Method and equipment for improving glass quality

A glass, quality technology, used in/or other glass substrates, clarification and homogenization, the production of glass substrates, can solve the problems of uneven temperature of glass liquid, high temperature of molten glass, stripes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

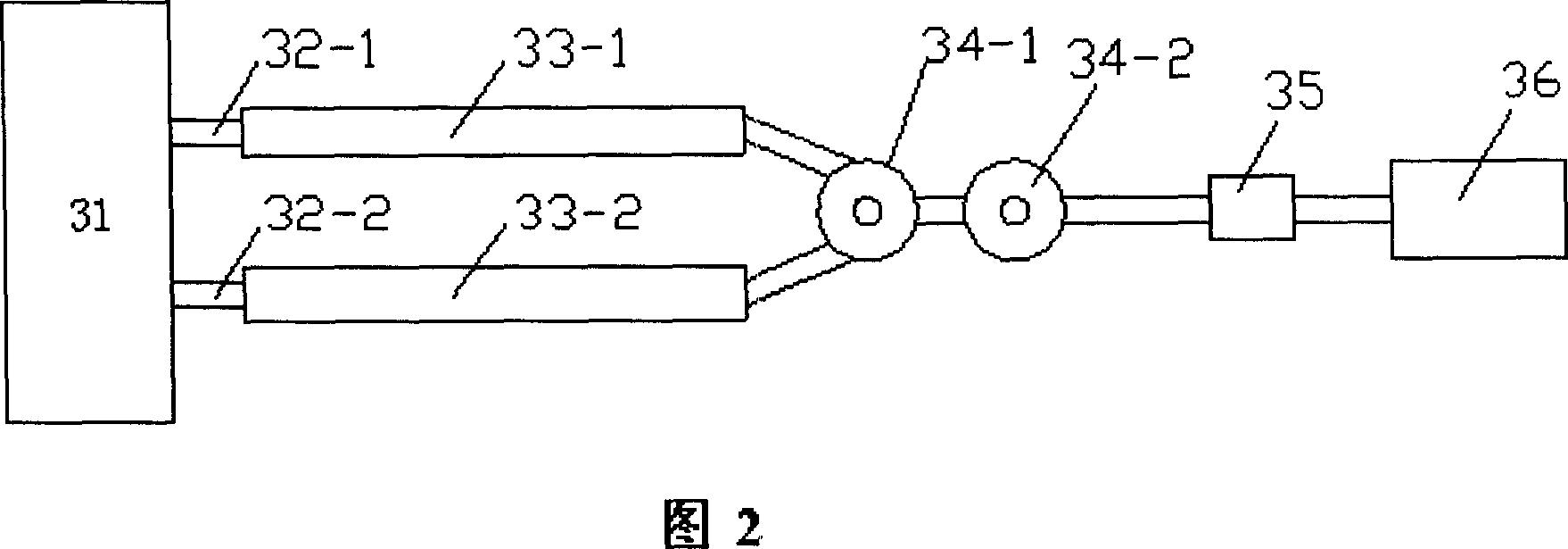

[0075] As shown in Figure 2, this example is 2 parallel clarification zones. Under the condition that the glass flow rate is 10 tons / day, the clarification zone is designed as a cylindrical shape. According to certain experiences and theories, the diameter, wall thickness and length of the clarification zone are determined as shown in the corresponding row of Example 2 in Table 1. Compared with Comparative Example 1, the amount of precious metal used in Example 2 is 20.48 kg less; the glass temperature difference is reduced from ±3°C to ±1°C; the number of bubbles larger than 0.1mm per kilogram of glass plate does not exceed 0.5; the clarification zone The operating temperature can drop from 1680°C to 1650°C; the life of the clarification zone is extended from 21 months to 26 months.

Embodiment 3

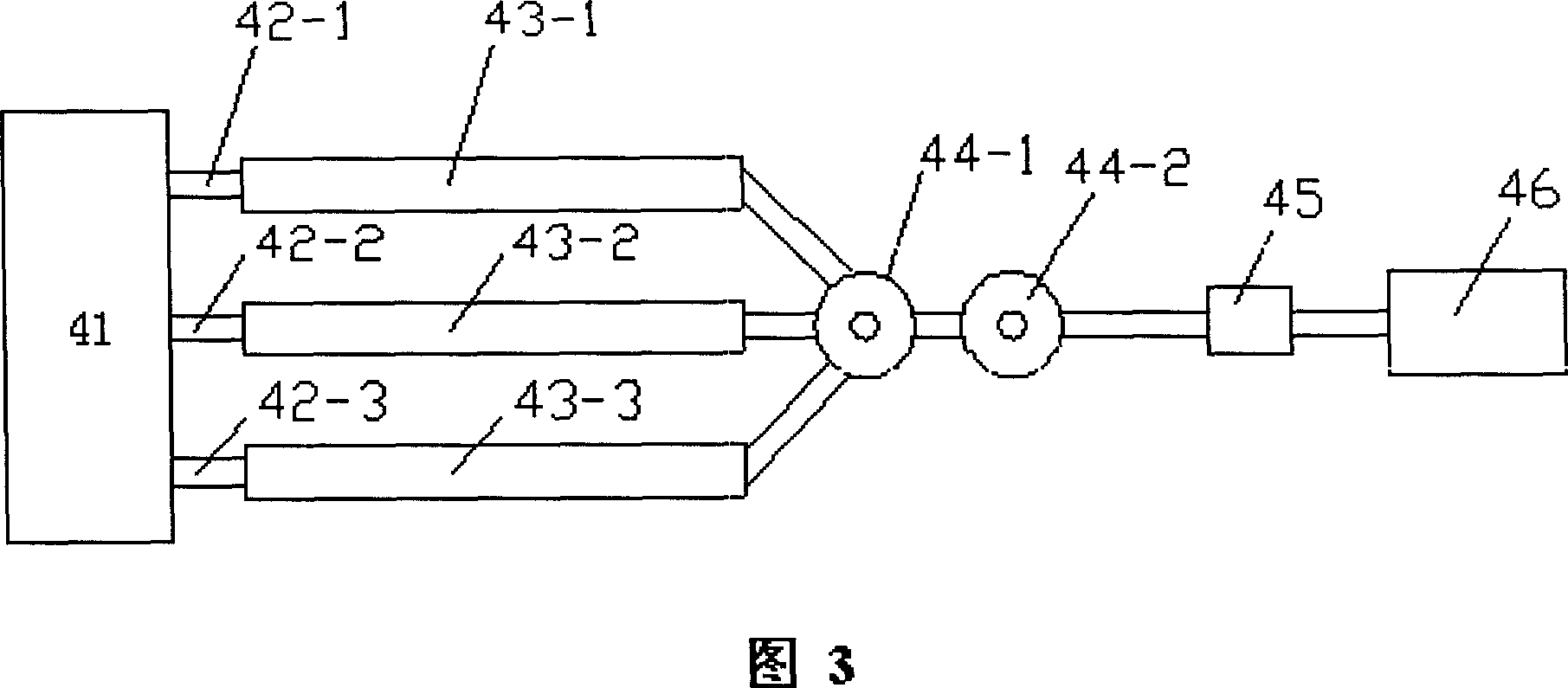

[0077] As shown in Figure 3, this example is three parallel clarification zones. Under the condition that the glass flow rate is 10 tons / day, the clarification zone is designed as a cylindrical shape. According to certain experiences and theories, the diameter, wall thickness and length of the clarification zone are determined as shown in the row corresponding to Example 3 in Table 1. Compared with Comparative Example 1, the amount of precious metal used in Example 3 is 36.65 kg less; the glass temperature difference is reduced from ±3°C to ±0.7°C; the number of bubbles larger than 0.1mm per kilogram of glass plate does not exceed 0.2; the clarification zone The operating temperature dropped from 1680°C to 1620°C, and the lifetime of the clarification channel was extended from 21 months to 26.5 months.

[0078] Through the above examples, it can be clearly seen that when the flow rate of glass is 10 tons / day, the two embodiments of the parallel clarification zone are more eff...

Embodiment 5

[0082] As shown in Figure 2, this example is 2 parallel clarification zones. Under the condition that the glass flow rate is 12 tons / day, the clarification zone is designed as a cylindrical shape. According to certain experiences and theories, the diameter, wall thickness and length of the clarification zone are determined as shown in the corresponding row of Example 5 in Table 1. Compared with Comparative Example 4, the amount of precious metal used in Example 5 is 35.68 kg less; the glass temperature difference is reduced from ±3.3°C to ±1.5°C; the number of bubbles larger than 0.1mm per kilogram of glass plate does not exceed 0.6; the clarification zone The operating temperature can drop from 1680°C to 1650°C; the life of the clarification zone is extended from 19 months to 24.5 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com