Photovoltaic glass edge portion defect detection system and corresponding method

A photovoltaic glass and defect detection technology, which is applied in the direction of optical defect/defect detection, image data processing, instruments, etc., can solve problems such as missed detection and worker fatigue, and achieve the effects of improving detection efficiency, reducing labor waste, and reducing detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to describe the technical content of the present invention more clearly, further description will be made below in conjunction with specific embodiments.

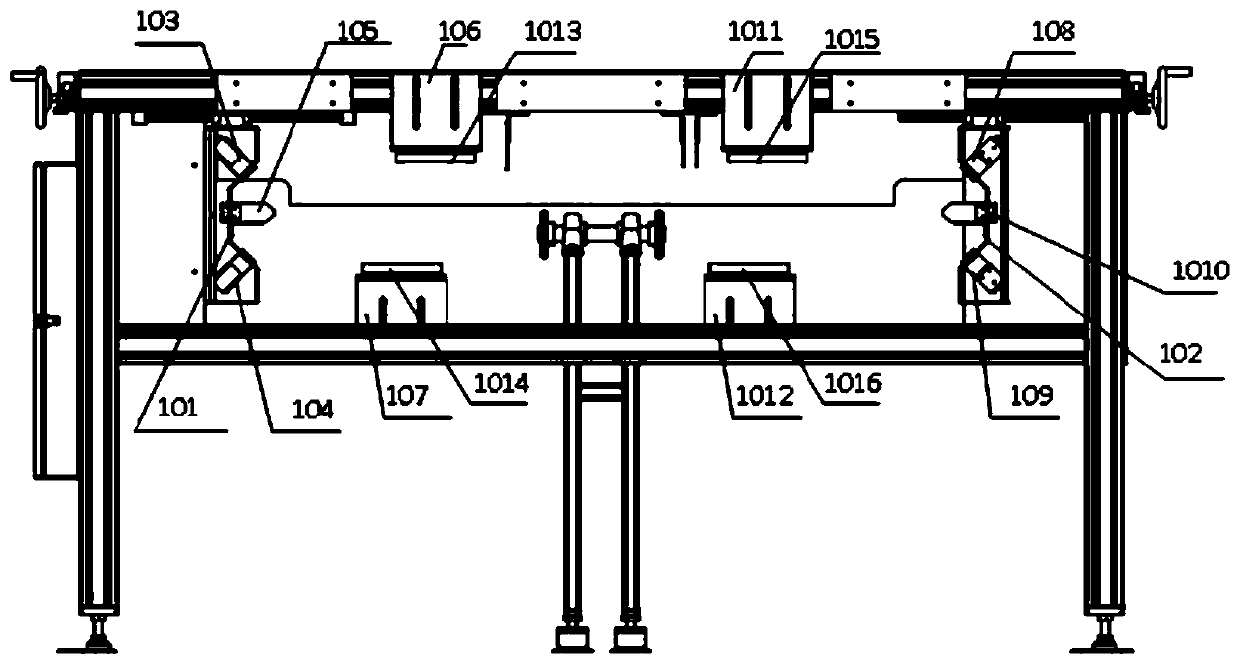

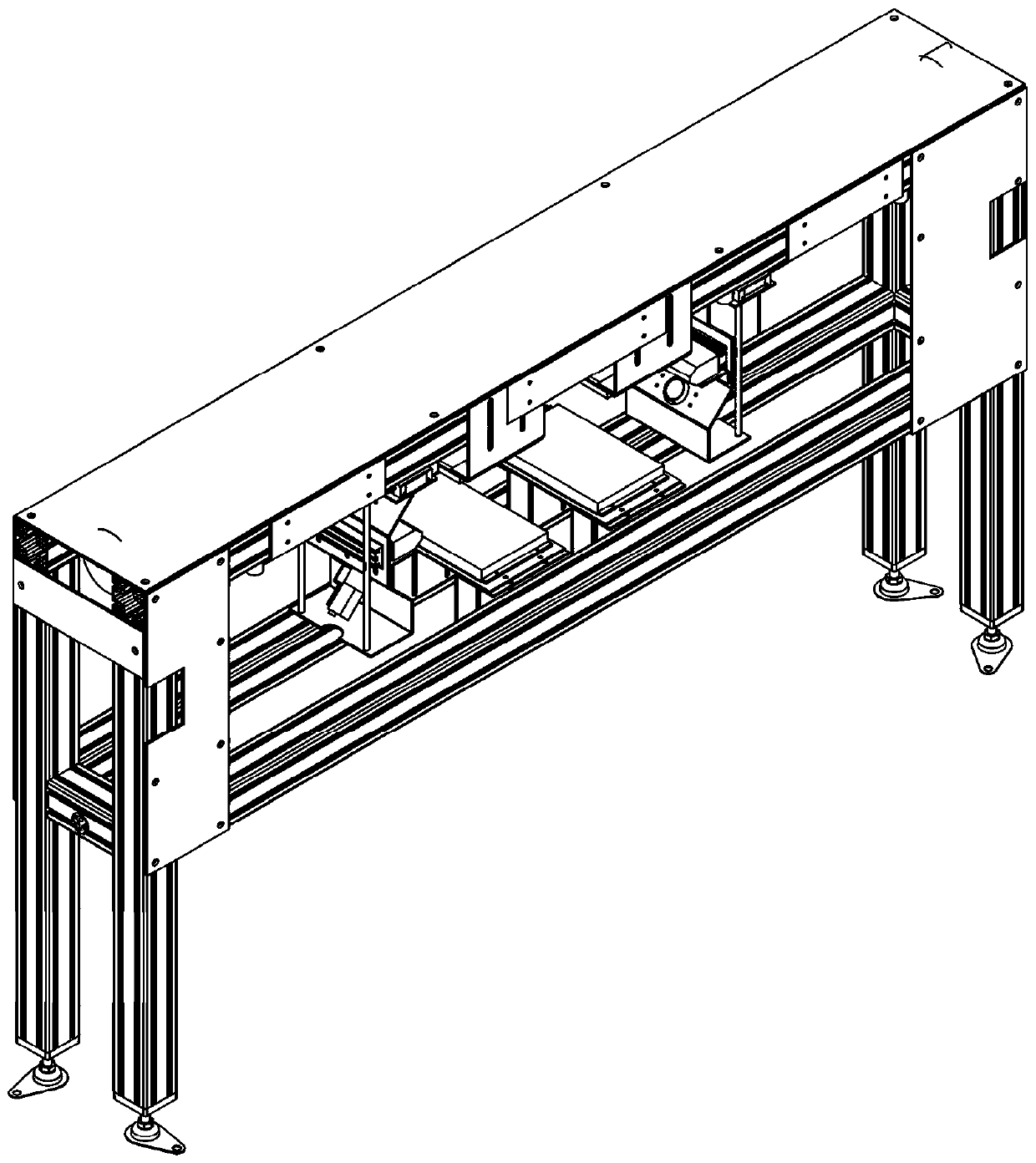

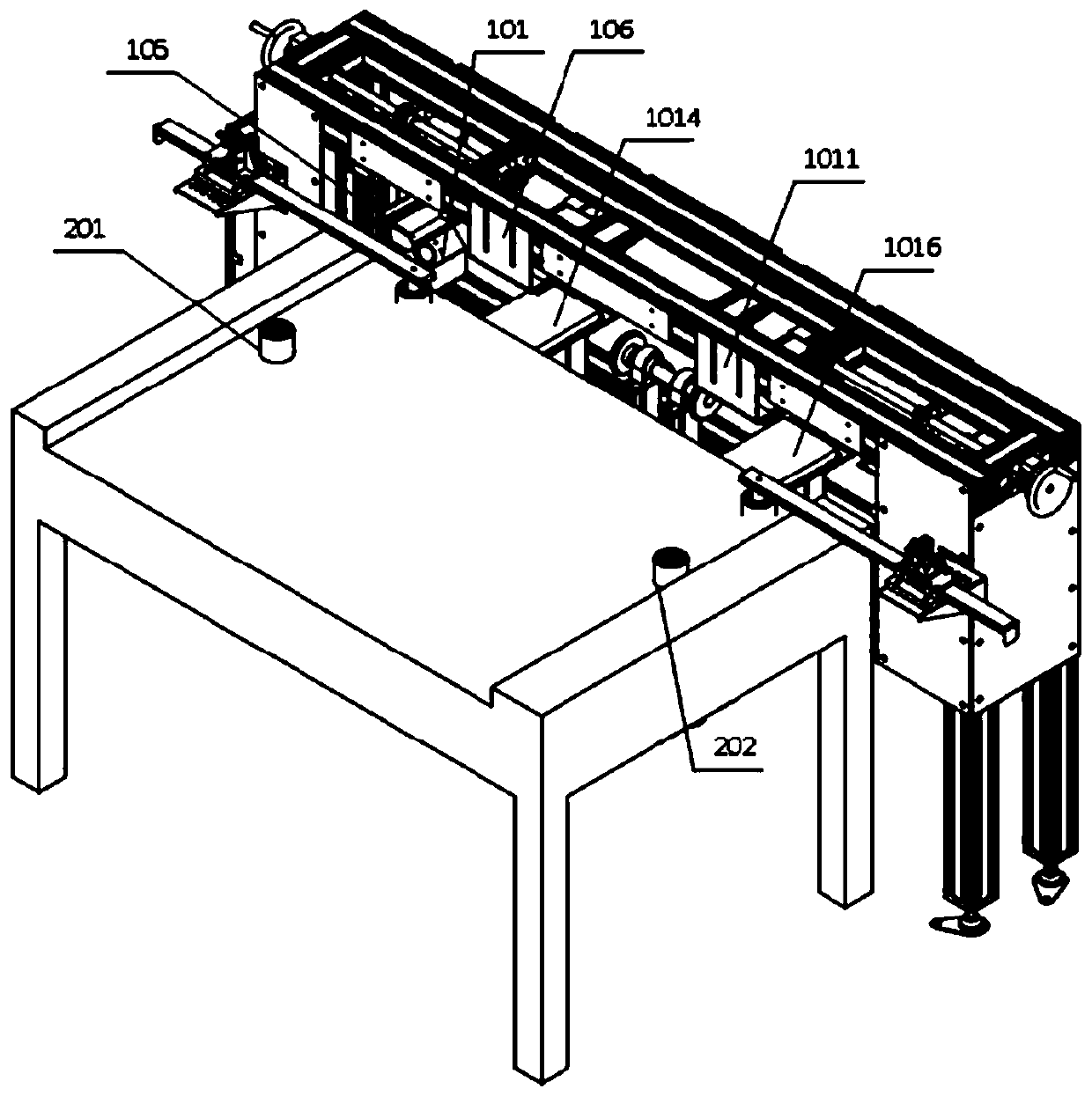

[0077] Such as figure 1 , 2 As shown, in this embodiment, the photovoltaic glass edge defect detection system is installed on the production roller table of photovoltaic glass, wherein the system includes:

[0078] A mechanical frame, through which the system is installed on the production roller table of the photovoltaic glass;

[0079] The light source module is used to provide light sources for the upper surface, lower surface and side surfaces of the photovoltaic glass, that is, the light source module is a device for setting a light source on the edge of the photovoltaic glass for lighting, and the light source module is installed on the on the mechanical frame;

[0080] The camera module is used to photograph the photovoltaic glass to generate a picture corresponding to the photovoltaic glass, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com