Touch screen glass laminate processing method capable of improving efficiency

A processing method and touch screen technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of low processing efficiency, waste of manpower and material resources, and high damage rate, so as to reduce the damage rate, improve processing efficiency and glass quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A touch screen glass lamination processing method for improving efficiency, the steps are as follows:

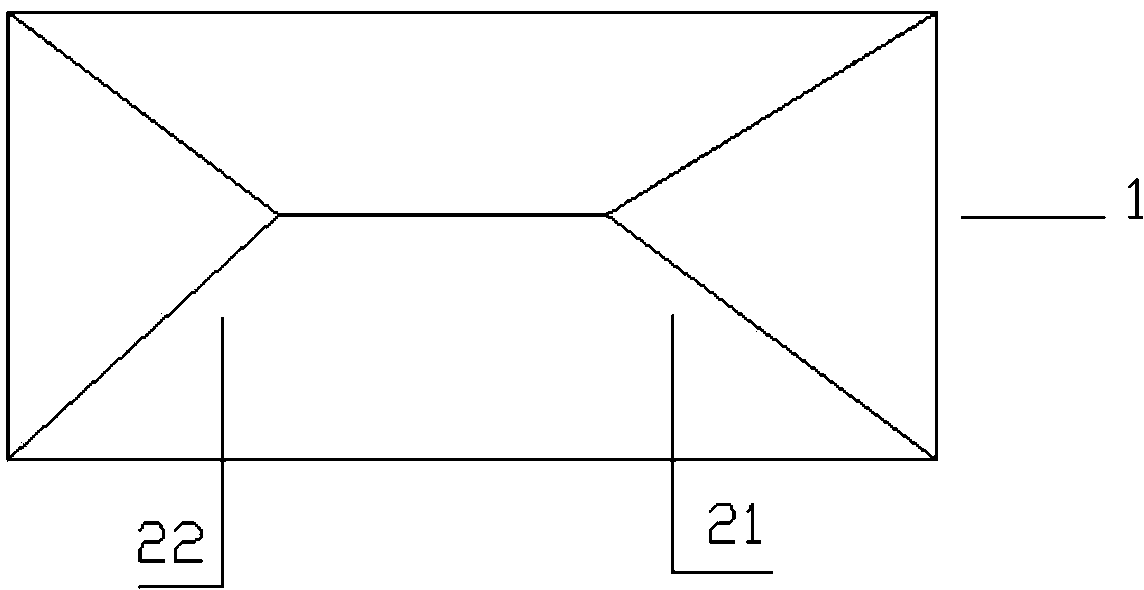

[0025] (1) Two or more pieces of touch screen glass are superimposed and bonded: first fix a piece of touch screen glass horizontally, then drop hydrolyzable UV glue on the glass in two Y shapes, and then cover another piece of touch screen glass on the dripping surface Hydrolyzed UV glue on the touch screen glass, and make the touch screen glass fully contact with the hydrolyzable UV glue, superimpose two pieces of touch screen glass; or repeat this step, stack multiple touch screen glass together;

[0026] (2) UV curing: UV radiation curing and fixing the superimposed touch screen glass;

[0027] (3) Cutting of laminated touch screen glass: cutting the fixed laminated touch screen glass according to processing requirements;

[0028] (4) UV glue hydrolysis: place the cut laminated touch screen glass in hot water at 85°C to 95°C and boil for 50 to 60 minutes;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com