A process for preparing active mixed materials by belt sintering of coal gangue

A technology of active mixed materials and coal gangue, which is applied in the field of active mixed materials prepared by coal gangue belt sintering, can solve the problems of low output and poor activity of coal gangue, and achieve the effects of high temperature, improved sintering permeability and enhanced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

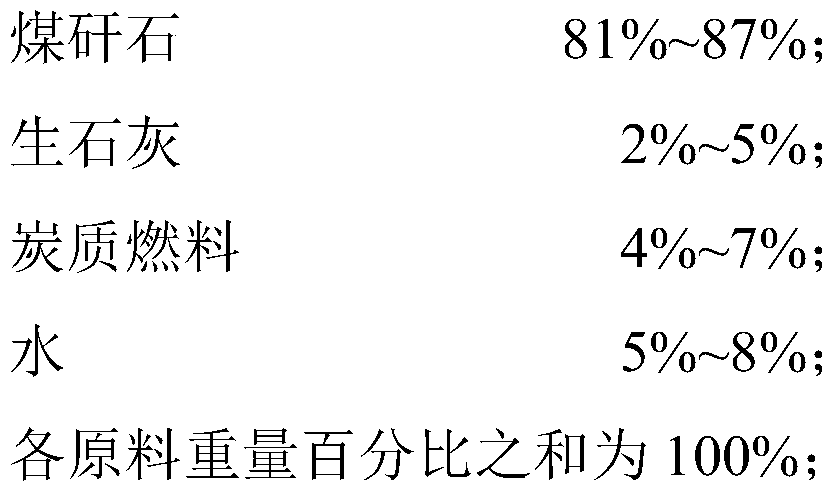

Method used

Image

Examples

Embodiment 1

[0040] Coal gangue powder crushed to -8mm, mixed with semi-coke with a mass ratio of 4%, quicklime with a mass ratio of 2% and water with a mass ratio of 5%, and then vigorously mixed in a cylinder mixer for 3 minutes, mixed The ore leveling belt is transported to the cylinder granulator. During the granulation process, water with a mass ratio of 1.5% is sprayed, and the rotation speed of the cylinder granulator is 40rpm, and the granulation time is 3min. The pellets obtained from granulation have a particle size of The mass ratio of +3mm is 72%, the water content is 7.5%, and the gas permeability resistance of the raw meal is 43Pa.

[0041] Coal gangue raw materials are distributed through the rollers in the belt sintering machine (the height of the material layer is 700mm), and then ignited, ventilated, sintered, and cooled. The ignition time is 2.5 minutes, the ignition temperature is 1100 ° C, the ignition negative pressure is 6KPa; the sintering negative pressure is 12KPa;...

Embodiment 2

[0045] Coal gangue powder crushed to -8mm, mixed with semi-coke with a mass ratio of 5%, quicklime with a mass ratio of 2.5% and water with a mass ratio of 5.5%, and then vigorously mixed in a cylinder mixer for 3 minutes; The ore leveling belt is transported to the cylinder granulator. During the granulation process, water with a mass ratio of 1.5% is sprayed, and the rotation speed of the cylinder granulator is 40rpm, and the granulation time is 3min; the pellets obtained from granulation have a particle size of The mass ratio of +3mm is 75%, the water content is about 7%, and the air permeability resistance of raw meal is 40Pa.

[0046] Coal gangue raw materials are distributed through the rollers in the belt sintering machine (the height of the material layer is 700mm), and then ignited, ventilated and sintered, and cooled; at the ignition time of 2.5min, the ignition temperature is 1150°C, and the ignition negative pressure is 6KPa; the sintering negative pressure is 14KPa...

Embodiment 3

[0050] Coal gangue powder crushed to -8mm, mixed with semi-coke with a mass ratio of 4%, quicklime with a mass ratio of 2.5% and water with a mass ratio of 5.0%, and then vigorously mixed in a cylinder mixer for 3 minutes; The ore leveling belt is transported to the cylinder granulator. During the granulation process, water with a mass ratio of 1.5% is sprayed, and the rotation speed of the cylinder granulator is 40rpm, and the granulation time is 5min; the pellets obtained from granulation have a particle size of The mass ratio of +3mm is 71%, the water content is about 7%, and the gas permeability resistance of raw meal is 44Pa.

[0051] Coal gangue raw materials are distributed through the rollers in the belt sintering machine (the height of the material layer is 700mm), and then ignited, ventilated and sintered, and cooled; at the ignition time of 2.5min, the ignition temperature is 1150°C, and the ignition negative pressure is 6KPa; the sintering negative pressure is 14KPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com