A kind of drain brick and its preparation method

A technology of pure calcium aluminate cement and particle size, which is applied in the field of refractory materials, can solve the problems of high cost of drain bricks, and achieve the effects of low cost, uniform overall performance, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

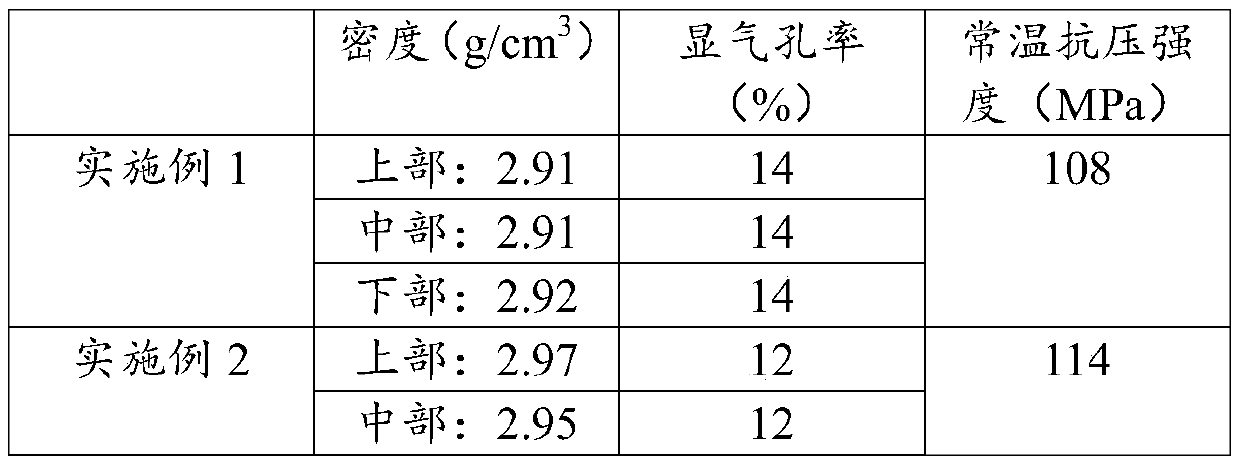

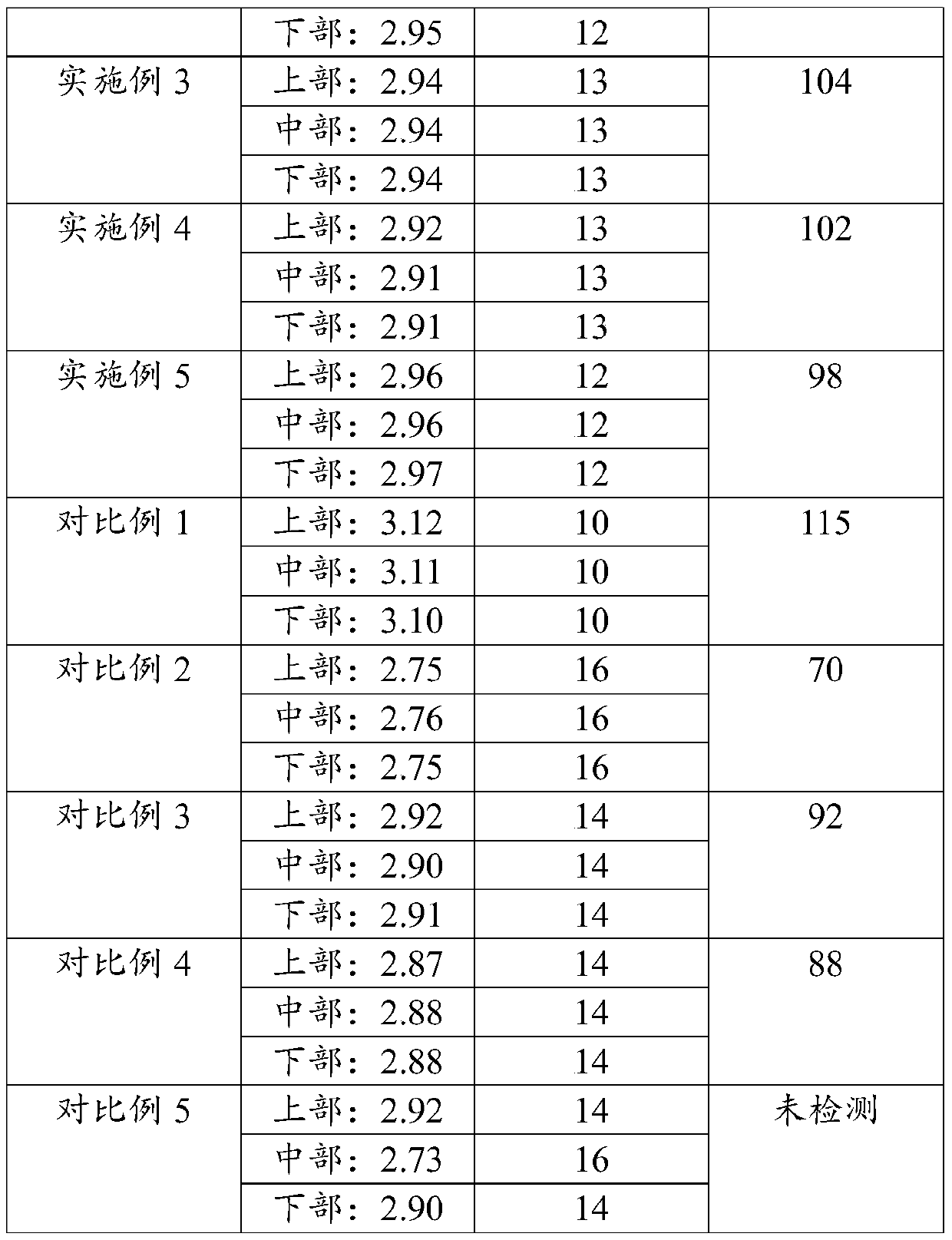

Examples

Embodiment 1

[0040] Prepare the drain bricks as follows:

[0041] 1. Weigh the following raw materials and mix them evenly:

[0042] Homogenized bauxite clinker 60Kg, wherein, Al in the homogenized material 2 o 3 The mass fraction is 78%. The homogenized material is composed of a homogenized material with a particle size of 5-3 mm, a homogenized material with a particle size of 3-1 mm, and a homogenized material with a particle size of 1-0 mm. The mass ratio 1:2:2, the density of the homogenized bauxite clinker is 2.8g / cm 3 ;

[0043] 20Kg of corundum, wherein the corundum is composed of corundum with a particle size of 1-0mm and corundum powder with a particle size of 240 mesh, the corundum with a particle size of 1-0mm and the corundum with a particle size of 240 mesh The mass ratio of the powder is 1:3, the corundum is white corundum, and the density of the corundum is 3.5g / cm 3 ;

[0044] Spinel 10Kg, the particle size of described spinel is 310 orders;

[0045] Al 2 o 3 20Kg...

Embodiment 2

[0051] Referring to the method described in Example 1 to prepare the drain brick, the only difference is that the ratio of the amount of each raw material is different (the particle size of each raw material is the same as that of Example 1), specifically, the homogenized bauxite clinker 50Kg , corundum 25Kg, spinel 15Kg, Al 2 o 3 25Kg, pure calcium aluminate cement 3Kg, silicon dioxide 1Kg and ADS 0.2Kg; Wherein, in the described homogenized alumina clinker, Al 2 o 3 The quality score is 75%.

Embodiment 3

[0053] Referring to the method described in Example 1 to prepare the drain brick, the only difference is that the ratio of the amount of each raw material is different (the particle size of each raw material is the same as that of Example 1), specifically, the homogenized bauxite clinker 70Kg , corundum 15Kg, spinel 8Kg, Al 2 o 3 15Kg, pure calcium aluminate cement 8Kg, silicon dioxide 2Kg and ADS 0.1Kg; Wherein, in the described homogeneous bauxite clinker, Al 2 o 3 The quality score is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com