Perovskite composite oxide LaFeO3 monodisperse micrometer hollow balls and preparation method thereof

A composite oxide and perovskite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

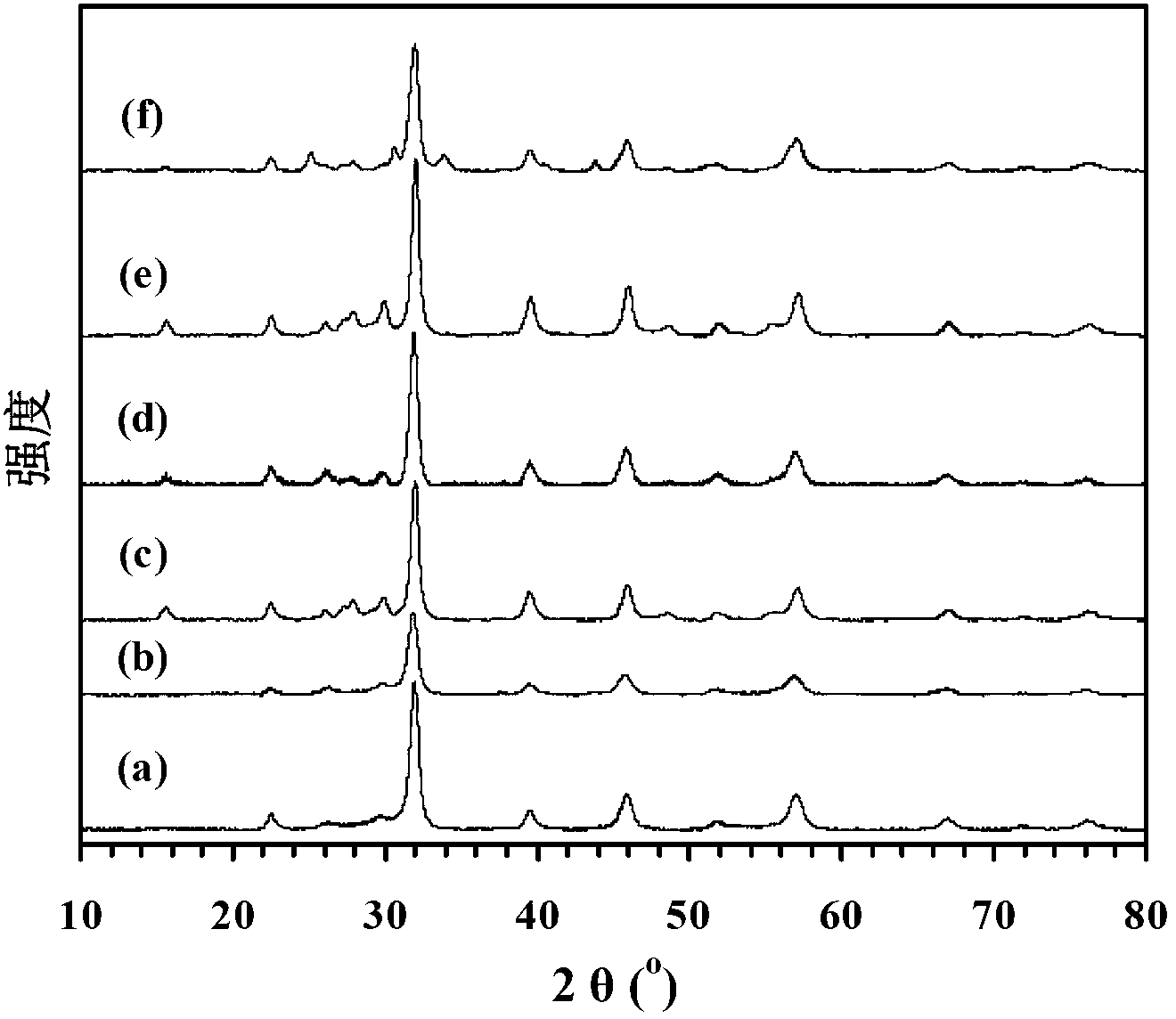

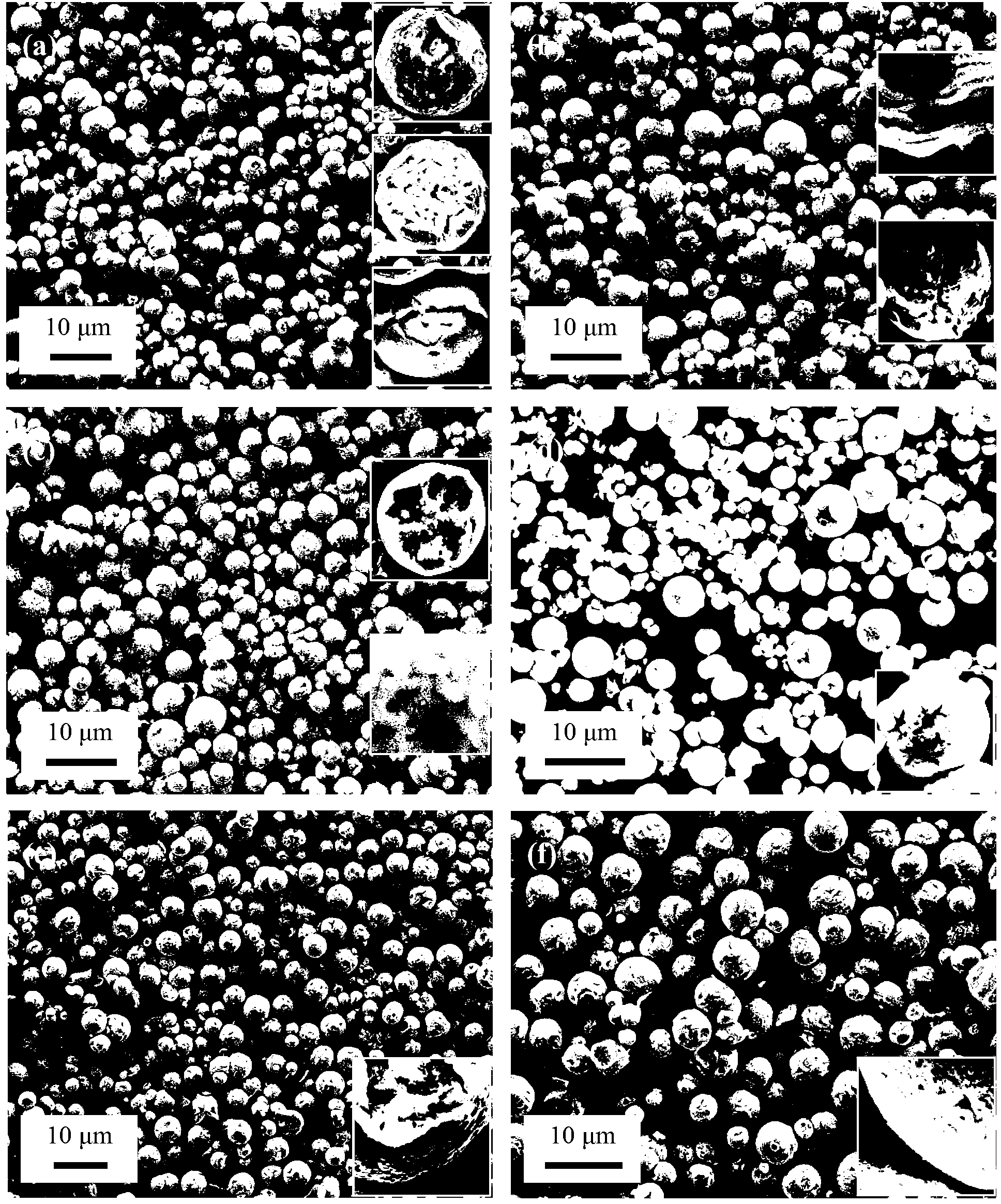

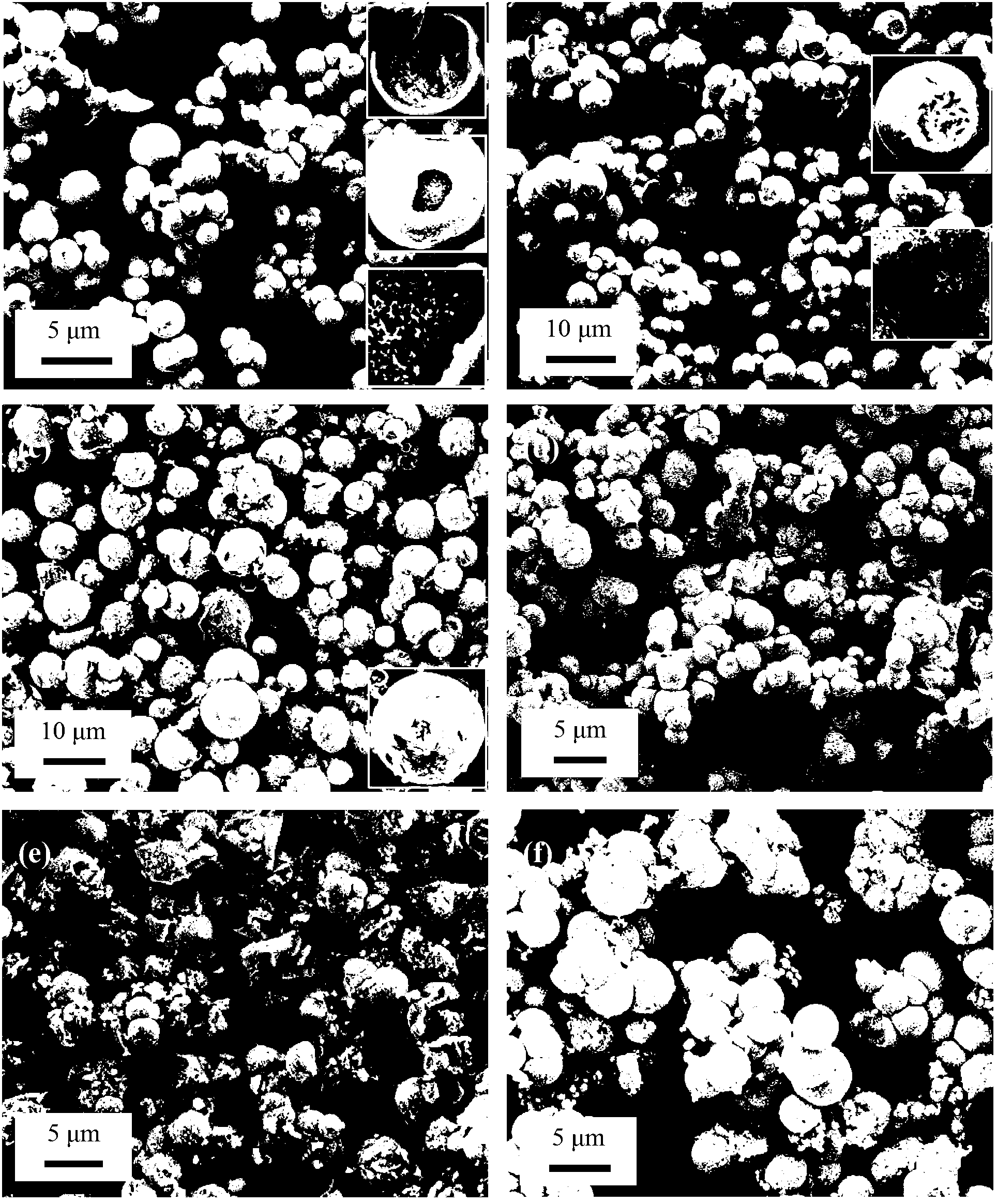

Embodiment 1

[0013] Example 1: Under stirring conditions, 0.01mol La(NO 3 ) 3 ·6H 2 O and 0.01molFe(NO 3 ) 3 9H 2 O was dissolved in 25mL deionized water, and 0.02mol citric acid and 0.03mol urea were added successively to form a uniform metal ion complex solution. in an autoclave and keep it warm at 110°C for 3 hours, then rise to 110°C for 4 hours after cooling to room temperature, cool to room temperature and filter, dry and grind the resulting product at room temperature, and finally place it in a muffle furnace in air Under the atmosphere, raise the temperature from room temperature to 400 °C at a rate of 3 °C / min and keep the temperature for 2 hours, continue to heat up to 650 °C and keep the temperature for 4 hours, and cool to room temperature to obtain LaFeO with better dispersion. 3 micron hollow spheres. The diameter of the microsphere is about 1.5-7 microns, and the wall thickness is about 300-500 nanometers.

Embodiment 2

[0014] Example 2: Under stirring conditions, 0.01mol La(NO 3 ) 3 ·6H 2 O and 0.01molFe(NO 3 ) 3 9H 2O was dissolved in 25mL deionized water, and 0.02mol citric acid and 0.03mol urea were added successively to form a uniform metal ion complex solution. in an autoclave and keep it warm at 110°C for 1 hour, then warm it up to 110°C for 5 hours after cooling to room temperature, cool to room temperature and filter, dry and grind the product at room temperature, and finally place it in a muffle furnace in air Under the atmosphere, raise the temperature from room temperature to 400 °C at a rate of 3 °C / min and keep the temperature for 2 hours, continue to heat up to 650 °C and keep the temperature for 4 hours, and cool to room temperature to obtain LaFeO with better dispersion. 3 micron hollow spheres. The diameter of the microsphere is about 2-6 microns, and the wall thickness is about 300-700 nanometers.

Embodiment 3

[0015] Example 3: Under stirring conditions, 0.01mol La(NO 3 ) 3 ·6H 2 O and 0.01molFe(NO 3 ) 3 9H 2 O was dissolved in 25mL deionized water, and 0.02mol citric acid and 0.03mol urea were added successively to form a uniform metal ion complex solution. In an autoclave and kept at 110°C for 5h, cooled to room temperature and filtered, the resulting product was dried and ground at room temperature, and finally placed in a muffle furnace in an air atmosphere at a rate of 3°C / min from room temperature to To 400°C and keep the temperature for 2h, continue to heat up to 650°C and keep the temperature for 4h, cool to room temperature, that is, well-dispersed LaFeO 3 micron hollow spheres. The diameter of the microsphere is about 2~7 microns, and the particle size is about 30~50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com