Method for preparing super fine hydrophobic silicon dioxide

A silicon dioxide, hydrophobic technology, applied in the direction of silicon oxide, etc., can solve the problems of long preparation time, less particle agglomeration, difficult to control and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

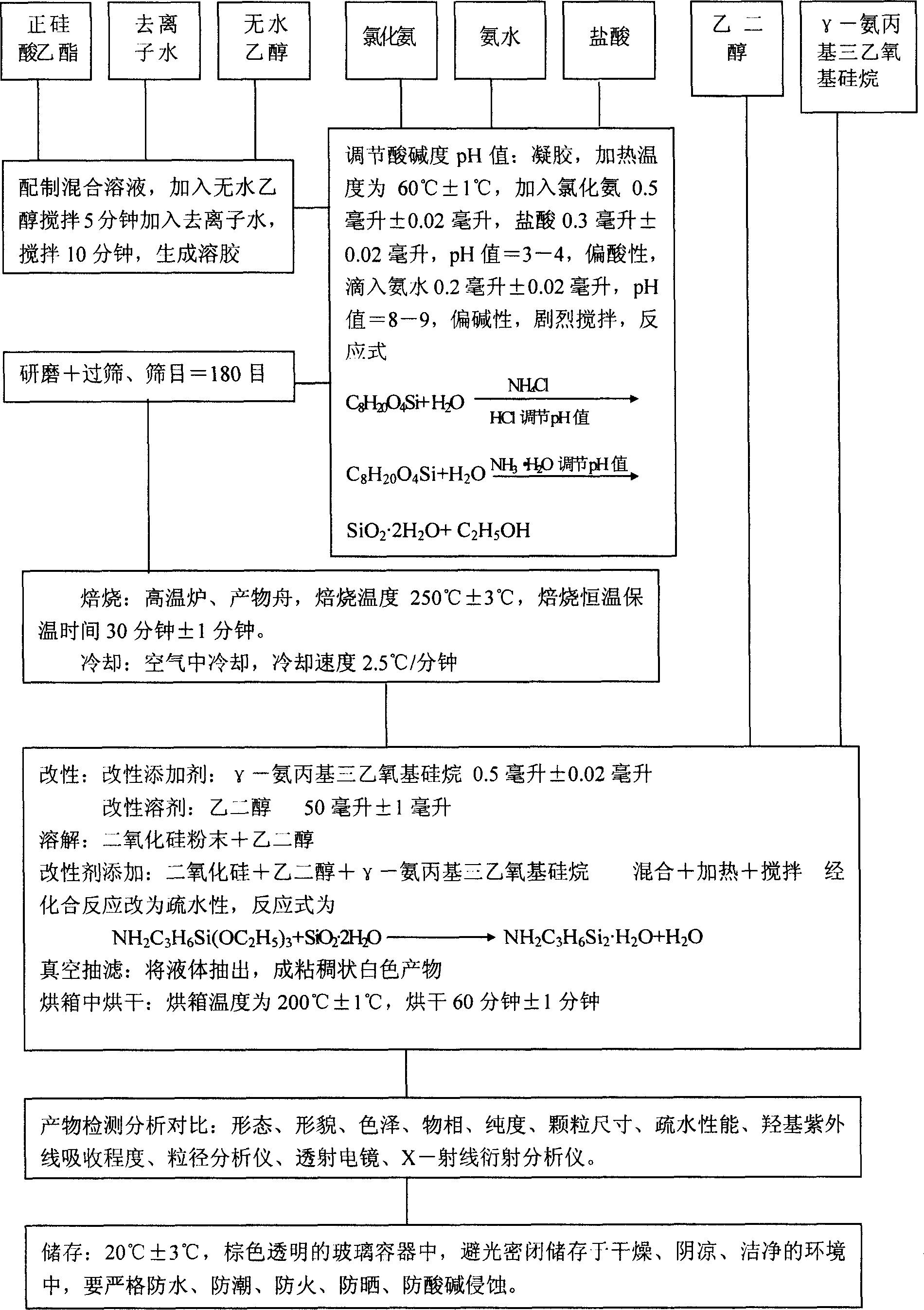

[0100] The present invention will be further described below in conjunction with accompanying drawing:

[0101] figure 1 As shown, the production of ultrafine hydrophobic silica powder must be carried out strictly according to the process flow chart, and each production parameter must be strictly controlled and operated in sequence.

[0102] The chemical materials required for the preparation of tetraethyl orthosilicate, absolute ethanol, deionized water, ammonium chloride, ammonia water, hydrochloric acid, ethylene glycol, and γ-aminopropyltriethoxysilane must be strictly selected. And the purity control is carried out, no impurities can intervene, and by-products are prevented from being generated.

[0103] The required chemical substances must be strictly controlled according to the proportioning and weighing, and must not exceed the maximum and minimum ranges.

[0104] The sol-gel is carried out continuously, and the acidity and alkalinity of the pH value has a great inf...

Embodiment 1

[0122] All production equipment is in ready working condition;

[0123] Select and weigh 5ml of tetraethyl orthosilicate, 50ml of absolute ethanol, 50ml of deionized water, 0.5ml of ammonium chloride, 0.20ml of ammonia water, 0.3ml of hydrochloric acid, 50ml of ethylene glycol, and γ-aminopropyl 0.5 ml of triethoxysilane;

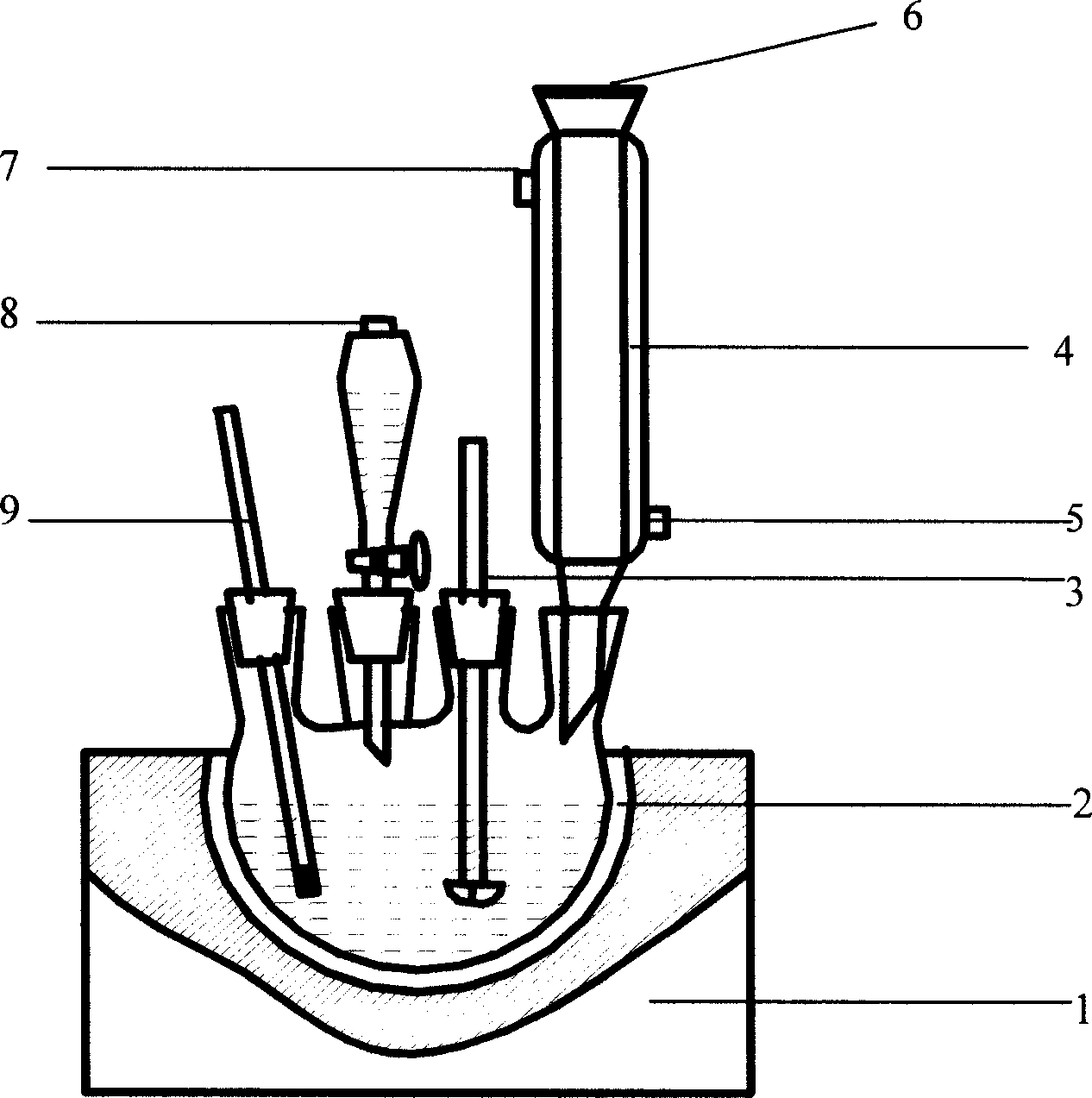

[0124] Sol, put 5 milliliters of the chemical substance ethyl orthosilicate in a three-necked flask, add 50 milliliters of absolute ethanol, after 5 minutes, drop in 50 milliliters of deionized water, stir evenly, and make it clear;

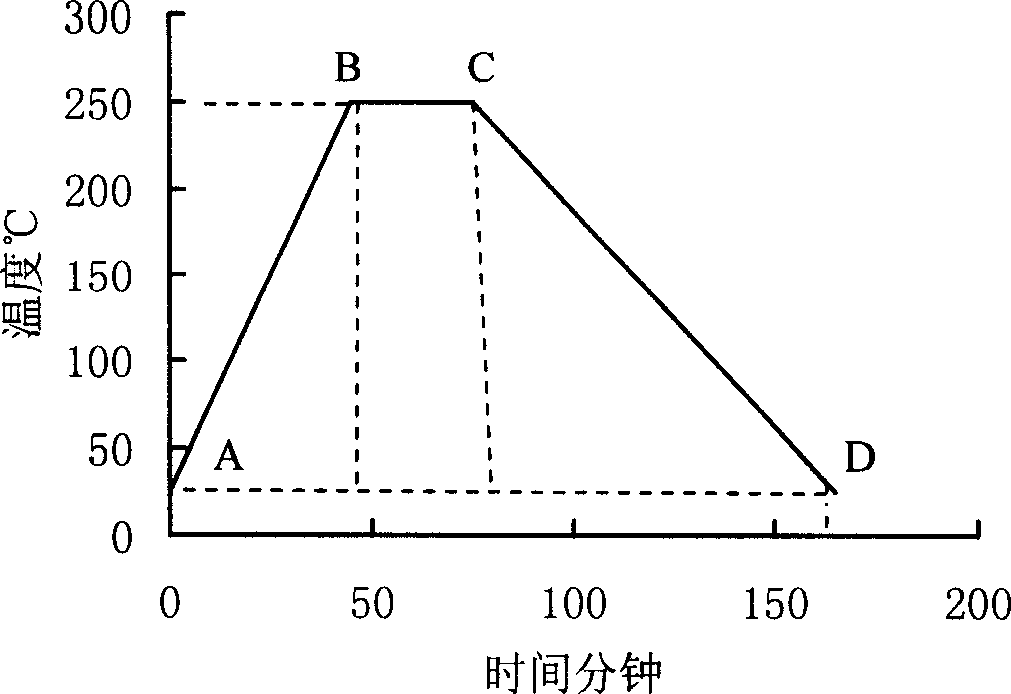

[0125] Adjust pH value: heating temperature 60℃±1℃

[0126] Add 0.5 ml of ammonium chloride and 0.3 ml of hydrochloric acid, stir vigorously for 3 minutes ± 0.3 minutes, keep warm at constant temperature for 12 minutes ± 1 minute, pH value = 3-4, slightly acidic;

[0127] Add 0.20 ml of ammonia water, stir vigorously with a stirrer for 15 minutes, pH=8-9, slightly alkaline;

[0128] Gel, forming a wet gel product;

[0129]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com