Glass coating equipment and magnetic fluid sealing device therein

A technology of magnetic fluid sealing and coating equipment, applied in the field of glass coating equipment and sealing devices, can solve the problems of air leakage, easy aging and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to make those skilled in the art more clearly understand the technical solution of the glass coating equipment and the magnetic fluid sealing device of the present invention, the specific implementation manner thereof will be described below with reference to the accompanying drawings.

[0008] Ferrofluids are also known as ferrofluids, ferrofluids, or ferrofluids. It combines the properties of magnetic materials and liquids with the ability to use magnetic fields to control rheological, thermophysical, and optical properties. It is a colloidal solution formed by highly dispersing ultrafine magnetic particles in a carrier liquid through a surfactant.

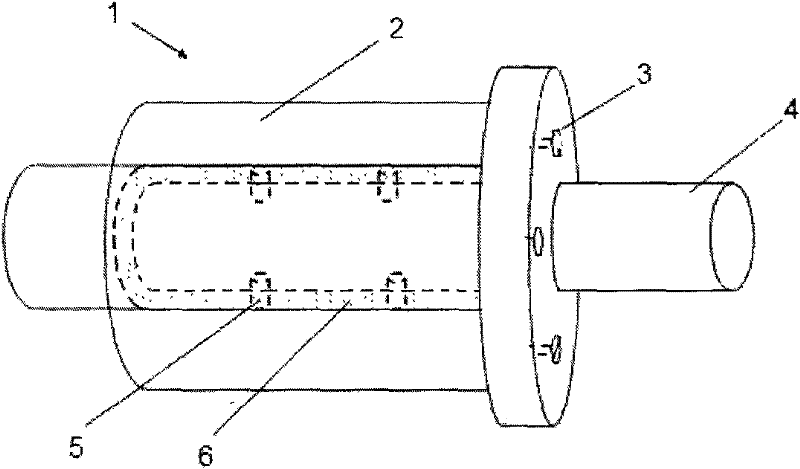

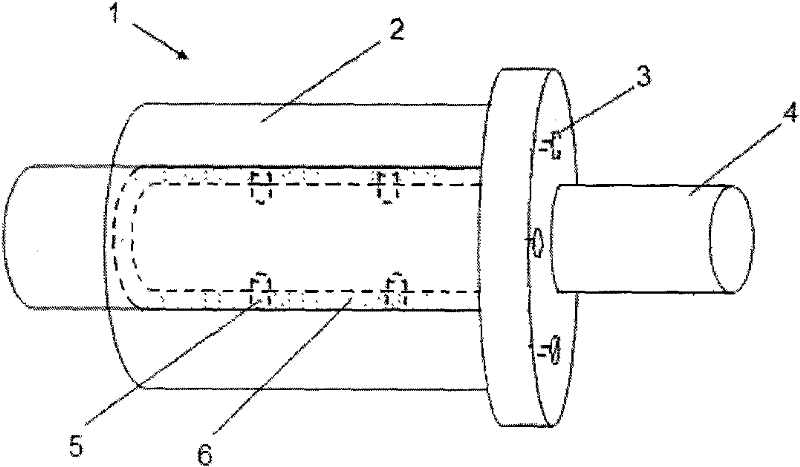

[0009] refer to figure 1 , the magnetic fluid sealing device 1 for glass coating equipment of the present invention, which includes an outer jacket 2, a micro screw 3, an inner shaft 4, a medium screw 5 and a magnetic fluid 6, the magnetic fluid includes magnetic powder and a surfactant, and 4 sets of inner shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com