Formed coke clean production method and equipment

A production method and technology for production equipment, which are applied in the field of clean production methods and equipment for molding coke, can solve the problems of high production energy consumption, many production processes, smoke and low strength, and achieve energy saving in production process, simple production control, and improved production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

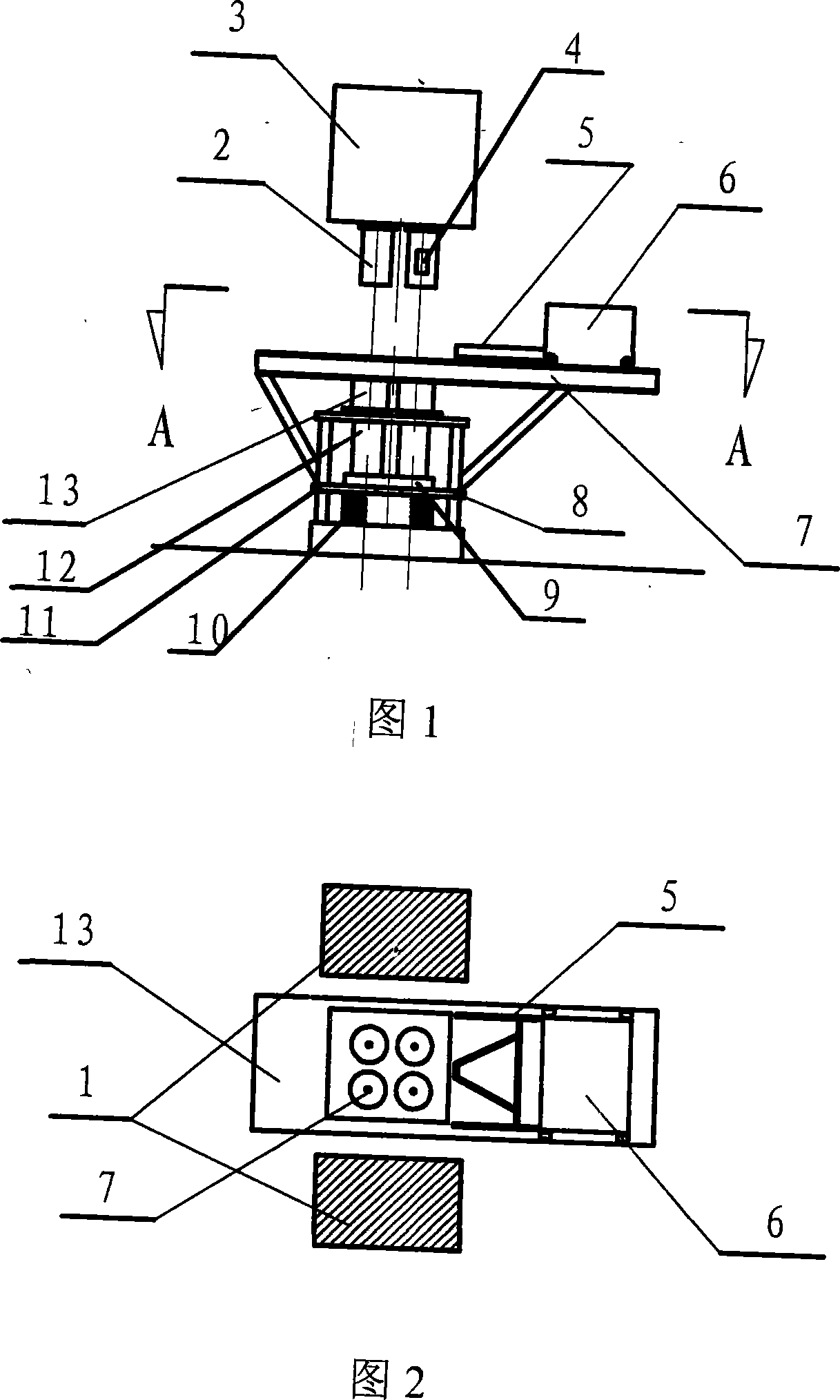

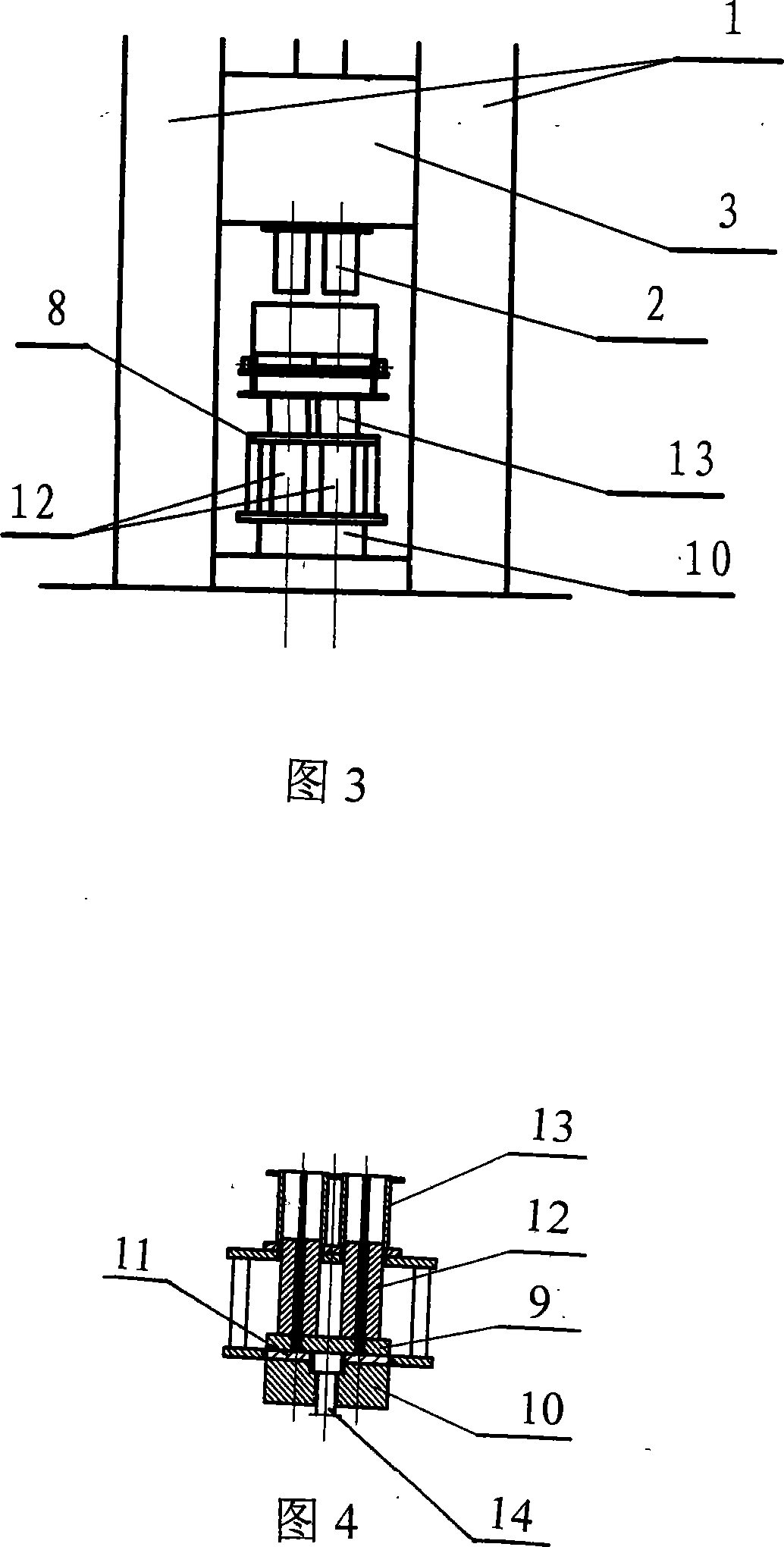

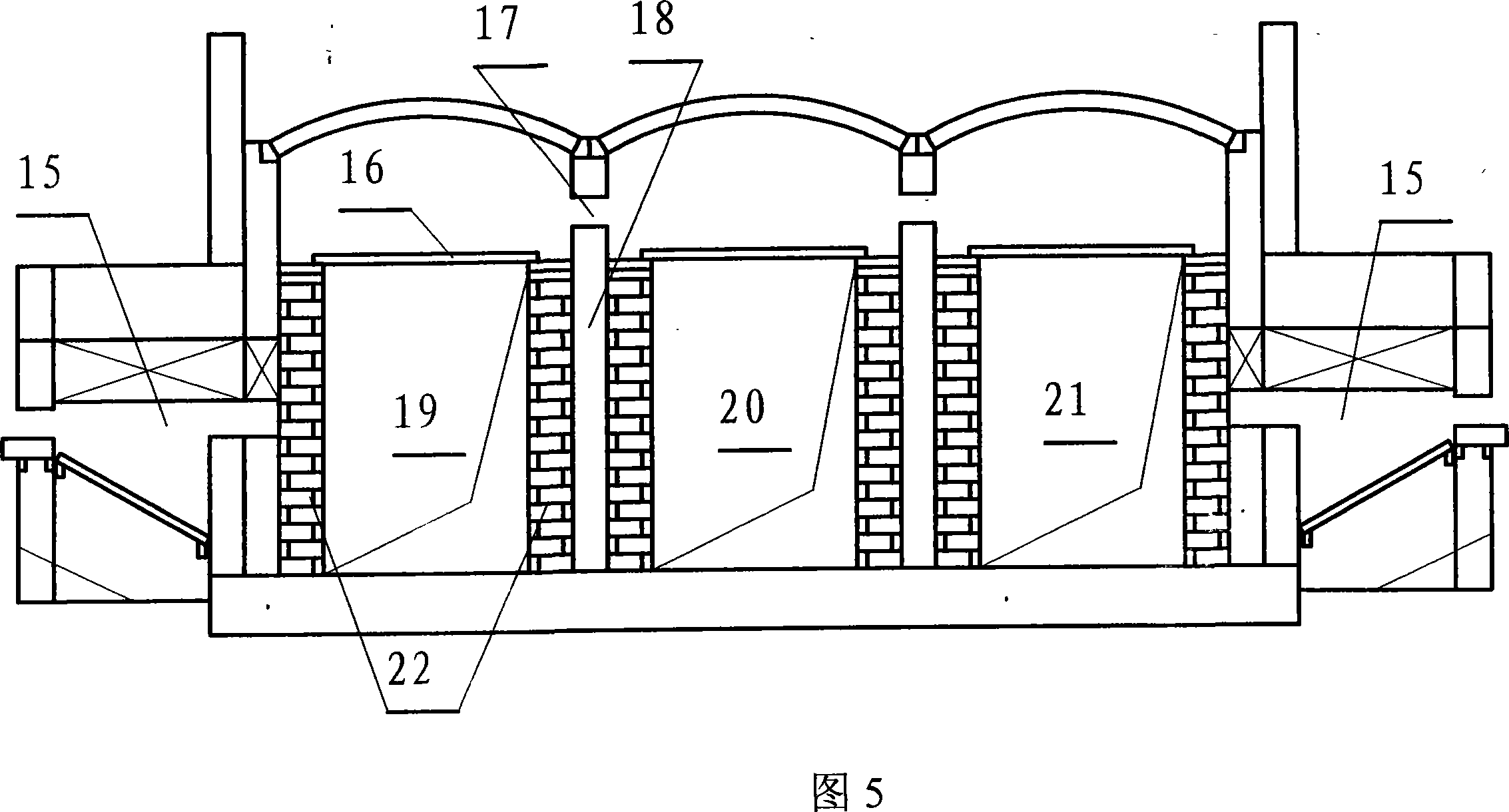

[0017] Take the four-cavity mold as an example for specific installation and use methods:

[0018] In Fig. 1, Fig. 2, Fig. 3, and Fig. 4, the die punches 2 are butt-welded on the mounting plate and fixed on the chute of the working slider 3 of the press with T-shaped bolts, and the punch accumulation discharge holes 4 are outward. , to facilitate discharge; the mold mounting bracket 8 is fixed on the press body; the mold core seat 11 is sunk into the lower opening of the mold mounting bracket 8 (machine plate) and fixed on the pressure base 10 of the press with bolts; the billet top plate 14 is inserted into the core rod of the core base 11 and falls on the core base 11; the ejector 12 is also inserted into the core rod of the core base 11 and falls on the top plate 9; Blank 12 falls on the upper mounting plate of mold mounting bracket 8 (mold supporting plate), and is fixed on the mold mounting bracket 8 with bolts. The feed truck runway platform 7 is fixed on the mold mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com