Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Poor improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon carbide particle reinforced aluminum-based composites

The invention discloses a method for preparing silicon carbide particle reinforced aluminum-based composites. The method comprises the steps: (a) using silicon carbide particles (SiCp) of different particle diameters according to a volume ratio of 1:1-2:1 to obtain mixed silicon carbide particles, adding the mixed silicon carbide particles to a mixer and stirring for 1-3.5 hours; (b) adding binder and pore-forming agent to the silicon carbide particle mixtures of different particle diameters, uniformly stirring; (c) delivering the silicon carbide particles on a press to obtain preforms by pressing, drying and preserving the preforms at a temperature of 80-120 DEG C; (d) pre-sinttering the SiCp mixture performs to obtain SiCp blanks; (e) removing impurities of the SiCp blanks, carrying out preoxidation for 1-2.5 hours at constant temperature of 1000-1100 DEG C; and (f) changing aluminum alloy in such a way: placing aluminum matrix material and the SiCp blanks together, adopting a free-infiltration method and maintaining the temperature for 2-4 hours to obtain the silicon carbide particle reinforced aluminum matrix composites. The preparation technology in the invention is simple, with a low cost and is easy to be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

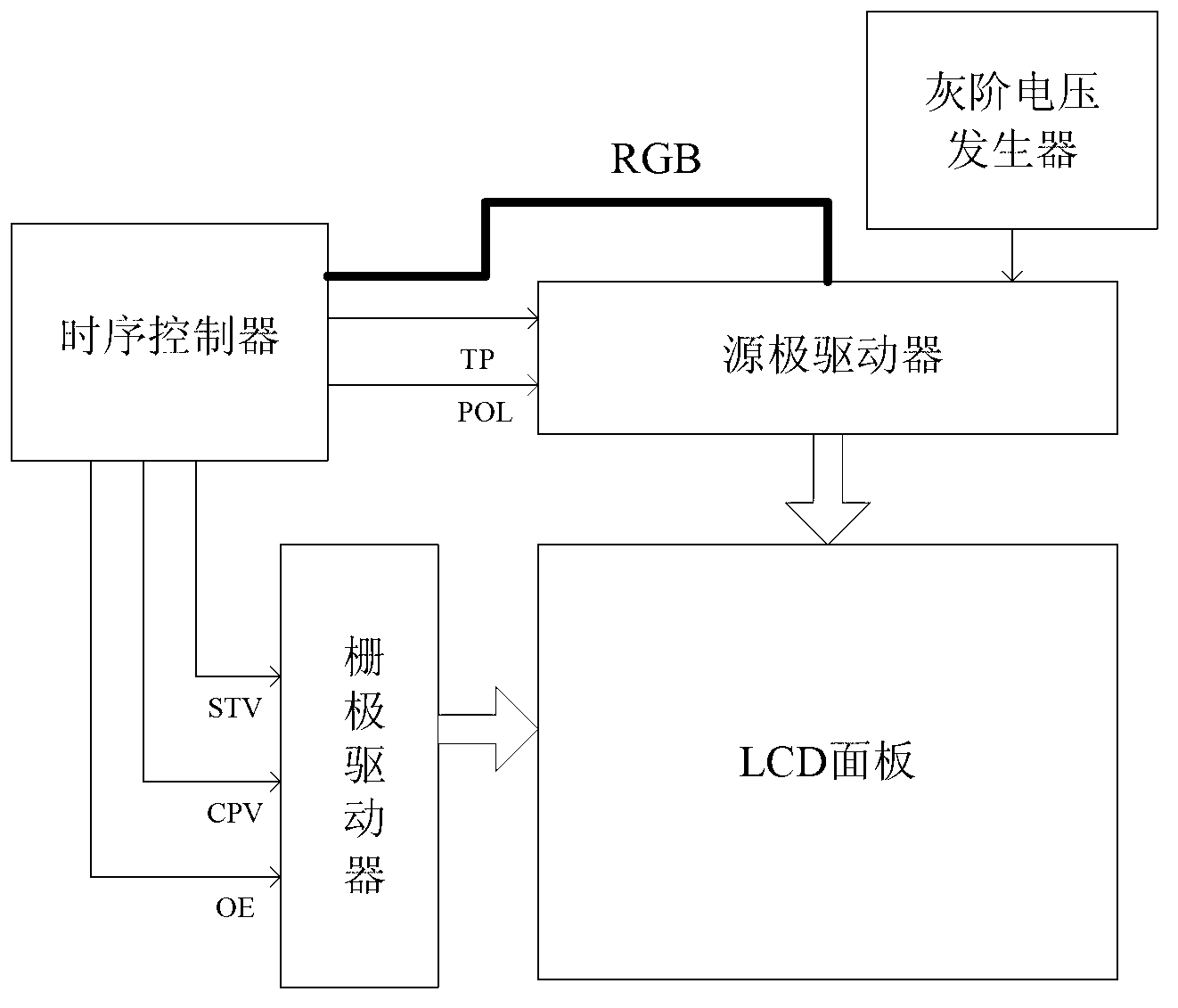

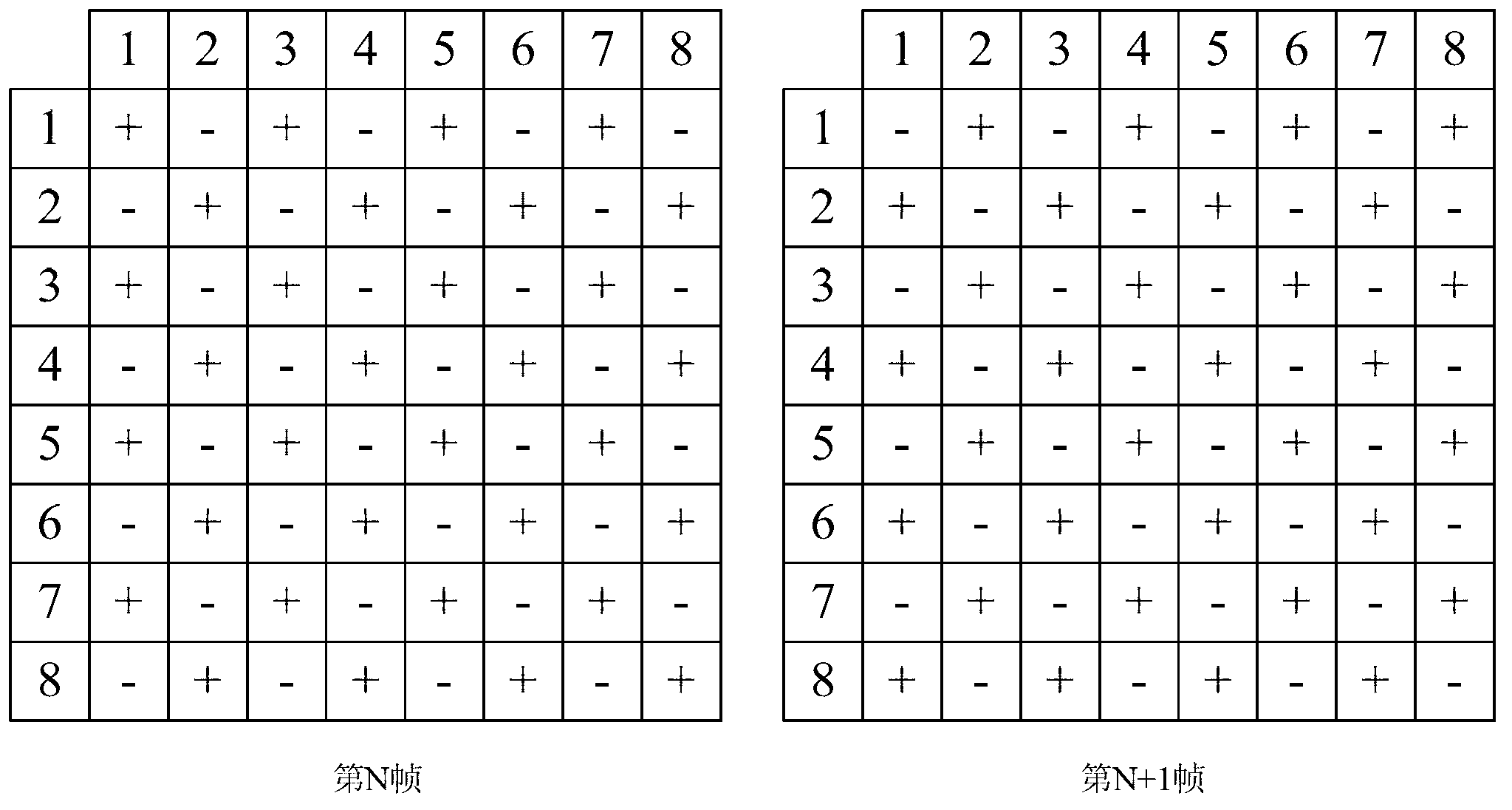

Liquid crystal display device and method and apparatus for driving liquid crystal display device

InactiveCN102842299AAvoid Pull EffectsPoor improvementStatic indicating devicesLiquid-crystal displayGray level

The invention provides a liquid crystal display (LCD) device and a method and apparatus for driving the LCD device, belonging to the liquid crystal display field. The method comprises the following steps: generating gray-scale data of sub-pixels according to the received image data; taking a plurality of sub-pixels as a processing unit, and generating polarity signals of gray-scale voltages corresponding to gray-scale data of each sub-pixel in the plurality of sub-pixels respectively, wherein the polarity signals of the gray-scale voltages are used for enabling the overall polarity of the gray-scale voltages of the plurality of the sub-pixels to approximate to zero; and outputting the gray-scale data of each sub-pixel and the corresponding polarity signals to a source driver of the LCD device. According to the LCD device and the method and apparatus for driving the LCD device provided by the invention, adverse effects of green adhesion, crosstalk, scintillation and the like caused by public voltage disturbance can be improved.

Owner:BOE TECH GRP CO LTD +1

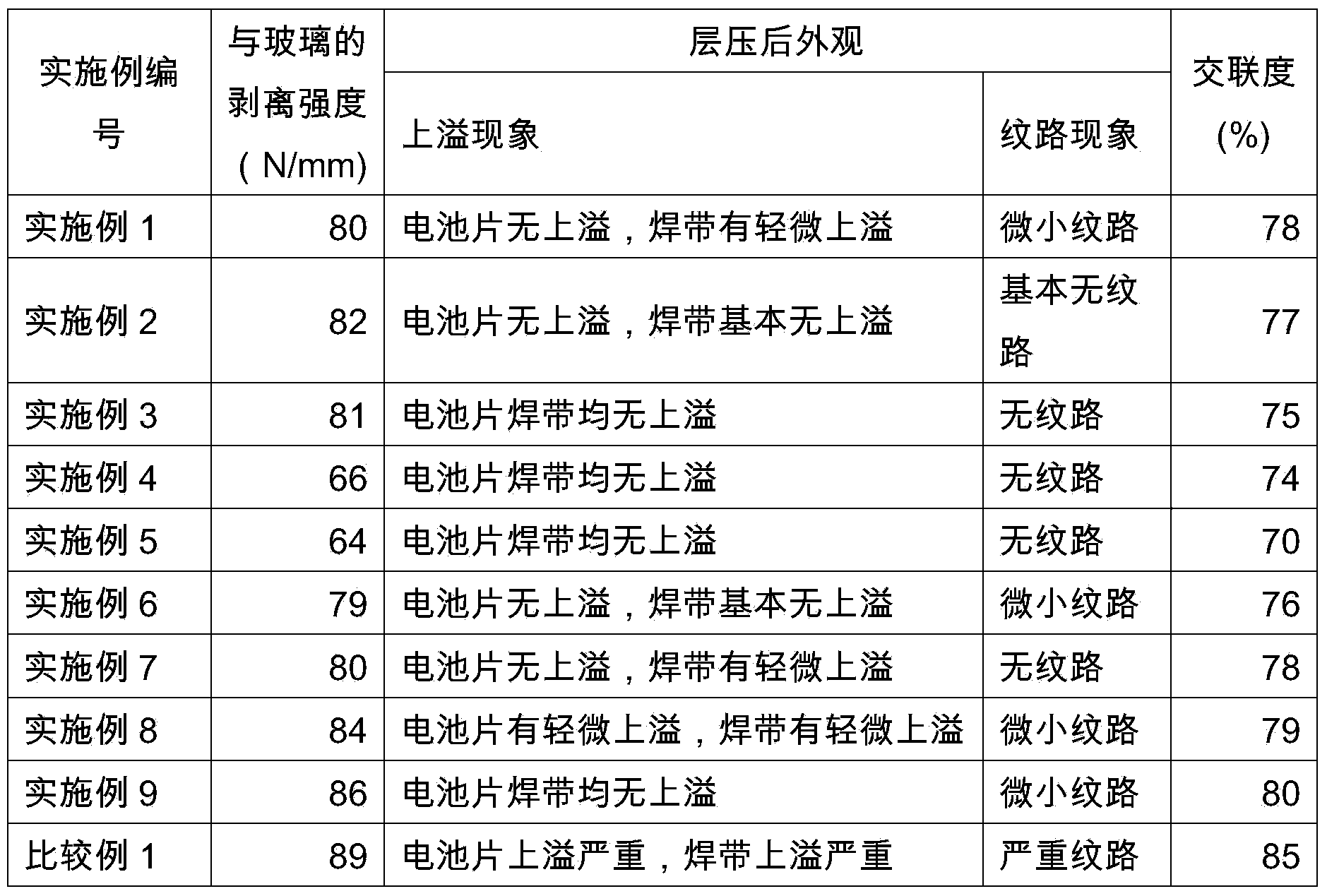

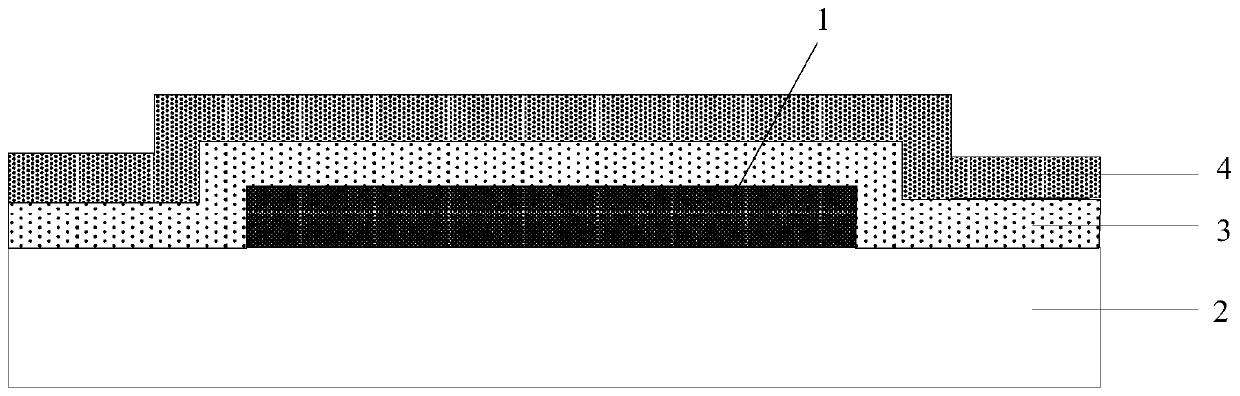

Solar battery piece packaging glue structure and preparation method thereof

ActiveCN103865420AAdhesion effectLow costFilm/foil adhesivesSynthetic resin layered productsCross-linkEngineering

The invention relates to a solar battery piece packaging glue structure and a preparation method thereof. The structure comprises a packaging glue layer and at least one partitioning membrane layer, or comprises a packaging glue layer, at least one layer of partitioning membrane and at least one adhesive layer distributed on one side, which is close to a battery piece, of the partitioning membrane, wherein the partitioning membrane is compounded with the packaging glue layer, or the partitioning membrane is compounded with the packaging glue layer and the adhesive layer; the flowability of the partitioning membrane is smaller than that of the packaging glue layer. According to the solar battery piece packaging glue structure, as one layer of the partitioning membrane with very low flowability is compounded with the packaging glue and the flowability of the partitioning membrane self is lower than that of the packaging glue, the packaging glue is harder to overflow, and moreover a good partitioning function is achieved for overflowing of the packaging glue with high flowability. When the structure is laminated, the packaging glue of a cross-linking system with high flowability at a lower layer can be fused with the partitioning membrane with low flowability at an upper layer at high temperature, so that sufficient binding force can be still maintained.

Owner:仇桂芬

Cleaning method and back-side defect reworking method for large-size sapphire substrate before annealing

InactiveCN105903694APoor improvementCleaning using toolsCleaning using liquidsMetallurgyChemical tank

The invention provides a cleaning method and back-side defect reworking method for a large-size sapphire substrate before annealing. The cleaning method for the large-size sapphire substrate before annealing is characterized in that a ground sheet is cleaned in a chemical tank and then manually brushed and scrubbed so that the surface granularity and cleanliness of the sapphire substrate can be effectively improved; and finally, acid-base soaking, drenching and spin-drying are conducted, the surface cleanliness of the annealed substrate reaches the standard that black and white points, color differences, fingerprints and stains are avoided, and the yield of the substrate can reach 90% or over. The invention further provides the back-side defect reworking method. By the adoption of the back-side defect reworking method, the problem that the roughness of the back side is inconsistent due to pure manual polishing can be solved. The cleaning method and back-side defect reworking method for the large-size sapphire substrate before annealing have the characteristics that dust on the surface of the sapphire substrate can be effectively reduced or removed, back-side defects of the substrate are greatly reduced, and the yield of finished products is greatly increased.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

Combined carbonaceous reducing agent for smelting metal silicon and preparation method thereof

ActiveCN102976330AMeet physical and chemical performance requirementsPoor improvementSilicon compoundsPetroleumPetroleum coke

The invention discloses a combined carbonaceous reducing agent for smelting metal silicon and a preparation method thereof. The combined carbonaceous reducing agent comprises refined pulverized coal and petroleum coke powder, wherein the refined pulverized coal accounts for 70-80% of the total weight; the refined pulverized coal is prepared from the raw material soft coal by oil agglomeration selective flocculation de-ashing treatment; the refined pulverized coal contains 75-80% of fixed carbon, 3.5-4.5% of ash content and 16-21% of volatile content by weight; and 2-3% of binder is added into the mixture of the refined pulverized coal and the petroleum coke powder, and then a combined carbonaceous reducing agent pellet is prepared by cold press molding briquetting and drying treatment. According to the invention, the ash content and impurities in the soft coal are removed by a flotation method, the petroleum coke powder serves as supplement of the fixed carbon, and the two are combined to obtain a combined carbonaceous reducing agent with high content of fixed carbon, low ash content and low content of impurities. Through the invention, the problem that the reducing effect is unsatisfactory by using the soft coal only is solved, the smelting efficiency and the product quality are improved, and the added value of the soft coal is increased.

Owner:KUNMING METALLURGY INST

Preparation method of transparent toughened polystyrene functional color masterbatch

The invention discloses a preparation method of a transparent toughened polystyrene functional color masterbatch and belongs to the technical field of polymer material modification. The preparation method is characterized in that GPPS as a base resin raw material, MBS and an oily flexibilizer as main functional assistants, a transparent pigment, and various processing auxiliary agents are mixed uniformly; and the mixture is mixed by a double-screw extruder and then is cut into the transparent toughened polystyrene functional color masterbatches by a water loop heating granulator. Through mixing use of the transparent toughened polystyrene functional color masterbatches and the GPPS raw material, material toughness is improved; undesirable effects produced by stress cracking on a workpiece is improved obviously; and transparent color effects of the GPPS raw material are obtained. The transparent toughened polystyrene functional color masterbatch does not influence material transparency, has wide application prospects in fields of household electrical appliance, office supplies, electronic and electrical products and package, and is especially suitable for injection molding of transparent refrigerator drawers.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

Acridine D-A type thermal activation delayed fluorescent material as well as preparation method and application thereof

InactiveCN108530357AImprove lackPoor improvementOrganic chemistrySolid-state devicesSynthesis methodsBiological activation

The invention provides an acridine D-A type thermal activation delayed fluorescent material. The acridine D-A type thermal activation delayed fluorescent material contains similar electron-donating group acridine, the integrated structure of the material is changed by introducing different electron-withdrawing groups such as a benzene ring, fluorine, carbazole and sulphone, light emission with high purity and multiple colors, particularly blue color is realized, and the problems of shortage of the existing blue light thermal activation delayed fluorescent material and bad performance are solved. The material is novel in structure, has excellent performance, can be synthesized through Ullmann coupling reaction, is simple in synthesis method and high in yield, can serve as a light-emitting layer material in an organic electroluminescent device, has high light-emitting efficiency and low efficiency roll-off, and can effectively reduce lighting voltage.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

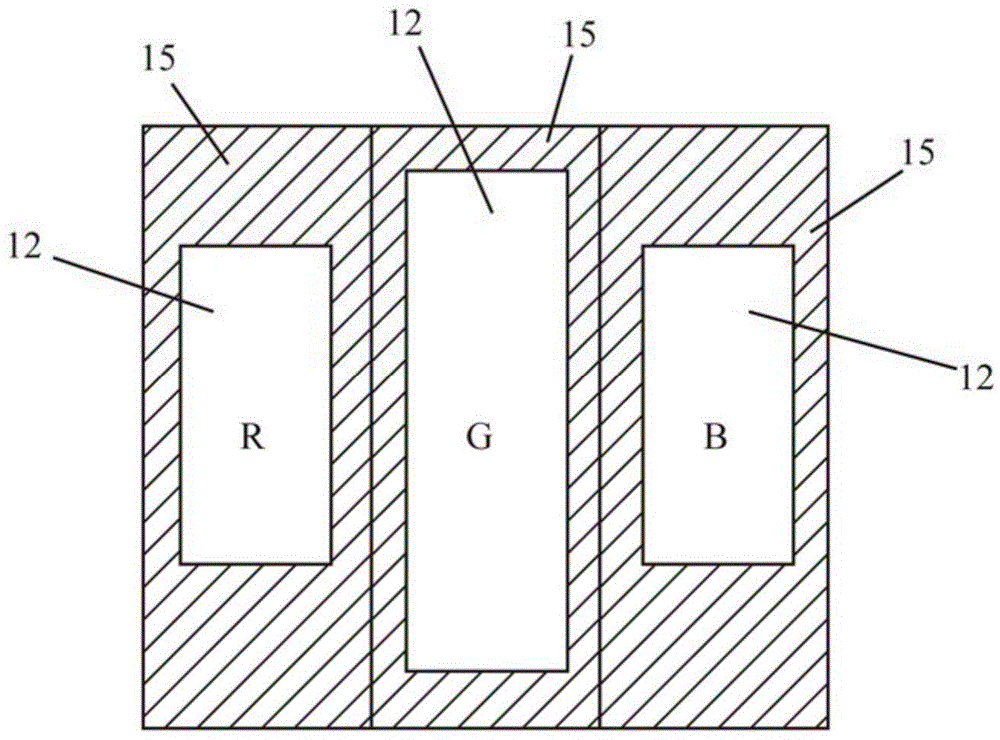

Black matrix structure, manufacturing method thereof, array substrate, color film substrate and display device

Owner:BOE TECH GRP CO LTD +1

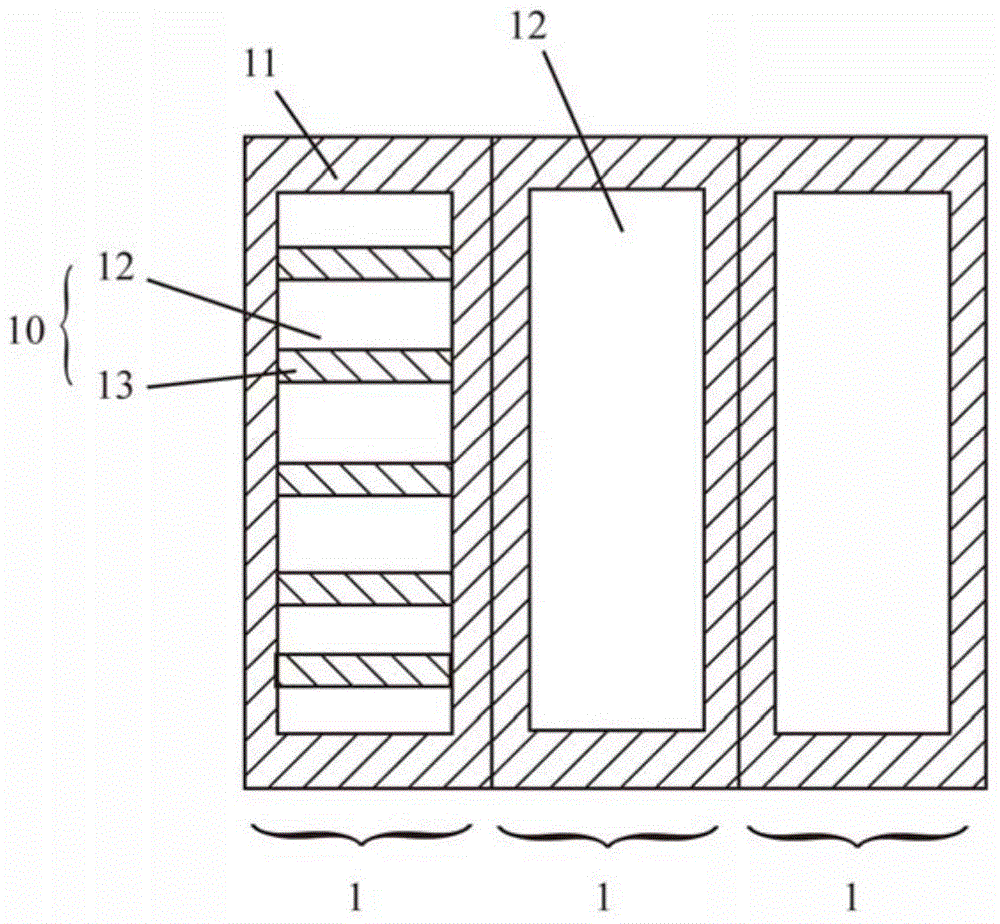

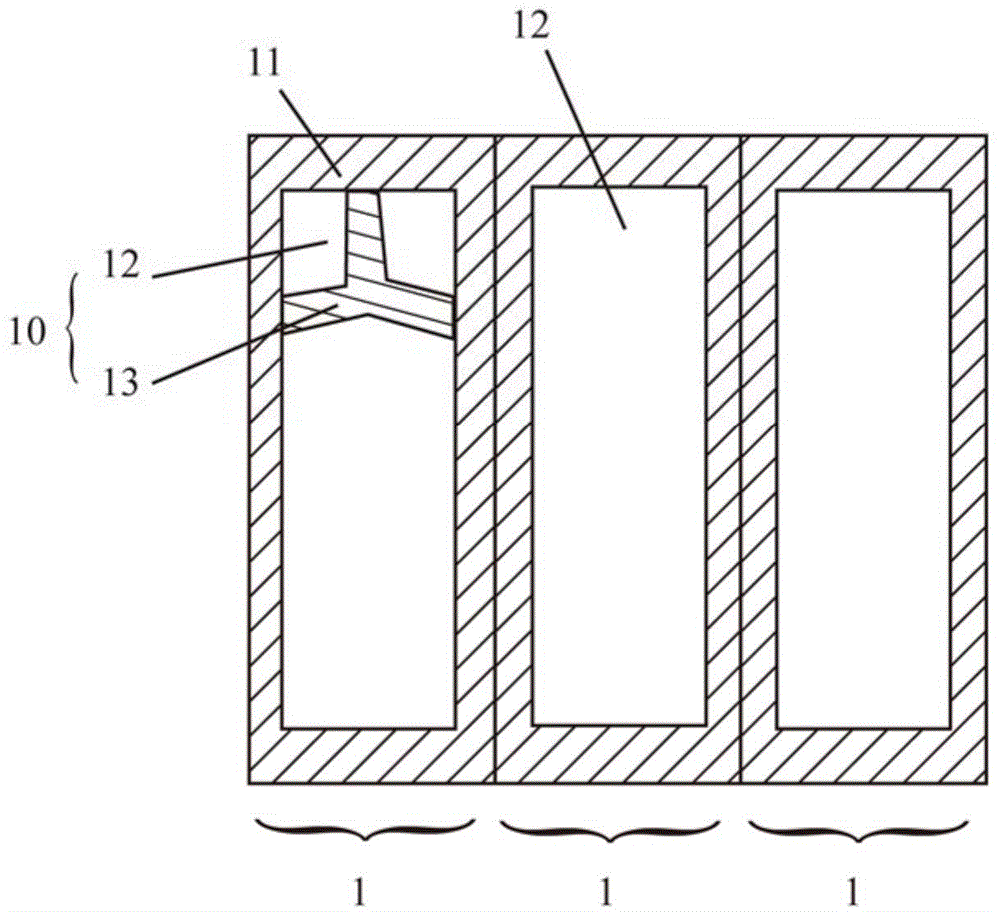

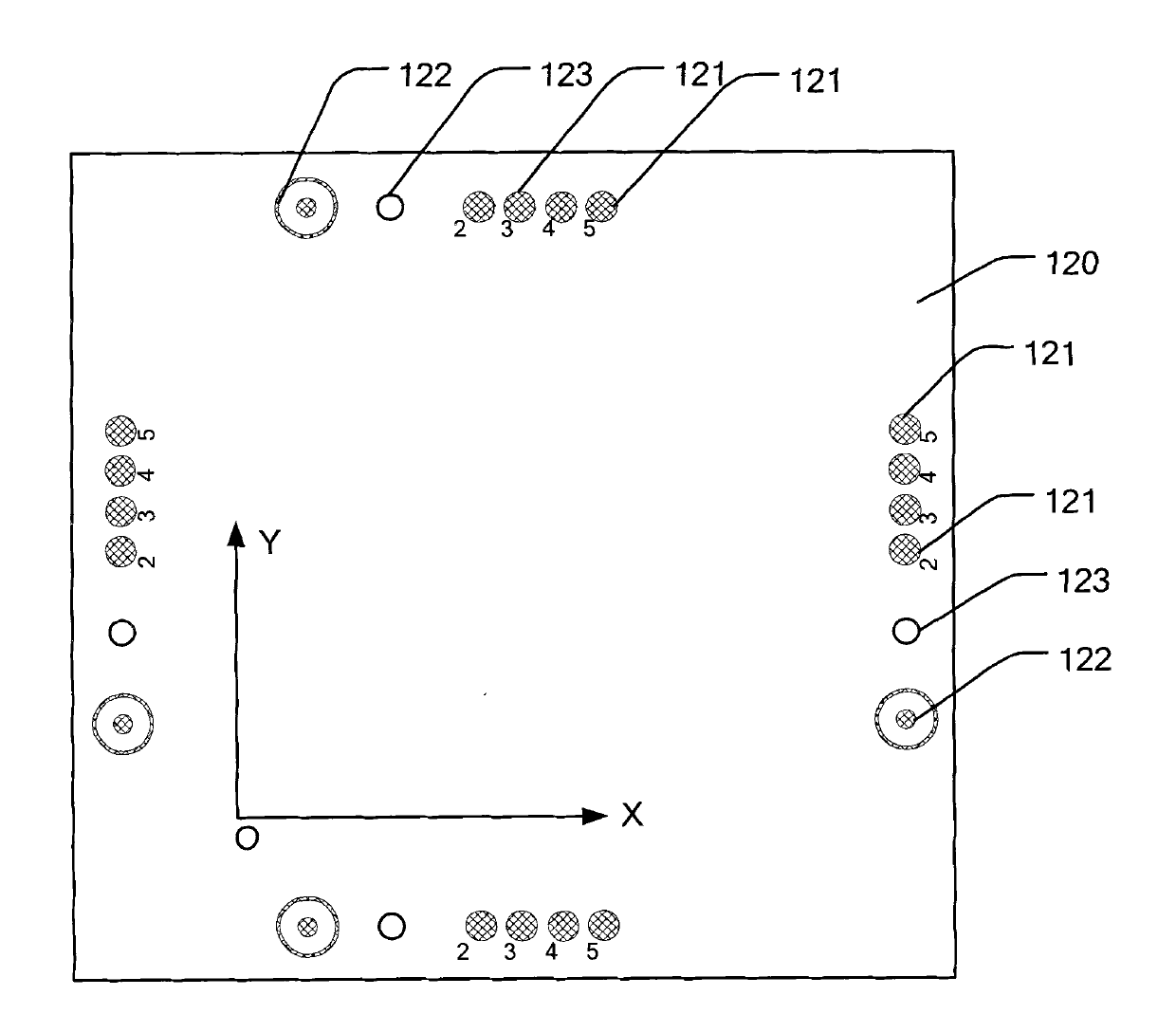

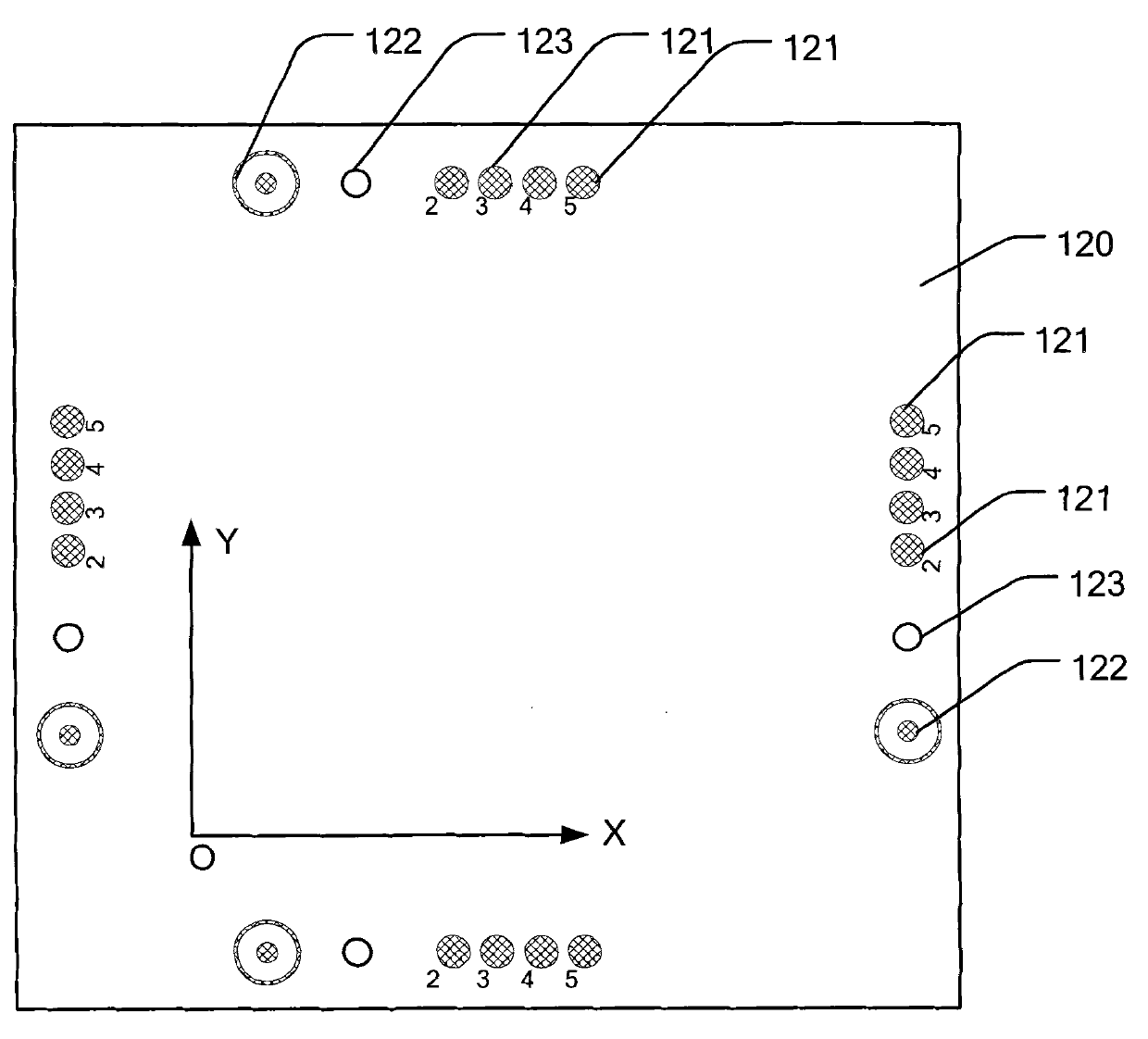

Method for measuring expansion and shrinkage of printed circuit board, and printed circuit board

InactiveCN101907454APoor improvementReduce scrap rateMeasurement devicesPrinted circuit detailsRejection ratePrinted circuit board

The invention discloses a method for measuring expansion and shrinkage of a printed circuit board, and the printed circuit board. The printed circuit board comprises two outer layer boards and at least two inner layer boards arranged between the two outer layer boards, wherein each side of each inner layer board is provided with a test point, and test points on opposite sides of each inner layer board are positioned in the same horizontal line or vertical line. Each side of each inner layer board is provided with the test point, the test points on the opposite sides of each inner layer board are positioned in the same horizontal line or vertical line, after the inner layer boards are pressed, whether the two test points of two opposite sides of each inner layer board are expanded or shrunk is measured, the expansion and shrinkage data can be accurately measured, and data support is provided for the subsequent adjustment or modification of inner layer film compensation; therefore, the adverse effect of the circuit board caused by expansion and shrinkage can be effectively improved and the rejection rate of the circuit board is reduced.

Owner:APCB ELECTRONICS SHENZHEN CO LTD

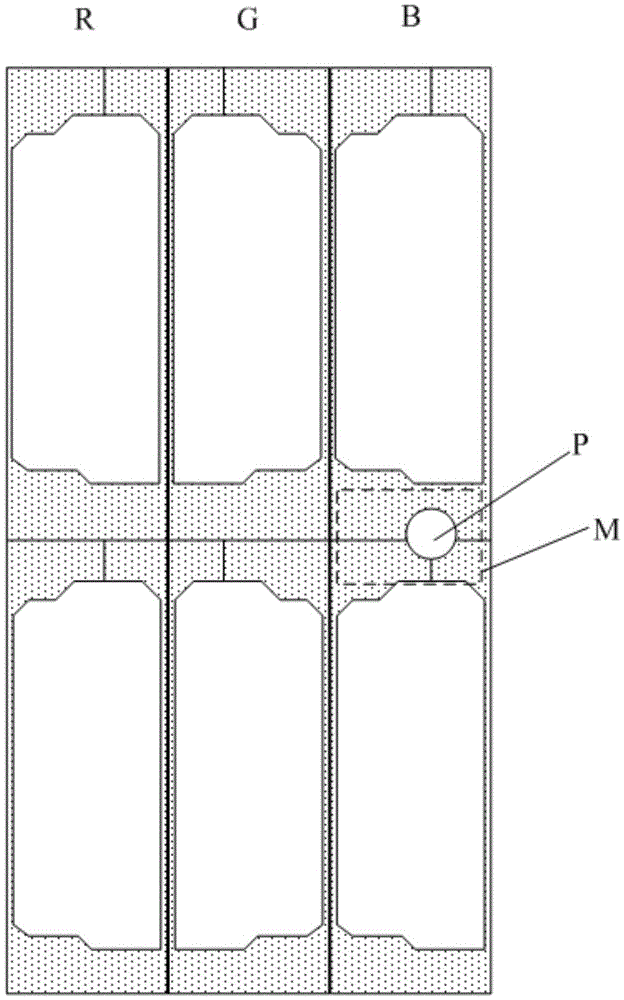

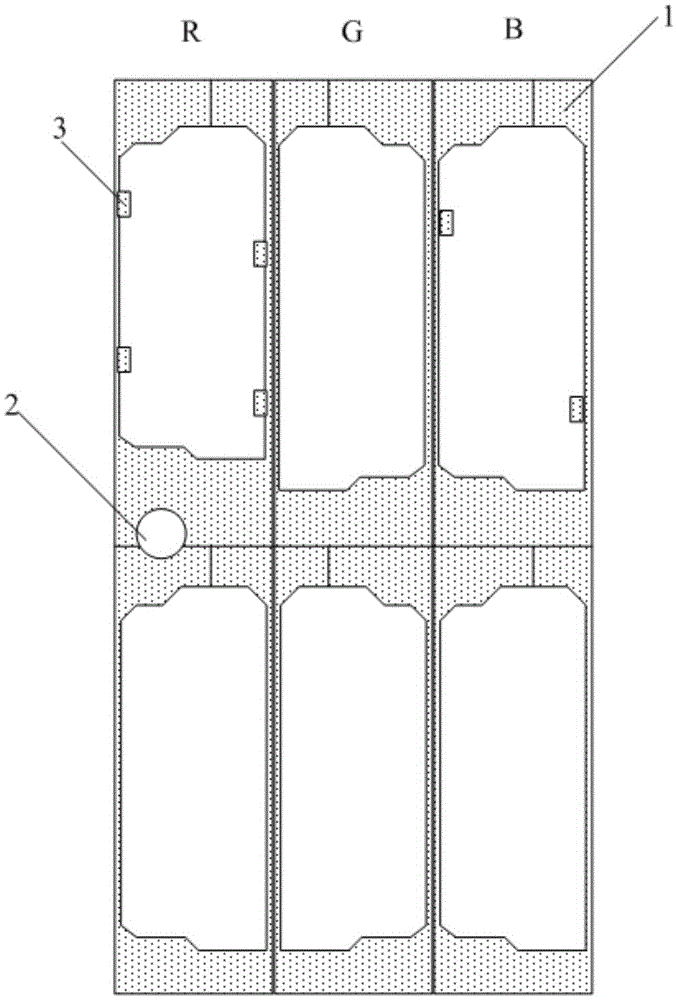

Display substrate and display device

InactiveCN105551390AIncrease widthReduce aperture ratioNon-linear opticsIdentification meansDisplay deviceComputer science

The invention discloses a display substrate and a display device. At least part of support columns of the display substrate are arranged in black matrix areas, each black matrix area is located between red pixels in every two adjacent rows of pixels and a same column of pixels, the width of black matrixes in the areas where the support columns are located is increased, and therefore compared with the prior art, the phenomenon that the blue points are bad due to the fact that the support columns are arranged in the black matrix areas corresponding to blue pixels can be effectively improved; through chromaticity simulation, it can be known that on the condition that the normal color temperature conditions are met, the influence of red pixel opening ratio decreasing on the color temperature is the least, therefore, the width of the black matrixes corresponding to red pixels can be increased, that is, the opening ratio of the red pixels can be decreased on the condition that the normal color temperature conditions are met. Accordingly, by arranging the support columns in the black matrix areas corresponding to the red pixels and correspondingly increasing the width of the black matrixes in the corresponding areas, the problem that the blue points of the display substrate are bad can be solved, and meanwhile the product with the better color displaying quality can be obtained.

Owner:BOE TECH GRP CO LTD +1

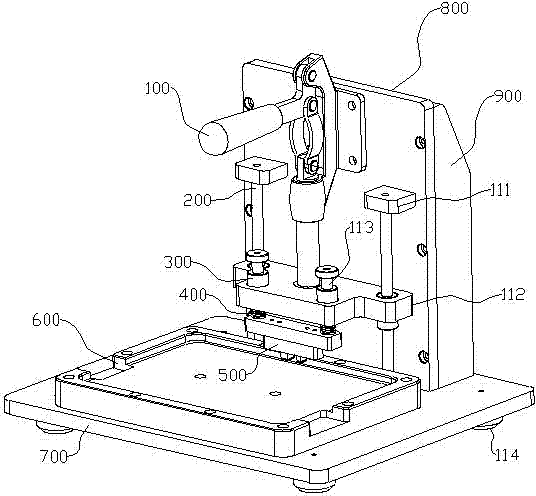

Camera module press fitting fixture

The invention discloses a camera module press fitting fixture comprising a base plate and a clamp fixing plate, wherein one side of the clamp fixing plate is provided with a fast clamp while the other side is provided with a reinforcement rib; two sides of the fast clamp are respectively provided with a vertical guide pillar, one side of each vertical guide pillar is provided with a guide pillar fixing plate while the other side is provided with a movable connection plate; two sides of the movable plate are respectively provided with a linear bearing, one end of each linear bearing is connected with a press fitting guide pillar while the other end is provided with a pressure spring. The camera module press fitting fixture has advantages that the automation degree is high, the situation of hand galling caused by hand press is avoided due to the fact that the force is exerted by the fast clamp, the pressure is controlled by adjusting the stroke of the spring, the pressure of each product is in a very small range, and thus badness caused by the pressure difference is improved greatly. The camera module press fitting fixture is capable of increasing the production efficiency, good in practical performance and novel in design so as to serve as an excellent innovation and have a very wide market promotion prospect.

Owner:KUSN MAIZHI FIXTURE TECH

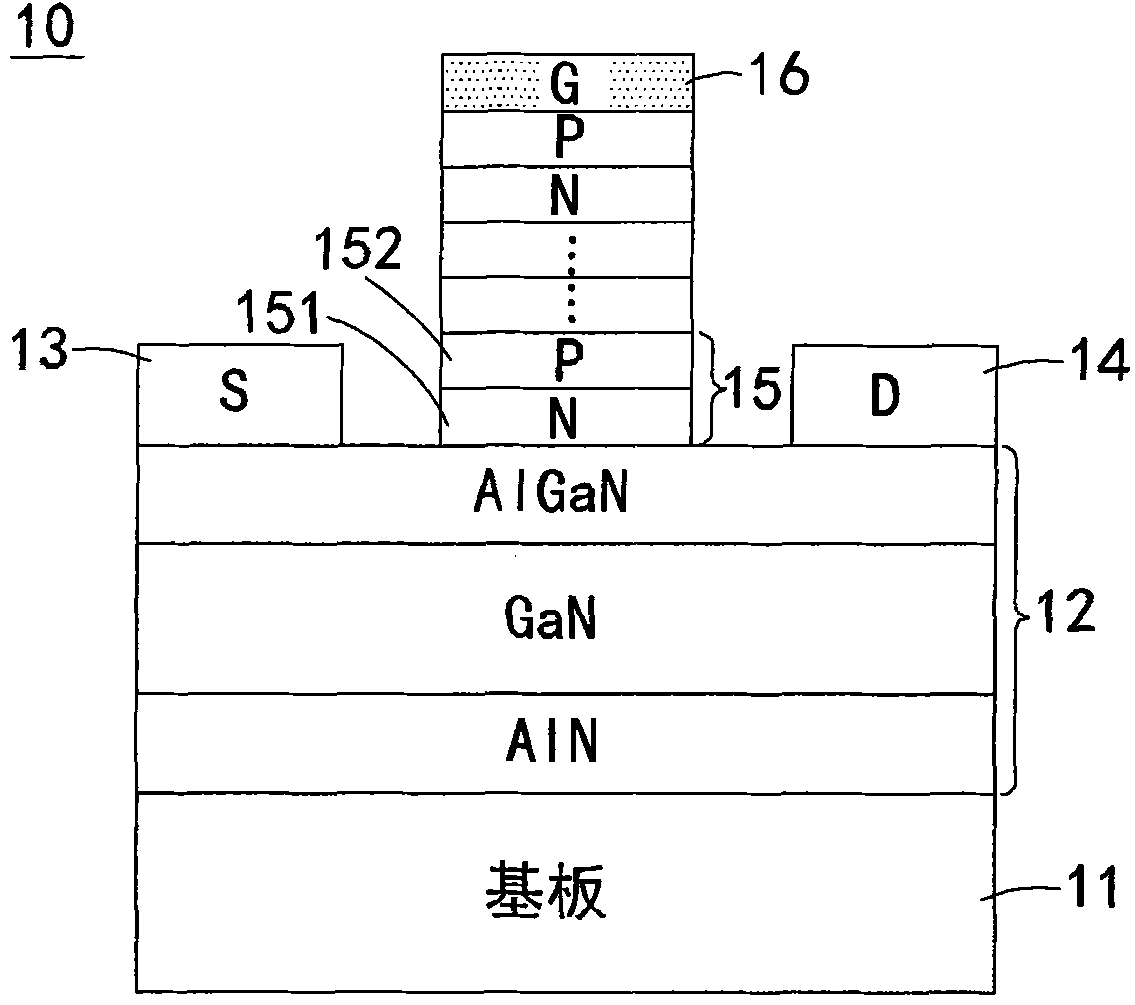

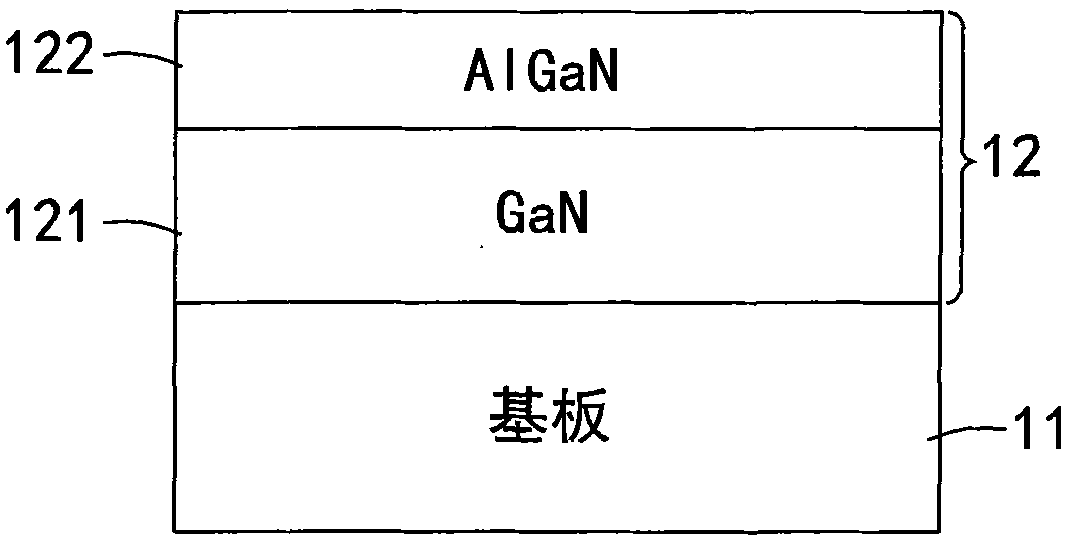

Enhanced high electron mobility transistor and manufacturing method thereof

ActiveCN102376760APoor performance improvementRaise the threshold voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsGallium nitride

The invention discloses an enhanced high electron mobility transistor and a manufacturing method thereof. The high electron mobility transistor comprises a buffer layer, a source electrode, a drain electrode, multiple P-N junctions and a grid electrode, wherein the buffer layer is epitaxial on a substrate; the source electrode and the drain electrode are formed on the buffer layer; the P-N junctions formed by multilayer stacks are formed on the buffer layer and between the source electrode and the drain electrode; the grid electrode is formed on the stacks of the P-N junctions; and each P-N junction is composed of a P-type semiconductor and an N-type semiconductor. The enhanced high electron mobility transistor and the manufacturing method thereof can improve the problem of poor efficiency of a depressed gate structure or an enhanced gallium nitride transistor manufactured by a carbon tetrafluoride plasma processing mode in the prior art, and greatly improve the threshold voltage of the enhanced high electron mobility transistor.

Owner:INFINITY COMM TECH INC

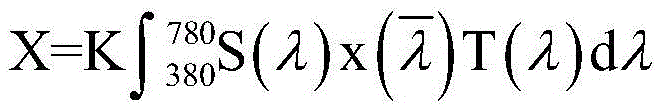

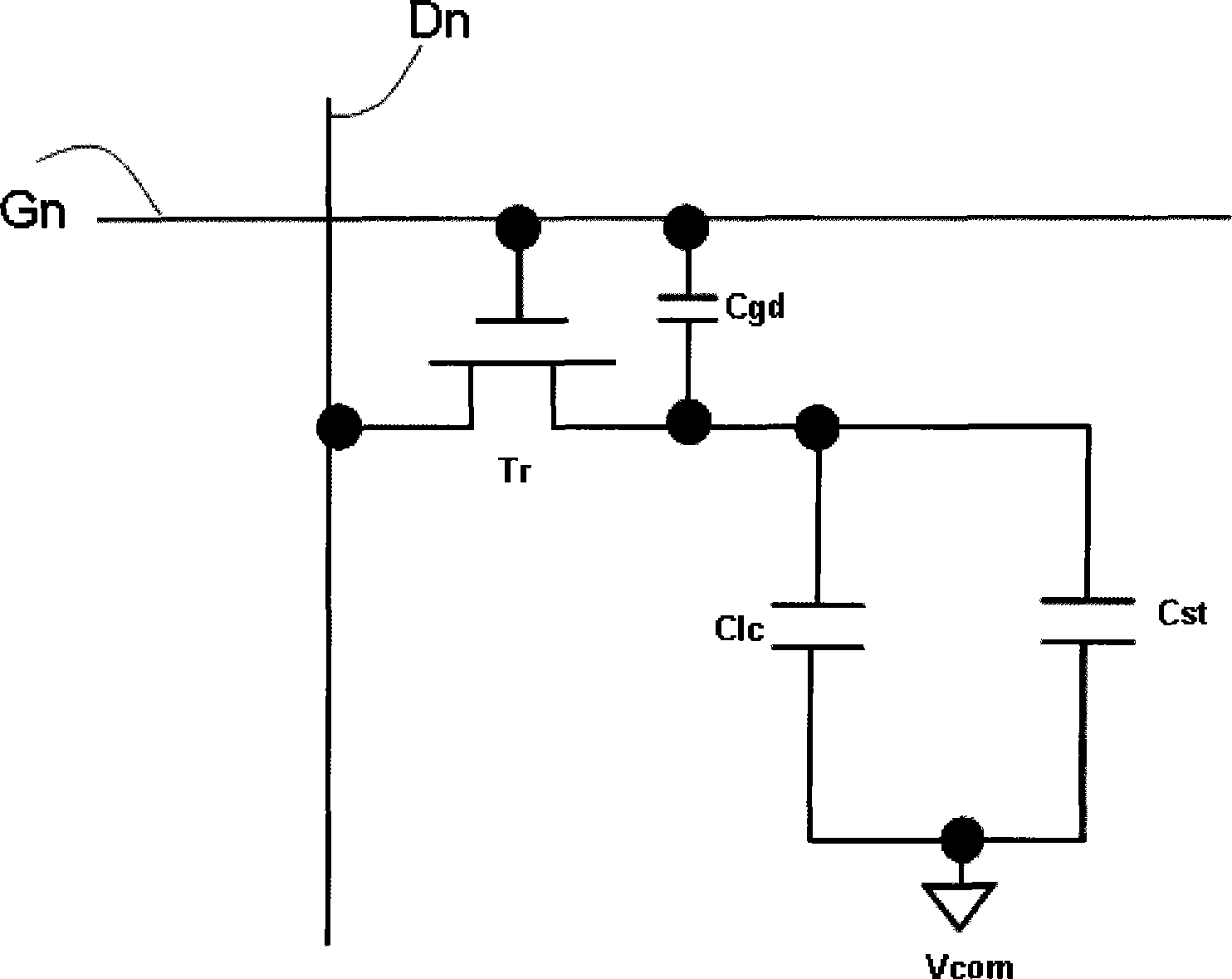

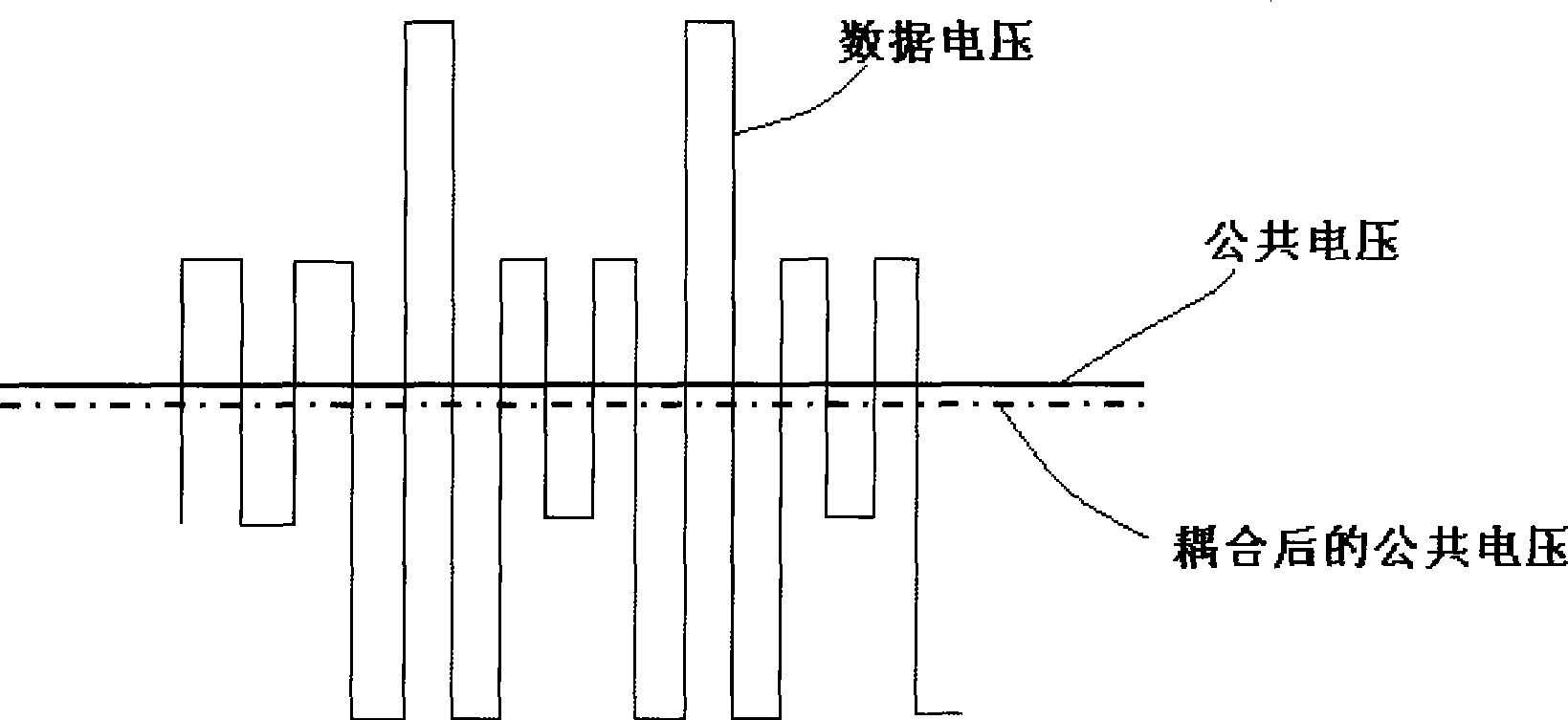

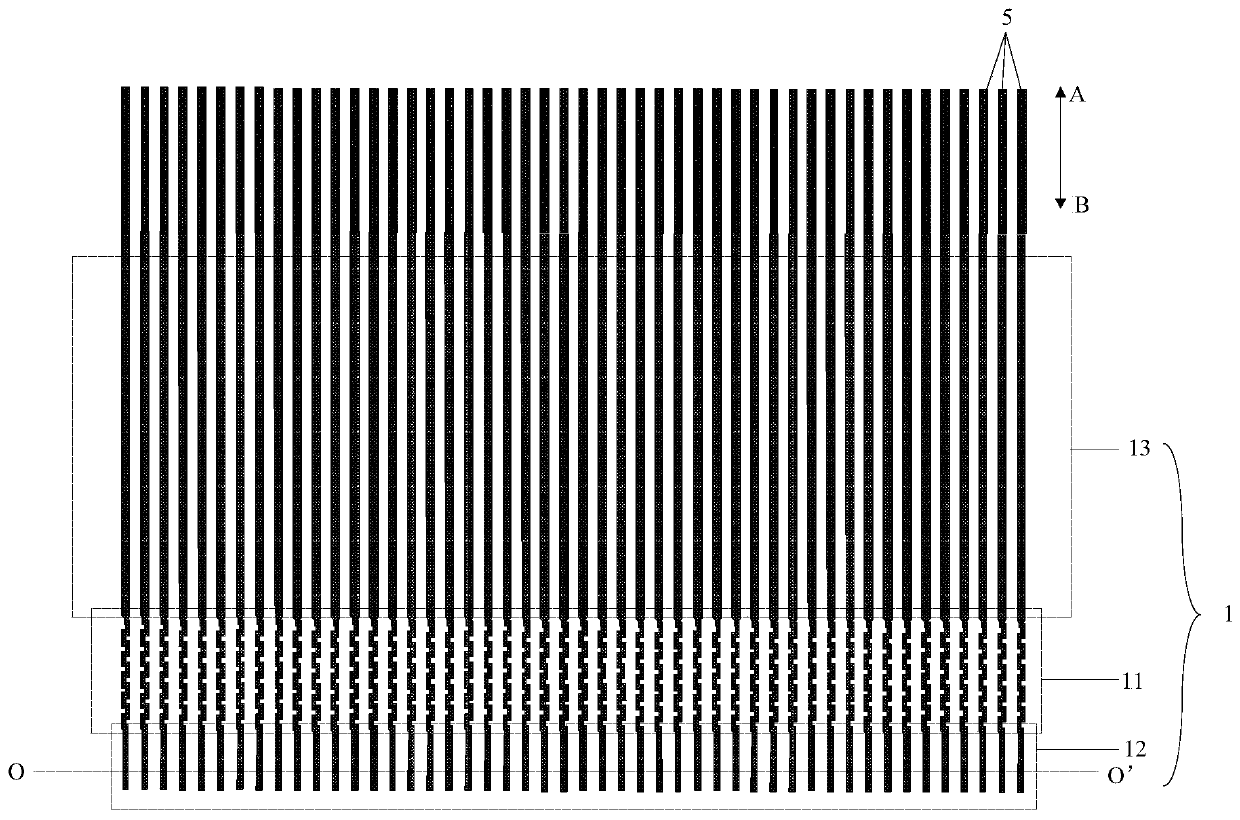

Driving method for liquid crystal display device

ActiveCN101419790APoor improvementImprove display qualityStatic indicating devicesLiquid-crystal displayData lines

The invention relates to a method for driving a liquid crystal display (LCD) device, and the LCD device comprises m lines and n rows of display pixels as well as one row or a plurality of rows of virtual pixels, and each of the pixels is controlled by a thin film transistor, each line of pixels are connected with a scanning beam, each row of display pixels are connected with a data link, and each row of virtual pixels are connected with a compensating data link, wherein, compensating data is generated for each line of pixels according to the whole polarity of the display data; the polarity of the compensating data is opposite to the whole polarity of the line of display data, wherein, m and n are signless integral. The method for driving the LCD device can improve the defect caused by the coupling of public voltage and enhance the display quality.

Owner:NANJING CEC PANDA LCD TECH

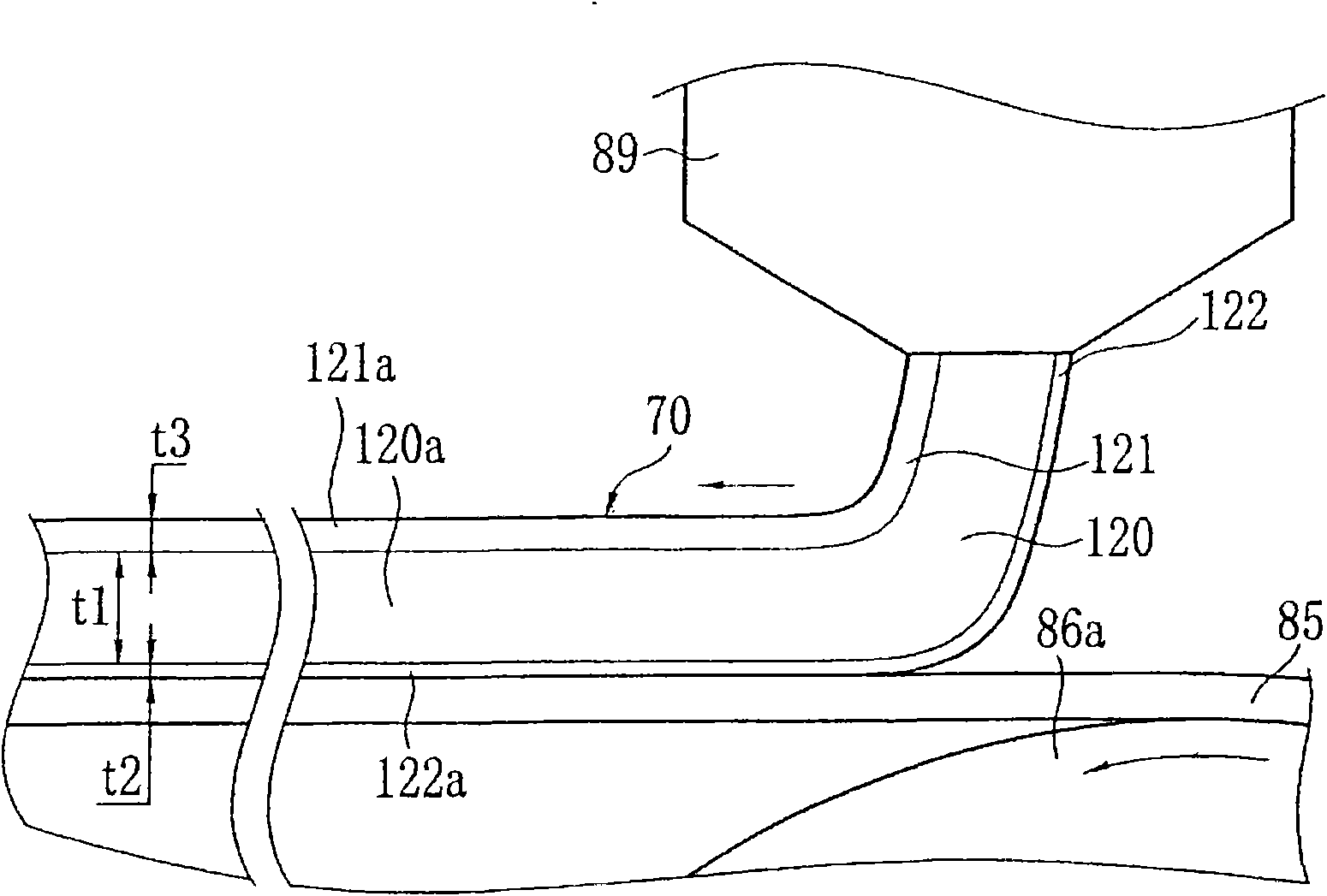

Coiling variable tension control technology for 300 series stainless steel

InactiveCN1945481AImprove shapeSolve the problem of overcurrentTotal factory controlProgramme total factory controlAutomatic controlInternal stress

The invention of roll changing tension controlling technology for 300 series stainless steel belongs to the field of heat-rolled steel control, which is controlled by the two-level computer. Its features are: the second-level computer completes sending the setting value, the coefficient of changing tension and the mark for distinction of different kinds of steel, the first computer completes the control of coiling changing tension to realize the automatic controlling production. The advantages are: 1. It resolves the allocation and release of hot strip coiling strip head and internal stress, 2. It can improve the shape of coiler, especially the head bad shape, 3. It solves the problem of over-current in coiler and saves the investment of equipment, 4. It also provides protection for improving the quality of 300-series cold-rolled stainless steel, and improves the problem of bad shape of head.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Surface treatment technology before conducting paint spraying on metal

InactiveCN107470105AImprove surface propertiesGood removal effectPretreated surfacesMetallic material coating processesSand blastingMaterials science

The invention discloses a surface treatment technology before conducting paint spraying on metal. The surface treatment technology comprises the following steps that (1) surface oil-removing treatment is conducted; (2) primary washing treatment is conducted; (3) acid pickling treatment is conducted; (4) secondary washing treatment is conducted; (5) primary sand blasting treatment is conducted; (6) surface soaking treatment is conducted; (7) secondary sand blasting treatment is conducted; and (8) cooling treatment is conducted. According to the surface treatment technology before conducting paint spraying on the metal, special surface treatment is conducted on a metal workpiece material before paint spraying, the surface performance of the metal workpiece material is effectively improved, the combining capacity of the metal workpiece material and coating is enhanced, the protecting effect of a paint coating is promoted, and the surface treatment technology has good using and promoting value.

Owner:当涂县宏宇金属炉料有限责任公司

Method for surface treatment by developing machine after electronic circuit board anti-soldering process

ActiveCN102281719AImprove process capabilityAchieve optimal resultsPrinted circuit secondary treatmentWater usePrinting ink

The invention relates to a method for carrying out surface processing on an electronic circuit board (PCB) by a developing machine after welding prevention processing, which comprises the following procedures of processing by a first developing trough, primary wind pressure tube water prevention, processing by a second developing trough, secondary wind pressure tube water prevention, processing by a third developing trough, tertiary wind pressure tube water prevention, medium pressure washing, processing by a punching water jet scalpel, composite washing, processing by a sponge roller, cold air drying, hot air drying, inspection and the like. In the invention, after spray disks of the developing troughs are structurally regulated and the punching water jet scalpel is added, no residual ink is generated at the bottom of a blink hole and no phenomenon of poor hole blockage of a through hole is generated; by a wind pressure water prevention mode, the defect that after the ink is rolled by the roller, the copper surface of the PCB is stained with the ink can be improved and the amount of printing ink on pad can be reduced; the water using amount can be saved; the speed of the developing machine can be improved, the production efficiency is promoted, the scrappage is reduced and the yield rate of the PCB can be promoted.

Owner:GULTECH WUXI ELECTRONICS CO LTD

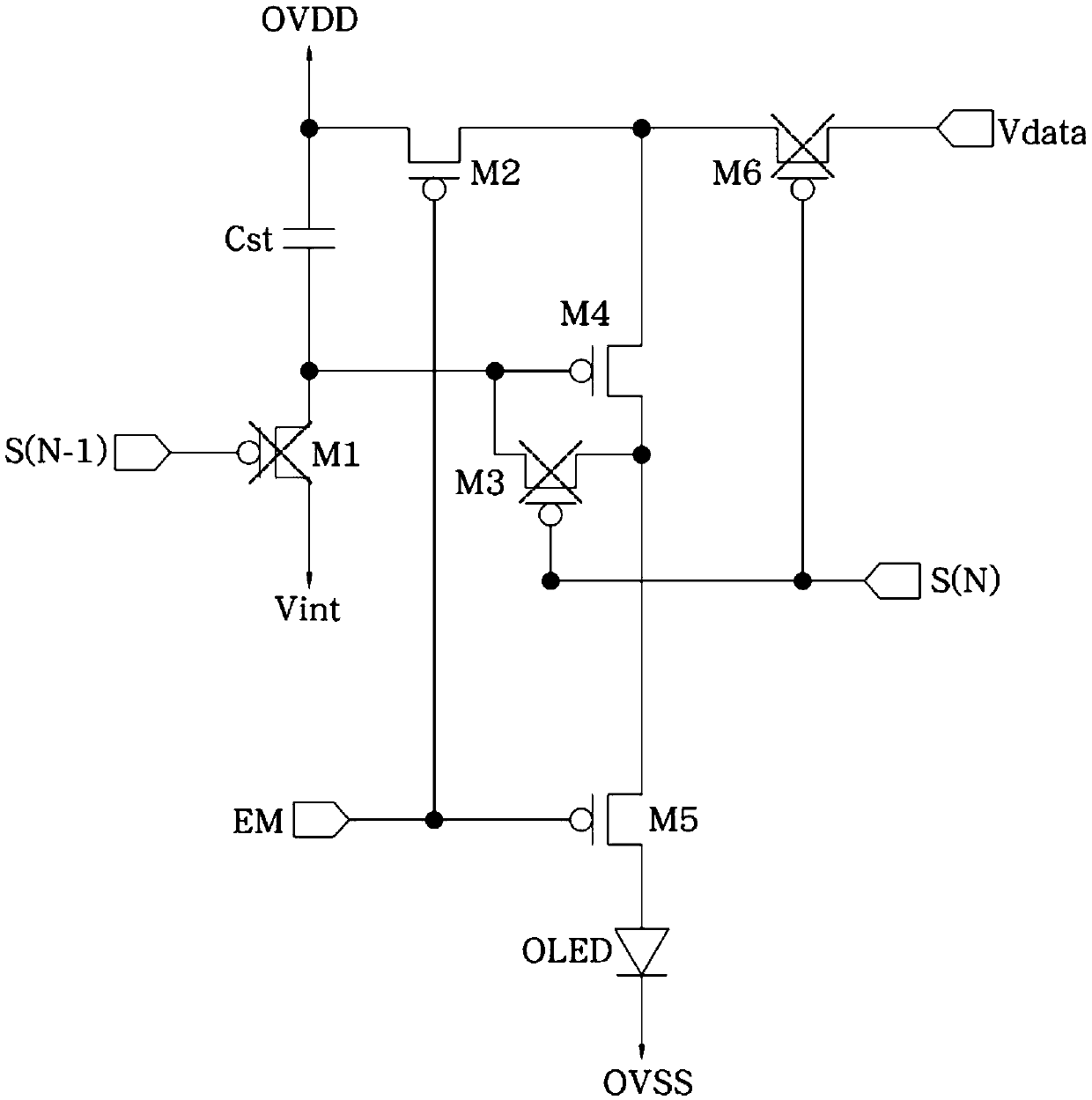

Pixel compensation circuit used for active organic light-emitting diode display

InactiveCN105513540APrevent leakagePoor improvementStatic indicating devicesElectricityControl signal

The invention provides a pixel compensation circuit used for an active organic light-emitting diode display. The pixel compensation circuit comprises a first switch, a second switch, a third switch, a fourth switch, a fifth switch, a sixth switch, a seventh switch and an organic light-emitting diode, wherein the control end of the first switch receives drive signals of the (N-1)-level grid electrode; the control end of the second switch receives an ignition control signal; the control end of the third switch receives drive signals of the N-level grid electrode; the control end of the fourth switch is electrically coupled to the first end of the first switch; the second end of the fifth switch is electrically coupled to the second end of the third switch; the control end of the sixth switch receives ignition control signals; the control end of the seventh switch receives drive signals of the N-level grid electrode; the anode of the organic light-emitting diode is coupled to the second end of the sixth switch, and the cathode of the organic light-emitting diode is coupled to a second voltage. Compared with the prior art, the fourth switch and the fifth switch form a bigrid framework, and the second end of the fifth switch is electrically coupled to the second end of the third switch, so that the situation of electricity leakage between a source electrode and the drain electrode of the third switch can be prevented, and a poor dimly bright point generated in a low gray-scale image is improved.

Owner:AU OPTRONICS CORP

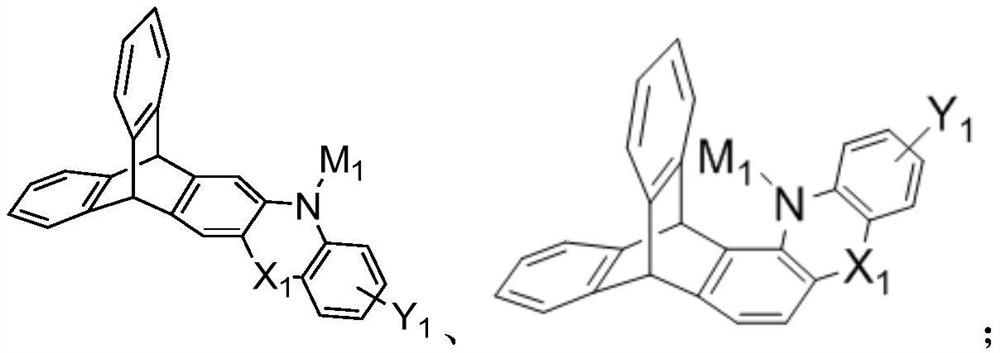

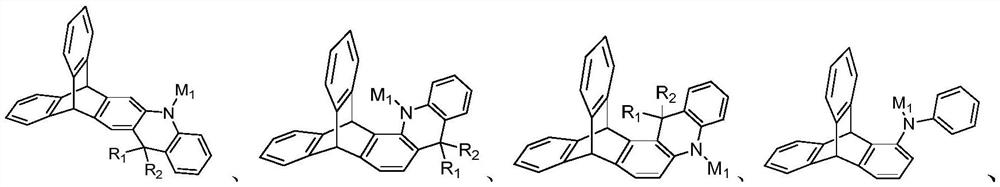

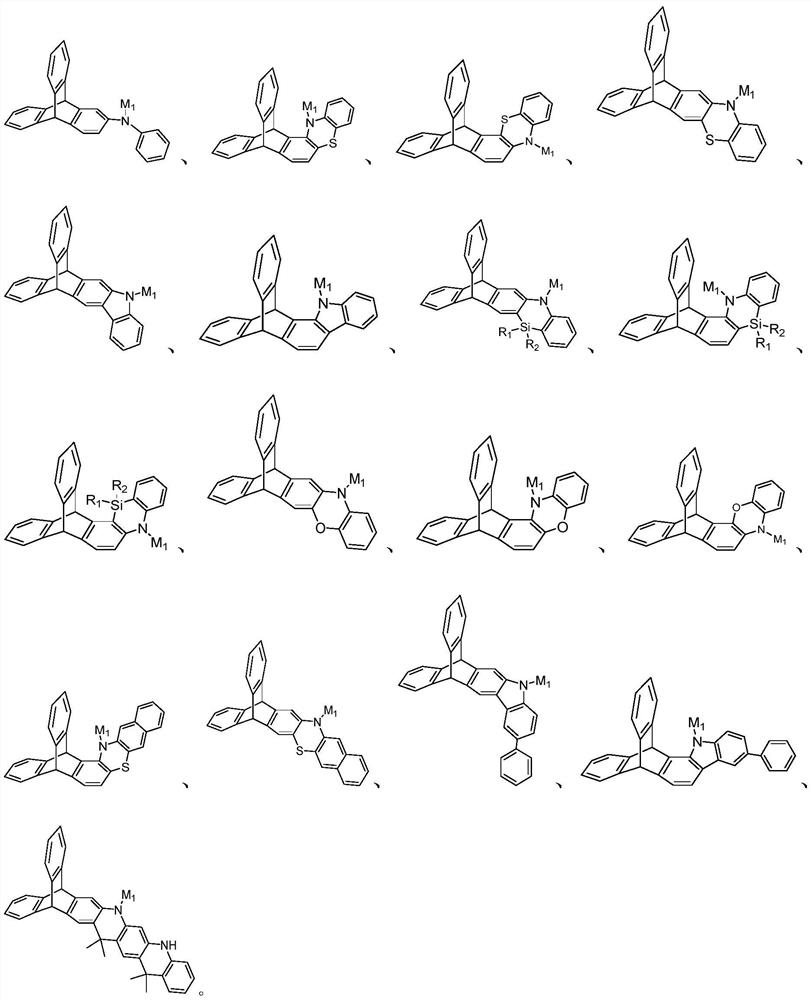

Triptycene D-A type thermal activation delayed fluorescence material, electronic device and application thereof

InactiveCN111995562APoor improvementHigh purityGroup 4/14 element organic compoundsSolid-state devicesHalogenSimple aromatic ring

The invention discloses a triptycene D-A type thermal activation delayed fluorescent material, an electronic device and an application thereof. The fluorescent material has one of the following structural general formulas: X1 is selected from non-bonding, single bond, -N (R1)-,-O-,-S-,-S=O-,-SO2-,-C (R1R2)-,-S (R1R2)-,-P (R1)-and-P=O (R1)-; M1 is selected from hydrogen, deuterium, alkenyl, alkynyl, amido, nitro, carbonyl, sulfuryl, halogen, cyano, alkyl, alkoxy, substituted C6-C60 aromatic ring groups, unsubstituted C7-C60 aromatic ring groups and C3-C60 aromatic heterocyclic groups; Y1 is selected from hydrogen, deuterium, alkenyl, alkynyl, amido, nitro, carbonyl, sulfuryl, halogen, cyano, alkyl, alkoxy, substituted C6-C60 aromatic ring groups, unsubstituted C7-C60 aromatic ring groups and C3-C60 aromatic heterocyclic groups.

Owner:SHENZHEN UNIV

Binary molybdenum alloy sputtering target material and preparation method thereof

ActiveCN111850490AGood compatibilityPoor improvementVacuum evaporation coatingSputtering coatingNiobiumTitanium powder

The invention provides a binary molybdenum alloy sputtering target material and a preparation method thereof. The sputtering target material comprises the components of, in parts by mass, 60-90 partsof molybdenum powder, 5-20 parts of niobium powder and 5-20 parts of titanium powder, the preparation method comprises the following steps that raw materials of the sputtering target material are evenly mixed, powder filling of a rubber sleeve is carried out, then isostatic cool pressing is carried out, and a green body is obtained; the obtained green body is sheathed, and hot isostatic pressing operation is carried out to obtain a sintered green body; the obtained sintered green body is heated, then hot rolling and leveling are carried out, and finally annealing is carried out to obtain a binary molybdenum alloy plate blank; and the obtained plate blank is subjected to machining such as grinding according to needs, and a final needed product is obtained. According to the binary molybdenumalloy sputtering target material and the preparation method thereof, the produced binary molybdenum alloy sputtering target material can be used for manufacturing a transition layer material used incooperation with a copper film layer in the TFT-LCD manufacturing process, the matching performance of the physical and chemical properties of the transition layer and the copper film layer is improved by adjusting proper binary components, and defects occurring in the TFT manufacturing process are improved.

Owner:LUOYANG SIFON ELECTRONICS

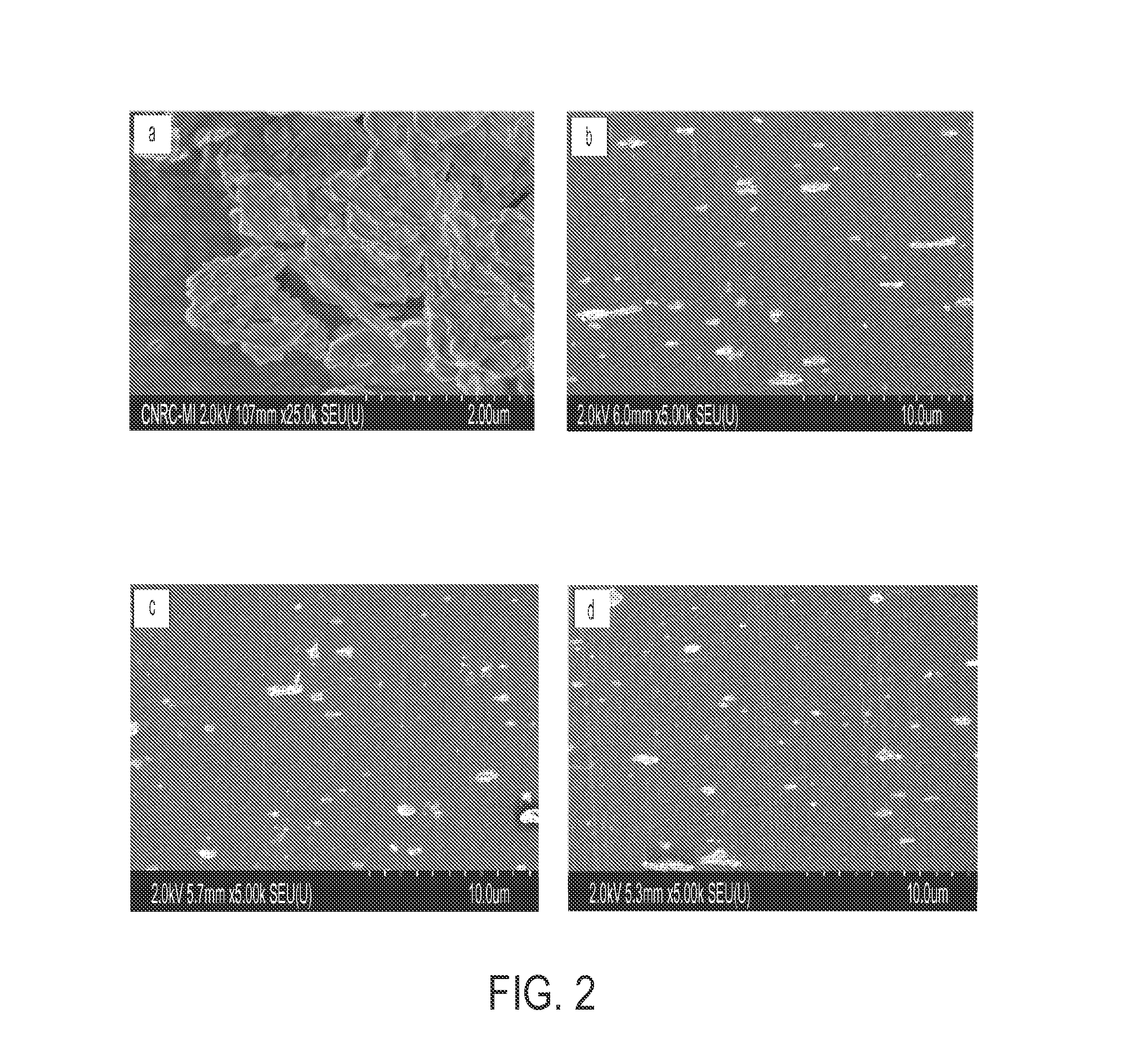

Pet nanocomposite materials and containers prepared therefrom

ActiveUS20160024283A1Good physical propertiesImpacting barrier propertyFibre treatmentContainer/bottle contructionChemical treatmentAqueous alcohol

PET nanocomposite materials exhibit improved physical properties in a PET composite as a result of the intercalation of non smectite-type clay materials while maintaining transparency and barrier properties. In some aspects, kaolin particles are modified with potassium acetate (KAc) to increase interlamellar distances and improve particle dispersion. In other aspects, calcined kaolin particles are used and may be chemically treated by an aqueous alcohol solutions method. Any loss in the molecular weight of PET composite can be offset by the further incorporation of surface compatibilizers such as silane coupling agents and other process additives such as molecular chain extenders.

Owner:CORP DE LECOLE POLYTECHNIQUE DE MONTREAL

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

ActiveCN101666887ANature of controlUniform optical propertiesCellulosic plastic layered productsPolarising elementsCelluloseLiquid-crystal display

The present invention provides a cellulose acylate laminate film having high expressibility, little optical unevenness and good releasability from a support. The cellulose acylate laminate film is characterized in that the cellulose acylate laminate film is obtained by preparing a skin layer B containing the cellulose acylate satisfying the formula (2) and a core layer containing a cellulose acylate satisfying the formula (1) into film on the support according to the order, wherein at least one of the core layer or the skin layer B contains a retardation-controlling agent, and the cellulose acylate laminate film is formed by stretching. Formula (1), Z1 is more than 2.0 but less than 2.7, wherein Z1 represents a total degree of acyl substitution of cellulose acylate; formula (2) Z2 is morethan 2.7, wherein Z2 represents a total degree of acyl substitution of cellulose acylate.

Owner:FUJIFILM CORP

Array substrate, display panel and display device

PendingCN110706602AImprove adhesionIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesFlexible circuitsDisplay device

The invention discloses an array substrate, a display panel and a display device to solve the problem that in the prior art, lead terminals are prone to falling off, and consequently the display panelis poor. The array substrate comprises a substrate body, a plurality of signal lines located on one face of the substrate body and extending in the first direction, and a plurality of lead terminalsconnected with the signal lines in a one-to-one correspondence mode. Each lead terminal comprises a binding area used for being bound with a flexible circuit board and a bending area located on the side, back on to the signal line, of the binding area, and the lead terminals are bent in the bending areas.

Owner:BOE TECH GRP CO LTD +1

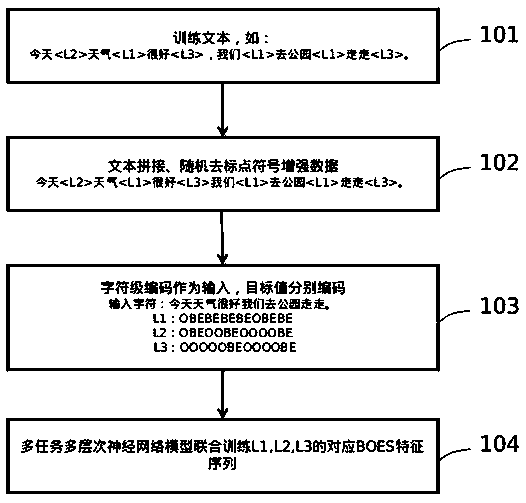

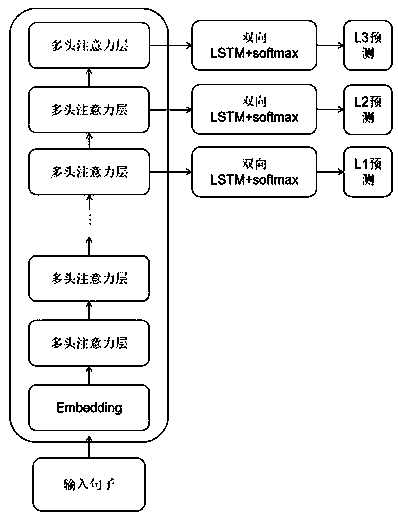

Text rhythm prediction method based on multi-task multi-level model

ActiveCN111339771AReduce errorsImprove utilizationSemantic analysisNeural architecturesSequence predictionPredictive text

The invention discloses a text rhythm prediction method based on a multi-task multi-level model, and the method is characterized in that the method comprises the following steps: 401, obtaining a prediction text; 402, performing character-level coding on the text to be predicted for the word table; step 403, performing sequence prediction by using a multi-task model; step 404, judging whether thesentences have long sentences without L2 and L3 or not; and step 405, combining output results of the L1, the L2 and the L3, overlapping boundary positions, performing selective combination accordingto priorities of the L3, the L2 and the L1, and returning an output result. The invention relates to the technical field of text rhythm prediction. The problems that rhythm information generation errors exist, information cannot be shared mutually, training and parameter adjustment are troublesome, boundary prediction of rhythm phrases and intonation phrases is not accurate enough, and long sentences have no rhythm phrase boundary or intonation phrase boundary easily are solved.

Owner:广州深声科技有限公司

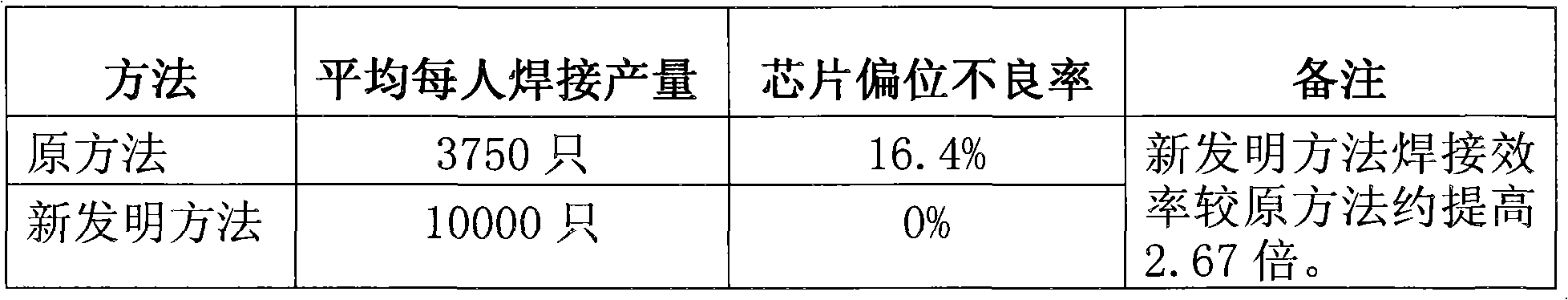

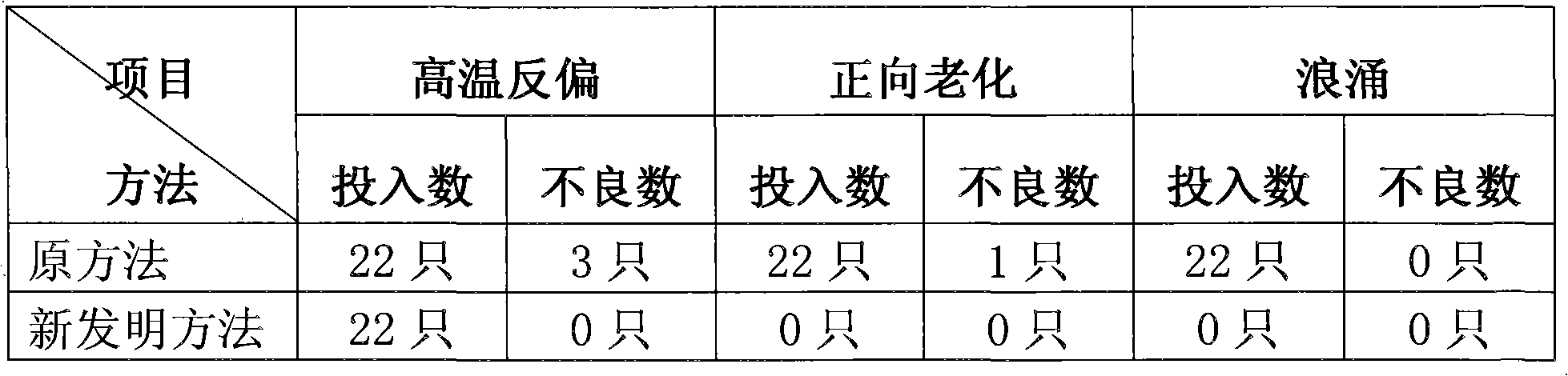

MBS bridge type rectifier welding procedure

ActiveCN101972876AImprove the poor welding deviationPoor improvementSoldering auxillary devicesBridge typeEngineering

The invention discloses an MBS bridge type rectifier welding procedure, including the following steps: a, chip P face prewelding is carried out, namely a soldering flake with uniform soldering tin amount is used for carrying out chip P face prewelding, so as to ensure N face of chip to be even; b, a solder paste wetting pen is used for wetting solder paste, namely the solder paste wetting pen is used for wetting quantitative solder paste on a tablet; c, a prewelding chip is positioned, namely the even N face of chip is positioned on the tablet by virtue of solder paste with higher viscosity after the step b; d, the tablets are combined; e, tunnel furnace welding is carried out. The invention has the beneficial effects that: soldering flake with uniform soldering tin amount is used for carrying out P face prewelding, so that solder paste amount of P face of chip can be fully ensured to certain extent; solder paste with higher viscosity is used for positioning the chip, thus overcoming the defect of welding deviation as viscosity of soldering flux is not high enough; the method has extremely less investment and operation convenience; time for manually adjusting deviated chip is greatly reduced, and efficiency is improved by more than 2.5 times; and the original welding deviation reject ratio is reduced to 0% from 15%.

Owner:CHONGQING PINGWEI ENTERPRISE

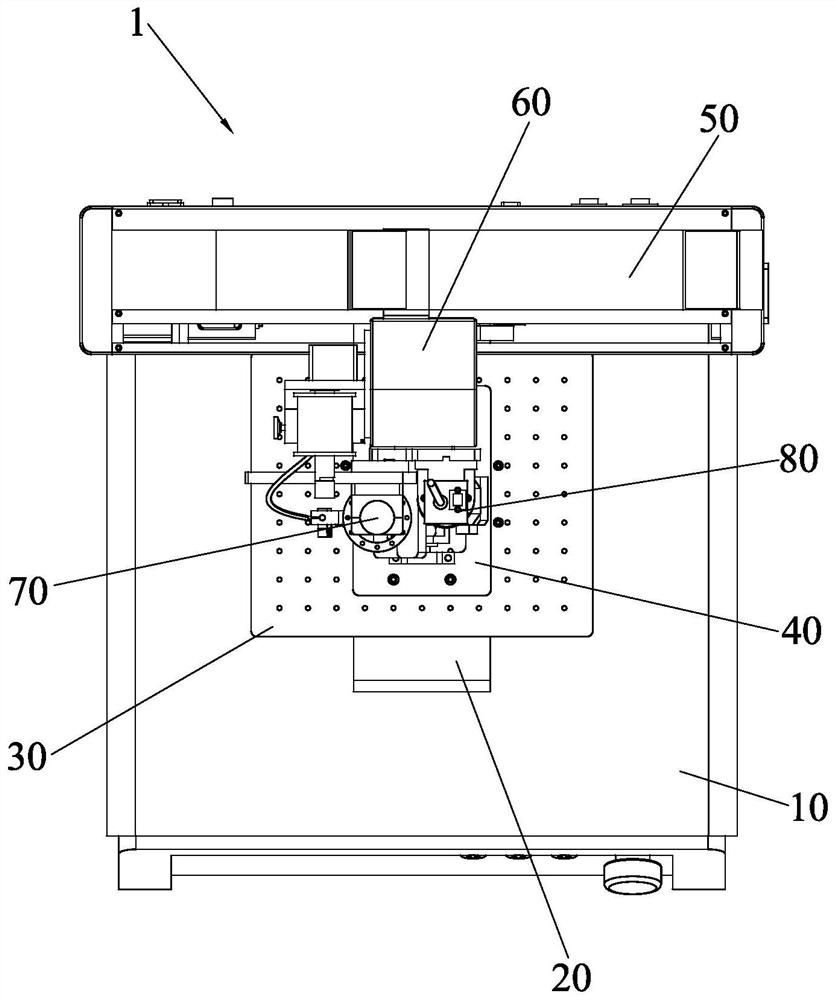

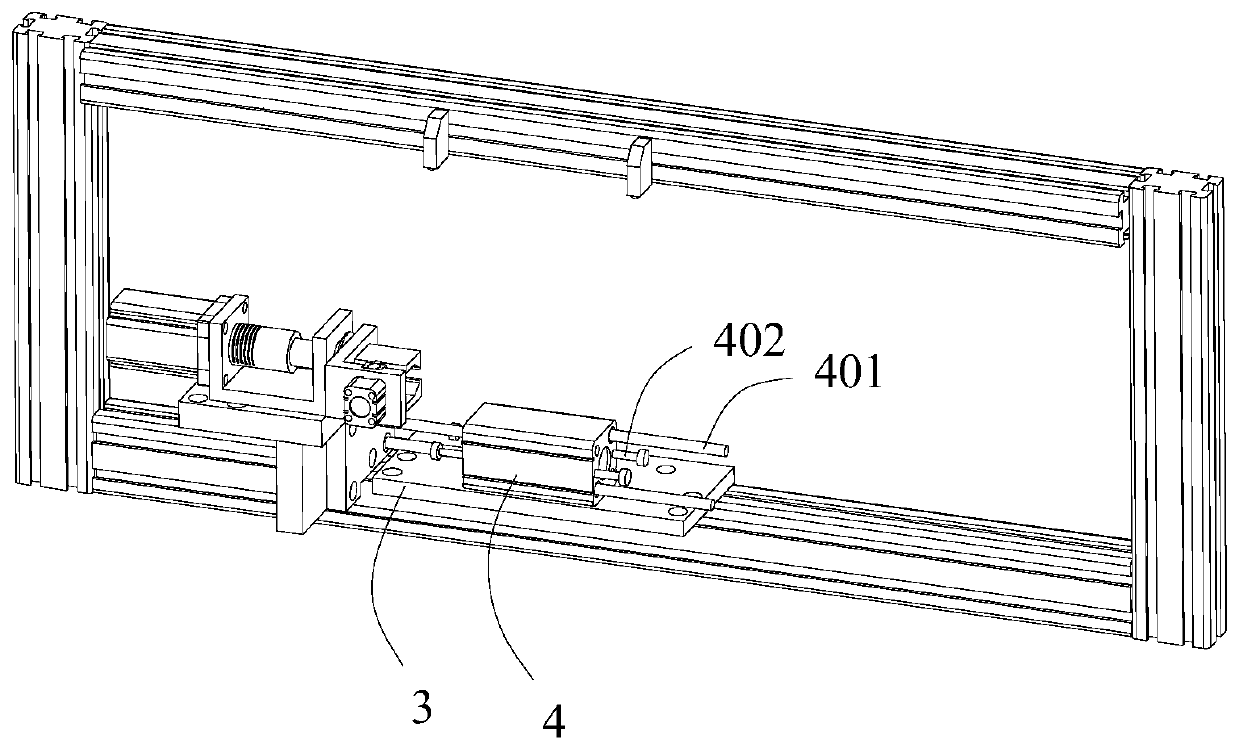

Table type soldering iron tin soldering equipment

PendingCN112170999AReduce use costReduce maintenance costsMetal working apparatusSolder feeding devicesEngineeringCamera module

The invention discloses table type soldering iron tin soldering equipment. The equipment comprises a machine box, a Y-axis linear module, a movable carrying table, a positioning and rotating mechanism, an X-axis linear module, a Z-axis linear module, a soldering iron tin soldering assembly and a camera module, the Y-axis linear module is arranged on a workbench of the machine box, the movable carrying table is arranged on the Y-axis linear module and can move forwards and backwards along with the Y-axis linear module, the positioning and rotating mechanism is arranged on the movable carrying table, the X-axis linear module is arranged above the workbench, the Z-axis linear module is arranged on the X-axis linear module, and the soldering iron soldering tin assembly and the camera module are arranged on the Z-axis linear module. A convenient table type structure is adopted, the equipment cost is low, and the placement position can be flexibly adjusted according to the layout of a plant;and a soldering iron soldering process is adopted, the process is mature, soldering iron use and maintenance cost is low, and tin soldering quality of products can be well guaranteed by replacing soldering iron according to the service life of the soldering iron.

Owner:厦门柔性电子研究院有限公司 +2

Moving magnet type loudspeaker

ActiveCN106792402ARealize functionImproving poor high-frequency transient responseElectrical transducersLoudspeakersTransient stateEngineering

The invention discloses a moving magnet type loudspeaker and relates to the technical field of electroacoustic products. The moving magnet type loudspeaker comprises a shell; a vibrating film and a voice coil parallel with the vibrating film are accommodated in the shell; a driving magnet is fixed on one side, near the voice coil, of the vibrating film; the voice coil forms an electromagnet after being electrified; and the voice coil and the driving magnet generate interaction force to drive the vibrating film to vibrate and generate sound. The moving magnet type loudspeaker solves the technical problem that the moving coil type loudspeaker is poor in high-frequency transient state response in the prior art. The moving magnet type loudspeaker provided by the invention is good in high-frequency transient state response, low in F0, high in sensitivity and high in integral performance, and can meet the performance requirement of high-fidelity equipment.

Owner:GOERTEK INC

High-end PCB metallization groove processing method

InactiveCN109600923AImprove circledImproving bad cloakPrinted circuit manufactureElectricityMilling cutter

The invention provides a high-end PCB metallization groove processing method. The high-end PCB metallization groove processing method is characterized by comprising the following steps of cutting material, drilling a hole one, sinking copper, board electricity, outer layer line, drawing electricity, drilling a hole two, etching, welding resistance, text, metallization, forming, FQC, FQA and packaging successively. The high-end PCB metallization groove processing method can effectively avoid the forming milling cutter from directly contacting with the metal wall of the special-shaped hole whenprocessing, thereby improving the defects of special-shaped hole burrs and the copper rolling; therefore, the product yield is greatly improved.

Owner:惠州市大亚湾科翔科技电路板有限公司

Battery core tab calibration device

InactiveCN110429319APoor improvementEasy to reworkAssembling battery machinesFinal product manufactureEngineeringElectrical and Electronics engineering

The invention discloses a battery core tab calibration device, which comprises a support, two CCD detectors mounted on the support, a base plate, a width adjusting cylinder, two stepping motors and two clip assemblies. The width adjusting cylinder is disposed on the base plate and is used for adjusting the distance between the two clip assemblies. The CCD detector is configured to detect deformation data of a battery core tab. Each clip assembly comprises a pair of mechanical clips. Each stepping motor is used for adjusting the angle of the mechanical clips for tab correction according to thedetected deformation data of the battery core tab. According to the battery core tab calibration device, after detecting tab deformation curvature and parallelism and the like through CCD, the tab iscorrected accurately, thereby effectively ensuring size range of the tab passing through a bus-bar hole, and improving the cases of defects and rework of the tab passing through bus-bar hole in the prior art. The device has the advantages of full-automatic operation, automatic detection, automatic calibration, no need of human intervention and no safety hazard.

Owner:深圳市天劲新能源研究院

Flower fertilizer and preparation method thereof

The invention discloses a flower fertilizer comprising the raw materials of, by weight: 10-15 parts of urea, 12-18 parts of potassium ore powder, 5-10 parts of a strain powder, 20-30 parts of sheep dung, 15-20 parts of soybean hulls, 18-22 parts of peat, 13-15 parts of an additive, and 2-3 parts of water. The invention also discloses a preparation method of the flower fertilizer. The method comprises the steps that: a, peat, soybean hulls, and sheep dung are uniformly mixed by stirring, and the mixture is fermented in a sealed tank, wherein a fermentation time is 15-25h; b, urea, potassium ore powder, strain powder, rice bran, and water are uniformly mixed by stirring; the mixture is added into the fermentation product in the step a, and mixing is carried out; and an obtained mixture is granulated in a granulator, such that the fertilizer is obtained. The fertilizer and the method have the advantages that: a natural fertilizer is adopted, such that phenomena of soil quality deterioration, soil surface crusting, and soil hardening can be effectively ameliorated; soil fertility can be increased; and soil quality can be improved.

Owner:蔡水花

Lithium battery negative electrode slurry dry preparation method

ActiveCN112397676AImprove the mixing effectPoor improvementElectrode manufacturing processesFinal product manufactureMetallurgySlurry

The invention belongs to the technical field of lithium battery slurry preparation, and particularly relates to a lithium battery negative electrode slurry dry preparation method. The method comprisesthe following steps: powder premixing, powder infiltration, powder kneading, high-speed stirring, slow stirring defoaming, sieving and discharging. All powder materials are put into a stirring tank of a stirrer, and the stirring effect is achieved through the steps of powder premixing, powder soaking, powder kneading, high-speed stirring, slow stirring defoaming and the like. The stirring effectof the lithium battery negative electrode slurry is improved and the production efficiency of the stirring process is improved in a dry stirring manner, so that the poor pole piece caused by the conditions of particles, lineation and the like due to the fact that the slurry is not uniformly dispersed in the coating process of the slurry is improved; a glue making step in the prior art is cancelled, so the slurry preparation time is shortened, and the powder stirring time can be saved by about 5 h in each batch; and the solid content of the slurry is increased and can be increased to 54-56% from 48-50% through conventional stirring, and the use amount of deionized water is reduced.

Owner:山东派智新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com