Method for preparing coking raw material through biomass hydrothermal carbonization treatment and application of coking raw material prepared by method to coking production

A hydrothermal carbonization and biomass technology, applied in the field of renewable energy utilization and coking, can solve the problems of low strength, impact on application, and high coke reactivity, and achieve the effects of excellent performance, low energy consumption and cost, and uniform and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

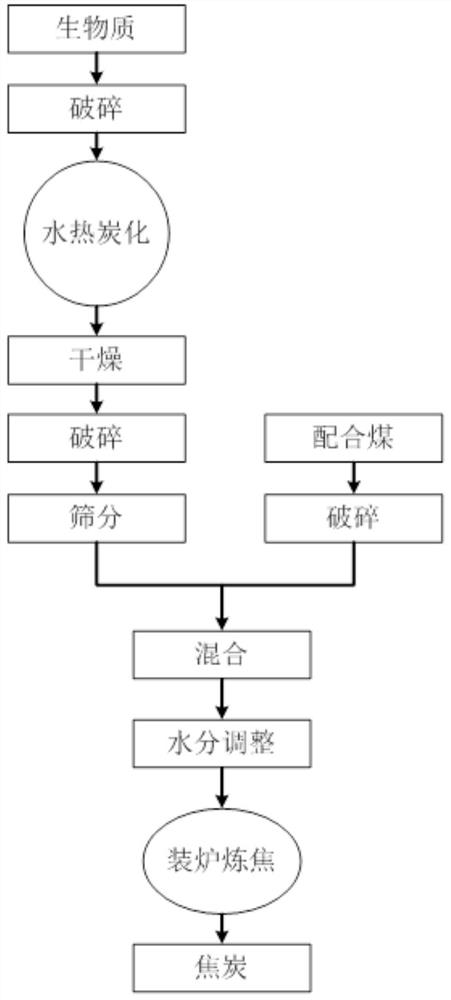

[0048] A method for preparing coking raw materials by hydrothermal carbonization of biomass, taking corn stalks from agricultural production as biomass raw materials as an example, comprising the following steps:

[0049] (1) The collected corn stalks are crushed into fragments with a particle size of less than 5mm by using a shearing mill. Mix the shredded corn stalks and coking waste water at a ratio of 2:1kg / L and add them into the autoclave; start heating after sealing the autoclave, start timing when the temperature rises to 160°C, and stop heating after 4 hours of reaction; temperature When the temperature drops to 60°C, the reactor is opened, and the reactant is transferred to the solid-liquid separation device to separate the solid product from the liquid product to obtain corn straw hydrothermal charcoal. The liquid phase product is deoiled, desalted and purified, and the remaining waste water is recycled; After the corn stalk hydrothermal charcoal was dried, the comp...

Embodiment 2~5

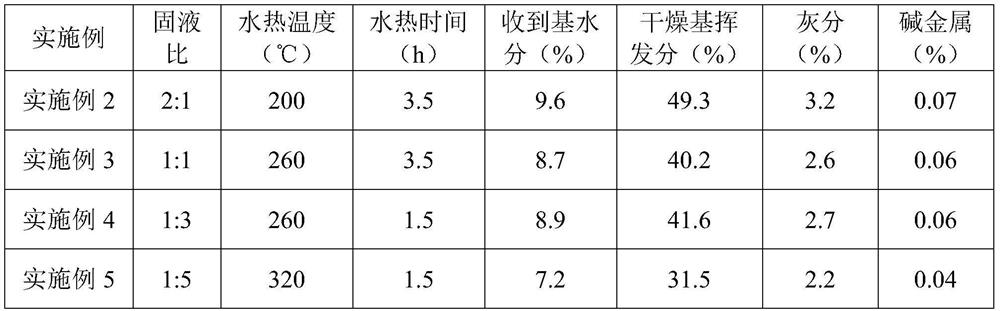

[0056] Embodiments 2 to 5 provide a method for preparing coking raw materials by hydrothermal carbonization of biomass. Compared with Example 1, the difference lies in the solid-to-liquid ratio of corn stalks and coking wastewater, the hydrothermal carbonization temperature, and the hydrothermal carbonization The time is shown in Table 1. Other preparation methods and application methods in coking production are roughly the same as in Example 1, and are not repeated here.

[0057] The preparation conditions of table 1 embodiment 2~5 and the technical index of the hydrothermal charcoal of preparation

[0058]

[0059] Coke performance prepared by table 2 embodiment 2~5

[0060] Example Volatile matter (%) Ash (%) CRI(%) CSR(%) M40(%) M10(%) Example 2 1.3 9.6 27.6 58.2 82.9 11.1 Example 3 1.2 9.3 27.3 59.2 83.2 10.9 Example 4 1.2 9.4 27.2 59.3 83.3 10.9 Example 5 1.1 9.1 26.9 60.3 84.6 10.5

[0061] It can ...

Embodiment 6~15

[0064] Compared with Example 1, the method for preparing coking raw materials by hydrothermal carbonization of biomass provided in Examples 6 to 15 is different in that the moisture content in the coking raw materials, the amount of corn stalk hydrothermal charcoal in the mixed coal (hydrothermal charcoal The mass content in the sum of blended coal), the volatile content and ash content of blended coal are shown in Table 3. Other preparation methods and application methods in coking production are roughly the same as in Example 1, and are not repeated here.

[0065] The preparation parameter of table 3 embodiment 6~15

[0066] Example Hydrothermal carbon content (%) Blended coal volatile matter (%) Mixed coal ash (%) Coking raw material moisture (%) Example 6 20 25.0 9.0 12.0 Example 7 17.5 25.0 9.0 12.0 Example 8 14.8 28.3 7.8 10.1 Example 9 12.6 28.3 7.8 10.1 Example 10 9.5 31.1 6.3 8.3 Example 11 6.8 31.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com