Complete set of energy-saving roasting technology for regenerated lithium iron phosphate

A lithium iron phosphate, roasting process technology, applied in the chemical industry, phosphorus compounds, sustainable manufacturing/processing, etc., can solve the problems of high synthesis cost, low lithium ion diffusion coefficient, large fuel consumption, etc., and achieve uniform carbon coverage treatment , Improve the diffusion coefficient and reduce the cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

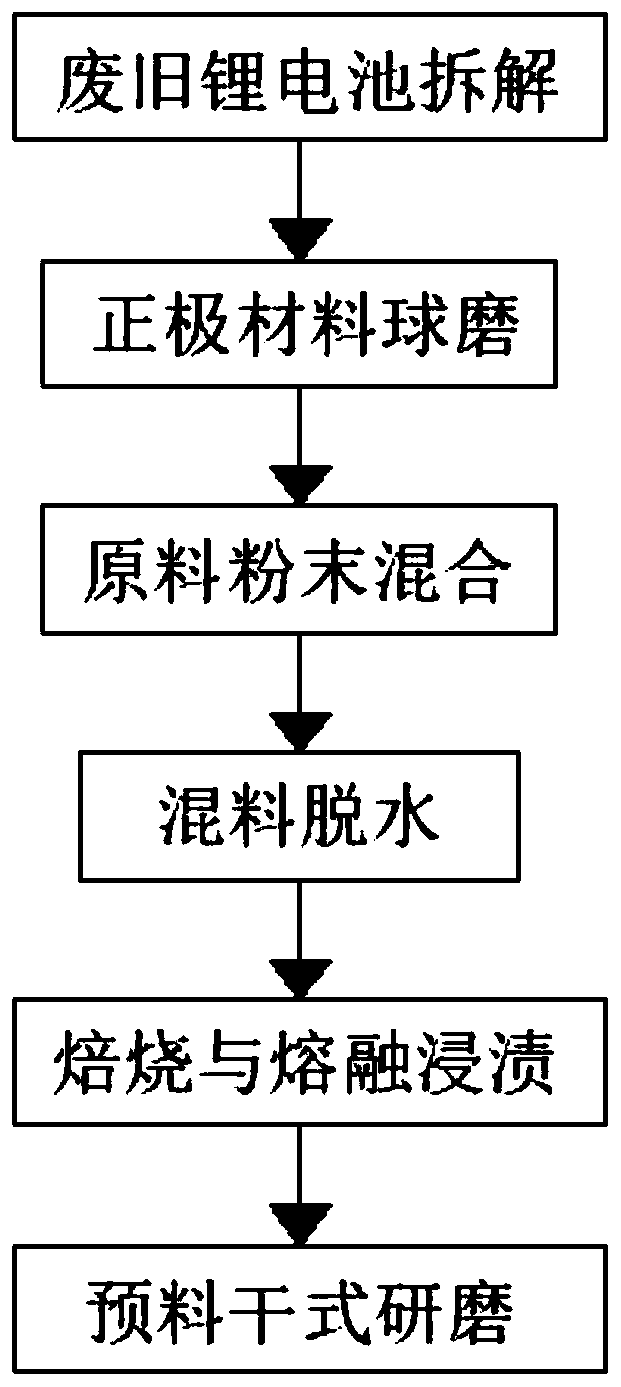

[0046] see Figure 1-3 , a complete roasting process for energy-saving regenerated lithium iron phosphate, comprising the following steps:

[0047] Step 1, disassemble the waste lithium battery, disassemble the collected waste lithium iron phosphate battery, take out the positive electrode sheet, and separate the positive electrode material from the positive electrode sheet;

[0048] Step 2, ball milling the positive electrode material, placing the obtained positive electrode material in a ball mill for ball milling to obtain ferrophosphorus raw material powder;

[0049] Step 3: Mix the raw material powder, mix the powder obtained by ball milling with the conductive carbon source, and use a stirring device to fully stir, mix the raw material powder with the conductive carbon source, and use the stirring device to mix the raw material powder and the conductive carbon source. , using an ultrasonic generator to process the mixture, which is convenient to enhance the mixing effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com