Precision casting forming method based on 3D printing technology

A 3D printing and precision casting technology, used in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of inability to achieve casting manufacturing, and do not use mold shell formation, saving production cycle, saving materials, and facilitating baking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

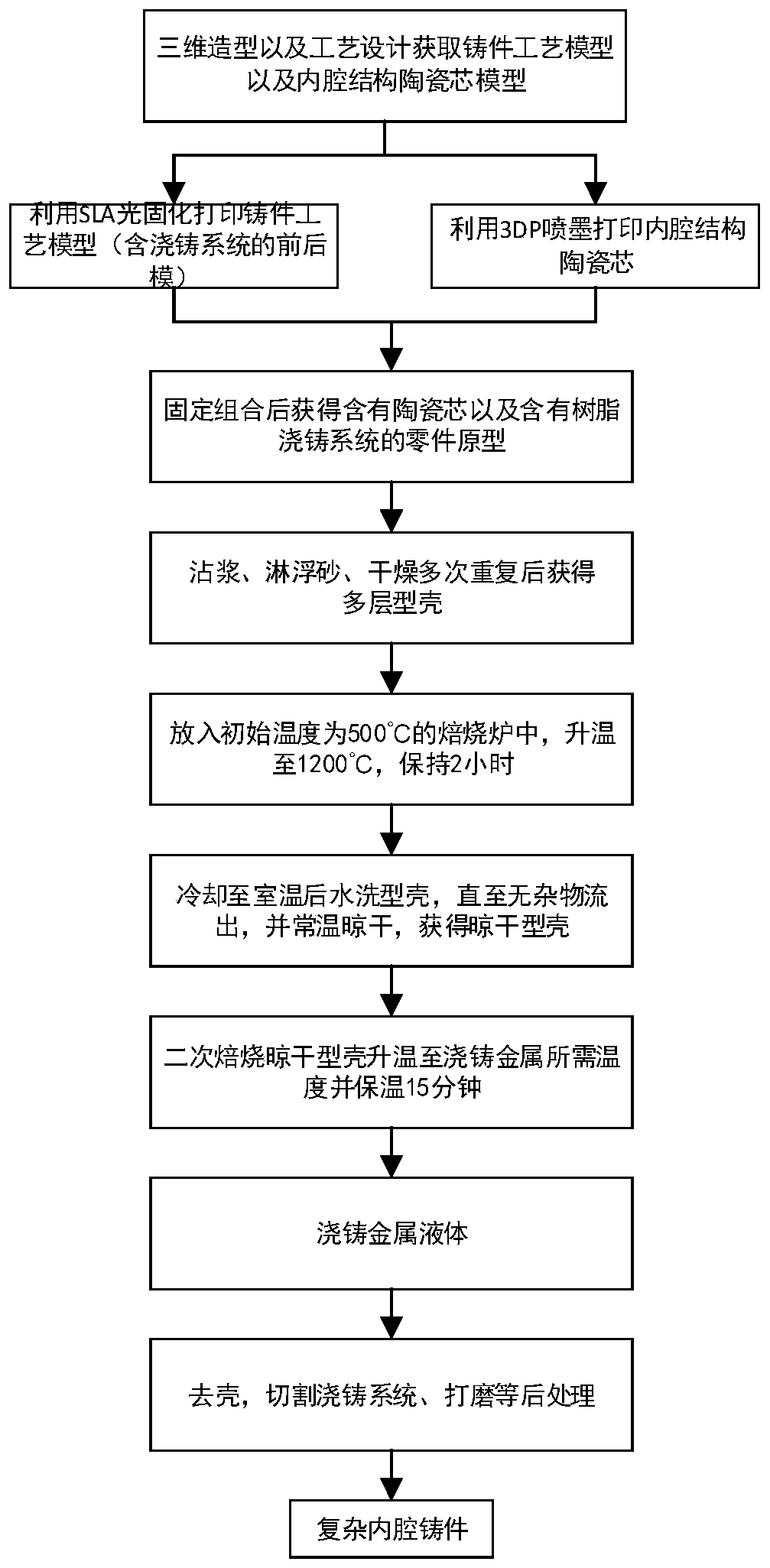

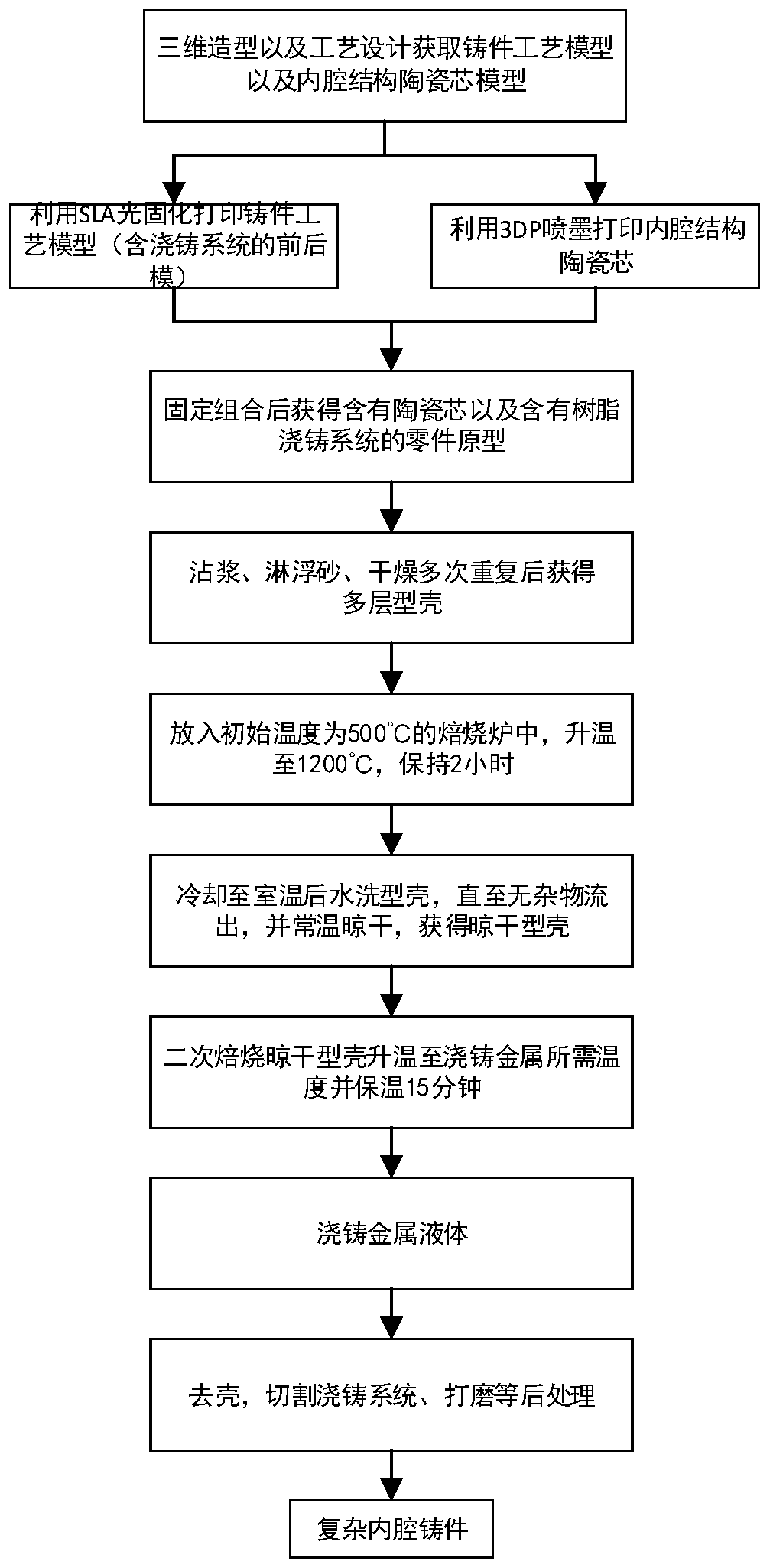

[0022] Such as figure 1 As shown, the precision casting molding method based on 3D printing technology of the present invention includes the following processes:

[0023] (1) 3D modeling software is used to draw the digital model of castings and casting system. The casting system is first designed, and then the procast software is used to analyze the mold flow, and then the casting system is improved to obtain the casting process model; at the same time, the casting process model is obtained according to the cavity of the casting. The digital model of the core is drawn, in which the core contains a positioning structure; the positioning structure is used to fix the ceramic core on the mold shell after firing.

[0024] (2) Partition the casting model according to the core structure, and divide it into at least two halves, so that the core can be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com