Colloidal silicate dispersion, method for its preparation and its use

A dispersion, silicate technology, used in sol preparation, gel preparation, colloid chemistry, etc., can solve problems such as poor compression resistance, brittleness, and easy dusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The adhesive of the present invention can be prepared by the following method.

[0056] 7.5g of mineral fibers containing 42.1% SiO 2 , 17.4% Al 2 o 3 , 17.3% CaO, 13.7% MgO, 5.8% FeO, 1.6% Na 2 O, 0.6% K 2 O, the rest are impurities, the fiber diameter is 3-4μm, and the length is 3-10mm. The mineral fiber is mixed with 100ml of 5M formic acid solution. For mixing, a high shear mixing agitator is used to ensure efficient mixing and speed up the dissolution process. The dissolution process takes 1-2hr to complete. When the fibers are completely dissolved, a small amount of polymer, eg, polyethylene glycol with a molar mass of 1000 to 10000, is added, about 1% by weight based on the total solids content of the solution. As the polymer is added, the solution is mixed continuously to stabilize the particles that have formed. By varying the amount of polymer and the time of addition, the point at which all fibers dissolve, the size of the solution particles is also va...

Embodiment 2

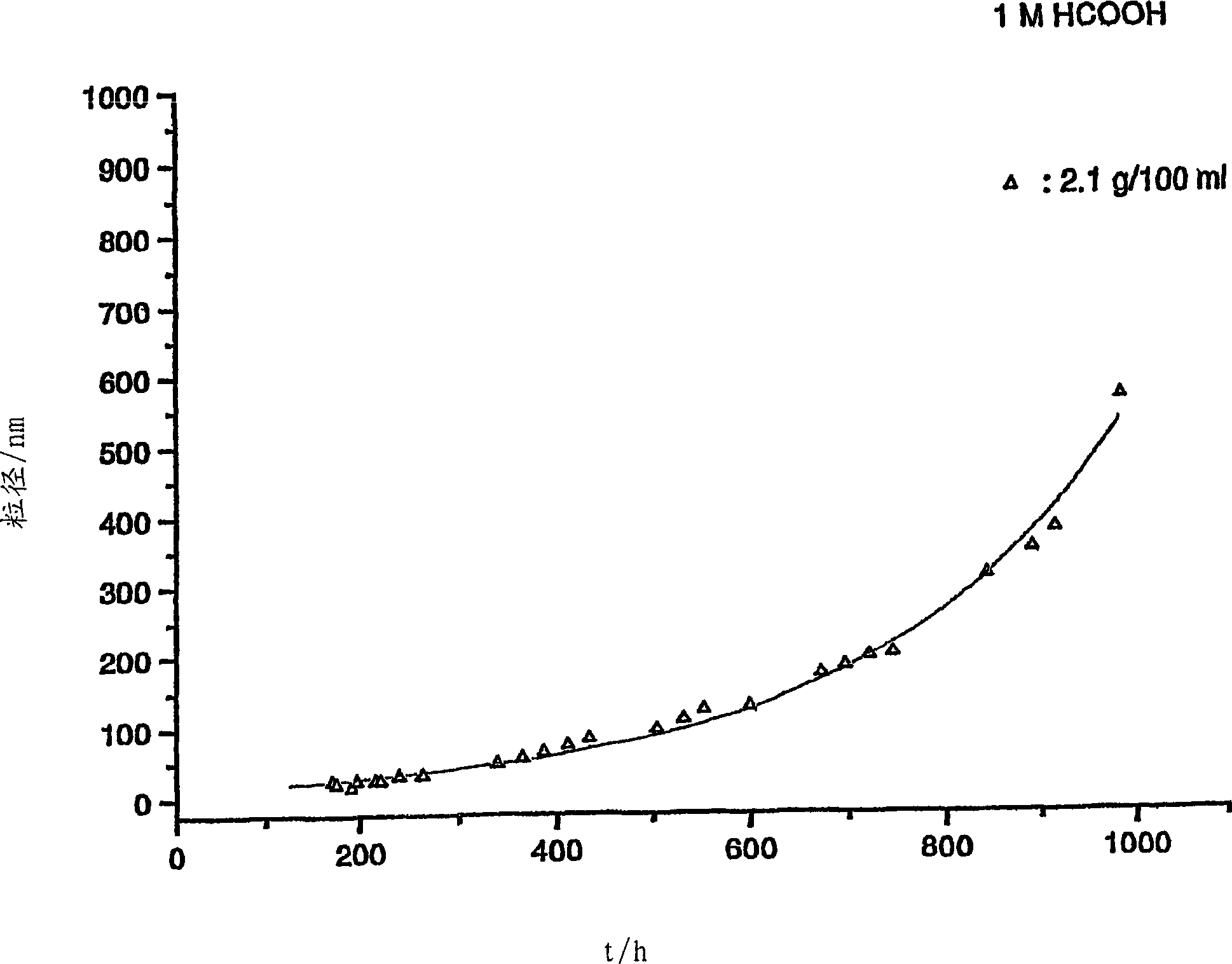

[0060] 2.1 g of fibers having a composition corresponding to Example 1 were dissolved in 100 ml of 1M formic acid solution. After the fibers were dissolved, impurities in the solution were removed by centrifugation. The samples were analyzed by light scattering metrology. Nucleation of primary particles occurs in solution, and the particles exhibit steady growth with increasing particle size over time, as shown in figure 1 middle.

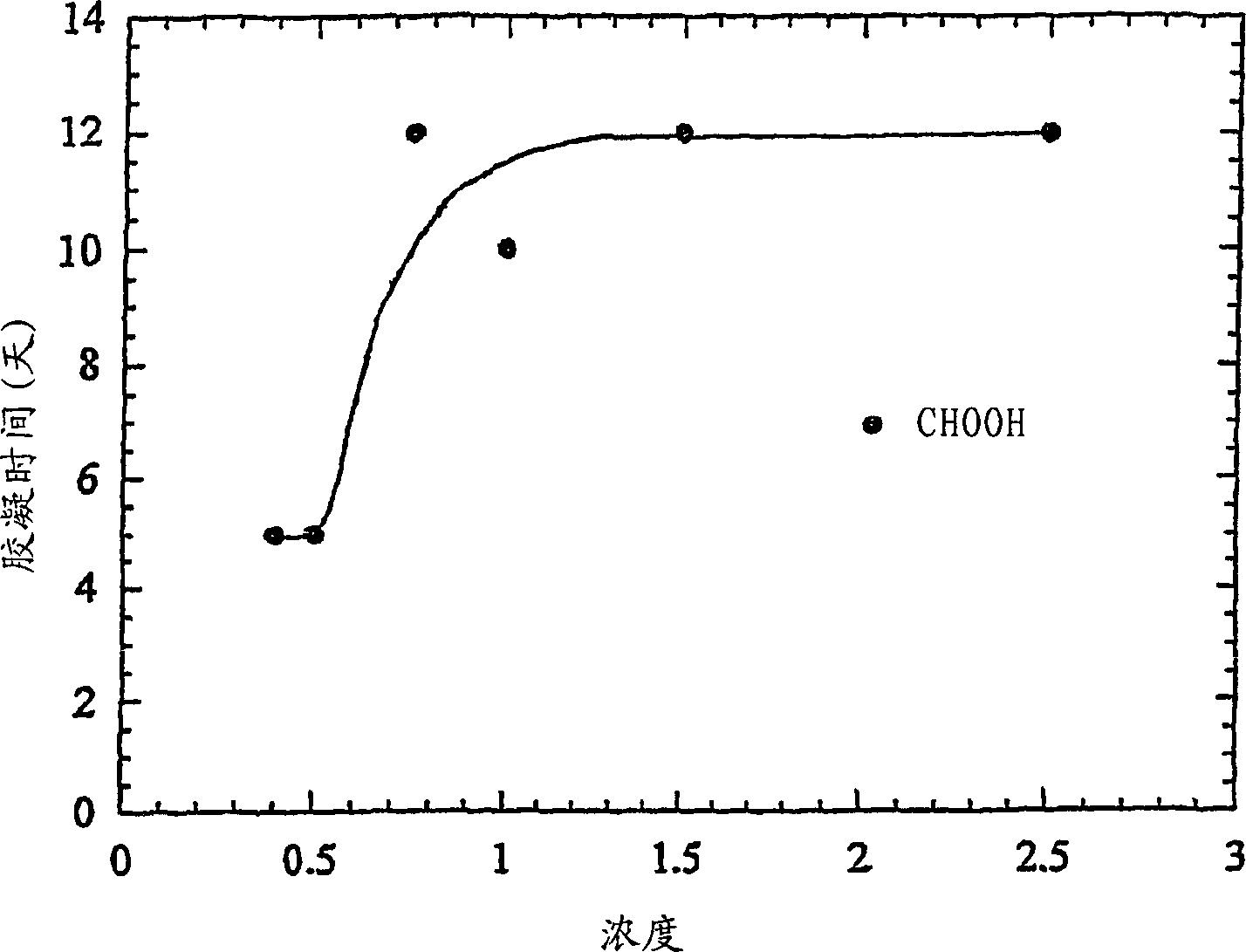

[0061] If the dispersion is not stabilized, it will gel over time, see results in figure 2 ,exist figure 2 A test performed by dissolving 1.15 g of fiber with the above composition in 100 ml of formic acid of various concentrations is demonstrated in . from figure 2 It can be seen that the range of gelation time is 5-12 days.

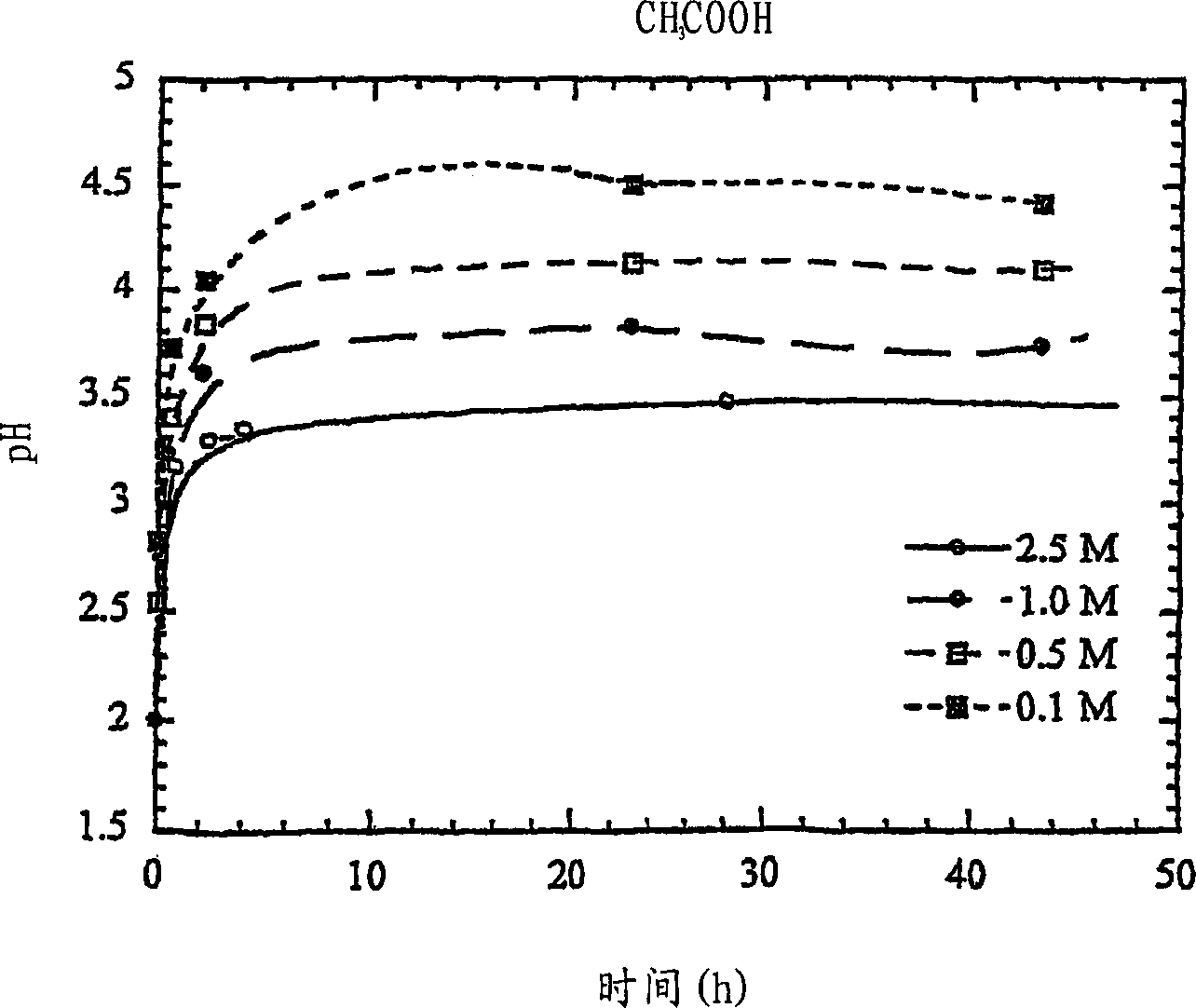

[0062] In order to study the change of pH as a function of time, 1.15g of fiber containing the above composition was dissolved in 100ml of variable concentration acetic acid solution, the results are shown in image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com