Gangue shale sintered brick production system

A production system, coal gangue technology, applied in the production, application, lighting and heating equipment of ceramic materials, etc., can solve the problems of long firing cycle of sintering kiln, achieve the effect of shortening firing cycle, improving production efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

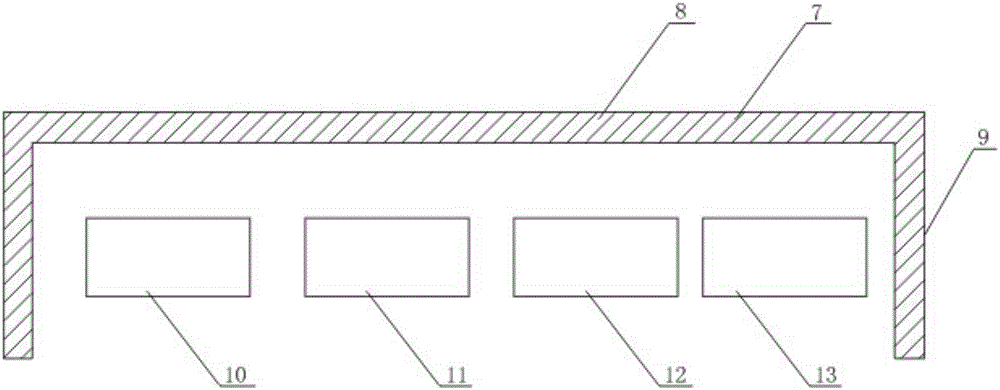

[0034] The coal gangue shale sintered brick production system includes a feeder 1, a feeding belt 2 connected to the feeding machine 1, the other end of the feeding belt 2 is connected to a mixer 3, the outlet of the mixer 3 is connected to an aging bin 4, and the aging bin 4 is connected with a pressure forming machine 5, and the pressure forming machine 5 is connected to a tunnel drying kiln 6 through a billet conveyor belt, and the tunnel drying kiln 6 is connected to a brick sintering kiln 7; the brick sintering kiln 7 includes a kiln roof 8, a kiln wall 9 and Kiln roof 8 and kiln wall 9 surround the working channel, which includes preheating section 10, roasting section 11, heat preservation section 12 and cooling section 13 successively in the length direction of working channel.

Embodiment 2

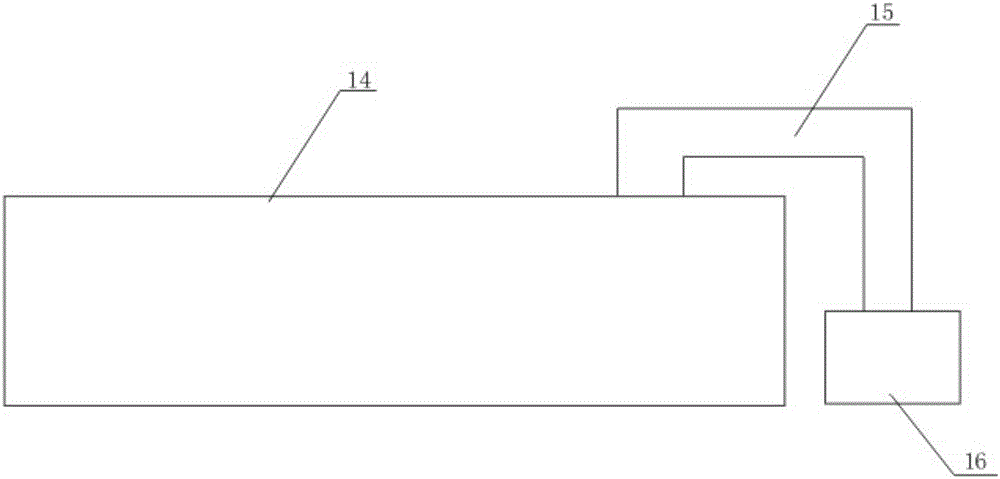

[0036] In this embodiment, on the basis of Embodiment 1, kiln temperature monitors and kiln pressure monitors are arranged in the working channel, and the kiln temperature monitors and kiln pressure monitors are respectively connected to the control system outside the brick sintering kiln 7 for signal connection. .

Embodiment 3

[0038] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the kiln wall 9 includes a refractory layer, a thermal insulation layer, and a thermal insulation layer arranged sequentially from inside to outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com