Method for producing aluminum oxide by utilizing high-alumina fly ash

A technology of high-alumina fly ash and alumina, which is applied in the field of metallurgy, can solve the problems of large slag phase flow rate in the ammonium sulfate sintering method, difficulty in recycling ammonia gas, and high impurity content in products, so as to avoid difficult recovery of acid medium and avoid high Corrosiveness, low production energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, pre-desilication treatment:

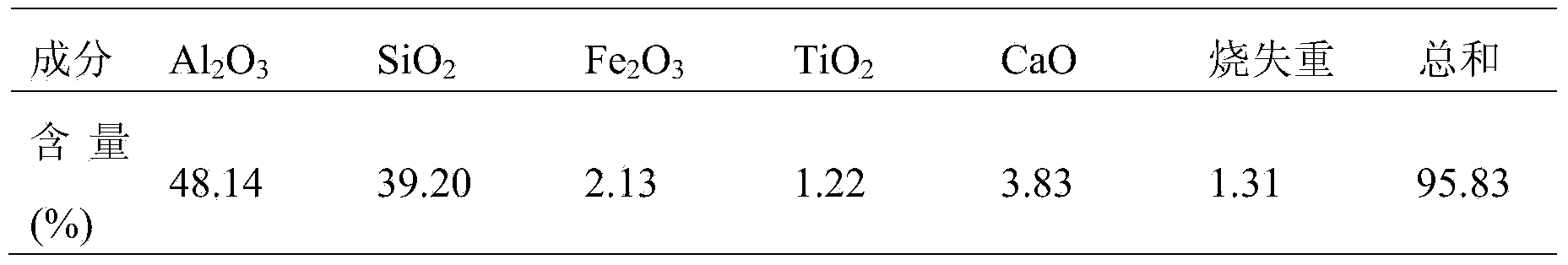

[0032] The raw material is high-aluminum fly ash from a thermal power plant in Inner Mongolia, and its main chemical composition is shown in Table 1:

[0033] Table 1 Chemical composition of high aluminum fly ash

[0034]

[0035] Mix high-alumina fly ash and 15% sodium hydroxide solution at a mass ratio of 1:2, place in a reaction kettle, keep warm at 110°C for 1 hour, cool to room temperature, filter and separate to obtain sodium silicate solution and desiliconized fly ash;

[0036] Slurry-wash the desiliconized fly ash at 80°C for 20 minutes, filter and separate, repeat the above step of washing twice, and dry the desiliconized fly ash filter cake at 105°C after filtering to obtain dry desiliconized fly ash;

[0037] The aluminum-silicon ratio of the dried desiliconized fly ash was measured to be 2.23.

[0038] Step 2. Alkali dissolution once:

[0039] Mix the dried desiliconized fly ash with 19% sodium hydroxide solution ...

Embodiment 2

[0056] Step 1, pre-desilication treatment:

[0057] The raw material is high-aluminum fly ash from a thermal power plant in Inner Mongolia, and its main chemical composition is shown in Table 1:

[0058] Table 1 Chemical composition of high alumina fly ash

[0059]

[0060] Mix high-alumina fly ash with 13.5% sodium hydroxide solution at a mass ratio of 1:5, place in a reaction kettle, keep warm at 97°C for 2 hours, cool to room temperature, filter and separate to obtain sodium silicate solution and desiliconized fly ash;

[0061] Slurry-wash the desiliconized fly ash at 80°C for 20 minutes, filter and separate, repeat the above step of washing twice, and dry the desiliconized fly ash filter cake at 105°C after filtering to obtain dry desiliconized fly ash;

[0062] The aluminum-silicon ratio of the dried desiliconized fly ash was measured to be 2.16.

[0063] Step 2. Alkali dissolution once:

[0064] Mix the dried desiliconized fly ash with 22% sodium hydroxide solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com