Preparation method of high-density ultrafine-aperture graphite

A fine-pore, high-density technology, applied in the field of ultra-fine-pore graphite preparation, can solve the problems of reducing the specific surface area and surface energy of graphite material particles, and the inability to form large-scale products, so as to reduce the specific surface area and surface energy, The effect of reducing processing cost and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

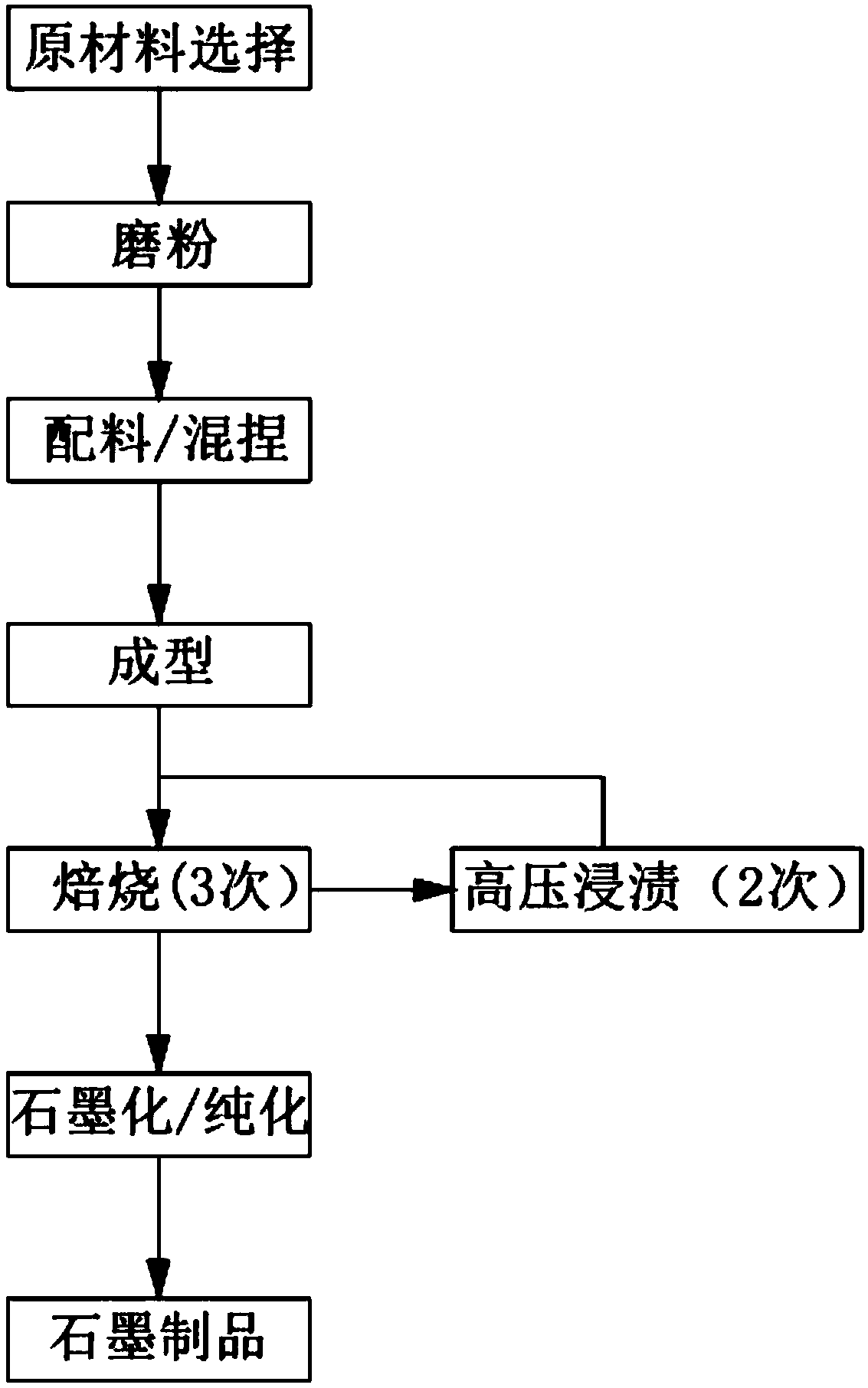

[0081] Such as figure 1 shown

[0082] 1. Raw materials: 70 parts by weight of petroleum coke with an average diameter of 10 μm and 30 parts by weight of pitch.

[0083] 2. Preparation method:

[0084] 1) Raw material selection

[0085] Choose from petroleum coke and pitch.

[0086] It mainly consists of the following raw materials and performance indicators:

[0087] Petroleum coke: fixed carbon content ≥98.5%, ash content ≤0.5%, boron (B), gadolinium (Gd) are less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) Less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.5%;

[0088] Asphalt: ash content ≤0.5%, volatile content 35-60%, coking value 40-70%, softening point 80-200℃, quinoline insoluble matter 8-25%, toluene insoluble matter 25-55% ;

[0089] 2) Ingredients, kneading

[0090] Put the petroleum coke and pitch into the kneader, the temperature is 350°C, and the kneading time is 100min.

[0091] 3) Isostatic pressing

[0092] Put the product obt...

Embodiment 2

[0106] Such as figure 1 shown

[0107] 1. Raw materials: 70 parts by weight of pitch coke with an average diameter of 30 μm and 30 parts by weight of pitch.

[0108] 2. Preparation method:

[0109] 1) Raw material selection

[0110] Select Pitch Coke and Pitch.

[0111] It mainly consists of the following raw materials and performance indicators:

[0112] Pitch coke: fixed carbon content ≥ 98.5%, ash content ≤ 0.5%, boron (B), gadolinium (Gd) less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) Less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.5%;

[0113] Asphalt: ash content ≤0.5%, volatile content 35-60%, coking value 40-70%, softening point 80-200℃, quinoline insoluble matter 8-25%, toluene insoluble matter 25-55% ;

[0114] 2) Ingredients, kneading

[0115] Put the pitch coke and pitch into the kneader, the temperature is 300°C, and the kneading time is 90min.

[0116] 3) Isostatic pressing

[0117] Put the product obtained in step 3) into a ...

Embodiment 3

[0131] Such as figure 1 shown

[0132] 1. Raw materials: 75 parts by weight of petroleum coke with an average diameter of 50 μm and 25 parts by weight of pitch.

[0133] 2. Preparation method:

[0134] 1) Raw material selection

[0135] Choose from petroleum coke and pitch.

[0136] It mainly consists of the following raw materials and performance indicators:

[0137] Petroleum coke: fixed carbon content ≥98.5%, ash content ≤0.5%, boron (B), gadolinium (Gd) are less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) Less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.5%;

[0138] Asphalt: ash content≤0.5%, volatile content 35-60%, coking value 40-70%, softening point 80-200℃, quinoline insoluble matter 8-25%, toluene insoluble matter 25-55% ;

[0139] 2) Ingredients, kneading

[0140] Put the petroleum coke and pitch into the kneader, the temperature is 200°C, and the kneading time is 85min.

[0141] 3) Isostatic pressing

[0142] Put the product obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com