Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Improve glass quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

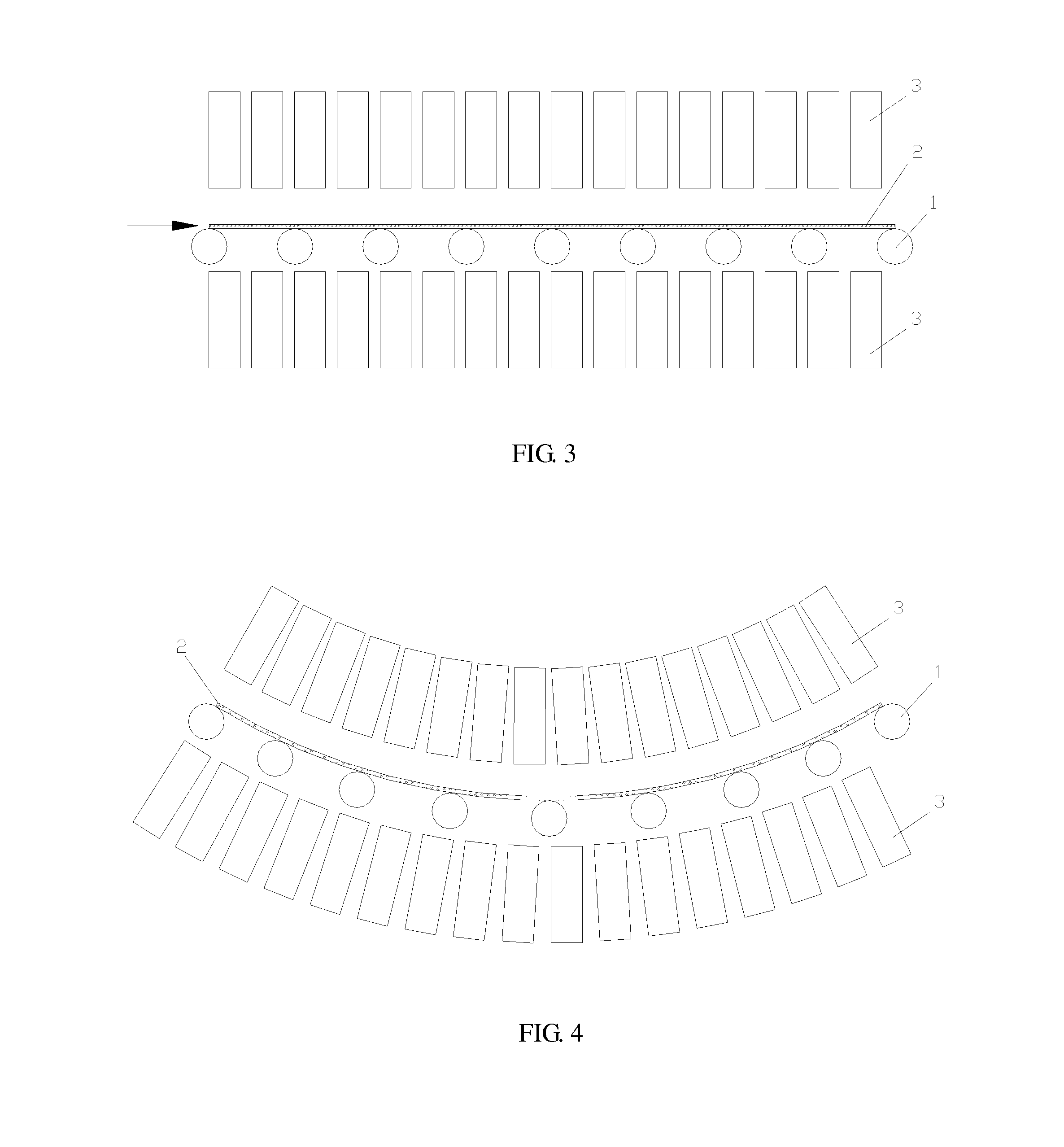

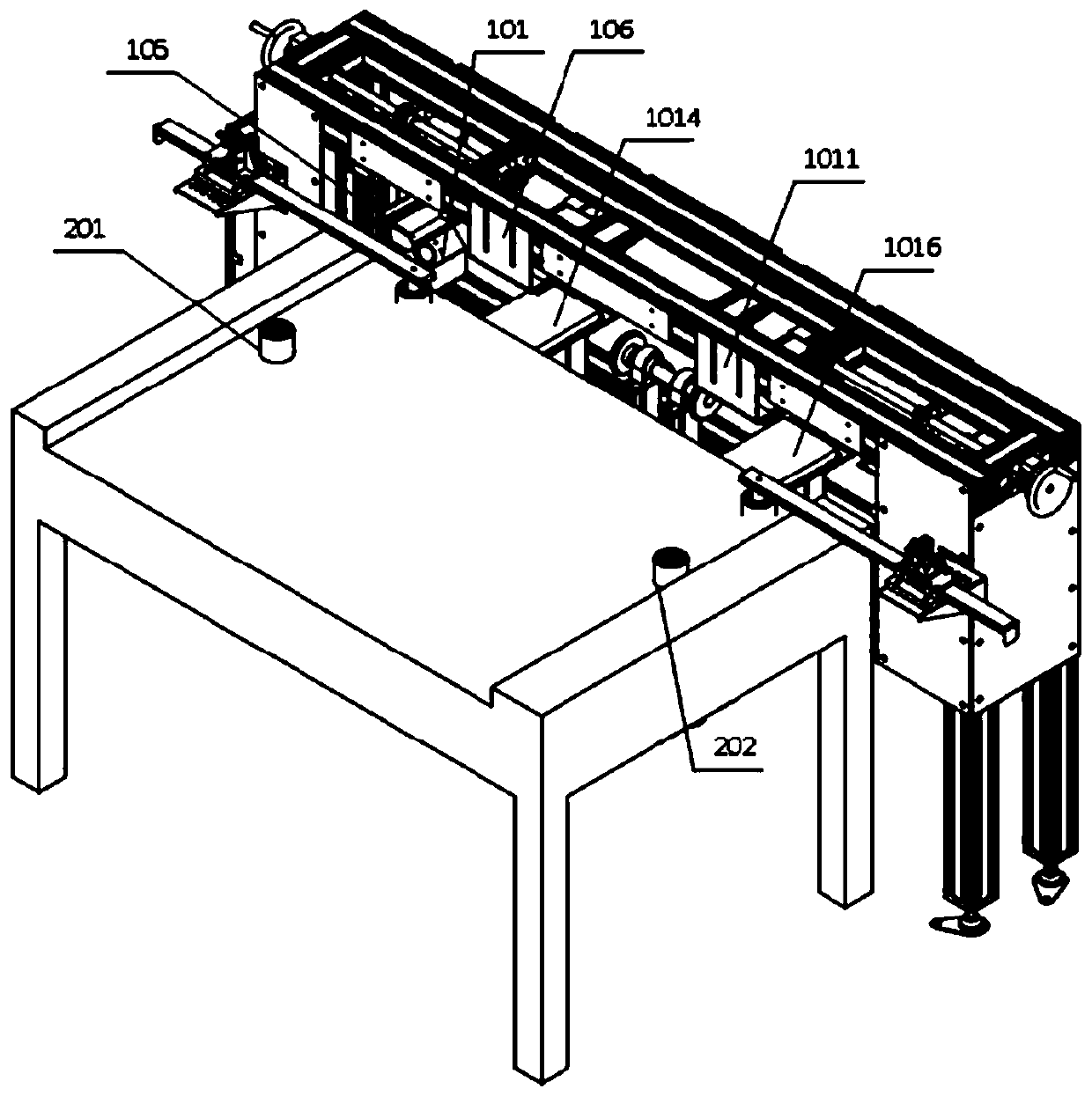

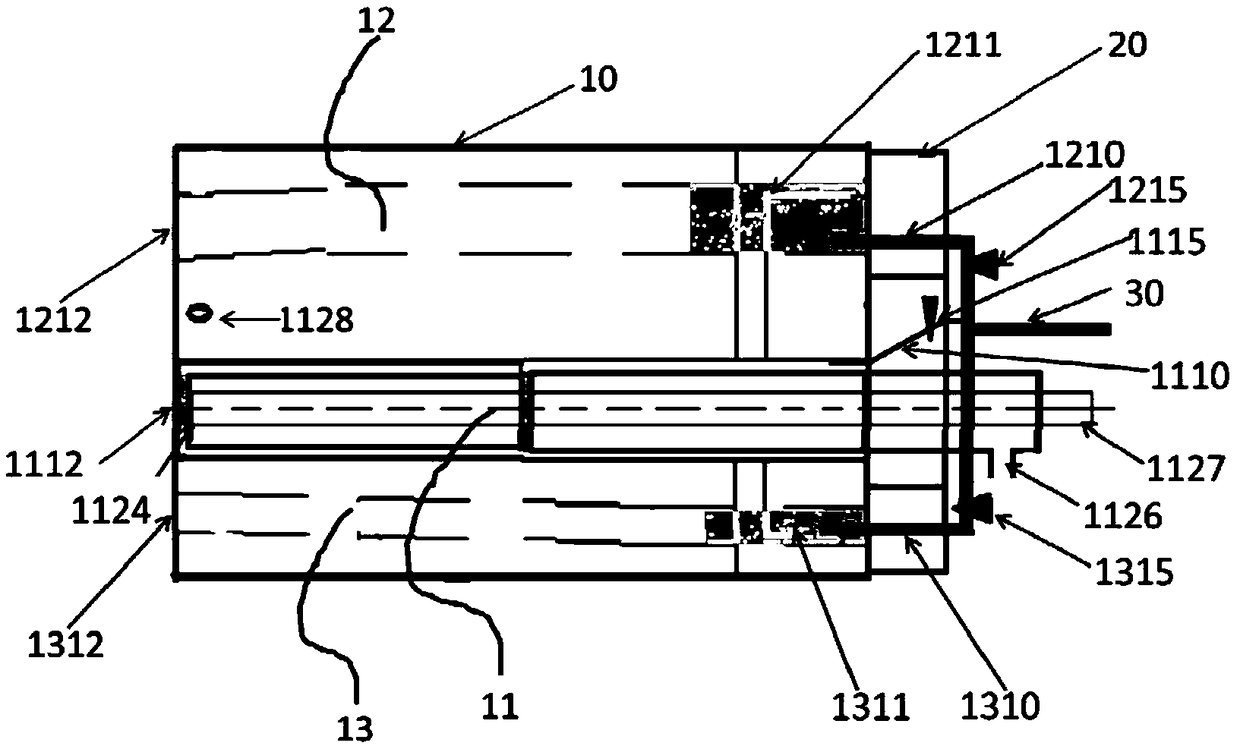

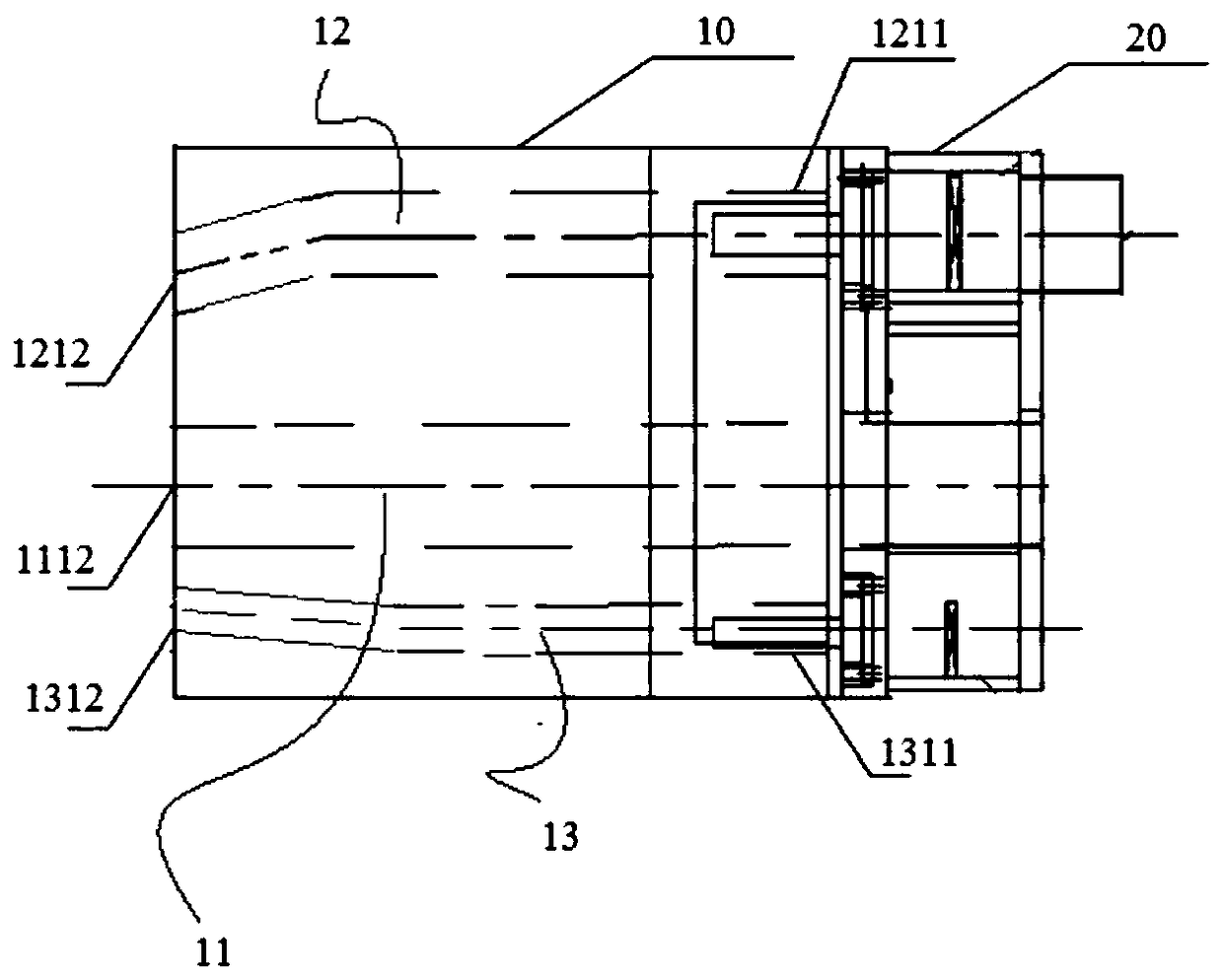

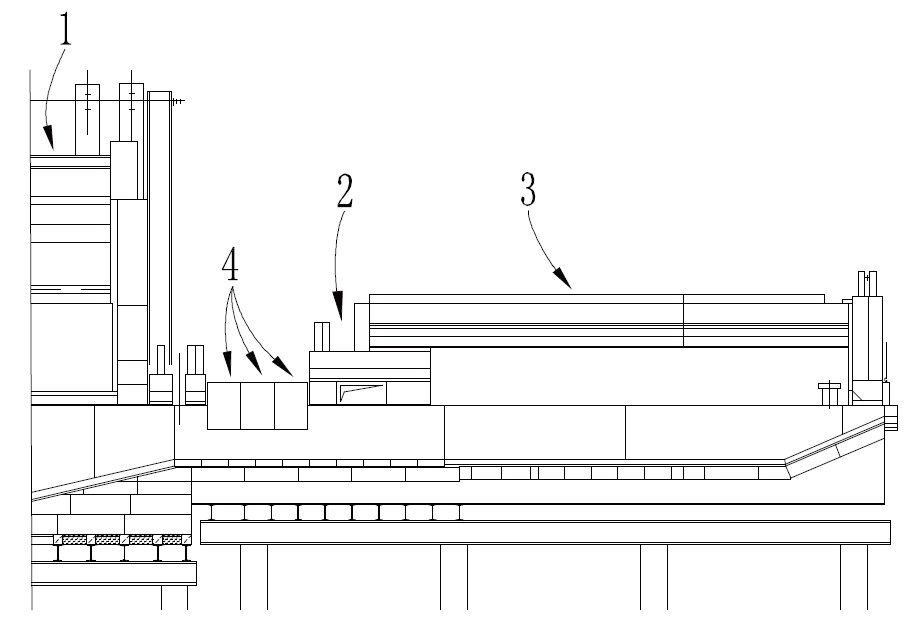

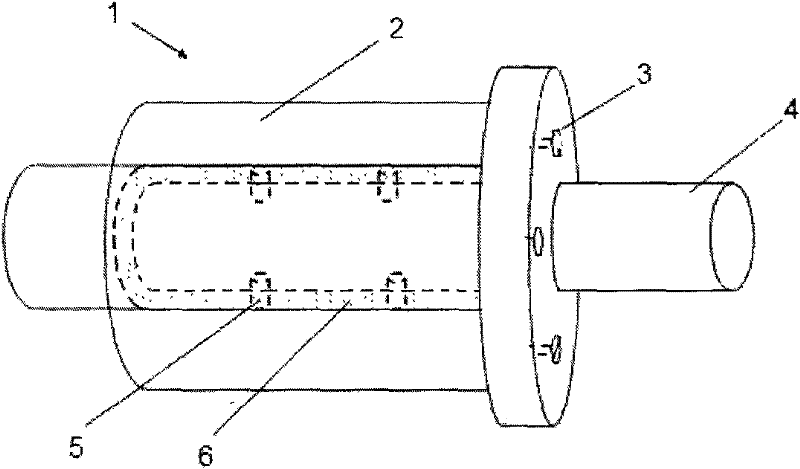

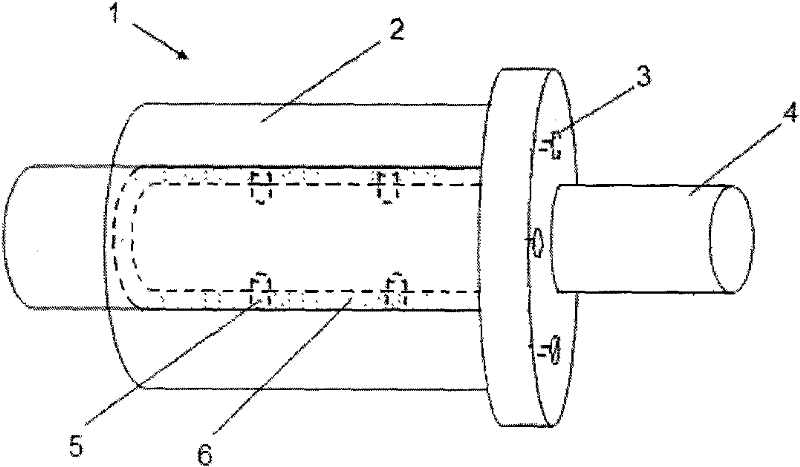

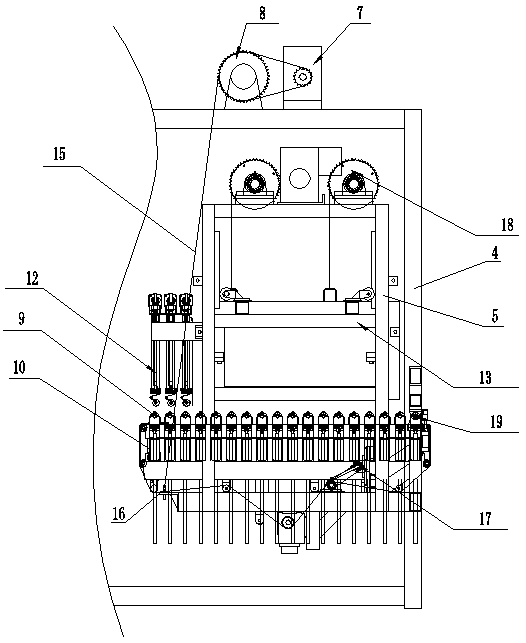

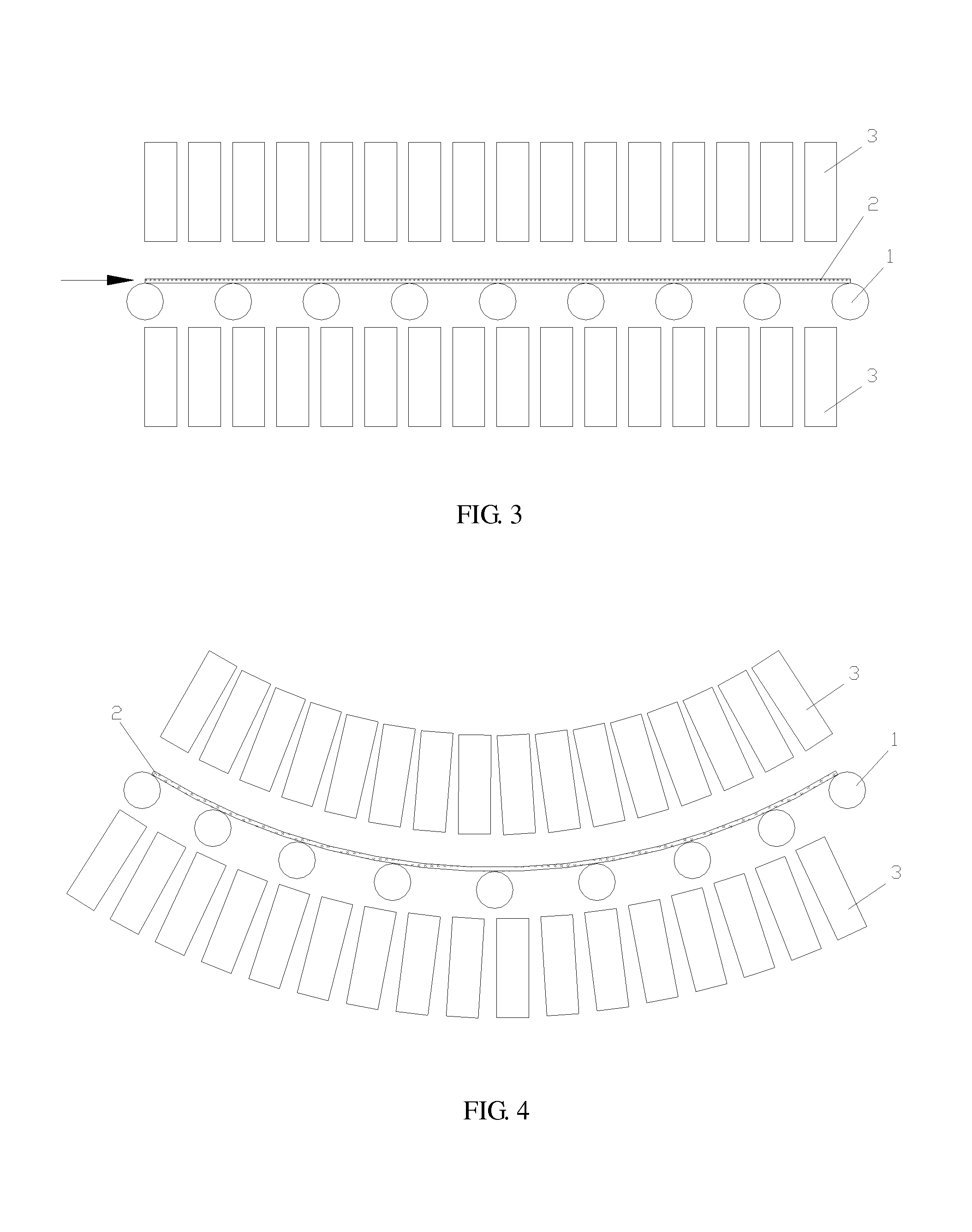

Method for manufacturing columnar curved tempered glass

ActiveUS20150121964A1Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

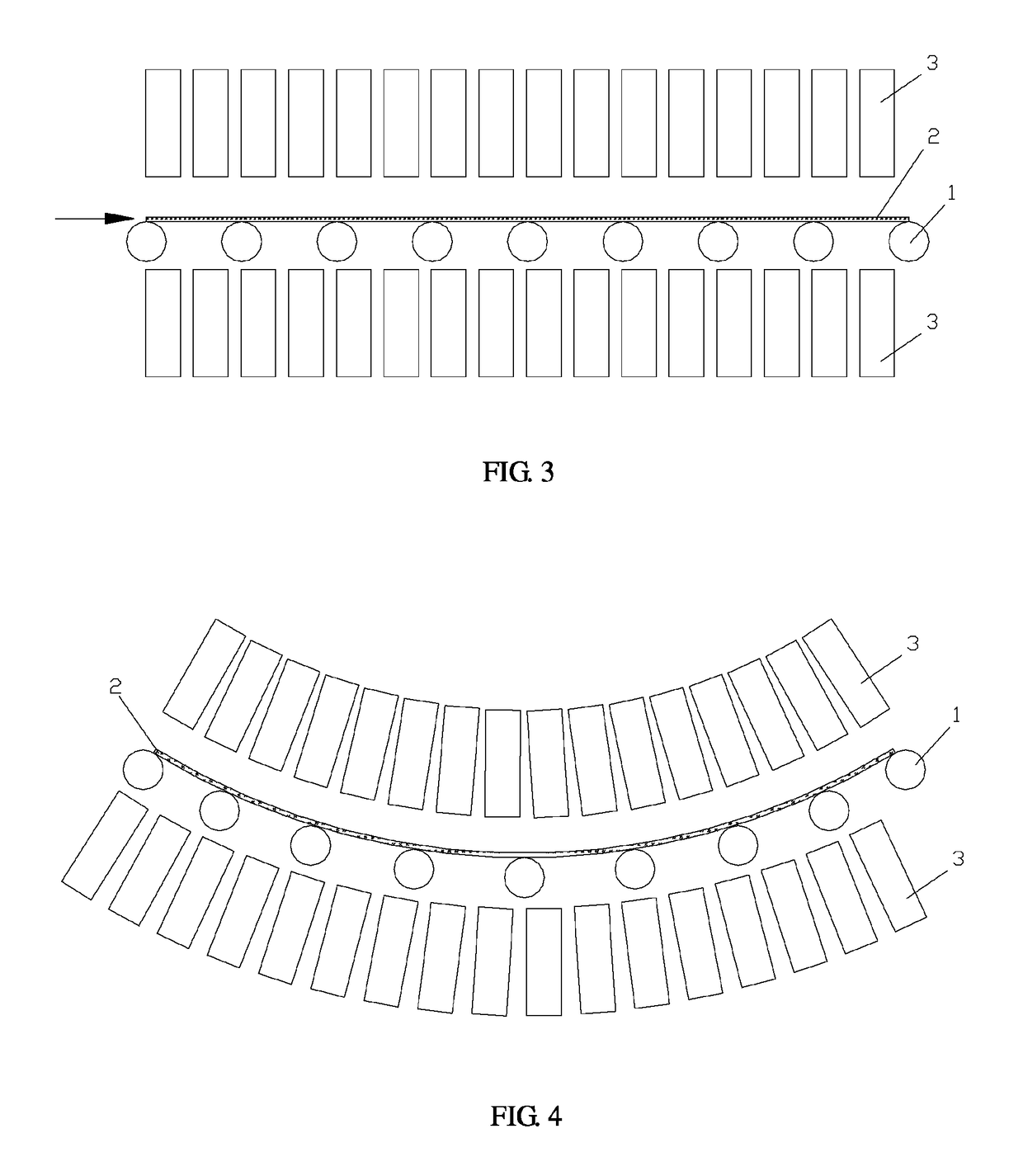

The present invention discloses a device for processing columnar curved tempered glass. The device mainly comprises a glass heating furnace, a glass bending mechanism and a glass tempering mechanism connected sequentially, wherein the arrangement of each supporting roller in the rollers supporting the high temperature flat glass is changed from planar arrangement in space into curved arrangement corresponding to the shape of the glass to be formed, so that the glass bending mechanism enables the glass to suffer bending deformation. Transferring rollers for outputting the formed curved glass in the axial direction of the supporting roller are arranged at the clearance of the rollers of the bending mechanism. In the present invention, bending shaping and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending shaping tempering are carried out by one bending appliance intensively, thereby providing a novel technological approach for processing columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

Device and method of plaining glasses or glass-ceramics

InactiveUS6588234B1Significantly effectiveImprove glass qualityGlass furnace apparatusGlass drawing apparatusEngineeringGlass-ceramic

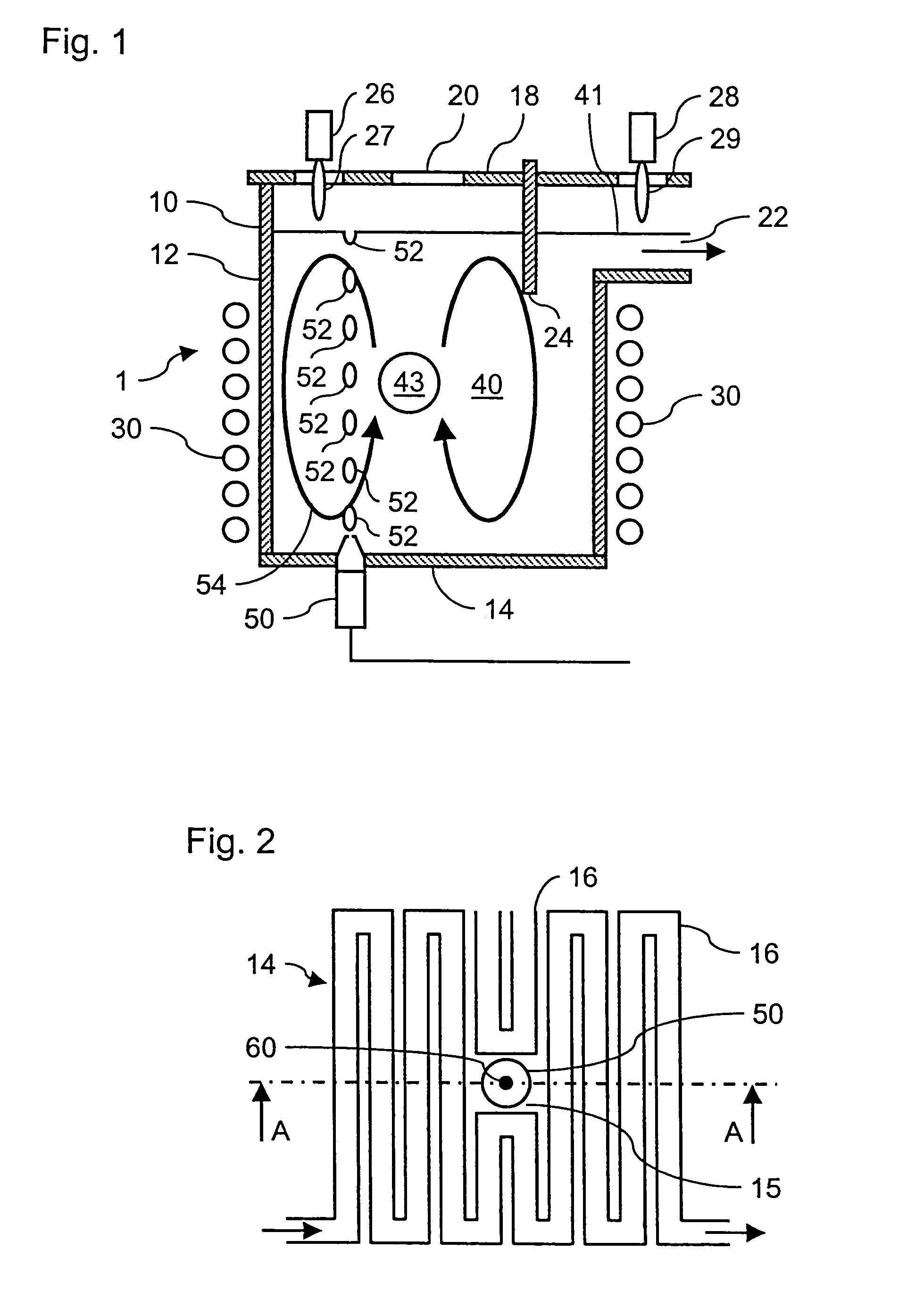

A device and method for the plaining of glasses or glass-ceramics. The device is provided with a melting vat, at least two plaining containers serially connected after the outlet of the melting vat, and at least one of the plaining containers is built in accordance with the skull principle from a plurality of metal tubes comprising a cooling agent connection and a high-frequency device for inductively coupling high-frequency energy into the contents of the plaining container.

Owner:SCHOTT AG

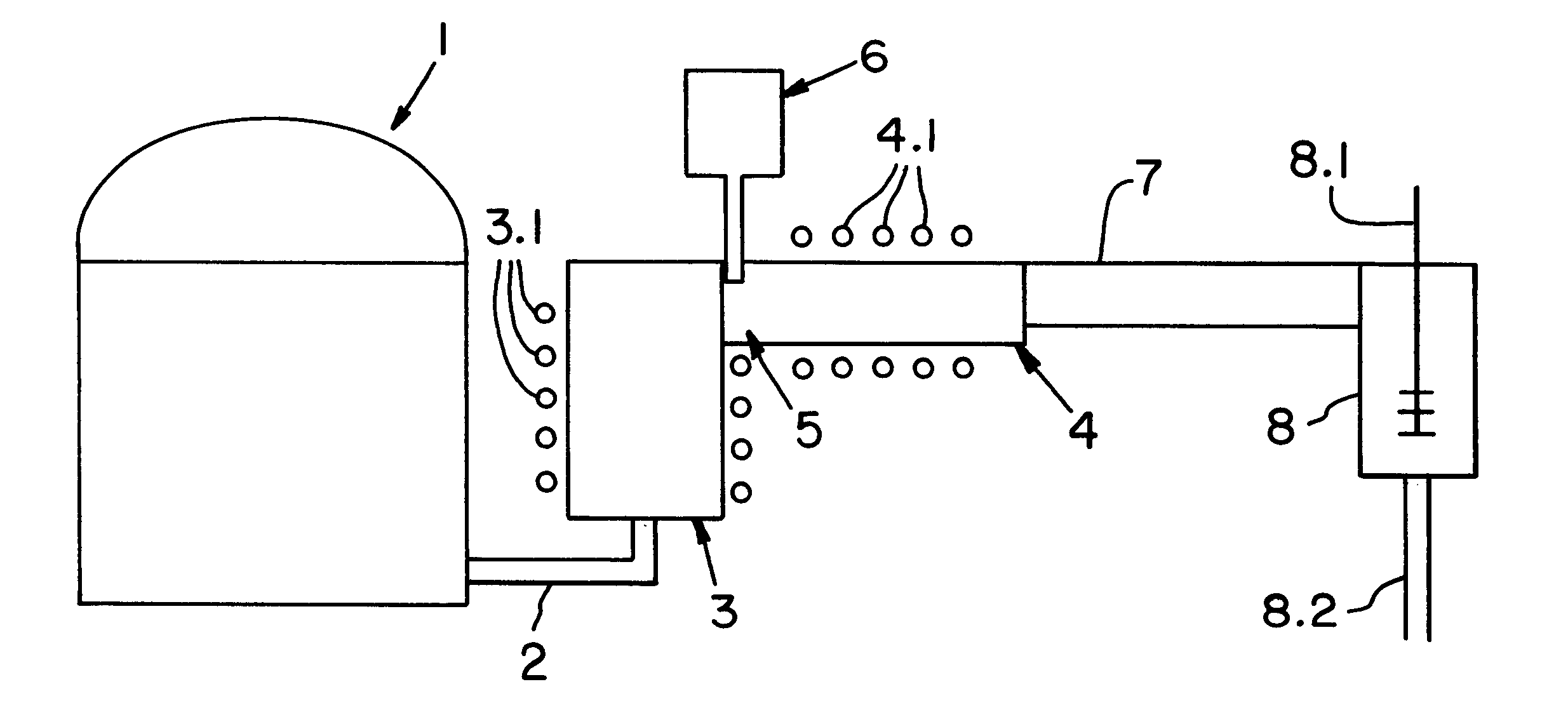

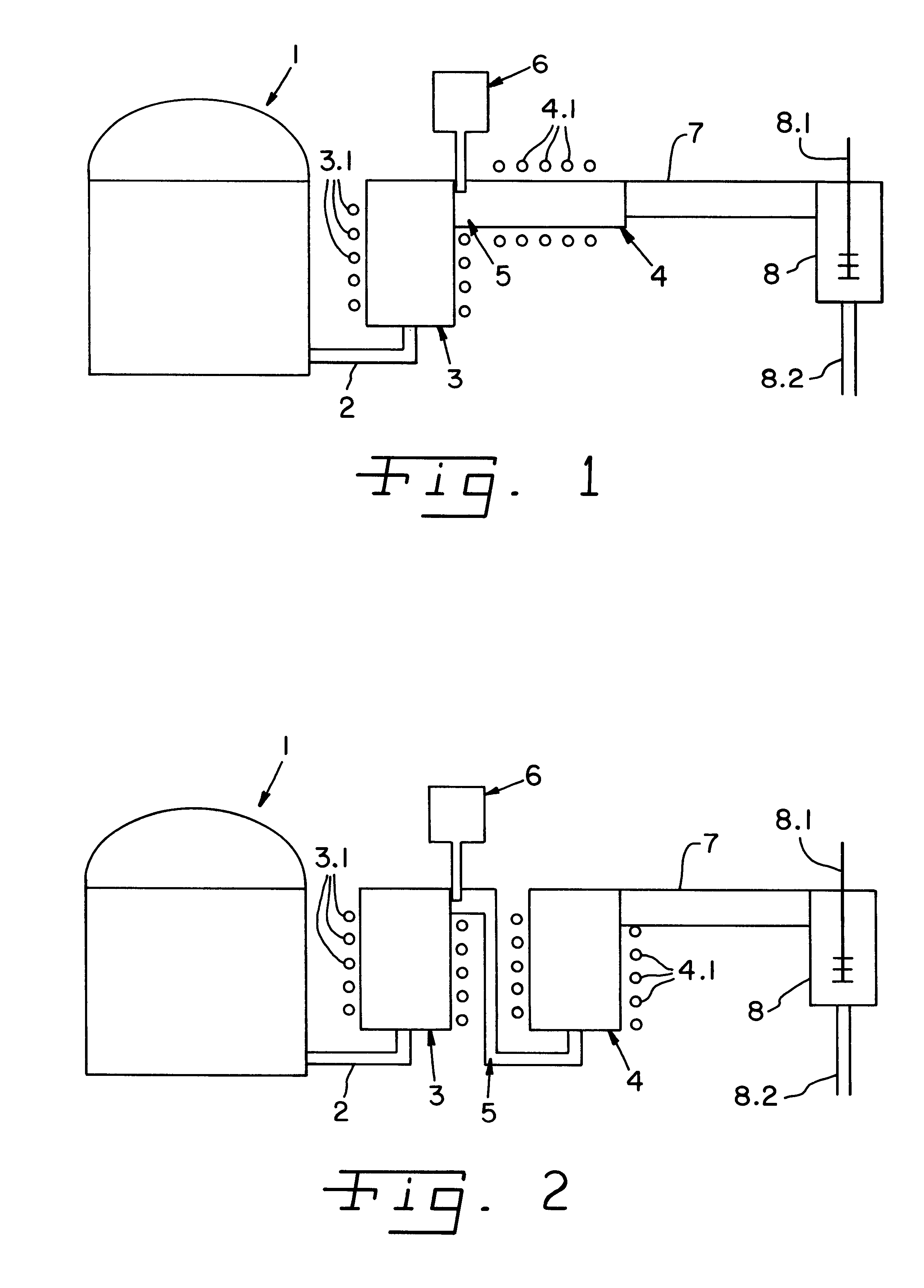

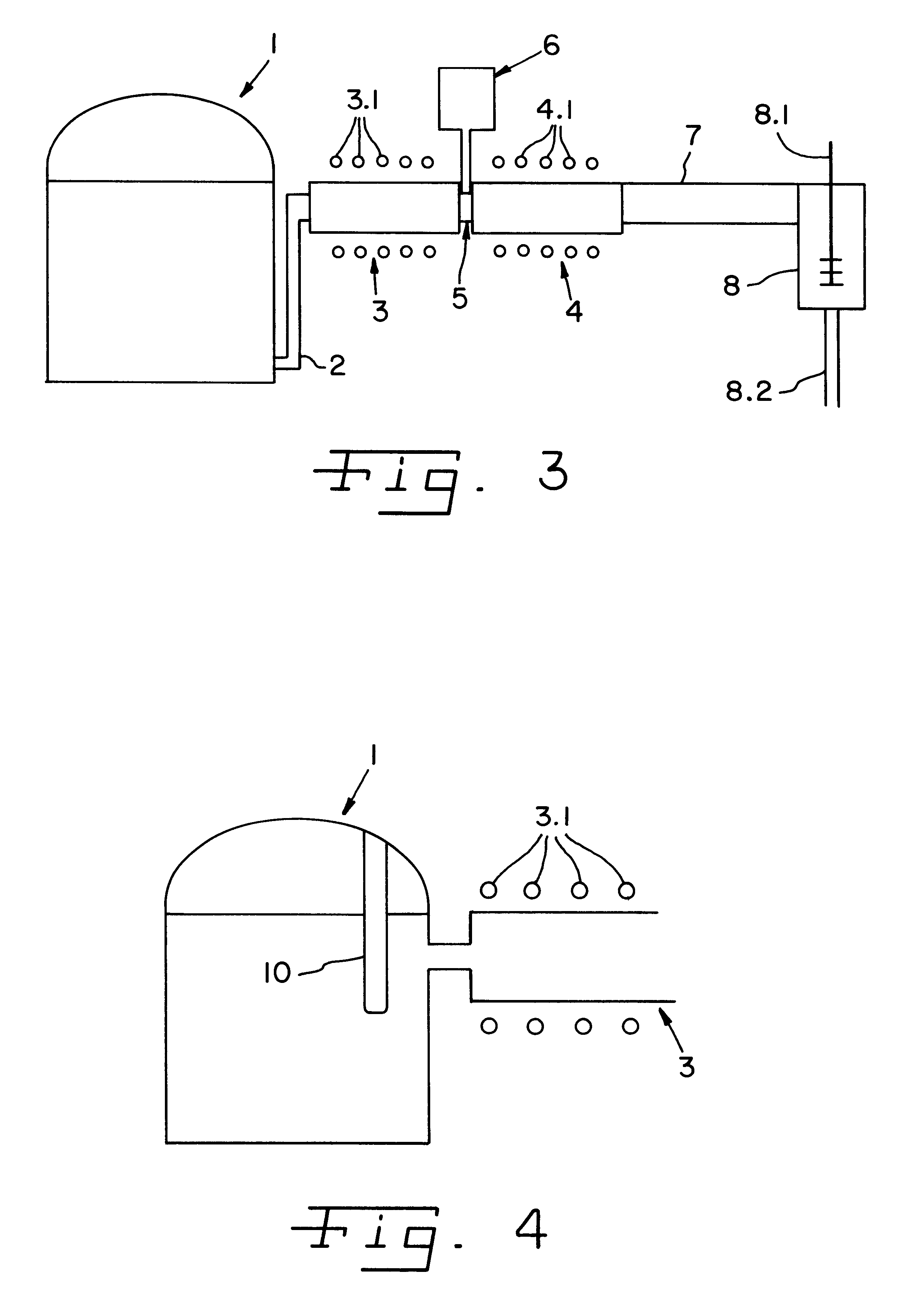

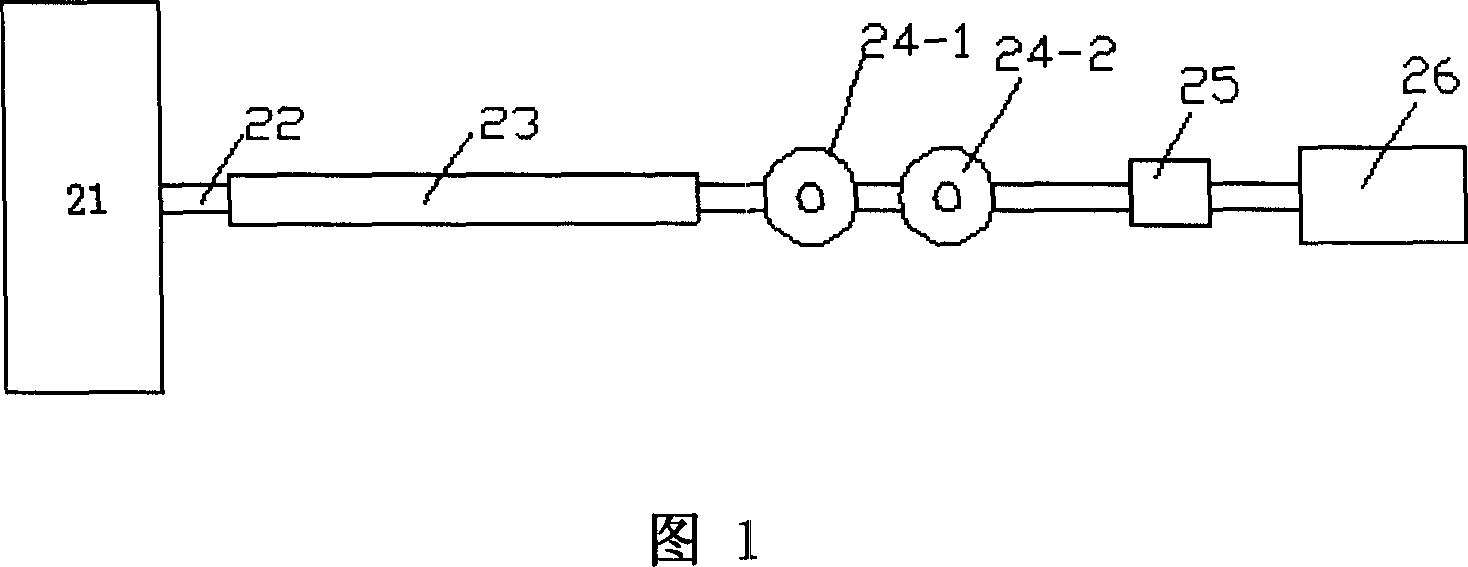

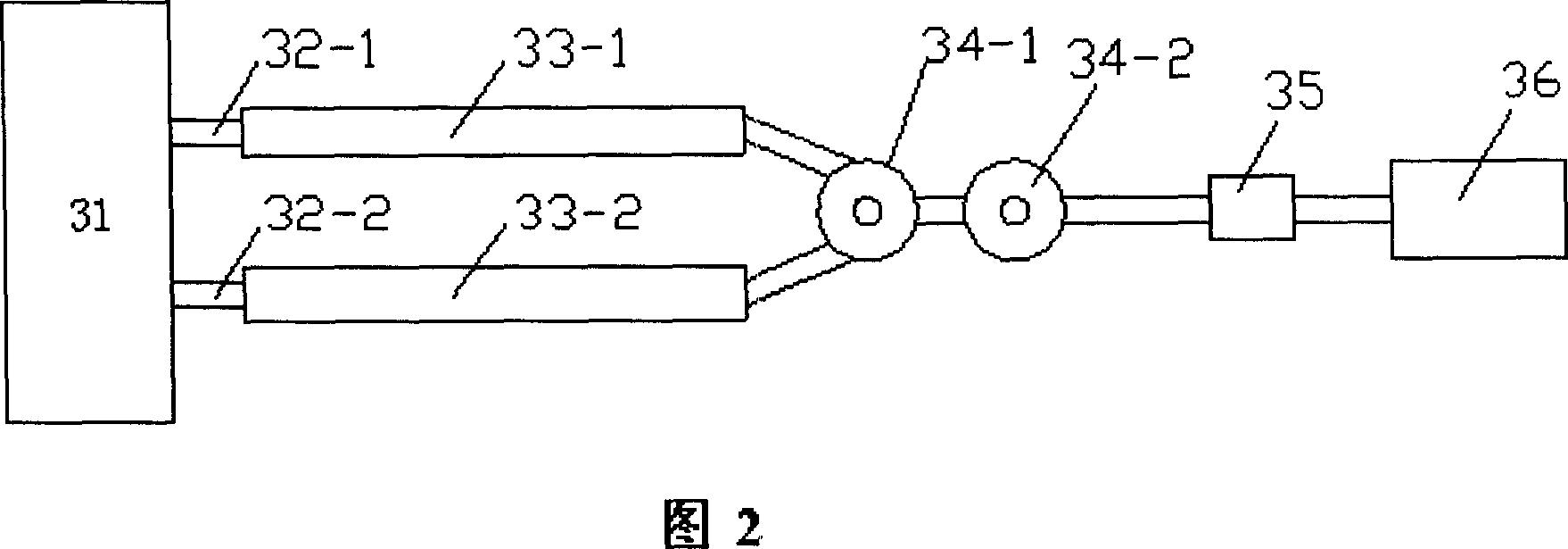

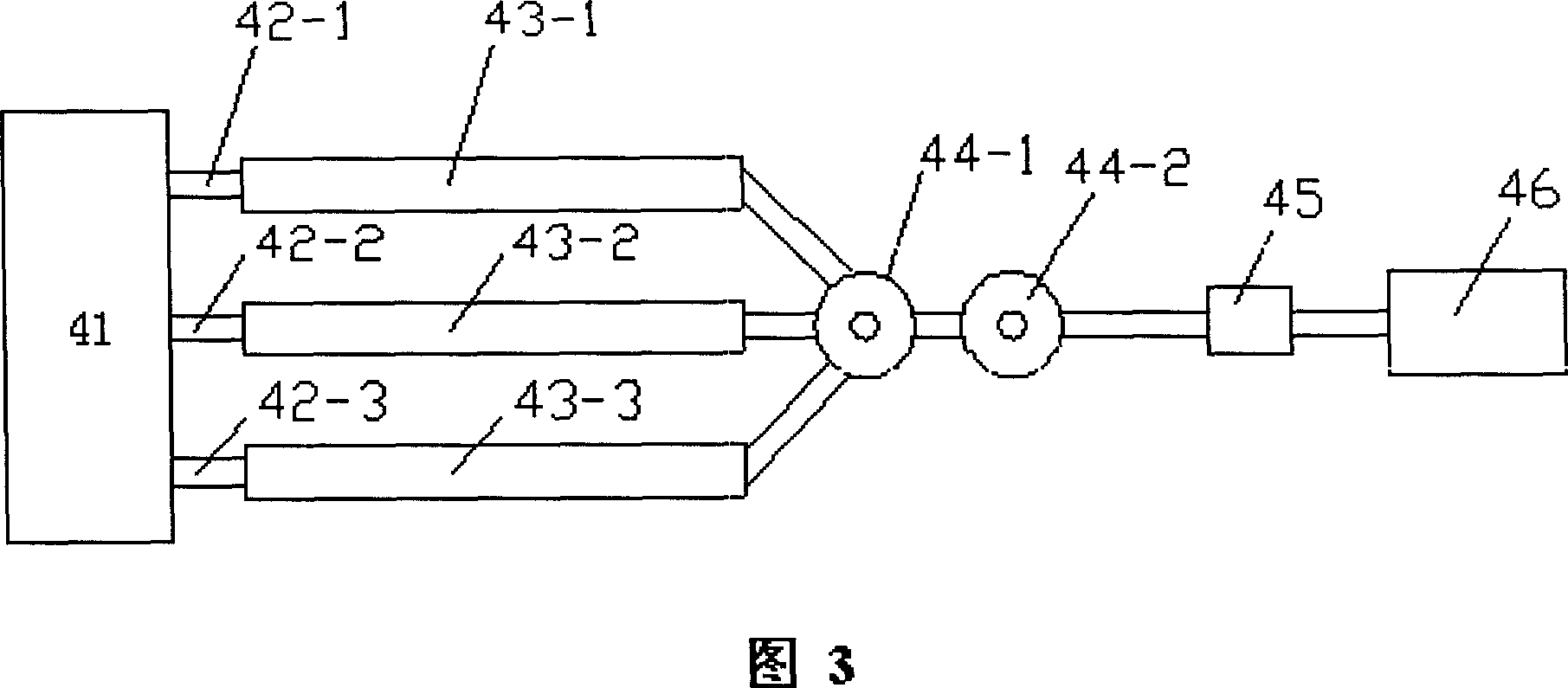

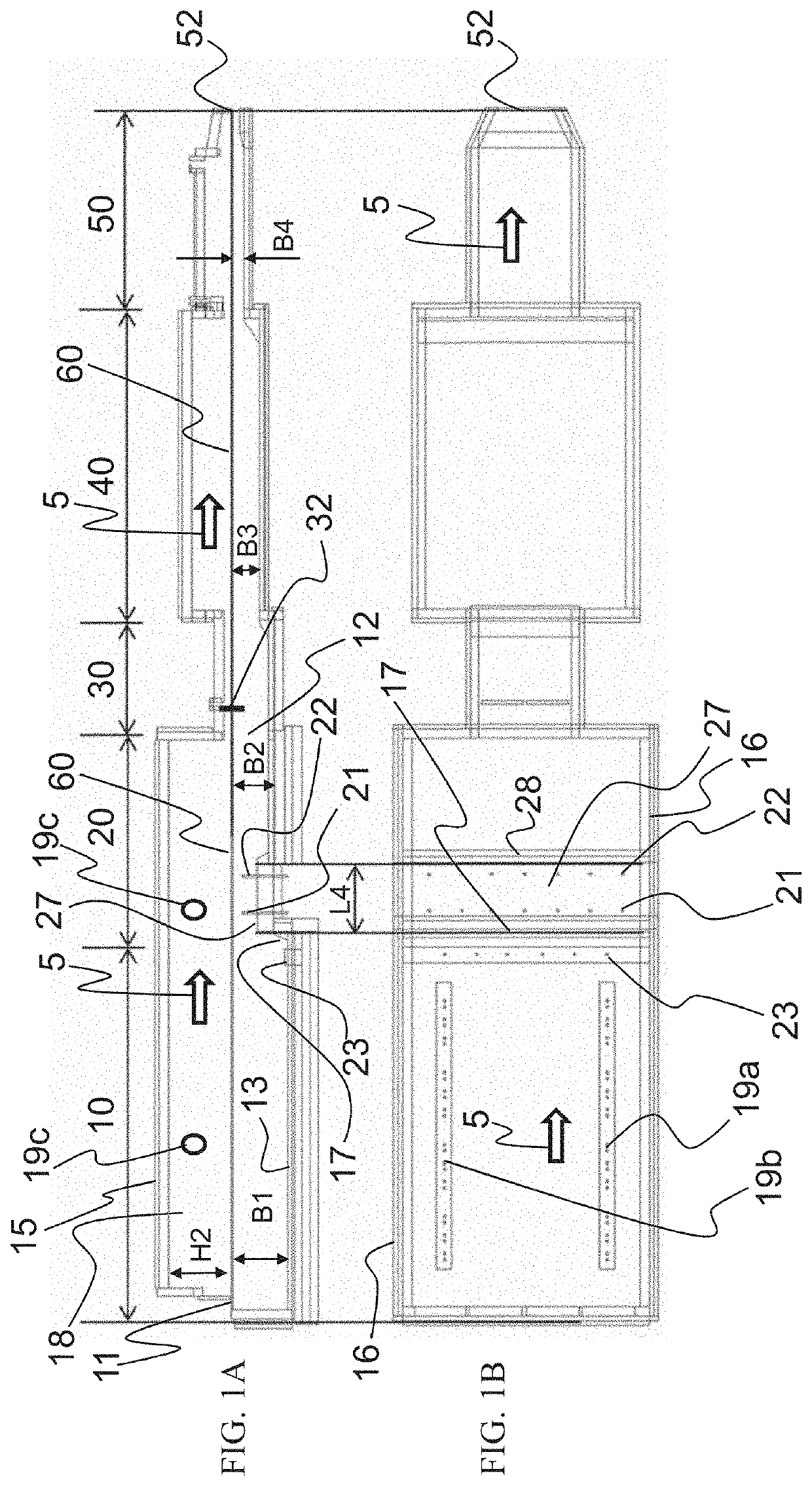

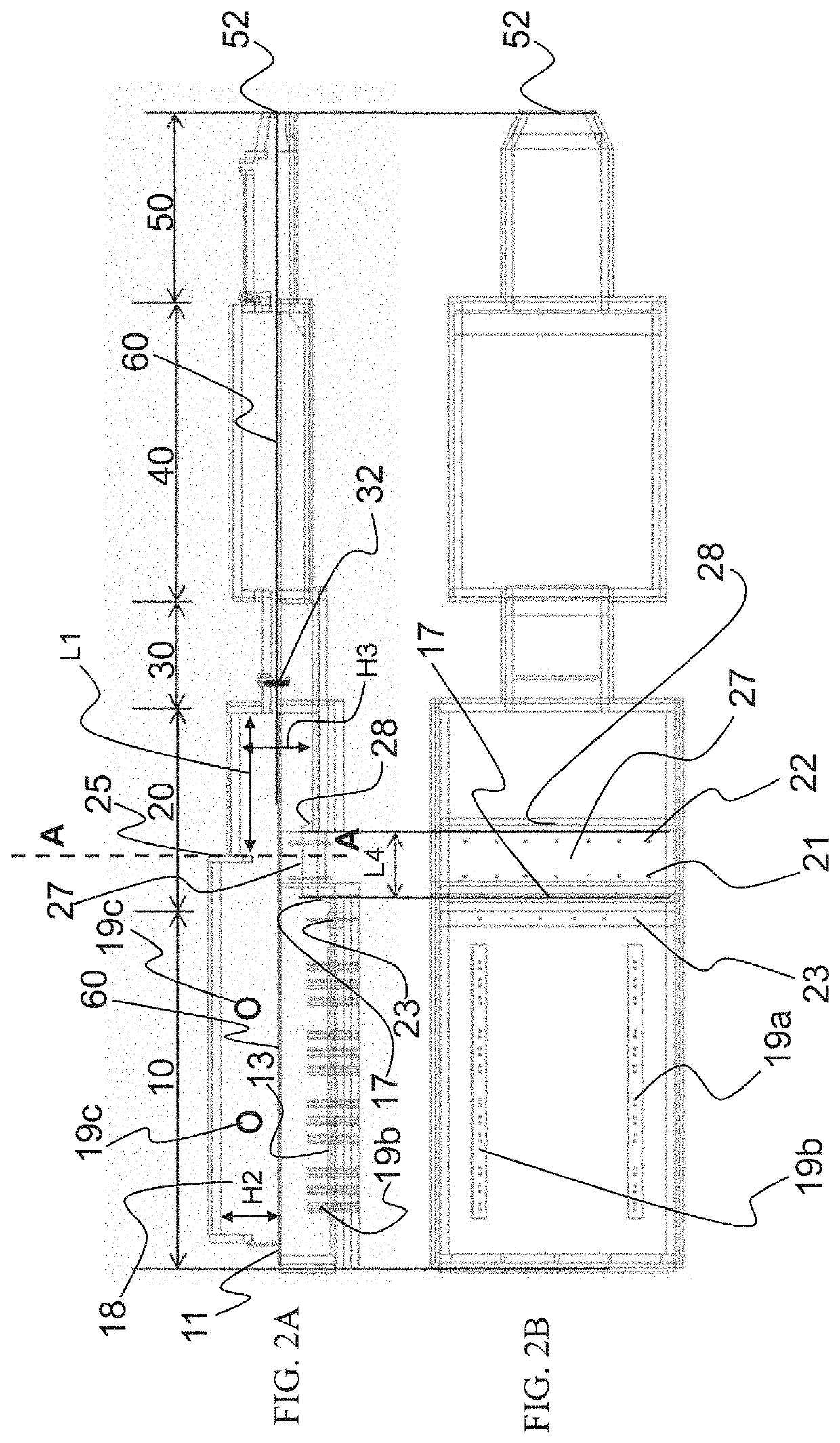

Method and equipment for improving glass quality

InactiveCN1948196AExhausted completelyQuality improvementGlass furnace apparatusGlass productionGlass meltingMolten glass

The present invention discloses a method for raising glass quality and its equipment. It includes glass melting furnace, clarifying zone and stirring zone, etc. It is characterized by that between glass melting furnace and stirring zone at least two parallel clarifying zones are set, the molten glass can parallelly flow through said clarifying zones, then can be collected in the stirring zone, so that it not only can meet the requirements for making large flow capacity of molten glass be passed through said clarifying zones, but also can raise glass quality.

Owner:HENAN ANCAI HI-TECH +1

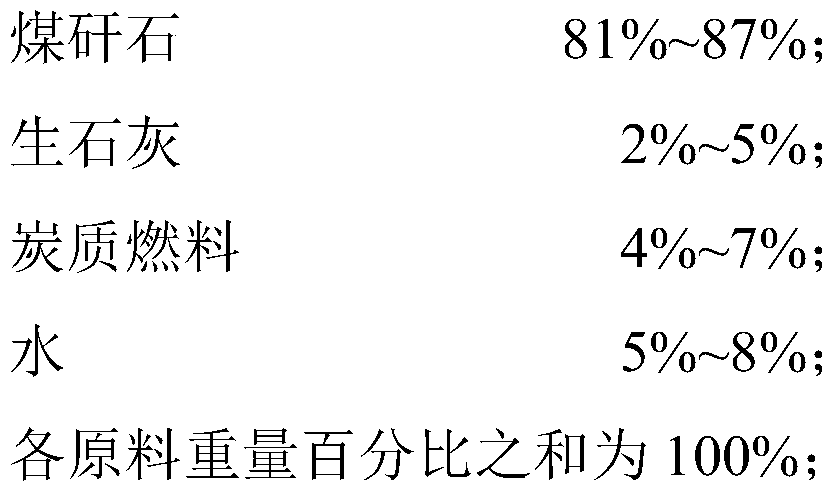

A process for preparing active mixed materials by belt sintering of coal gangue

The invention discloses a process for preparing an activated mixed material through strand sintering of coal gangue. The process comprises the following steps: (1) crushing; (2) preparing materials, and uniformly mixing, namely sufficiently and uniformly mixing crushed coal gangue, quick lime, a carbon fuel and water in a cylinder mixing machine in a set ratio; (3) pelletizing, namely pelletizingthe uniformly mixed minerals into beads of a preset granularity; (4) sintering, namely performing allocation, ignition, air sucking sintering and cooling on the pelletized beads in a strand air sucking sintering machine; (5) crushing and finely grinding, namely crushing the sintered material, and finely grinding till a set specific surface area, thereby obtaining the activated mixed material. Theinvention provides the process for preparing an activated mixed material through strand sintering of coal gangue, by virtue of the properties that a combustion zone is high in temperature and short intime in the sintering process, a vitric phase can be formed, meanwhile, the sintered material mainly contains an oxidation atmosphere, harmful components such as organic matters, residual carbon andsulfur in the coal gangue can be removed at a high temperature, and the cementing property, the freezing resistance and the durability of cement are protected from adverse influence of the harmful components.

Owner:CENT SOUTH UNIV

Method for manufacturing columnar curved tempered glass

ActiveUS9630870B2Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

The present invention discloses a method for processing a columnar curved tempered glass. The method specifically comprises the following steps. Bending and tempering of the high temperature flat glass are divided into two stations. Bending is firstly carried out on the high temperature flat glass output by a heating furnace; the columnar extending direction of the curved glass is perpendicular to the direction the glass output from the heating furnace in the bending process, and then the formed curved glass is output to a tempering station in the columnar extending direction thereof to undergo tempering. In the present invention, bending and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending and tempering are carried out by a single bending device intensively, thereby providing a novel technological approach for processing the columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

Device and method for melting a substance with the occurrence of a low level of contamination

InactiveUS7296441B2Improve homogeneityImprove smelting effectPot furnacesGlass drawing apparatusOxidation-Reduction AgentOxygen

The invention relates to an apparatus and a method for low-contamination melting of high-purity, aggressive and / or high-melting glass or glass-ceramic. According to the invention, for this purpose a melt is heated in a crucible or melting skull crucible by means of high-frequency radiation and is mixed or homogenized in the melting crucible. It is preferable for a gas nozzle, from which gas bubbles, e.g. oxygen bubbles (known as O2 bubbling), escape into the melt, to be provided at the base of the crucible. This alone makes it possible to achieve surprising multiple benefits in the melting skull crucible. Firstly, unmelted batch which drops into the melt in solid form, for example from above, is melted down more quickly as a result of more intensive mixing with the liquid fraction of the melt, secondly the temperature distribution in the melt is made more even, thirdly a uniform distribution or mixing of different glass constituents is achieved, and fourthly the redox state of the glass can be adjusted.

Owner:SCHOTT AG

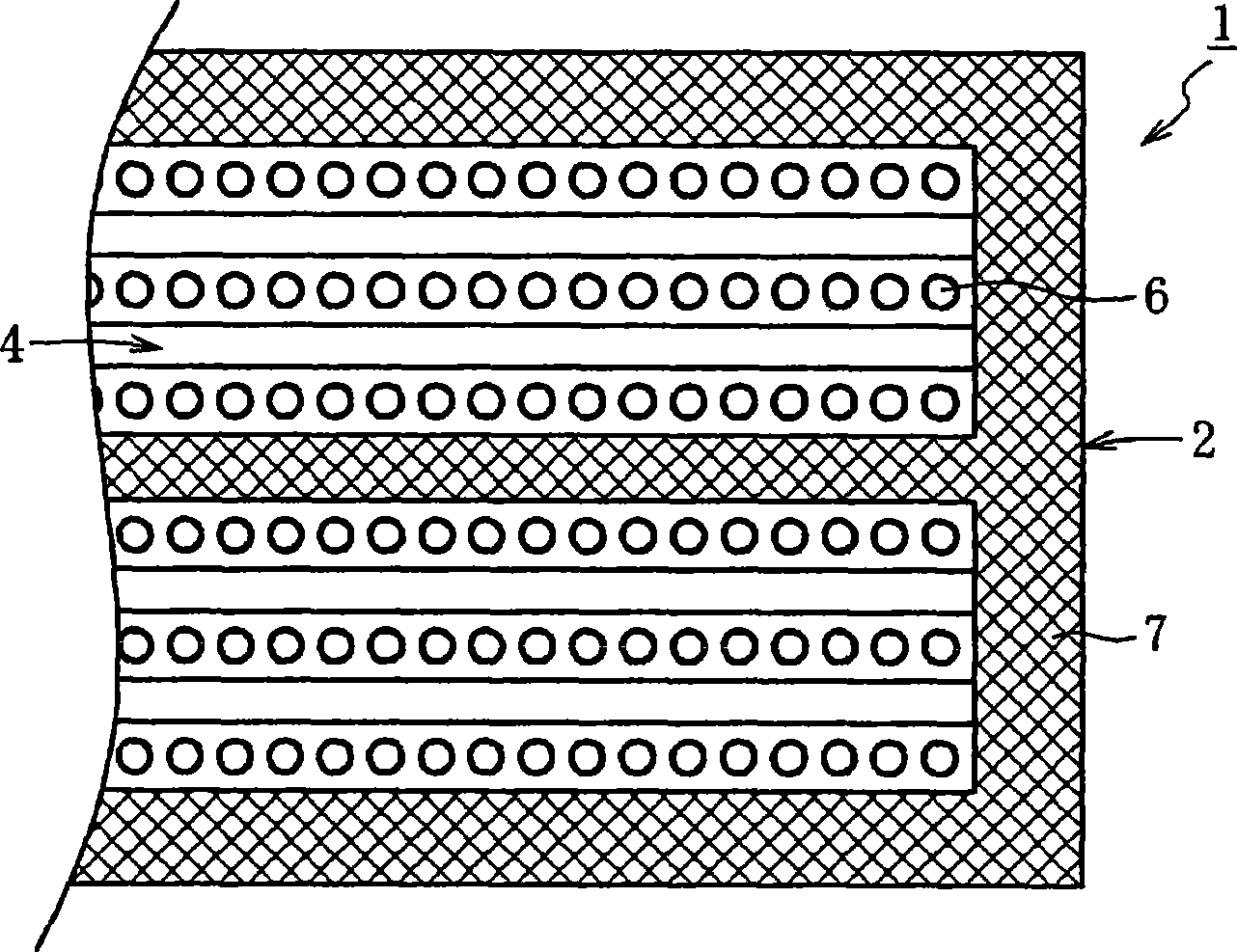

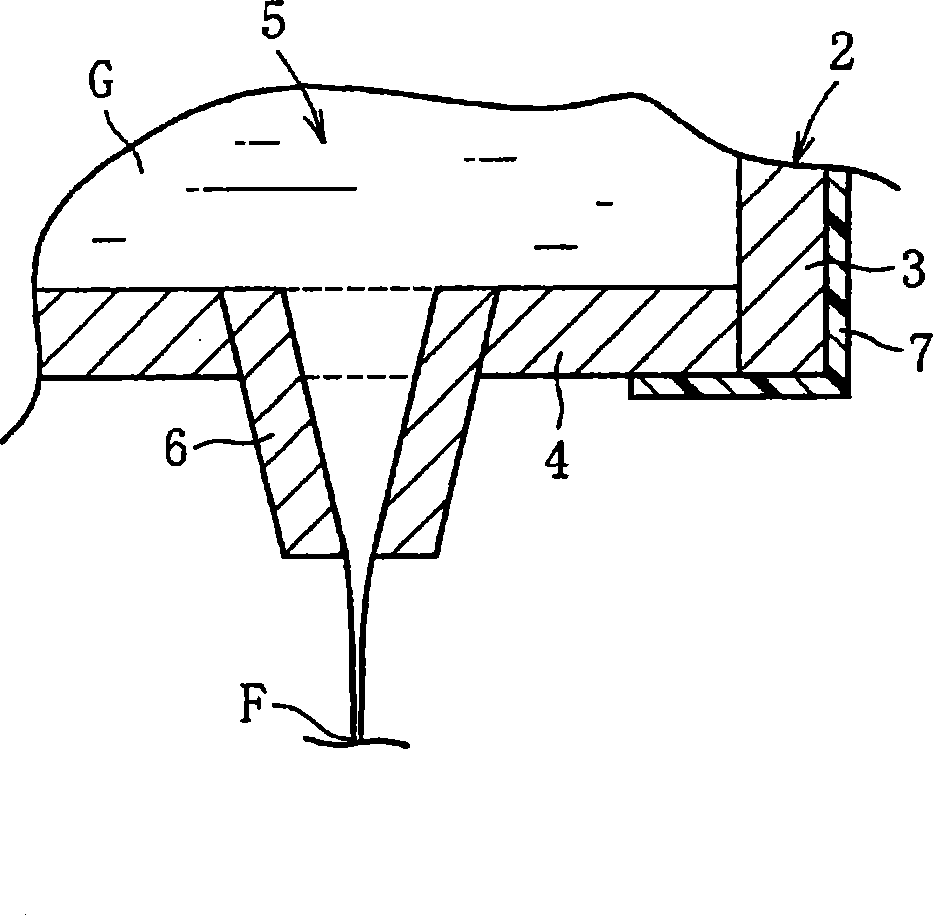

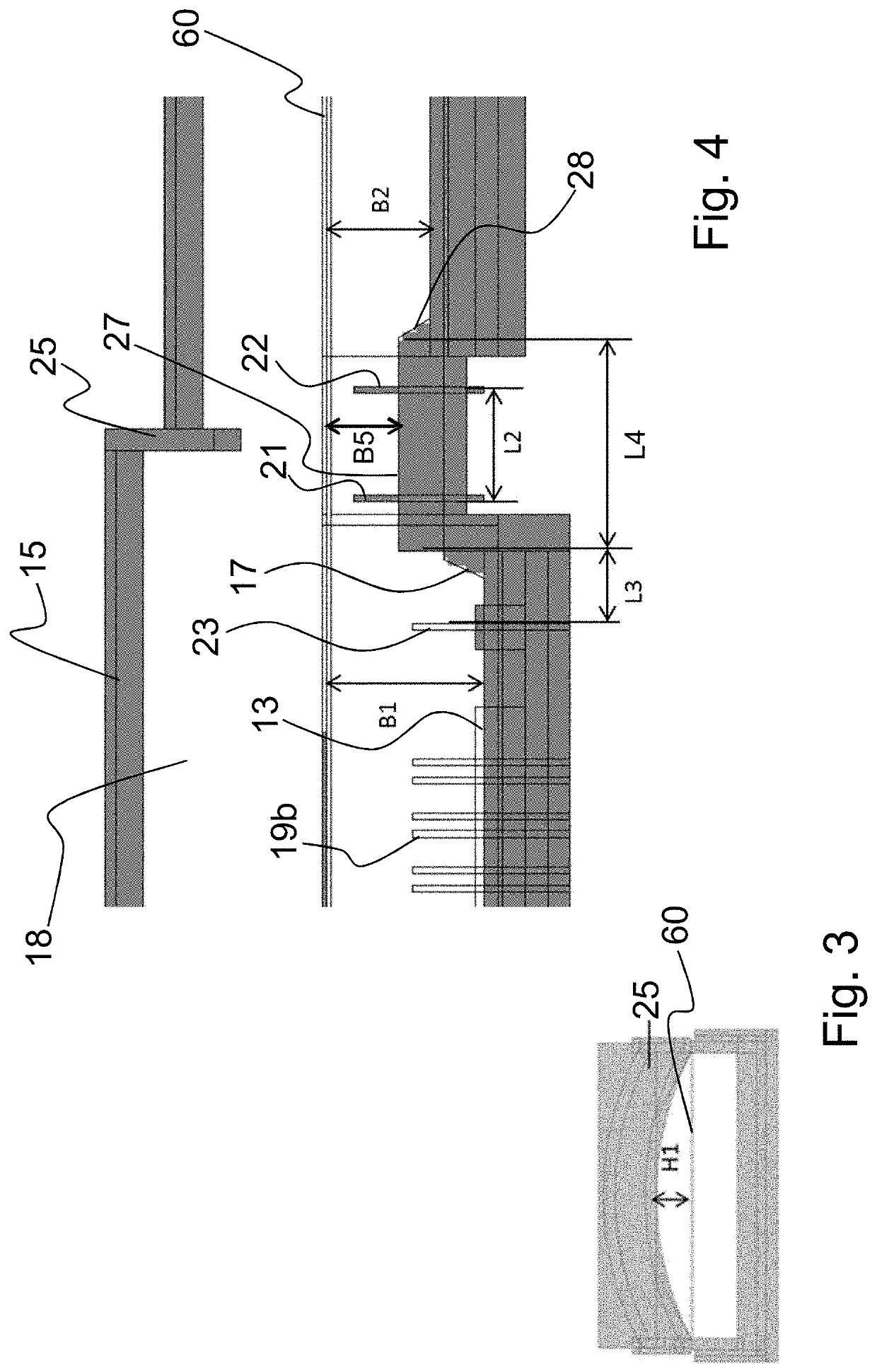

Bushing for production of glass continuous filament, equipment for producing glass continuous filament and process for production of the filament using the equipment

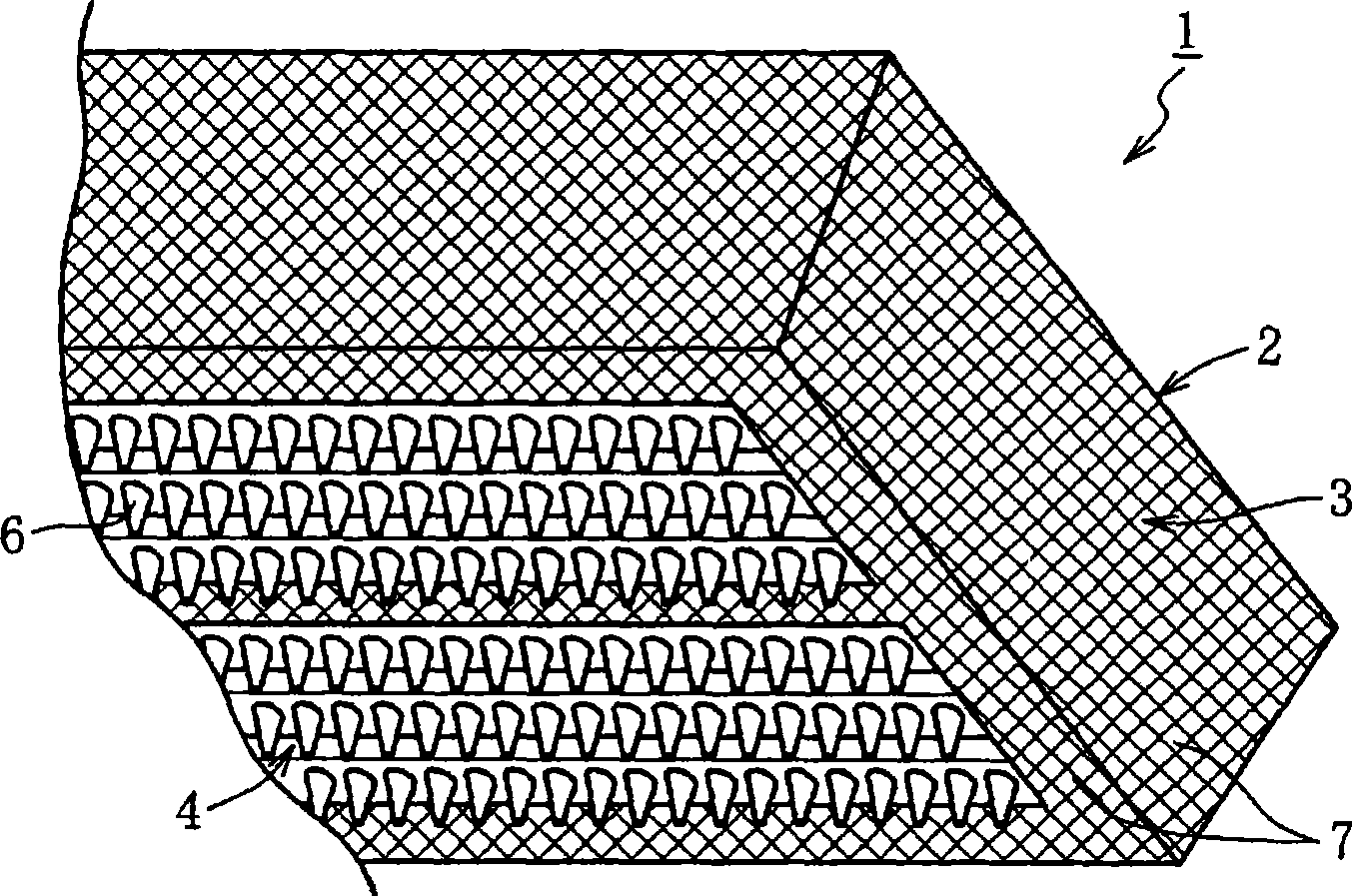

ActiveCN101506113AQuality improvementInhibition productionGlass making apparatusSpinnerette packsGlass fiberGlass cover

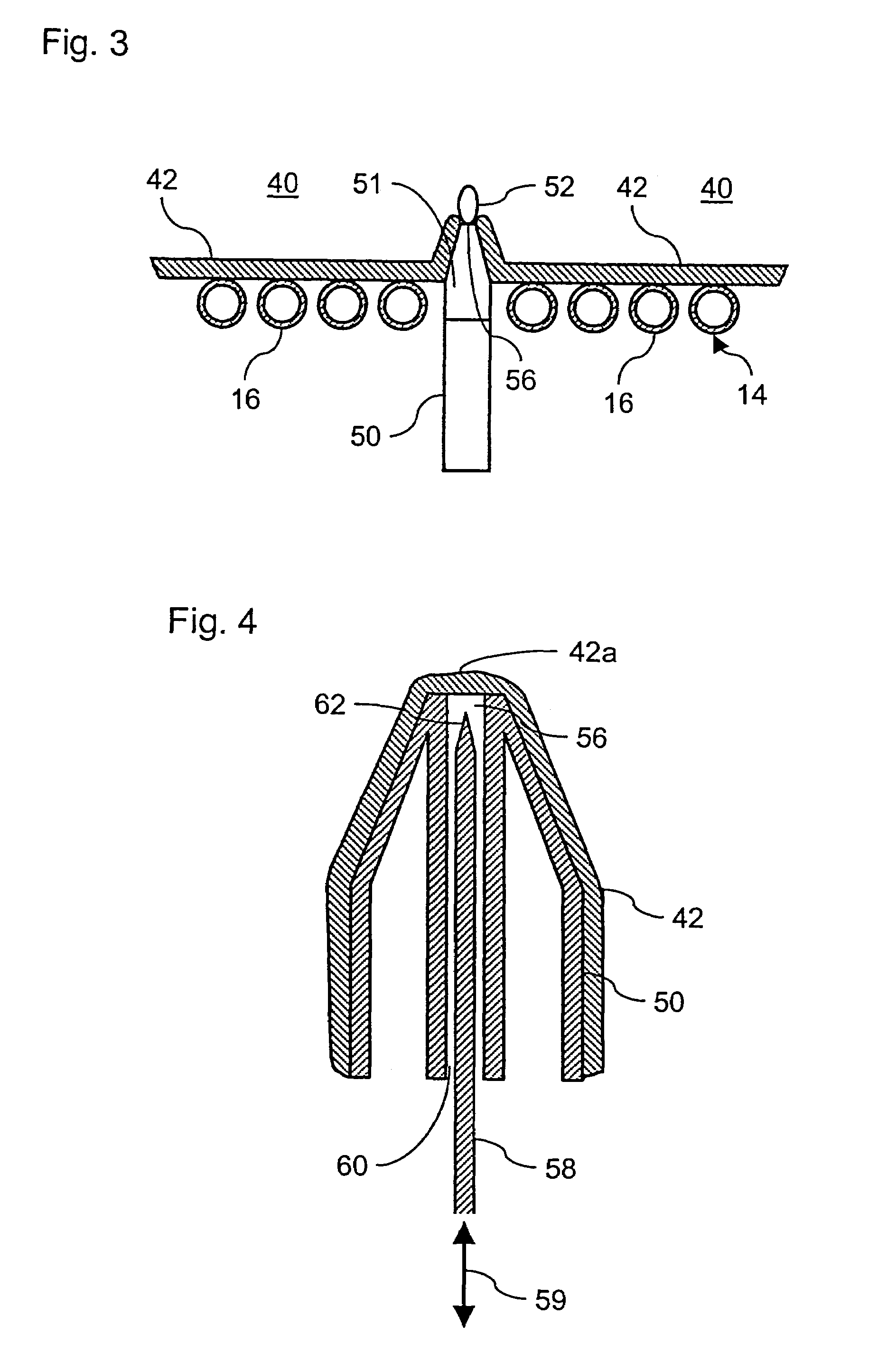

To provide a bushing of strong structure which is reduced in the quantity of substance evaporated from the bushing and enables the formation of high-precision glass filaments. A bushing (1) for producing glass continuous filaments (F) by making molten glass (G) flow out through nozzles (6) of a bushing plate (4), wherein a coating film (7) made of a material selected from the group consisting of ceramics, glass-ceramics and glass covers the outside surface of the bushing plate (4) except the outer peripheral surfaces of the nozzles (6) and the end face; a process for the production of glass continuous filaments by producing glass filaments for composite materials with the bushing (1) while watching the outside surface of the bushing plate (4) and the state of spinning; and a process for the production of the bushing (1) which comprises the bushing body formation step of assembling a bushing body (2), the coating step of forming a coating on at least the outside surface of the bushing plate (4) of the bushing body (2), and the baking step of heating the coating to convert it into a dense-structure film.

Owner:NIPPON ELECTRIC GLASS CO LTD

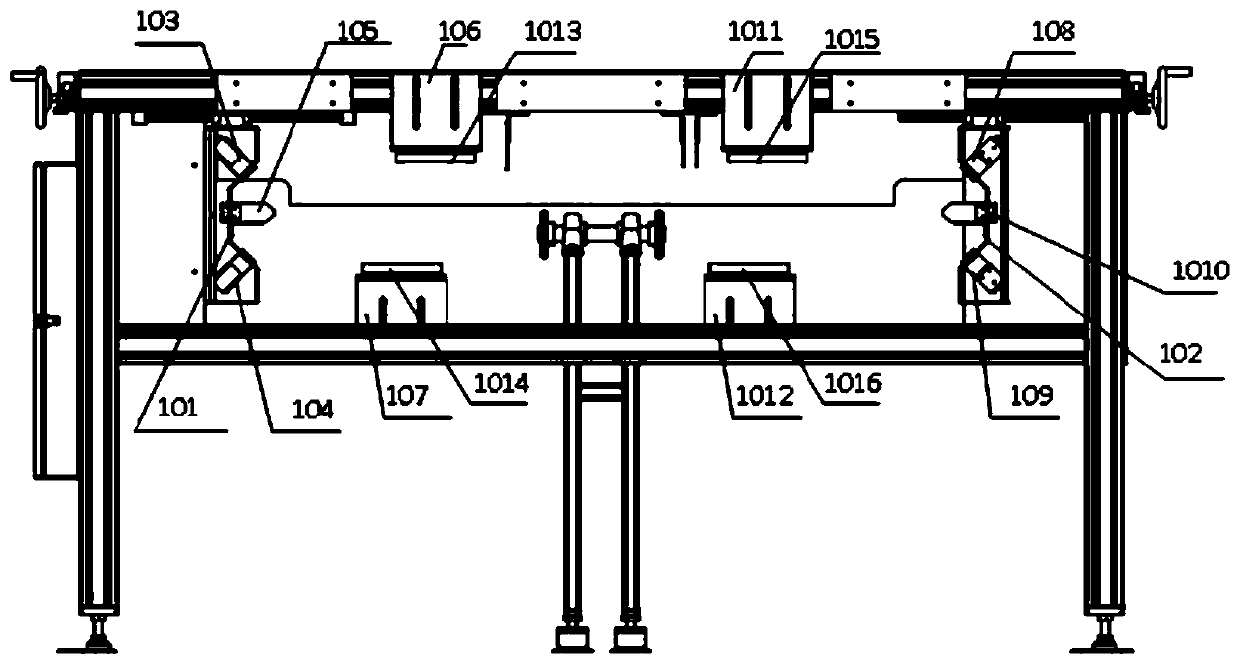

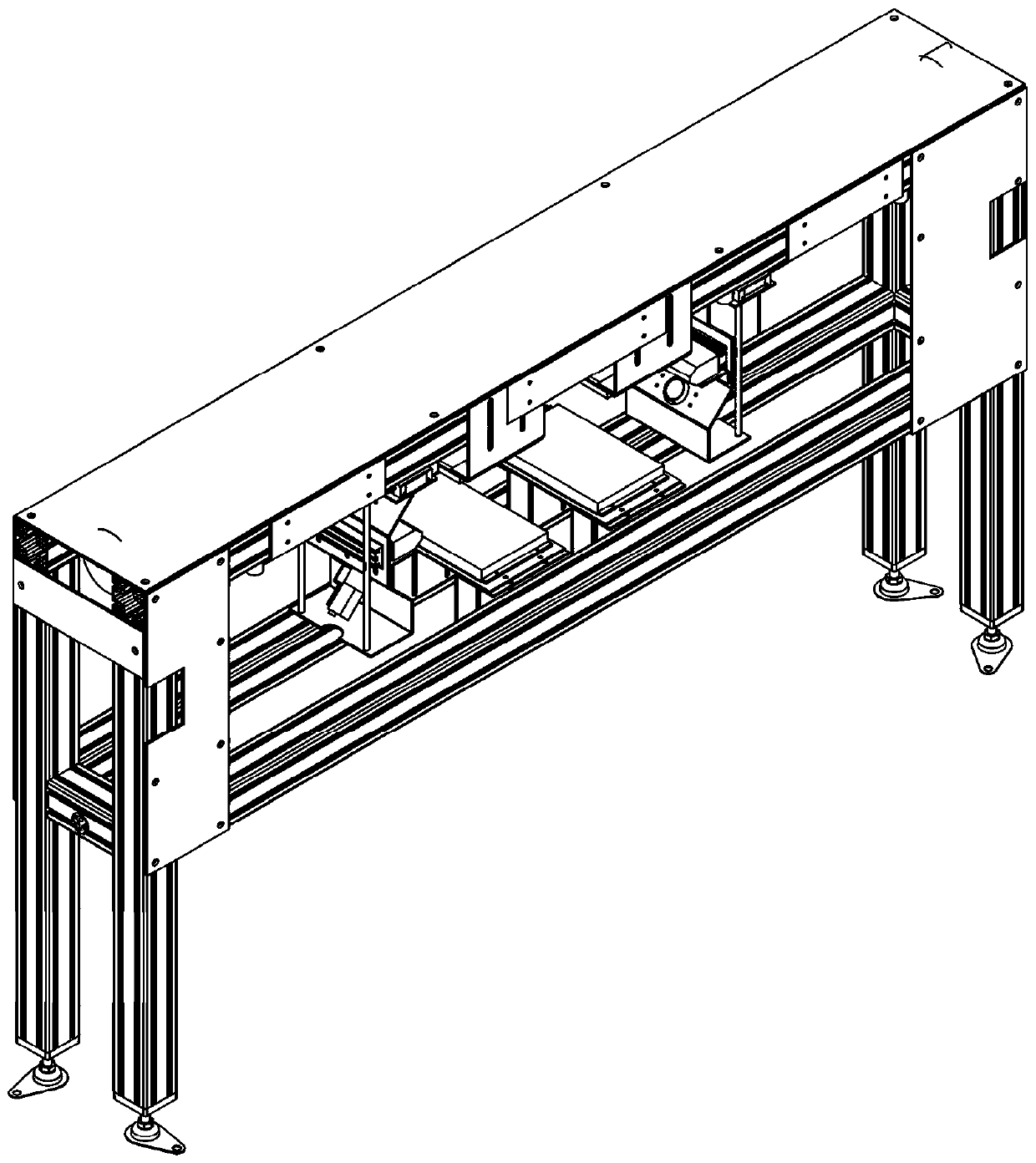

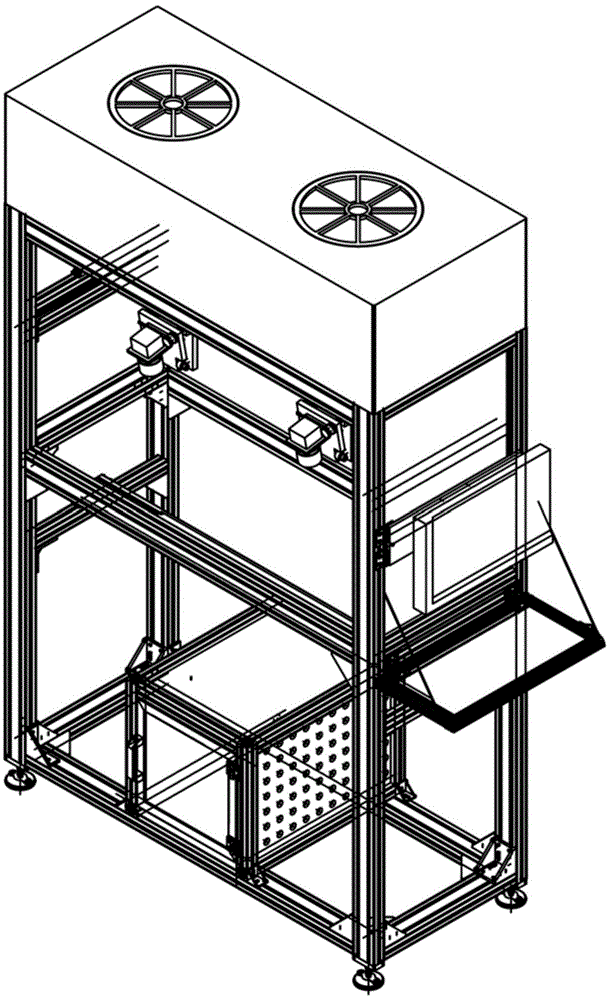

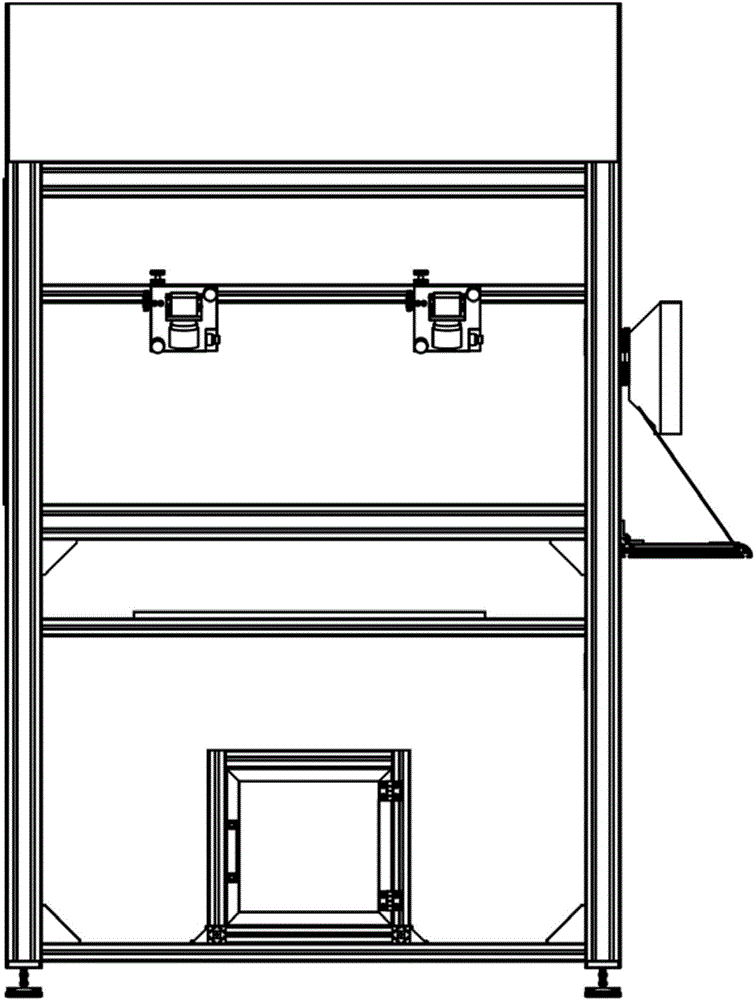

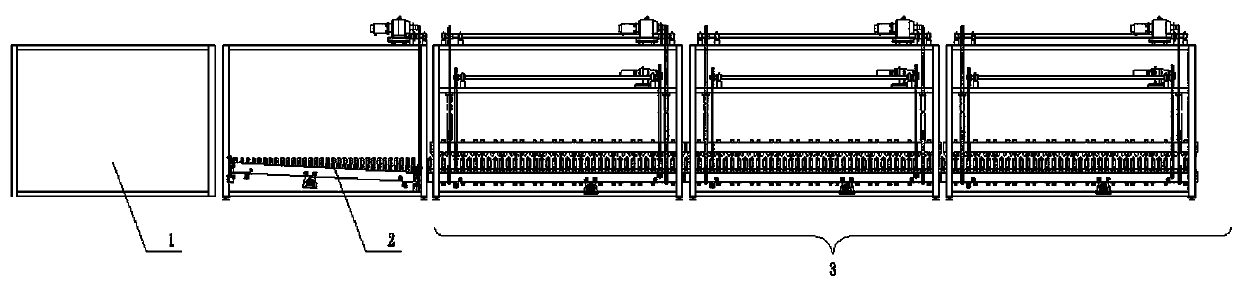

Photovoltaic glass edge portion defect detection system and corresponding method

ActiveCN109916910AImprove detection efficiencyHigh degree of automationImage analysisOptically investigating flaws/contaminationMachine visionEngineering

The invention relates to a photovoltaic glass edge portion defect detection system and a corresponding method. The system is installed on a production roller way of photovoltaic glass. The system comprises a mechanical frame, a light source module, a camera module and an edge portion defect detection module. A corresponding method for realizing photovoltaic glass edge portion defect detection is combined to control the system. A machine vision detection technology is used to realize the automatic detection of a photovoltaic glass edge portion. Detection accuracy can reach 0.5mm, and an omission ratio is less than 0.5%, which is obviously better than manual detection and improves the detection efficiency of the photovoltaic glass. By using the photovoltaic glass edge portion defect detection system and the corresponding method, labor force wastes can be effectively reduced, detection cost is decreased, detection precision and glass quality are increased, an automation degree of an enterprise is reinforced, large scale popularization of a glass automatic detection system can be realized, and a wide application range is achieved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Impervious anticorrosion pouring material

InactiveCN101475385AStrong resistance to glass chemical attackGood chemical stabilityGranularityZircon

The invention discloses a seepage and corrosion resistant casting material. The casting material comprises an A composition, a B composition and a C composition, wherein the weight percentage of various compositions is calculated by the 100 total weight percentage of the casting material; the A composition is a uniform mixture of the following compositions: 13 to 18 percent of 5-7 mm fused zircon corundum, 12 to 20 percent of 3-5 mm fused zircon corundum, 19 to 27 percent of 1-3 mm fused zircon corundum and 12 to 18 percent of 0-1 mm fused zircon corundum; the B composition is a uniform mixture of the following compositions: 3 to 5 percent of activated alumina micro powder, 2 to 4 percent of low-iron silica fume, 3 to 7 percent of desilicate zirconium, 2 to 10 percent of zircon powder and 2 to 10 percent of white alundum powder; and the C composition is a uniform mixture of the following compositions: 1 to 3 percent of alumina cement and 0.05 to 0.15 percent of sodium tripolyphosphate. The seepage and corrosion resistant casting material has the advantage of strong capacity of resisting corrosion of glass chemistry and the like.

Owner:宜兴市中韩窑业工程有限公司

Fuel feeding proportion adjustable combustor

ActiveCN109489038AImprove flammabilityImprove glass qualityBurnersFuel supply regulationMultifuelCombustor

The invention discloses a fuel feeding proportion adjustable combustor. The combustor comprises a fireproof unit, a metal part, a fuel flow control device, a fuel-third oxidizing agent feeding system,a first oxidizing agent feeding system and a second oxidizing agent feeding system, wherein the fuel-third oxidizing agent feeding system comprises a fuel burner as a plurality of third oxidizing agent channels; the first oxidizing agent feeding system comprises a plurality of first oxidizing agent channels; the second oxidizing agent feeding system comprises a plurality of second oxidizing agentchannels. The fuel burner comprises second fuel injection pipes located at the center and first fuel injection pipes defined by the outer walls of the second fuel injection pipes and the inner wall of the burner. The combustor provided by the invention can be used for a multi-fuel kiln furnace and can adjust the feeding proportions of various fuels.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Energy saving ultra clear glass kiln

InactiveCN102417289AImprove energy savingReduce widthGlass furnace apparatusDirect communicationKiln

An energy saving ultra clear glass kiln comprises a plurality of cooling forehearth limbs and a melting zone, a clarification zone and a neck that are successively connected. At least one neck is included, and each neck is connected to at least one cooling forehearth limb and provided with a molten glass deep separation apparatus. One the one hand, each neck communicates with at least one cooling forehearth limb, namely a cooling transverse pathway is canceled, and a structure form of direct communication to the forehearth limb is employed; the cooling forehearth limb becomes an independent cooling portion, is in a small cooling portion arrangement and has little heat radiation; therefore, an area of the cooling portion is reduced, and molten glass flow in the cooling portion is smooth, and each ton of molten glass (discharge) accounts for 0.1-0.15m<2> of the cooling portion. on the other hand, the arrangement of molten glass deep separation apparatus compresses width of the neck, increases length of the neck, reduces a circulation section area of the molten glass at the neck, separates the molten glass in the neck and plays a role of reducing backflow of the molten glass. Thereby, the amount of the molten glass with obviously reduced temperature in the cooling portion flowing back to the clarification zone and the melting zone through the neck is effectively reduced, and liquid flow of the molten glass is much reasonable. The kiln has good energy saving effect.

Owner:陈永林

Optical glasses and their uses

InactiveUS7605099B2Increase in numberIncrease refractive indexGlass/slag layered productsOptical elementsRefractive indexVolumetric Mass Density

The optical glass has an index of refraction (nd) greater than or equal to 1.70, an Abbé number (νd) greater than or equal to 35 and a density (ρ) less than or equal to 4.5 g / cm3. Optical elements made with this optical glass are especially desirable in optical data transfer applications, particularly in read-write devices with movable read-write heads. The glass compositions required to make optical glass with these properties are described.

Owner:SONIONKIRK +1

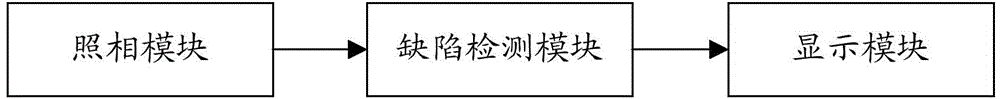

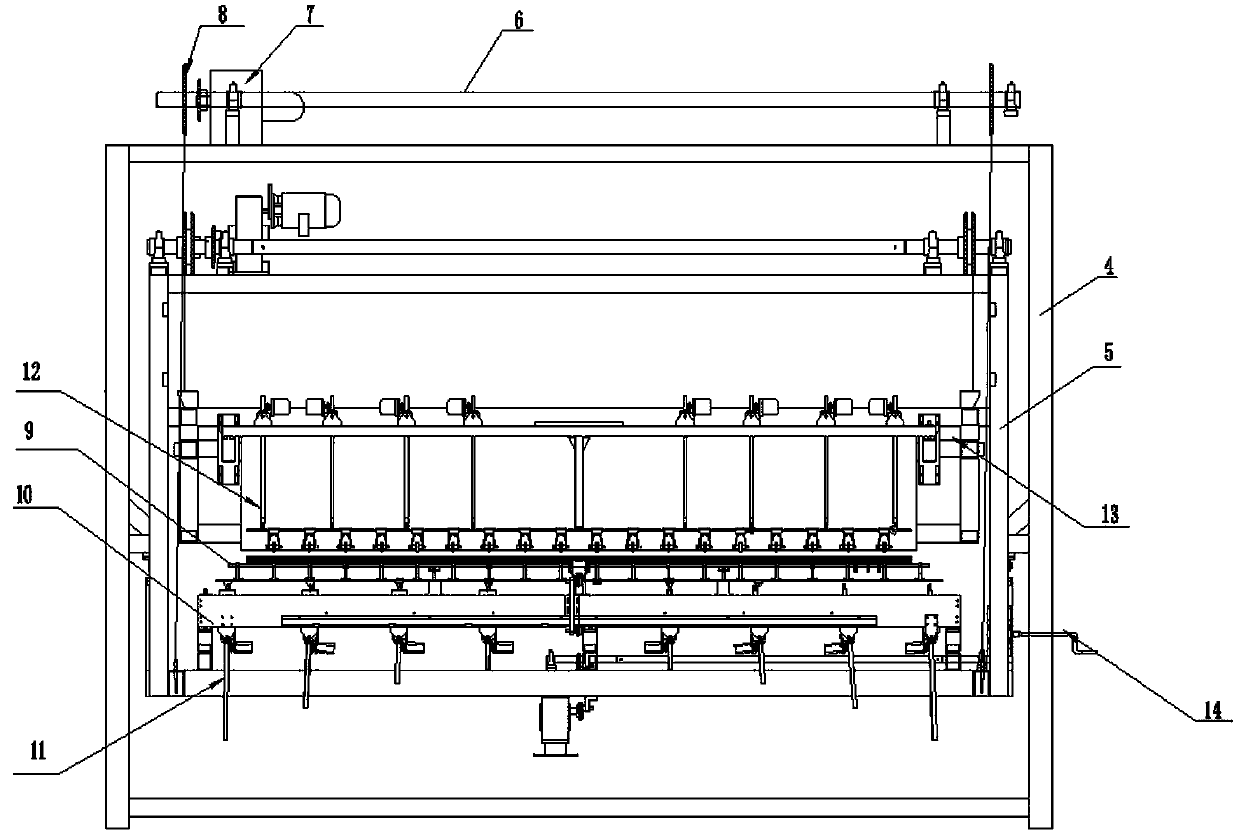

System for realizing automatic detection of electronic glass defects

InactiveCN104359925AImprove detection efficiencyHigh degree of automationImage analysisMaterial analysis by optical meansComputer visionArtificial intelligence

The invention relates to a system for realizing automatic detection of electronic glass defects. The system comprises a photographing module, a defect detecting module and a display module, wherein the photographing module is used for acquiring an image of electronic glass; the defect detecting module is used for analyzing the image of the electronic glass to obtain a plurality of divided objects and treating each divided object by a defect location process and a defect classification process to obtain defect type of each divided object; the display module is used for displaying the information of the defect type of each divided object. By adopting the system for realizing the automatic detection of the electronic glass defects, the detection efficiency for the electronic glass is improved, waste of labor is reduced, the detection cost is lowered, the detection accuracy and the glass quality are improved, automation degree of an enterprise is increased, large-scale popularization of an automatic glass detection system is facilitated, and the system has a relatively wide application range.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

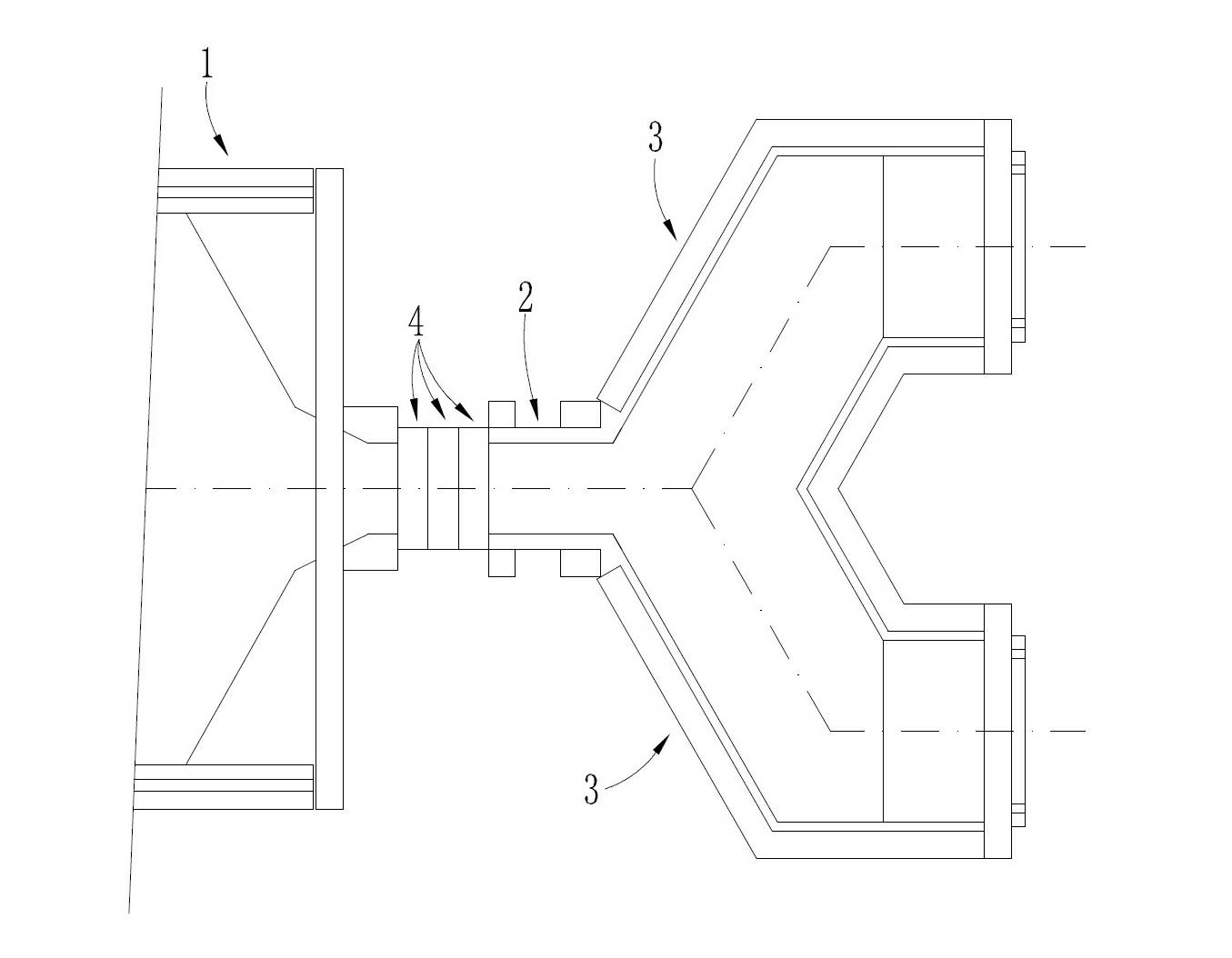

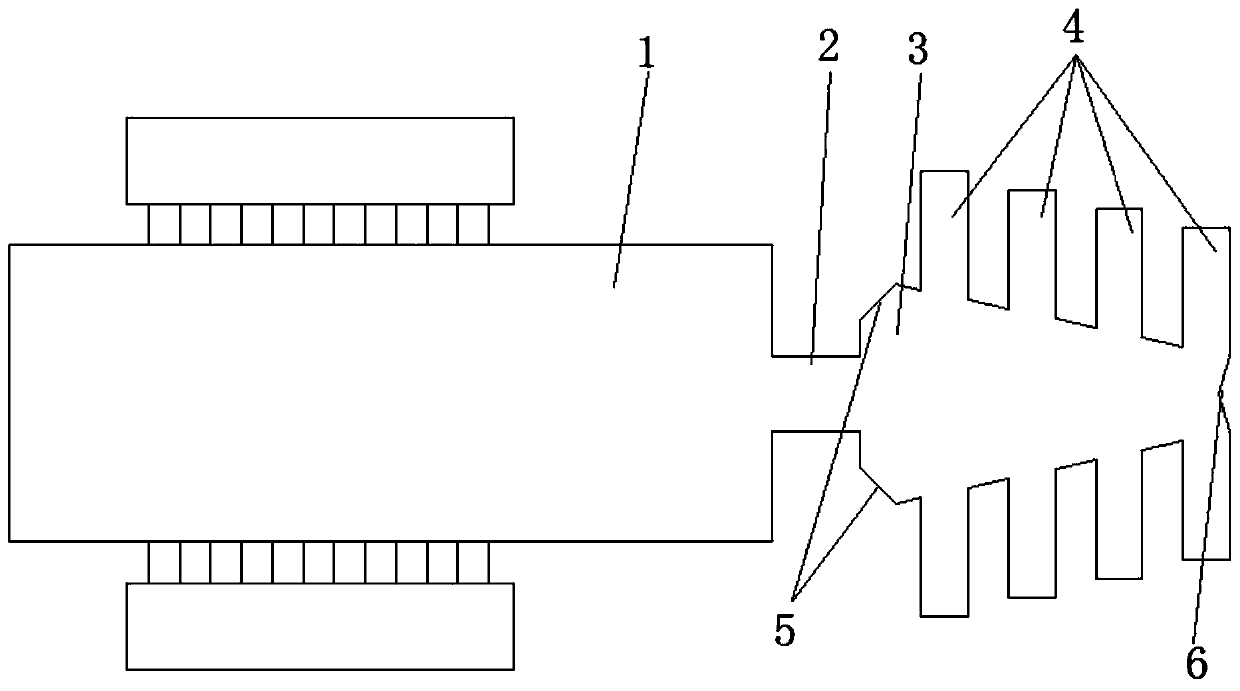

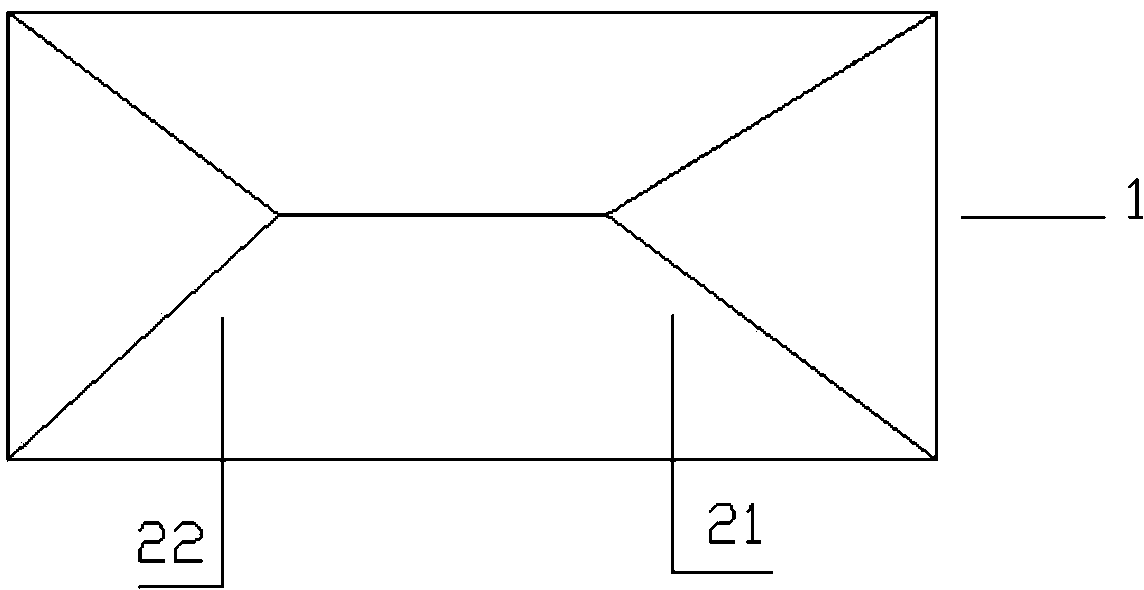

One-kiln multi-line molten glass shunting melting furnace

ActiveCN111333306AImprove uniformityImprove glass qualityGlass furnace apparatusHalogen/halogen-acidsFlat glassKiln

The invention discloses a one-kiln multi-line molten glass shunting melting furnace, which comprises a melting part, a neck, a working part and branch paths, wherein the melting part is communicated with the working part through the neck, the melting part is used for heating, melting and clarifying molten glass, the front portion of the working part is wide, the rear portion of the working part isnarrow, and a plurality of the branch paths are arranged on two sides of the working part. According to the invention, the novel one-kiln multi-line molten glass shunting melting furnace can meet thelow-energy-consumption plate glass production of a 800-1250 ton large-tonnage melting furnace, can improve the uniformity of molten glass in each branch path and the glass quality, and can effectively solve the quality problems of large temperature difference of molten glass in each branch path, poor uniformity and the like in the molten glass shunting process of a one-kiln multi-line melting furnace, particularly a one-kiln melting furnace with more than four lines.

Owner:北海长利新材料科技有限公司

Lead-free glass tubing, especially for encapsulating diodes and diodes encapsulated with same

InactiveUS6864197B2Crystal stableWater-resistantSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceDiode

The lead-free glass tubing of the SiO2—B2O3—R2O—BaO—ZnO—TiO2 system has a composition, in percent by weight on an oxide basis, consisting essentially of: SiO2, 34 to 52; B2O3, 10 to 25; Al2O3, 0 to 25; Li2O, 2 to 6; Na2O, 4 to 10; K2O, 2 to 6; CaO, 0 to 4; BaO, 1 to 5; ZnO, 4 to 12; TiO2, 2 to 6, and at least one refining agent in an effective amount for refining. An encapsulated diode consisting of a diode encapsulated with this lead-free glass tubing is also disclosed.

Owner:SCHOTT AG +1

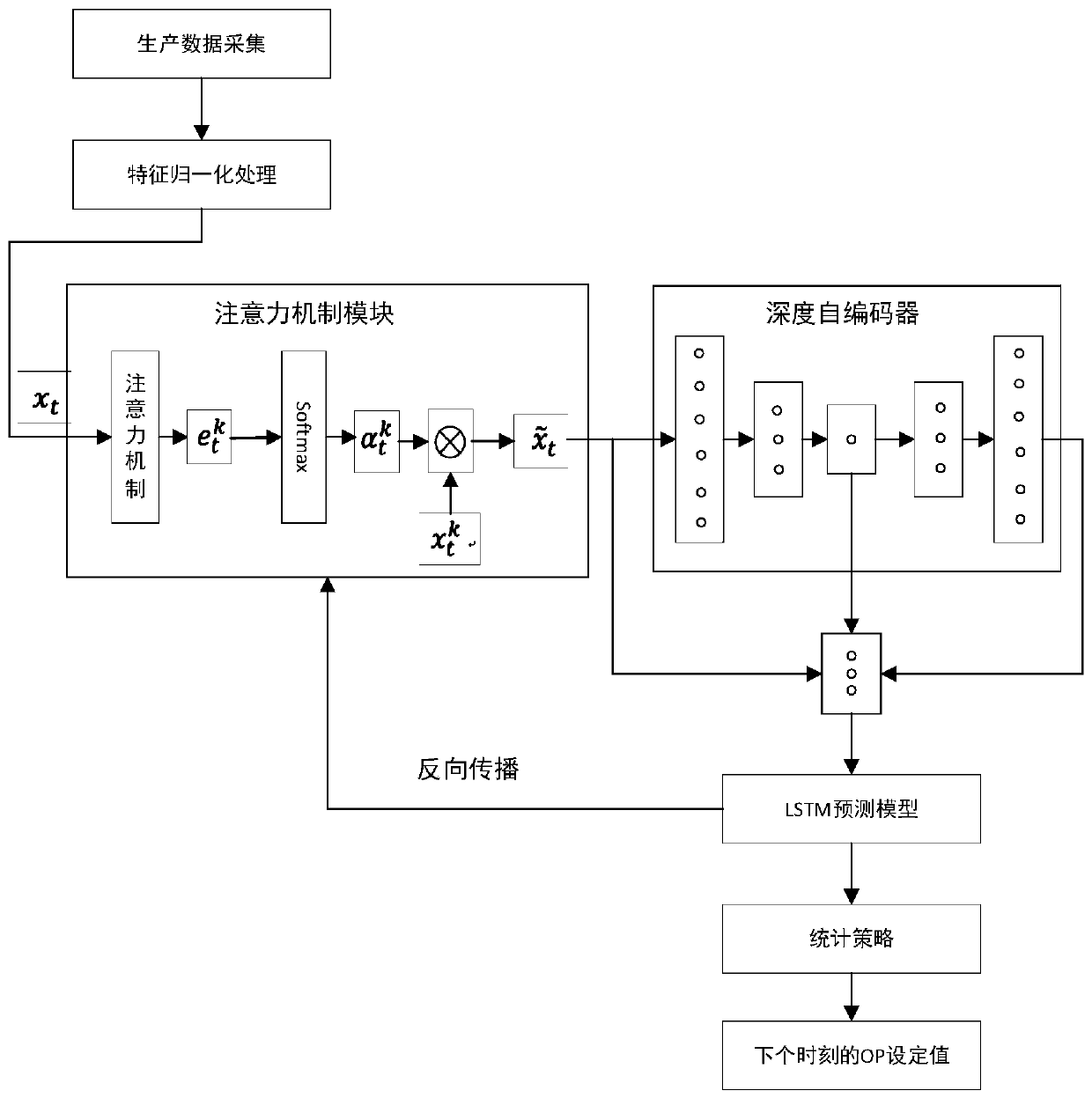

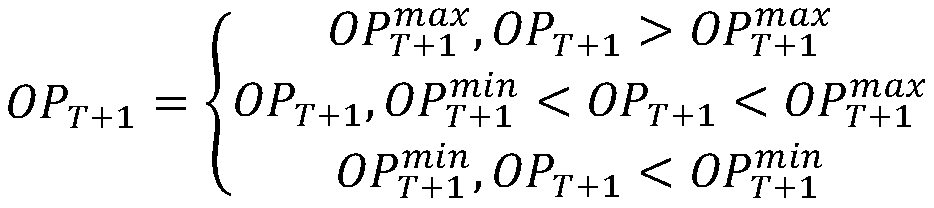

Glass furnace temperature intelligent prediction control method based on attention mechanism and auto-encoder

ActiveCN110347192ARealize intelligent controlRealize dynamic controlTemperature control using electric meansFurnace temperatureGlass furnace

The invention provides a glass furnace temperature intelligent prediction control method based on an attention mechanism and an auto-encoder. The glass furnace temperature intelligent prediction control method comprises the following steps: collecting production historical data related to preprocessing glass furnace temperature prediction control; according to an input variable obtained through preprocessing, using the attention mechanism to obtain the input variable with an attention weight of each smelting furnace temperature at each moment; obtaining two representation vectors including relative Euclidean distance and cosine similarity according to the reconstruction error of the depth auto-encoder, and forming a final low-dimensional representation in combination with potential representations generated by an encoder in the depth auto-encoder; according to the low-dimensional representation, using an LSTM prediction model to obtain predicted values of the temperature of the smelting furnace in a plurality of subsequent time steps; according to a control mode of combining the LSTM prediction model and a statistical strategy, intelligently adjusting the natural gas flow and the oxygen flow of the glass furnace on line, so that the temperature fluctuation of the glass furnace is intelligently controlled, the glass product quality is improved, and the energy consumption is reduced.

Owner:WUHAN UNIV OF TECH

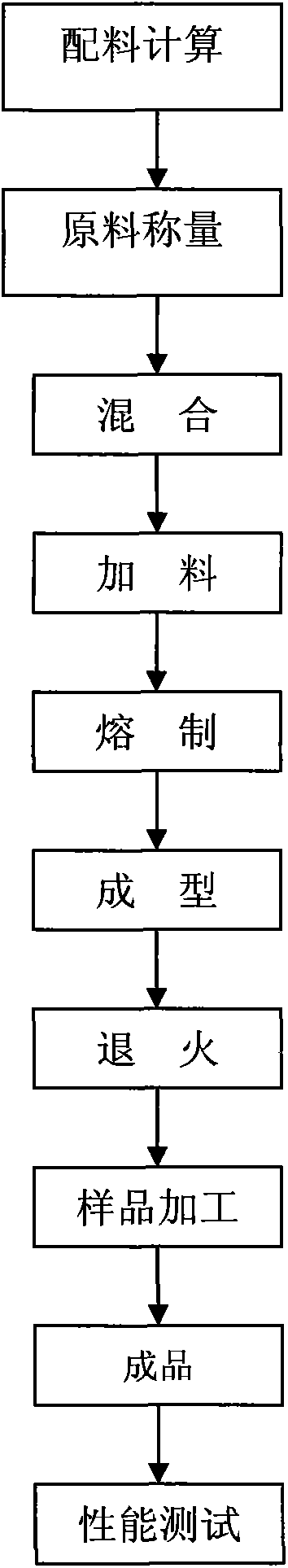

Low-temperature electric melting formula for transparent glass, process method thereof and transparent glass prepared through low-temperature electric melting formula and process method

The invention provides a low-temperature electric melting formula for transparent glass, a process method thereof and the transparent glass prepared through low-temperature electric melting formula and the process method. The transparent glass is prepared through the following steps: taking Cab-O-sil, boric acid, borax, calcite, primary zinc, barium carbonate, sodium carbonate and the like as main raw materials and sodium nitrate and the like as auxiliary raw materials, burdening, mixing, founding, molding and annealing. The transparent glass comprises the following main components by weight: 55-68% of SiO2, 0.01-0.05% of Fe2O3, 0.5-6% of B2O3, 0.5-3% of Al2O3, 3-8% of CaO, 0-5% of ZnO, 9-18% of Na2O, 2-10% of K2O, 1-10% of BaO, and 0-1% of Li2O. According to the invention, a technology of electric melting by a kiln is adopted, so that the melting temperature is lowered effectively, the energy consumption is reduced, and the quality of the transparent glass is improved. The formula and the process are suitable for manufacturing various glass crafts.

Owner:ARIAMOTION DALIAN

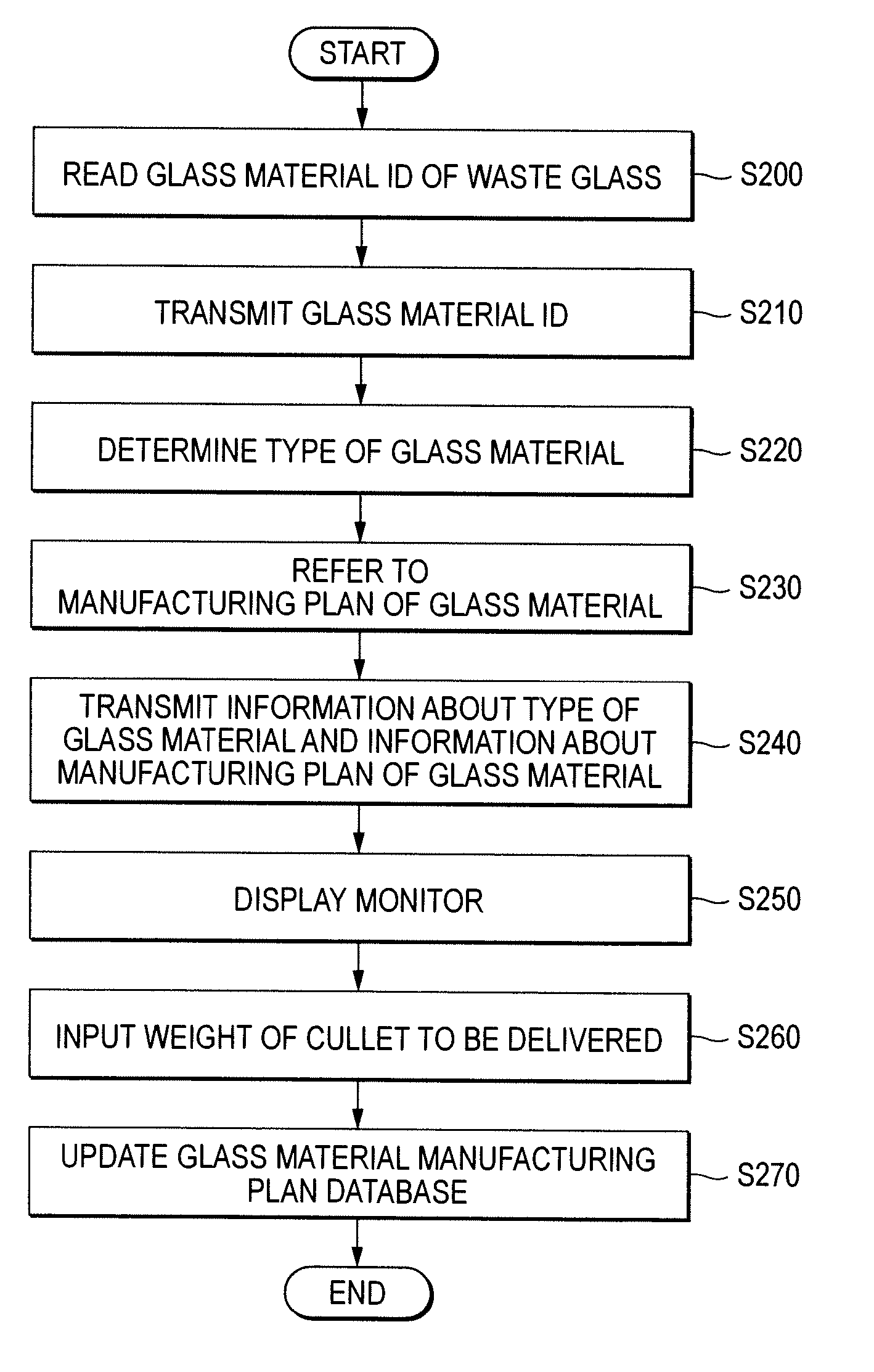

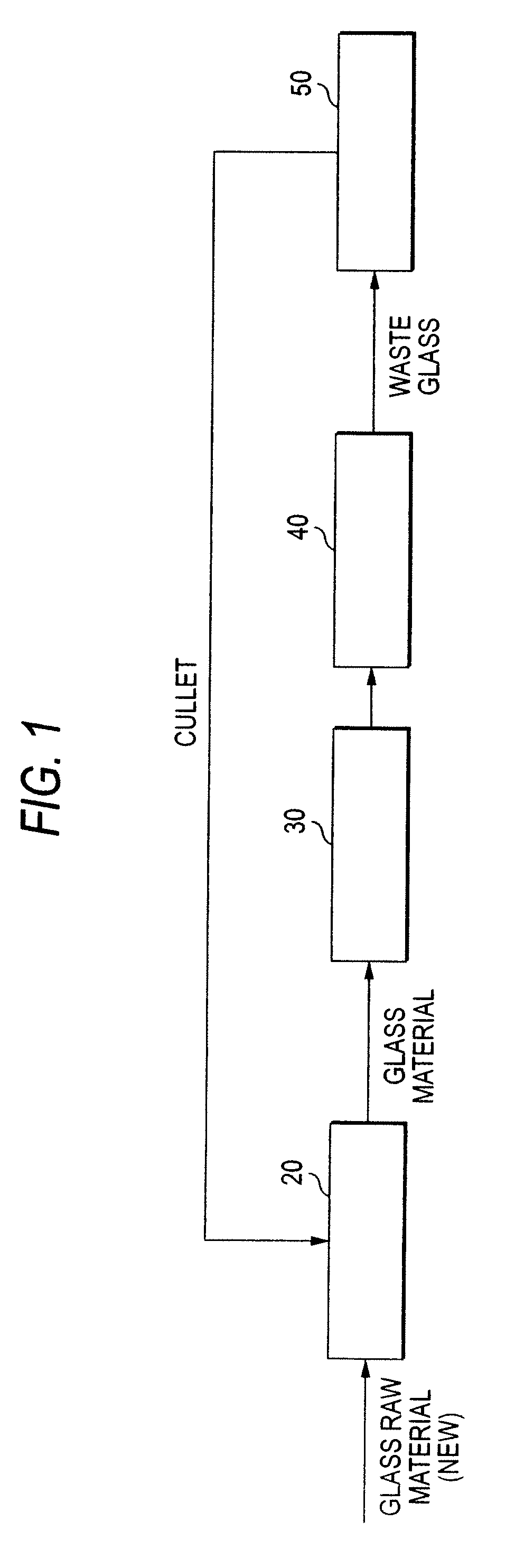

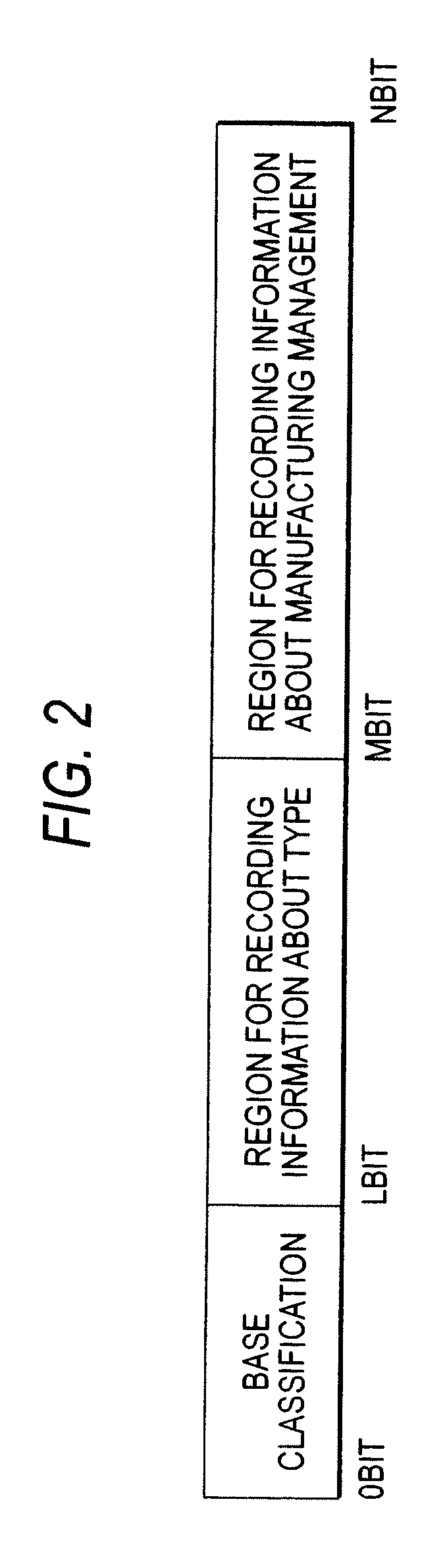

Support System for Recycling Glass Material

InactiveUS20060261163A1Easy to classifyEasy to separateElectric signal transmission systemsDigital data processing detailsSupporting systemDisplay device

A support system for recycling a glass material to which an electronic tag is attached, the support system includes: a first storing device for storing information about plural types of glass materials corresponding to plural glass material identification data that are stored in electronic tags attached to glass materials; a reading device for reading a glass material identification data from an electronic tag that is attached to a discarded glass material; a determining device for determining a particular type of the discarded glass material based on the glass material identification data read by the reading device by referring to information about the types of glass materials stored in the first storing device; and a displaying device for displaying the type of the discarded glass material.

Owner:NIPPON SHEET GLASS CO LTD

Glass fiber composition, glass fiber and composite material therefrom

The present invention provides a glass fiber composition, glass fiber and composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 56-64% SiO2, 12-18% Al2O3, 0.1-1% Na2O, 0.1-1% K2O, 0.1-1% Fe2O3, 0.05-1% Li2O+Bi2O3, 19-25% CaO+MgO+SrO, 0.1-1.5% TiO2 and 0-1% CeO2, wherein a weight percentage ratio C1=Li2O / Bi2O3 is greater than 1, and a weight percentage ratio C2=(MgO+SrO) / CaO is 0.4-1, and a weight percentage ratio C3=MgO / (MgO+SrO) is greater than 0.7. Said composition reduces the amount of bubbles, viscosity and crystallization risk of the glass, thereby making it more suitable for large-scale production with refractory-lined furnaces.

Owner:JUSHI GRP CO

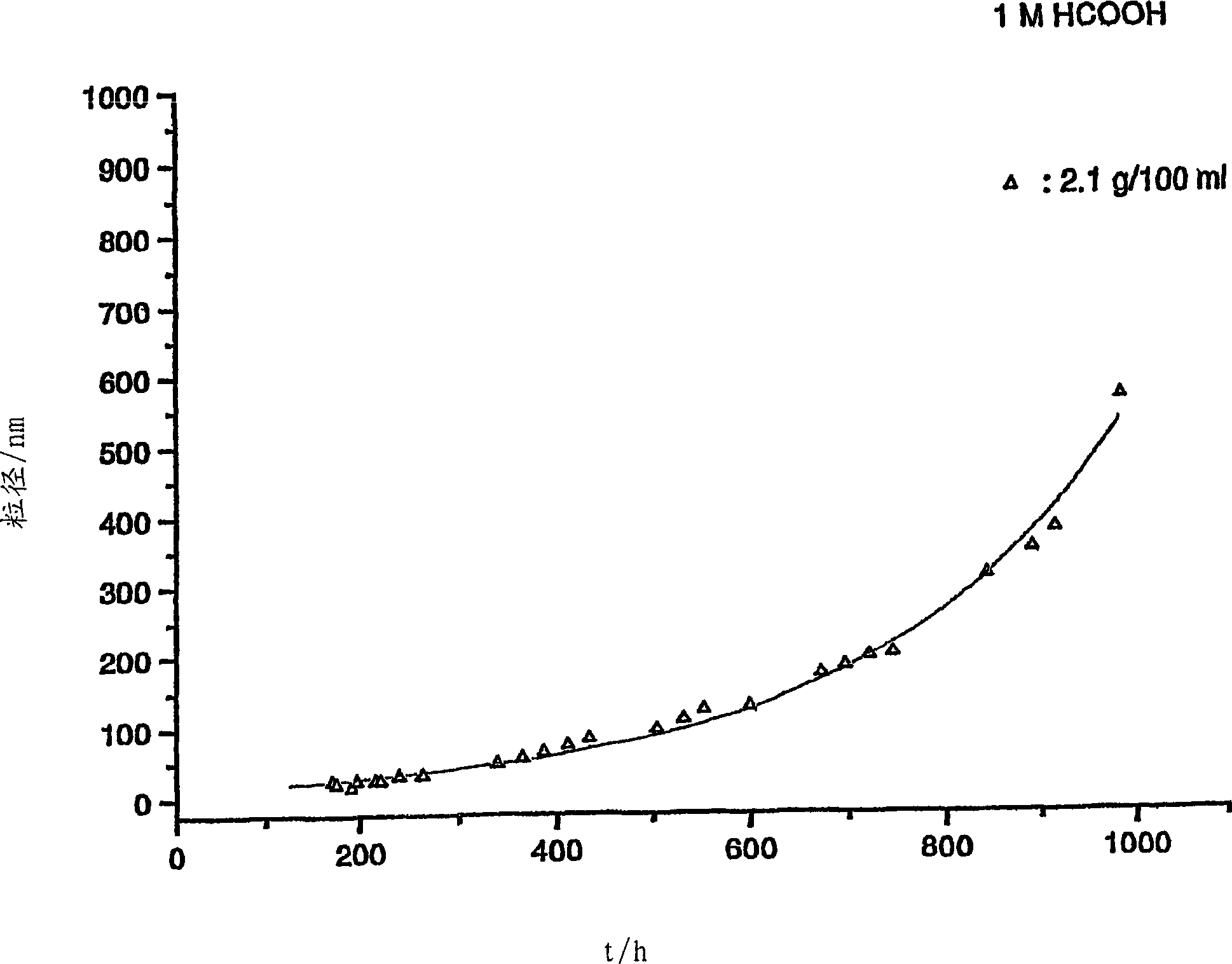

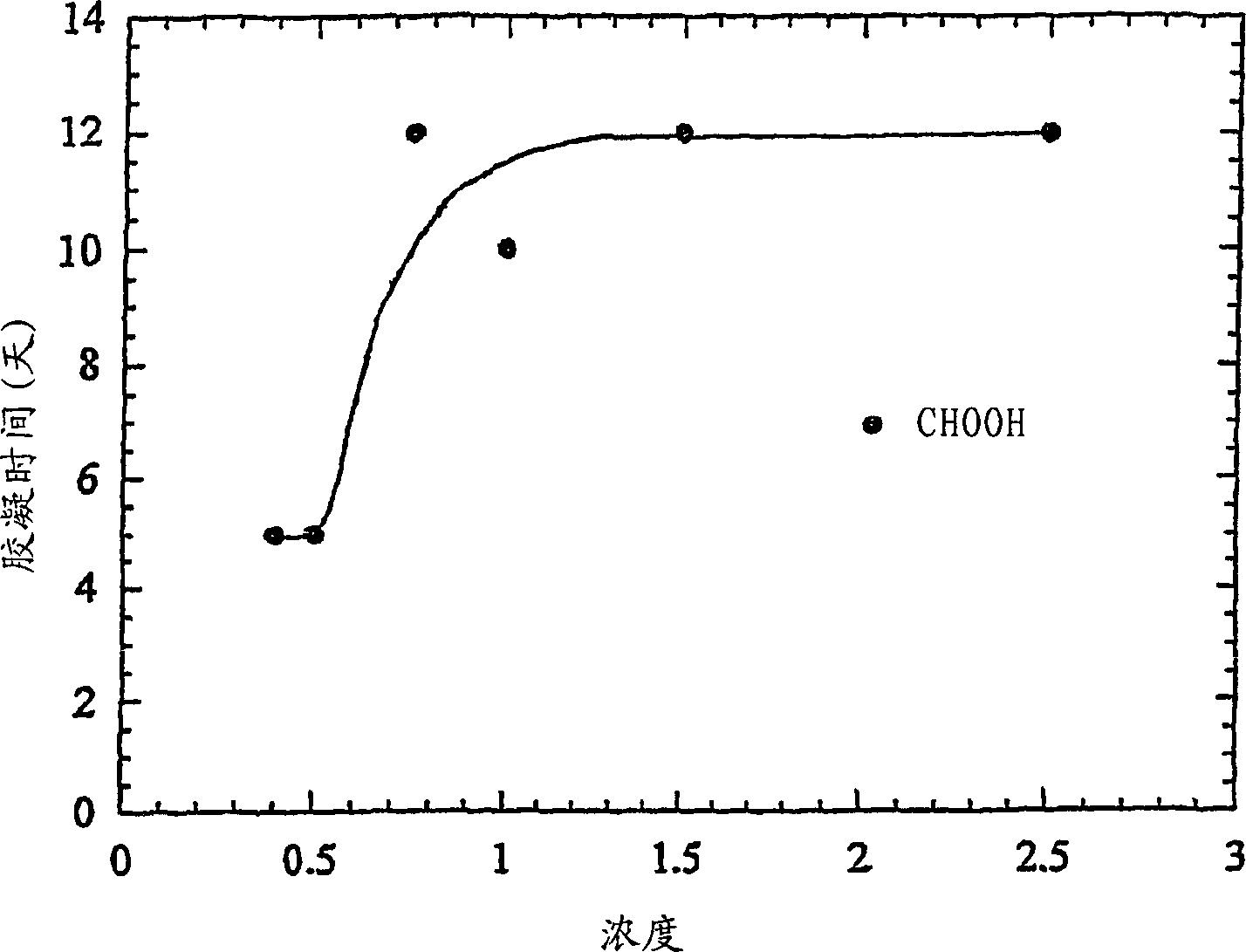

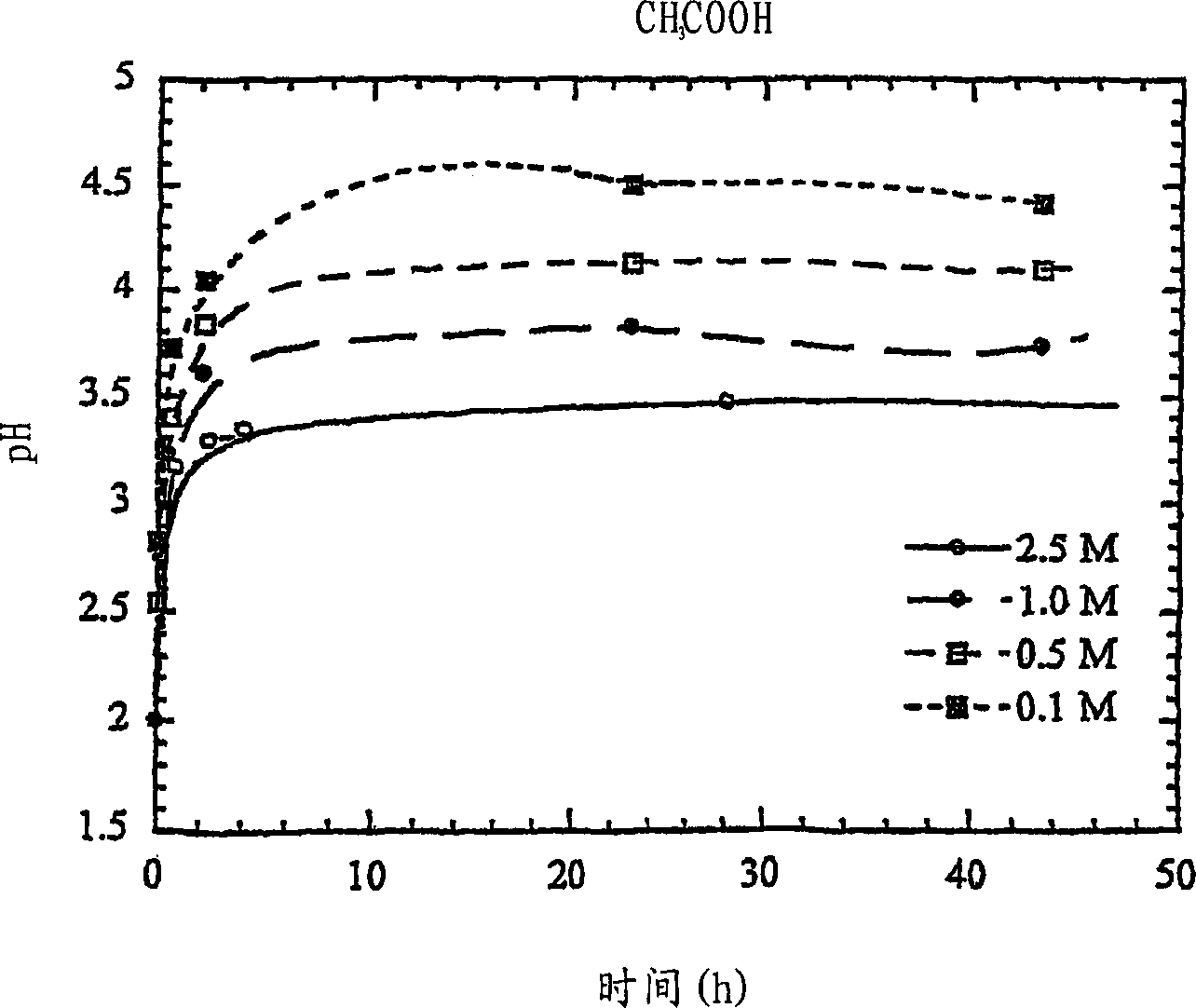

Colloidal silicate dispersion, method for its preparation and its use

The present invention is directed to a colloidal aqueous silicate dispersion containing silica and alumina, the molar ratio between silica and alumina being 2 - 12, as well as to a method for its preparation. Said method is characterized by dissolving a particulate mineral material, such as a mineral wool or fibre product containing silica and alumina in a molar ratio of 2 - 12 in an aqueous solution, nucleating and stabilizing the so obtained solution, and optionally adjusting the dry matter content of the dispersion so obtained. The said dispersion can also be made to gel. The invention is also directed to the use of the dispersion as a binder.

Owner:PAROC GRP OY

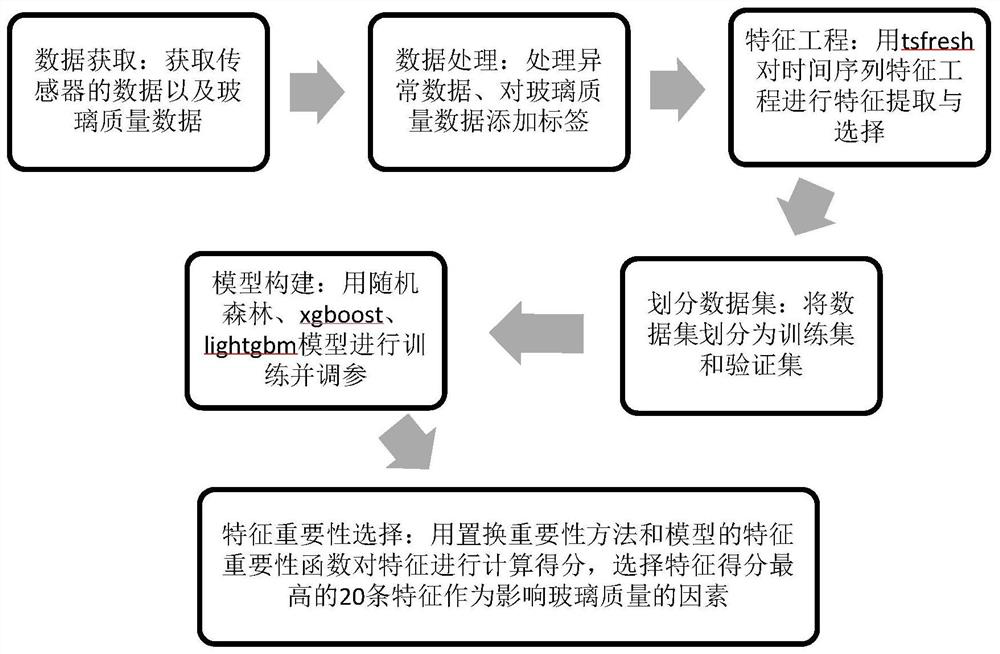

Time sequence classification analysis method and system for glass quality influence factors

ActiveCN112749763AImprove glass qualityEasy to implementEnsemble learningCharacter and pattern recognitionEnvironmental geologyData science

The invention provides a time sequence classification analysis method and system for glass quality influence factors, and the method comprises the steps: obtaining original time sequence data collected by each sensor on a glass production line and corresponding glass quality data, and adding a label to the glass quality data according to a glass quality index; segmenting the time sequence data to correspond to glass quality labels; performing feature construction on the processed time sequence data through data analysis, and analyzing and finding out relatively important time sequence features; dividing a training set and a verification set, respectively using a random forest, xgboost and lightgbm modes to construct a time sequence classification model, and iteratively training the model; the importance score obtained on the basis of a Permutation implication feature selection method and the importance score obtained by weighting results obtained by feature importance functions of corresponding models on the basis of prediction accuracy of a random forest model, an xgboost model and a lightgbm model are integrated, and a factor analysis result influencing the glass quality is obtained so as to correspondingly control factors on a glass production line.

Owner:WUHAN UNIV OF TECH

Glass coating equipment and magnetic fluid sealing device therein

The invention discloses glass coating equipment. The glass coating equipment comprises a coating chamber, a vacuum conversion chamber, a target and a magnetic fluid sealing device; the magnetic fluid sealing device comprises an outer sleeve, a micro screw, an inner shaft, a medium screw and magnetic fluid; the magnetic fluid comprises magnetic powder and interface active agent; the inner shaft is sleeved in the outer sleeve and axially parallel to the outer sleeve; the inner shaft and the outer sleeve are connected and fixed by the micro screw and the medium screw; a clearance is formed between the inner shaft and the outer sleeve; and the magnetic fluid is filled in the clearance between the inner shaft and the outer sleeve. The equipment effectively solves the problems that the vacuum sealing device in the conventional glass coating equipment is easily aged and deformed and leaks air and the like, and realizes high sealing of the target in the glass coating equipment.

Owner:江苏宇天港玻新材料有限公司

Schmelzwanne und glasschmelzanlage

PendingUS20200102240A1Reduce widthReduce flow rateGlass furnace apparatusTank furnacesMelting tankCombustor

A melt tank for the production of a glass melt having a low portion of bubbles. The melt tank includes an inlet opening, an outlet opening, a floor, at least two side walls that adjoin the floor, a roof. The glass melt having a first bath depth in a melting segment, a second bath depth in a refining segment, and a third bath depth over a threshold between and smaller than the first and second bath depths. An electrical produced first heat energy is supplied via a multiplicity of electrodes that extend into the glass melt and a second heat energy is produced by the combustion of fossil fuel via at least one burner. Also, a method for producing a glass melt.

Owner:BETEILIGUNGEN SORG

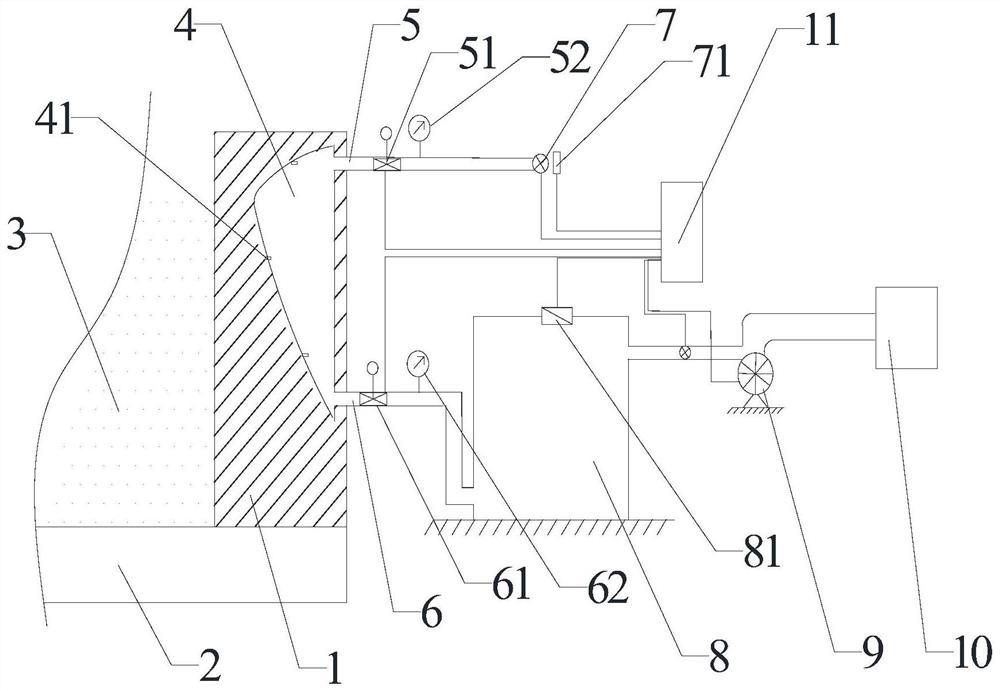

System for effectively controlling erosion of glass melting furnace

The invention relates to the technical field of glass production, in particular to a system for effectively controlling erosion of a glass melting furnace. The system comprises a melting furnace body and a cooling device; the melting furnace body comprises a pool wall brick and a cooling chamber arranged in the pool wall brick; the side wall of the cooling chamber is concaved towards the junction of a glass liquid flushing liquid level in the glass melting furnace and a pool wall brick in an arc shape, and the cooling device comprises a PLC, a chamber temperature sensor, a cooling air fan, a cooling air inlet pipe and a cooling air outlet pipe. The invention has the beneficial effects that intelligent digital integrated fine monitoring and precise control are realized by arranging a novel glass melting furnace pool wall brick structure with a special cooling chamber and an auxiliary cooling device; and the effect that the pool wall is not eroded or is less eroded can be achieved.

Owner:福州新福兴玻璃科技有限公司 +4

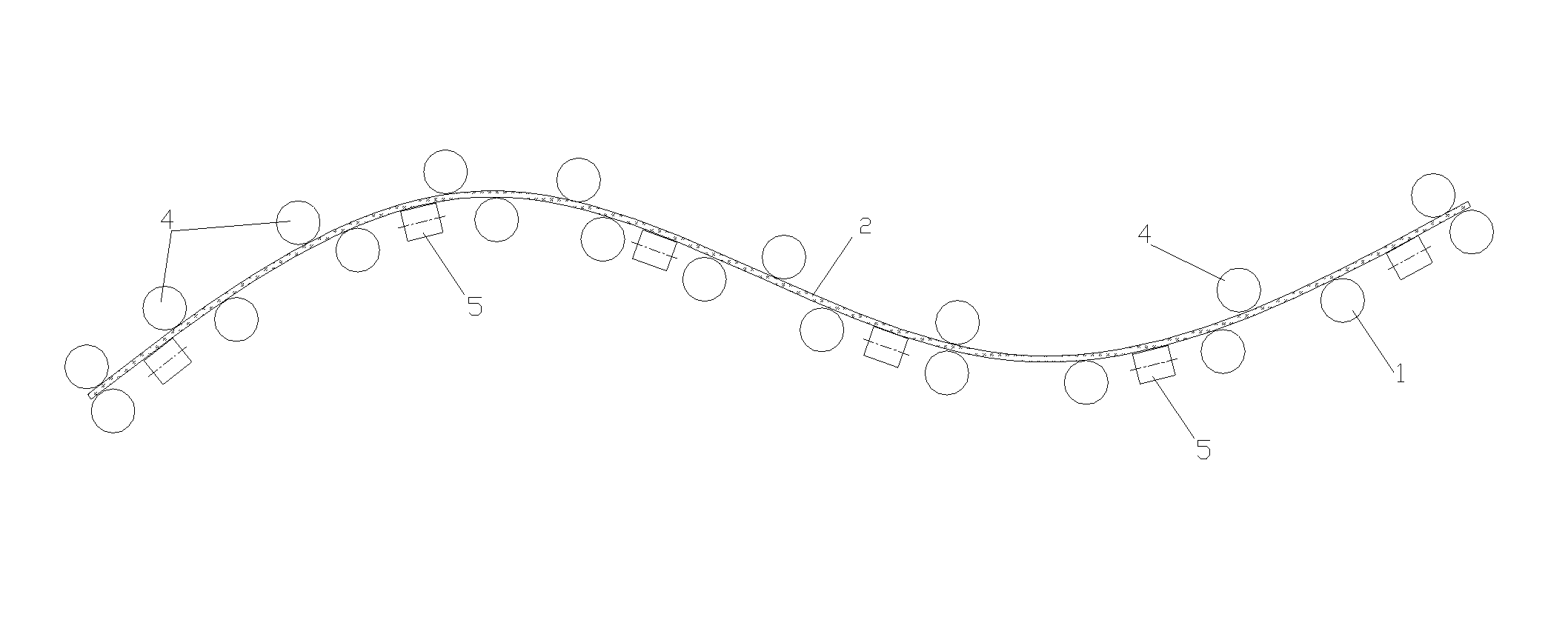

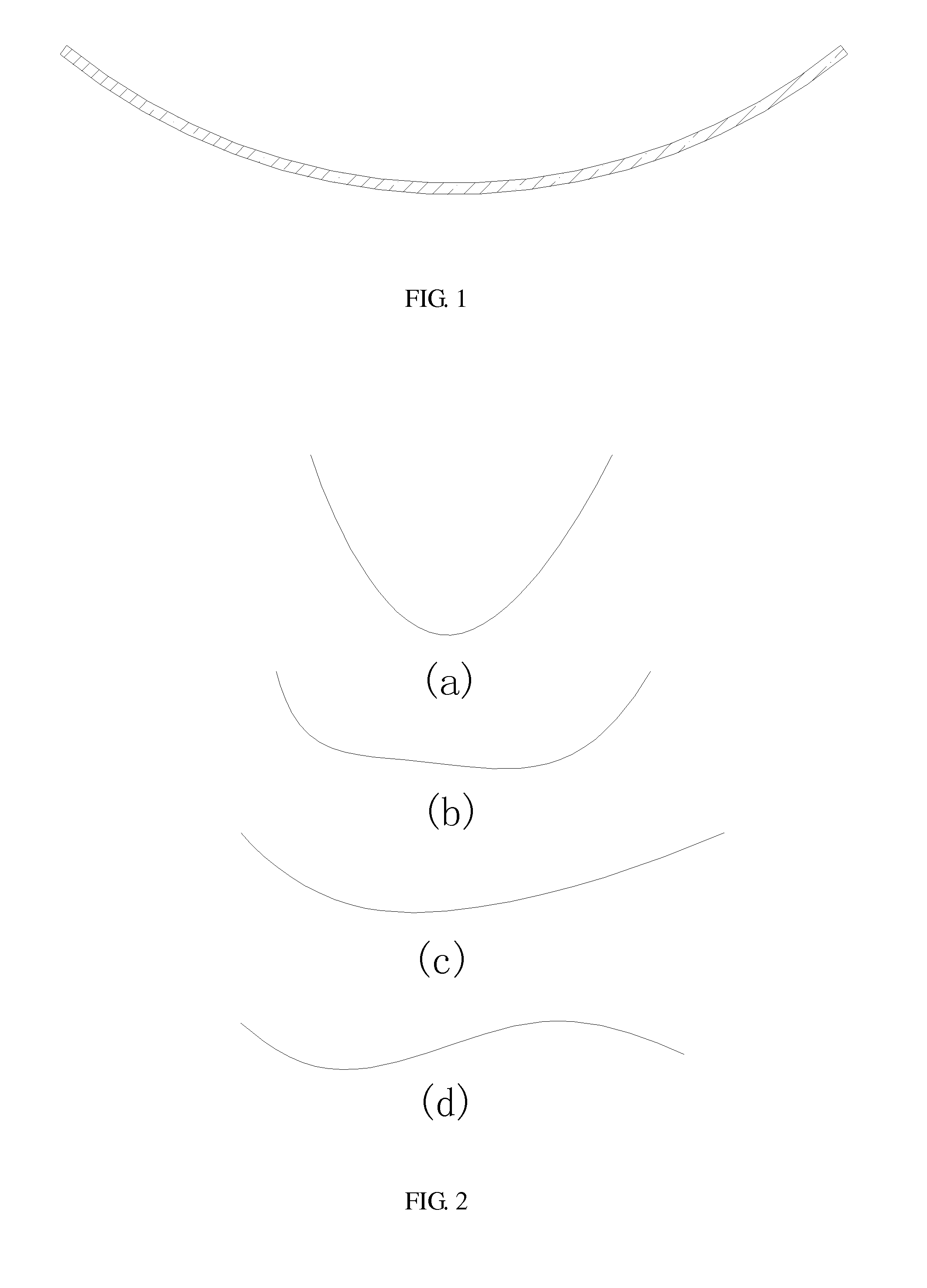

Curved glass flexible shaft bending tempering forming method

ActiveCN111423103AGood for production efficiencySolve technical problems that are difficult to formGlass transportation apparatusGlass reforming apparatusHeating furnaceTempering

The invention discloses a curved glass flexible shaft bending tempering forming method. When in production of the curved glass, after the glass is discharged from a heating furnace, the glass is preformed in the trend that the two side parts in the transverse direction are kept on the same plane and the middle part in the transverse direction gradually sinks along the conveying direction, then enters a forming and toughening section under the condition that the two side parts in the transverse direction are supported, and is finally formed and toughened to finish the bending and toughening manufacturing of the curved glass. After the method is adopted, when the glass gradually becomes arc and enters the forming tempering section, the flexible shaft roller ways are always arranged at the two side parts of the glass in the transverse direction to be used as supports, and the edge parts are not suspended, so that the wave bending phenomenon of the edge parts is eliminated.

Owner:LUOYANG LANDGLASS TECH CO LTD

One kiln multi-line molten glass shunt melting furnace

ActiveCN111333306BImprove uniformityImprove glass qualityGlass furnace apparatusHalogen/halogen-acidsFlat glassMaterials science

The invention discloses a one-kiln multi-line molten glass shunting melting furnace, which comprises a melting part, a neck, a working part and branch paths, wherein the melting part is communicated with the working part through the neck, the melting part is used for heating, melting and clarifying molten glass, the front portion of the working part is wide, the rear portion of the working part isnarrow, and a plurality of the branch paths are arranged on two sides of the working part. According to the invention, the novel one-kiln multi-line molten glass shunting melting furnace can meet thelow-energy-consumption plate glass production of a 800-1250 ton large-tonnage melting furnace, can improve the uniformity of molten glass in each branch path and the glass quality, and can effectively solve the quality problems of large temperature difference of molten glass in each branch path, poor uniformity and the like in the molten glass shunting process of a one-kiln multi-line melting furnace, particularly a one-kiln melting furnace with more than four lines.

Owner:北海长利新材料科技有限公司

Touch screen glass laminate processing method capable of improving efficiency

The invention relates to touch screen glass processing and specifically relates to a touch screen glass laminate processing method capable of improving efficiency. The touch screen glass laminate processing method comprises the following steps: (1), horizontally fixing a piece of touch screen glass firstly, then, dropwise adding hydrolysable UV (ultraviolet) glue on the glass in the shape of two Ys, covering the other piece of touch screen glass on the touch screen glass which is dropwise added with the hydrolysable UV glue, enabling the touch screen glass to sufficiently contact with the degradable UV glue, and superposing and adhering the two pieces of touch screen glass; (2), carrying out UV radiation onto the superposed touch screen glass for curing and fixing; (3), cutting the fixed superposed touch screen glass into shapes according to processing needs; (4), placing the cut superposed touch screen glass in hot water of 85 DEG C-95 DEG C for cooking for 50 minutes-60 minutes; and (5), peeling off and flaking the superposed touch screen glass. The touch screen glass laminate processing method provided by the invention is free of corrosion and damages on glass, improves machining efficiency and glass quality very well, and greatly reduces a breakage rate in a cutting and processing process.

Owner:文仁光

Glass and preparation method thereof

InactiveCN111662010AIncrease temperatureReduce the effect of transmission streaksMineralogySoftening point

The invention relates to the technical field of glass preparation, and provides glass and a preparation method thereof. The glass provided by the invention is prepared from SiO2, Al2O3, CaO, MgO, Na2Oand Fe2O3, in terms of 71.9 to 72.1 parts by weight of SiO2, the content of Al2O3 is 1.25 to 1.35 parts, the content of CaO is 8.65 to 8.75 parts, the content of MgO is 3.35 to 3.45 parts, the content of Na2O is 13.4 to 13.6 parts, and the content of Fe2O3 is 0.595 to 0.605 part. The components and the content of the glass are adjusted; the softening point temperature and the hardening forming temperature of the glass are effectively increased under the condition that the original main body performance of the glass is kept unchanged, and the influence of a forming area in a float process on glass transmission stripes is reduced by promoting rapid forming and hardening of the glass, so that the quality of the glass transmission stripes is improved.

Owner:XINYI GLASS (TIANJIN) CO LTD

Method for manufacturing columnar curved tempered glass

ActiveUS20150047395A1Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

The present invention discloses a method for processing a columnar curved tempered glass. The method specifically comprises the following steps. Bending and tempering of the high temperature flat glass are divided into two stations. Bending is firstly carried out on the high temperature flat glass output by a heating furnace; the columnar extending direction of the curved glass is perpendicular to the direction the glass output from the heating furnace in the bending process, and then the formed curved glass is output to a tempering station in the columnar extending direction thereof to undergo tempering. In the present invention, bending and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending and tempering are carried out by a single bending device intensively, thereby providing a novel technological approach for processing the columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

Glass fiber

The invention relates to the technical field of inorganic non-metallic materials, in particular to a glass fiber. The glass fiber comprises the following compositions of 52-59 wt% of SiO2, 13-18 wt% of Al2O3, 12-19.9 wt% of CaO, 0.5-9 wt% of MgO, 0.1-4 wt% of B2O3, 0.1-1.2 wt% of of TiO2, 0.1-0.8 wt% of Fe2O3 and 0.1-0.8 wt% of of Na2O and K2O in total. According to the glass fiber, the matching relation of all the compositions in the glass is accurately controlled so that the glass fiber can be ensured to have excellent formability, introduction of F2 is canceled, introduction of B2O3 is reduced, and the raw mineral material cost is greatly reduced. The experiment result shows the forming temperature of the glass fiber is not larger than 1,210 DEG C, and the devitrification ceiling temperature is lower than 1,100 DEG C.

Owner:CHONGQING POLYCOMP INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com