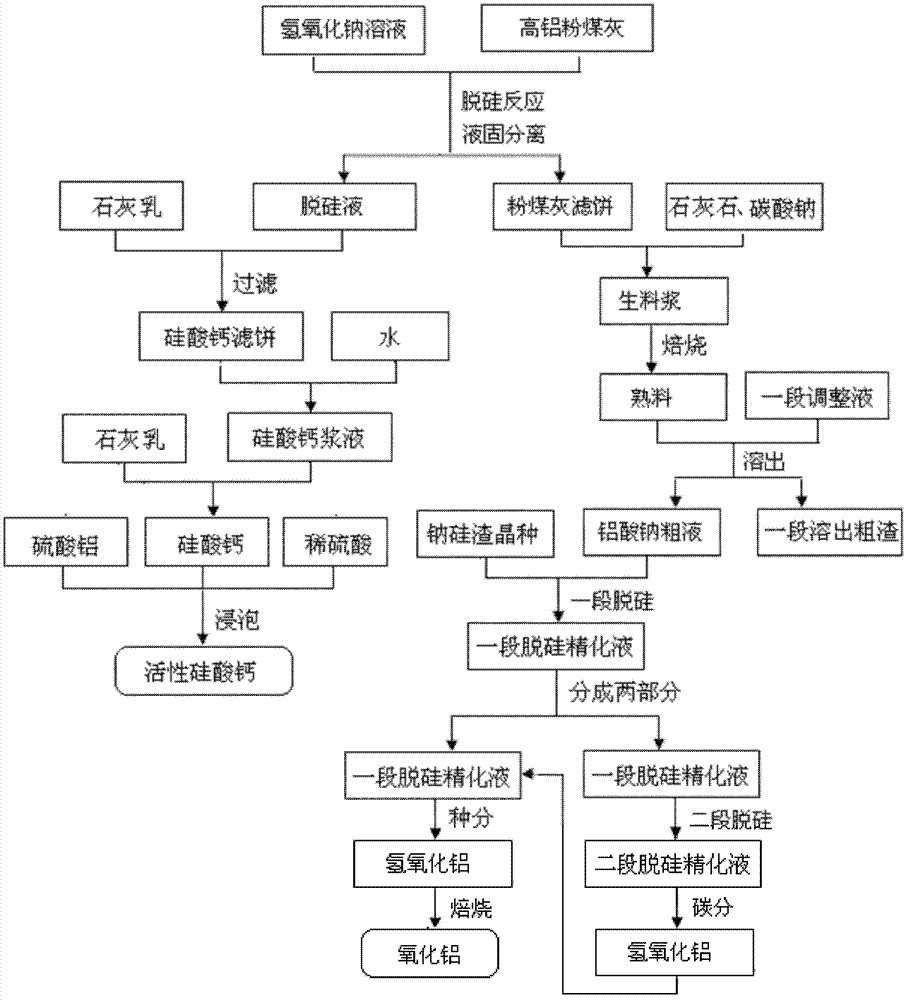

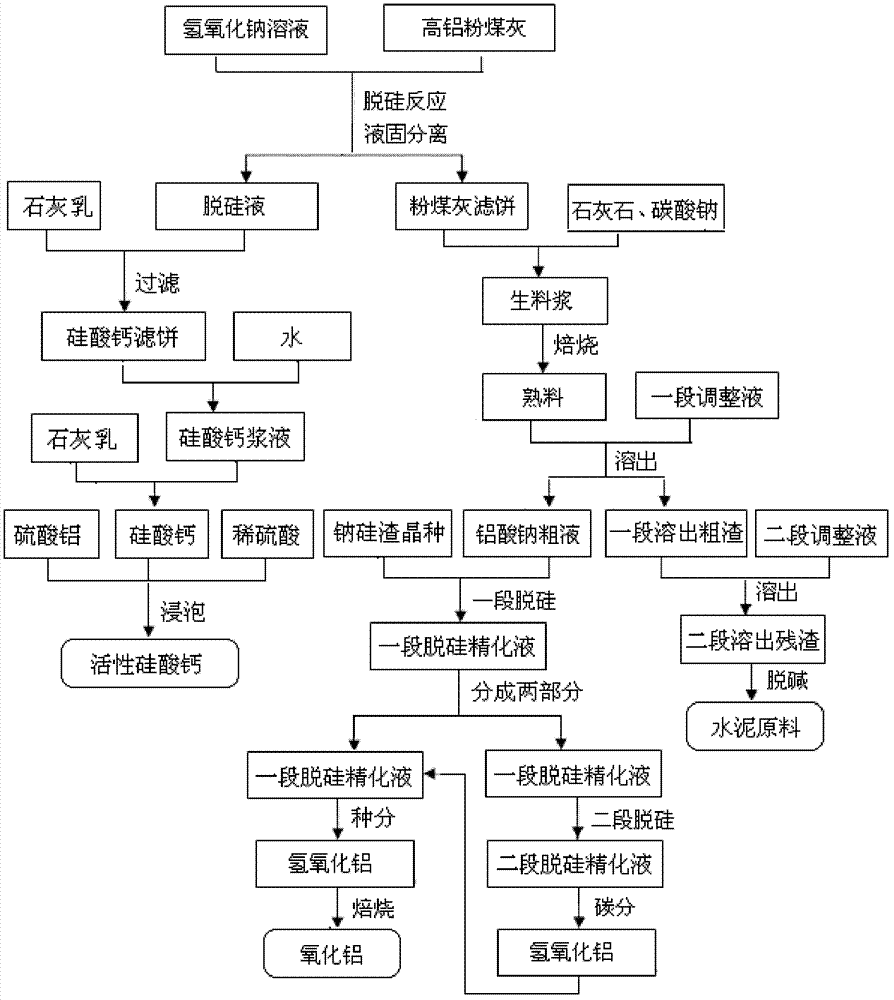

ActiveCN102249253BExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateChemical industry

The invention provides a method for producing alumina and co-producing active calcium silicate with high-alumina fly ash. The steps include: first reacting high-alumina fly ash with sodium hydroxide solution to perform pre-desilication to obtain liquid-phase desiliconization liquid and Desiliconized fly ash in solid phase; add milk of lime to the desiliconized liquid for causticization reaction, the solid phase is active calcium silicate, and the finished product is obtained by pressure filtration and flash drying; add limestone and carbonic acid to the desiliconized fly ash The sodium solution is formulated into a qualified raw slurry, and then the qualified raw slurry is roasted into clinker, and the liquid phase dissolved in the clinker is sodium aluminate crude solution; the sodium aluminate crude solution is desiliconized, carbonized, and seeded in the first and second stages. Metallurgical grade alumina that meets the requirements can be obtained after processes such as calcination and roasting. The invention overcomes the defects in the prior art, realizes less material flow and slag formation, relatively low energy and material consumption and production costs, high alumina extraction rate, and co-produces active calcium silicate with high added value, which can be used Widely used in chemical industry.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Method for preparing high-strength petroleum fracturing propping agent from low-grade bauxite

The invention discloses a method for preparing a high-strength petroleum fracturing propping agent from low-grade bauxite. In the method, low-grade bauxite used as a raw material is treated by a mineral dressing method to increase the aluminum-silicon ratio; and then, the raw material is mixed with auxiliary materials to prepare the high-strength petroleum fracturing propping agent. The method comprises the following steps: (1) selecting a representative low-grade bauxite ore sample, crushing and grinding the raw ore, and increasing the aluminum-silicon ratio of the raw material through an anionic oleic acid collector direct flotation or cationic amine collector reverse flotation method; and (2) grinding the floated bauxite with the increased aluminum-silicon ratio, then mixing with the auxiliary materials according to a certain ratio, further mixing and pulverizing in a jet pulverizing machine, then granulating in a coating machine to obtain a green compact having an appropriate particle size, and sintering the green compact in a rotary kiln to obtain the high-strength petroleum fracturing propping agent. According to the invention, the process is simple and environment-friendly, the low-grade bauxite can be utilized, and the production cost is low.

Owner:KUNMING METALLURGY INST

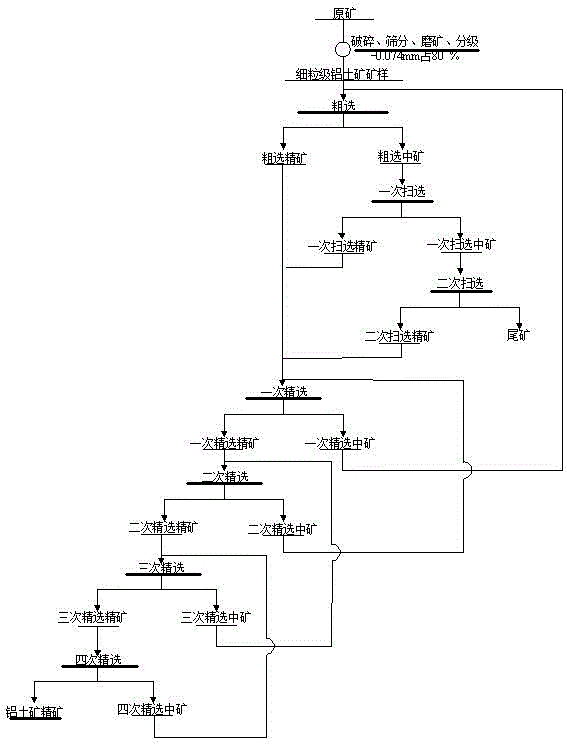

Step-by-step desiliconizing and upgrading method for high-aluminum and high-silicon bauxite

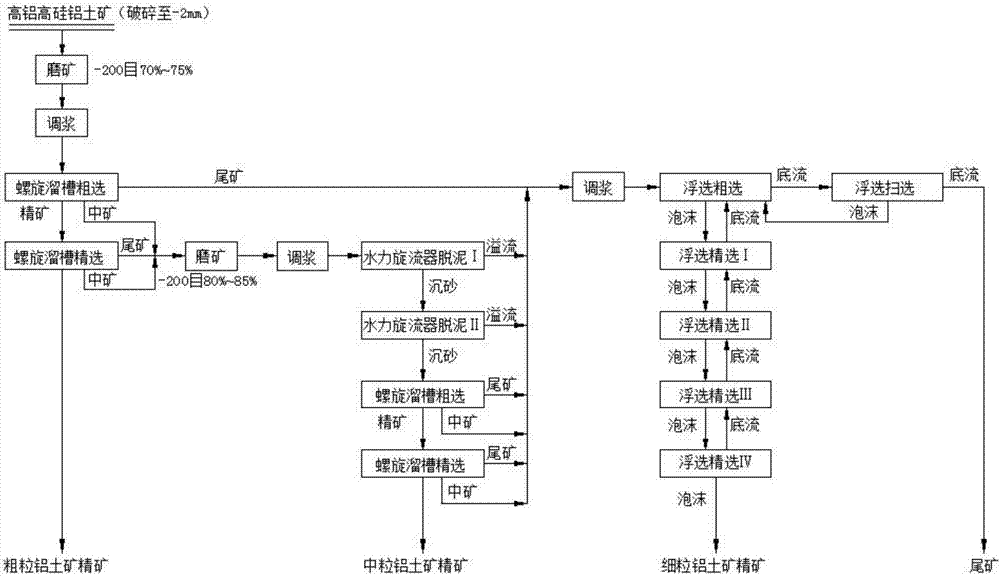

ActiveCN106902975AReduce the amount of oreReduce economic costsFlotationWet separationHigh aluminumCyclone

The invention belongs to the technical field of mineral processing engineering and relates to a step-by-step desiliconizing and upgrading method for high-aluminum and high-silicon bauxite. The method comprises the steps that firstly, the high-aluminum and high-silicon bauxite is subjected to rough grinding, slurry mixing is conducted, a spiral chute is adopted to conduct the first step of desiliconizing, and coarse grain bauxite concentrate ores are obtained through roughing and concentrating; secondly, middlings in the first step are combined and reground, slurry mixing is conducted, the second step of desiliconizing is conducted through a hydraulic cyclone and the spiral chute in sequence, specifically, desliming is conducted through the hydraulic cyclone firstly, settled sand of slime is subjected to roughing and concentrating through the spiral chute, and medium grain bauxite concentrate ores are obtained; and thirdly, the middlings and tailings obtained in the first and second steps are combined and subjected to floatation desiliconizing, fine grain bauxite concentrate ores are obtained through a closed floatation process. By means of the step-by-step desiliconizing and upgrading method that the coarse grain ores are enriched in the spiral chute after rough grinding, after the middlings are reground, the medium grain ores are enriched in the hydraulic cyclone united with the spiral chute, and tailing fine slime flotation is conducted to enrich the fine grain ores, the bauxite concentrate ores of different grain grades are obtained by stages, so that the step-by-step desiliconizing and upgrading method has the advantages that drug consumption is low, the recovery rate is high, and desiliconizing is thorough.

Owner:KUNMING UNIV OF SCI & TECH

Pipeline and dwell tank desiliconization method of fly ash

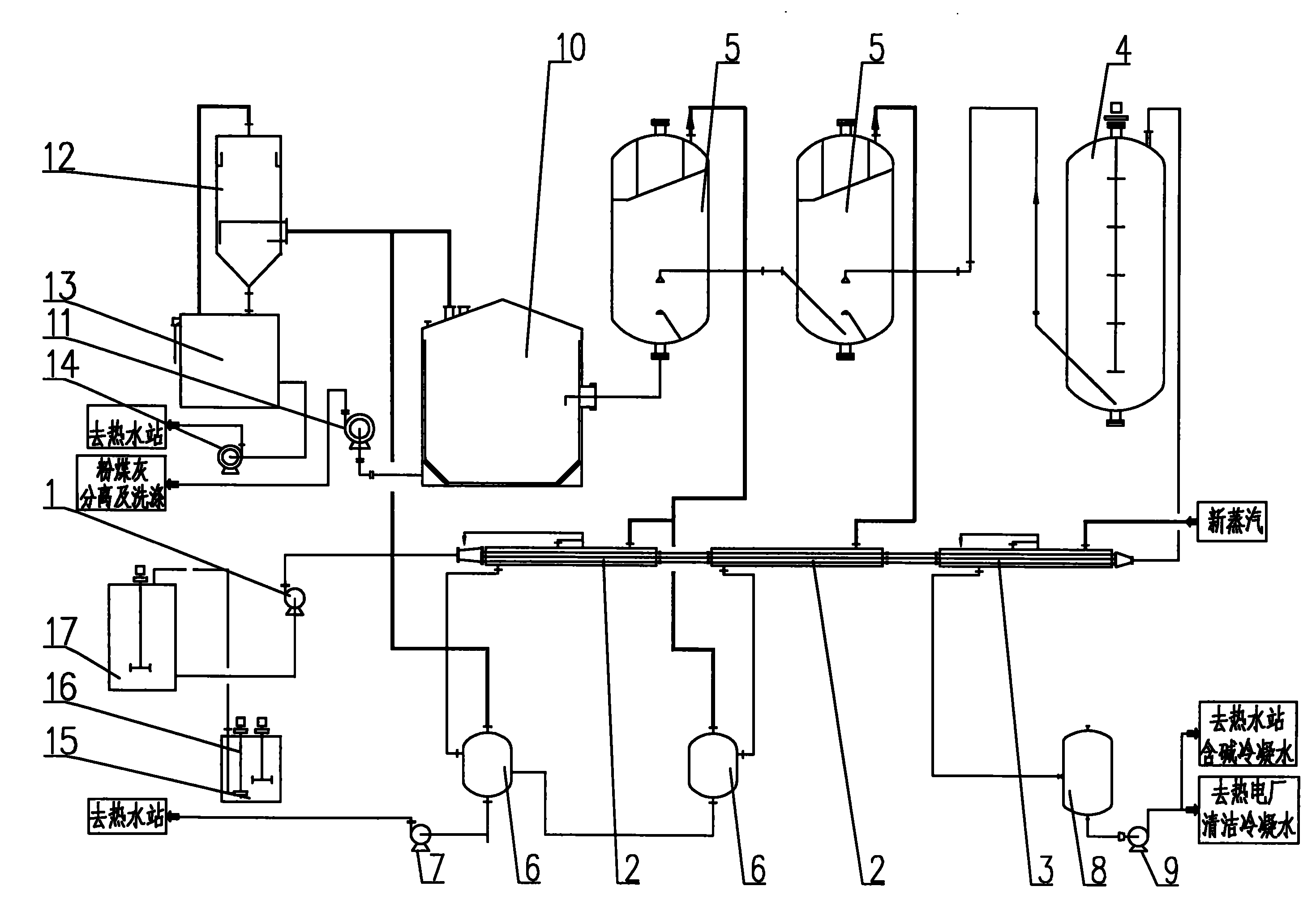

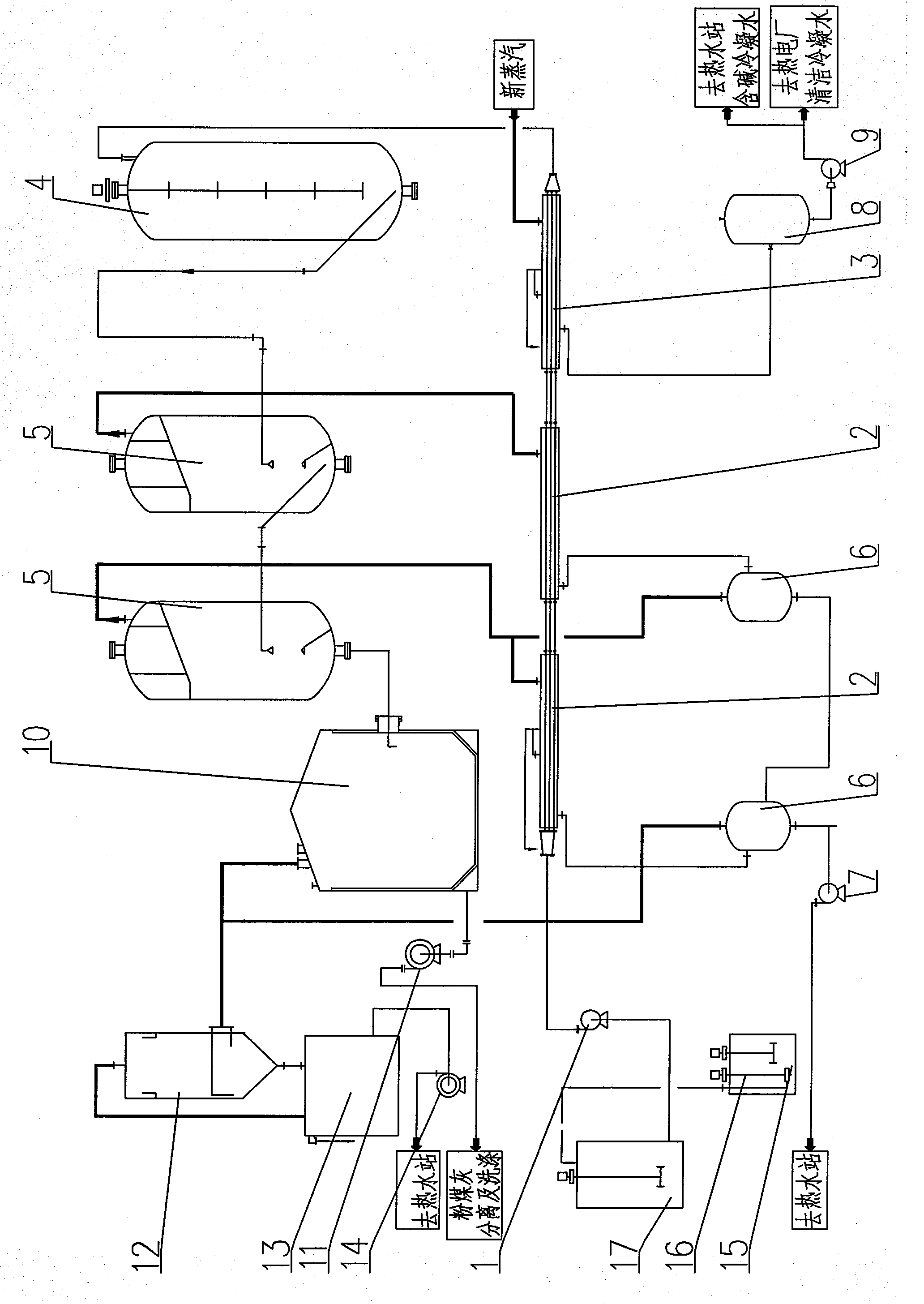

InactiveCN101811713AImprove heat utilizationReduce energy consumptionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationBuffer tankSilicon dioxide

The invention relates to a pipeline and dwell tank desiliconization method of fly ash, which comprises the technical process that the fly ash is added into an NaOH solution to be prepared into fly ash material pulp; the materials are sent into a secondary multi-inner-pipe sleeve pipe preheater to be preheated to 70 to 75 DEG C; the preheated fly ash material pulp enters a multi-inner-pipe heater to be heated to 130 to 135 DEG C; then, material pulp enters a heat insulation dwell tank for dwelling 1 to 2 hours in the heat insulation dwelling tank; desiliconized material pulp enters a secondary flash evaporator; the material pulp gradually carries out temperature reduction and pressure reduction according to the grades; then, the material pulp enters a buffer groove; the material pulp is sent into a conventional fly ash separation and washing work procedure through a buffer pump; the material pulp in the buffer tank enters a water cooling type steam lack recovering device in a steam lack mode; and the heat is absorbed by low-temperature circulation water. The method of the invention has the characteristics of high heat utilization rate, low energy consumption, low investment, low operation cost, simple process flow, convenient production operation, convenient cleaning and maintenance and the like, can improve the aluminum-silicon ratio of the fly ash material pulp, and can remove 30 to 35 percent of silicon dioxide in the fly ash.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Method for wet-process extraction of alumina from high-aluminum fly ash

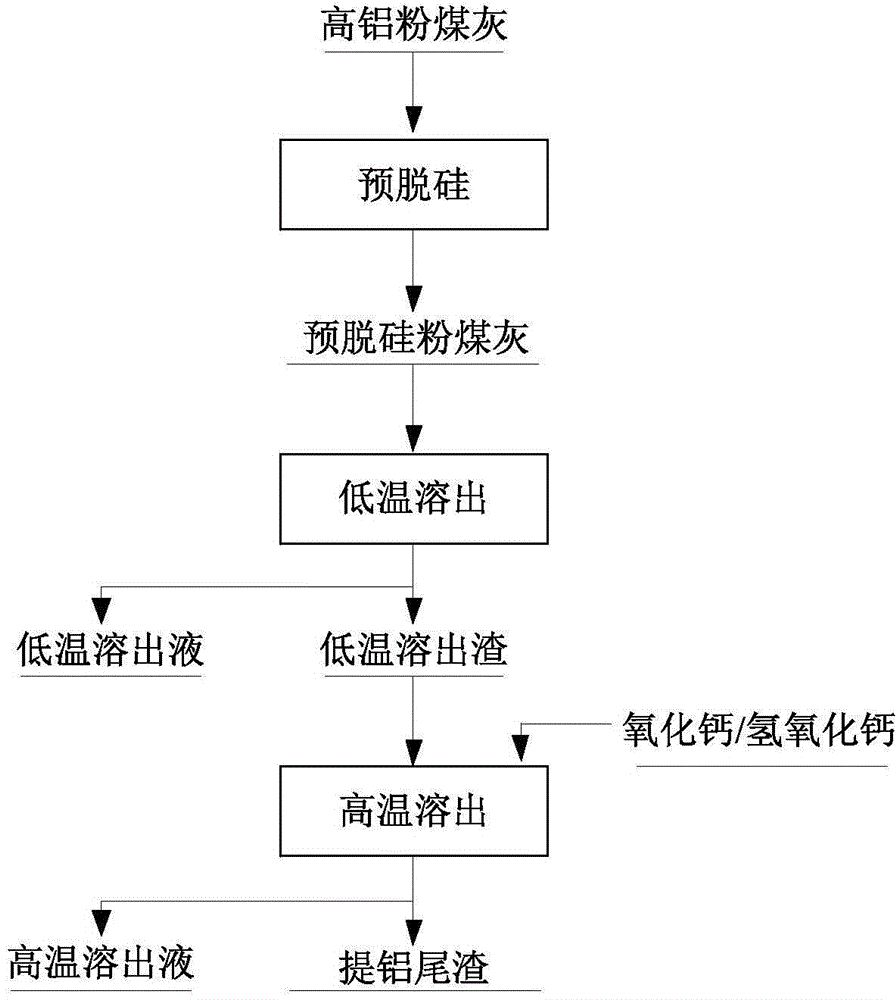

ActiveCN106145169AObvious superiorityIncrease Al-Si RatioSolid waste disposalAluminium oxides/hydroxidesDecompositionPrecipitation

The invention provides a method for wet-process extraction of alumina from high-aluminum fly ash, and the method comprises the following steps: 1)silicon pre-removal treatment of the high-aluminum fly ash; 2)low temperature wet dissolution of part of alumina from silicon-pre-removed fly ash; 3)high temperature wet dissolution of the alumina from low temperature dissolution slag; 4)mixing of dissolution solutions of the step 2)and the step 3)and seeded precipitation spent liquor for evaporation concentration crystallization for preparation of hydrated sodium aluminate crystals, or mixing of the dissolution solution of the step 2)and the seeded precipitation spent liquor for evaporation concentration crystallization for preparation of the hydrated sodium aluminate crystals, and returning of the dissolution solution of the step 3)back to the step 2)as a dissolution medium; and 5)dissolving of the hydrated sodium aluminate crystals in a dilute alkali solution, silicon removal and seed decomposition to obtain aluminum hydroxide, and calcination to obtain an alumina product. According to the method, the alumina is step-by-step dissolved, dissolution temperature and dissolution pressure are low, energy consumption is low, requirement of equipment materials is low, process is simple, aluminum and silicon both are effectively utilized, and the method adopts a full-wet process, and is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

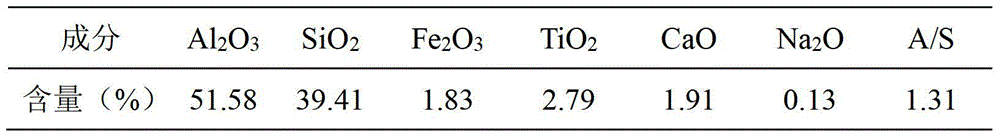

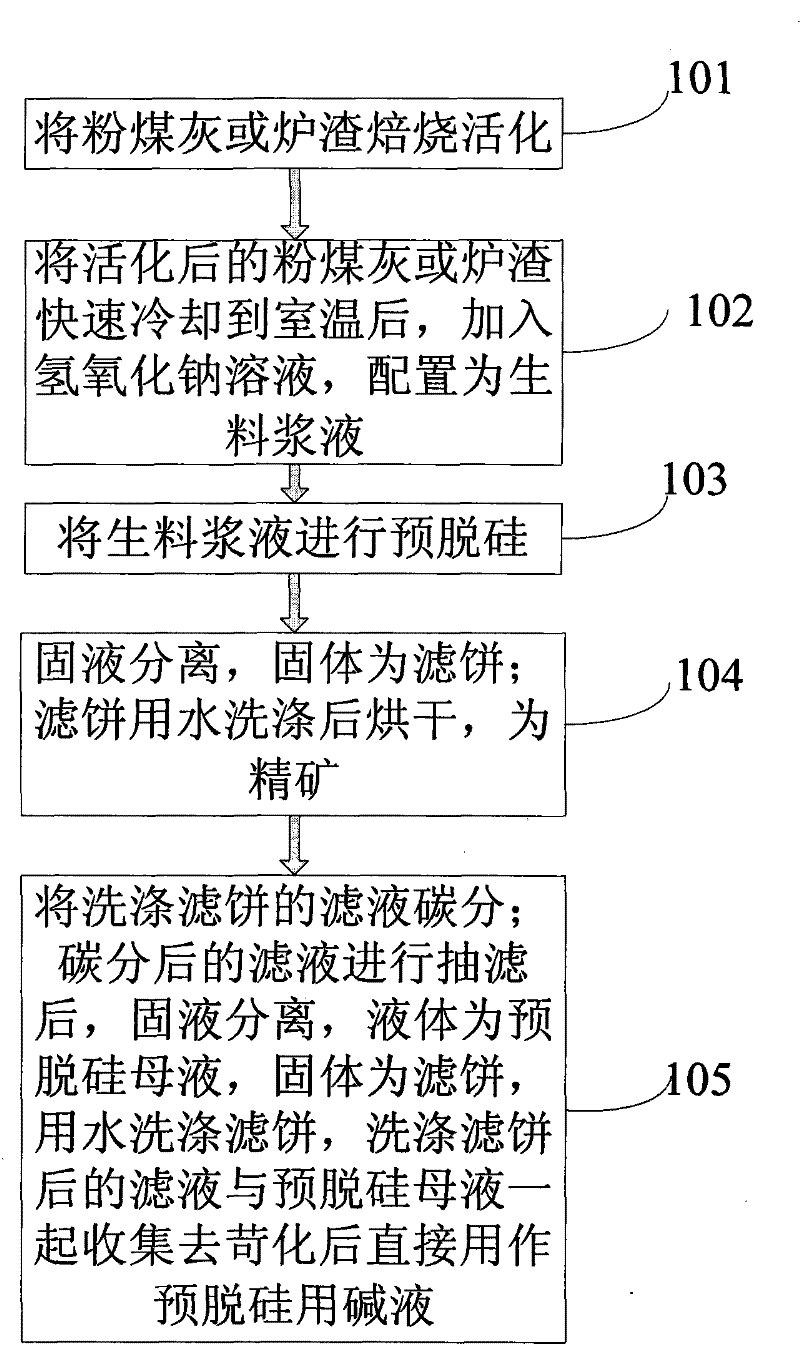

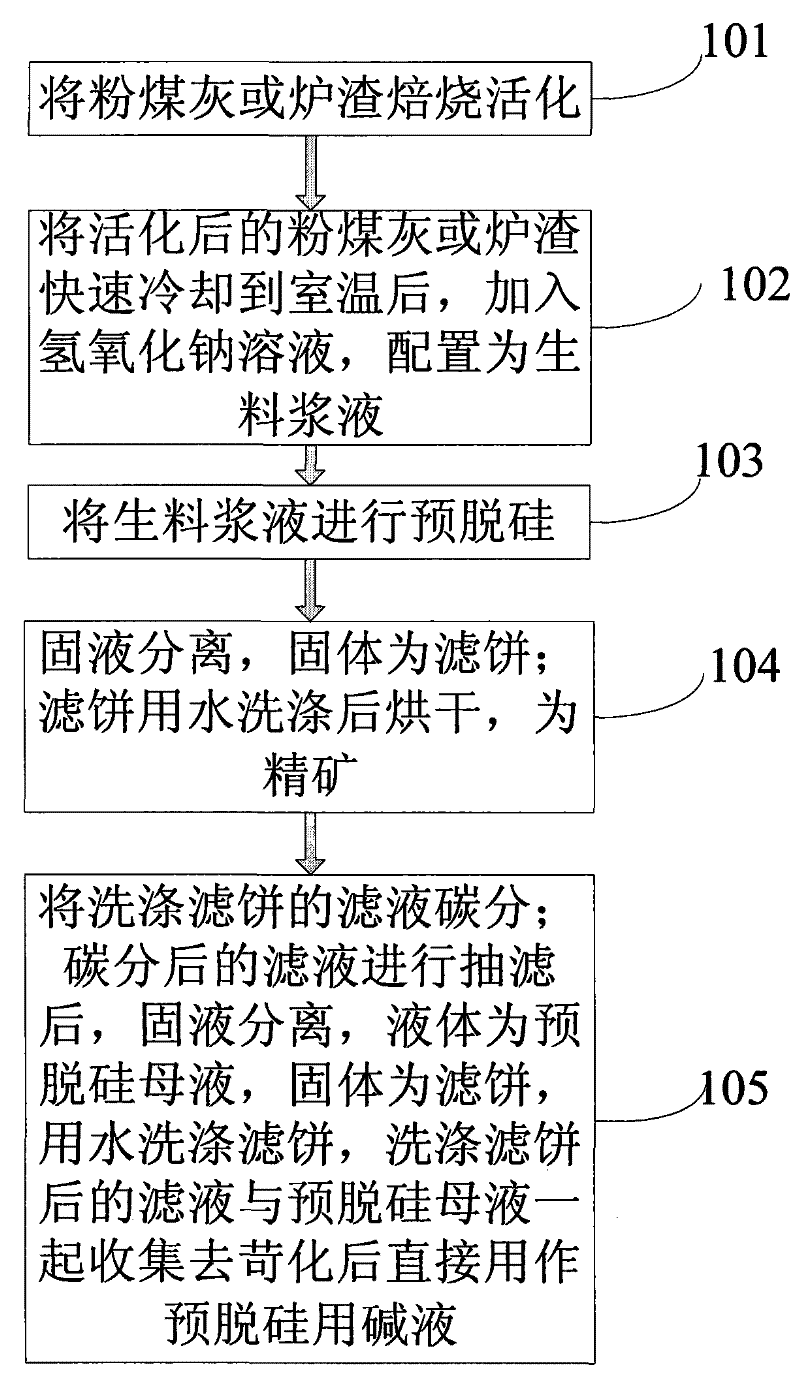

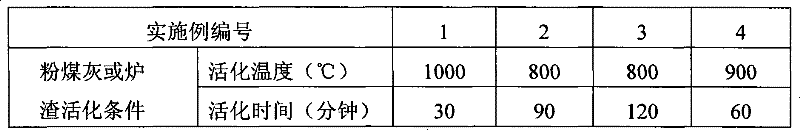

Pre- desiliconizing method from fly ash or slag

ActiveCN101306928BIncrease Al-Si RatioReduce the amount of raw material to be burnedSolid waste managementCooking & bakingSlag

The invention relates to a method for the comprehensive application of fly ash or slag, in particular to a method for the predesilication of the fly ash or the slag. The method mainly comprises the process flows including the baking and the activation of the fly ash or the slag, the formula process of the raw meal of activated the fly ash or the slag and a sodium hydroxide solution and the production of white carbon black. Through adopting a technological line during which the fly ash or the slag are baked and activated at first and then a sodium hydroxide solution is used to extract noncrystalline silicon oxide at a low temperature, the method ensures that the mass ratio of aluminum oxide and silicon oxide of desilicated fly ash reaches to 2.14; therefore, the method breaks a new path totake the fly ash or the slag as a raw material source for extracting metallurgical-grade aluminum oxide, thereby increasing the comprehensive utilization value of the fly ash and the slag.

Owner:北京世纪地和控股有限公司

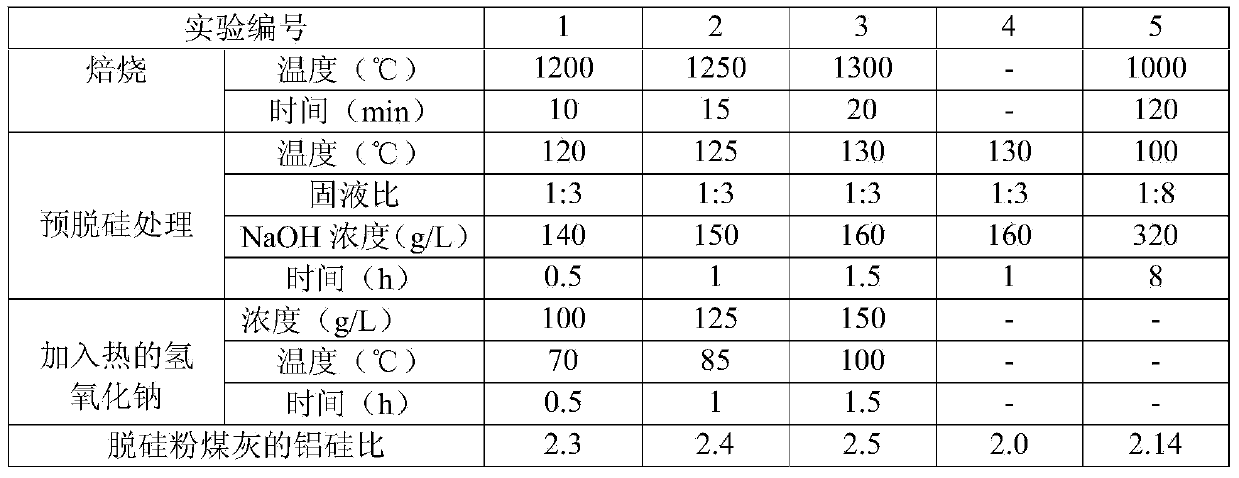

Production method of desiliconized coal ash

ActiveCN104043639ASimple production methodSimple processSolid waste disposalAluminium oxides/hydroxidesPhysical chemistrySlurry

The invention provides a production method of desiliconized coal ash. The method comprises the following steps: (1) roasting and activating coal ash; (2) after cooling the activated coal ash to the room temperature, mixing the activated coal ash with 140-160g / L sodium hydroxide for carrying out pre-desiliconization, so as to generate coal ash slurry; (3) after cooling the coal ash slurry to 70-80 DEG C, enabling the coal ash slurry to react with 100-150g / L sodium hydroxide at 70-100 DEG C, and filtering, washing and drying reaction products, so as to generate the desiliconized coal ash. By utilizing the production method, the aluminum-silicon ratio of the produced desiliconized coal ash can reach 2.3-2.5, and the production method has the advantages of simple process, low cost and high aluminum-silicon ratio.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Preparation method of homogeneous bauxite applicable to smelting of brown fused alumina

InactiveCN102583470AExpand the scope of useIncrease Al-Si RatioAluminium oxides/hydroxidesAluminiumTunnel kiln

The invention discloses a preparation method of homogeneous bauxite applicable to smelting of brown fused alumina. The preparation method is characterized by comprising the steps as follows: firstly, bauxite containing 65% to 69% of Al2O3 and bauxite containing 70% to 72% of Al2O3 are crushed to be less than or equal to 30 mm, roasted to 1000 DEG C in a rotary kiln for 2 hours, cooled and then crushed to be less than or equal to 0.074 mm; secondly, the crushed bauxite containing 65% to 69% of Al2O3 is screened, and the part which is 240 mesh to 0.074 mm is taken as material A for standby; thirdly, the crushed bauxite containing 70% to 72% of Al2O3 is screened, and the part which is 325 mesh to 0.074 mm is taken as material B for standby; fourthly, the materials A and B are intensively mixed and uniformly stirred according to the proportion of 1:1, and then are placed in a flour milling machine to produce the homogeneous bauxite which is less than or equal to 200 mesh; and fifthly, the homogeneous bauxite is shaped, roasted to 1150 DEG C in a tunnel kiln for 3 hours, cooled, and crushed to 30mm to 1mm to obtain a raw material finished product.

Owner:贵州黄平富城实业有限公司

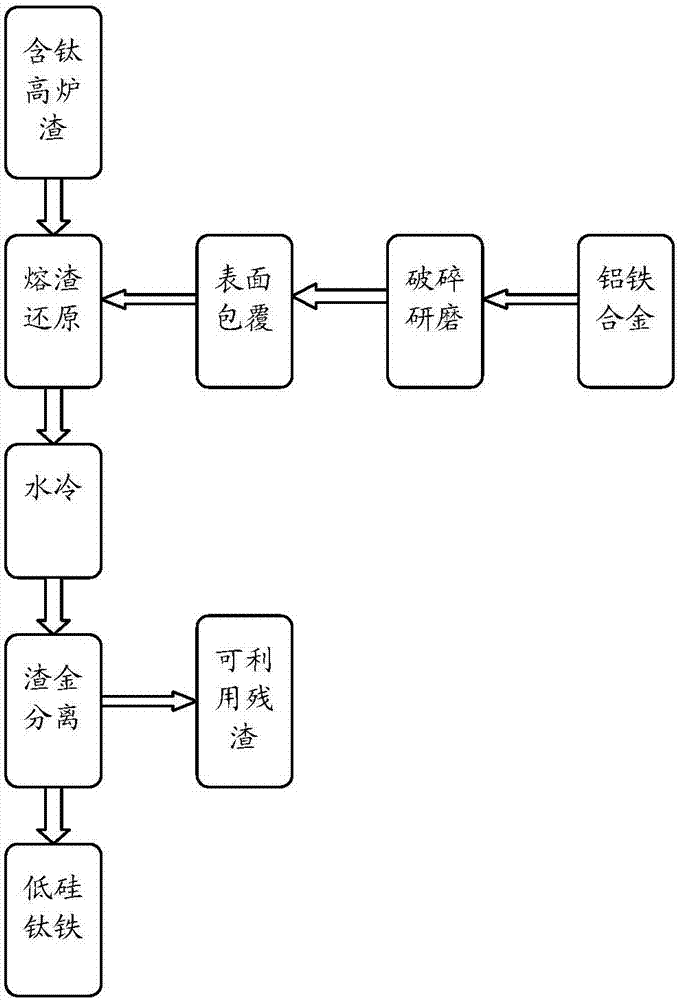

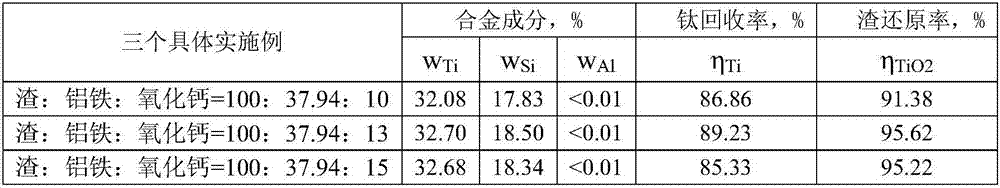

Process for smelting low-silicon ferrotitanium by fusing titanium-containing blast furnace slag

ActiveCN107400741ALow melting pointIncrease alkalinityRecycling and recovery technologiesTemperature controlCrucible

The invention discloses a process for smelting low-silicon ferrotitanium by fusing titanium-containing blast furnace slag. The process comprises the following steps: preparing slag, ferro-aluminium and calcium oxide in a mass ratio of 100 to 37.94 to (10-15); crushing ferroaluminum alloy, grinding the ferroaluminum alloy into powder with particles sizes which are more than or equal to 300 meshes, adding calcium oxide, mixing a calcium oxide mixture until the surface of the ferroaluminum alloy powder is uniformly coated; putting the titanium-containing blast furnace slag into a magnesia crucible, putting the magnesia crucible into a resistance furnace, carrying out furnace heating to 1450-1650 DEG C, and carrying out constant-temperature control; uniformly adding the mixed material into a fusion tank in a speed of 4.5g / min-5.5g / ml, and after the adding, maintaining the temperature for 5-10 minutes; taking out the material at 1450-1650 DEG C, carrying out water cooling, and drying; and separating slag and alloy by virtue of a mechanical method. According to the process, the particle size of the ferroaluminum alloy powder is more than 300 meshes; and meanwhile, by controlling the adding speed so as to control the reduction reaction time of aluminum and silicon, so that the reduction efficiencies of aluminum and silicon are improved, the consumption of the ferroaluminum alloy powder is reduced, the contentsof silicon and residual aluminum in the alloy is reduced, the process cost is lowered, and the silicon decrease and the titanium increase in the alloy are realized.

Owner:ANGANG STEEL CO LTD

Method for producing silicon dioxide and alumina by using fly ash

This invention discloses a method for extracting SiO2 and Al2O3 from fly ashes. The method comprises: activating fly ashes, leaching with more than 40 wt. % NaOH solution so that Si is stripped out in the form of sodium cilicate, introducing CO2 to prepare SiO2, adding CaO or CaCO3 into the leaching residue, calcining to obtain a clinker, preparing Al2O3 by Bayer method, and preparing cement from the waste residue. The method extracts Si at first, thus increasing the Al / Si ratio in the leaching residue. Treated leaching residue can be directly subjected to Bayer method to extract Al2O3, which largely simplify Al2O3 extraction process and increase Al2O3 utility. The method has such advantages as simple process, low investment, and high product added value.

Owner:PINGSHUO INDAL

Clay ore desiliconisation method

InactiveCN1995413AIncrease Al-Si RatioBroaden sources of raw materialsProcess efficiency improvementClay mineralsSilicon

The invention discloses a utilizing method of clay mineral source, which is characterized by the following: sintering clay with NaOH; removing silicon; transmitting SiO2 in the clay into non-crystal pattern to react easily for alkaline; keeping inert property for aluminium; improving the Al / Si rate of clay.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method of fast-flotation of bauxite with low Al/Si (aluminum/silicon) ratio

The invention relates to a method of the fast-flotation of bauxite with low Al / Si (aluminum / silicon) ratio, particularly a method for directly separating a part of bauxite concentrate with high floatability, coarse fraction and high Al / Si ratio on the basis of rough flotation or the combination of rough flotation and one-step concentration. The invention not only simplifies the whole technological process and accelerates the flotation, but also reduces the water consumption and reagent consumption and ensures better flotation effect; the invention overcomes the shortcomings of lengthy technological process, complicated operating procedures, high reagent consumption, severe technological slime entrainment, low economic benefit and the like; and the invention develops a novel method having the advantages of low process circulation load, high flotation index and good separating effect and reducing the water consumption and the reagent consumption.

Owner:CENT SOUTH UNIV

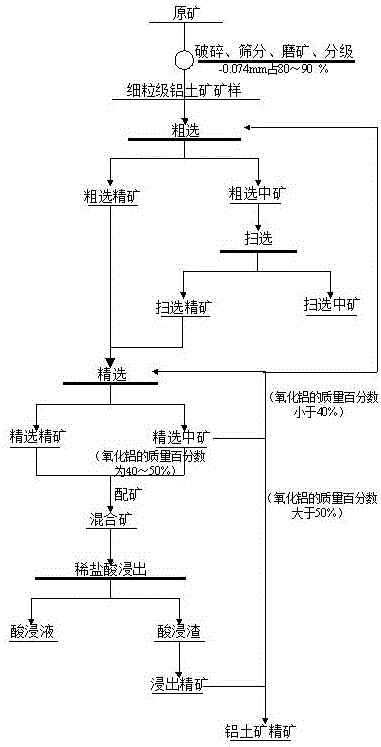

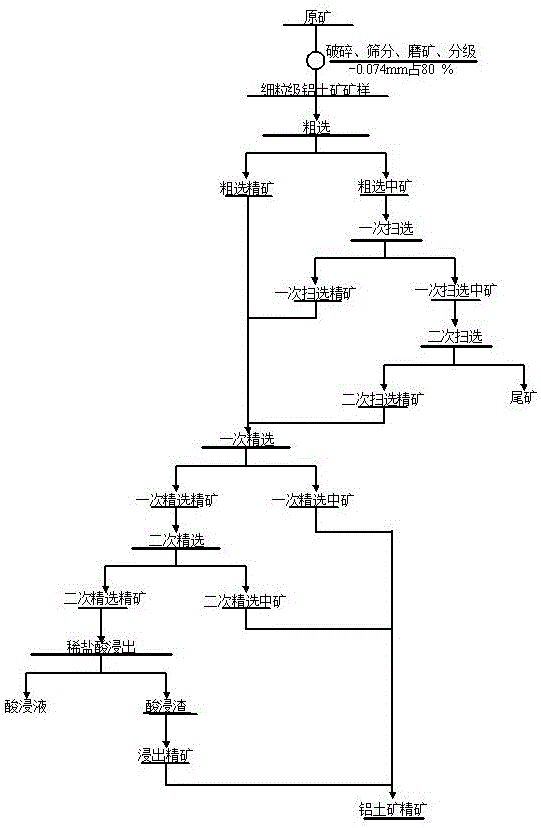

Carbonate type high-silicon bauxite beneficiation method

The invention relates to a carbonate type high-silicon bauxite beneficiation method, and belongs to the technical field of mineral processing. The method mainly comprises the following steps that firstly, carbonate type high-silicon bauxite (raw ore) is smashed, screened, ground and graded; then the graded bauxite is sorted through a roughing-scavenging-selection flotation method, and the bauxite rough concentrate and middlings with different qualities are obtained; the bauxite rough concentrate and middling products obtained through flotation are matched in proportion to obtain mixing ore, the mixing ore and diluted hydrochloric acid are mixed and react, and solid-liquid separation is carried out to obtain pickle liquor and acid leaching slag; and the acid leaching slag is washed and dried to obtain leached concentrate, the leached concentrate and the middlings with the mass percent of aluminum oxide larger than 50% are combined to obtain the qualified bauxite with high alumina-silica ratio and high Al2O3 grade. As for the carbonate type high-silicon bauxite, the new process including two sections including flotation desilication and diluted hydrochloric acid leaching is provided, and the better sorting index can be obtained compared with a traditional process.

Owner:KUNMING UNIV OF SCI & TECH

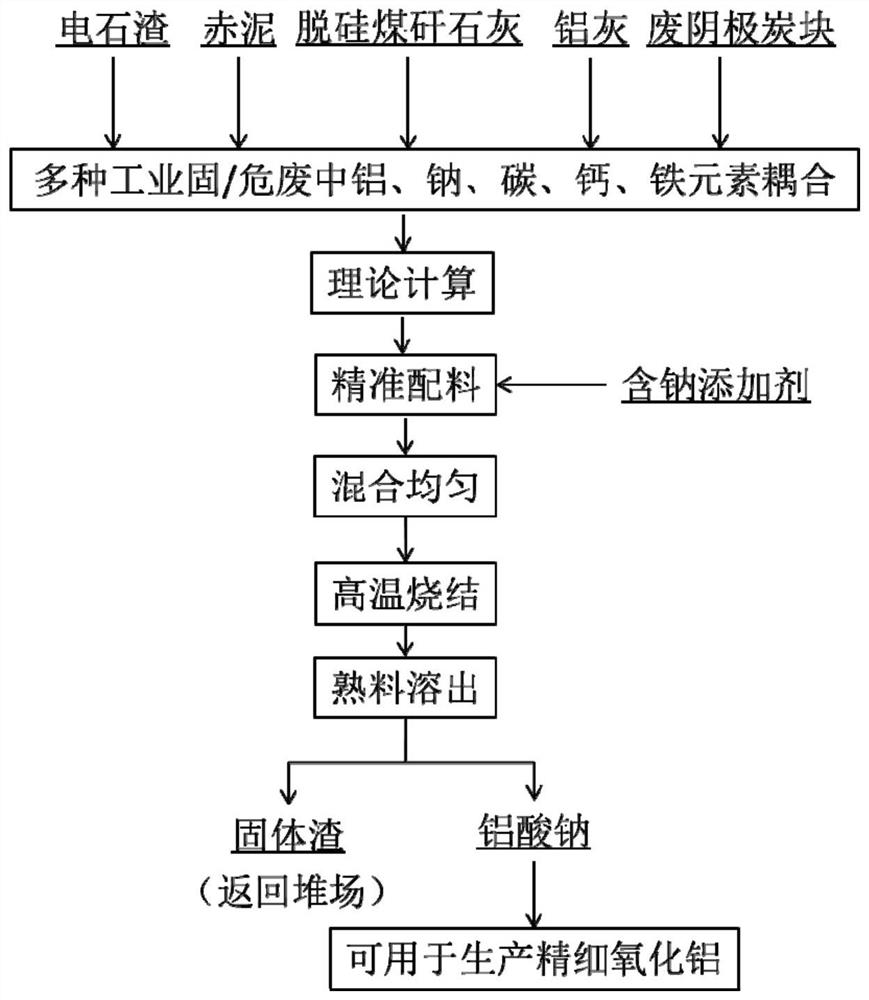

Coupling use method utilizing various industrial solid/dangerous wastes

ActiveCN112591776AAchieve reductionIncrease Al-Si RatioSolid waste disposalTransportation and packagingRed mudSlag

The embodiment of the invention discloses a coupling use method utilizing various industrial solid / hazardous wastes, and belongs to the field of industrial solid waste resource utilization. The coupling use method comprises the following steps: firstly, selecting pre-desiliconized coal gangue ash, aluminum ash, red mud, waste cathode carbon blocks and carbide slag as raw materials, then adding oneor more of sodium hydroxide, sodium carbonate and sodium bicarbonate as additives to prepare a uniformly mixed raw material, then sintering the raw material at a high temperature to obtain clinker, and finally, dissolving out the clinker to obtain solid slag and sodium aluminate. According to the method disclosed by the invention, aluminum-containing and sodium-containing components in the raw material can be converted into sodium aluminate in a sintering process by utilizing a coupling use method of various industrial solid / dangerous wastes, the calcium-containing component is easy to separate after being combined with impurity silicon, the carbon-containing component provides part of heat required by sintering, and the iron-containing component reduces the temperature required by sintering; and the standard dissolution rate of alumina in the sintered clinker is greater than 92%, and the standard dissolution rate of sodium oxide is greater than 94%.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725BIncrease Al-Si RatioLow firing temperatureAlkaline-earth metal silicatesCement productionCalcium silicateAluminium hydroxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon andcalcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxideto obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

Preparation method and application of desiliconized fly ash

InactiveCN108285163AIncrease Al-Si RatioMaximize resource utilizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFly ashSilicon

The invention provides a preparation method and application of desiliconized fly ash. The preparation method comprises the following steps that 1) ball milling treatment is conducted on high-aluminumcoal gangue to obtain high-aluminum coal gangue powder; 2) the coal gangue powder is calcined to obtain high-aluminum fly ash; 3) the high-aluminum fly ash and an acid treatment agent solution are mixed for acid treatment, and a filter cake is filtered and washed to obtain acid-treated fly ash; 4) the acid-treated fly ash and a sodium hydroxide solution are mixed for pre-desiliconization treatment, and a filter cake is filtered and washed to obtain the desiliconized fly ash, wherein the aluminum-silicon ratio of the desiliconized fly ash is 3.2-3.8. By means of the preparation method, the desiliconized fly ash with the aluminum-silicon ratio of 3.2-3.8 is prepared with the coal gangue as a raw material, the preparation process is simple and easy to operate, and the preparation cost is low.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

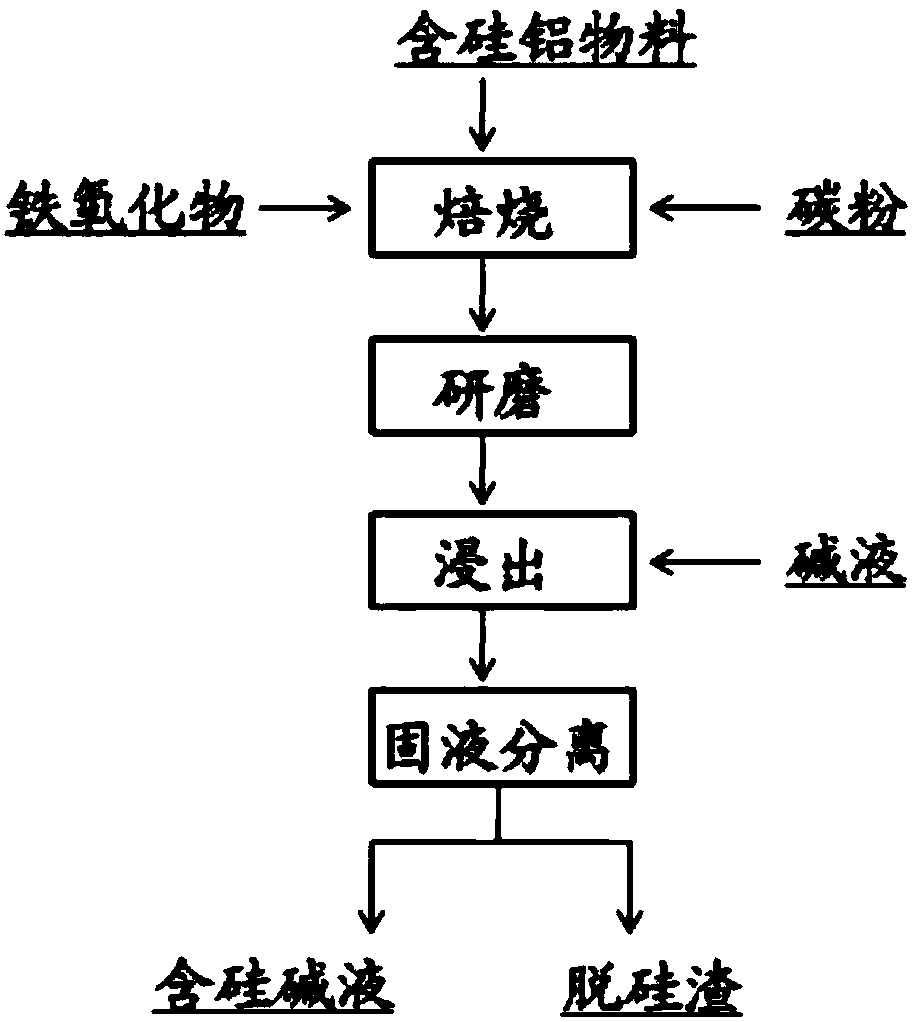

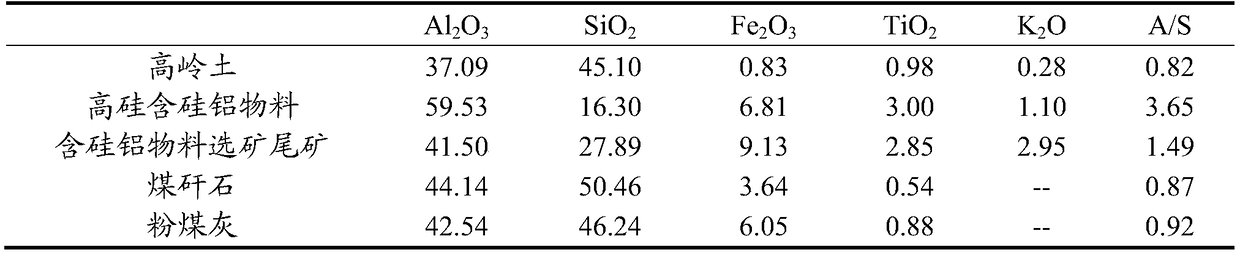

Silicon removal method of silicon-aluminum-containing material

InactiveCN109231245AIncrease Al-Si RatioFacilitate alkali leaching desilicationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlurrySodium hydroxide

The invention provides a silicon removal method of a silicon-aluminum-containing material. The silicon removal method comprises the following steps: taking iron oxide, the silicon-aluminum-containingmaterial and carbon powder and carrying out ore proportioning and grinding; then uniformly mixing to obtain a raw material, wherein the mol ratio of the iron oxide to aluminum oxide in the silicon-aluminum-containing material and carbon is (2 to 2.4) to 4 to (1 to 1.2); roasting the obtained raw material at 1050 to 1200 DEG C for 30 to 60min to obtain a clinker; after grinding the clinker, addinginto a sodium hydroxide solution and immersing with alkali; and carrying out solid-liquid separation on ore slurry obtained by alkali immersion to obtain silicon-containing alkali liquid and silicon removal dreg. According to the silicon removal method provided by the invention, aluminum and silicon in the silicon-aluminum material can be efficiently separated and the removal rate of silicon oxideis high. The silicon removal method has the advantages of simple technological flow and low cost, and silicon removal of aluminosilicate minerals including kaolin, illite, pyrophyllite and the like can be realized, and difficult-to-treat high-silicon aluminum-containing minerals including silicon-aluminum-containing material mill tailings, coal gangue, fly ash, a high-iron silicon-aluminum-containing material and the like can be subjected to silicon removal; and the silicon removal method has a wide application prospect and good economic benefits.

Owner:CENT SOUTH UNIV

Preparation method for desiliconized fly ash

The invention provides a preparation method for desiliconized fly ash. The preparation method comprises the following steps: 1) performing acid treatment on high-aluminum fly ash, performing filtering, and washing a filter cake to obtain acid-treated fly ash; 2) performing normal-pressure pre-desiliconization treatment on the acid-treated fly ash by adopting a first alkali solution, performing filtering, and washing a filter cake to obtain primary-desiliconization fly ash; and 3) performing normal-pressure pre-desiliconization treatment on the primary-desiliconization fly ash by adopting a second alkali solution, performing filtering, and washing a filter cake to obtain the secondary-desiliconization fly ash, wherein a concentration of the first alkali solution is smaller than a concentration of the second alkali solution. The preparation method provided by the invention can greatly improve an aluminum-silicon ratio of the desiliconized fly ash, wherein the aluminum-silicon ratio can reach 2.7-3.0; and the preparation method has the advantages of a simple process, low energy consumption and low investment costs.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

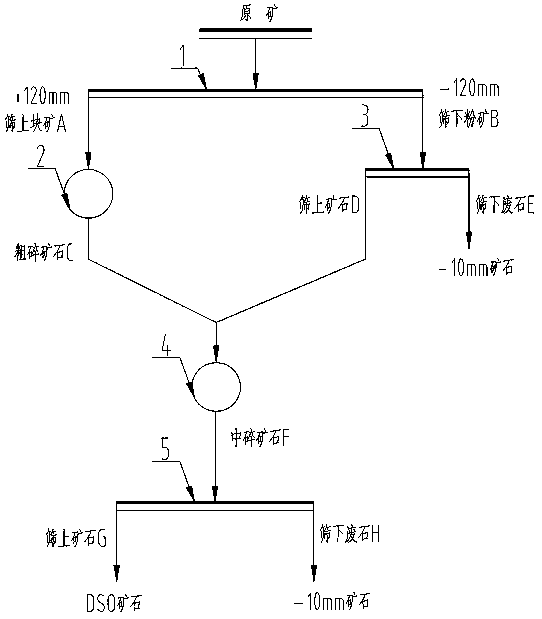

Dry-screening pre-selecting waste-discarding mineral separation technology for monohydrallite with low alumina silica ratio

InactiveCN109290028AIncrease the Al-Si RatioReduce consumptionSolid separationGrain treatmentsSeparation technologyResource utilization

The invention relates to a dry-screening pre-selecting waste-discarding mineral separation technology for monohydrallite with the low alumina silica ratio. The process comprises the steps of directlyscreening raw ore through a bar screen so as to obtain plus sieve lump ore and minus sieve powder ore, carrying out first-section dry-screening and waste-discarding on the minus sieve powder ore through a first vibrating screen, and producing (0 to 10mm) minus sieve waste ore and plus sieve ore; and coarsely crushing the plus sieve lump ore, combining the crushed plus sieve lump ore and the plus sieve ore of the first vibrating screen, carrying out intermediate crushing, carrying out second-section dry-screening and waste-discarding on the ore subjected to intermediate crushing through a second vibrating screen, and producing (0 to 10mm) minus sieve waste rock and plus sieve ore, wherein the plus sieve ore is a final DSO product. According to the process provided by the invention, after the raw ore is subjected to two sections of dry-screening pre-selecting waste-discarding selection, the discarded waste rock yield reaches up to 30 percent, the alumina silica ratio of ground monohydrallite is improved by about 10 percent, the mineral separation and monohydrallite smelting cost can be reduced, the monohydrallite ore with the low alumina silica ratio is favorably developed and utilized, and the resource utilization rate is improved.

Owner:CHINA NERIN ENG

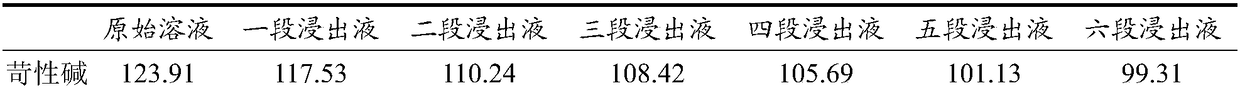

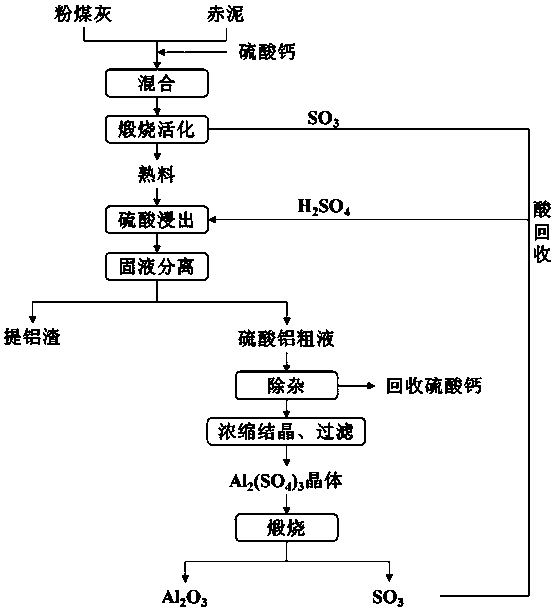

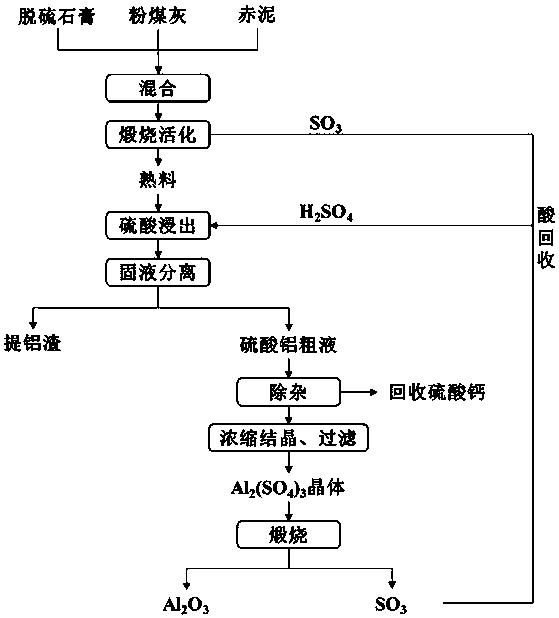

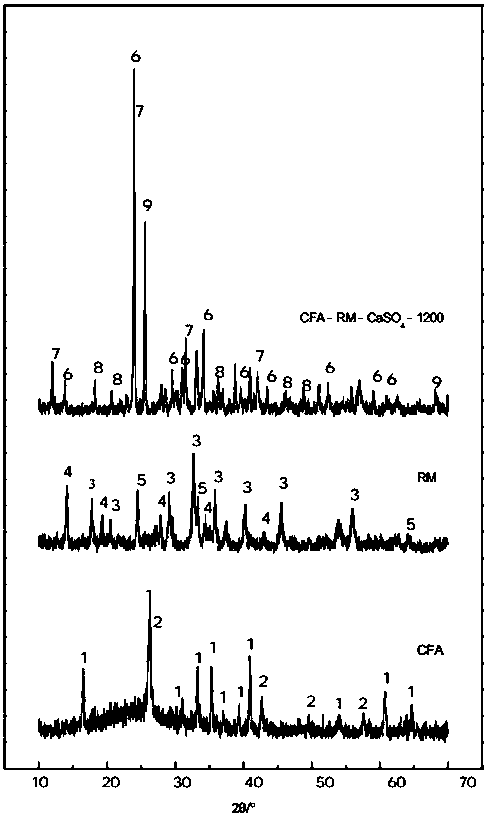

Method for simultaneously extracting aluminum oxide from two aluminum-containing waste residues of fly ash and red mud

InactiveCN110540223AIncrease Al-Si RatioEfficient recyclingSulfur compoundsAluminium oxide/hydroxide preparationRed mudCalcination

The invention relates to a method for simultaneously extracting aluminum oxide from two aluminum-containing waste residues of fly ash and red mud, and belongs to the technical field of solid waste comprehensive utilization. A purpose of the present invention is to solve the problems of high recycling difficulty and high cost of fly ash and red mud. According to the method, the aluminum-silicon ratio in fly ash is increased by using red mud; desulfurized gypsum or calcium sulfate, fly ash and red mud are subjected to mixed calcination to activate the fly ash so as to improve the extraction rateof aluminum oxide; sulfur trioxide and sulfur dioxide released through calcination can be recycled to prepare sulfuric acid for a subsequent acid leaching process; and calcium sulfate can be recovered during aluminum sulfate impurity removal so as to achieve the recycling of the activating agent. According to the present invention, with the method, the three kinds of solid wastes can be treated at the same time while the extraction cost can be reduced.

Owner:TAIYUAN UNIV OF TECH

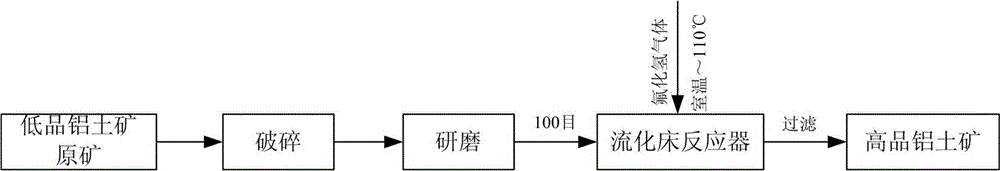

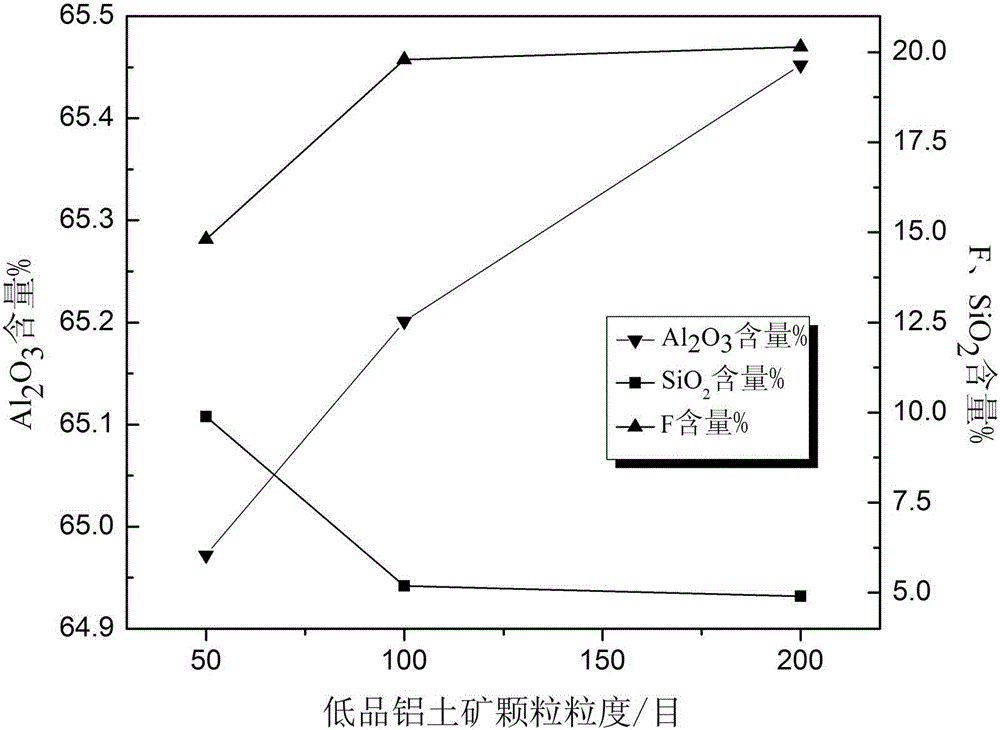

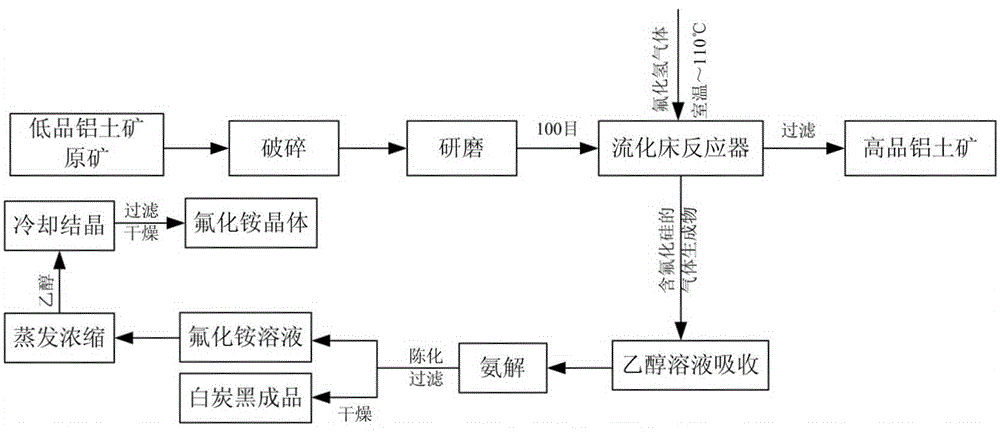

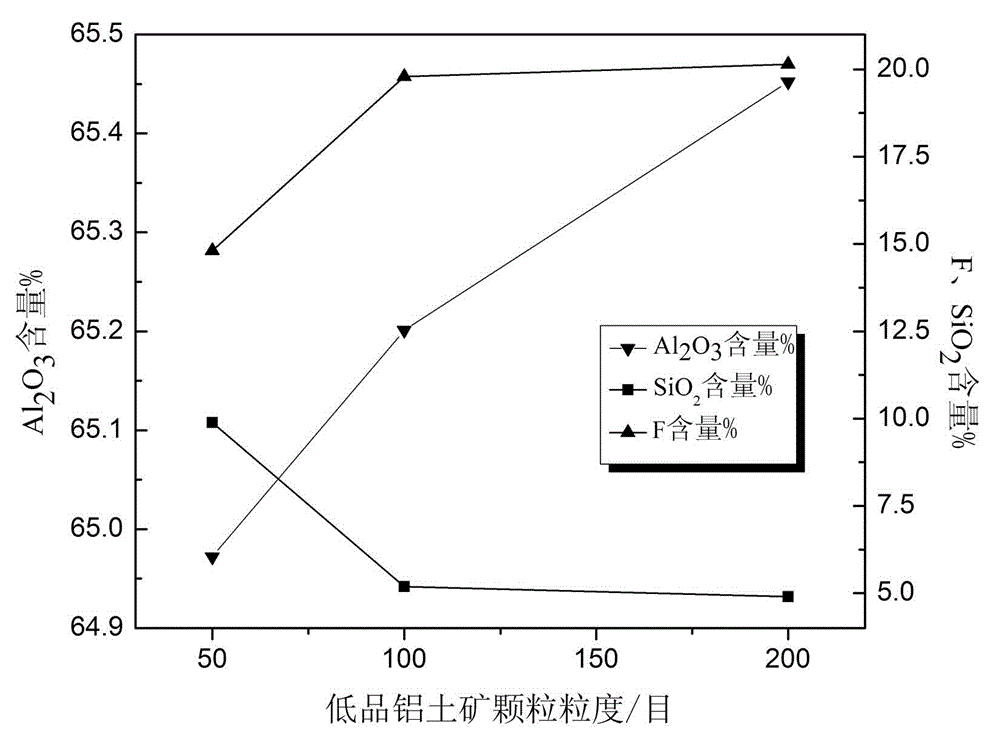

Process of removing silicon from low-grade bauxite by adopting chemical floatation method

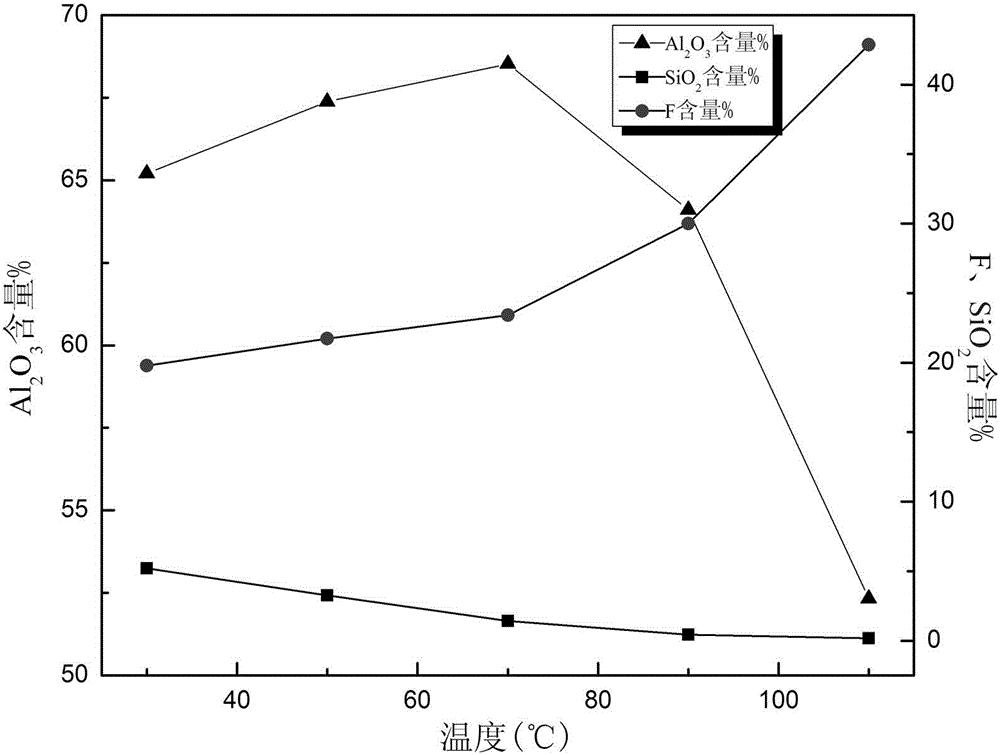

InactiveCN105197971ATake advantage ofIncrease Al-Si RatioAluminium oxides/hydroxidesHydrogen fluorideFluidized bed

The invention provides a process of removing silicon from low-grade bauxite by adopting a chemical floatation method. The process comprises the following steps: placing 50-mesh to 100-mesh low-grade bauxite particles and hydrogen fluoride gas into a fluidized bed reactor, facilitating a reaction of 10 to 30 minutes at the room temperature of 110 DEG C to obtain silicon-removed solid residue; washing and filtering the silicon-removed solid residue by using clear water to obtain the high-grade bauxite. The method is an effective process of removing the silicon from the low-grade bauxite, can improve the aluminum-silicon ratio of the low-grade bauxite and facilitate the subsequent and sufficient application of the low-grade bauxite.

Owner:洛阳国兴矿业有限公司

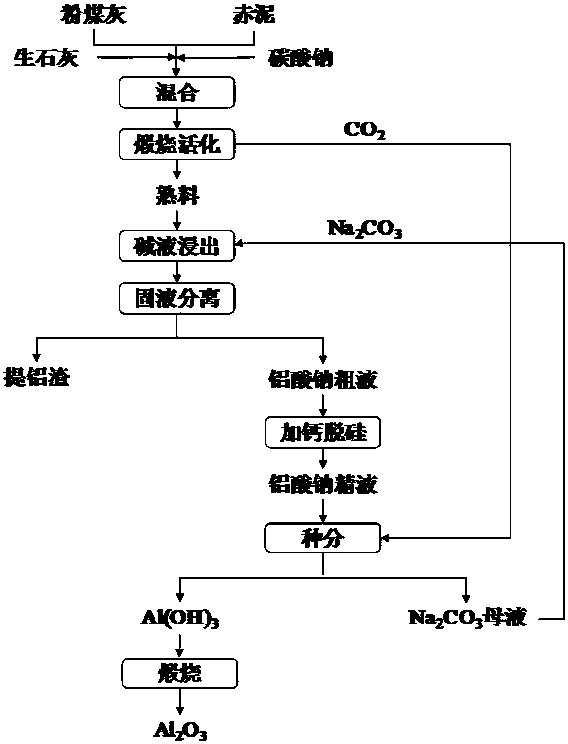

Method for simultaneously extracting aluminum oxide from coal ash and red mud

InactiveCN110482582ALow impurity contentHigh purityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudFiltration

The invention discloses a method for simultaneously extracting aluminum oxide from coal ash and red mud. The invention belongs to the field of solid waste comprehensive utilization. The problems of high red mud utilization difficulty, and high difficulty, high energy consumption and high cost of a coal ash utilization method can be solved. According to the invention, the coal ash, the red mud, quick lime and sodium carbonate are mixed and calcined and activated at 700-1400 DEG C, and gas CO2 generated by calcination can be used for preparing Al(OH)3 in the sodium aluminate solution seed precipitation process; and the clinker is ground and leached with a 1-10% sodium carbonate solution, solid-liquid separation is carried out after leaching to obtain a sodium aluminate crude solution, and desilicication, seed precipitation, filtration and calcination are performed on the sodium aluminate crude solution to obtain the alumina product. The red mud is added to increase the aluminum-silicon ratio in the fly ash, CaO and Na2O in the red mud are utilized to activate mullite, the consumption of quick lime and sodium carbonate of the activating agent is reduced, the extraction cost of the flyash aluminum oxide is reduced while the extraction rate of the aluminum oxide is increased, and efficient utilization of the two solid wastes is realized.

Owner:TAIYUAN UNIV OF TECH

Method of recovering fluorine resource in process of processing low-grade bauxite by chemical floatation method

InactiveCN105197959AHigh recovery rateReduce consumptionSilicaAmmonium halidesAqueous ethanolExhaust fumes

The invention provides a method of recovering a fluorine resource in a process of processing low-grade bauxite by a chemical floatation method. The method comprises the following steps: placing low-grade bauxite particles with a particle size of 50 meshes to 100 meshes and hydrogen fluoride gas into a fluidized bed reactor, reacting for 10 to 30 minutes at a room temperature of 110 DEG C to obtain silicon-removed solid residue and a gas product containing silicon fluoride; absorbing the gas product by adopting an ethanol aqueous solution to obtain a hydrolysis product containing the silicon dioxide; adding ammonium water into the hydrolysis product at the temperature of 70 to 90 DEG C until the pH value is 6 to 8; then aging for 0.5 to 2 hours at the temperature of 70 to 90 DEG C to obtain turbid liquid; sequentially performing the steps such as filtering, decompressing, concentrating and crystallizing the turbid liquid to recover ammonium chloride solid. The method is mainly used for recovering the fluorine resource from the disintegration waste gas of the low-grade bauxite processed by the chemical floatation method, so that waste is converted to treasure, and the method has the advantages of environmental friendliness, energy conservation and low cost.

Owner:洛阳国兴矿业有限公司

Method for preparing silicon dioxide and aluminum oxide from coal ash

ActiveCN101993084BMild desilication reactionWeak corrosiveSilicaSolid waste disposalFoam concreteHigh pressure

The invention relates to a method for preparing silicon dioxide and aluminum oxide, in particular to a method for preparing silicon dioxide and aluminum oxide from coal ash. In the method, the coal ash, sodium carbonate and calcium oxide are used as raw materials, the sodium carbonate is causticized in situ by the calcium oxide, and is dissolved with alkali in a high-temperature high-pressure reaction system to form sodium silicate, calcium carbonate and desiliconized coal ash solid, wherein the sodium silicate solution is carbonated by CO2 to form silicon dioxide; and aluminum oxide and foamconcrete can be prepared from the calcium carbonate and the desiliconized coal ash by a soda lime sintering method. Residues after aluminum oxide preparation can be used as a raw material for preparing a tail gas purification absorbent in cement and chemical plants and coal burning boilers, and the foam concrete. Compared with the prior art, the method has the advantages of weak reacting solutioncorrosion, high desiliconization rate, low metal content of prepared sodium carbonate and high white carbon black quality, high aluminum oxide extraction rate and the like; meanwhile, the raw material source is wide, the process is simple, the production cost is low, and the product additional value is high.

Owner:CHINACOAL PINGSHUO GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com