Household ceramic produced by comprehensively utilizing various tailings and manufacturing method thereof

A tailings and daily-use technology, which is applied in the field of ceramic product manufacturing, can solve the problems of low-grade ceramic products, waste of porcelain clay resources, waste of ceramic raw materials, etc., and achieve the effects of avoiding waste of resources and energy, saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

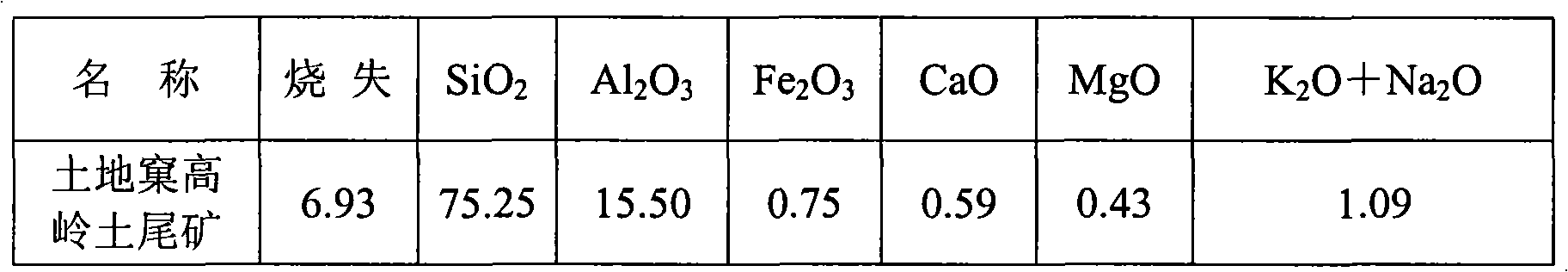

[0043] In terms of weight percentage, the blank formula of daily-use ceramics is:

[0044] Chengkeng soil tailings 20 Guodong porcelain clay tailings 17 land nest kaolin tailings 22 feldspar 16 clay 25.

[0045] The manufacture method of producing the above-mentioned household ceramics by utilizing the china clay tailings comprises the following steps:

[0046] ① Separately sort and screen the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings to remove impurities;

[0047] ② Separately pulverize the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings from which impurities have been removed;

[0048] ③Mix the clay, feldspar, Chengkeng soil tailings, Guodong porcelain clay tailings and Tuke kaolin tailings;

[0049] ④The above-mentioned ingredients are obtained through the processes of ball milling, sieving, iron removal, pressure filtration, rough refining, aging and vacuum mud refining;

[0050] ⑤ The blank i...

Embodiment 2

[0060] In terms of weight percentage, the blank formula of daily-use ceramics is:

[0061] Chengkeng soil tailings 18 Guodong porcelain clay tailings 17 land nest kaolin tailings 21 feldspar 17 clay 27.

[0062] The manufacture method of producing the above-mentioned household ceramics by utilizing the china clay tailings comprises the following steps:

[0063] ① Separately sort and screen the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings to remove impurities;

[0064] ② Separately pulverize the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings from which impurities have been removed;

[0065] ③Mix the clay, feldspar, Chengkeng soil tailings, Guodong porcelain clay tailings and Tuke kaolin tailings;

[0066] ④The above-mentioned ingredients are obtained through the processes of ball milling, sieving, iron removal, pressure filtration, rough refining, aging and vacuum mud refining;

[0067]⑤ Making the b...

Embodiment 3

[0077] In terms of weight percentage, the blank formula of daily-use ceramics is:

[0078] Chengkeng soil tailings 20 Guodong porcelain clay tailings 15 land nest kaolin tailings 22 feldspar 16 clay 27.

[0079] The manufacture method of producing the above-mentioned household ceramics by utilizing the china clay tailings comprises the following steps:

[0080] ① Separately sort and screen the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings to remove impurities;

[0081] ② Separately pulverize the Chengkeng soil tailings, Guodong porcelain clay tailings and Tudike kaolin tailings from which impurities have been removed;

[0082] ③Mix the clay, feldspar, Chengkeng soil tailings, Guodong porcelain clay tailings and Tuke kaolin tailings;

[0083] ④The above-mentioned ingredients are obtained through the processes of ball milling, sieving, iron removal, pressure filtration, rough refining, aging and vacuum mud refining;

[0084] ⑥ The blank i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com