High-strength epoxy structural adhesive for adhering carbon fiber composite materials

A technology of epoxy structural adhesive and composite material, applied in the direction of epoxy resin adhesive, adhesive type, conjugated diene adhesive, etc. surface damage and other problems, to achieve the effect of small performance attenuation, high bonding strength and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

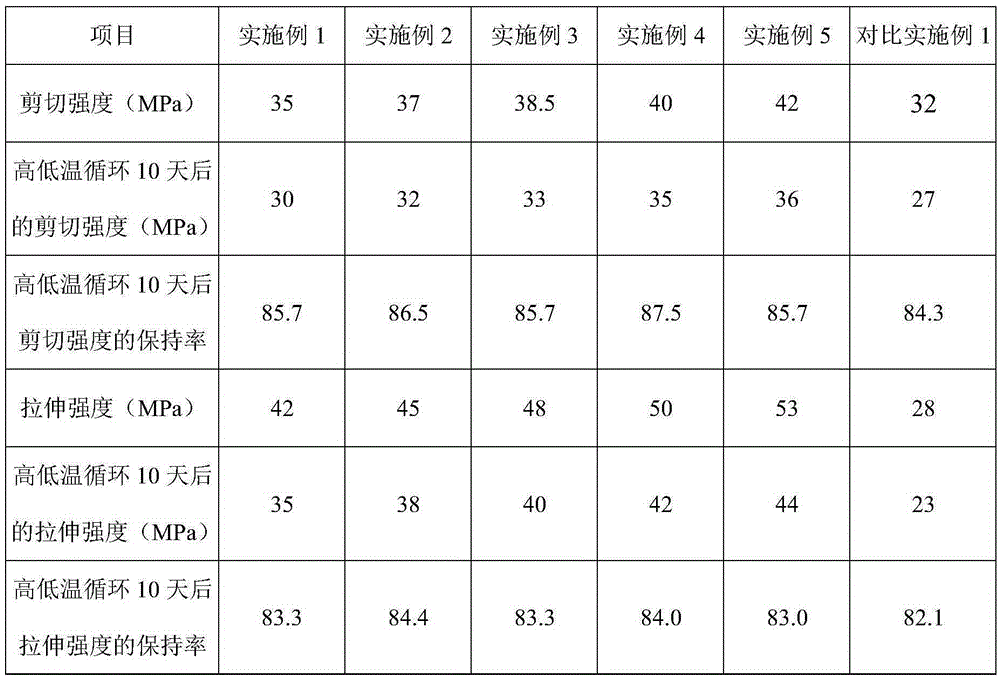

Examples

Embodiment 1

[0031] A high-strength epoxy structural adhesive for bonding carbon fiber composite materials, which is composed of A component and B component, and the components and mass fractions contained in the A component are: E51 / polybutadiene rubber 40 parts of polymer, 60 parts of mixed epoxy resin, 0.2 part of reinforced graphene, 5 parts of SBM / MAM copolymer, 6 parts of ETBN toughening agent, 0.1 part of dispersant, 1 part of nano-sized attapulgite, hydrophilic 1 part of fumed silica and 0.5 part of silane coupling agent; wherein, the specific surface area of the reinforced graphene is 150m 2 / g, the pH value is 7.0; the epoxy equivalent of the hybrid epoxy resin is 117-127 g / eq; the particle size of the nano-scale attapulgite is 100 nm; the hydrophilic fumed silica has a Specific surface area (BET method) is 360m 2 / g.

[0032] The components and their parts included in the B component are: 85 parts of modified polyamide, 15 parts of flexible polyamide, 3 parts of ATBN reactiv...

Embodiment 2

[0041] A high-strength epoxy structural adhesive for bonding carbon fiber composite materials, which is composed of A component and B component, and the components and mass fractions contained in the A component are: E51 / polybutadiene rubber 45 parts of polymer, 55 parts of mixed epoxy resin, 0.25 part of reinforced graphene, 6 parts of SBM / MAM copolymer, 7 parts of ETBN toughening agent, 0.2 part of dispersant, 2 parts of nano-sized attapulgite, hydrophilic 2 parts of fumed silica and 0.8 part of silane coupling agent; wherein, the specific surface area of the reinforced graphene is 200m 2 / g, the pH value is 8.0; the epoxy equivalent of the hybrid epoxy resin is 117~127g / eq; the specific surface area (BET method) of the hydrophilic fumed silica is 400m 2 / g; the particle size of the nano-scale attapulgite is 200nm.

[0042] The components and the number of parts contained in the B component are: 88 parts of modified polyamide, 12 parts of flexible polyamide, 4 parts of ATB...

Embodiment 3

[0051] A high-strength epoxy structural adhesive for bonding carbon fiber composite materials, which is composed of A component and B component, and the components contained in the A component and their mass parts are: E51 / polybutadiene rubber 50 parts of polymer, 50 parts of mixed epoxy resin, 0.3 parts of reinforced graphene, 7 parts of SBM / MAM copolymer, 8 parts of ETBN toughening agent, 0.3 parts of dispersant, 3 parts of nano-scale attapulgite, hydrophilic Type fumed silica 3 parts, silane coupling agent 1.0 parts. Wherein, the specific surface area of the enhanced graphene is 250m 2 / g, the pH value is 7.0; the epoxy equivalent of the mixed epoxy resin is 117~127g / eq; the particle diameter of the nano-scale attapulgite is 300nm; the hydrophilic fumed silica The specific surface area (BET method) is 400m 2 / g.

[0052] The components and parts contained in the B component are: 90 parts of modified polyamide, 10 parts of flexible polyamide, 5 parts of ATBN reactive li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com