Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

609results about How to "Low firing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

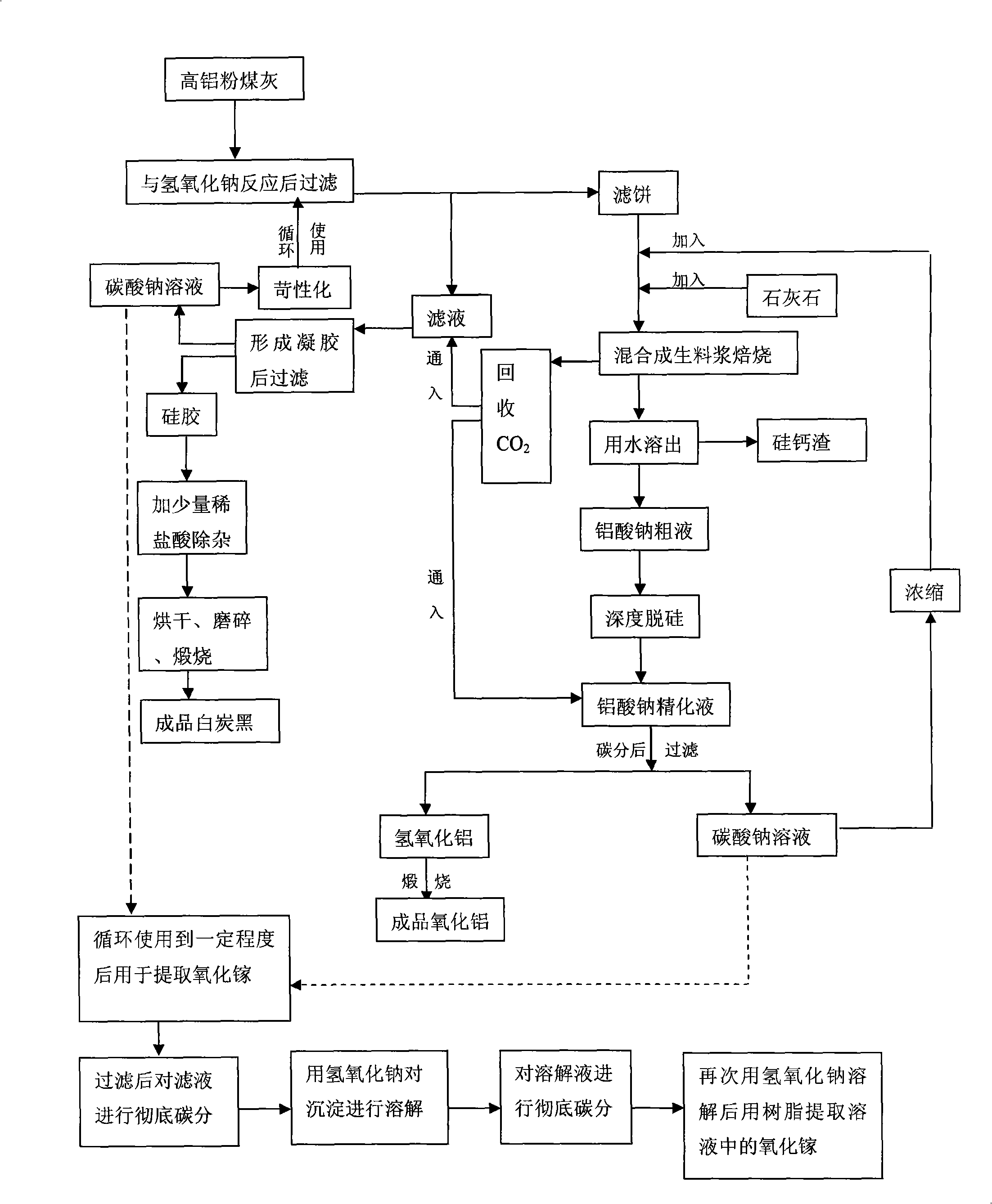

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

Production method of concave convex stick ceramic grain filter

InactiveCN100423808CGood film-hanging performanceImprove stabilityFiltration separationClaywaresRough surfaceWater quality

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

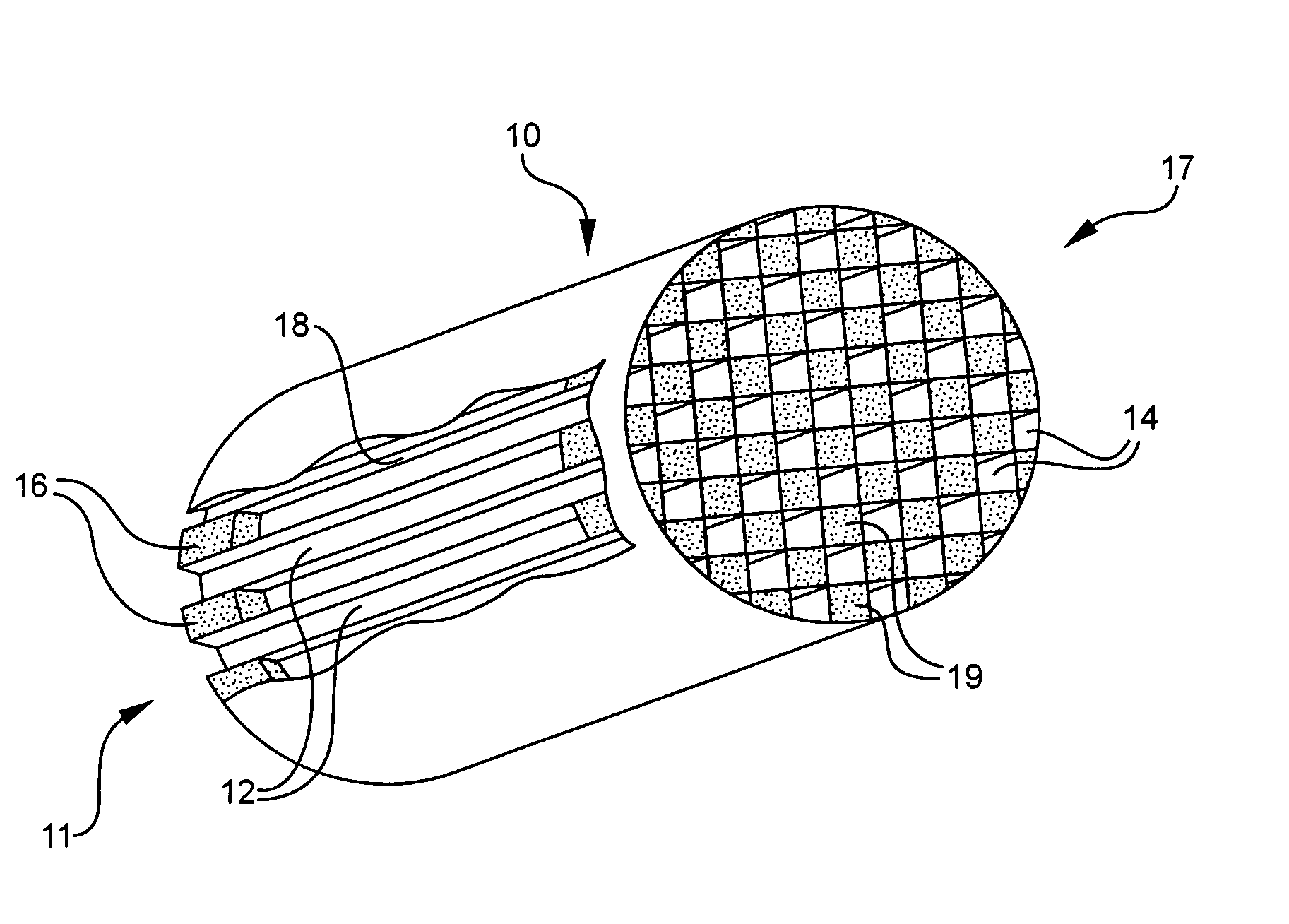

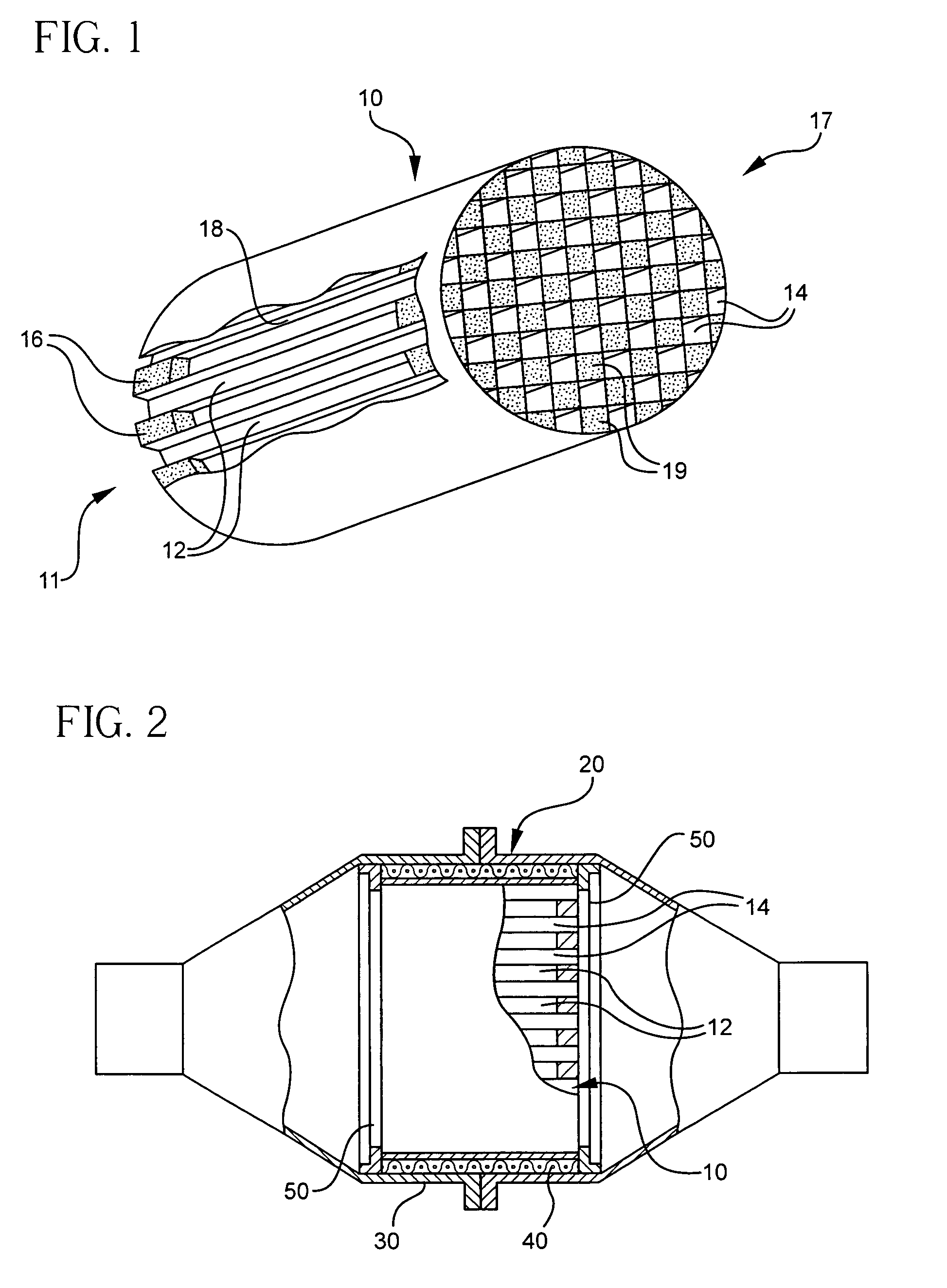

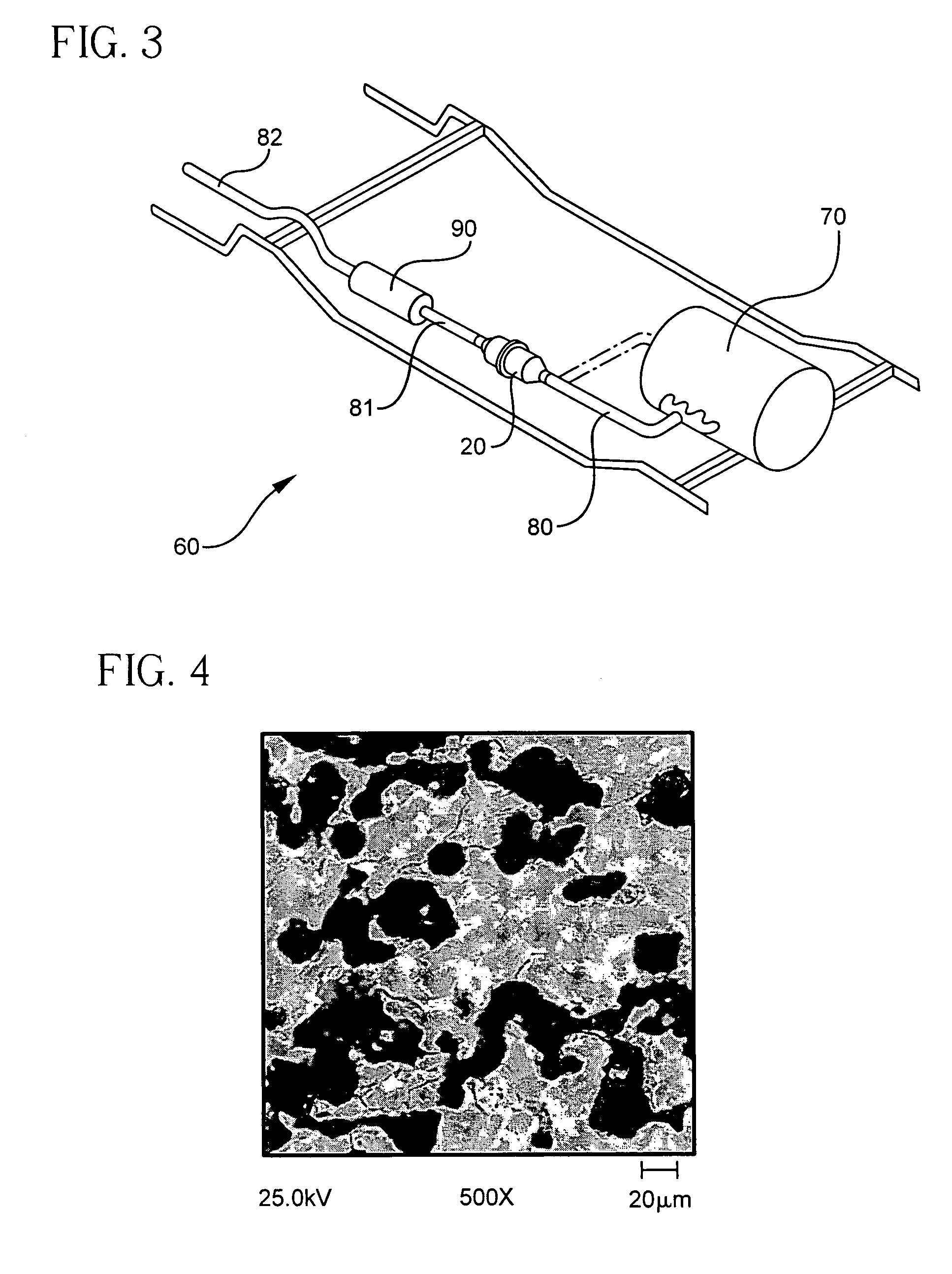

Aluminum titanate ceramic articles and methods of making same

ActiveUS7259120B2Reduced strengthLower firing temperatureInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

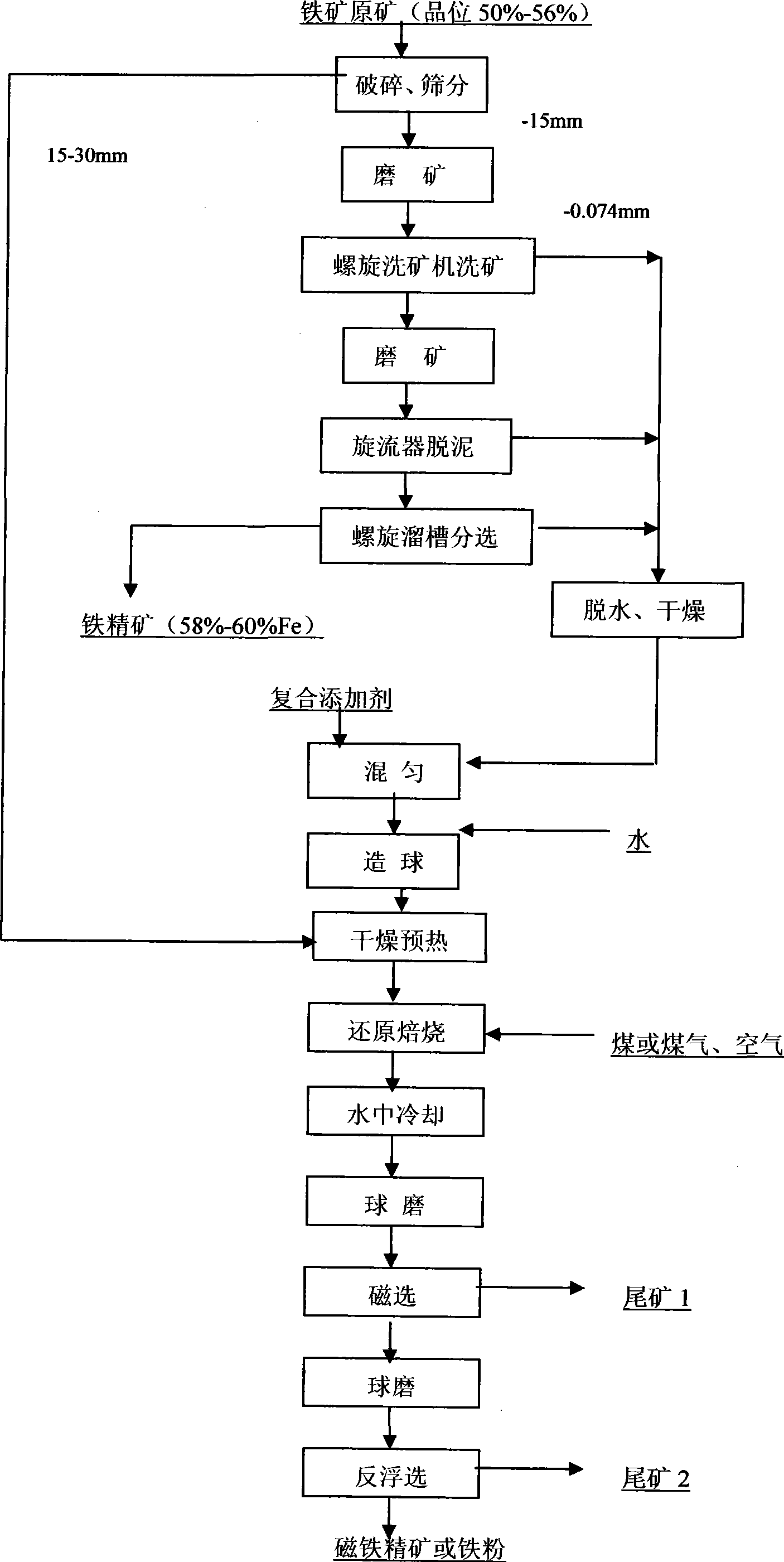

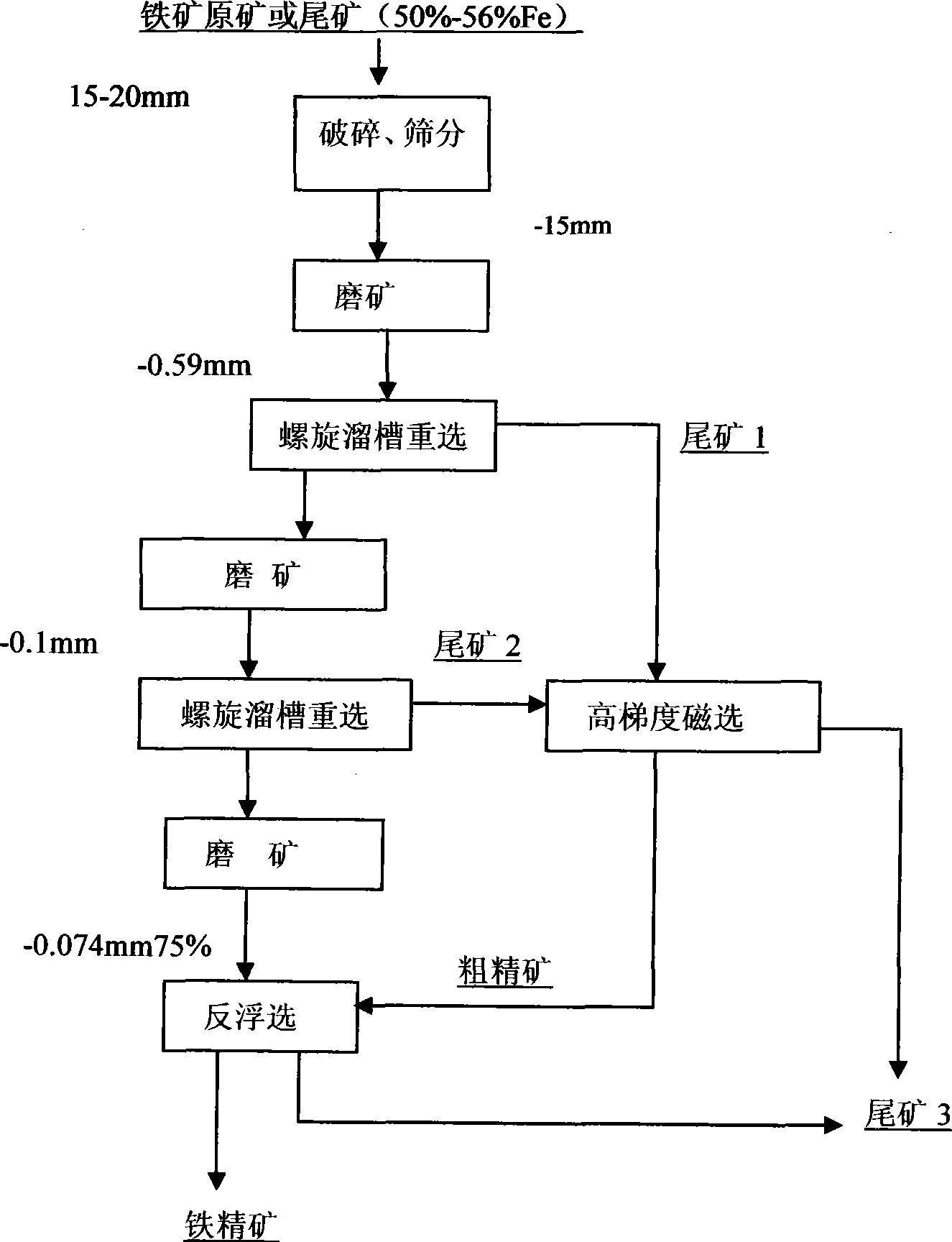

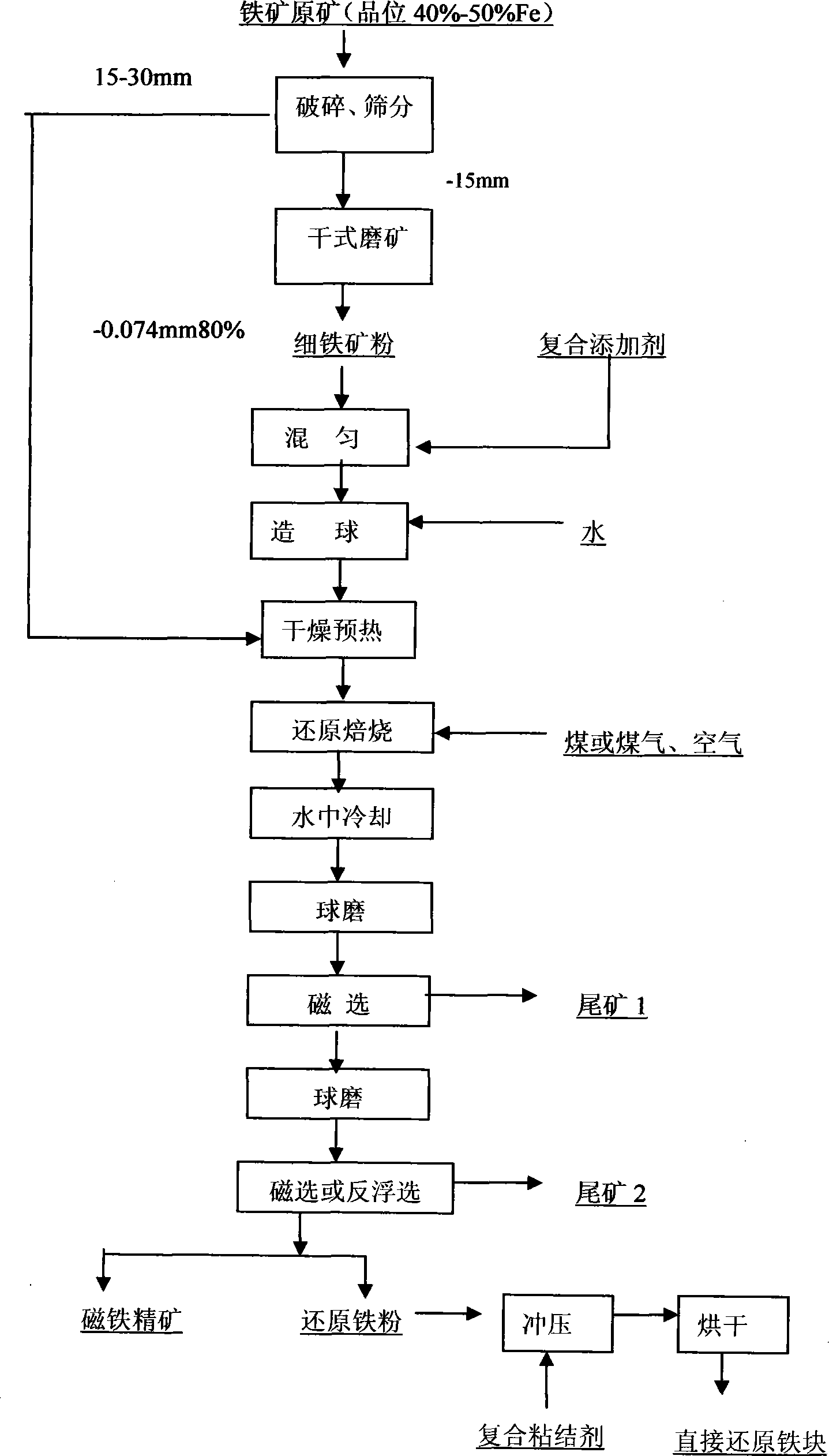

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

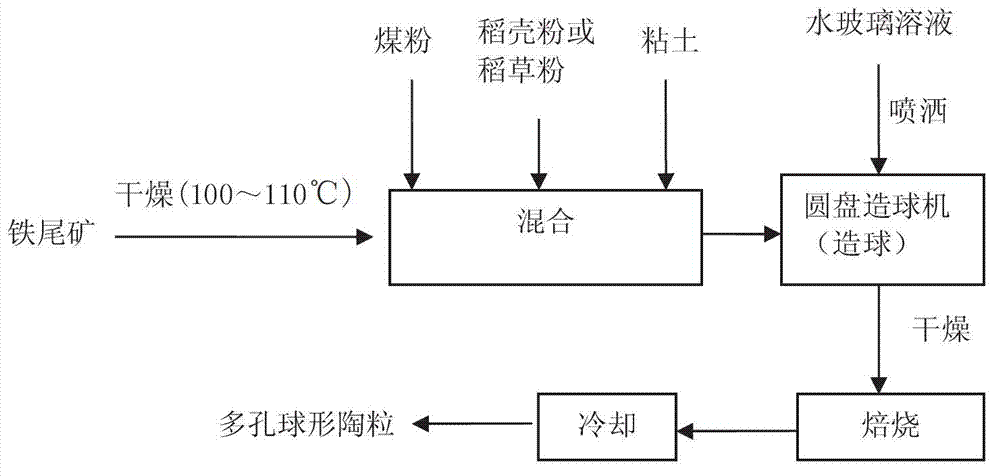

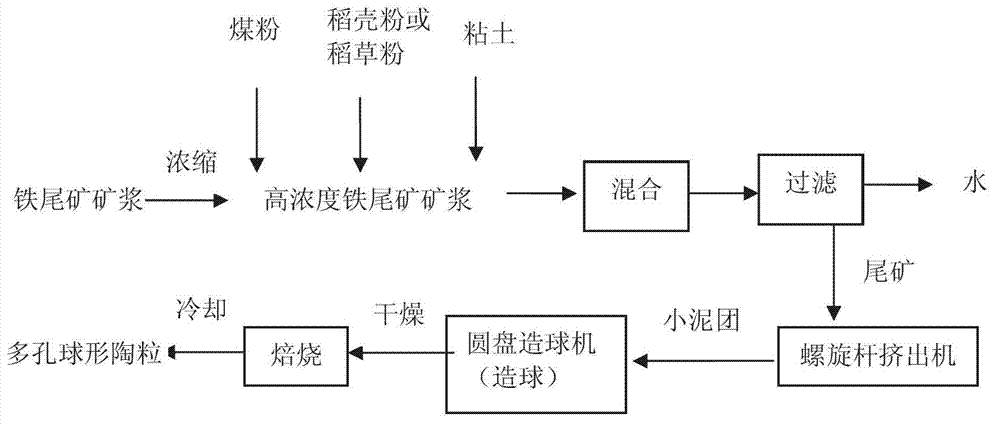

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

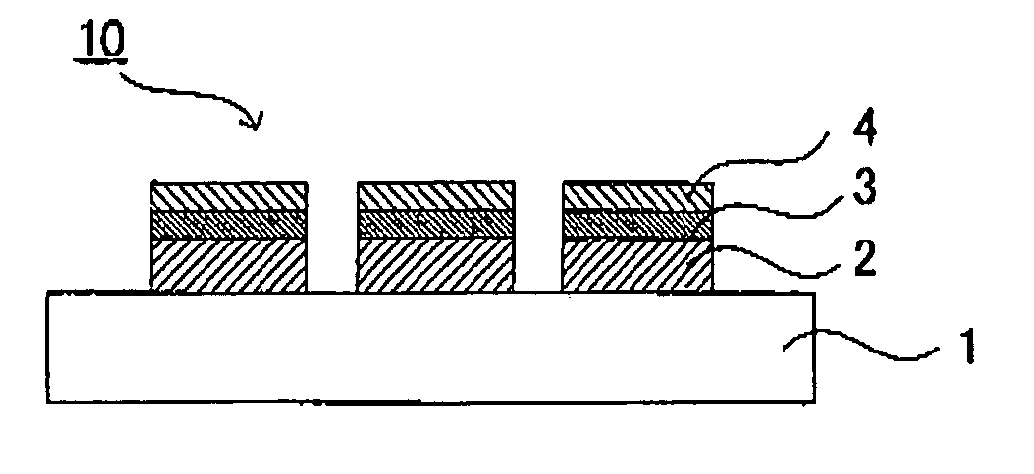

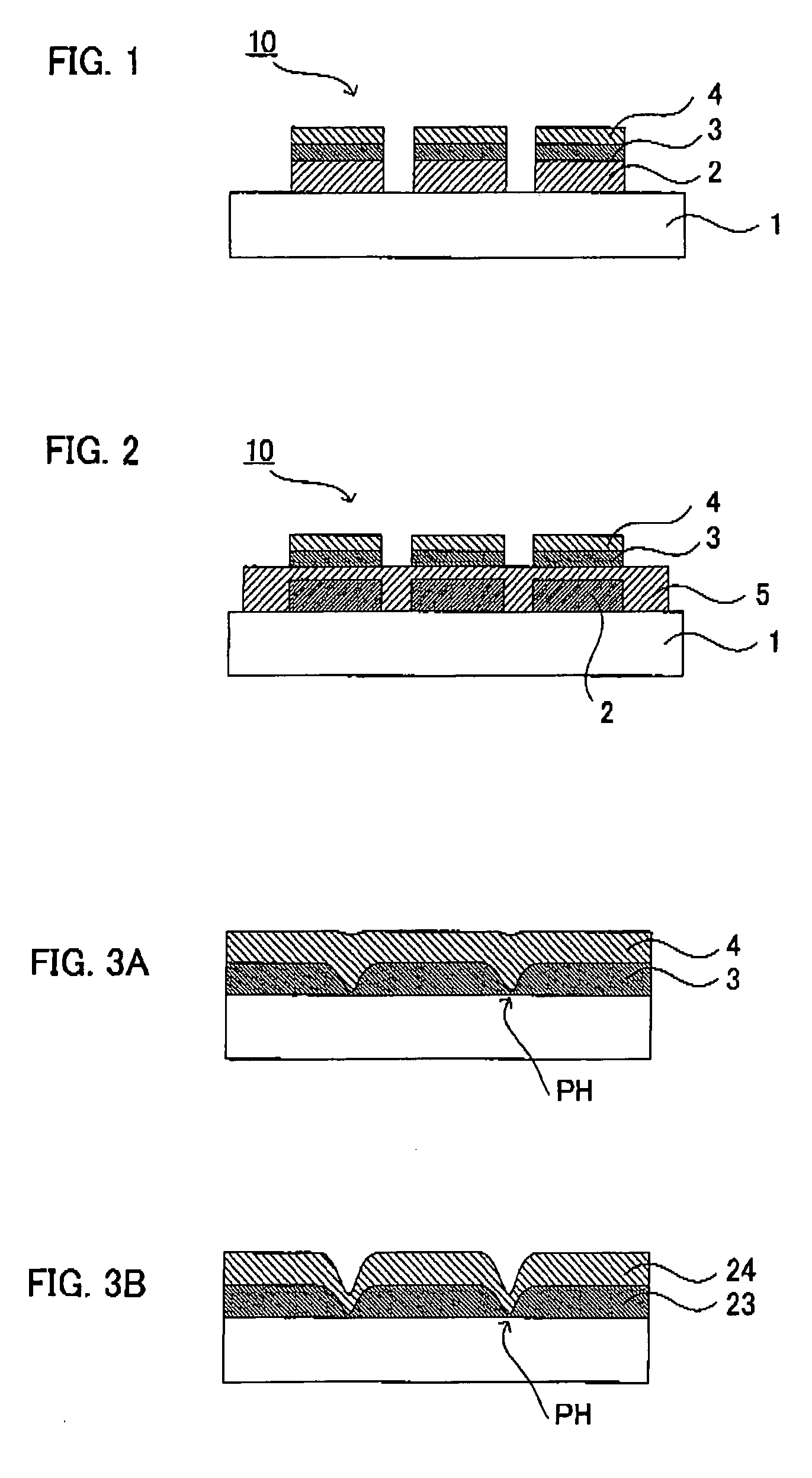

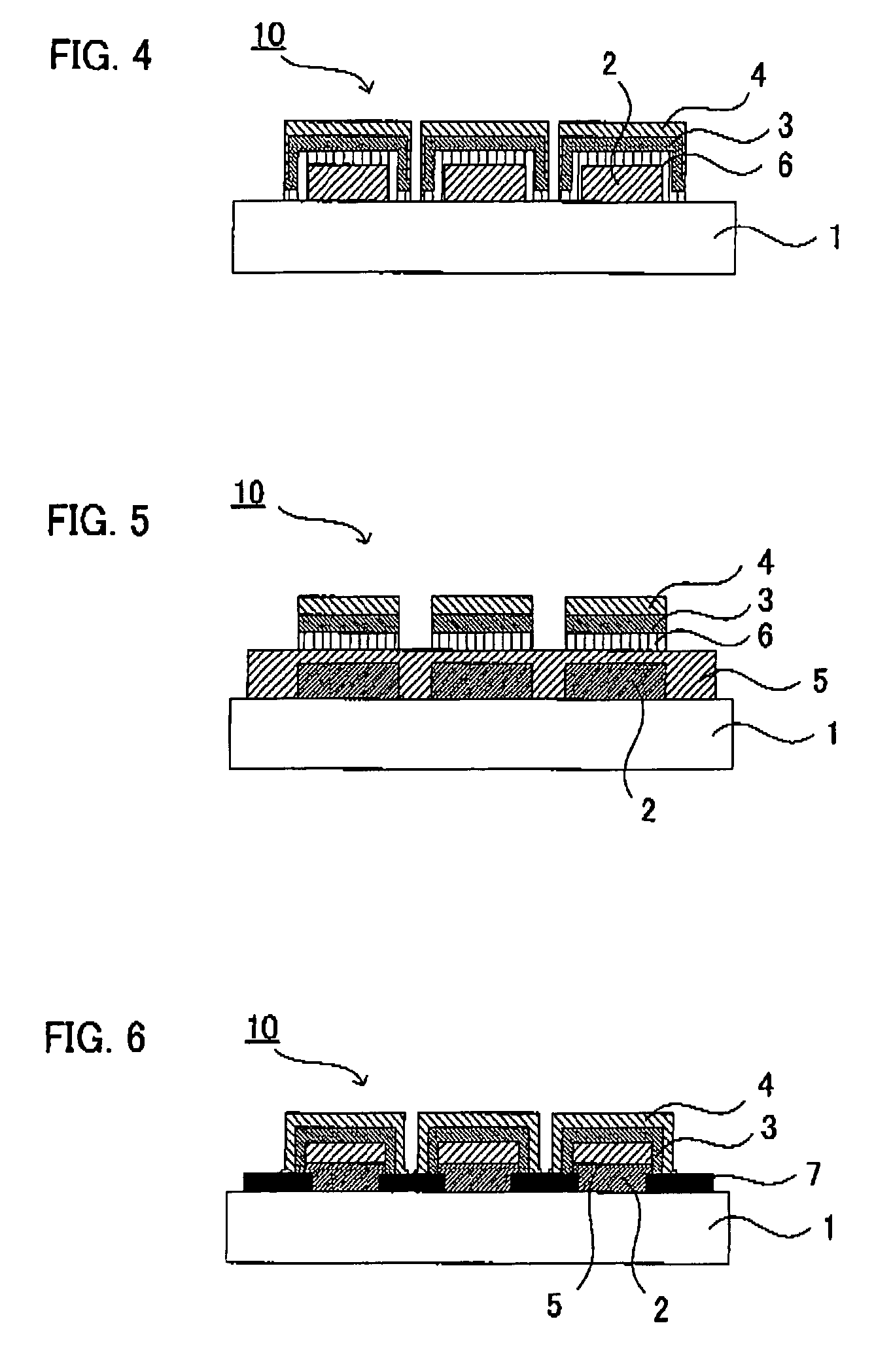

Color filter substrate for organic EL element

InactiveUS20070003743A1Good image displayInhibition of defect generationMaterial nanotechnologySolid-state devicesDisplay deviceDark spot

The main object of the present invention is to provide an inexpensive color filter substrate for an organic EL element and an organic EL display device which are capable of displaying good images having no defects such as dark spots. To attain the object, the invention provides a color filter substrate for an organic EL element having a substrate, a colored layer formed in a pattern form on / over the substrate, and a transparent electrode layer and a conductive layer laminated, in any order, on / over the colored layer, wherein the conductive layer is a coated film.

Owner:DAI NIPPON PRINTING CO LTD

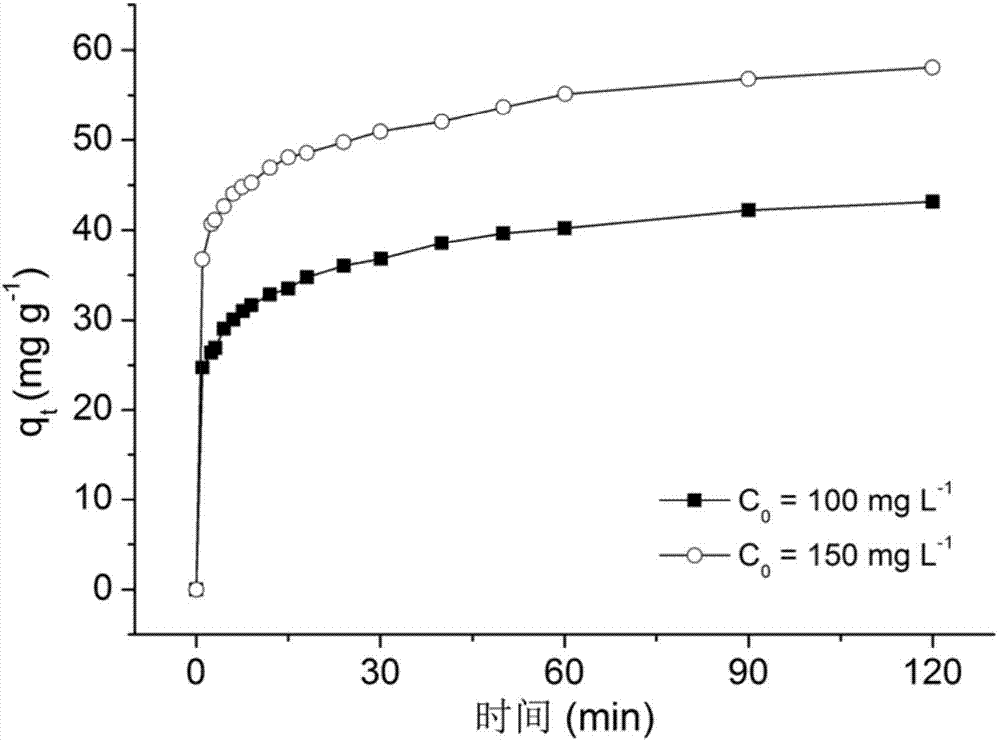

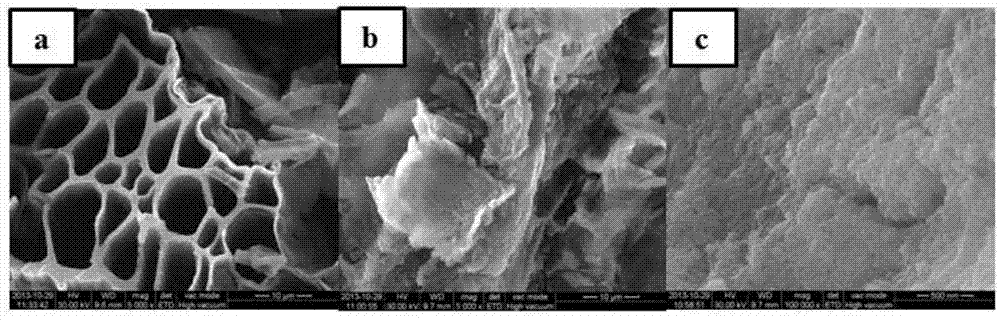

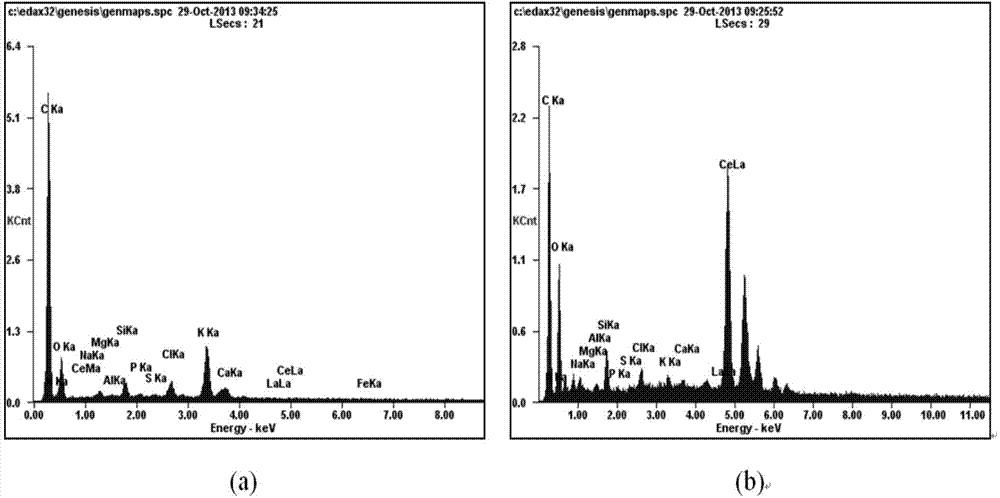

Improved charcoal-based phosphorous removal adsorbent and preparation method thereof

ActiveCN103877937AImprove adsorption capacityEfficient removalOther chemical processesWater/sewage treatment by sorptionRare-earth elementSorbent

The invention discloses an improved charcoal-based phosphorous removal adsorbent and a preparation method of the improved charcoal-based phosphorous removal adsorbent. The method comprises the following steps: loading light rare earth elements to charcoal under optimized conditions, and preparing a high-efficiency environment-friendly charcoal-based phosphorous removal adsorbent; impregnating the cleaned and dried plant powder by using a cerium chloride solution with a certain concentration, and regulating a mass ratio of the original material of charcoal to Ce element to be 5-15 percent; adding an alkaline solution to control the pH value of the system to be more than 10, stirring, washing by using ethanol, centrifuging and drying; putting the prepared material into a muffle furnace, performing temperature programming and pyrolysis under anoxic conditions through the sealing measure, and controlling the pyrolysis temperature and pyrolysis time; washing the material by using distilled water after the pyrolysis is ended and cooling is performed, centrifuging, drying, screening, and obtaining the final product. The phosphorous removal adsorbent prepared in the invention has excellent adsorptive property on phosphate radical, the adsorptive property can reach 77.52mg / g, and a charcoal-based material which is environment-friendly and excellent in adsorptive property is provided for adsorbing and purifying phosphorous-containing wastewater.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

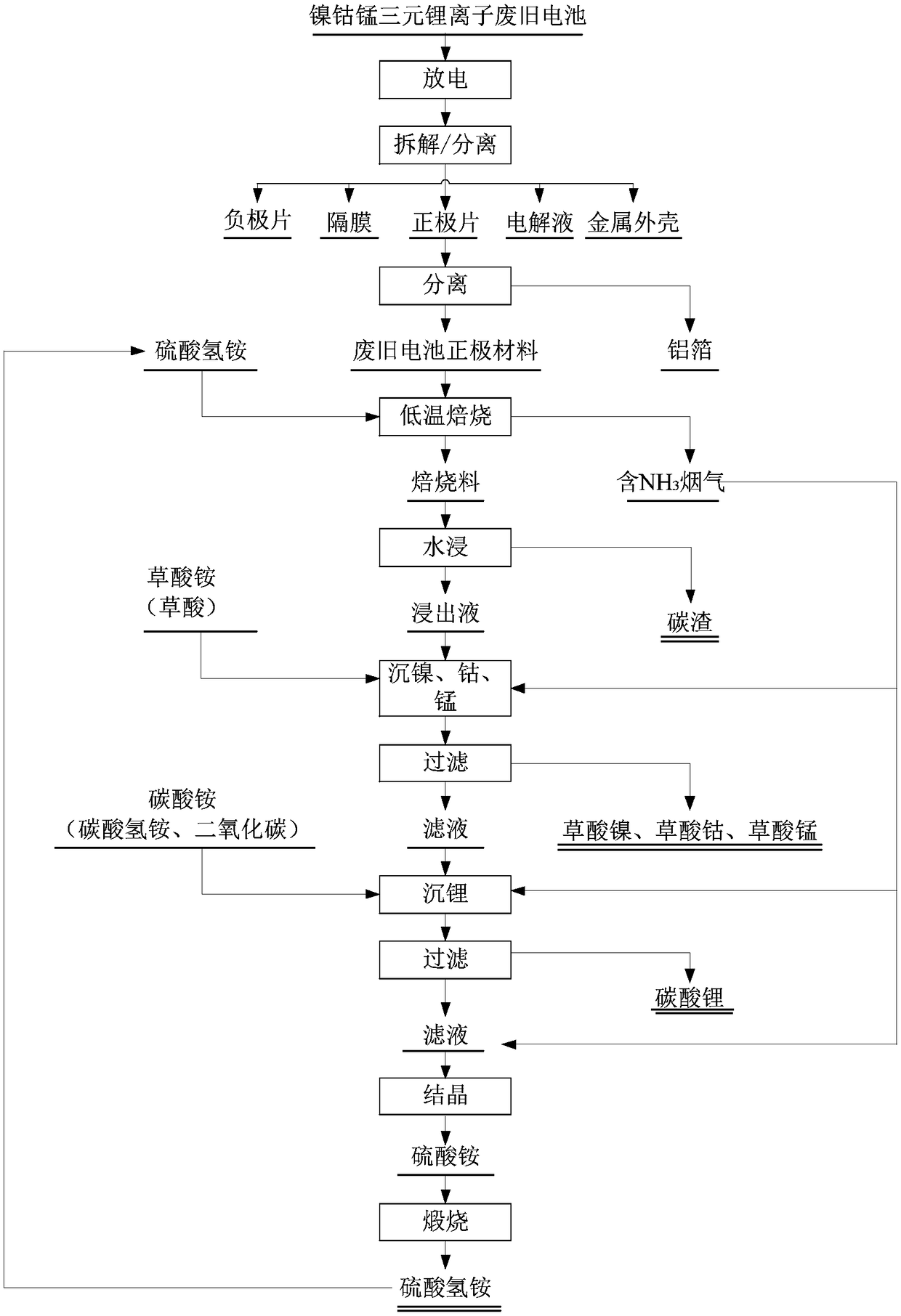

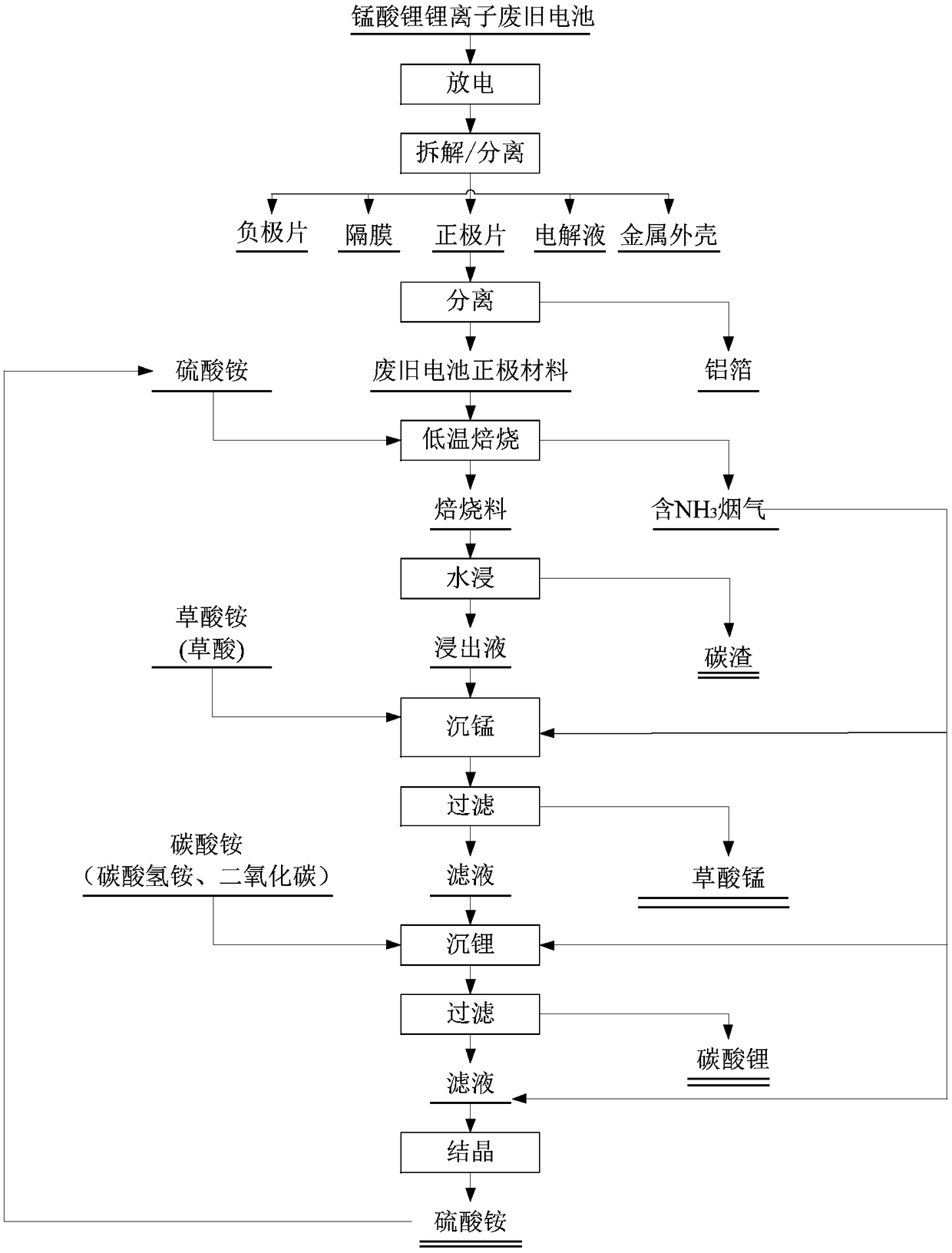

Method for recovering valuable metals from positive electrode material of waste lithium ion battery

ActiveCN108767354AHigh recovery rateAvoid it happening againWaste accumulators reclaimingProcess efficiency improvementLithium-ion batteryMaterials science

The invention provides a simple, efficient and environment-friendly method for recovering valuable metals from a positive electrode material of a waste lithium ion battery; the method comprises the following steps of performing discharging of a salt solution; performing disassembling to separate a positive plate; performing smashing on the positive plate to separate a positive electrode material and an aluminum foil; performing mixed low-temperature roasting on the positive electrode material and a roasting agent ammonium sulfate and / or ammonium bisulfate; performing leaching on the roasted material and separating to obtain carbon and a lixivium; adding a precipitant into the lixivium, and regulating the pH value by using NH<3>-containing flue gas, performing deposition on other metals except Li, and carrying out solid-liquid separation; regulating the pH value of a filtrate by using the NH3-containing flue gas, adding ammonium carbonate or ammonium bicarbonate or pumping CO<2> gas, and carrying out lithium precipitation to obtain a lithium carbonate product. The preparation process is simple, the process conditions are mild, the time required by the process is short, a large amount of acid and alkali do not need to be consumed, and the cost is low; and in addition, recovery of the valuable metals and carbon from the positive electrode material can be effectively realized, themethod is green and environment-friendly, and a large amount of solid waste and wastewater cannot be generated.

Owner:CENT SOUTH UNIV

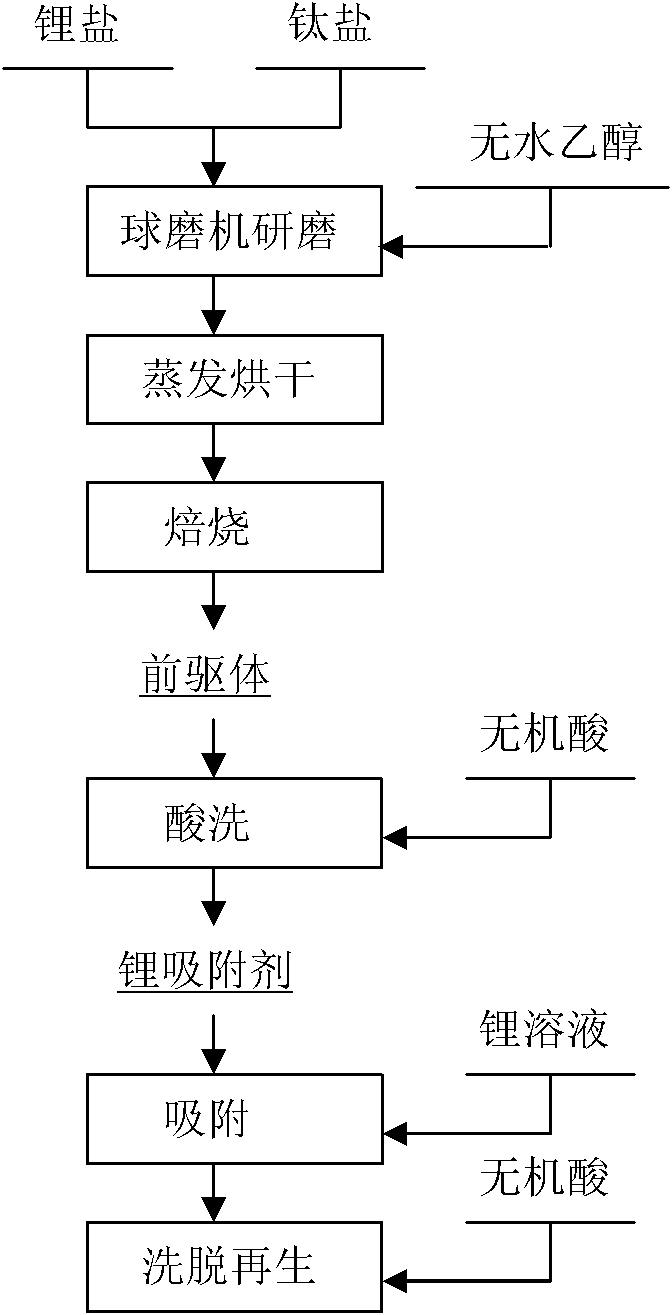

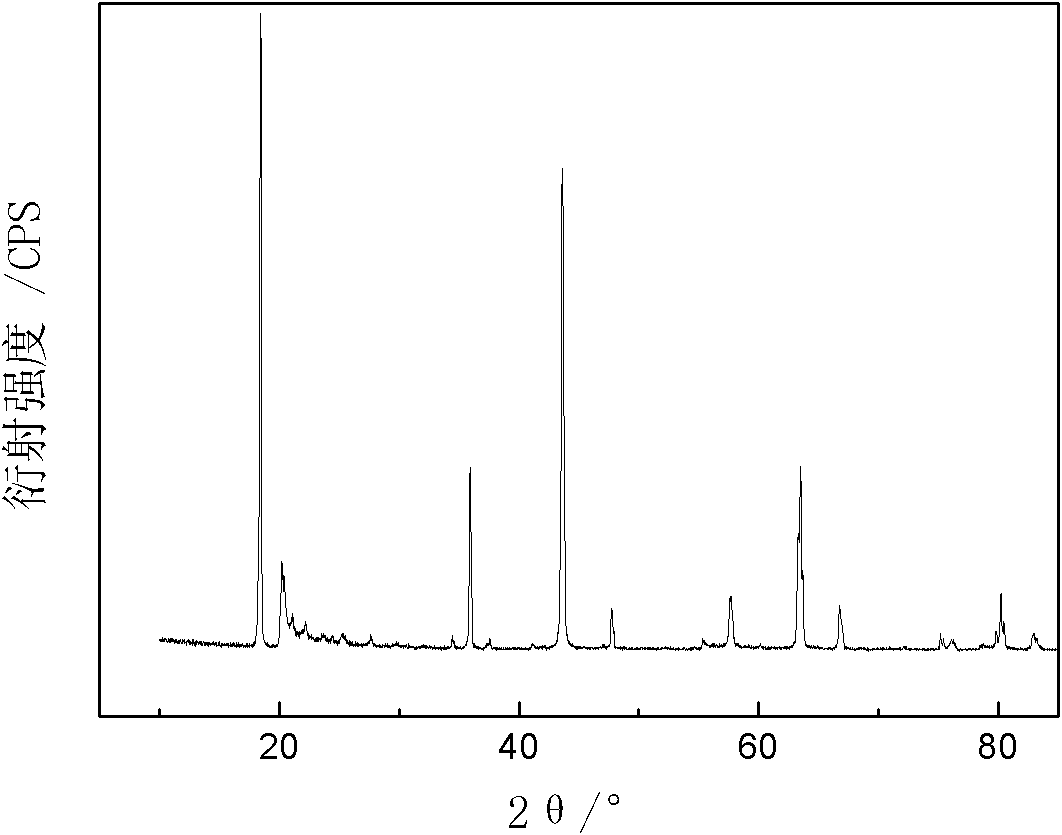

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

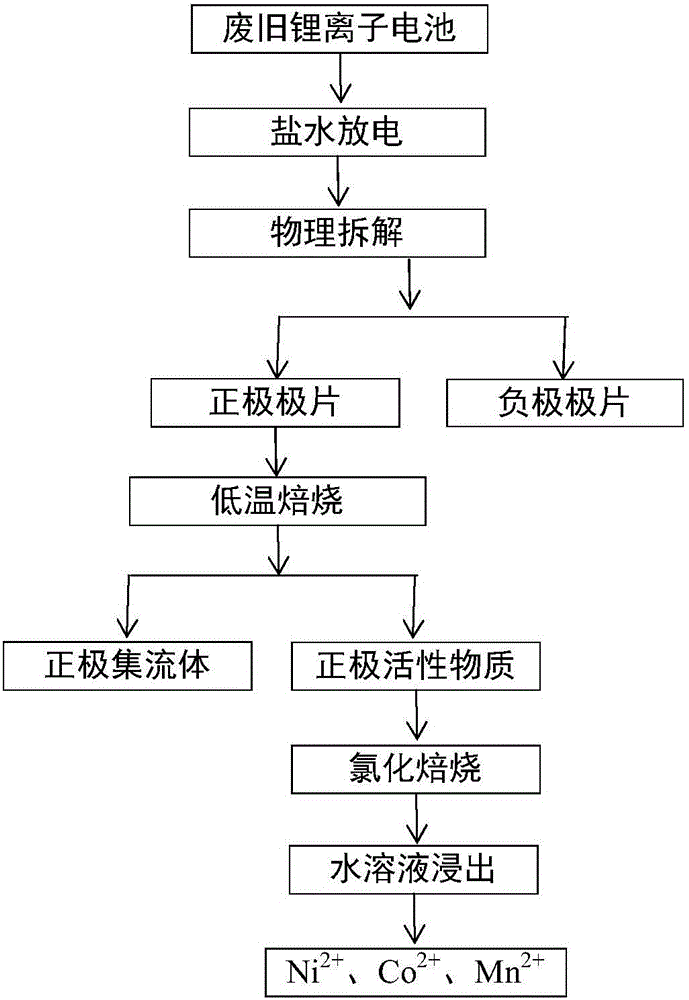

Method for recovering valuable metals from cathode materials of waste lithium ion batteries

InactiveCN106848469AEfficient recyclingReduce recycling costsWaste accumulators reclaimingBattery recyclingMetal leachingChloride

The invention discloses a method for recovering valuable metals from cathode materials of waste lithium ion batteries. The method comprises the following steps: the waste lithium ion batteries are discharged and dismantled, and cathode plates are separated out; the cathode plates are subjected to pyrolysis for glue removal, and current collectors and active materials are separated out; the active materials are mixed with chloride for chloridizing roasting; a solid product of chloridizing roasting is leached with water, and aleachate containing valuable metal ions is obtained. The method overcomes the defect that a large quantity of mineral acids and bases is needed to be consumed in the traditional metal leaching and recovering process of the cathode materials of the waste lithium ion batteries, adopts simple process, is low in cost and environment-friendly and has great industrial application value.

Owner:CENT SOUTH UNIV +1

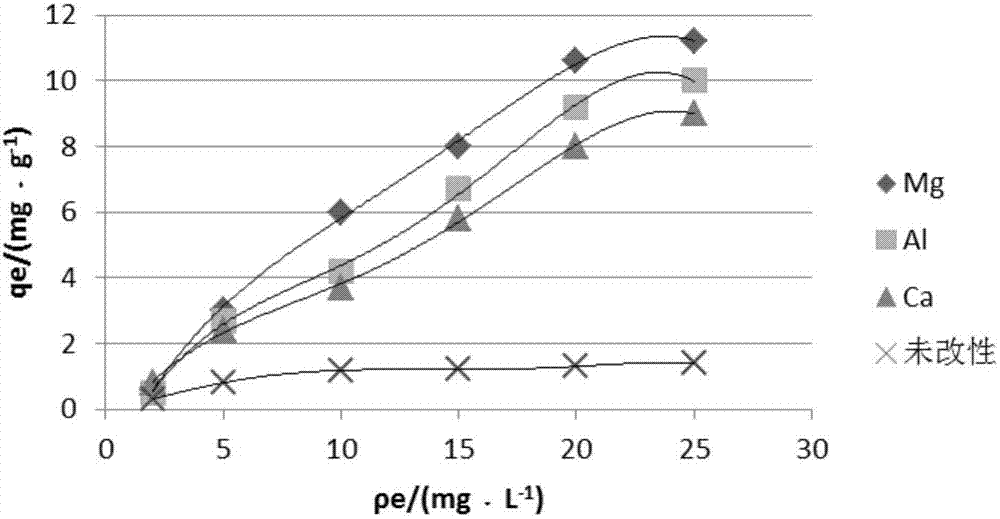

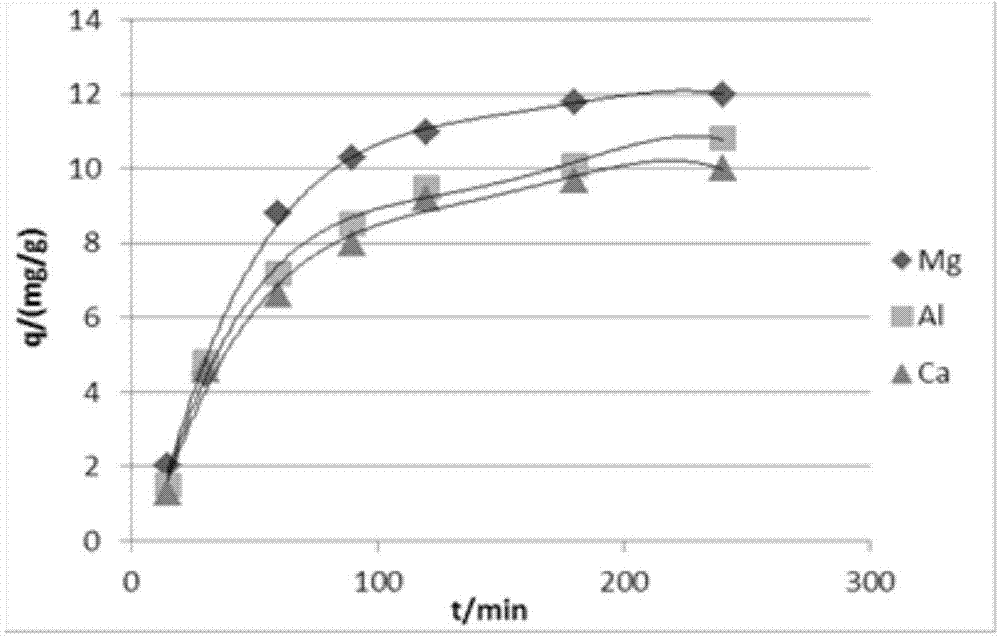

Metal element improved biochar-based nitrate radical adsorbent and preparation method thereof

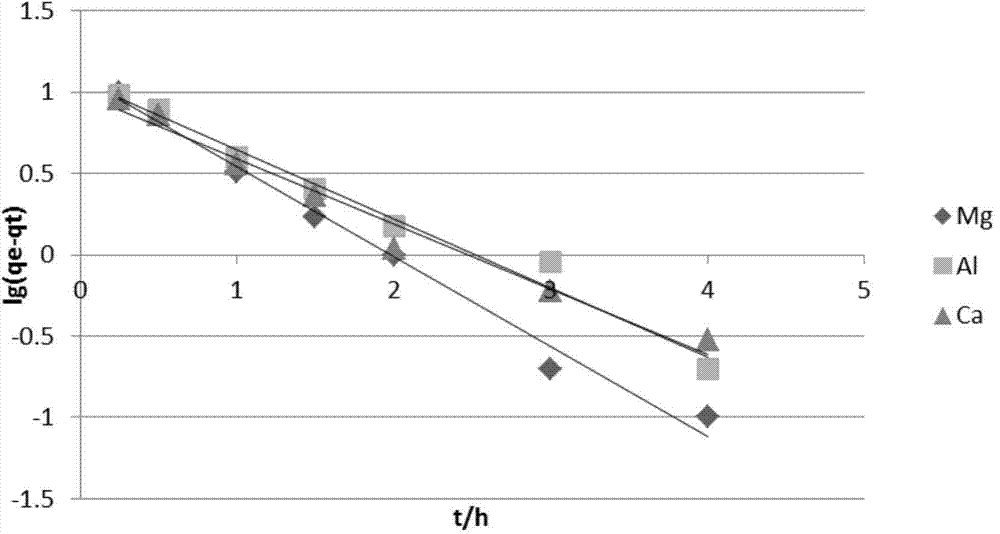

InactiveCN104258812AEfficient removalReduce pollutionOther chemical processesWater contaminantsAdsorption equilibriumSorbent

The invention discloses a metal element improved biochar-based nitrate radical adsorbent and a preparation method thereof. Straws are used as raw materials, and metal ions are impregnated, pyrolyzed and washed under certain conditions, so a metal ion improved cbiochar is prepared. According to the metal element improved biochar-based nitrate radical adsorbent and the preparation method thereof disclosed by the invention, by using adsorption research on nitrate radical waste water and comparing the adsorption effect of the biochar before and after improvement, the improved biochar prepared by the preparation method disclosed by the invention has good adsorption effect for potassium nitrate, wherein Mg<2+> improved wheat straw biochar has optimal adsorption effect for nitrate nitrogen; compared with the unmodified biochar, the Mg<2+> improved biochar prepared under the optimizing conditions has the advantages that the adsorption performance is improved by 10 times, and the adsorption equilibrium can be realized in a shorter time. The modified biochar adsorbent is a green adsorbent with application potential and can be used for effectively removing the nitrate nitrogen in a water body; besides, the effects of fixing carbon, reducing discharge and relieving the non-point source pollution are achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

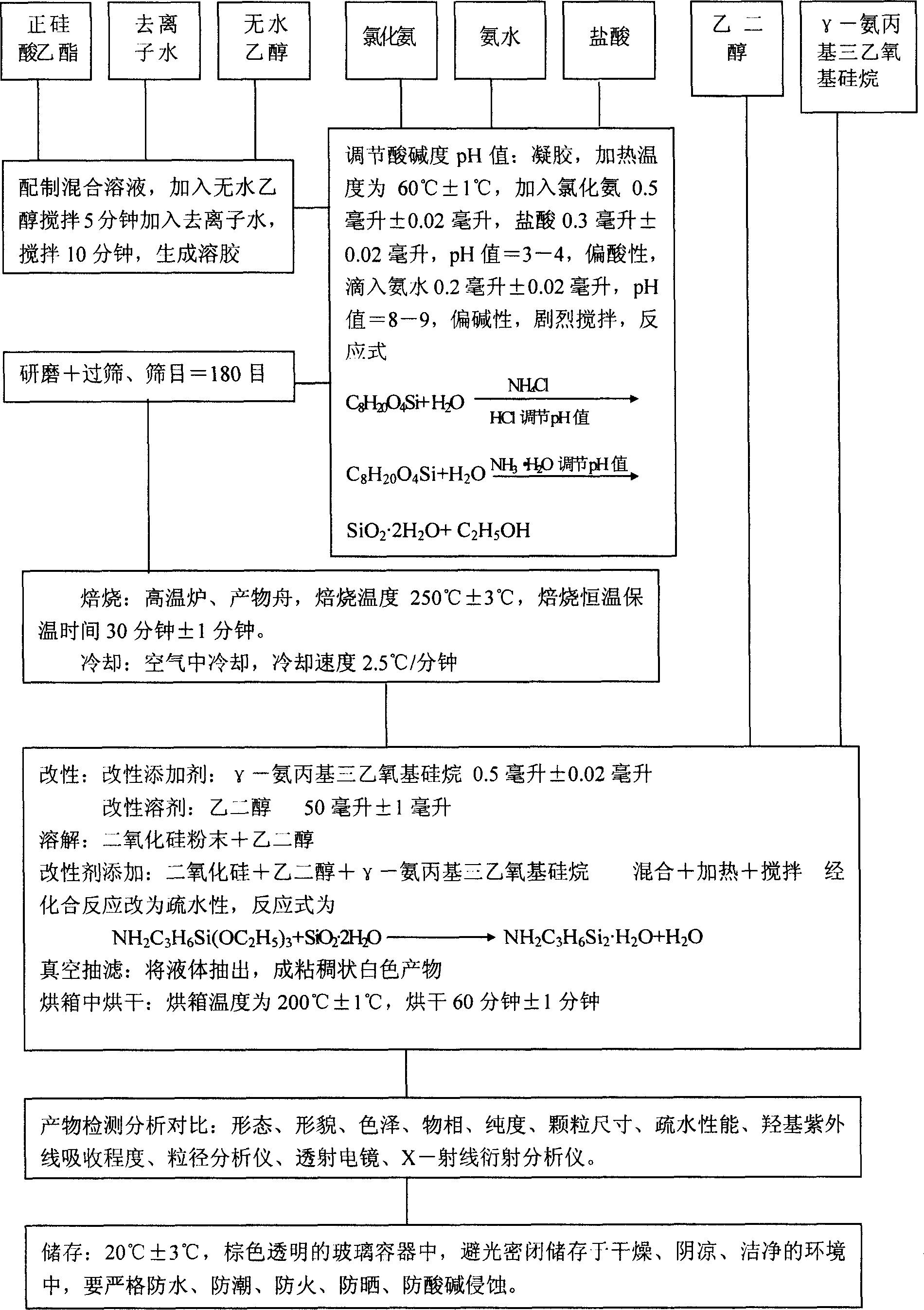

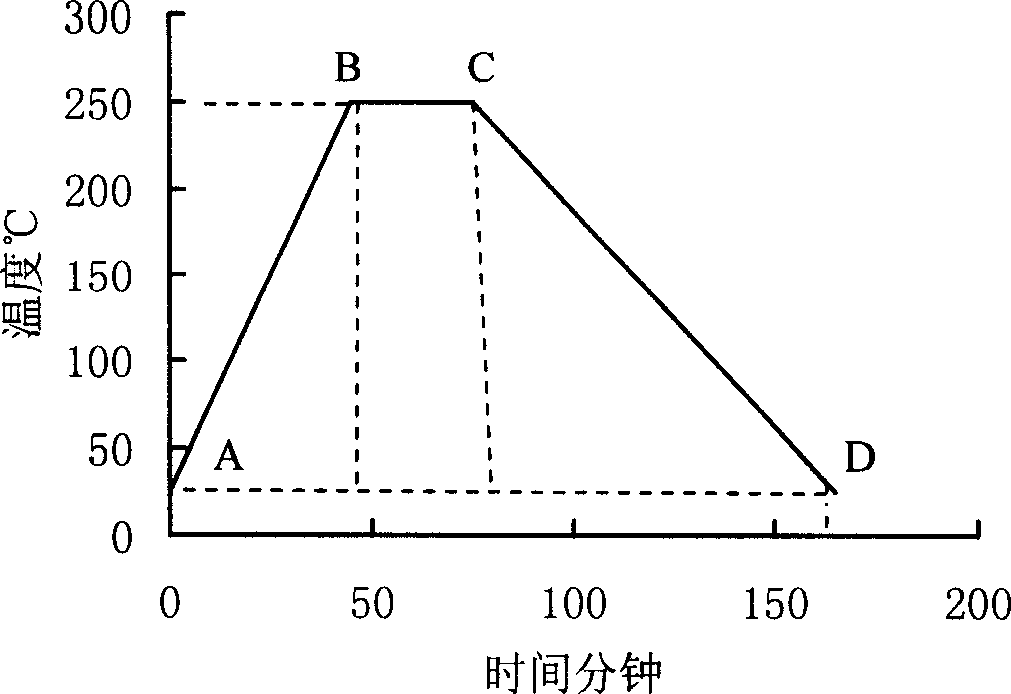

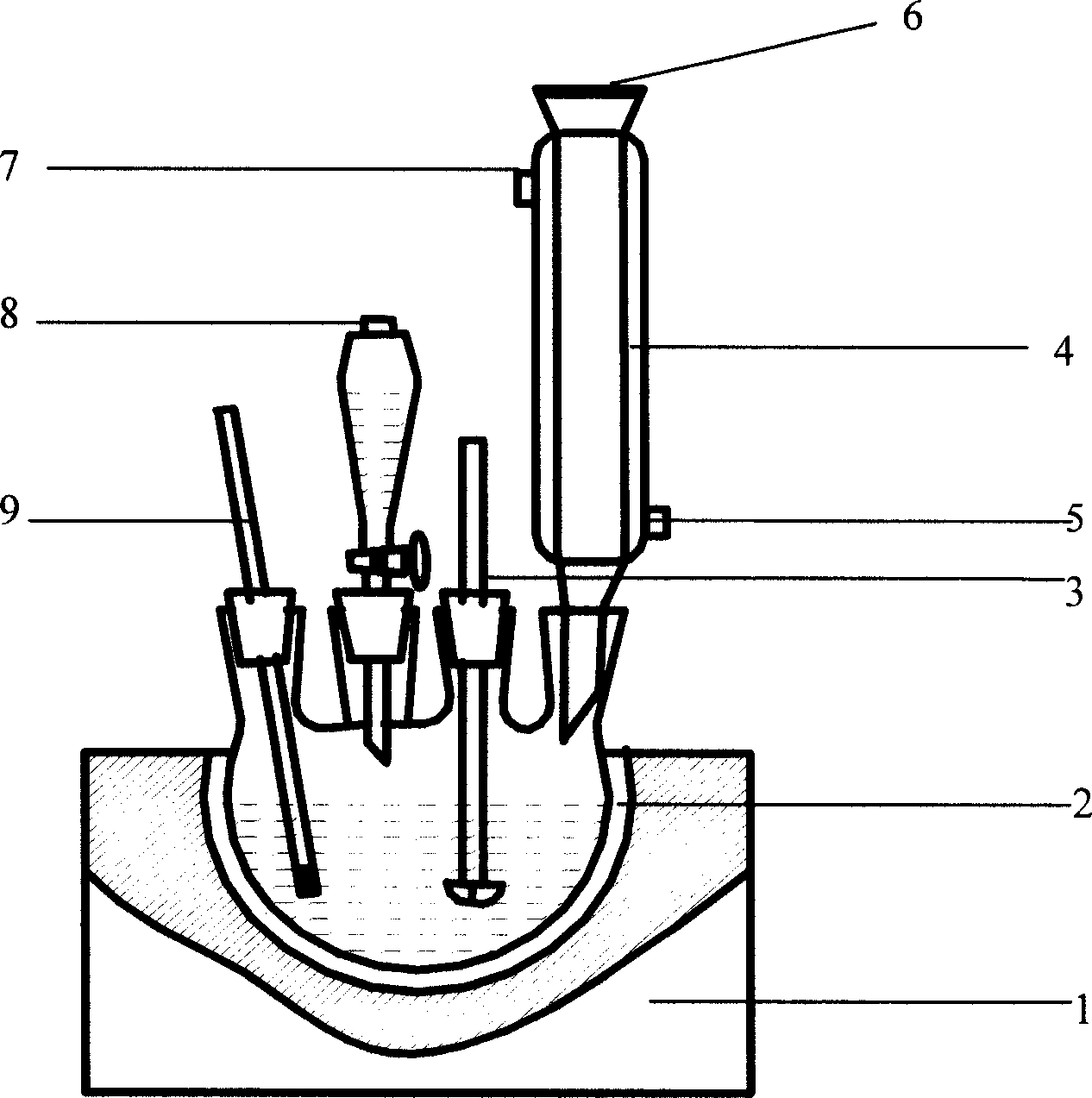

Method for preparing super fine hydrophobic silicon dioxide

InactiveCN1757598AHigh purityUniform particle distributionSilicon oxidesCooking & bakingPolymer science

A process for preparing the superfine hydrophobic SiO2 includes such steps as proportionally mixing ethyl n-silicate, ammonium chloride, de-ionized water, absolute alcohol, hydrochloric acid, ammonia water, gamma-aminopropyltriethoxy silane and ethanediol, preparing sol, preparing gel, baking, grinding, sieving, calcining, cooling, hydrophobic modifying, reaction, filter, baking and examining.

Owner:TAIYUAN UNIV OF TECH

Processing method for recycling aluminum dross

ActiveCN101913634ANo pollutionReduce pollutionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsPtru catalyst

The invention discloses a processing method for recycling aluminum dross, which comprises the following steps: adding crushed limestone and catalyst to aluminum dross, thoroughly homogenizing and mixing the three materials, carrying out catalyzed calcination on the thoroughly homogenized and mixed materials in a calcination reaction furnace, and directly grinding the calcined products or grinding the calcined products after cooling, thus obtaining the calcium aluminate powder product. The processing method has a simple operational process, and can not cause new environmental pollution, thereby according with the policy for industry development. The invention recycles the aluminum dross, simultaneously reduces environmental pollution caused by the aluminum dross, improves the environmental management on surrounding areas, and also provides a reasonable and effective way to recycle waste aluminum dross. Thus, the invention has obvious economic benefits and social benefits.

Owner:HENAN KETAI WATER PURIFYING MATERIALS

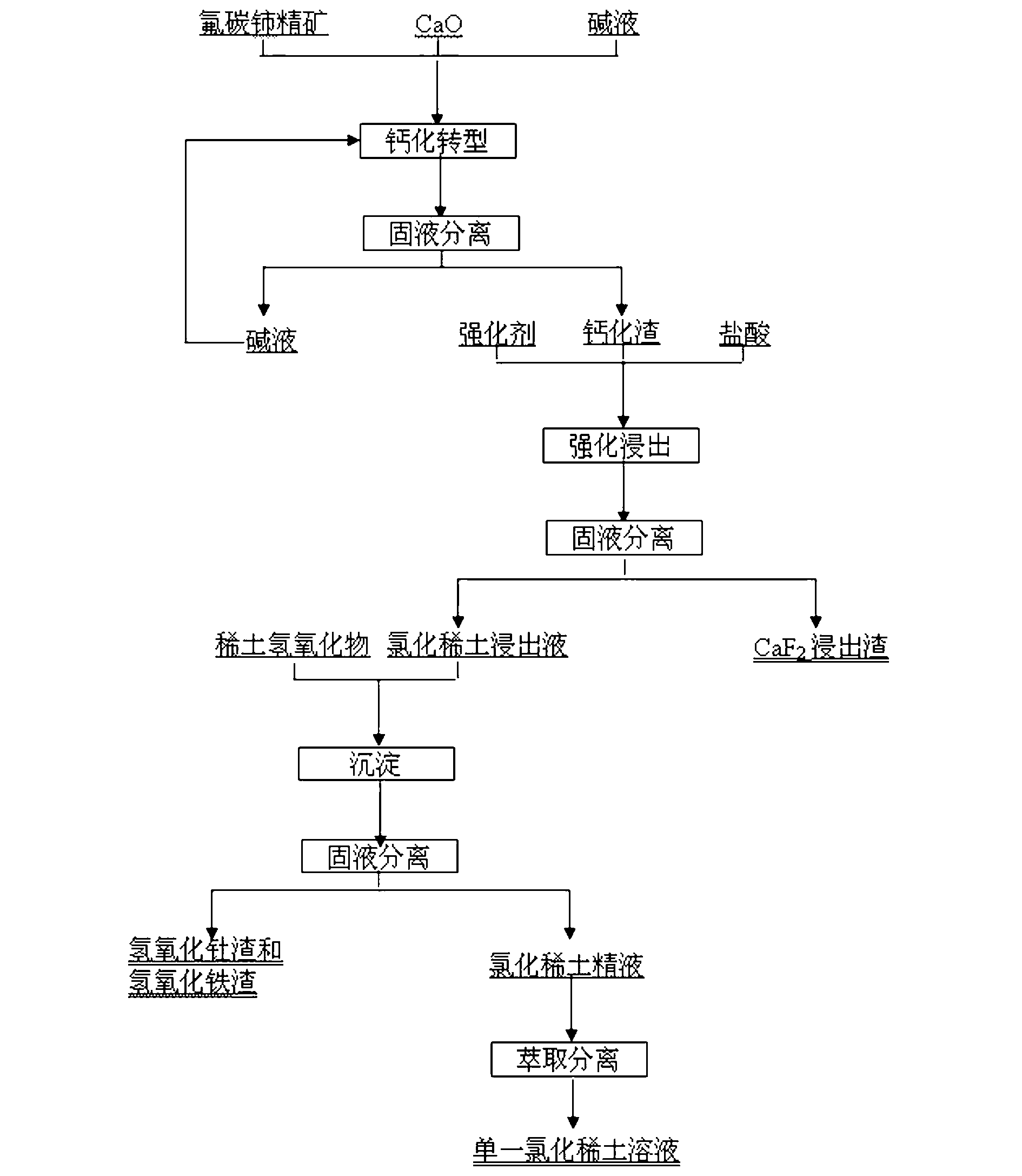

Method for comprehensively recycling rare earth and fluorine in process of treating bastnaesite

The invention provides a method for comprehensively recycling rare earth and fluorine in a process of treating bastnaesite. The method comprises the steps of: carrying out oxidizing roasting on the bastnaesite, leaching a roasted mixture by adopting hydrochloric acid to obtain a rare earth chloride solution containing less cerium and fluorine-containing and cerium-rich slag, wherein a roasting additive is added in the bastnaesite in the roasting process and / or a catalytic leaching additive is added in the mixture in a hydrochloric acid leaching process; and then separating and recycling rare earth chloride from the fluorine-containing and cerium-rich slag. According to the method provided by the invention, the consumption of a large quantity of chemical raw materials can be reduced, the pollution to the environment in a use process is greatly reduced, and the production cost is also greatly lowered. According to the method, the procedures of multiple times of solid-liquid separation and the like are eliminated, the process is simplified, the manipulation strength is reduced, the rare earth loss is reduced, the rare earth yield is increased, and especially the hydrochloric acid leaching recycling rate of high-valent non-cerium rare earth is increased. The method provided by the invention realizes fluorine-free emission in the whole process, and has the characteristics of low consumption, high efficiency and the like.

Owner:GRIREM ADVANCED MATERIALS CO LTD

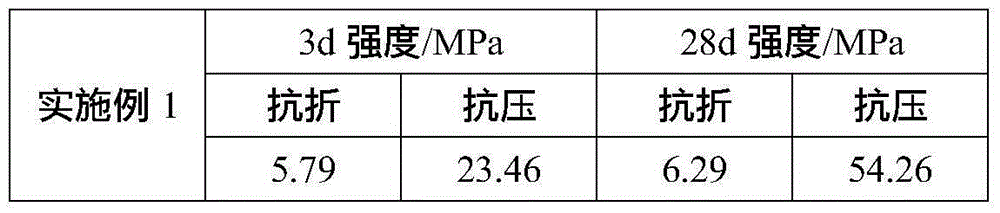

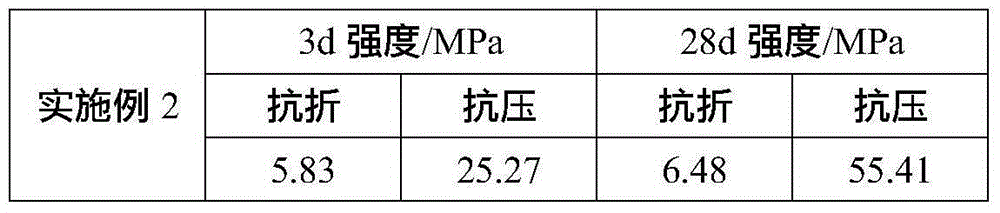

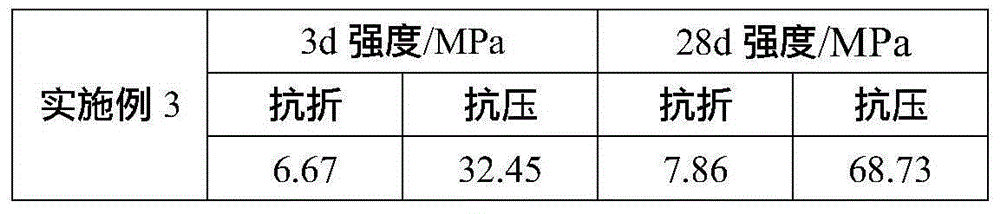

Belite-sulphoaluminate-ferrous aluminate cement and preparation method thereof

ActiveCN105060745ALow firing temperatureImprove performanceCement productionToxic industrial wasteMaterials science

The invention discloses belite-sulphoaluminate-ferrous aluminate cement which comprises the following components by mass percent: 38-70% of beta-C2S, 27-37% of C4A3S-(refer to the description) and 3-25% of C4AF. The invention further discloses a preparation method of the belite-sulphoaluminate-ferrous aluminate cement. The preparation method comprises the following steps: with industrial waste residue and industrial gypsum as the raw materials, mixing the raw materials with aluminous corrective addition namely bauxite or tailing bauxite, forming, performing hydrothermal reaction, crushing, calcining and grinding to obtain the belite-sulphoaluminate-ferrous aluminate cement. According to the invention, the low-carbon belite-sulphoaluminate-ferrous aluminate cement is prepared at low temperature; in addition, limestone is not used, so that no carbon dioxide is generated to increase the environmental pressure; moreover, the calcining temperature is low, so that the energy consumption is low, and the preparation method is a low-carbon and environment friendly preparation method.

Owner:天瑞集团萧县水泥有限公司

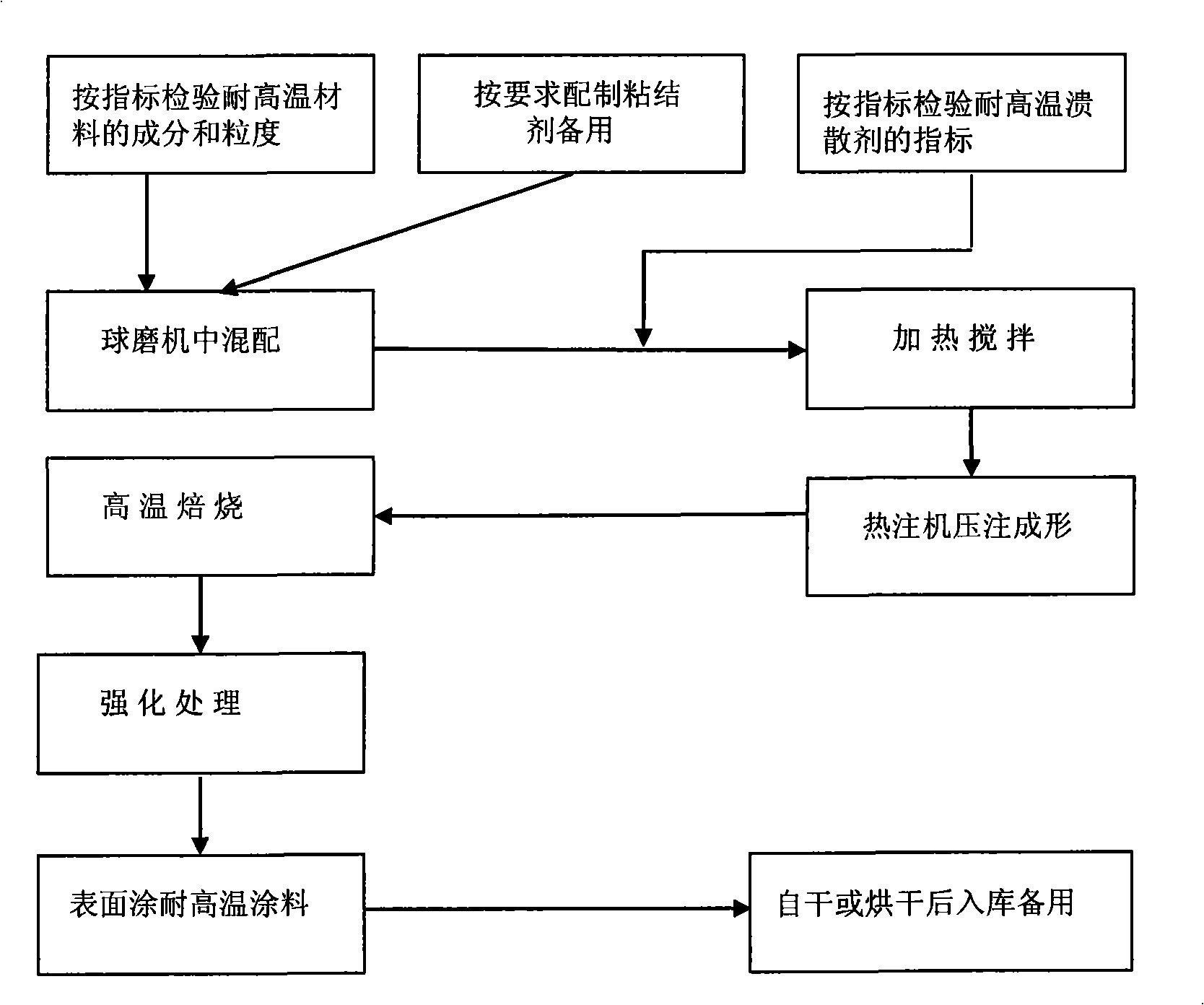

Ceramic core for silica sol precision casting and manufacturing process thereof

InactiveCN101537473AShorten roasting timeLow firing temperatureFoundry mouldsMould handling/dressing devicesTemperature resistanceChoice making

The invention discloses a ceramic core for silica sol precision casting and a manufacturing process thereof. Main body components of the ceramic core comprise refined quartz powder and a proper amount of collapsing agent, and the surface of the ceramic core is coated with high-temperature resistant paint with a thickness of 0.1 to 0.2 millimeter; and at the same reasonable manufacturing processes such as mixing, core making and roasting are adopted. In the ceramic core for casting, the unique material mixing and manufacturing processes are adopted, and the reasonable use of the refined quartz powder and the collapsing agent improves the collapsibility of the ceramic core after casting considerably, the high-quality high-temperature resistant material in ingredients enables the core to resist the erosion of high-temperature molten metals, and the high-temperature resistant paint on the surface of the ceramic core not only improves the high temperature resistance during casting, but also increases the cooling speed of the molten metal.

Owner:上海市机械制造工艺研究所有限公司

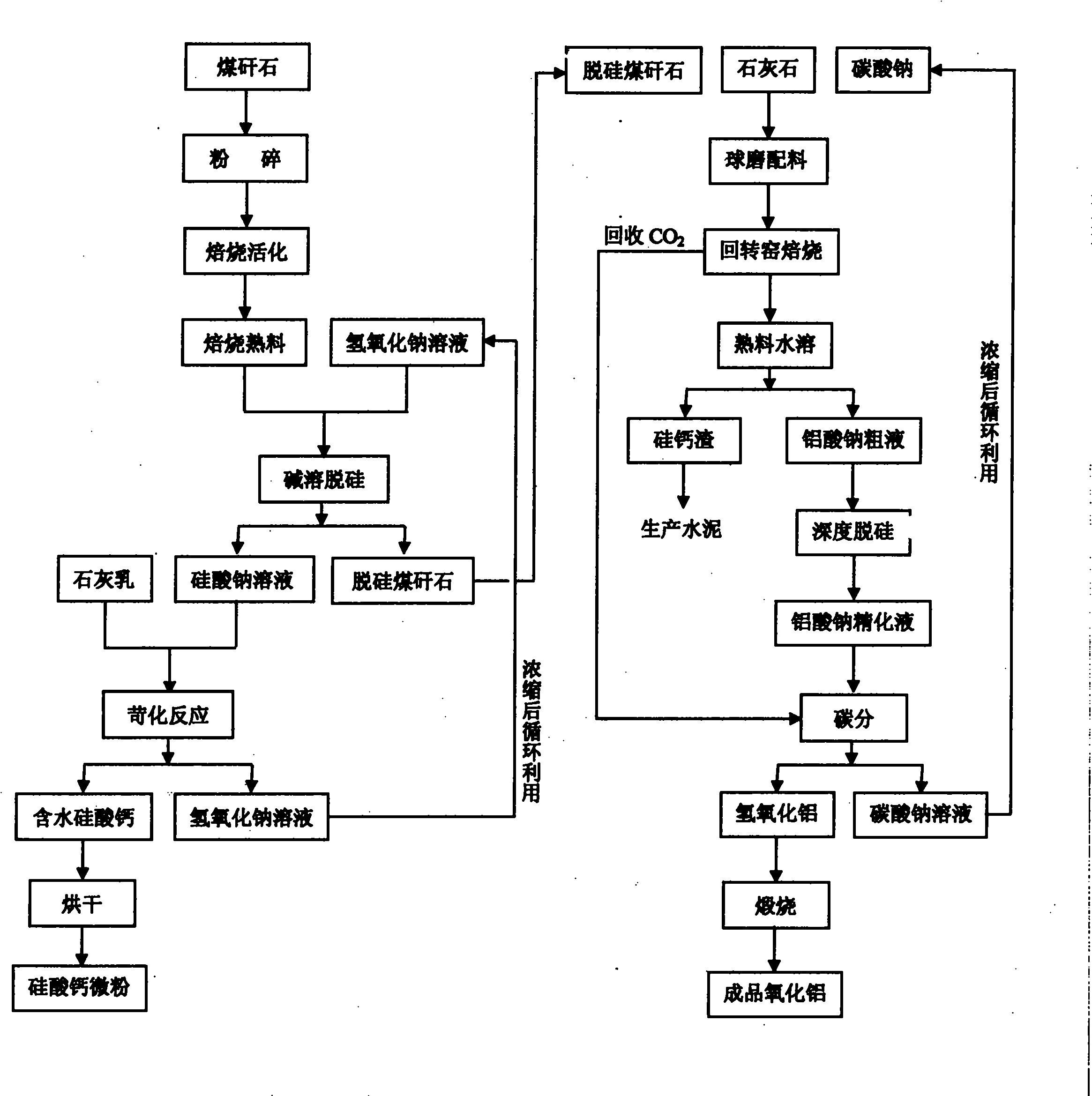

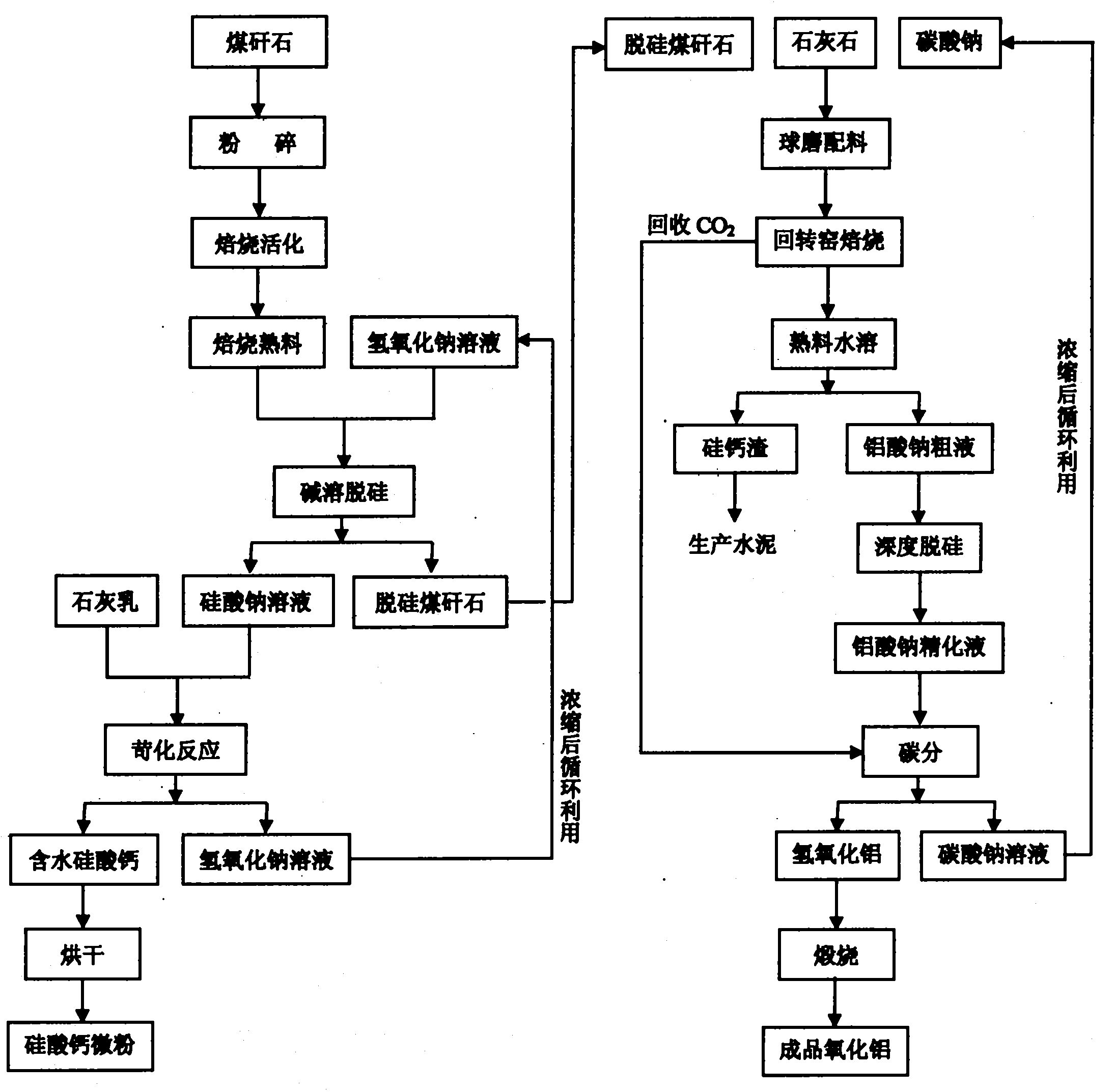

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

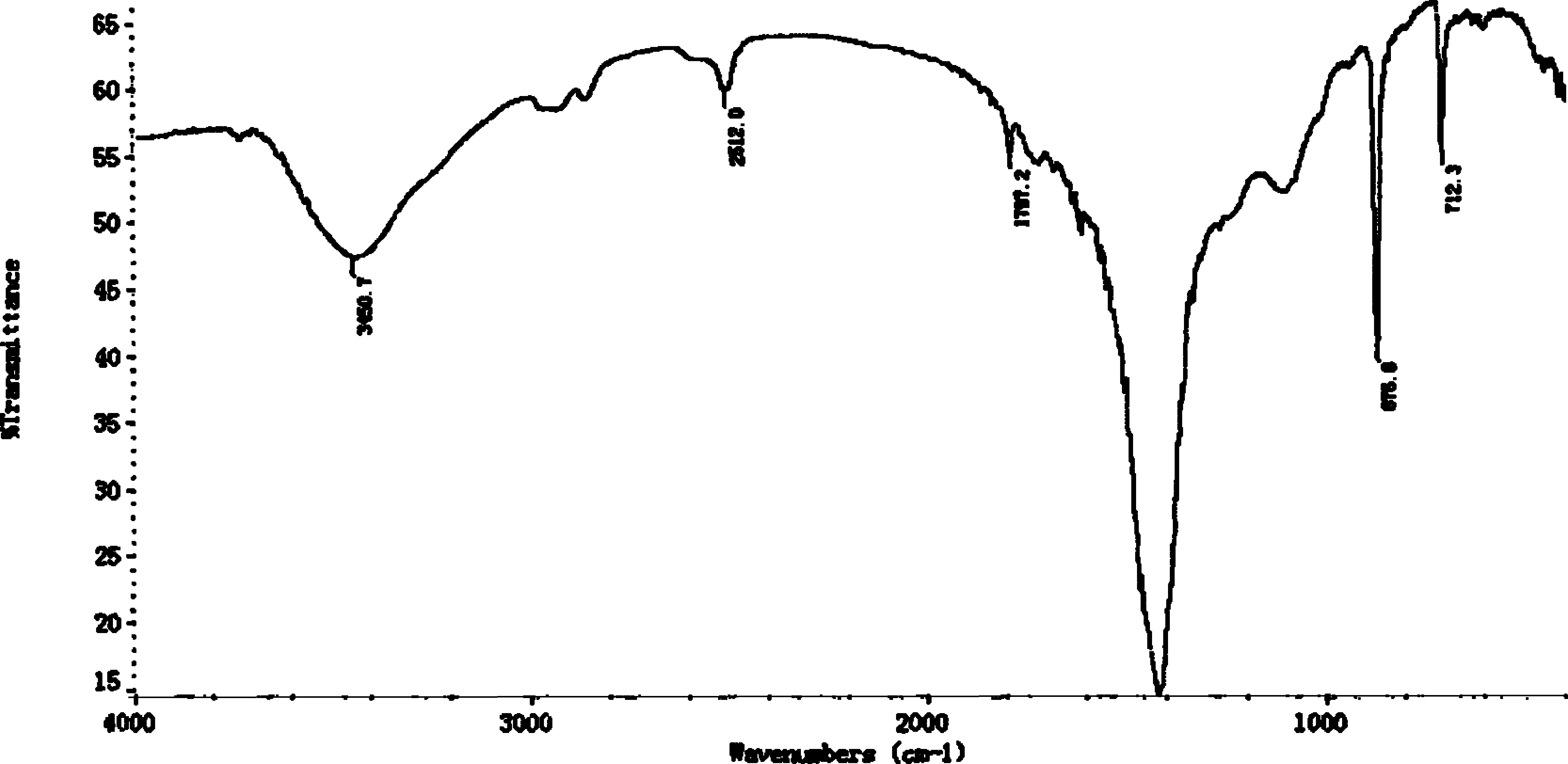

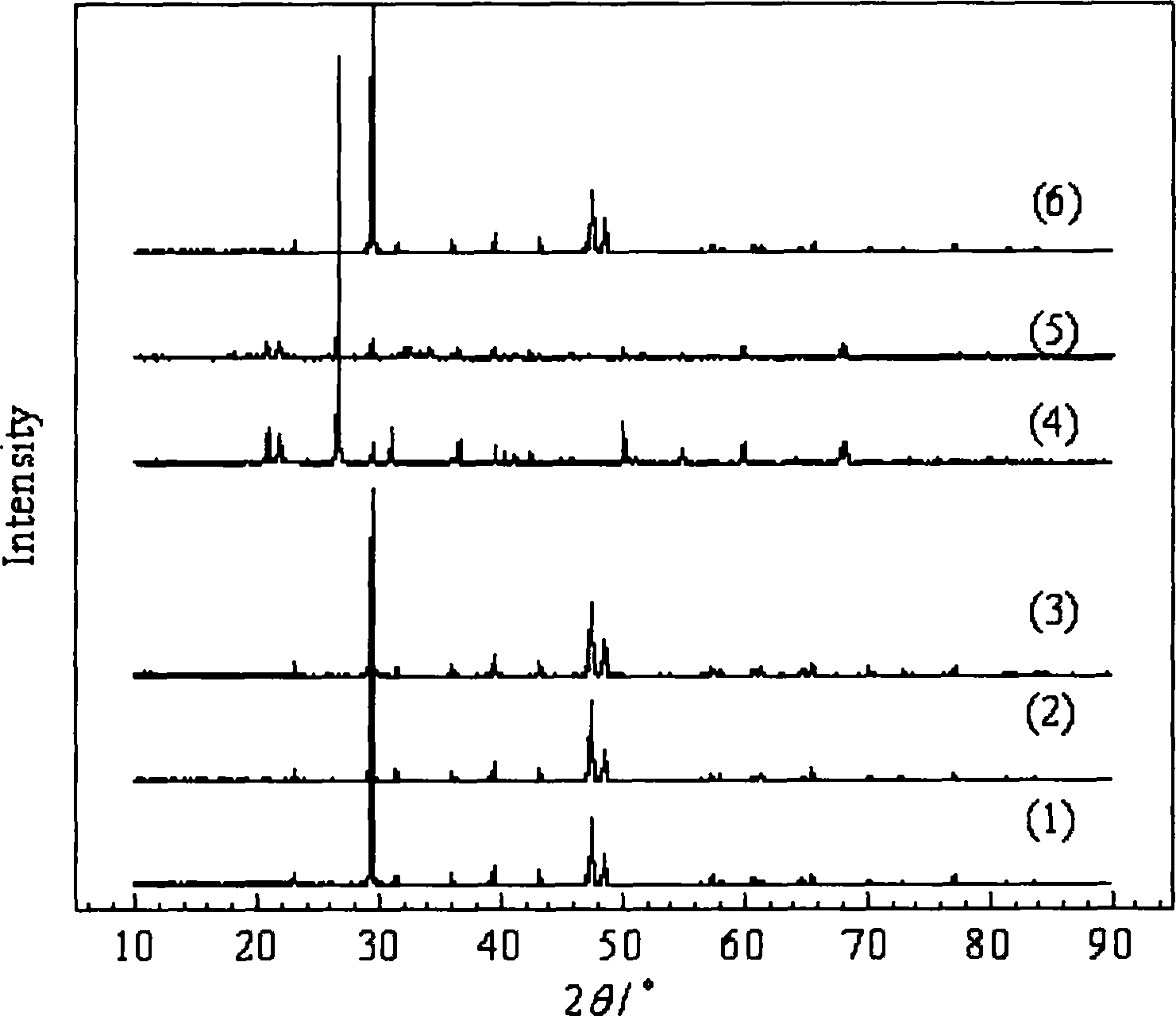

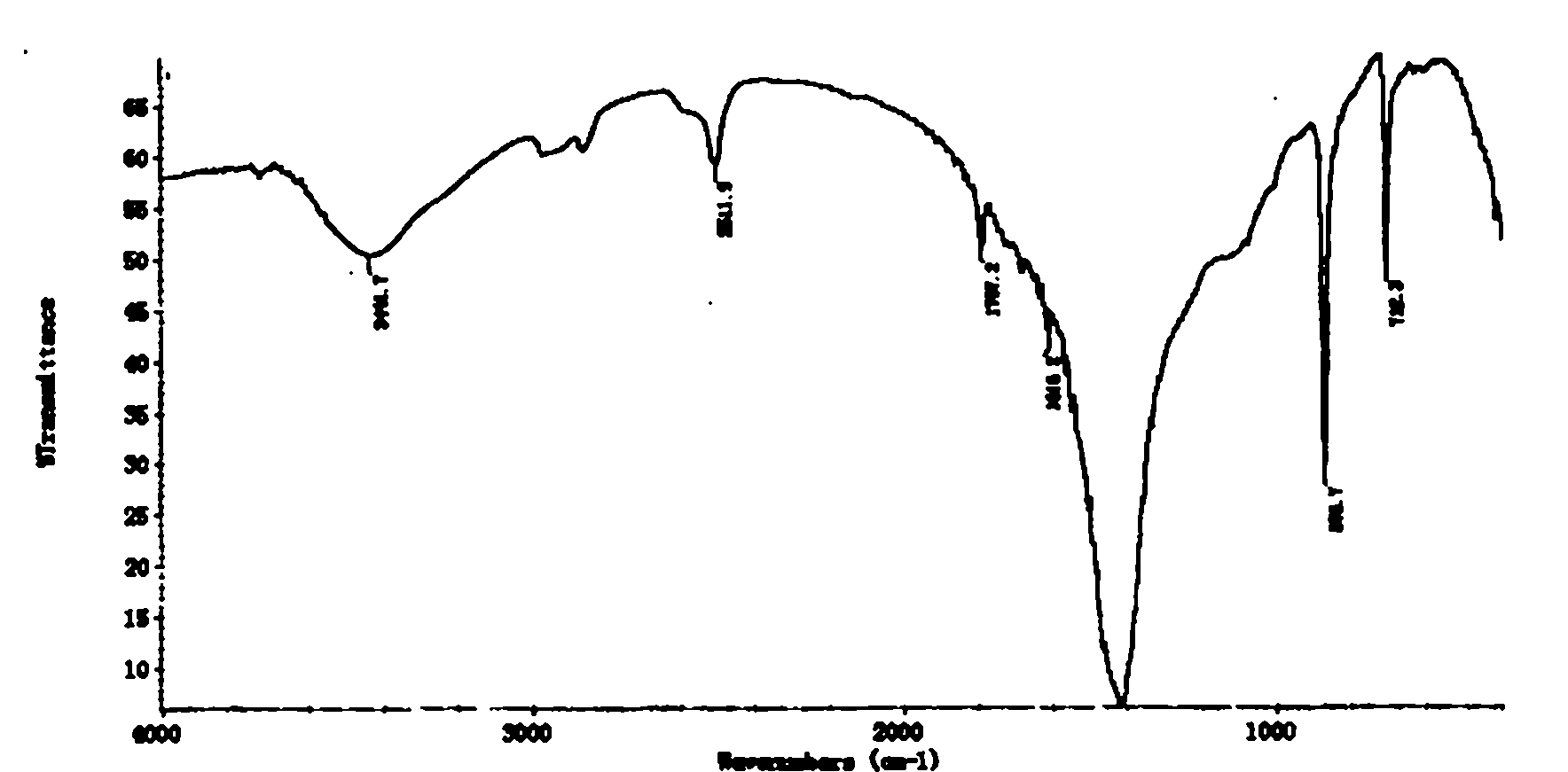

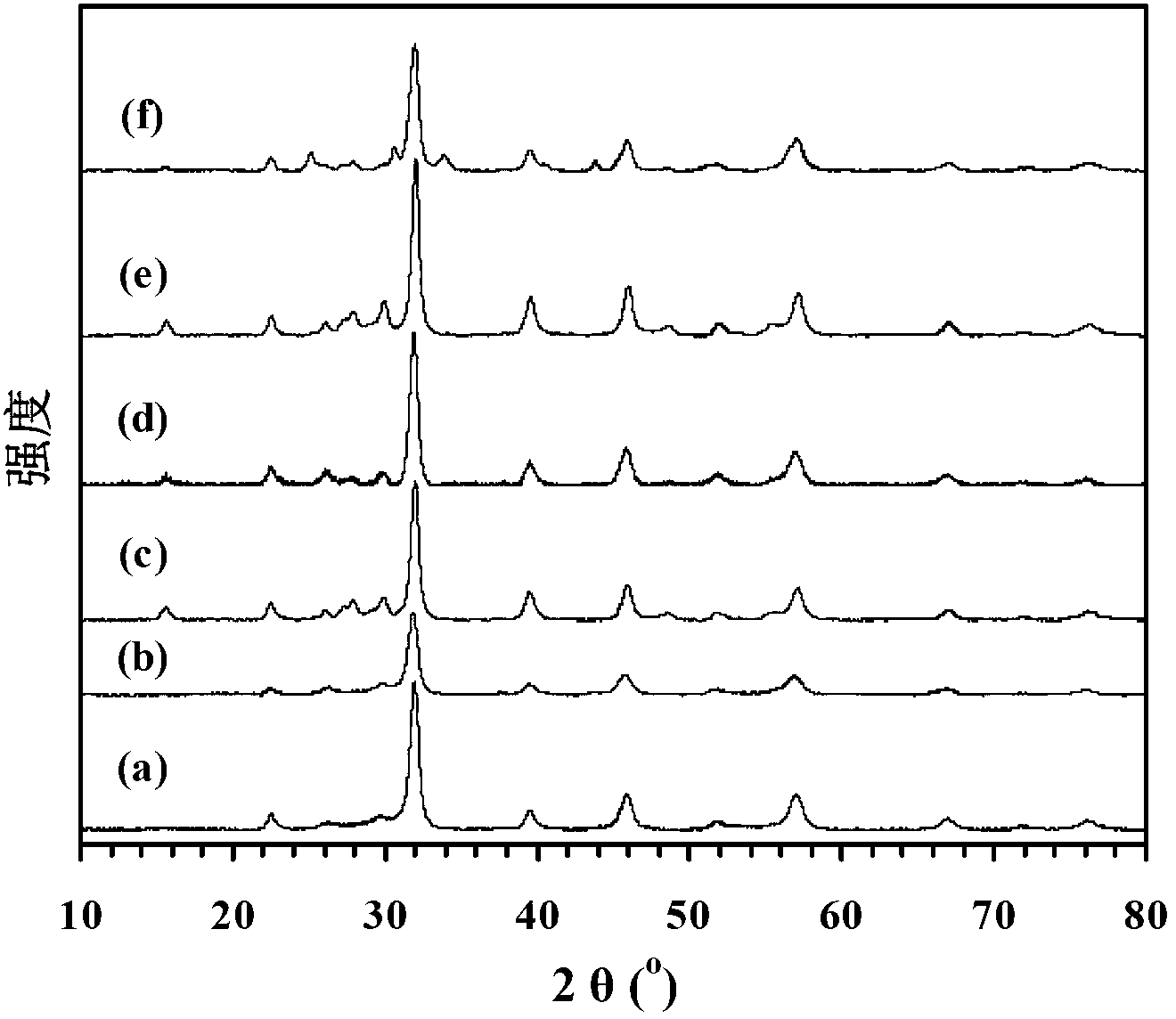

Shell powder and preparation method thereof

InactiveCN102311137ALow firing temperatureReduce the number of roastingCalcium/strontium/barium carbonatesCalcium/strontium/barium oxides/hydroxidesCooking & bakingCalcite

The invention relates to shell powder and a preparation method thereof. The invention provides the high-quality shell powder and solves the technical problems of reducing the baking temperature, shortening time and reducing energy consumption. The preparation method of theshell powder comprises the following steps of: washing ruditapes philippin (known as ruditapes philippinarum in the southern part of China, clam in Liaoning province, China, and surf clam in Shandong province, China), clams, oysters, scallop and conchs, drying, pulverizing, adding an auxiliary agent, mixing, baking, grinding, and sifting to prepare powder; determining that the powder has the main component of CaCO3 and a small amount of CaO by using an infrared spectrograph, a powder X-ray spectrograph and a specific surface measurement device; placing in the air; and then converting CaO to [Ca(OH)2]. The shell powder belongs to calcite type crystal, can be used as a natural material and for replacing a chemical product and has broad application prospect.

Owner:BEHAN NEW ENVIRONMENTALLY FRIENDLY CONSTR MATERIALS CO LTD JILIN PROVINCE

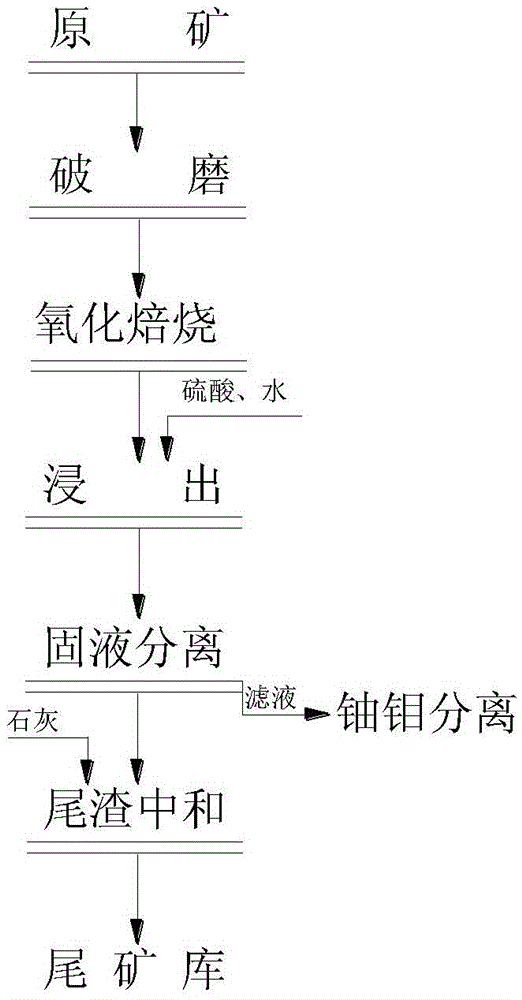

Method for preprocessing wrapped uranium-molybdenum ores through oxidizing roasting

The invention belongs to the technical field of uranium-molybdenum ore processing, specifically relates to a method for preprocessing wrapped uranium-molybdenum ores through oxidizing roasting, aims to overcome the shortages of prior art and further improve the leaching rate of valuable metal such as uranium, molybdenum, and the like, and provides a method for improving the leaching rate of uranium and molybdenum in wrapped uranium-molybdenum ores through an oxidizing roasting pretreatment. Through the oxidizing roasting treatment, the colloidal sulfur-molybdenum ore wrapping is destroyed, thus the oxidation of molybdenum ores in the wrapped uranium-molybdenum ores is promoted, and molybdenum becomes easier for leaching. After oxidizing roasting treatment, uranium and molybdenum can be leached out under a lower acid degree at a lower temperature, the leaching rate of uranium can reach 90% or more, the leaching rate of molybdenum can reach 80% or more, the leaching rates are improved by 5% and 30% respectively compared with the conventional method, moreover, no oxidizing agent is used during the leaching process, and the liquid and solid in leached ore slurry can be separated easily. The method has the advantages of low burning temperature, high oxidation rate of uranium and molybdenum, simple technology, little consumption of reagent, and low production cost.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

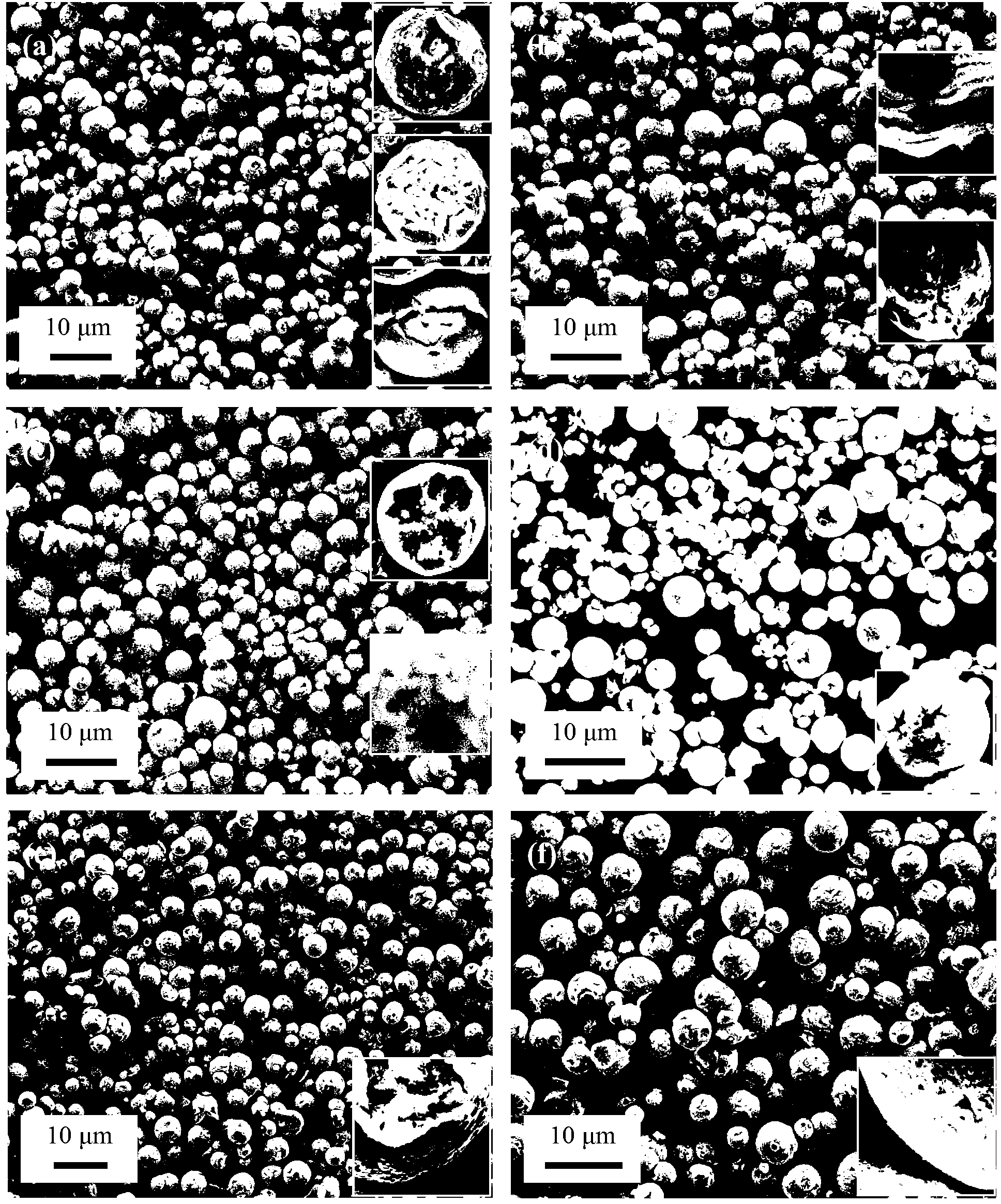

Perovskite composite oxide LaFeO3 monodisperse micrometer hollow balls and preparation method thereof

The invention relates to perovskite composite oxide LaFeO3 monodisperse micrometer hollow balls and a preparation method thereof, and belongs to the technical field of micro nanometer functional materials. The micrometer hollow balls are in a monodisperse state, the outer diameter of each micrometer hollow ball is between 1 and 7 micrometers, and the micrometer hollow balls are in a perovskite crystalline phase. The preparation method comprises the following steps of: stirring a mixed solution containing urea serving as an additive, citric acid serving as a complexing agent, deionized water serving as a solvent and metal nitrate uniformly, transferring the mixed solution to an autogenous pressure kettle, putting into a constant temperature box, keeping temperature for a certain time, cooling naturally, performing suction filtration on the obtained products, drying, grinding, and roasting at high temperature to obtain the highly-monodispersed LaFeO3 micrometer hollow balls. According to the preparation method, a template is not needed to be utilized, the reaction time is short, the preparation process is environment-friendly, and the operation is easy to implement.

Owner:BEIJING UNIV OF TECH

Casting method of magnesium alloy casting

InactiveCN103231016AGuaranteed decompositionGuaranteed fillingFoundry mouldsFoundry coresInterfacial reactionCasting mold

The invention provides a casting method of a magnesium alloy casting. With the method, advantages of different casting methods are utilized, and defects of the methods are overcome. With a special shell preparation method and a method for preventing magnesium alloy-casting mold interfacial reaction, a unique casting technology suitable for thin-wall complex magnesium alloy part production is formed. The method has important significance for developing magnesium alloy performance advantages and satisfying automotive magnesium alloy application requirements.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Method for preparing casting shell of fired mold

InactiveCN105414485AShorten roasting timeLow firing temperatureFoundry mouldsFoundry coresSurface layerNanotechnology

The invention discloses a method for preparing a casting shell of a fire mold. The method comprises a surface layer preparing step, a transition layer preparing step, a back layer preparing step, a dewaxing step and a roasting step. According to the method for preparing the casting shell of the fire mold, the roasting time of the shell is shortened, the roasting temperature of the shell is reduced, and energy can be saved; and the residue strength of the shell is reduced, the shell removing performance of the shell is improved, cleaning of the shell after casting is facilitated, and the production efficiency is improved.

Owner:HUZHOU NANFENG MACHINERY MFG

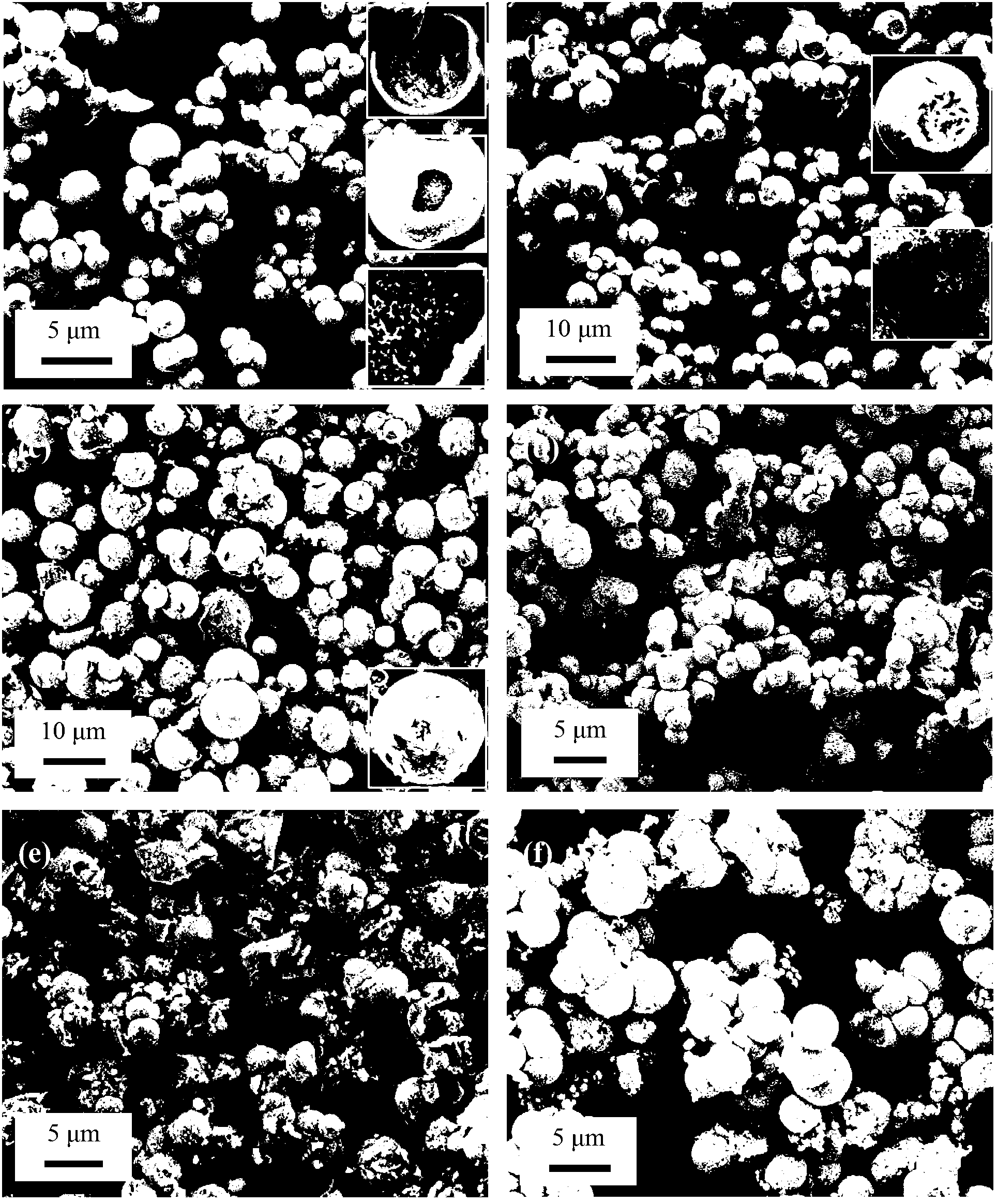

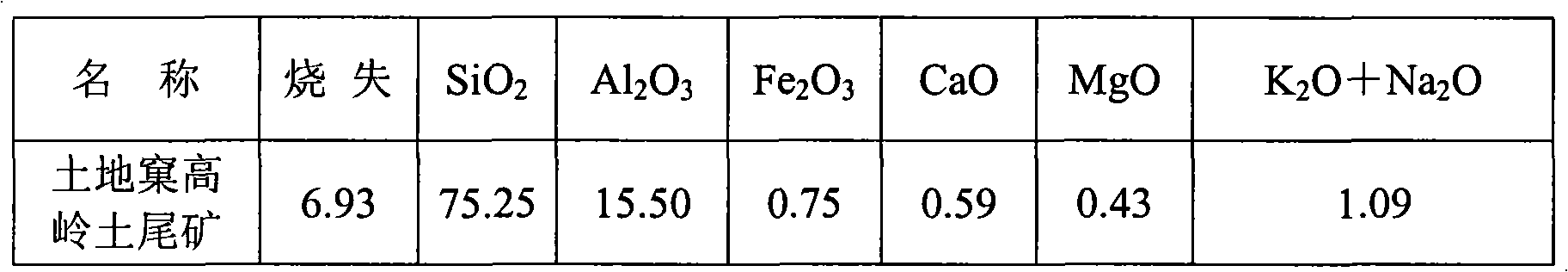

Household ceramic produced by comprehensively utilizing various tailings and manufacturing method thereof

The invention discloses a household ceramic manufacturing method. The blank of the household ceramic is prepared from the following raw materials in percentage by weight: 18 to 20 percent of Chengkeng clay tailing, 15 to 17 percent of Guodong china clay tailing, 19 to 22 percent of Tudike kaolin tailing, 16 to 17 percent of feldspar and 24 to 27 percent of clay. The manufacturing method comprises the following steps of: screening the Chengkeng clay tailing, the Guodong china clay tailing and the Tudike kaolin tailing according to classes, removing impurities, crushing, mixing according to a proportion, performing ball milling, sieving, iron removal, pressure filtration, coarse refining, ageing, and vacuum pugging to obtain a blank, drying, and glazing; and firing to obtain the household ceramic finished product. Various tailings are compounded, and the tailings account for 52 to 59 percent of the total mass of the raw materials. The household ceramic has the advantages of low production cost, high finished product ratio, stable structure, lower firing temperature, effective prevention of waste and energy waste, light environmental pollution and suitability for popularization.

Owner:广东宝丰陶瓷科技发展股份有限公司

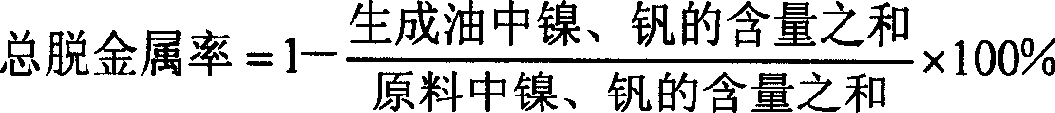

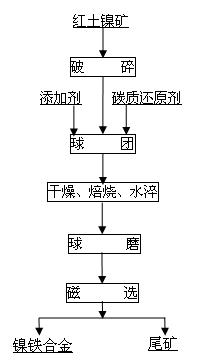

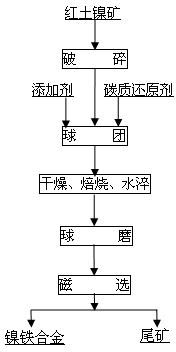

Method for producing ferronickel from lateritic nickel ores

The invention relates to a method for producing ferronickel from lateritic nickel ores, particularly a method for producing ferronickel from lateritic nickel ores by metallizing reduction roasting-magnetic separation. The method is characterized by comprising the following steps: adding additives and a carbonaceous reducing agent into lateritic nickel ores, carrying out reduction roasting, quenching with water, grinding, and carrying out magnetic separation to obtain the ferronickel alloy. In the method, the magnetic separation is directly carried out to obtain the ferronickel alloy powder with high nickel grade; the additives are added to lower the reduction temperature; not all the materials need to be heated to 1500 DEG C, thereby lowering the energy consumption; and the technique has slight influence on the environment, and thus, is an economical method for producing ferronickel from lateritic nickel ores, thereby having wide application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for preparing ceramic material by virtue of copper tailings

ActiveCN105541296ARealize resource utilizationGood environmental benefitsCeramic materials productionClaywaresSocial benefitsSlag

The invention discloses a method for preparing a ceramic material by virtue of copper tailings, and belongs to the fields of industrial solid waste resource comprehensive utilization and environmental protection. The method comprises the following steps of ball-milling and mixing 35 to 55 parts by weight of copper tailings, 25 to 40 parts by weight of steel slag, 10 to 25 parts by weight of clay, 0 to 15 parts by weight of feldspar, 0 to 10 parts by weight of talc and the like, and executing the procedures of sieving, drying, pressing or extrusion molding, sintering and the like to obtain the ceramic material, wherein the firing temperature is 1,080 to 1,160 DEG C. According to the method, the ceramic material is synergistically prepared from the copper tailings and the steel slag, and the ratio of the using amount of industrial solid waste to the total weight of the raw materials in the ceramic material reaches 65 to 85 percent, so that the industrial solid waste can be resourcefully utilized in large scale, and obvious social benefits and environmental benefits can be achieved; the copper tailings and the steel slag are small in granularity, so that ball-milling energy consumption in a ceramic material production process can be reduced; the sintering temperature is lower, so that the sintering energy consumption of the ceramic material can be reduced, and economic benefits are achieved; the method is relatively simple in process and easy to popularize and use.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

Method for decomposing bastnaesite through calcification transformation-leaching

The invention belongs to the technical field of rare earth metallurgy, and particularly relates to a method for decomposing bastnaesite through calcification transformation-leaching. The method comprises the following the steps of: carrying out activation pretreatment on rare earth ore concentrate, carrying out calcification transformation pretreatment on the activated ore, carrying out acid leaching on transformed slag, extracting rare earth chloride fine liquid to finally obtain a solution with thorium-iron slag and cerium chloride or lanthanum chloride or praseodymium chloride or neodymium trichloride, and efficiently separating valuable elements such as a rare earth element, a fluorine element and a thorium element. According to the method, energy consumption and fuel consumption are reduced, and when the low-temperature baking is carried out below 500 DEG C, only carbonates are decomposed, so that the reaction activity of the rare earth ore concentrate is supplied, and simultaneously the waste of fluorine resources and the emission pollution are avoided; and therefore, the method belongs to a green clean technology.

Owner:NORTHEASTERN UNIV

Method for making archaistic semimatte thin glaze for Ru porcelain

The invention discloses a method for making an archaistic semimatte thin glaze for a Ru porcelain, which comprises the following steps: respectively taking 4-10% of kaoline, 55-65% of melilite, 18-22% of calcite, 4-6% of white feldspar, 6-10% of black feldspar and 1-3% of plant ash as raw materials for making the glaze; calcining the kaoline for 4-6 hours at a temperature of 880-920 DEG C for future use; mixing the melilite, the calcite, the white feldspar, the black feldspar and the plant ash with the calcined kaoline, adding water to the obtained mixture to carry out wet grinding on the obtained mixture, and removing natant iron to obtain a glaze material; selecting the kaoline as a blank material, adding the water and a water reducing agent to the blank material to carry out the wet grinding on the kaoline, and then, making slurry into a blank, and sintering the blank to obtain a biscuit; adding the water to the glaze material to adjust the concentration of the glaze material, immersing the biscuit in the glaze, and finishing the biscuit; putting the biscuit in a kiln, ventilating the kiln, increasing a temperature to 1050 DEG C, and then, reducing an inlet air amount, so that a fuel in the kiln is combusted incompletely in an anaerobic condition, and gradually increasing the temperature to 1135 DEG C; and preserving heat for 10 minutes, and then, decreasing the temperatureto 900 DEG C, stopping a fire, and cooling the obtained product, thereby completing the making.

Owner:刘冬青

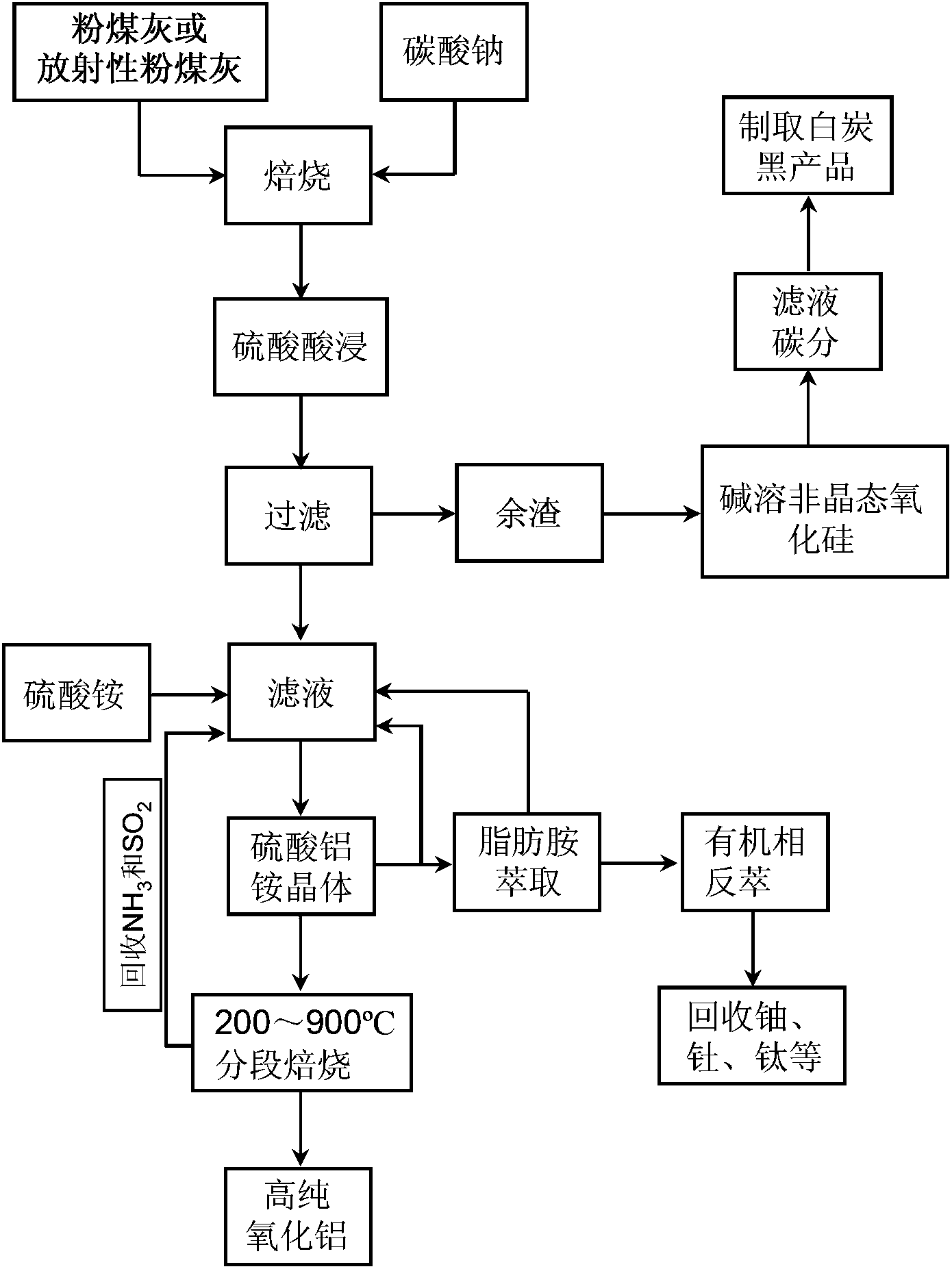

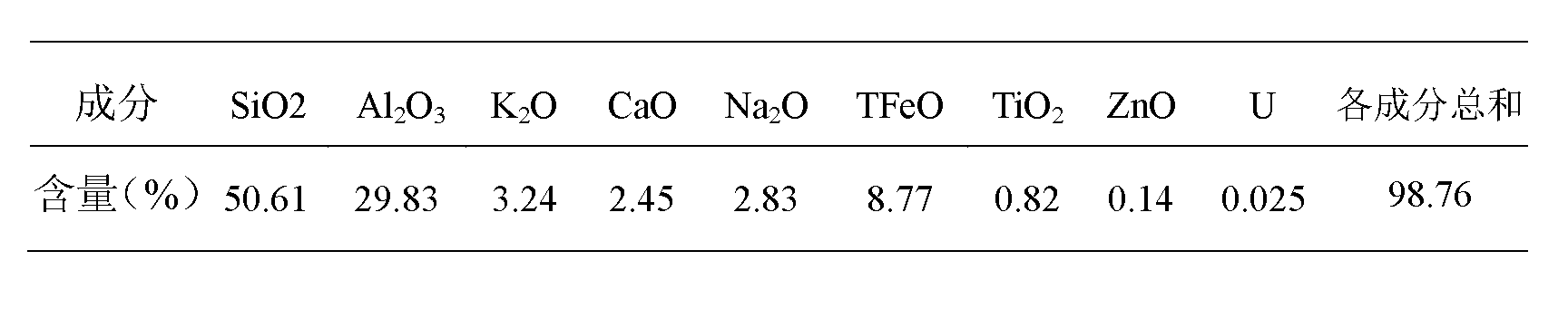

Process method for producing high-purity aluminum oxide and silicate by using pulverized fuel ash

ActiveCN102701242ALow firing temperatureEnergy savingSilicaSolid waste disposalOxidePulverised fuel ash

The invention discloses a process method for producing high-purity aluminum oxide and silicate by using pulverized fuel ash and belongs to the technical field of pulverized fuel ash resource utilization. Aluminum oxide and parts of silicon oxide in the pulverized fuel ash and uranium, thorium and other elements in radioactive pulverized fuel ash are recycled by means of the process method, accordingly the pulverized fuel ash resource utilization and remarkable reduction of solid wastes are achieved, quantity of tailings does not reach quarter of weight of original pulverized fuel ash, and the purity of the aluminum oxide and the silicate produced by means of the process method is high. The industrialization of the process flow of the process method is easily achieved.

Owner:TSINGHUA UNIV

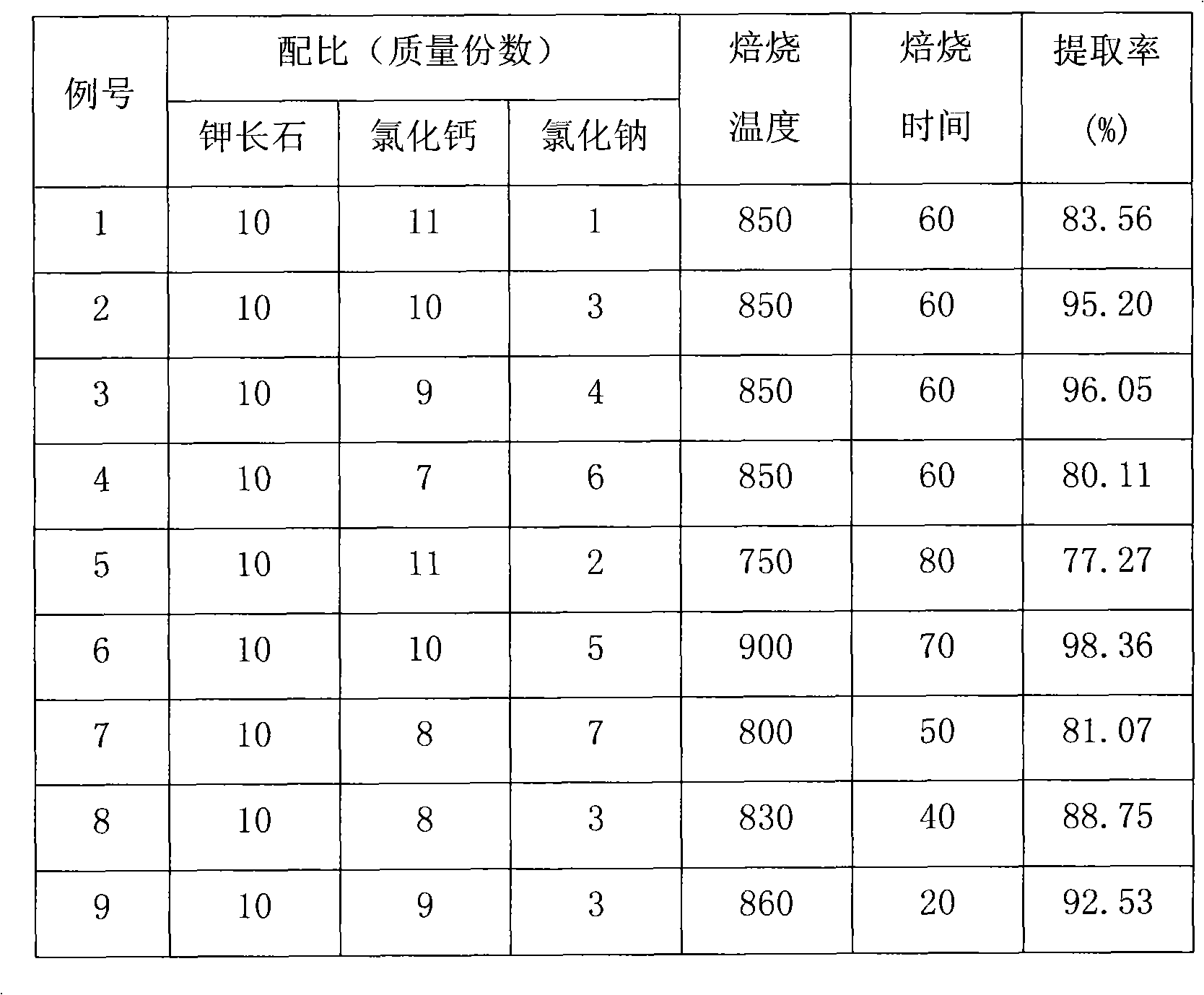

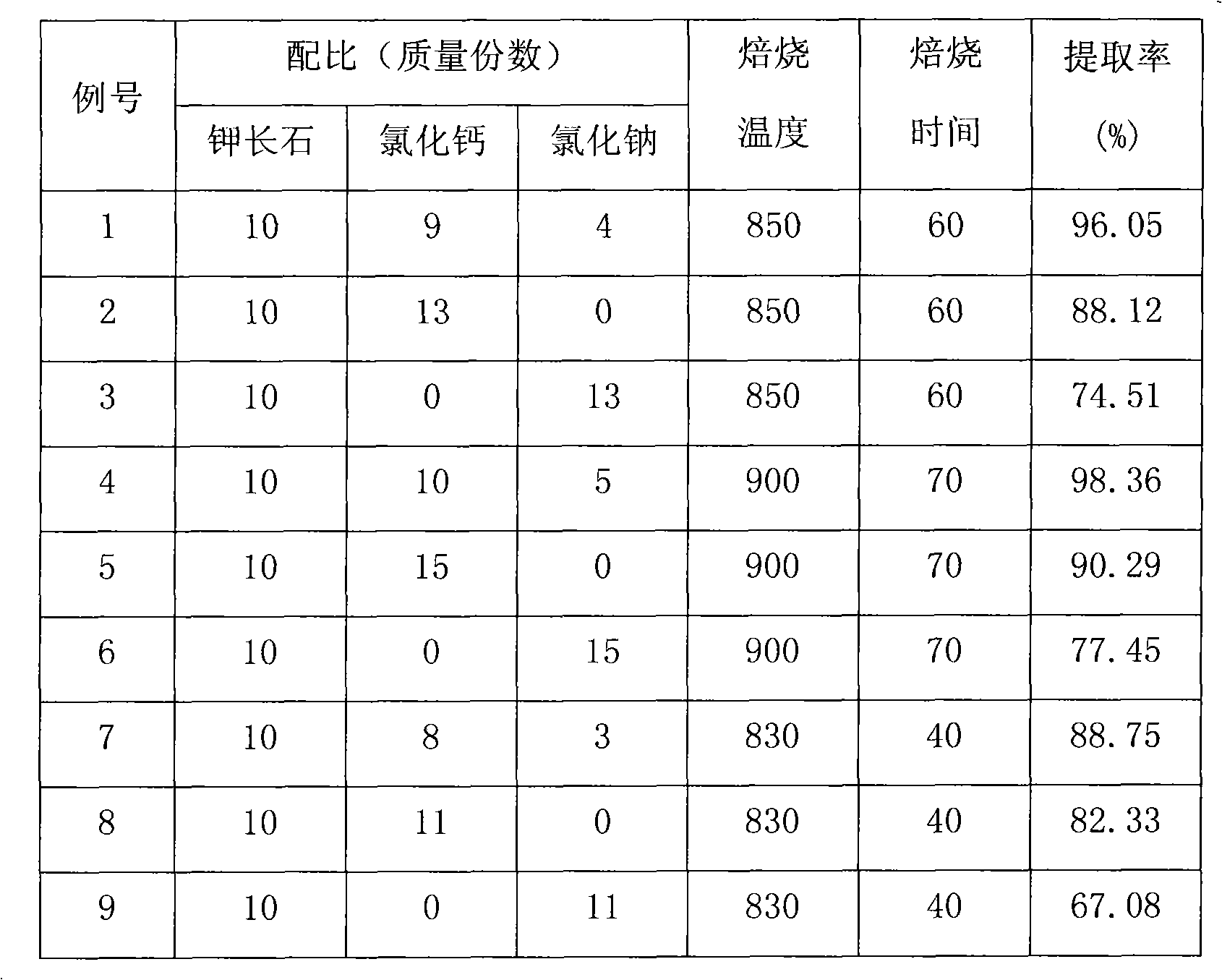

Method for decomposing potassium feldspar to extract soluble potassium

InactiveCN101831561AHigh extraction rateLow firing temperatureProcess efficiency improvementPotassium feldsparAnorthite

The invention discloses a method for decomposing potassium feldspar to extract soluble potassium, comprising the following steps of: crushing and grinding potassium feldspar used as a raw material; mixing with the ground potassium feldspar, calcium chloride and sodium chloride which are used as a combined assistant, and fully stirring, wherein the ratio by mass part of the potassium feldspar to the calcium chloride to the sodium chloride is 10:(7-11):(1-6); roasting the mixture at the temperature of 750-900DEG C for 20-80 minutes; leaching the product with water; and evaporating, condensing and separating the filtered filtrate to obtain a potassium chloride product. The potassium chloride product can be used for producing potassic fertilizer; and main components of filter residue are anorthite and soda feldspar which can be used for producing cement, microcrystalline glass and other building materials. In the method, the selected assistant has low price and wide sources and the obtained potassium extract rate is high; in addition, the method is applicable for the production of extracting the potassium from the potassium feldspar.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com