Preparation method of graphene uniform dispersion

A technology of uniform dispersion and graphene, applied in the direction of graphene, nano-carbon, etc., can solve the problems of complicated film transfer process, high raw material price, complicated process, etc., and achieve the effect of good peeling, high conductivity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

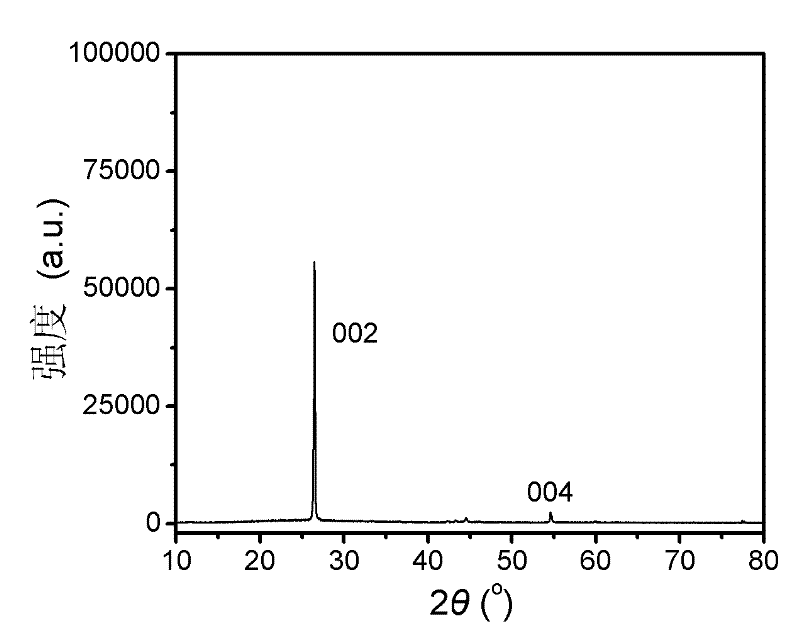

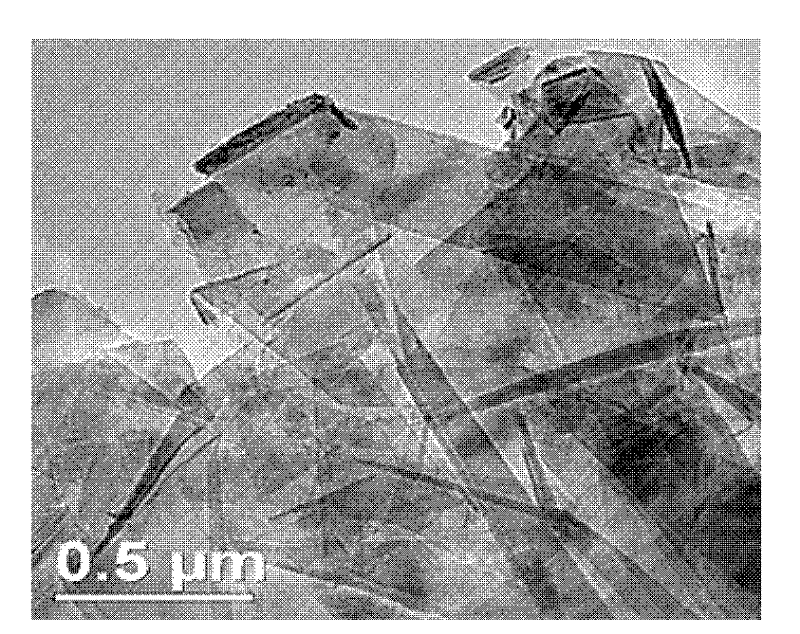

[0021] Take 1g of expandable graphite powder, add 1000mL 0.2g / L polysorbate-80 aqueous solution, heat the autoclave to 200℃, keep the stirring speed at 200rpm for hydrothermal insulation treatment for 6 hours, then centrifuge the slurry at 1000rpm for 20min, The obtained upper layer solution is the graphene dispersion. The dispersion was allowed to stand for 2 hours at room temperature without sedimentation, indicating good stability. figure 1 , 2 The 002 and 004 peaks are the characteristic peaks of graphitization. The intensity of the 002 and 004 peaks of graphene is much lower than that of graphite, indicating that the number of effective exfoliated layers of graphite is reduced; the 001 characteristic peak of graphite oxide does not appear at 10.6° in the XRD graph of graphene It shows that the degree of oxidation is small and the conjugate structure on the surface is less damaged.

Embodiment 2

[0023] Take 10g of high-temperature pyrolytic graphite powder, add 1000mL 2g / L sodium dodecylbenzene sulfonate aqueous solution, heat the autoclave to 160℃, keep the stirring speed 180rpm for hydrothermal insulation treatment for 10 hours, then centrifuge the slurry at 1500rpm After 40 minutes of separation, the upper layer solution obtained is the graphene dispersion, and the dispersion is allowed to stand at room temperature for 2 hours without sedimentation, indicating good stability. The XRD pattern of the obtained product is similar to that of Example 1. The intensity of the 002 and 004 peaks of graphene is relatively lower than that of graphite, and the 001 characteristic peak of graphite oxide does not appear at 10.6°.

Embodiment 3

[0025] Take 100g expandable graphite powder and add it to 1000mL 20g / L polyether P-123 aqueous solution, heat the autoclave to 180℃, keep the stirring speed 160rpm for hydrothermal treatment for 16 hours, then centrifuge the slurry at 2000rpm for 30min to obtain the upper layer solution It is a graphene dispersion, and it is allowed to stand for 2 hours at room temperature without sedimentation, indicating that the dispersion is stable. The XRD pattern of the obtained product is similar to that of Example 1. The intensity of the 002 and 004 peaks of graphene is relatively lower than that of graphite, and the 001 characteristic peak of graphite oxide does not appear at 10.6°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com