Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Guaranteed fire resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molding sand and preparation method

ActiveCN1872450AImprove surface qualityThe preparation method is reasonableFoundry mouldsFoundry coresHigh surfaceGraphite

A moulding sand is prepared from zircon sand (or powder), graphite powder and water glass through proportionally and sequentially mixing. Its advantages are high surface quality of casting mould and high refractory performance.

Owner:武汉重工铸锻有限责任公司

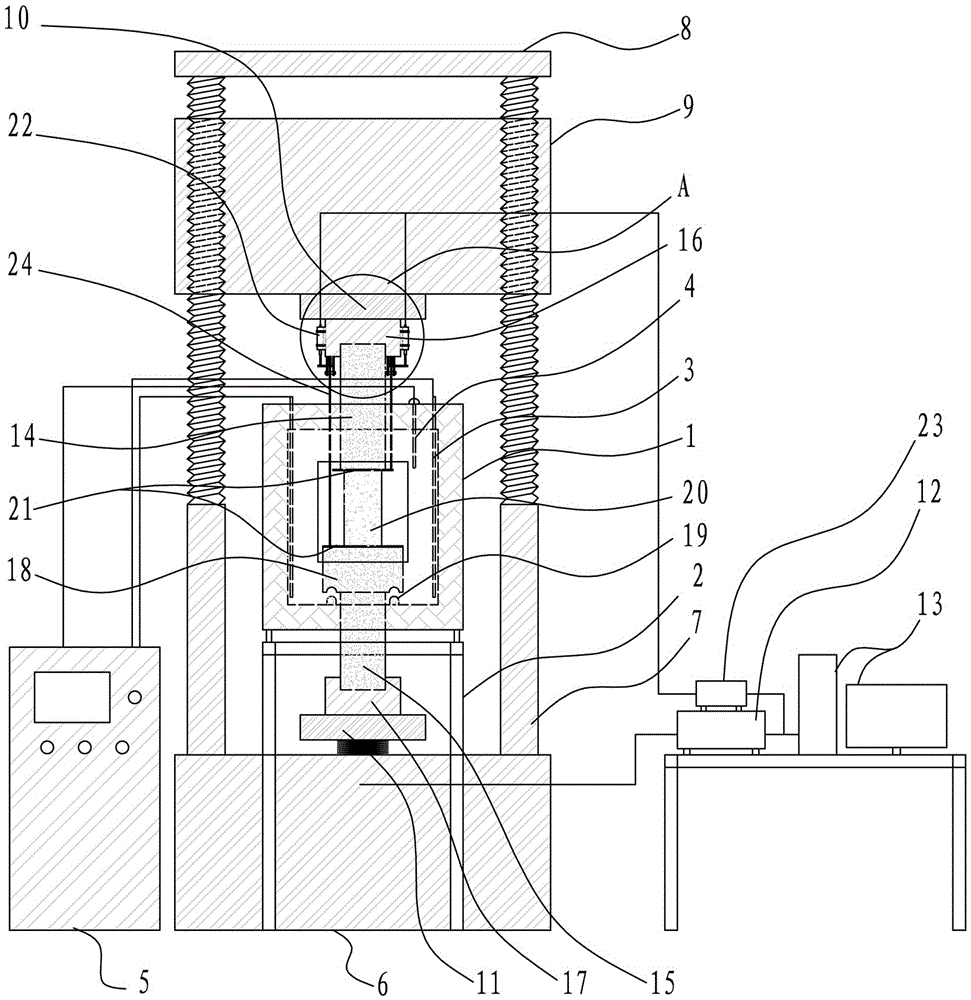

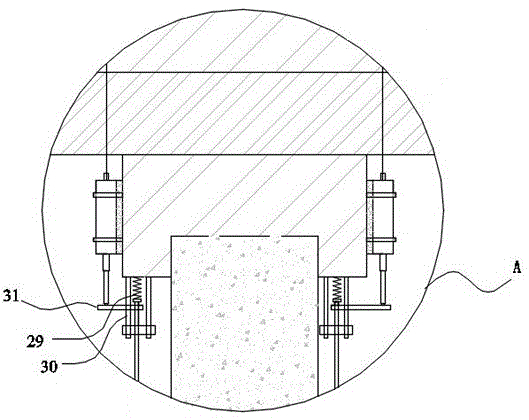

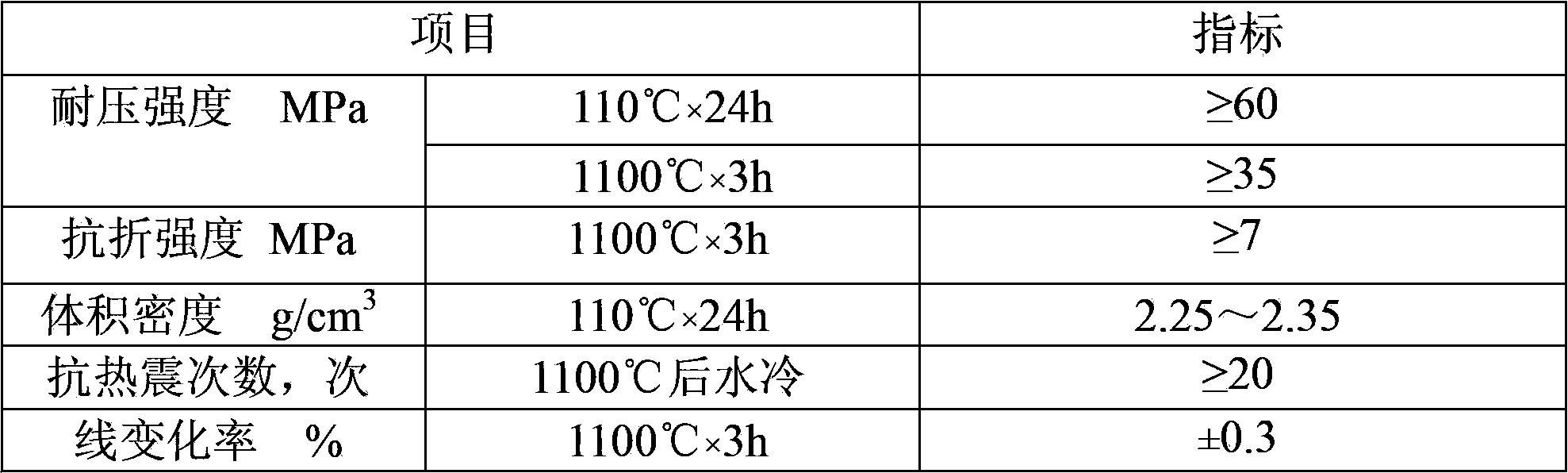

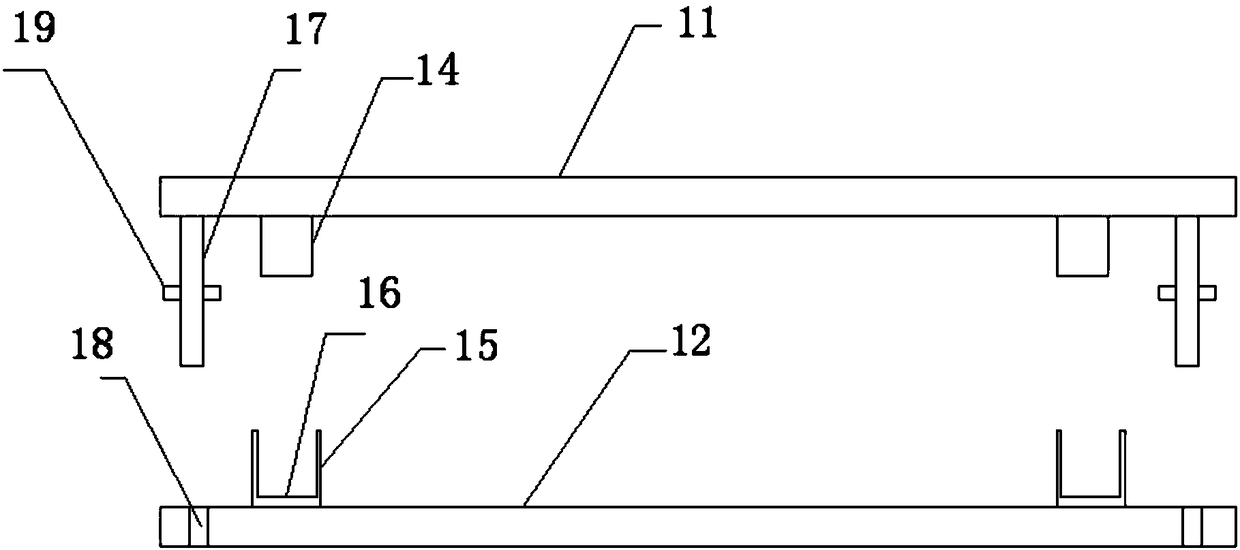

Concrete material in-high-temperature compression testing machine and in-high-temperature compression testing method

ActiveCN105424498AGuaranteed high temperatureGuaranteed fire resistanceMaterial strength using tensile/compressive forcesEngineeringFire resistance

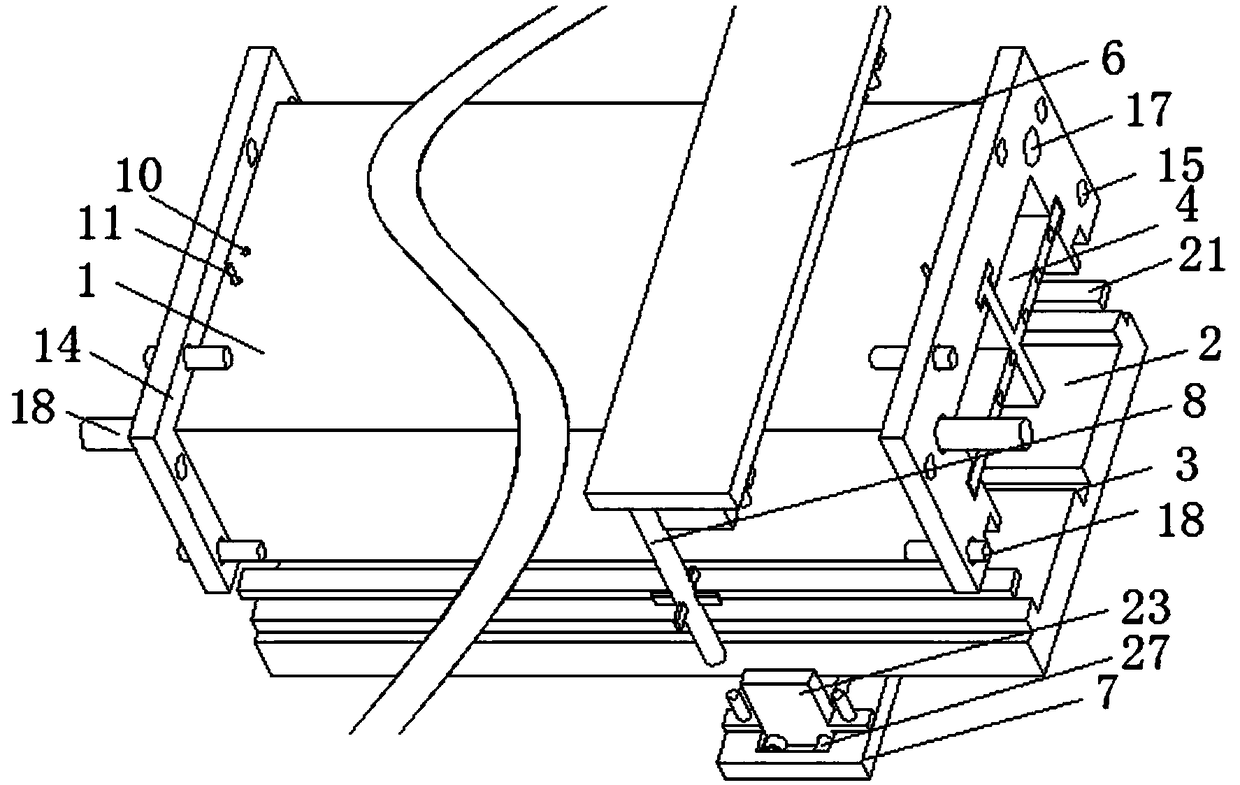

The invention provides a concrete material in-high-temperature compression testing machine and an in-high-temperature compression testing method. The concrete material in-high-temperature compression testing machine comprises loading equipment for applying pressure on a concrete test-piece, heating equipment for heating the concrete test-piece, and a displacement acquisition device for measuring the deformation of the concrete test-piece. According to the concrete material in-high-temperature compression testing machine, the heating equipment and the loading equipment for concrete testing are skillfully combined together, and are assisted by the displacement acquisition device, so that a comprehensive testing system capable of being used for concrete test-piece in-high-temperature compression testing is formed, synchronization of heating and loading is realized, a concrete environment in high temperature due to fire can be truly simulated, a test result obtained by performing a concrete material test through the concrete material in-high-temperature compression testing machine is very close to actual compressive property of concrete in high temperature due to fire, and a guarantee is provided for researching high temperature performance and fire resistance of a concrete material.

Owner:HENAN INST OF ENG +1

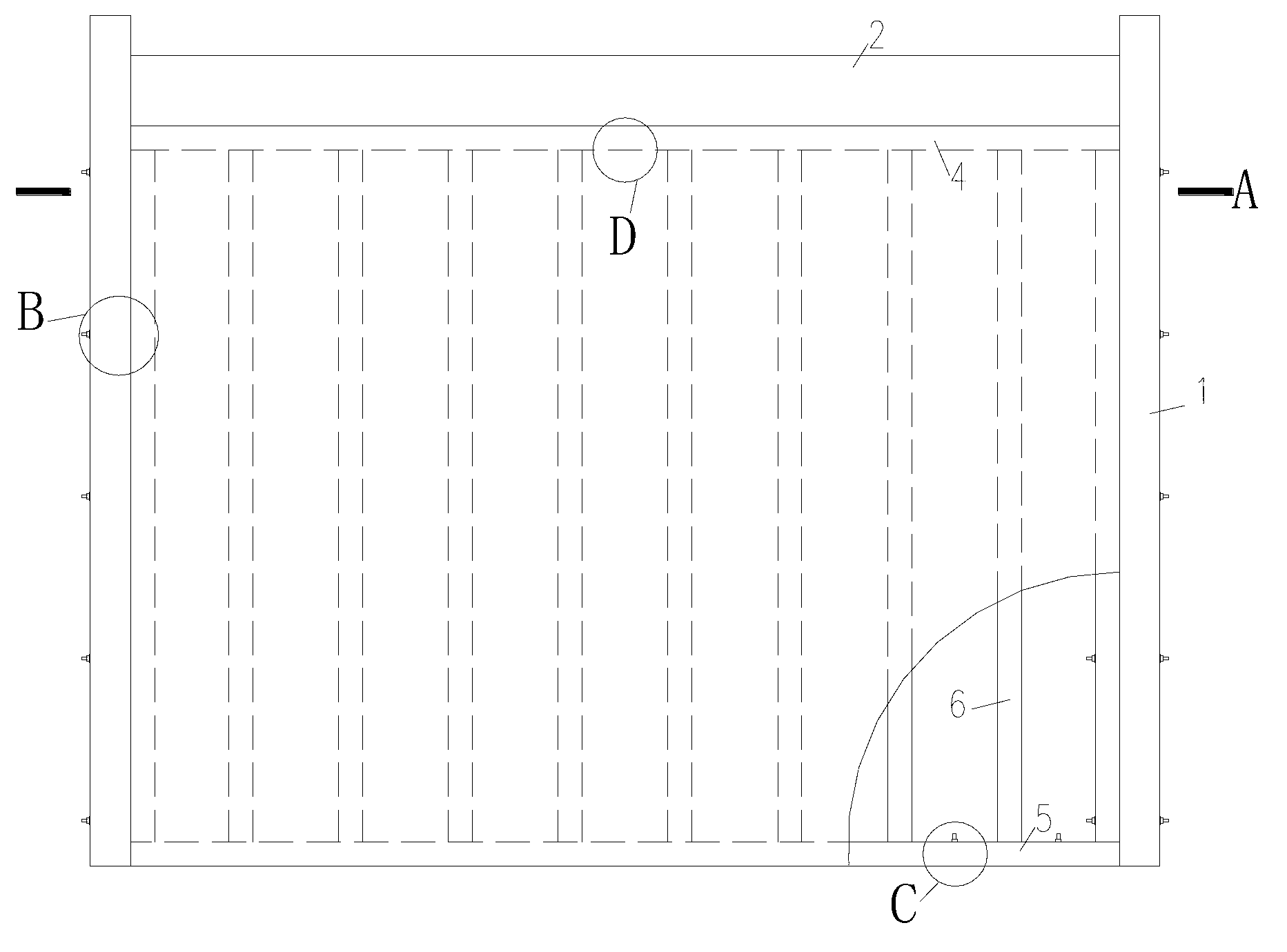

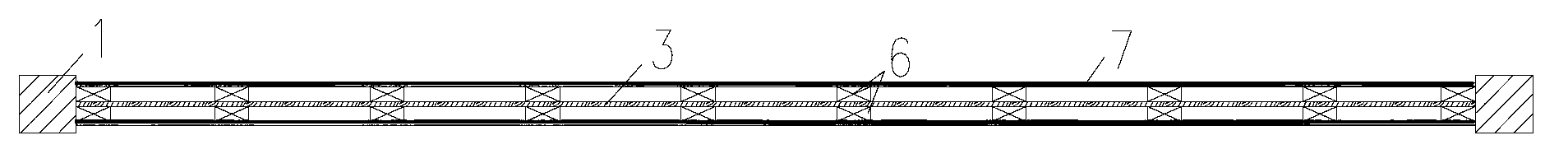

Wood frame shear wall

The invention discloses a wood frame shear wall which comprises a wood frame column, a wood frame beam, a wood-base structural slab, a top beam plate, a bottom beam plate, studs and a gypsum board, wherein the wood-base structural slab is arranged in the middle of the wall; the plurality of studs are respectively arranged between the top beam plate and the bottom beam plate, thus forming stud frames; the stud frames are symmetrically arranged at the two sides of the wood-base structural slab; the peripheries of the stud frames are connected with the wood frame beam and the wood frame column through bolts; and the gypsum board is arranged at the outer sides of the stud frames, and the edge of the gypsum board is parallel and level to the outer sides of the stud frames. According to the wood frame shear wall, a shingle and the studs are integrated into a whole. The wood frame shear wall is large in lateral rigidity resistance and good in ductility, has high lateral resistance and energy-dissipating capacity, can favorably make breakthrough in height and span of a timber architecture. The wood frame shear wall is wide in application prospect, can be applied to multi-floor and medium and high-rise wood frame structure buildings, and remarkably improves the lateral resistance of the whole structure.

Owner:南京工业大学建筑设计研究院有限公司

Window structure body

InactiveCN104662248AMake sure to look outPrevent snoopingMechanical apparatusMirrorsOptoelectronicsGlass sheet

Owner:MIRAI KIKAKU

Sound absorption wall

The invention discloses a sound absorption wall, which comprises an inner wall, alkali-free glass sound absorption cotton, metal acoustical boards and keels, wherein embedded elements are arranged in the inner wall; the keels are welded on the embedded elements; the metal acoustical boards are fixed on the keels through screw bolts and screw nuts; and a position between the inner wall and the metal acoustical boards is filled with the alkali-free glass sound absorption cotton. The metal acoustical board perforation rate of the sound absorption wall can reach 40 percent or above. Compared with the prior art, the sound absorption wall has the advantages that the sound absorption efficiency is greatly improved; the structural stability is very good; deformation is avoided; the service life is long; the metal sound absorption wall achieves a good fireproof effect, is nonflammable and has high sound absorption efficiency; the installing and fixing mode of the metal acoustical boards is simple; the single-piece fixation of the metal acoustical boards is realized; and the fixation of other metal acoustical boards cannot be influenced by the mounting or the dismounting of any one metal acoustical board.

Owner:STATE GRID CORP OF CHINA +1

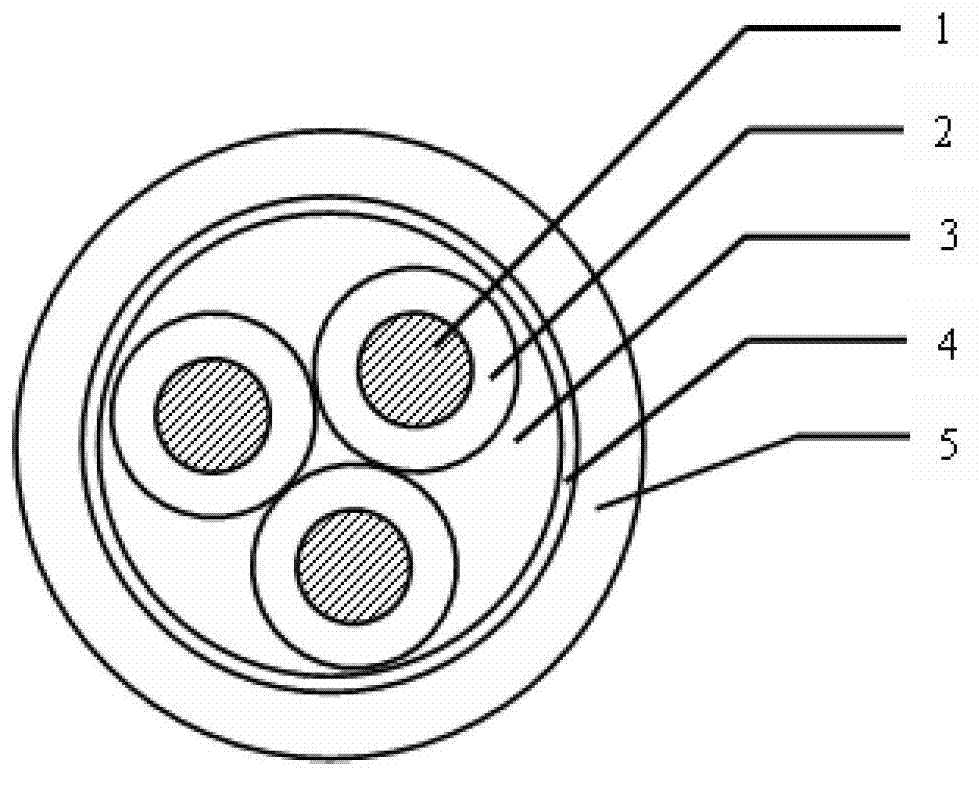

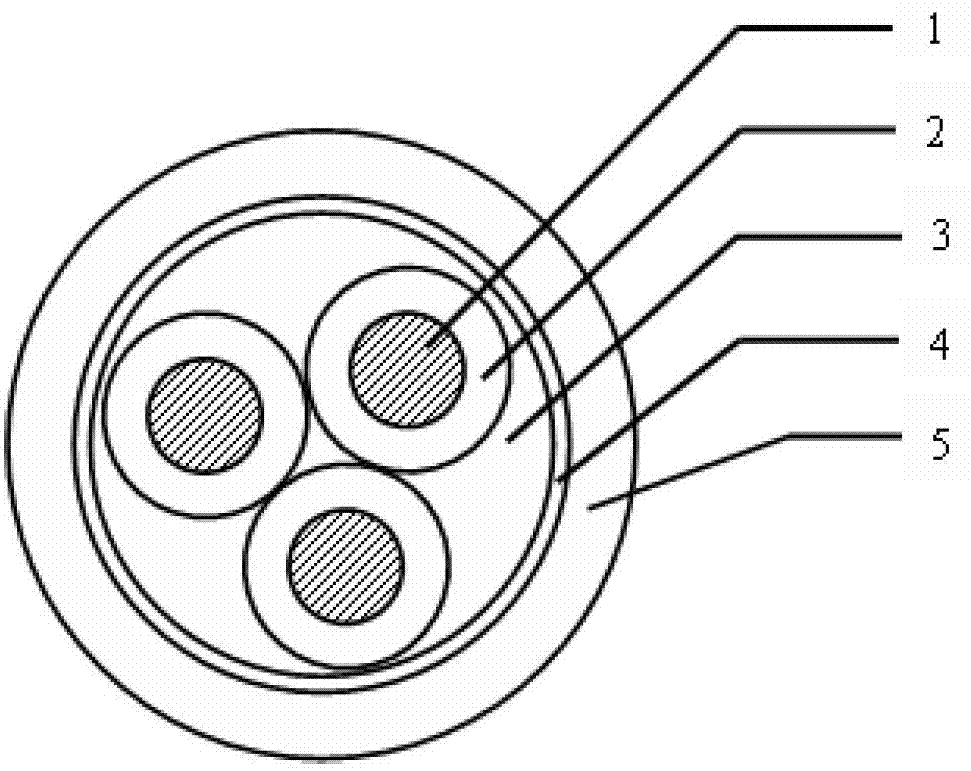

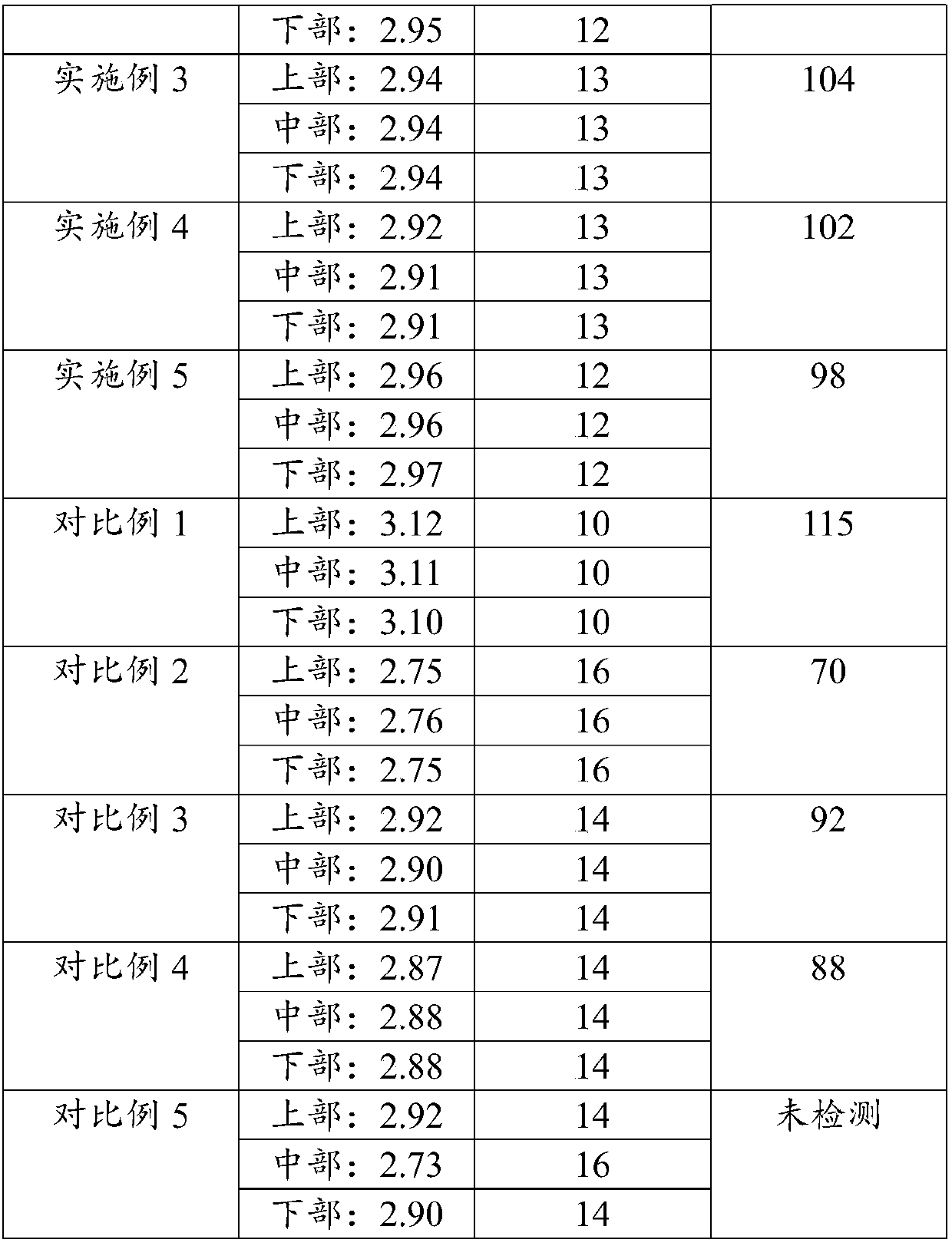

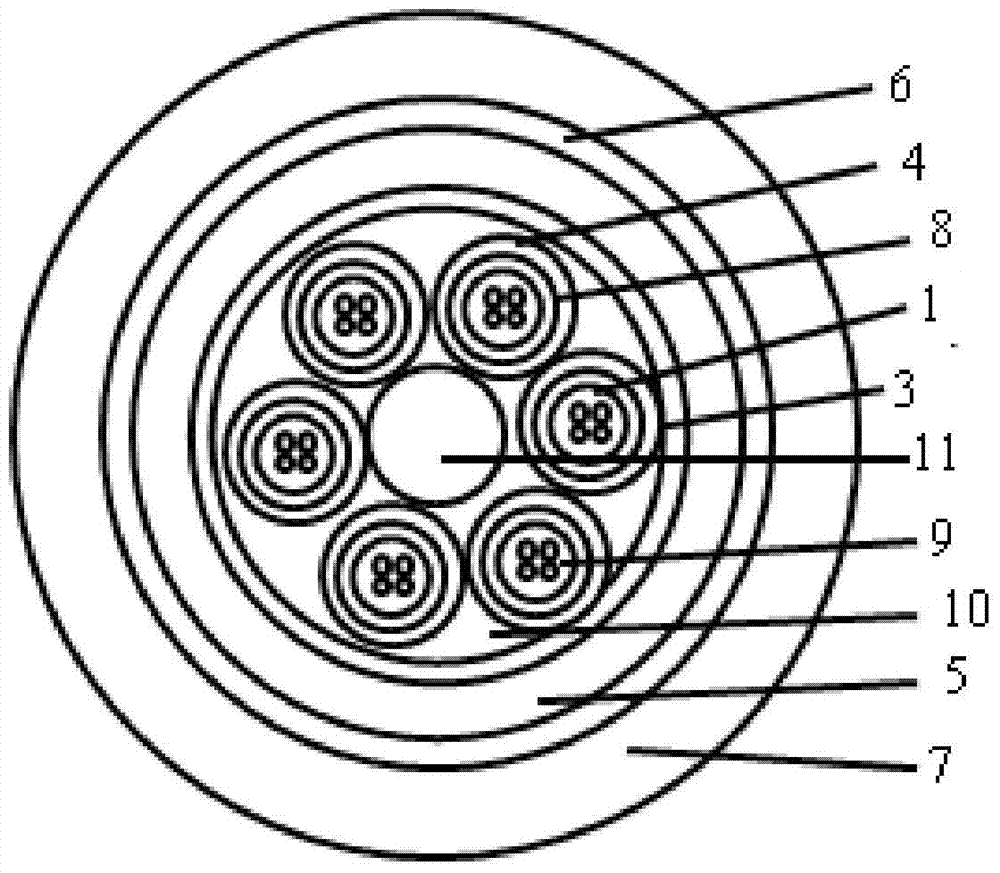

High-flame-retardance fireproof cable made of inorganic materials

ActiveCN102855985AImprove machineryImprove insulation performanceInsulated cablesInorganic insulatorsCopper conductorSpontaneous combustion

The invention discloses a high-flame-retardance fireproof cable made of inorganic materials. The high-flame-retardance fireproof cable comprises a plurality of wire cables, a fire-resistant layer made of inorganic materials and a flame-retardant jacket. The fire-resistant layer made of the inorganic materials is extruded on the wire cables; the flame-retardant jacket is sleeved on the fire-resistant layer made of the inorganic materials; each wire cable consists of a copper conductor and a vitrified silicon rubber insulating layer extruded on the copper conductor; and a filling layer is filled in the fire-resistant layer made of the inorganic materials. The high-flame-retardance fireproof cable is characterized in that the fire-resistant layer made of the inorganic materials comprises, by weight, 85% of magnesium hydroxide, 6% of serpentine powder, 4% of magnesium calcium carbonate, 3% of sodium silicate and 2% of chlorinated paraffin which are squeezed to form the fire-resistant layer made of the inorganic materials. The insulating layer is made of vitrified silicon rubber, and because the insulating layer has high fire resistance and the vitrified silicon rubber is vitrified at a high temperature, the insulating performance of the cable is guaranteed during spontaneous combustion of the cable and external fire disasters. Besides, as the fire-resistant layer made of the inorganic materials is totally made of the inorganic materials by cold stirring and extruding, the materials cannot be combusted during the fire disasters, and flame-retardant and fireproofing effects can be achieved effectively.

Owner:上海安捷防火智能电缆有限公司

High-flame-retardance fireproof cable made of inorganic materials

ActiveCN102855985BImprove machineryImprove insulation performanceInsulated cablesInorganic insulatorsSpontaneous combustionCopper conductor

The invention discloses a high-flame-retardance fireproof cable made of inorganic materials. The high-flame-retardance fireproof cable comprises a plurality of wire cables, a fire-resistant layer made of inorganic materials and a flame-retardant jacket. The fire-resistant layer made of the inorganic materials is extruded on the wire cables; the flame-retardant jacket is sleeved on the fire-resistant layer made of the inorganic materials; each wire cable consists of a copper conductor and a vitrified silicon rubber insulating layer extruded on the copper conductor; and a filling layer is filled in the fire-resistant layer made of the inorganic materials. The high-flame-retardance fireproof cable is characterized in that the fire-resistant layer made of the inorganic materials comprises, by weight, 85% of magnesium hydroxide, 6% of serpentine powder, 4% of magnesium calcium carbonate, 3% of sodium silicate and 2% of chlorinated paraffin which are squeezed to form the fire-resistant layer made of the inorganic materials. The insulating layer is made of vitrified silicon rubber, and because the insulating layer has high fire resistance and the vitrified silicon rubber is vitrified at a high temperature, the insulating performance of the cable is guaranteed during spontaneous combustion of the cable and external fire disasters. Besides, as the fire-resistant layer made of the inorganic materials is totally made of the inorganic materials by cold stirring and extruding, the materials cannot be combusted during the fire disasters, and flame-retardant and fireproofing effects can be achieved effectively.

Owner:上海安捷防火智能电缆有限公司

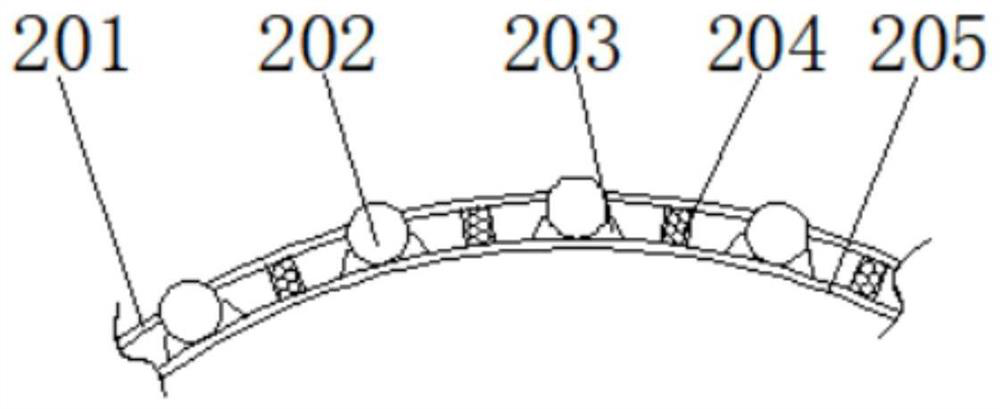

Drain brick and preparation method thereof

The invention relates to a drain brick and a preparation method thereof. The drain brick comprises a drain brick main body, and the drain brick main body is mainly prepared from the following raw materials in parts by weight: 50-70 parts of homogenized calcined bauxite, 15-25 parts of corundum, 8-15 parts of spinel, 15-25 parts of Al2O3, 3-8 parts of calcium aluminate cement, 1-2 parts of silicondioxide and 0.1-0.3 part of an additive, wherein the mass fraction of Al2O3 in the homogenized calcined bauxite is 75-85%. The drain brick has the advantages of favorable performance, high safety andreliability, low cost and high performance cost ratio. The preparation method is simple to operate, does not need high-temperature sintering, and is molded through vibration only.

Owner:河南新拓耐火材料有限公司

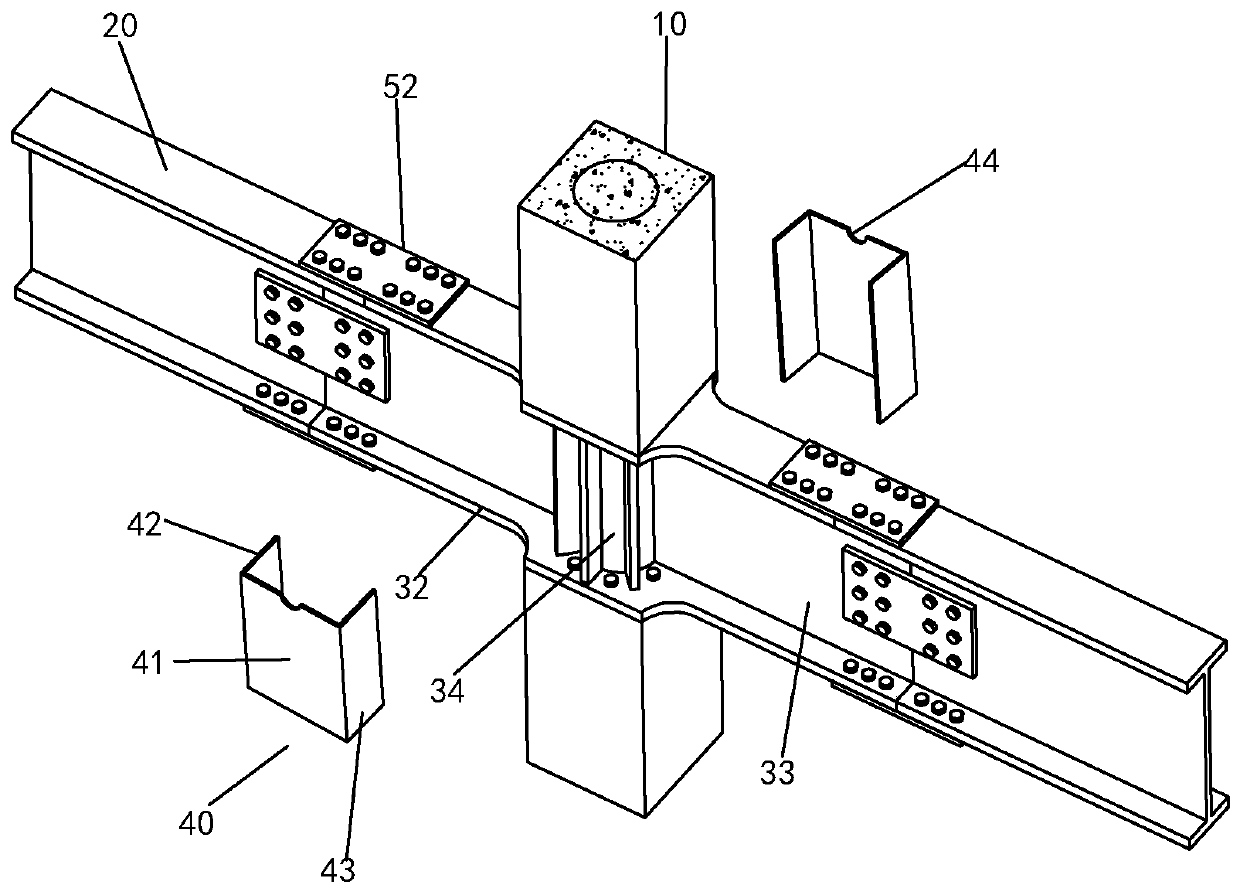

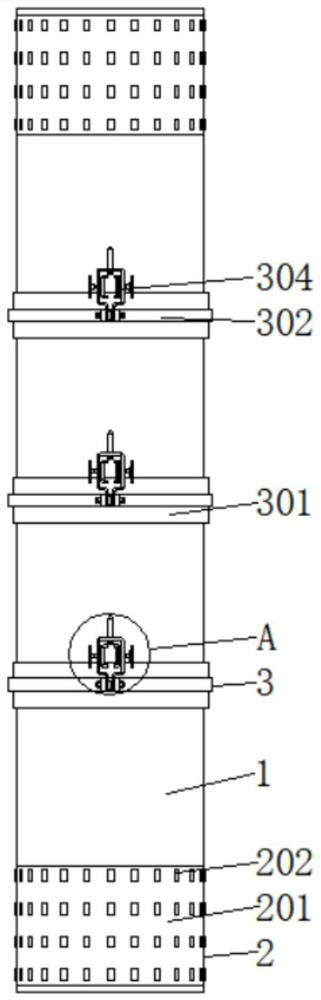

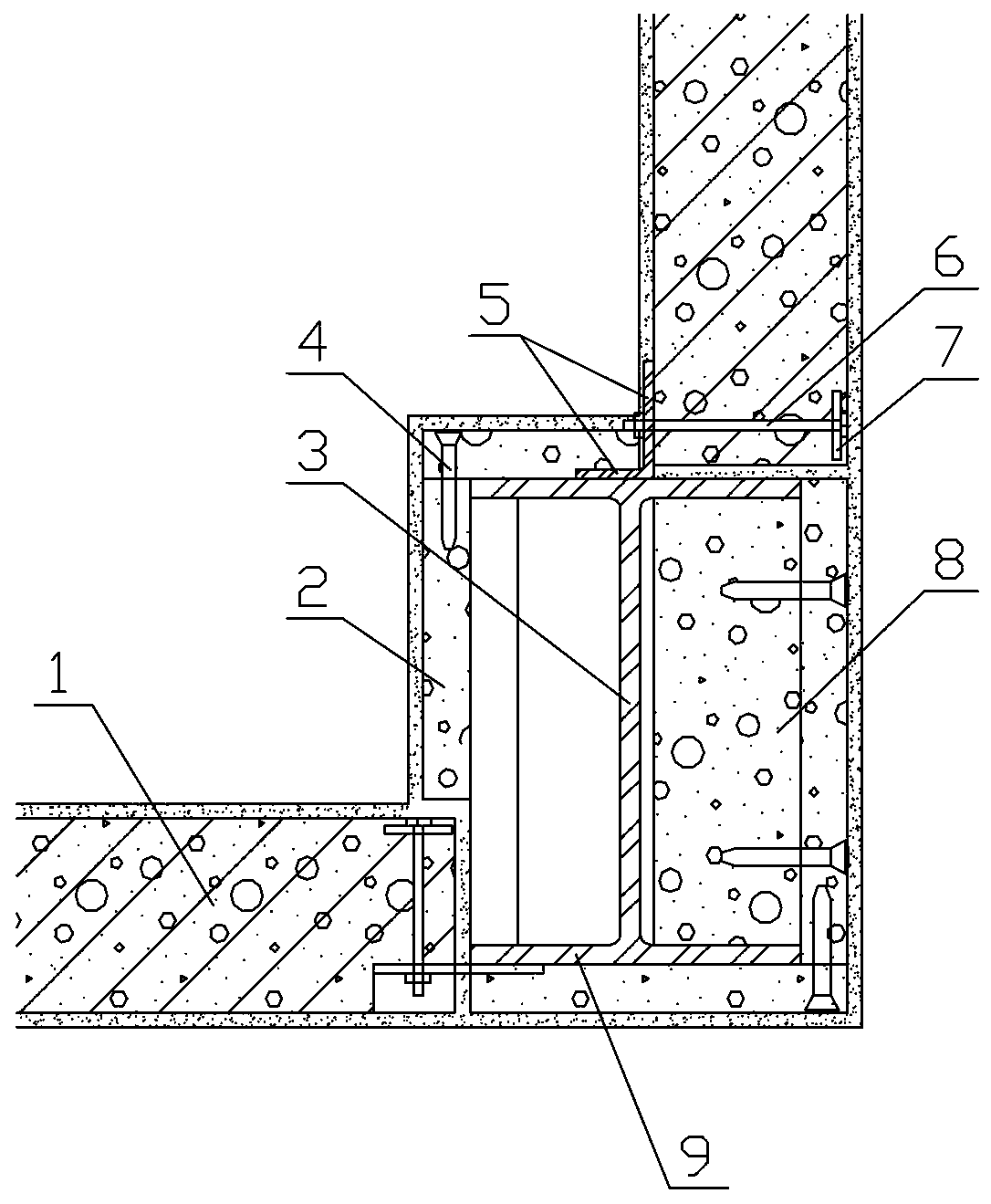

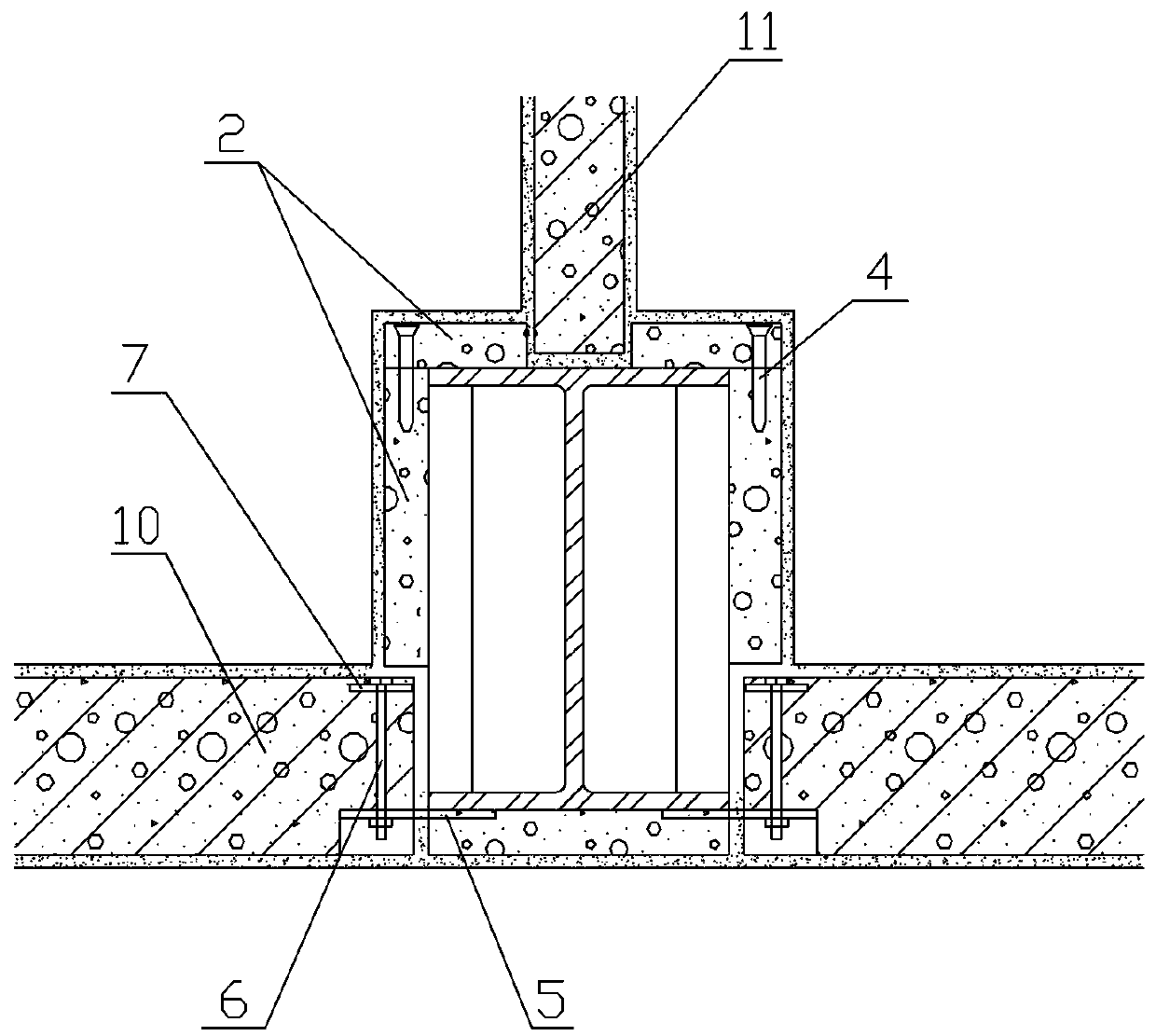

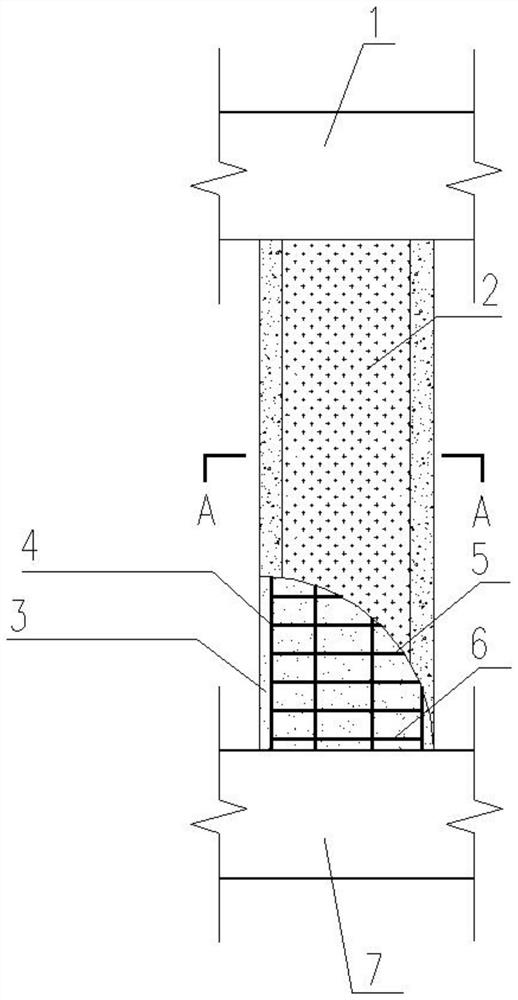

Assembled composite concrete-filled steel tube column-steel beam connecting structure and assembling method

PendingCN109811903AImprove construction progressGuaranteed StrengthBuilding constructionsSteel tubeMaterials science

The invention discloses an assembled composite concrete-filled steel tube column-steel beam connecting structure and an assembling method. The assembled composite concrete-filled steel tube column-steel beam connecting structure comprises a composite concrete-filled steel tube column and a steel beam, and further comprises a node ring, a connecting sheet and a plurality of connecting components, wherein reinforcing round steel tubes are embedded into the composite concrete-filled steel tube column; the node ring is provided with an upper flange, a lower flange and a web plate; a run-through connecting tube is arranged on the web plate; a plurality of reinforcing ribs are arranged on the periphery of the connecting tube; the upper flange and the lower flange are connected to the upper end and the lower end of the web plate respectively, and are provided with openings adapted to the end parts of the connecting tube; one end of the concrete-filled steel tube column is inserted into the opening, and a sleeve thereof is fixedly connected to the upper flange or the lower flange through the connecting components; the connecting sheet hoods the connecting tube and is fixed to the upper flange, the lower flange and the web plate in a sealing manner, and one or more small holes are formed therein; the steel beam is fixed to the upper flange, the lower flange and the web plate through theconnecting components. The assembled composite concrete-filled steel tube column-steel beam connecting structure guarantees the reliability of node connection, so that the construction of a node is simpler.

Owner:HUAQIAO UNIVERSITY

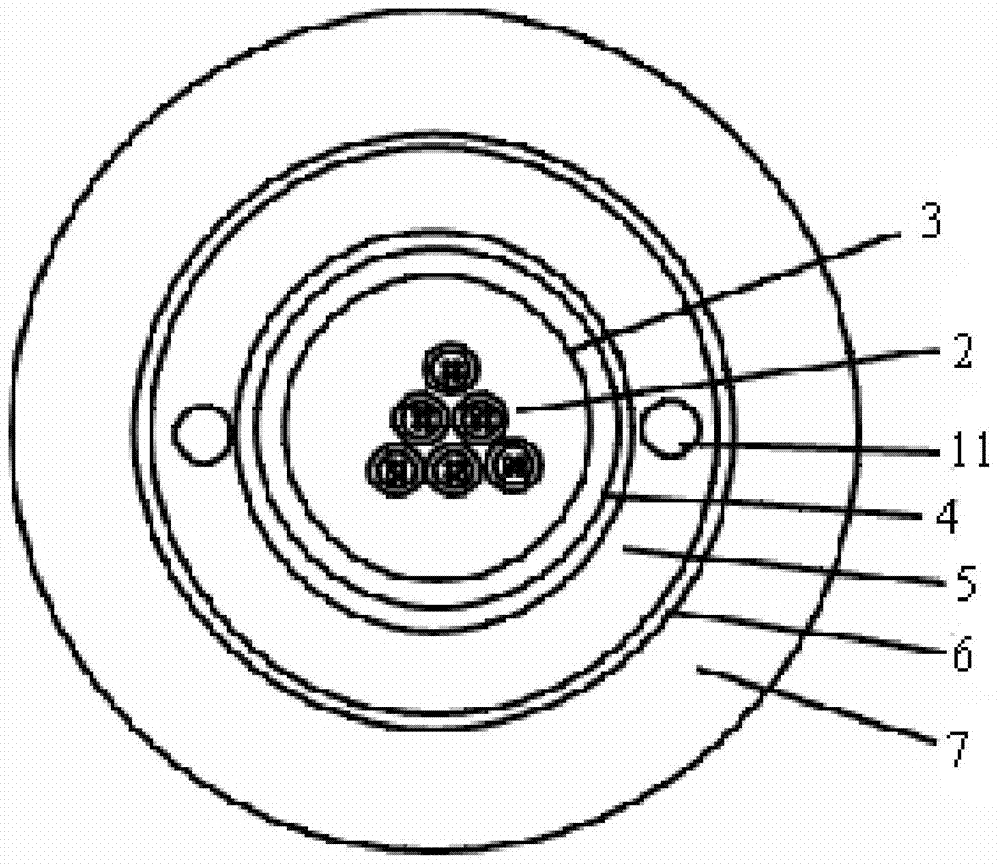

Flame-retardant and fire-retardant cable with high performance

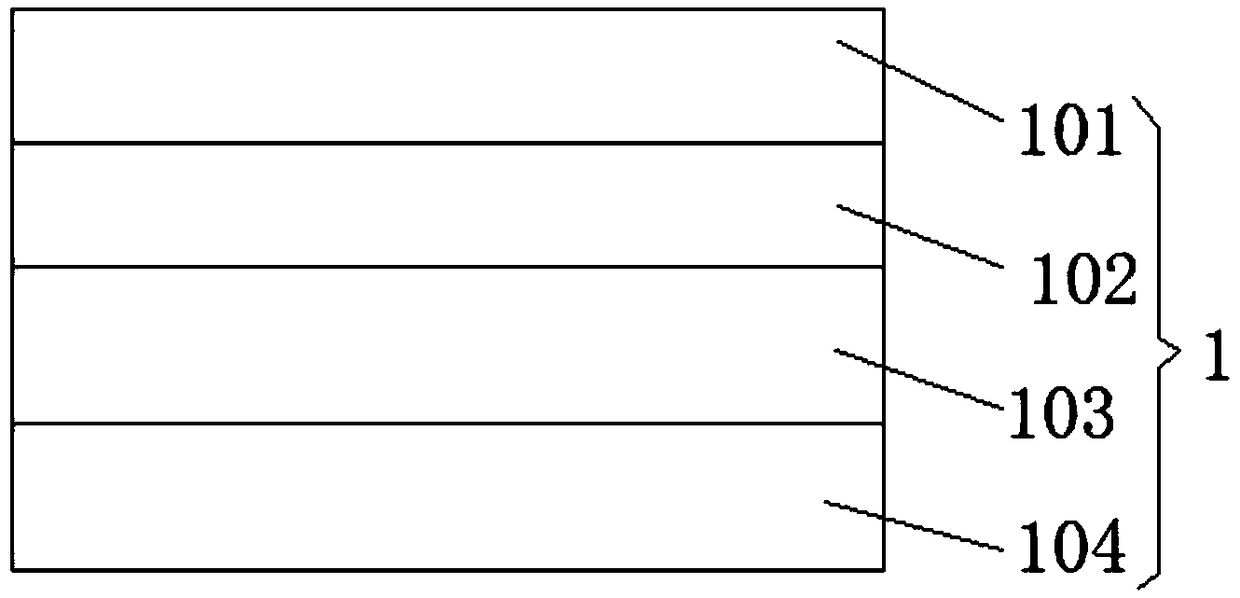

InactiveCN104199156AGuaranteed fire resistanceImprove flame retardant safety performance levelFibre mechanical structuresFiberHigh density

The invention relates to a flame-retardant and fire-retardant cable with high performance. The flame-retardant and fire-retardant cable comprises a cable core, reinforcing pieces and a protection layer, wherein the protection layer wraps outside the cable core and the reinforcing pieces; the protection layer is composed of water-blocking tape, a ceramic fiber tape and an outer protection sleeve; the outer protection sleeve is the outermost layer of the protection layer. According to the flame-retardant and fire-retardant cable with high performance, micro beam tubes are longitudinally wrapped by ceramic fiber high-performance flame-retardant material, two flame-retardant inner protection sleeves made of non-metal material are embedded in the outer side of the wrapped tape in an extruding manner, and after a fluorophlogopite tape is longitudinally wrapped, the flame-retardant outer protection sleeve is also formed in an extruding manner; and therefore, high density capacity of the optical fiber cable is improved, and meanwhile the excellent flame-retardant of the cable is ensured by multiple measures such as the dual-layer flame-retardant protection sleeves, the ceramic fiber tape, the mica tape and the like.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Fireproof mud used for power cable and preparation method thereof

The invention discloses fireproof mud used for installation of a power cable, and belongs to the technical field of fireproof mud. The fireproof mud is composed of, by weight, the raw materials of 25-28 parts of condensed polycyclic aromatic hydrocarbon resin, 15-20 parts of epoxy resin, 8-10 parts of chlorinated paraffin, 14-18 parts of clay, 11-13 parts of porcelain clay powder, 7-9 parts of perlite, 6-9 parts of quartz sand, 5-7 parts of bauxite chamotte, 2-4 parts of magnesium hydroxide, 6-8 parts of tributyl citrate, 4-6 parts of ethylene glycol, 7-9 parts of ammonium phosphate, 2-4 parts of antioxidant, 1-2 parts of anti-corrosion agent and 1-3 parts of antistatic agent. The invention further discloses a preparation method of the fireproof mud used for installation of the power cable. The fireproof mud is easy to prepare, environmentally friendly, low in pollution and good in durability, and has the effects of good fire resistance, corrosion resistance, water resistance and static resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Molding sand used for special casting mould surface and preparation method thereof

InactiveCN103521682AImprove liquidityImprove finenessFoundry mouldsFoundry coresSodium metasilicateCopper oxide

The invention discloses molding sand used for a special casting mould surface. The molding sand is prepared from the following raw materials in parts by weight: 300-330 parts of zircon sand, 55-65 parts of fused magnesite, 12-18 parts of aluminum-magnesium spinel, 20-25 parts of kyanite, 3-5 parts of tributyl citrate, 3-4 parts of copper oxide, 10-15 parts of wood fibers, 2-4 parts of carboxymethyl cellulose, 12-20 parts of graphite powder, 6-9 parts of sodium metasilicate and an appropriate amount of water. According to the molding sand disclosed by the invention, the zircon sand is selected as a main molding material aiming at the characteristics of high casting strength requirements and good fire resistance degree; the quality of the casting mould surface can be obviously improved by the added fused magnesite, aluminum-magnesium spinel and kyanite through processes of roasting, grinding, dispersing and the like; meanwhile, the carboxymethyl cellulose, the graphite powder and the sodium metasilicate are added, so that mobility of the molding sand is increased, mould charging capacity is improved, fire resistance performance is ensured, and molding sand fineness is strengthened. Besides, the molding sand disclosed by the invention is suitable for casting a product with a fine process, high in yield and precise in dimension.

Owner:HEFEI CITY TENVER PRECISION CASTING

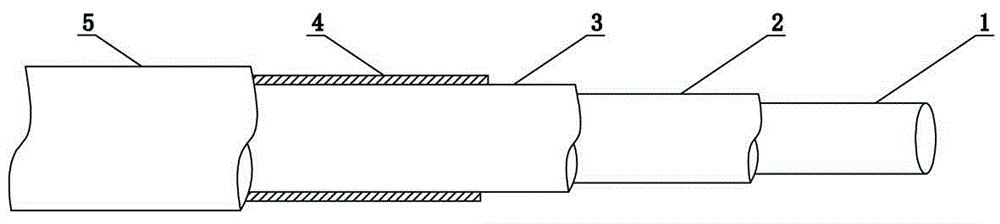

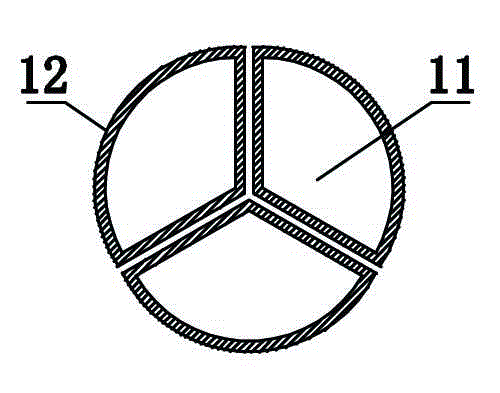

Aluminum alloy cable

InactiveCN103151108AReduce weightImprove electrical performancePower cablesMetal/alloy conductorsElectrical conductorBasalt fiber

The invention provides an aluminum alloy cable. The aluminum alloy cable comprises an aluminum alloy conductor, a heat-insulation inflaming retarding layer, a metal sheath, a bituminous coating and an outer sheath, wherein the aluminum alloy conductor is formed by three aluminum alloy cable cores and insulating layers which respectively cover the three aluminum alloy cable cores; the section of each aluminum alloy cable core is a solid sector-shaped section; the section of the aluminum alloy conductor is a circular section formed by the three solid sector-shaped sections; the aluminum alloy conductor is covered by the heat-insulation inflaming retarding layer formed by basalt fiber cloth; the metal sheath formed by an aluminum alloy covers the heat-insulation inflaming retarding layer; the bituminous coating is arranged on the metal sheath; and the outer sheath covers the bituminous coating. The aluminum alloy cable disclosed by the invention has the advantages of compact structure, good flexibility, great tensile strength, stable electric performance, good creep resistance, good fire resistance and long service life.

Owner:HENAN KAIQI POWER IND

Ultrahigh-safety ceramic wire and cable design and method

ActiveCN111816358AHigh mechanical strengthHigh strengthClimate change adaptationInsulated cablesLow smoke zero halogenEngineering

The invention discloses an ultrahigh-safety ceramic wire and cable design and method. The invention relates to the technical field of ceramic electric wires and cables. A ceramic cable main body and an easy-to-disassemble installation mechanism are included, the upper and lower sides of the outer wall of the ceramic cable main body are both provided with wear-resistant protection mechanisms, and the easy-to-disassemble installation mechanism is located in the middle of the outer wall of the ceramic cable main body. According to the ultrahigh-safety ceramic wire and cable design and method, anoxygen barrier layer, a steel wire rope, a ceramic layer and an insulating layer are arranged; the overall toughness of the ceramic wire cable can be effectively enhanced through the steel wire rope;the ceramic layer can effectively guarantee the fireproof and insulating functions, the insulating layer is prepared through low-smoke halogen-free irradiation crosslinking, the insulating layer can effectively separate an external object from the copper core, an electric leakage phenomenon can be effectively avoided, and stable utilization of the ceramic wire and cable can be effectively guaranteed.

Owner:贵阳中安科技集团有限公司

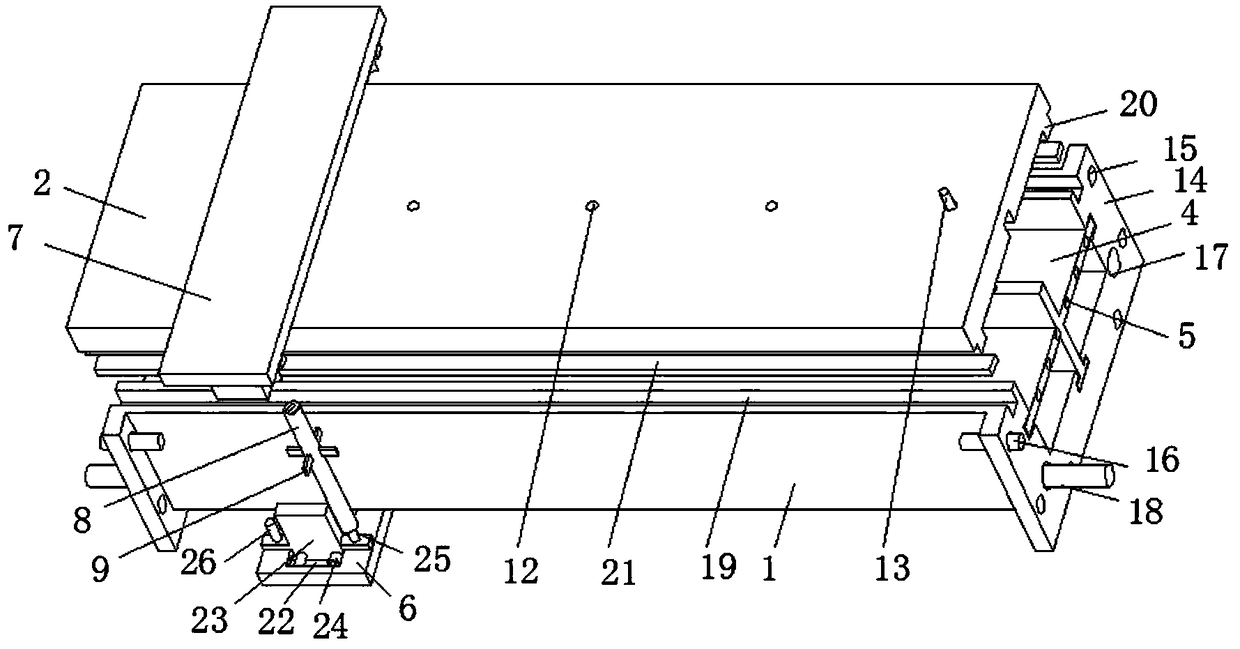

Anti-skinning spray coating material for cement kiln

ActiveCN102815955BGood thermal shock resistanceImprove high temperature strengthPyrophylliteSpray coating

The invention relates to a refractory spray coating material, in particular to an anti-skinning spray coating material for a cement kiln. The anti-skinning spray coating material comprises flint clay, SiC, Guangxi white mud, alpha-Al2O3 micro powder, high-aluminum fine powder, SiC fine powder, pure calcium aluminate cement, spodumene, pyrophyllite and polypropylene fibers. The anti-skinning spray coating material for the cement kiln can play an effectively anti-skinning role at the positions of a feed pipe, a smoke chamber and the like of the cement kiln, is excellent in medium-temperature and high-temperature resistance and outstanding in thermal shock stability performance and can avoid cracking during rapid temperature rise. Besides, the anti-skinning spray coating material for the cement kiln is rapid in construction by the aid of a semi-dry spray coating construction mode, and is low in rebound rate after construction.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Fire-resistant low-voltage bus duct

InactiveCN108649510AAvoid enteringImprove cooling effectCooling bus-bar installationsTotally enclosed bus-bar installationsMulti materialBusbar

The invention discloses a fire-resistant low-voltage bus duct. The fire-resistant low-voltage bus duct comprises a shell body, wherein the outermost side of the shell body is provided with an anticorrosive material layer, the inner side of the anticorrosive material layer is provided with a fire-resistant material layer, the lower portion of the fire-resistant material layer is provided with a load-bearing material layer, the inner lower portion of the load-bearing material layer is provided with a first insulating material layer, the top end of the shell body is connected with a cover plate,the shell body and the cover plate are both provided with connecting grooves, and the connecting grooves are internally slidably connected with partition frames. The fire-resistant low-voltage bus duct has the advantages that busbars installed internally are more loose, thereby providing convenience for heat dissipation, a multilayer insulating structure is adopted to separate the busbars, therebybeing capable of effectively preventing the busbars from being inferred by one another, the shell body is compounded by adopting various materials, thereby ensuring the integral corrosive resistanceand fire resistance, the integral connection is more tight, thereby being capable of effectively preventing the outside water and dust from entering the bus duct, and the safety of the use is ensured.

Owner:江苏中天电气有限公司

High-performance autoclaved aerated concrete integrated board exterior wall structure for prefabricated building

InactiveCN109594690AGuaranteed stiffnessFirmly connectedWallsClimate change adaptationFireproofingSteel bar

The invention relates to a high-performance autoclaved aerated concrete integrated board exterior wall structure for a prefabricated building. The exterior wall structure comprises high-performance autoclaved aerated concrete integrated board bodies and I-type structural steel columns, wherein an iron piece provided with a bolt hole is embedded and welded on a reinforcement main steel bar in the end of each high-performance autoclaved aerated concrete integrated board body, and the overall exterior wall of the prefabricated building is formed by sequential bolted connection and welding of theend parts of the high-performance autoclaved aerated concrete integrated board bodies through steel connectors, the iron pieces and wing plates or web plates in the I-type structural steel columns orI-type structural steel beams. One brand-new connection form of fabricated exterior wallboards is provided for the fabricated exterior wall structure, so that not only can the rigidity of the structure connection be improved greatly, but also properties including energy saving, environmental protection, sound insulation, noise reduction, light weight, high strength, insulation, fireproofing, flameretardance, efficient installation and the like of the exterior wallboards are guaranteed forcefully, and the exterior wall structure has good popularization and application values.

Owner:HUBEI SHENZHOU BUILDING MATERIAL

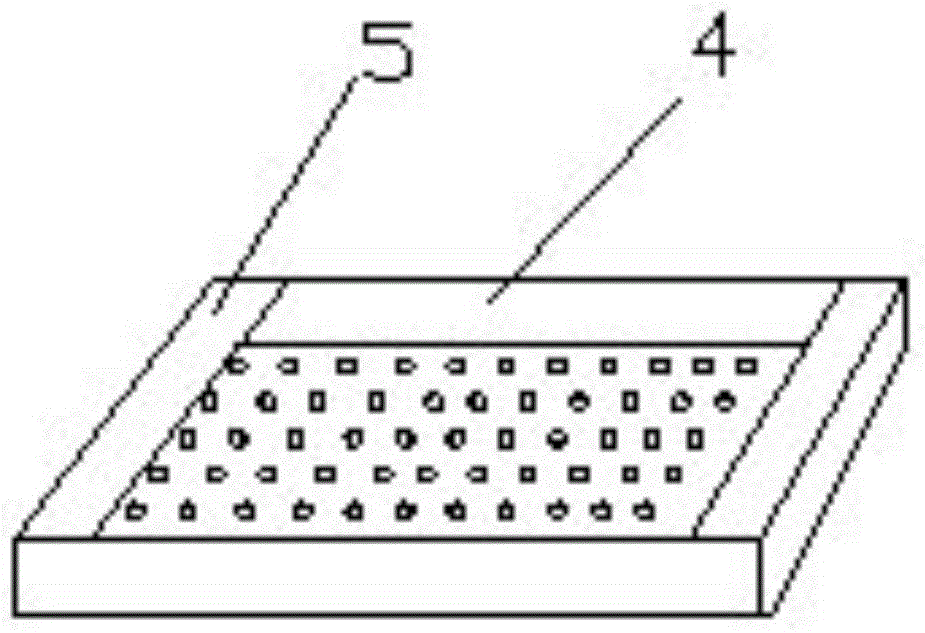

Anti-backfire vent device

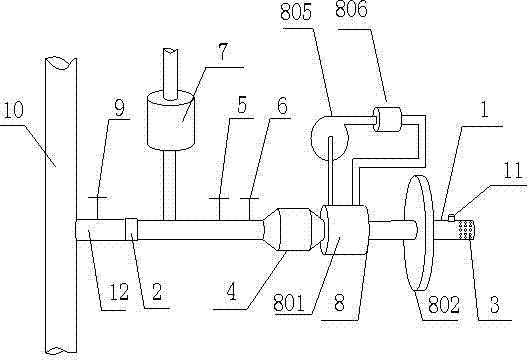

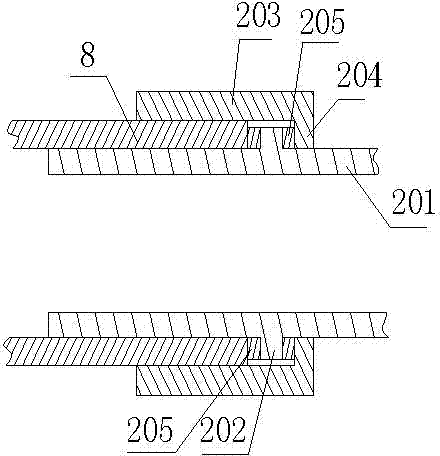

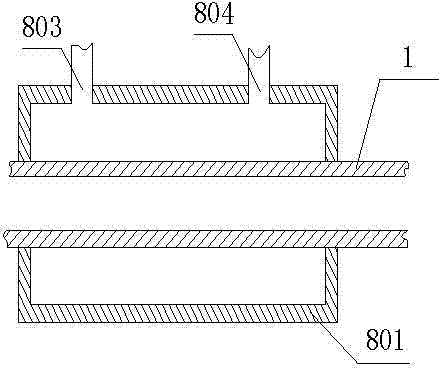

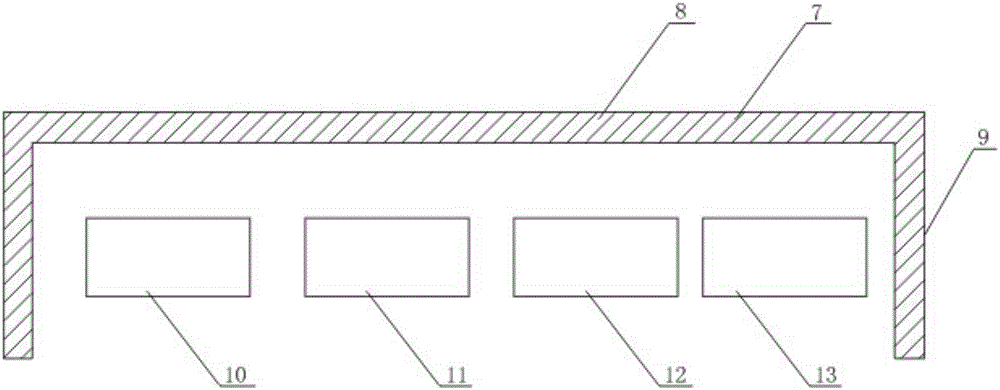

The invention discloses an anti-backfire vent device. The anti-backfire vent device comprises a vent pipeline (1). A connector (2) is arranged at one end of the vent pipeline (1), and a combustion head (3) is arranged at the other end of the vent pipeline (1). A fire stopper (4), a pressure regulating valve (5) and a switching valve (6) are arranged in the vent pipeline (1). A gas adding device (7) is connected to the position, close to the connector (2), of the vent pipeline (1). The vent pipeline (1) is further provided with a fire stopping and cooling device (8). The anti-backfire vent device has the advantages that the fire stopping and cooling device is arranged, and therefore heat is prevented from being transmitted to the fire stopper through a pipeline, strong wind is prevented from blowing flames to the fire stopper, and the fire stopping effect is guaranteed.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Gangue shale sintered brick production system

InactiveCN106082971AAdd cooling sectionReduce CooldownOpen field furnacesCeramic materials productionHeating timeBrick

This invention describes a gangue shale sintered brick production system, comprising a feeding unit, a feeding belt connected with the feeding unit; the other end of the feeding belt is connected with a stirring unit, an outlet end of the stirring unit is connected with an aging cabin that is connected with a press former, the press former is connected with a tunnel drying kiln through a green brick conveyer belt, and the tunnel drying kiln is connected with a sintered brick sintering kiln. The sintered brick sintering kiln includes a roof, a wall and a working passage composed of the roof and the wall, the working passage includes a preheating segment, a sintering segment and a temperature-holding segment and a cooling segment sequentially in an extension direction. The system has a simple whole process, is easy to operate and high in reliability, and has greatly improved production efficiency. After being dried, a green brick is transferred to the green brick sintering kiln through a kiln car, and by adding the cooling segment to the sintered brick sintering kiln, cooling time is shorter than that of traditional natural cooling, heating time for the preheating time and the temperature-holding time is shortened, sintering cycle is greatly shortened on the whole and quick sintering is implemented.

Owner:四川乔丰新材料科技有限公司

High-strength novel chemical foaming cement and preparation method thereof

ActiveCN105622159AGuaranteed insulation effectGuaranteed sound insulationCeramicwareFiberHydrogen Sulfate

The invention discloses high-strength novel chemical foaming cement and a preparation method of the high-strength novel chemical foaming cement. The high-strength novel chemical foaming cement is prepared from the following raw materials in parts by weight: 70 to 80 parts of cement, 20 to 30 parts of pulverized fuel ash, 45 to 55 parts of water, 0.2 to 0.4 part of fiber, 0.8 to 1 part of foam stabilizer, 0.07 to 0.08 part of coagulation accelerator, 4.8 to 5 parts of foaming agent, 0.05 to 0.15 part of sodium hydrogen sulfate and 0.2 to 0.225 part of thiourea. The high-strength novel chemical foaming cement disclosed by the invention has the advantages of high strength, low water absorption, light weight, environment protection, low cost and the like while having the capability of keeping the heat preservation performance, the heat resistance, the sound resistance, the fire resistance and the like of original foaming cement, is excellent in performance and can be applied to aspects of interior and exterior wall heat preservation materials of a building, a fire barrier zone, a roof heat preservation material, industrial / military / civil heat preservation and sound insulation, traffic / factory environment noise treatment and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Novel casting molding sand

InactiveCN110315024AReduce air permeabilityGuaranteed fire resistanceFoundry mouldsFoundry coresApatiteMetallurgy

The invention discloses novel casting molding sand. The novel casting molding sand comprises the following raw materials of, in parts by weight, 1250-1310 parts of reclaimed sand, 5-35 parts of freshsand, 10-15.6 parts of molding sand adhesives, 13-15.4 parts of dust, 4-9 parts of coal powder, 1-5 parts of starch, 2-8 parts of olivine sand and 3-8 parts of apatite powder. According to the novel molding sand, the thickness degree of sand grains can be changed, the compactness of a sand mold is ensured, the air permeability of the molding sand is effectively reduced, meanwhile, the fire resistance and the plasticity of the molding sand can be ensured, in addition, the casting dust is added again and used, so that the problem of the casting roughness is solved, the problem that no place canbe used for processing the dust due to the fact that the environment-protecting situation is severe is also solved, the production cost is greatly reduced, and the environment is protected.

Owner:YUANDA VALVE GRP CO LTD

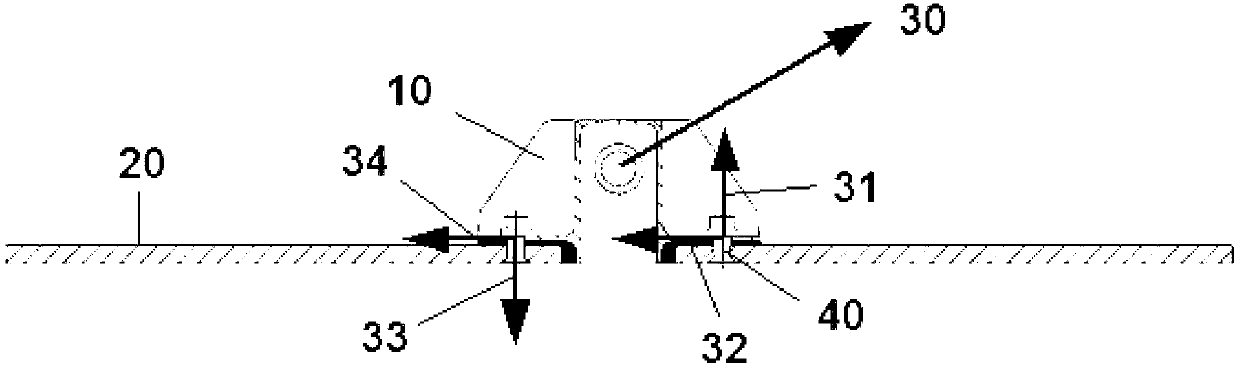

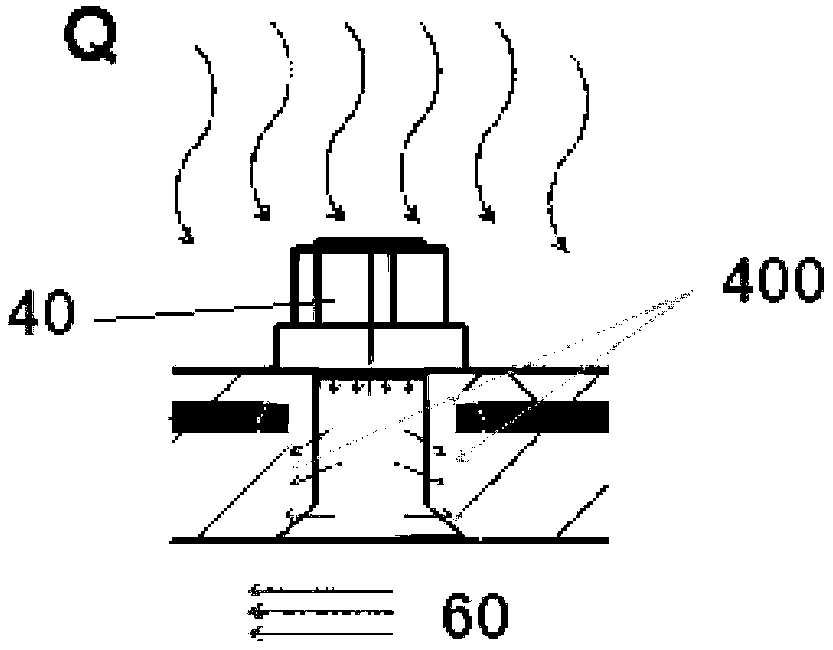

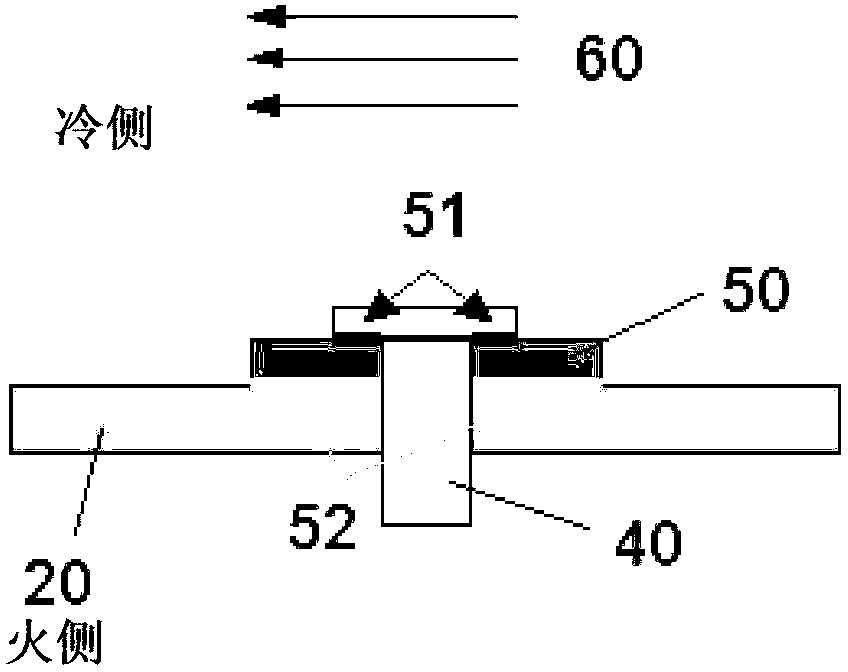

Joint attaching structural element to composite part and aircraft including the joint

InactiveCN103213668AGuaranteed fire resistanceFuselage framesAircraft lighting protectorsCold sideEngineering

Owner:EADS飞机设计有限公司

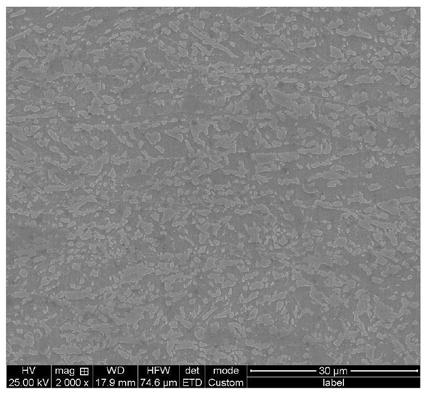

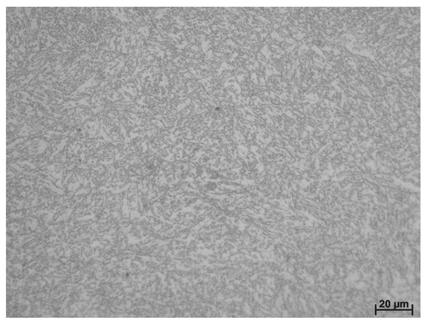

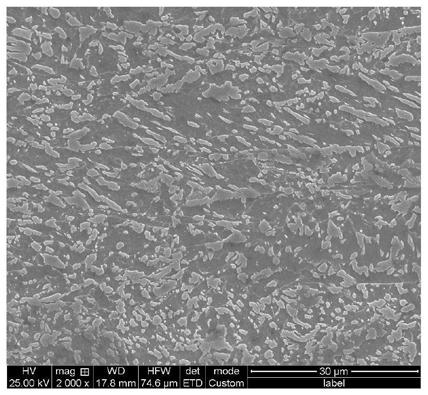

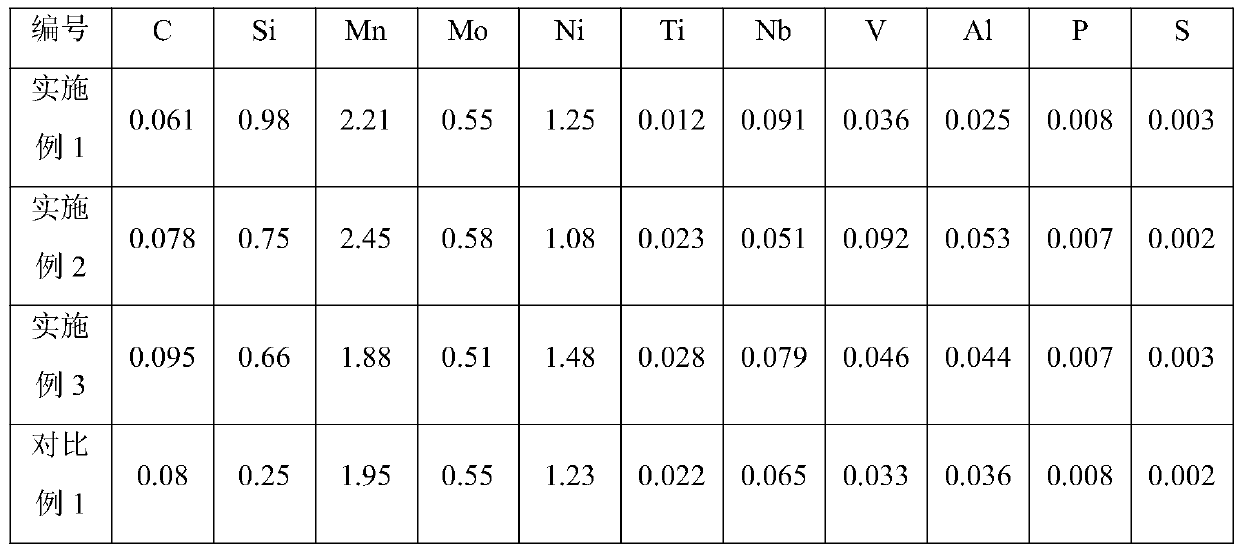

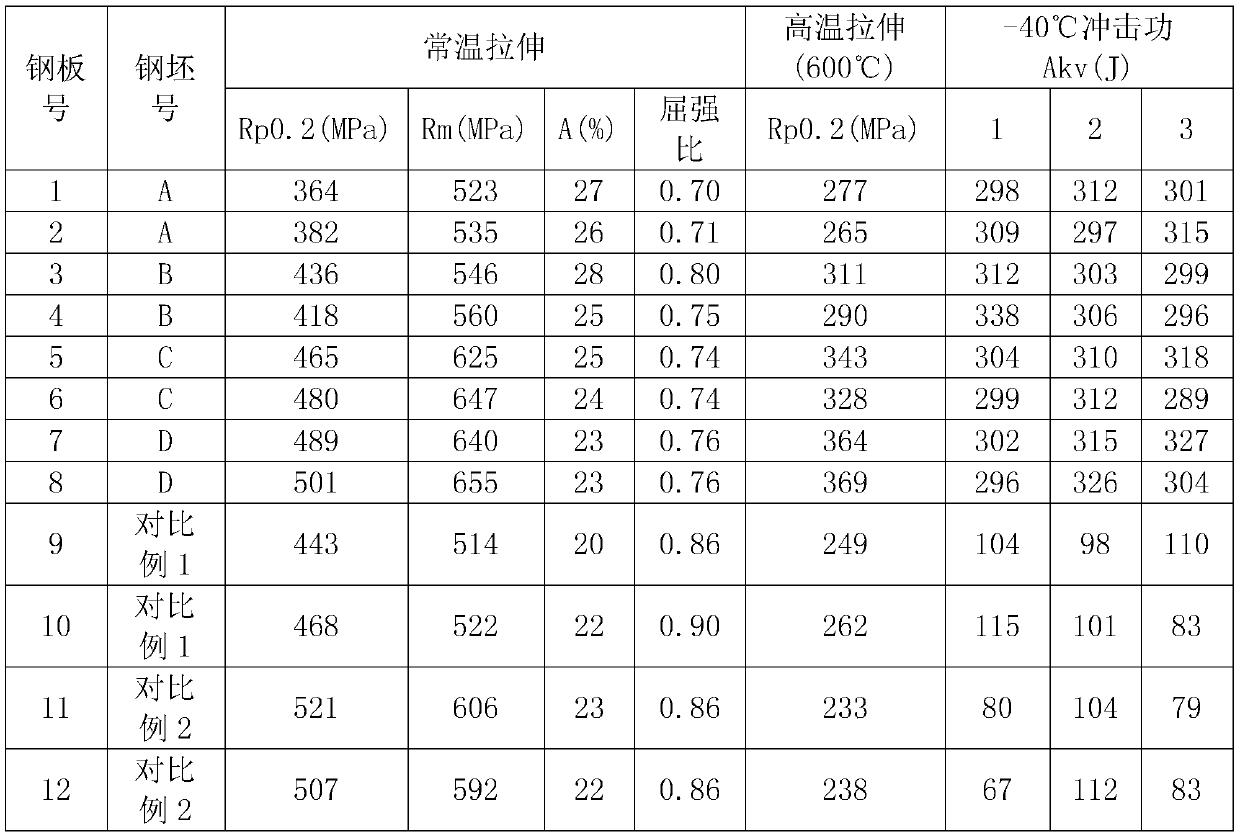

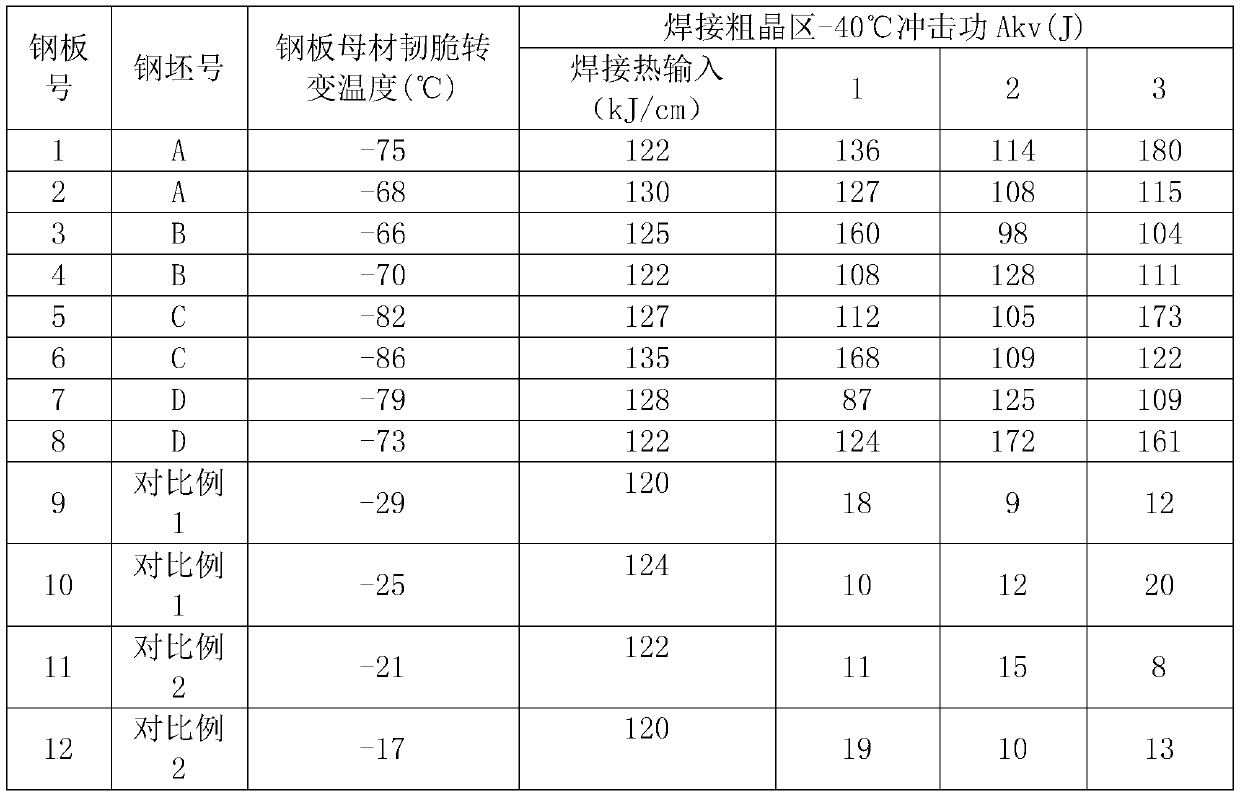

Anti-shock, corrosion resisting and fire resisting steel and preparing method thereof

ActiveCN111154962AHigh yield strengthSufficient yield strengthFurnace typesHeat treatment furnacesMaterials scienceCorrosion

The invention discloses anti-shock, corrosion resisting and fire resisting steel and a preparing method thereof, and belongs to the technical field of building structure steel. The problems that in the prior art, the anti-shock, corrosion resisting and fire resisting steel preparing technology is complex, and technology control difficulty is large are solved. The anti-shock, corrosion resisting and fire resisting steel comprises chemical components including, by mass percent, 0.06%-0.10% of C, 0.65%-1.00% of Si, 0.80%-1.20% of Mn, 0.50%-0.60% of Mo, 1.00%-1.50% of Ni, 0.72%-1.00% of Cr, 0.25%-0.40% of Cu, 0.01%-0.03% of Ti, 0.05%-0.10% of Nb, 0.03%-0.10% of V, 0.015%-0.055% of Al, smaller than 0.015% of P, smaller than 0.005% of S, smaller than 0.003% of O, smaller than 0.005% of N and thebalance Fe and inevitable impurities. The preparing method comprises smelting and casting and two-stage controlled rolling. The preparing method is simple and easy to control, and the comprehensive performance of the prepared anti-shock, corrosion resisting and fire resisting steel is good.

Owner:CENT IRON & STEEL RES INST +1

Wearing-resistant fire-resistant coating for air compressor and preparation method of coating

InactiveCN107227099AGood self-extinguishingImprove heat resistanceFireproof paintsAnti-corrosive paintsEpoxyWear resistant

The invention discloses a wearing-resistant fire-resistant coating for an air compressor and belongs to the technical field of coatings. The coating comprises the following raw materials in parts by weight: 36-40 parts of a brominated epoxy resin, 18-24 parts of polyvinylidene fluoride, 10-12 parts of aluminum silicate, 5-7 parts of emery powder, 3-5 parts of cast stone powder, 6-7 parts of zinc oxide, 2-5 parts of expanded perlite, 6-8 parts of m-dihydroxybenzene (diphenyl phosphate), 5-7 parts of melamine phosphate, 9-11 parts of triethyl citrate, 3-5 parts of sodium silicate, 0.5-1 part of carboxymethylcellulose, 1-3 parts of a defoaming agent, 0.2-0.8 part of an anti-electrostatic agent, 4-6 parts of a coupling agent, 14-18 parts of methanol and 17-20 parts of water. The invention further discloses a preparation method of the wearing-resistant fire-resistant coating for the air compressor. The coating is relatively high in wearing resistance and fireproof effect, high in corrosion resistance and long in service life.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Smart bus slot connector for data center

InactiveCN109193527AAvoid enteringImprove sealingTotally enclosed bus-bar installationsData centerEngineering

The invention relates to an intelligent bus slot connector for a data center, include a housing and a cover plate, a sealing groove is arranged on both sides of the upper end of the shell, a seal block adapted to the sliding groove structure is arranged on both sides of the cover plate, the cover plate is sealingly connected with the shell through the sealing blocks on both sides and the sealing grooves on both sides of the upper end of the shell, a fixing groove is equidistantly spaced at the bottom end of the shell, a fixing plate is mounted on the fixing groove, the fixing plate is detachably connected with the fixing groove, Between each two adjacent fix plates, a placement cavity is for, connecting plates are respectively installed at that front and rear ends of the case, connecting holes and connecting columns are respectively symmetrically arranged at the two ends of the connecting plate, a cavity is arranged in the cover plate, and a hole groove communicating with the cavity isarranged on one side of the cover plate.

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

Anti-aseismic fire-resistant steel and preparation method thereof

ActiveCN111074158AImprove high temperature strengthGuaranteed fire resistanceEarthquake resistantChemical composition

The invention discloses anti-aseismic fire-resistant steel and a preparation method thereof, and belongs to the technical field of steel for a building structure. The anti-aseismic fire-resistant steel consists of the following chemical components in percentage by mass: 0.06%-0.10% of C, 0.65%-1.00% of Si, 1.85%-2.50% of Mn, 0.51%-0.60% of Mo, 1.00%-1.50% of Ni, 0.01%-0.03% of Ti, 0.05%-0.10% of Nb, 0.03%-0.10% of V, 0.015%-0.055% of Al, less than 0.015% of P, less than 0.005% of S, less than 0.003% of O, less than 0.005% of N, and the balance of Fe and inevitable impurities. The preparation method for the anti- aseismic fire-resistant steel comprises the following steps: smelting and casting; and performing two-stage control rolling. The preparation method is simple and easy to control, and the prepared anti-aseismic fire-resistant steel has good combination property.

Owner:CENT IRON & STEEL RES INST +1

Flame-retardant cable

InactiveCN105469881AWarranty Strength RequirementsGuaranteed service lifeClimate change adaptationInsulated cablesCopperUltimate tensile strength

The invention discloses a flame-retardant cable, which comprises a core material, wherein the core material is formed by twisting an iron-based alloy wire, a copper-based alloy wire and an aluminum-based alloy wire; a flame-retardant filler coats the outside of the core material; a damp-proof layer is arranged on the outer side of the flame-retardant filler; a lightweight woven mesh coats the outside of the damp-proof layer; and an insulating layer is arranged on the outer side of the lightweight woven mesh. By means ofthe iron-based alloy wire, the copper-based alloy wire and the aluminum-based alloy wire in the flame-retardant cable, the strength requirement and the conductivity requirement of the core material are met; the flame-retardant filler can ensure fire-resistant and flame-retardant characteristics in the working process; and the product cost can also be reduced.

Owner:叶玉浩

Energy-saving composite refractory brick

The invention discloses an energy-saving composite refractory brick and relates to a refractory brick. The energy-saving composite refractory brick comprises a work layer, a refractory material layer and a heat insulating layer, wherein the work layer is coated with a paint with high radiation energy; bonding surfaces among the work layer, the refractory material layer and the heat insulating layer are concave-convex surfaces, and the work layer, the refractory material layer and the heat insulating layer are in seamless connection with one another; at least two cylindrical cavities are arranged in the refractory material layer; the heat insulating layer is made of light material; the cavities are filled with a thermal insulating material, and both the refractory material layer and the heat insulating layer are added with mullite granules. The energy-saving composite refractory brick has the advantages that the dissipation of heat in a kiln can be reduced, energy is saved, and the service life of the kiln is prolonged.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

Welding high heat input anti-seismic refractory steel plate and manufacturing method thereof

The invention discloses a welding high heat input anti-seismic refractory steel plate and a manufacturing method thereof, wherein the steel plate comprises the following chemical components in percentage by weight: 0.01-0.10% of C, 0.08-0.25% of Si, 0.30-0.80% of Mn, 0.05-0.20% of Mo, 0.05-0.12% of Nb, 0-0.6% of Cu and balance of Fe and unavoidable impurities, and the invention further designs a manufacturing method for the welding high heat input anti-seismic refractory steel plate; The welding high heat input anti-seismic refractory steel plate and the manufacturing method thereof provided by the invention can reduce the use cost of the alloy, and has high strength, high toughness, welding heat input amount of more than 120 kJ / cm and fire resistance.

Owner:NANJING IRON & STEEL CO LTD

Method for assembling prefabricated part reinforcing column through concrete

The invention provides a method for assembling a prefabricated part reinforcing column through concrete. The method comprises the steps that a painting layer or a cushion layer on the surface of a component is chiseled away to a concrete base layer for treatment; the surface of the base layer and the surface of a concrete prefabricated part are coated with adhesives; the concrete prefabricated part is fixed; the concrete prefabricated part is clamped with a clamp, and is properly pressurized; impurities in a hole channel are removed, a prestressed steel strand is manually pulled, and the steel strand is tensioned and fixed; pipeline grouting and anchor sealing are conducted; and after the adhesive is cured, the clamp is dismantled. Vertical steel bars of the concrete prefabricated parts are connected through a sleeve grouting technology, and fine aggregate concrete or grouting materials are poured at connecting positions of the prefabricated parts and anchor sealing positions for sealing treatment. According to the method, a fabricated concrete column and brick column reinforcing method is provided, the method is good in corrosion resistance and fire resistance, saves energy and is environmentally friendly, the method can effectively improve the mechanical property of the concrete column, the reinforcing effect is guaranteed, standardized fabricated parts are adopted in the construction process, on-site wet operation is greatly reduced, the labor consumption is reduced, the construction efficiency is improved, the cost is reduced, and the construction period is shortened.

Owner:SHAANXI ACAD OF ARCHITECTONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com