Curved glass flexible shaft bending tempering forming method

A technology of curved glass and molding method, which is applied in the direction of glass tempering, glass molding, glass remolding, etc., can solve the problems of difficult molding of glass edges, etc., and achieve the effect that is beneficial to production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

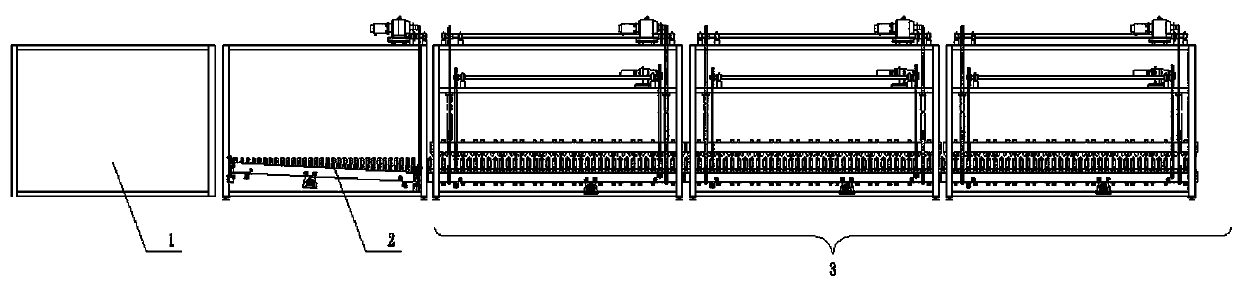

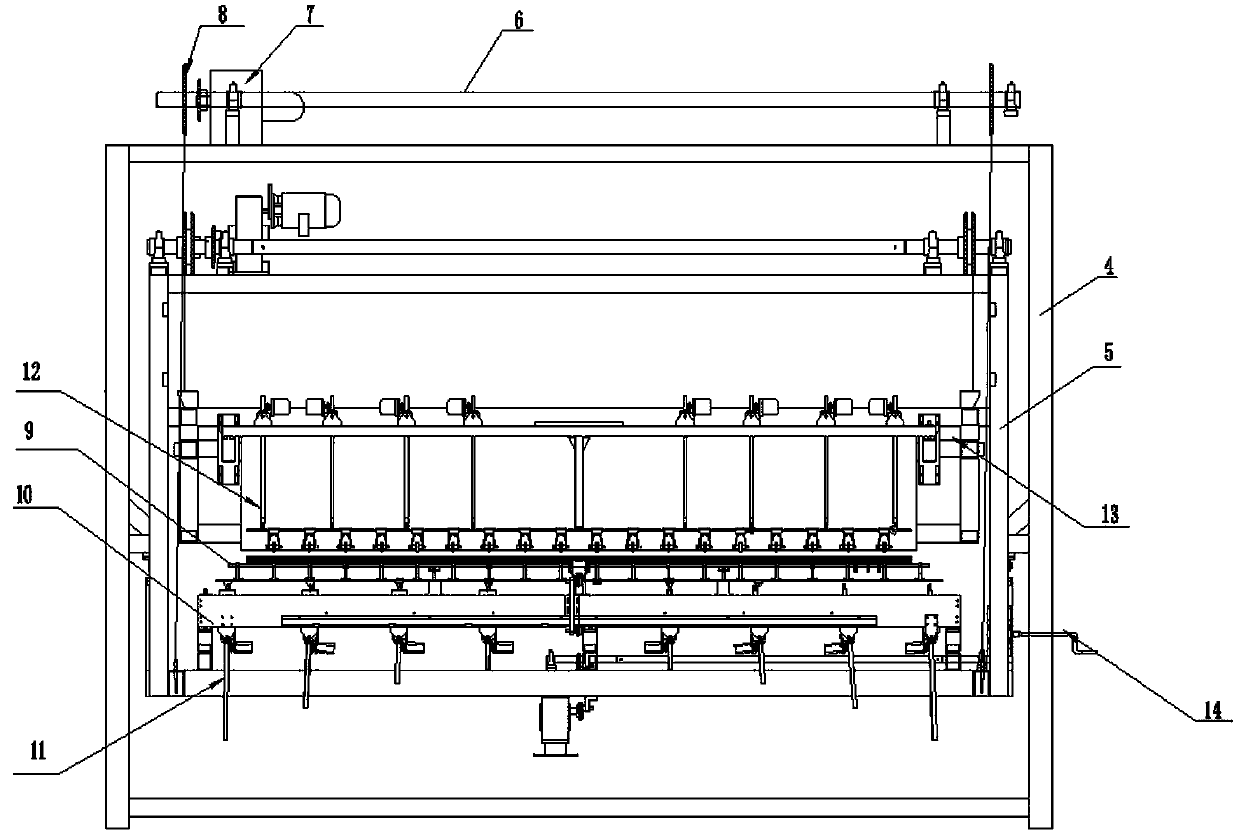

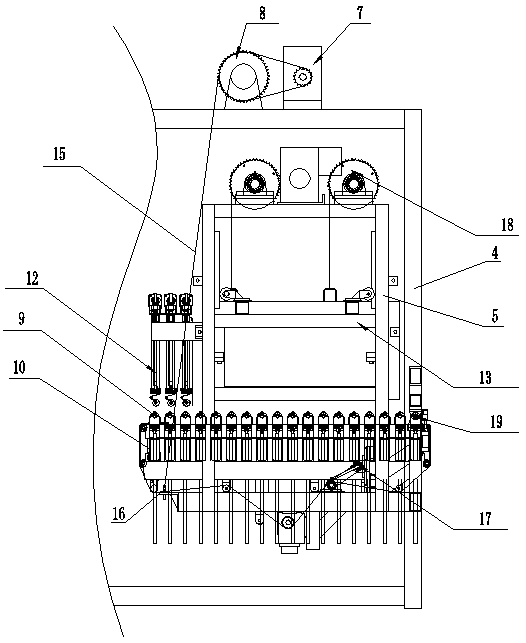

[0046] Embodiment 1: as figure 2 , 3 As shown, the transition section 2 includes a main frame 4 and a sub-frame 5, and a plurality of aluminum profile square tubes 10 are fixedly arranged at intervals along the glass conveying direction on the sub frame 5, and each aluminum profile square tube 10 is correspondingly arranged A flexible shaft roller table 9 parallel to it, and the corresponding gradual arc mechanism 11 realizes the bending of the flexible shaft roller table 9 into an arc, and the roller table surface formed by multiple flexible shaft roller tables 9 in a straight line state It is coplanar with the inner roller surface of the heating furnace 1; the end of the sub-frame 5 close to the heating furnace 1 is rotatably connected with the main frame 4 in a hinged manner, and its rotation axis and the first flexible shaft roller in a straight state The central axis of the road 9 is collinear and parallel to the ceramic roller table 25 of the heating furnace 1, and the...

Embodiment 2

[0057] Embodiment 2: In this embodiment, the arrangement of the flexible shaft roller table 9 and the gradual arc-changing mechanism 11 is different from that of Embodiment 1, and the rest of the structure is the same.

[0058] In this embodiment, the aluminum profile square tubes 10 are arranged on the sub-frame 5 at intervals along the direction perpendicular to the glass conveying direction, the length direction of the aluminum profile square tubes 10 is consistent with the glass conveying direction, and the flexible shaft roller table 9 is perpendicular to the aluminum profile square tube 10 are set, and each flexible shaft roller table 9 is rotatably installed on a plurality of aluminum profile square tubes 10 through the roller table seat.

[0059] The gradual arcing mechanism 11 adopts a chain plate structure 22 commonly used in the field, which can also be called a tooth plate structure. The chain plate structure 22 can be provided with two groups, which are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com