Method for preparing blast furnace blowing semicoke from low-rank coal based on high-pressure hydrothermal reaction

A technology of hydrothermal reaction and low-rank coal, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as high energy consumption, difficulty in waste heat recovery and utilization, unsatisfactory product quality, etc., and achieves simple operation of equipment, reduction of Steam vaporization consumes heat and has excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

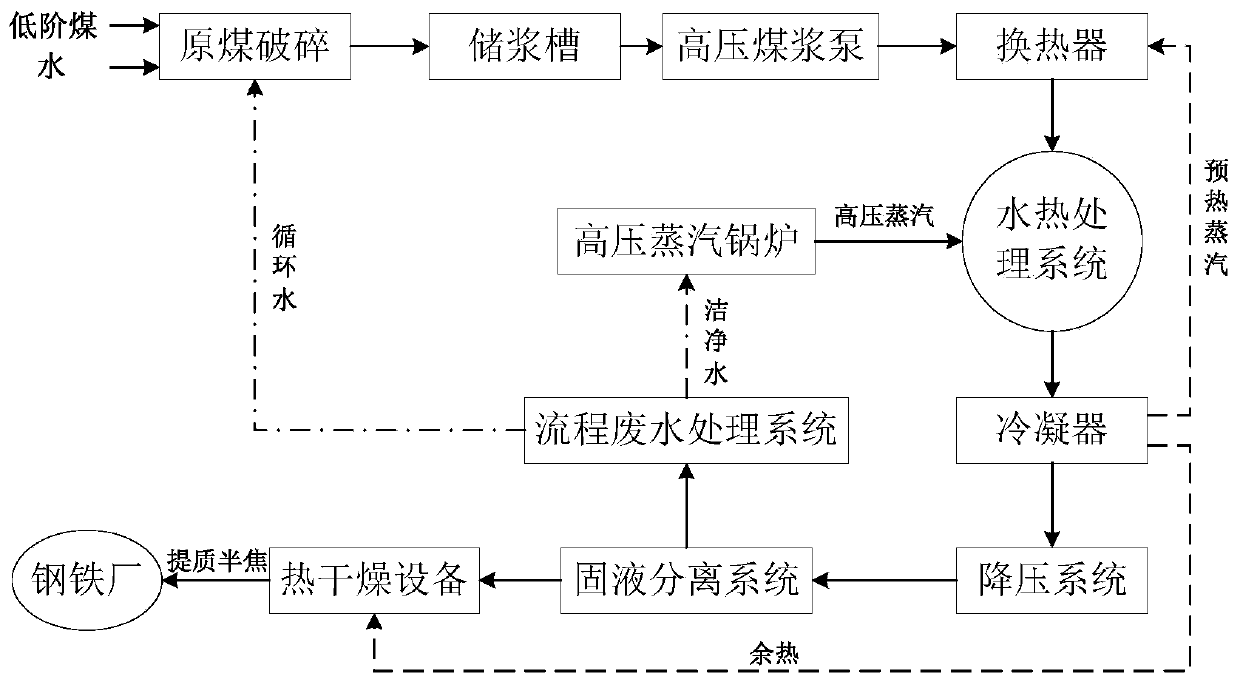

[0030] The method of preparing blast furnace injection semi-coke from low-rank coal based on hydrothermal reaction, such as figure 1 shown, including the following steps:

[0031] (1) Low-rank coal raw coal pretreatment: crush the low-rank raw coal to a level less than 1mm, transport the crushed coal powder to the slurry storage tank through pipelines, and add water to the pulverized coal in the slurry storage tank to stir and mix, control The coal slurry moisture in the slurry storage tank is 40%;

[0032] (2) Coal slurry preheating treatment: After the coal slurry in the slurry storage tank is pressurized to 0.1MPa by a high-pressure coal slurry pump, it is transported to the coal slurry heat exchanger through a pipeline for preheating, and the coal slurry is preheated to 80°C;

[0033] (3) Hydrothermal carbonization treatment: The pressurized and preheated coal slurry is injected into the hydrothermal treatment system through pipelines, and the hydrothermal carbonization t...

Embodiment 2-5

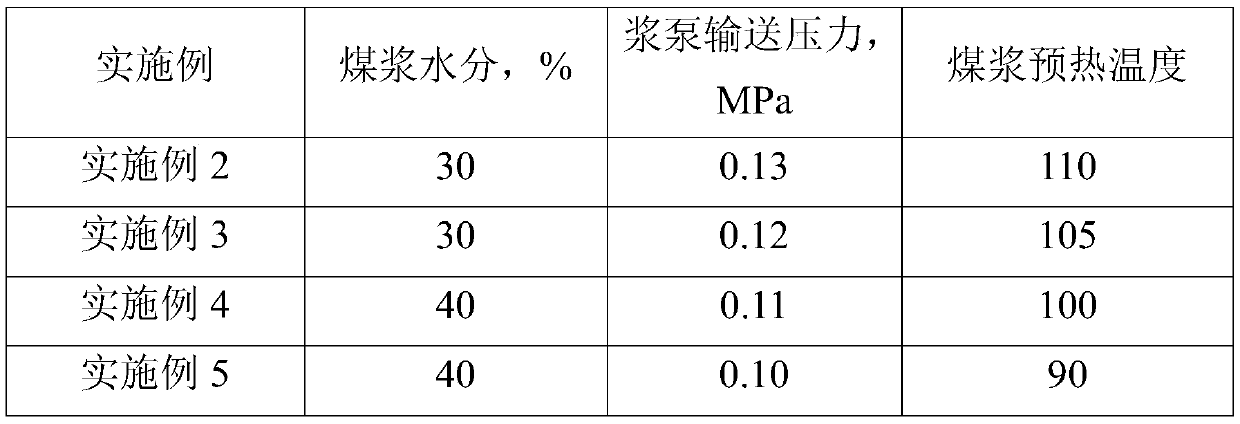

[0038] Embodiment 2-5 provides a method for preparing blast furnace injection semi-coke from low-rank coal based on hydrothermal reaction. Compared with Embodiment 1, the difference is that the coal in step (1) and step (2) is changed The moisture content of the slurry, the delivery pressure of the high-pressure coal slurry pump, and the preheating temperature of the coal slurry are shown in Table 1.

[0039] Table 1 Coal slurry moisture content, high-pressure coal slurry pump delivery pressure and coal slurry preheating temperature corresponding to Examples 2 to 5

[0040]

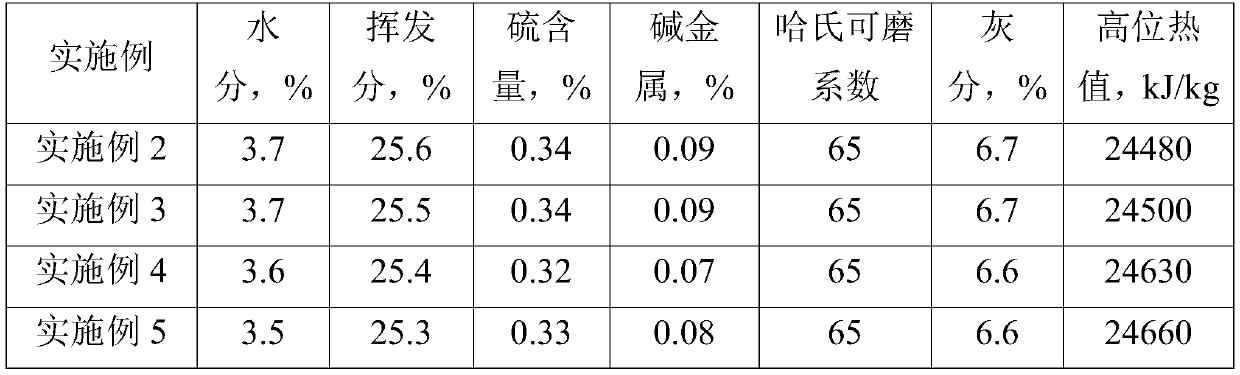

[0041] The quality-improving semi-coke prepared in each embodiment was tested, and the results are shown in Table 2:

[0042] Performance of the upgraded semi-coke prepared in step (5) in Table 2 Examples 2-5

[0043]

[0044] As can be seen from Table 2, the water heat content of the air-dried base of the upgraded semi-coke prepared in Examples 2 to 5 is between 3.2% and 3.5%, the volatile matter ...

Embodiment 6~13

[0046] Examples 6-13 provide a method for preparing blast furnace injection semi-coke from low-rank coal based on hydrothermal reaction. Compared with Example 1, the difference is that the hydrothermal carbonization temperature and treatment in step (3) are changed Time, the specific values of each embodiment corresponding hydrothermal carbonization temperature and processing time are as shown in table 3:

[0047] Table 3 Embodiment 6~13 corresponding hydrothermal carbonization temperature and processing time

[0048] Example heating temperature, ℃ Processing time, h Example 6 300 4 Example 7 320 3.5 Example 8 340 3 Example 9 360 2 Example 10 380 1.5 Example 11 400 1 Example 12 340 4 Example 13 340 2

[0049] The quality-improving semi-coke prepared in each embodiment was tested, and the results are shown in Table 4:

[0050] Performance of the upgraded semi-coke prepared in step (5) in Table 4 Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com