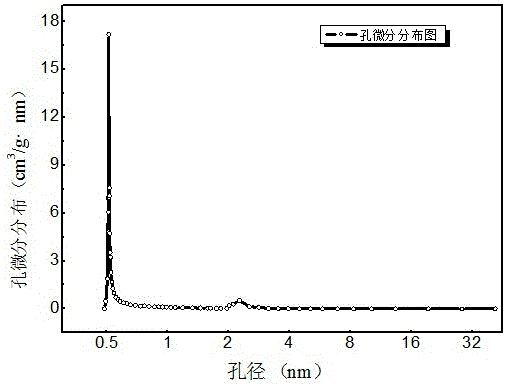

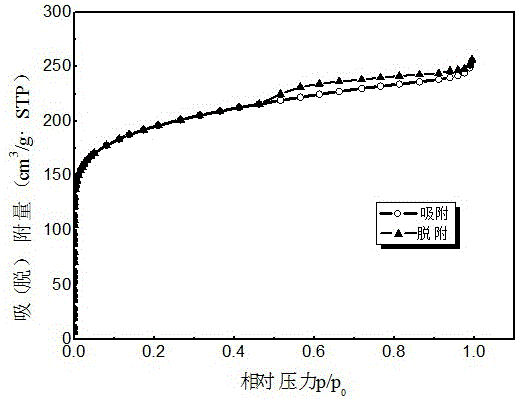

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

A gas separation, ultra-microporous technology, applied in hydrogen separation, chemical instruments and methods, hydrogen separation by selective and reversible absorption, etc., can solve problems such as difficulty in effectively tailoring the pore size distribution of products, equipment corrosion, and high production costs. Achieve the effect of favorable carbon source loading, increased equipment capacity, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A uniform ultramicroporous activated carbon for gas separation and a preparation method thereof, comprising the steps of:

[0030] Step 1. Grinding and pulverizing the raw material semi-coke, passing through a 150-200 mesh sieve, drying to obtain blue-coke powder, mixing KOH accounting for 15wt% of the raw material semi-coke, activating agent accounting for 5wt% of the raw material semi-coke and water to prepare into an impregnating liquid, wherein the quality of water is 0.8 times that of the raw material semi-coke; then add the semi-coke to the impregnating liquid and soak at room temperature for 24 hours to obtain the preparatory material;

[0031] Step 2, the preparatory material that step 1 is made moves in the tubular furnace, in N 2 Controlled thermal decomposition under protective atmosphere, where N 2 The flow rate of the protective atmosphere is 200~250ml / min; the control thermal decomposition is to first raise the temperature of the tube furnace to 370°C at ...

Embodiment 2

[0035] A uniform ultramicroporous activated carbon for gas separation and a preparation method thereof, comprising the steps of:

[0036] Step 1: Grind industrial waste semi-coke powder, pass through a 150-200 mesh sieve, and dry to obtain semi-coke powder. Mix KOH accounting for 10 wt% of the raw material semi-coke, an activation aid accounting for 10 wt% of the raw material semi-coke, and water. Prepare an impregnating solution, wherein the quality of water is 1.2 times that of the raw material semi-coke; then add the semi-coke to the impregnating solution and soak at room temperature for 18 hours to obtain a preparatory material;

[0037] Step 2, the preparatory material that step 1 is made moves in the tubular furnace, in N 2 Controlled thermal decomposition under protective atmosphere, where N 2 The flow rate of the protective atmosphere is 200ml / min; the control thermal decomposition is to first raise the temperature of the tube furnace to 350°C at a heating rate of 4~6...

Embodiment 3

[0041] A uniform ultramicroporous activated carbon for gas separation and a preparation method thereof, comprising the steps of:

[0042] Step 1. Grind industrial waste semi-coke powder, pass through a 150-200 mesh sieve, and dry to obtain semi-coke powder. Mix KOH accounting for 5wt% of the raw material semi-coke, an activation aid accounting for 10wt% of the raw material semi-coke, and water. Prepare an impregnation solution, wherein the quality of water is 1.2 times that of the raw material semi-coke; then add the semi-coke to the impregnation solution and soak at room temperature for 12 hours to obtain a preparatory material;

[0043] Step 2, the preparatory material that step 1 is made moves in the tubular furnace, in N 2 Controlled thermal decomposition under protective atmosphere, where N 2 The flow rate of the protective atmosphere is 300ml / min; the control thermal decomposition is to first raise the temperature of the tube furnace to 400°C at a heating rate of 4~6°C / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com