Shell powder and preparation method thereof

A shell powder, shell technology, applied in the direction of calcium carbonate/strontium/barium, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of high reaction temperature, complicated process, numerous preparation equipment, etc., and reduce roasting. The effect of temperature, simple preparation process and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

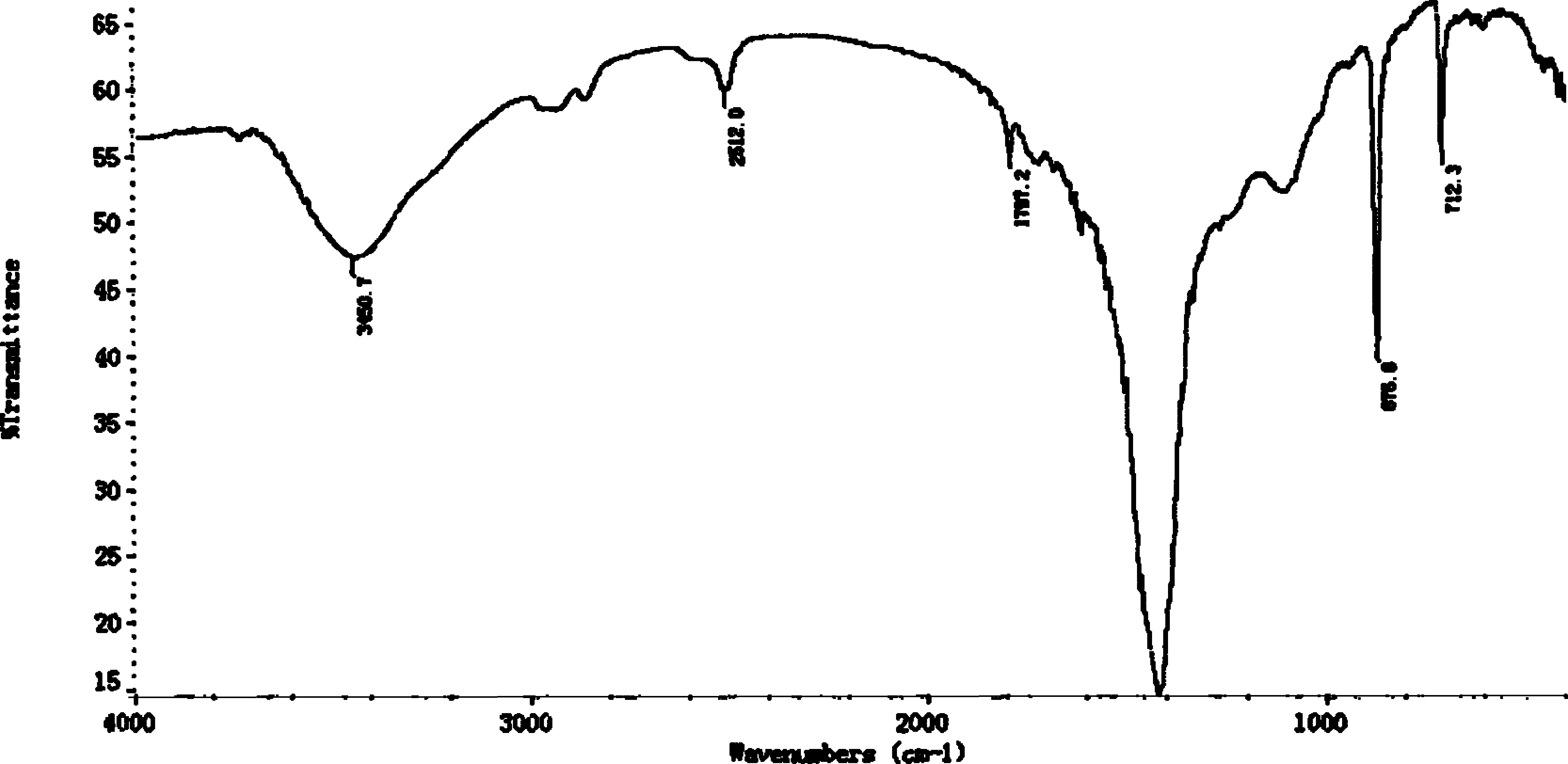

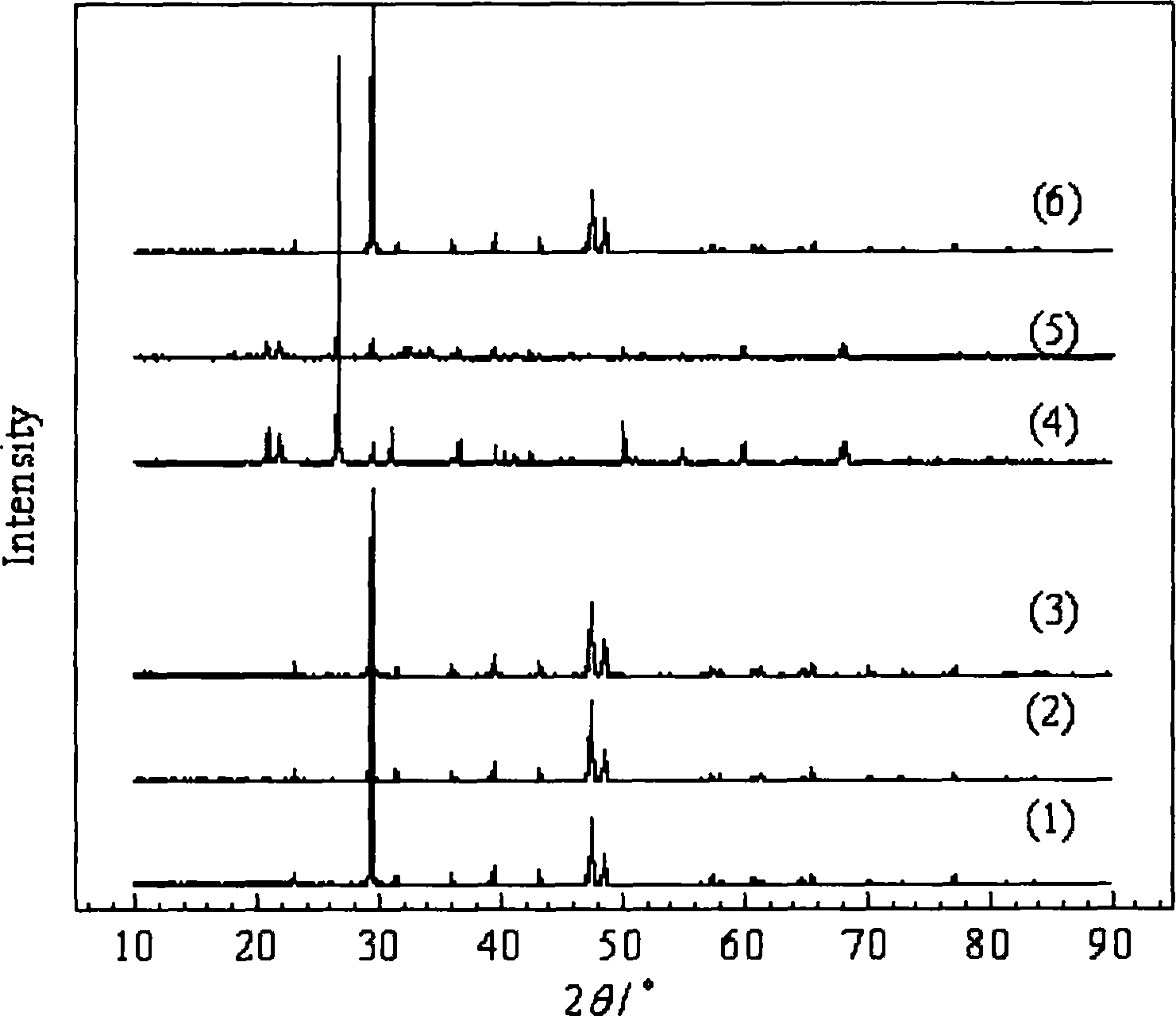

Image

Examples

Embodiment 1

[0027] The shell powder is prepared from clam Meretrix meretrix and its preparation method.

[0028] 1. Wash the clam (Petera meretrix) with water, dry or dry it naturally, use a multifunctional pulverizer to preliminarily pulverize the powder of the clam (Peteria meretrix) and then pass through a sieve to reach a value of φ<1.7mm.

[0029] 2. Add a small amount of additives according to the ratio set in the experiment.

[0030] When the mass ratio of clams (Clams carbai) and additives is 15:1 and roasted at 600° C. for 30 minutes, the obtained clams (Clams carbai) powder is gray (No. 01 in Table 1).

[0031] When the mass ratio of Meretrix meretrix (Chebai) to additives is 20:1 and roasted at 800°C for 60 minutes, the obtained clam (Chebai) powder is white with a specific surface of 2.5m 2 / g (see Table 1 No. 03).

[0032] If no additives are added, the mass ratio of clams (Carbai) to additives is 20:0, and roasted at 800°C for 60 minutes, the obtained clam (Carbai) powder ...

Embodiment 2

[0040] The shell powder is prepared from Philippine clams (commonly known as clams in the south, clams in Liaoning and clams in Shandong) and its preparation method.

[0041] 1. Take Philippine clams, wash them with water, dry them or dry them naturally, and use a multifunctional pulverizer to sieve the powder of Philippine clams to reach φ<1.7mm.

[0042] 2. Add a small amount of additives according to the ratio set in the experiment.

[0043] When the mass ratio of Philippine clams and additives is 15:1 and roasted at 600°C for 30 minutes, the obtained Philippine clam powder is gray (No. 02 in Table 1).

[0044] When the mass ratio of Philippine clams and additives is 20:1, and roasted at 800°C for 60 minutes, the obtained Philippine clam powder is white, with a specific surface of 3.5m 2 / g (see Table 1 No. 04).

[0045] If no additives are added, the mass ratio of Philippine clams to additives is 20:0, and roasted at 800°C for 60 minutes, the obtained Philippine clam pow...

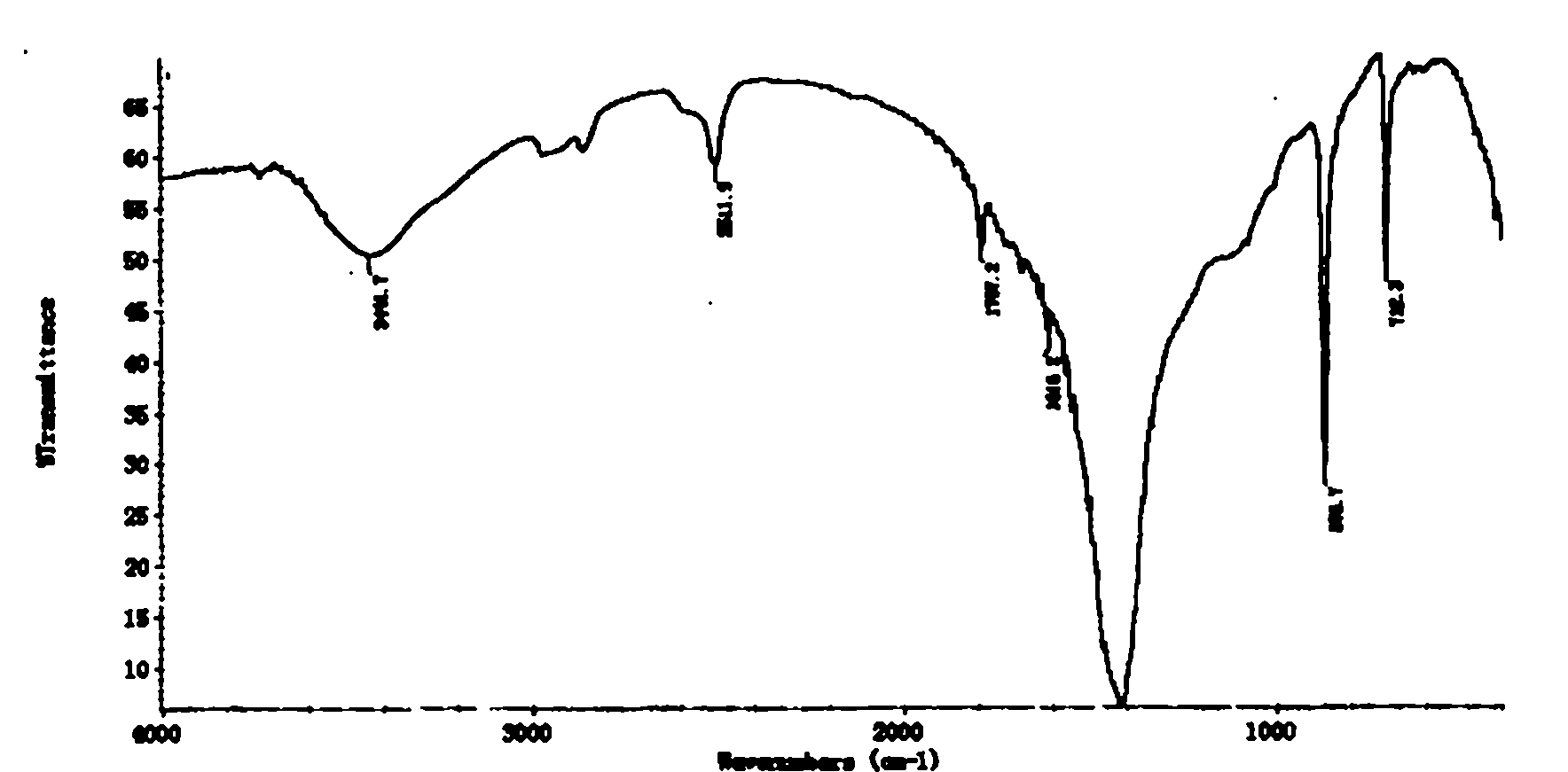

Embodiment 3

[0050] Shell powder prepared from snail shells and a preparation method thereof.

[0051] 1. Take the snail shell, wash it with water, dry it or dry it naturally, use a multi-functional pulverizer to preliminarily crush the snail shell powder, and then pass it through a sieve to reach φ<1.7mm.

[0052] 2. Add a small amount of additives according to the ratio set in the experiment.

[0053] When the mass ratio of snail shells and additives is 20:1, and roasted at 800°C for 30 minutes, the obtained snail shell powder is light gray (No. 10 in Table 1).

[0054] When the mass ratio of snail shells to additives is 20:1 and roasted at 800°C for 60 minutes, the obtained snail shell powder is white with a specific surface of 3.2m 2 / g (see Table 1 No. 09).

[0055] This example proves that the optimal conditions for forming snail shell powder are: the mass ratio of snail shell powder to additives is 20:1, the roasting temperature is 800° C., and the roasting time is 60 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com