Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Achieve optimal results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

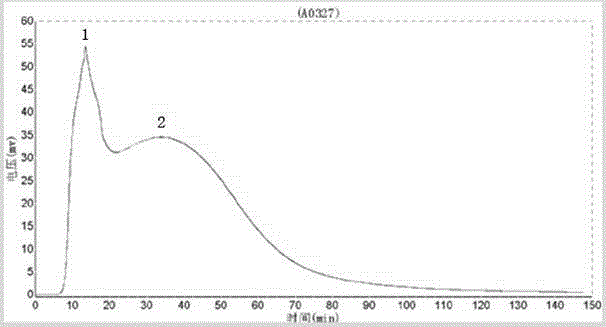

Formation method for lithium ion secondary battery

InactiveCN101315994AOvercoming performance deficienciesImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureLithiumPhysical chemistry

The invention provides a formation method used for a lithium ion secondary battery. The method comprises the following steps that: electrolyte is injected into the lithium ion secondary battery and then aged; subsequently, the lithium ion secondary battery is charged; the charging method comprises a first charging process and a second charging process; after the first charging process is completed, the electrolyte is injected into the lithium ion secondary battery again; the injected electrolyte before the first charging process and the electrolyte which is injected into the lithium ion secondary battery after the first charging process respectively and independently are mixed solution which contains the electrolyte lithium salt and the chain-shaped acid ester; wherein, the electrolyte injected into the lithium ion secondary battery before the first charging process also contains film-forming additive; the electrolyte which is injected into the lithium ion secondary battery again after the first charging process also contains overcharging additive. The formation method of the lithium ion secondary battery of the invention can effectively improve the comprehensive electrochemical performance of the battery.

Owner:SHANGHAI BYD

Data cleaning and indexing method

ActiveCN106611053AImprove the efficiency of integration transformationEasy to set upDatabase management systemsRelational databasesProcess mechanismData center

The invention discloses a data cleaning and indexing method, belonging to the field of data retrieval. The data cleaning and indexing method comprises the following specific processes of: (1), cleaning and importing data: cleaning structured data, and cleaning unstructured data; (2), establishing metadata: 1, obtaining the metadata, integrating different metadata in multiple sources of a data centre through a metadata obtaining process, and performing unified storage management by using a database as a metadata knowledge base; 2, publishing the metadata, and managing publishing of the metadata by establishing a set of metadata publishing process; and 3, accessing the metadata, creating a set of metadata access permission conferring and managing process mechanism, and controlling effective access of a valid user to metadata data; and (3), constructing an index: obtaining data attributes on a distributed data cluster of the data centre through metadata access. The overall data attributes are very clear; the structured and unstructured data are distinguished definitely; for different data structural types, a cleaning tool can be selected in a targeted manner; therefore, the best cleaning conversion effect can be realized; and the data integration conversion efficiency can be greatly increased.

Owner:河南信安通信技术股份有限公司

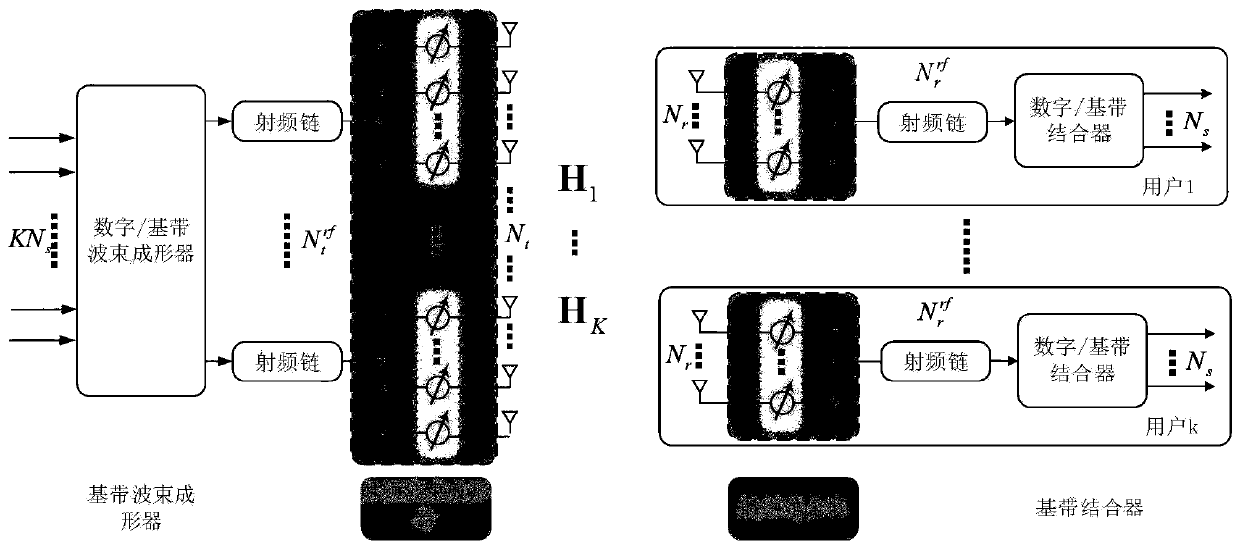

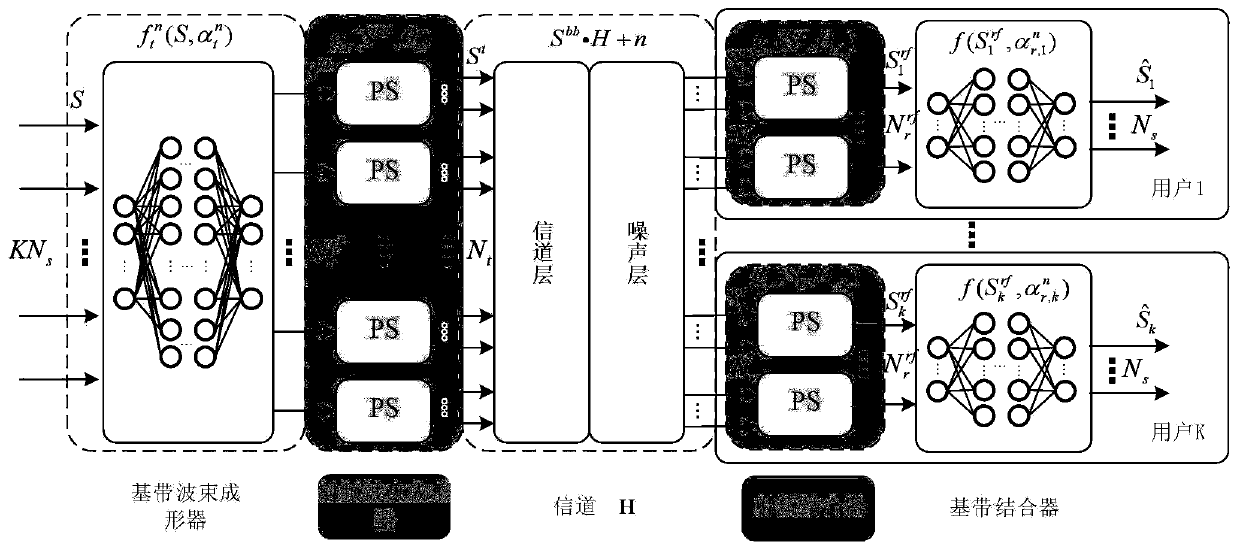

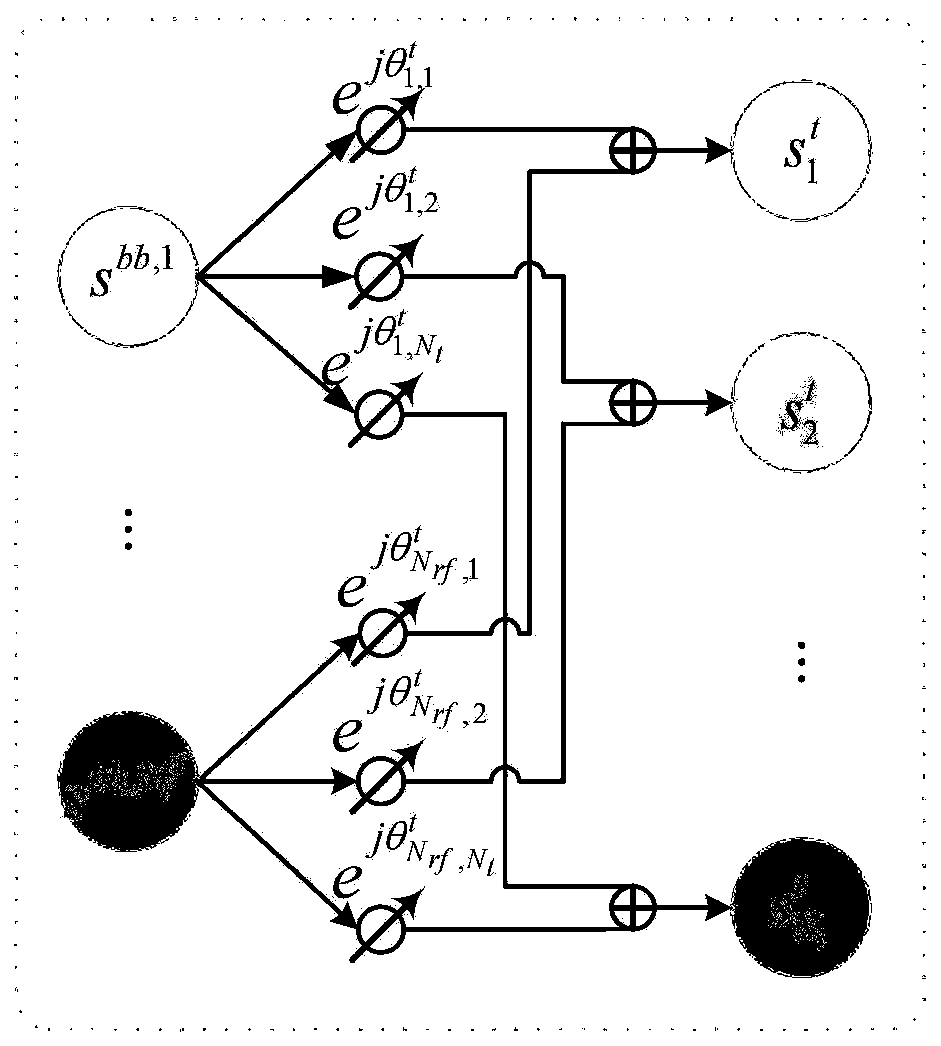

Millimeter wave MIMO hybrid beam forming optimization method based on deep learning

ActiveCN110535500AChange the priority factorChange optimization prioritySpatial transmit diversityHybrid beamformingEngineering

The invention discloses a millimeter wave MIMO hybrid beam forming optimization method based on deep learning. According to the millimeter wave MIMO hybrid beam forming optimization method based on deep learning, constraint conditions in a traditional millimeter wave large-scale MIMO hybrid beam forming optimization problem can be mapped into a neural network, and a multi-user hybrid beam formingsystem is completely converted into an equivalent neural network. Therefore, a complex non-convex optimization problem in hybrid beam forming can be converted into end-to-end unsupervised optimizationsimilar to an auto-encoder, and joint optimization can be carried out on a plurality of beam forming matrixes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

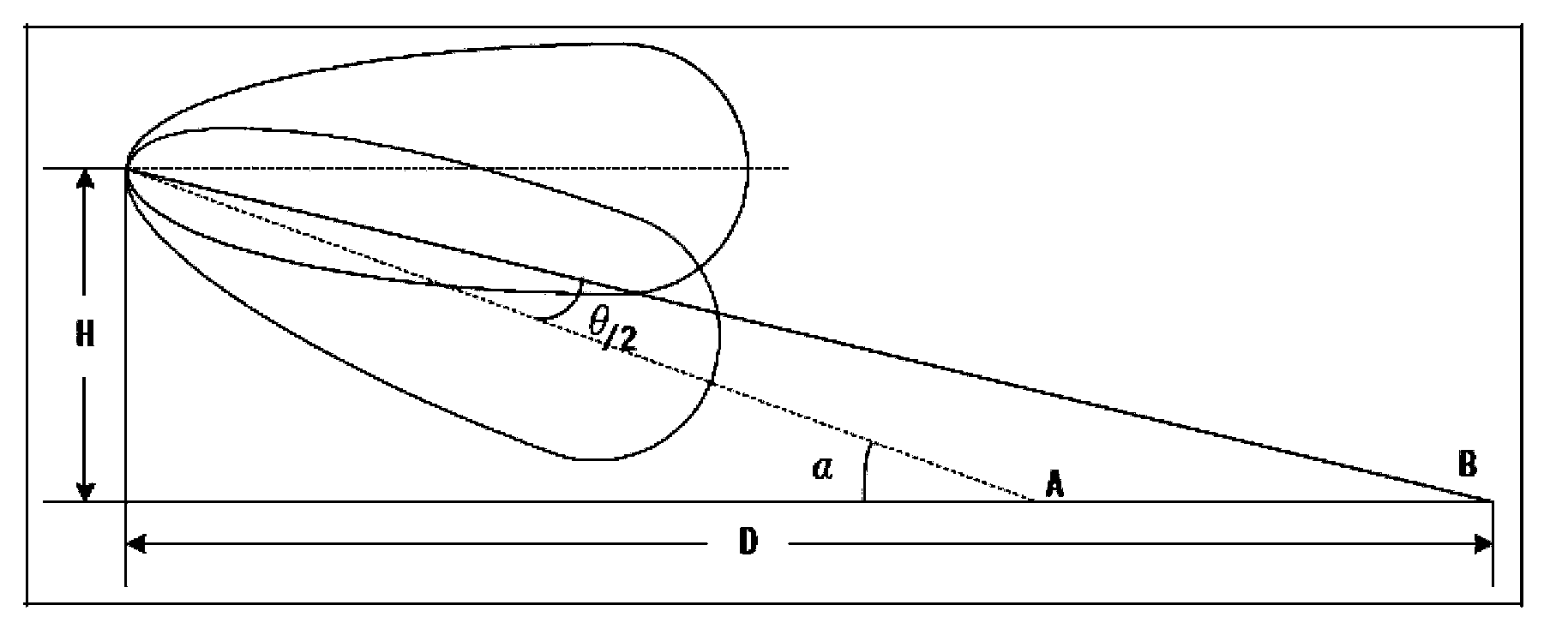

A method and a system for determining the downward inclination angles of antennas

ActiveCN103686758ASuppress interferenceFull Coverage GuaranteedTransmitters monitoringNetwork planningControl cellEngineering

The application provides a method and a system for determining the downward inclination angles of antennas in order to resolve a problem of ineffectively-controlled cell interference and coverage caused by unreasonably-arranged downward inclination angles of the antennas. The method comprises: obtaining the normal direction and the positional information of antennas in all cells in a preset area; successively determining cells subjected to interference in the rest cells by using the ith cell as an interference source cell and according to the normal direction and the positional information of the antenna in the ith cell and the positional information of rest cells except the ith cell; respectively calculating the cell distance between the ith cell and each cell subjected to interference; calculating the coverage distance of the ith cell according to the cell distance; calculating an initial antenna downward inclination angle of the ith cell according to the coverage distanct; and comparing the initial antenna downward inclination angle with a preset antenna downward inclination angle in order to determine the actual antenna downward inclination angle of the ith cell. The antenna downward inclination angle determined by the method is reasonable so as to guarantee the coverage of the own cell and inhibit adjacent cell interference.

Owner:DATANG MOBILE COMM EQUIP CO LTD

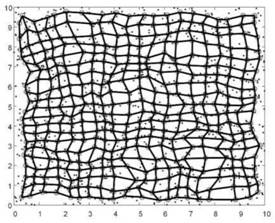

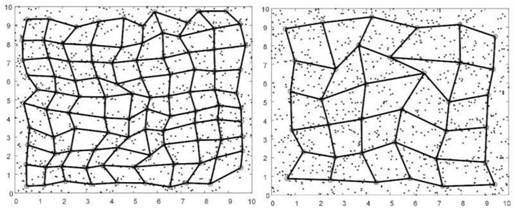

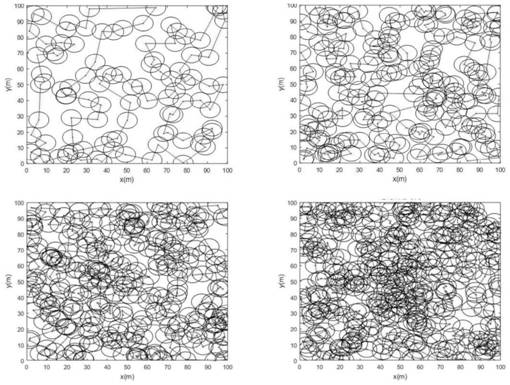

Bionic vision self-motion perception map drawing method, storage medium and equipment

ActiveCN111813113AImprove accuracyAchieve optimal resultsNavigational calculation instrumentsPosition/course control in two dimensionsGyroscopeComputer graphics (images)

The invention discloses a bionic vision self-motion perception map drawing method, a storage medium and equipment. The method comprises steps of building a scene memory unit representing a spatial position and an environment landmark template according to the environment information collected by a bionic vision perception system, and generating a corresponding scene memory database; acquiring self-motion information according to a gyroscope and an accelerometer, performing direction and displacement encoding, and updating pose sensing information; correcting the self-motion information by adopting a scene memory bank and an environment landmark template; and drawing and correcting the bionic self-motion perception map according to the mutual relation among the environmental landmark template, the scene memory unit and the self-motion perception. The method is advantaged in that self-motion sensing errors can be reduced by using the visual sensing template, and precision of self-positioning and accuracy of closed-loop detection of the scene memory unit are improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

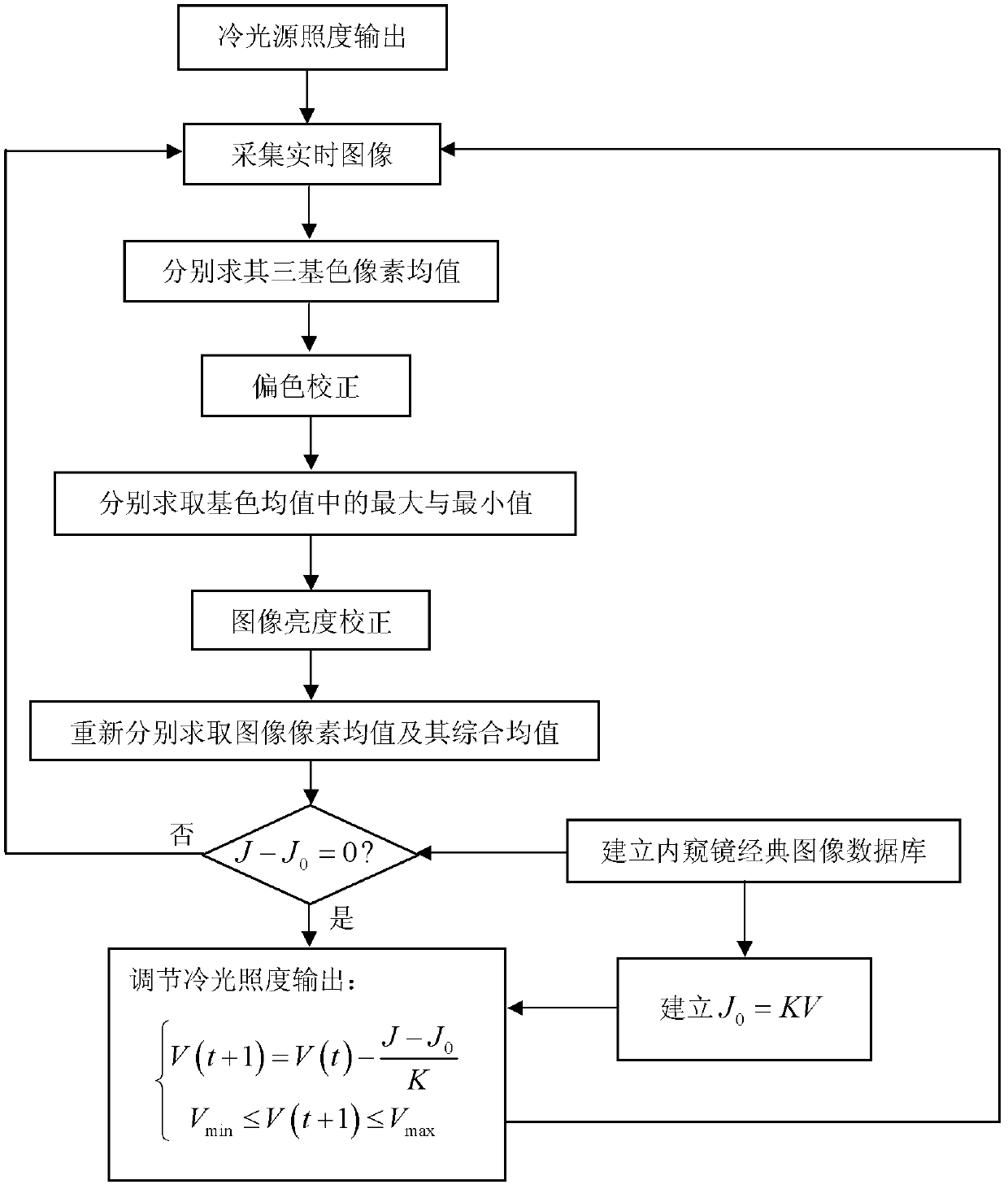

Method for intelligently adjusting endoscope illuminance

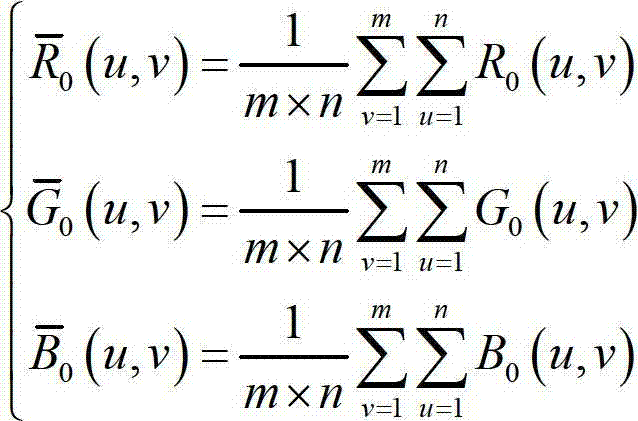

ActiveCN102641109AImprove the level ofRealize intelligent adjustmentSurgeryEndoscopesColor imageIlluminance

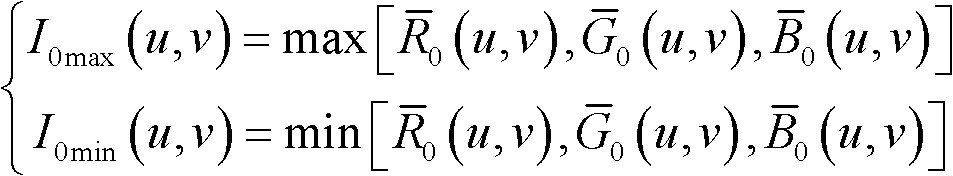

The invention discloses a method for intelligently adjusting the endoscope illuminance, which comprises the following steps of: step 1, initializing; step 2, outputting standard illuminance by a cold light source of an endoscope; step 3, when the endoscope is in a working state, observing and acquiring the interior real-time image of a human organ; step 4, respectively obtaining the pixel values R1(u, v), G1(u, v), B1(u, v) and the average values bar(R)1(u, v), bar(G)1(u, v), bar(B)1(u, v) of the pixel values of the R, G and B three primary colors of an RGB real-time color image; step 5, carrying out color cast correction on the real-timely acquired image; step 6, selecting the maximum and minimum from the pixel values of the three primary colors after the color cast correction; step 7, correcting the image brightness; step 8, calculating the image pixel average value after the image brightness correction and the comprehensive average value thereof; and step 10, comparing J and J0 in the database, and adjusting the illuminance output of the cold light source. According to the method, the endoscope illuminance can be intelligently adjusted to realize an optimized effect no matter how the endoscope is bent.

Owner:SHANGHAI JIAO TONG UNIV SUBEI RES INST

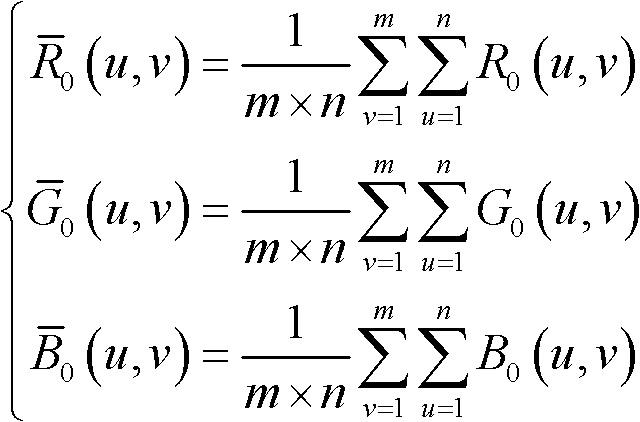

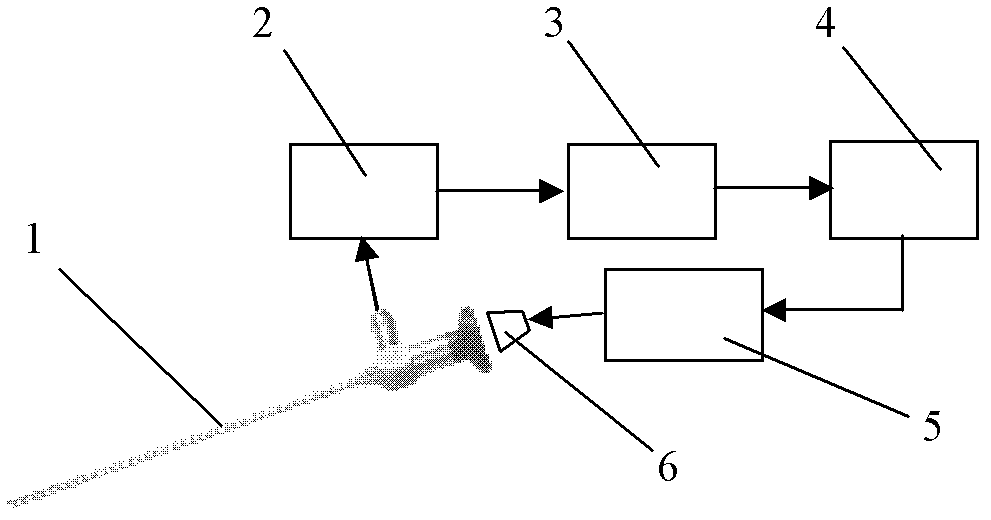

Intelligent adjusting device of endoscope illumination

ActiveCN102846301AConvenient for clinical operationAchieve optimal resultsSurgeryColor imageControl signal

The invention discloses an intelligent adjusting device of endoscope illumination. The device comprises a medical endoscope, an image acquisition card, a signal processor, a controller, a switching power supply module and a cold light source. Light emitted by the cold light source is sent to the medical endoscope which converts light signals into image signals and transmits the image signals to the signal processor through an image output interface and the image acquisition card; the signal processor receives and processes the image signals transmitted by the image acquisition card, performs color cast correction and image brightness correction on images acquired in real time by establishing classic color images and a color characteristic data bank of the color images, and transmits illumination output control instructions of the cold light source to the controller; and the controller changes switching control signal output phases according to the control instructions of the signal processor to enable direct voltage output by the switching power supply module to change correspondingly, so that the working voltage of the cold light source is changed, and the illumination output by the cold light source is optimized.

Owner:SHANGHAI JIAO TONG UNIV SUBEI RES INST

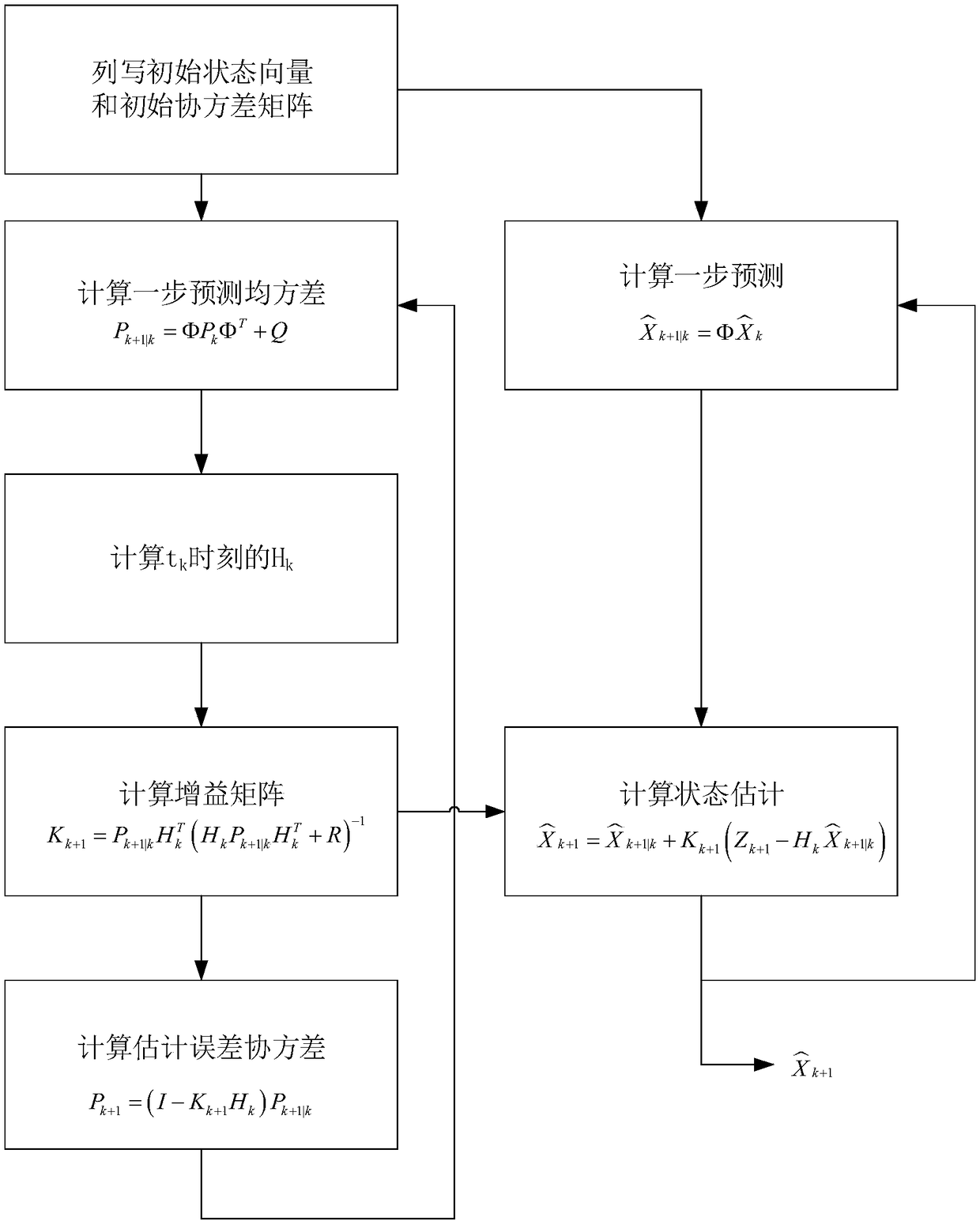

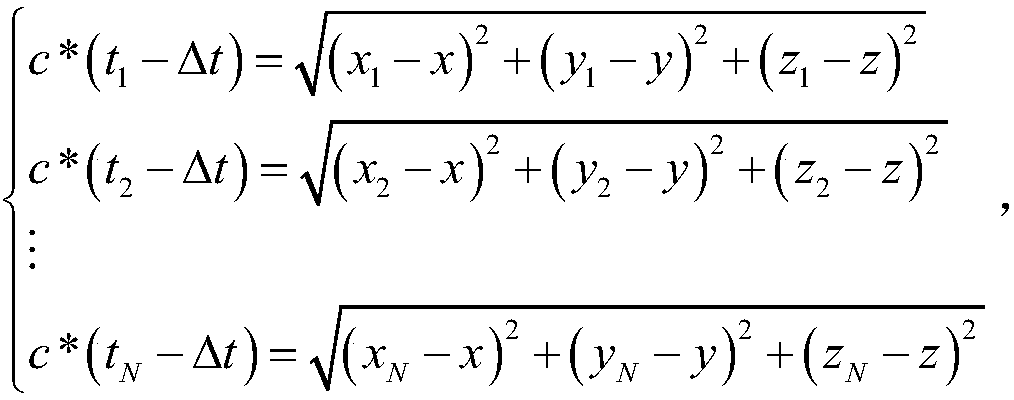

UWB positioning method based on taylor series expansion of mixed least square method

ActiveCN109283490AAchieve optimal resultsImprove anti-interference abilityPosition fixationLocation information based serviceLeast squaresBase station

The invention provides a UWB positioning method based on taylor series expansion of a mixed least square method. The UWB positioning method based on taylor series expansion of the mixed least square method comprise the steps that firstly, the mixed least square method is used for directly processing the time when a pulse signal sent by a UWB tag is received by a base station to obtain a positioning initial value; then a taylor series expansion algorithm is used for processing the obtained initial positioning value again to enable the initial positioning value to be more accurate; and finally,an extended Kalman filter is used for connecting the obtained discrete positioning points into a track through a motion model to achieve the optimization effect on positioning accuracy. The UWB positioning method has high positioning precision and good anti-interference effect, and effectively improves positioning efficiency.

Owner:SOUTHEAST UNIV

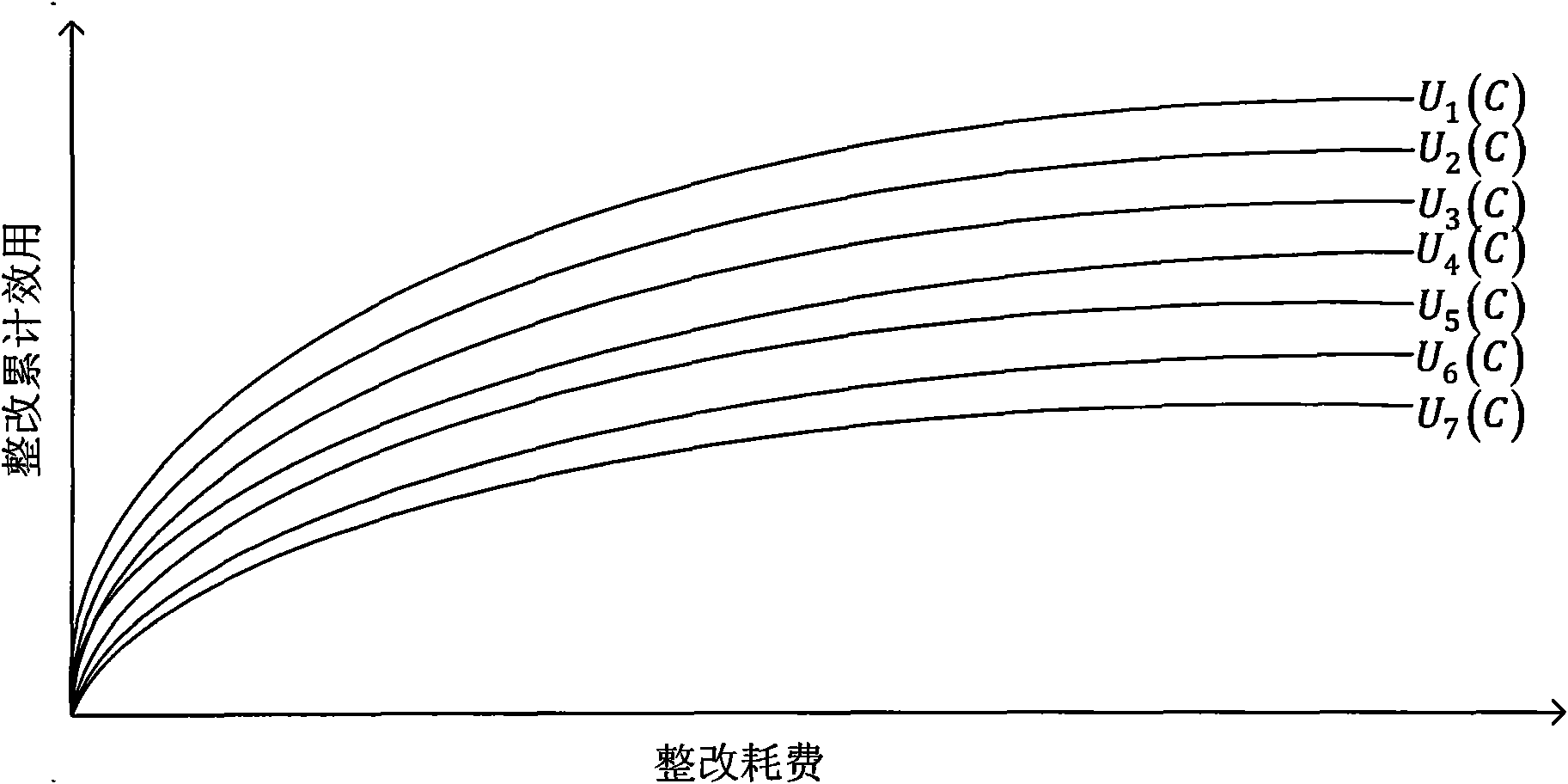

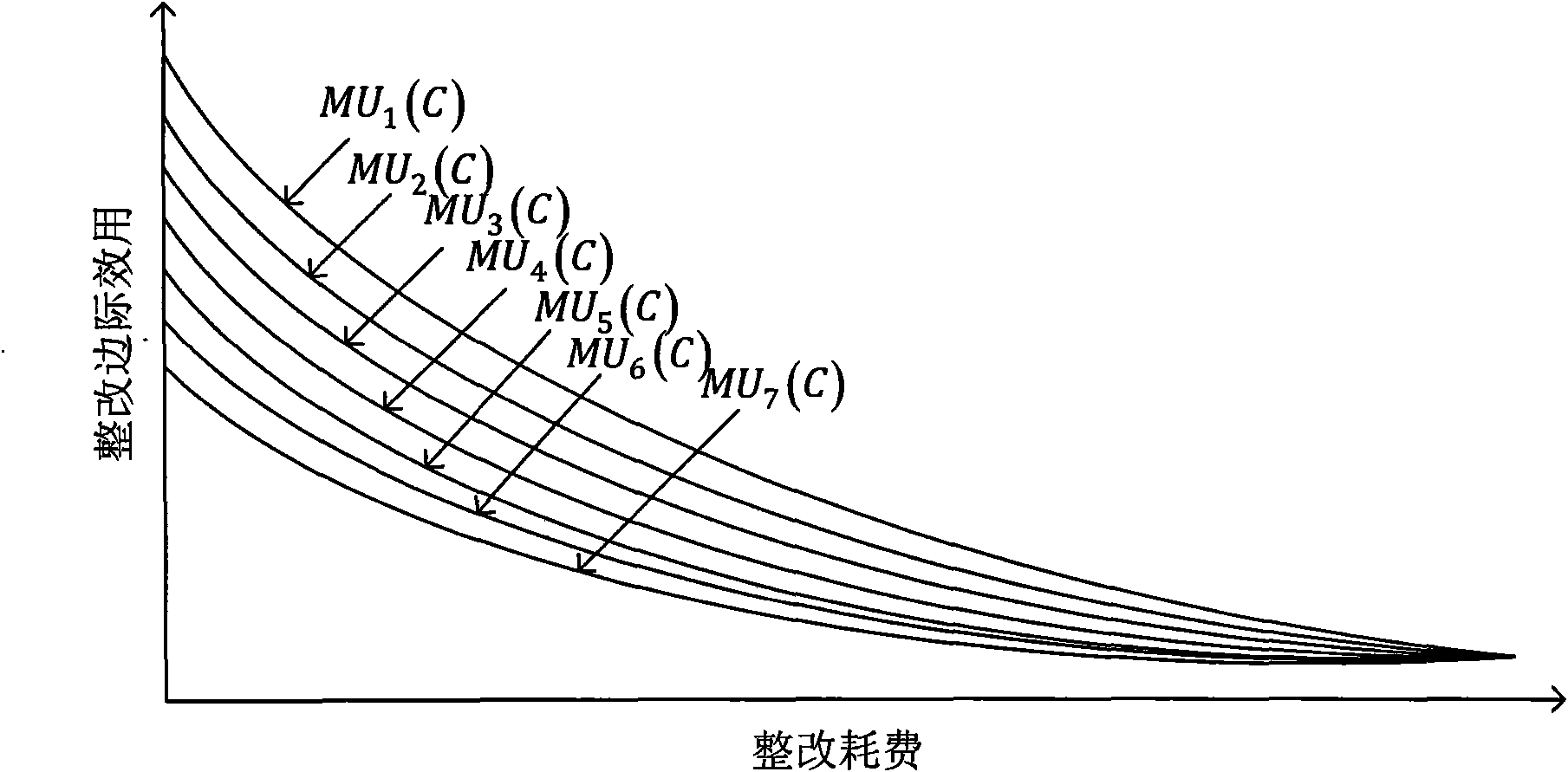

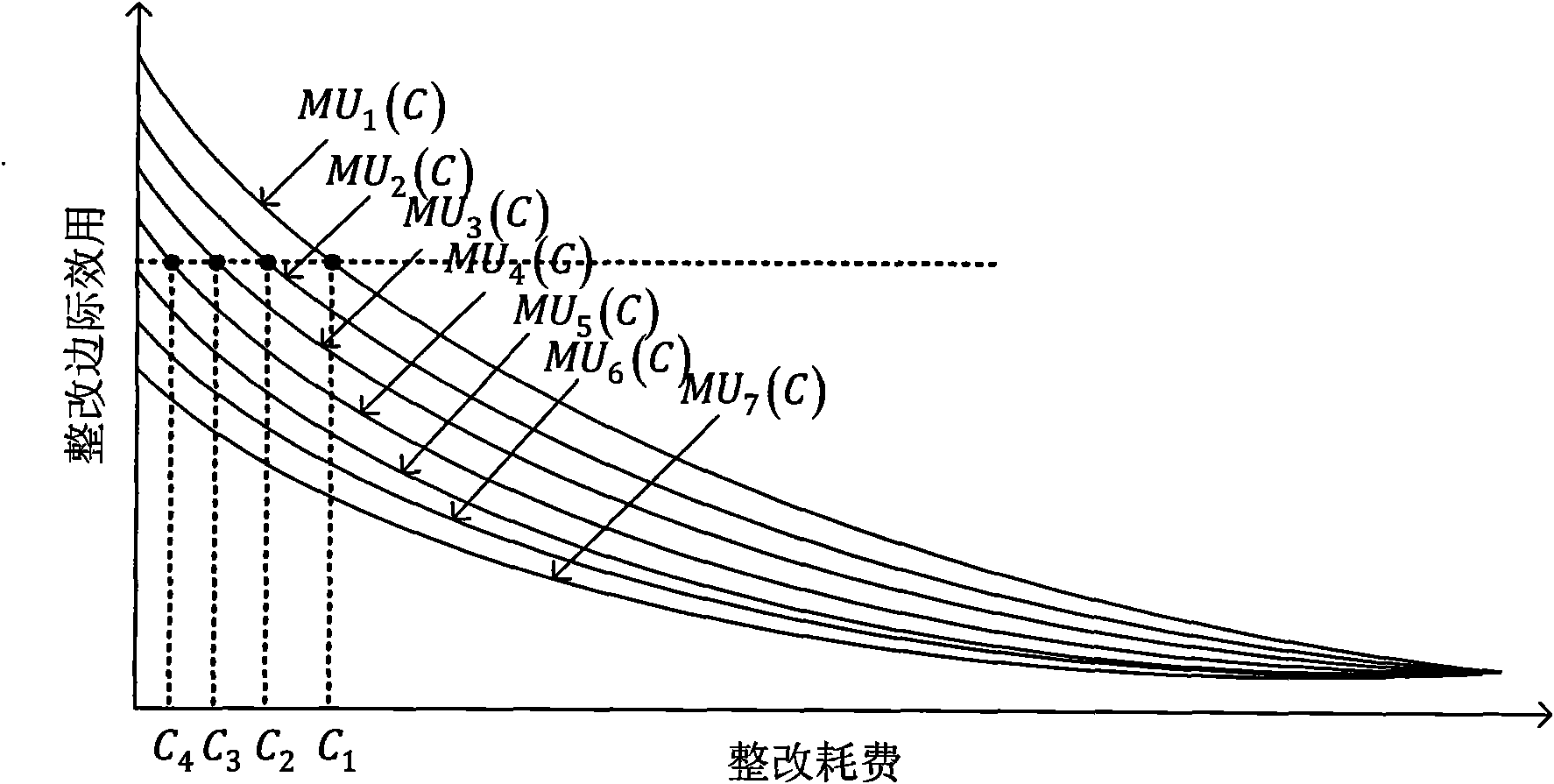

Digital model-based method for optimizing and allocating electromagnetic compatibility indexes

ActiveCN101957890AAchieve optimal resultsTransmission monitoringSpecial data processing applicationsFactor baseComputer science

The invention discloses a digital model-based method for optimizing and allocating electromagnetic compatibility indexes. The technical scheme comprises the following steps of: analyzing the frequency of interference frequency points and simulating by using a computer to obtain an overall reformation index; optimizing and simulating adjustable factors, and combining the actual expense required inthe engineering to obtain a digital model of a utility-expense ratio relation; extracting marginal utility curves of the adjustable factors based on the model; and obtaining the optimal allocation indexes according to an equimarginal utility principle. In the index allocation, the marginal utility of each reformation factor is extracted according to the utility-expense ratio relation in the process of reforming each factor of three electromagnetic compatibility factors. According to a principle that the marginal utility of the reformation effect is gradually decreased in the practical situation, under the condition that the sum of sub-indexes meets the requirement of an overall index, when the marginal utility of each factor is equal, the optimum effect of the index allocation can be achieved.

Owner:BEIHANG UNIV

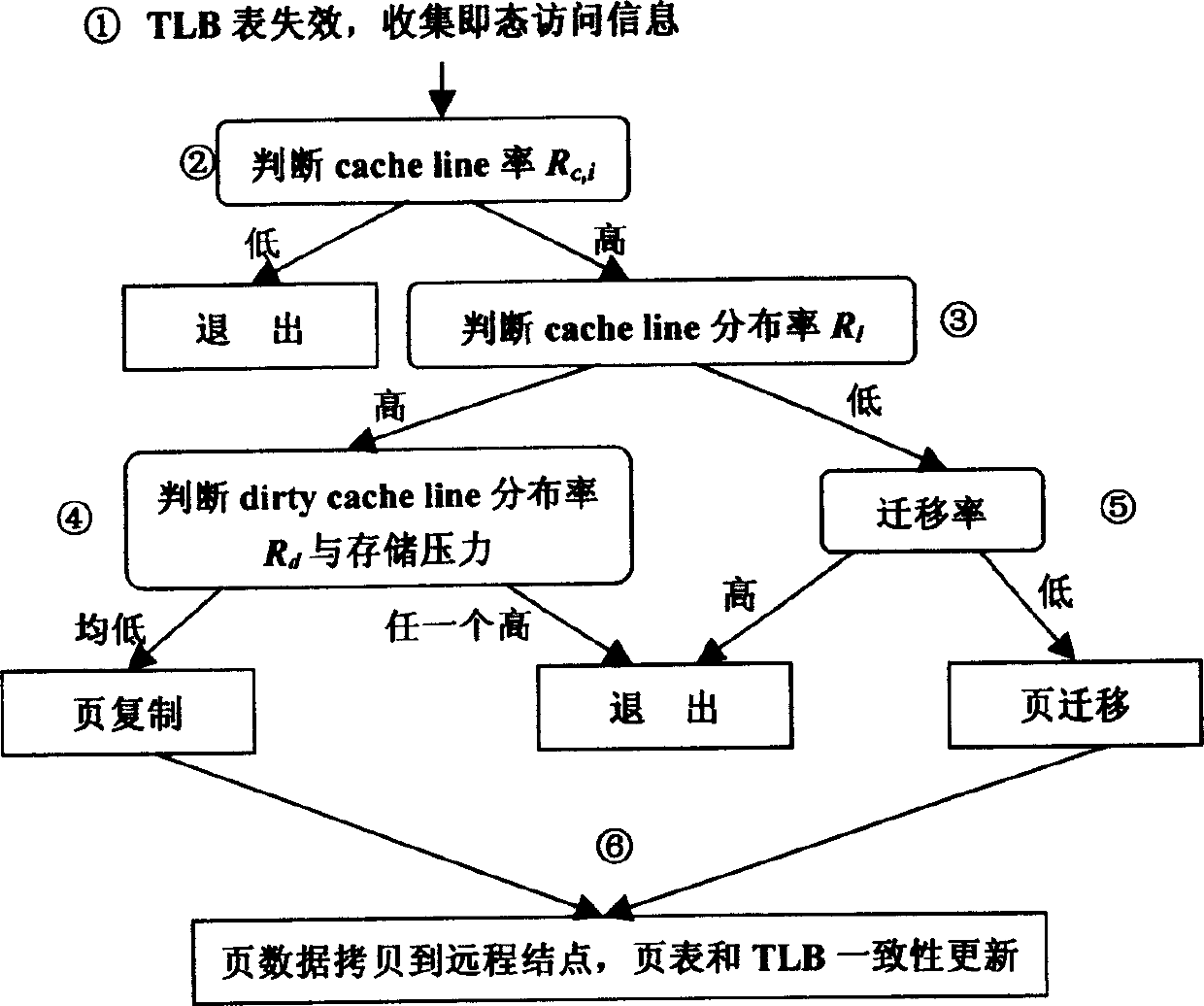

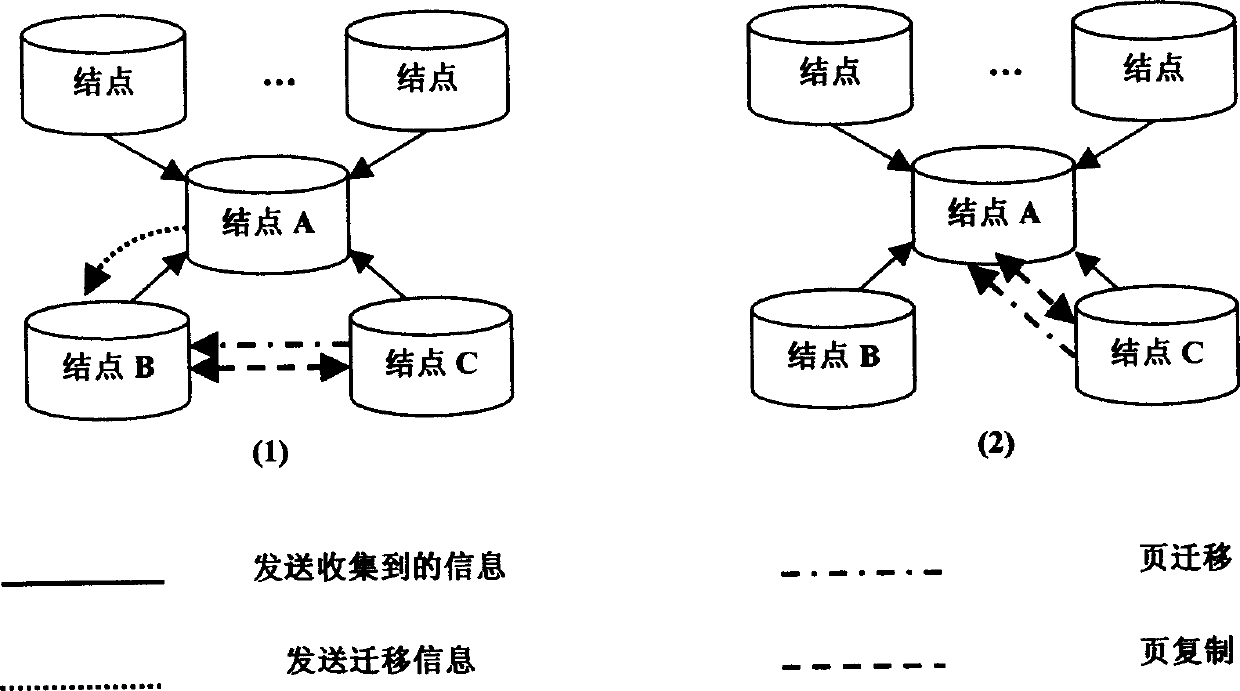

Dynamic page transport method based on immediate state access information

InactiveCN1560745ALimited versatilityTake advantage ofMemory adressing/allocation/relocationPage table

The invention discloses a page shifting method based on instant accessing information, the concrete steps are: 1. gathers the access state of each joint in a special time after igniting tactic and uses it as the instant accessing information of the page; 2. judging the cacheline rate Rc, i of accounted page, determines if continues the tactic or not; 3. judges the cacheline distribution rate R1 of the accounted page, determines if uses it as the duplicated page or shifting page; 4. to the candidate duplicated page, determines if carries on page duplication or not according to the comparison, otherwise quits the tactic directly; 5 to the candidate shifting page, judges if carries on page shift to it, otherwise the tactic quit directly; 6. refers the tactic result, calls the page shift or the page duplicating functions, the page data is copied to the remote joint and carries on consistency updating to the page table and TLB.

Owner:NAT UNIV OF DEFENSE TECH

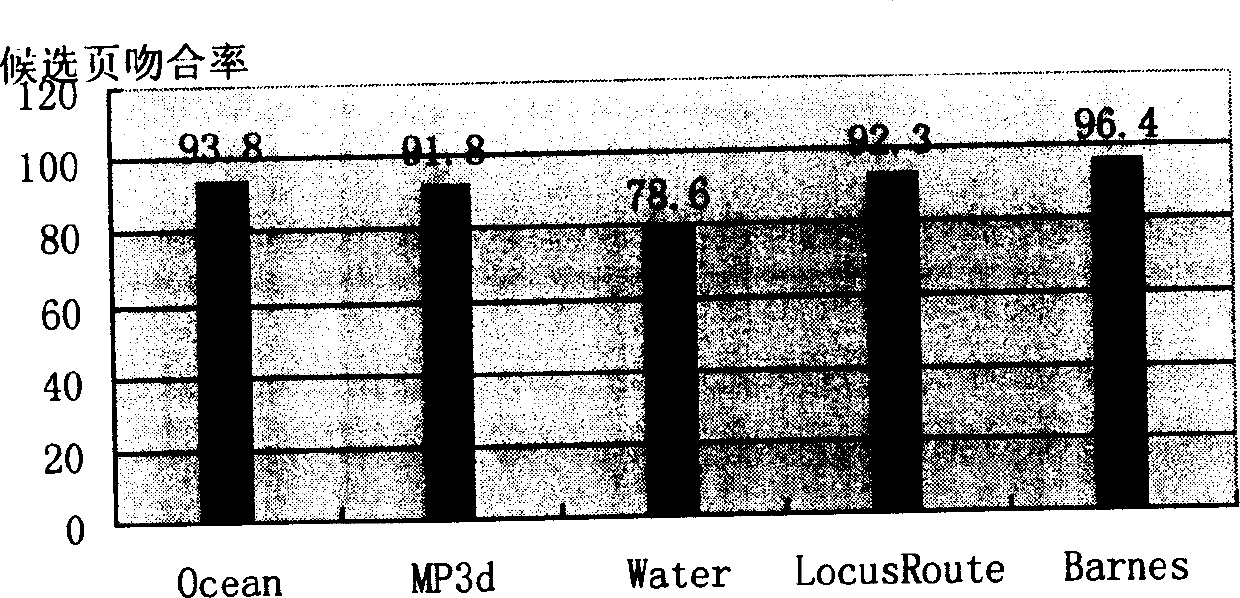

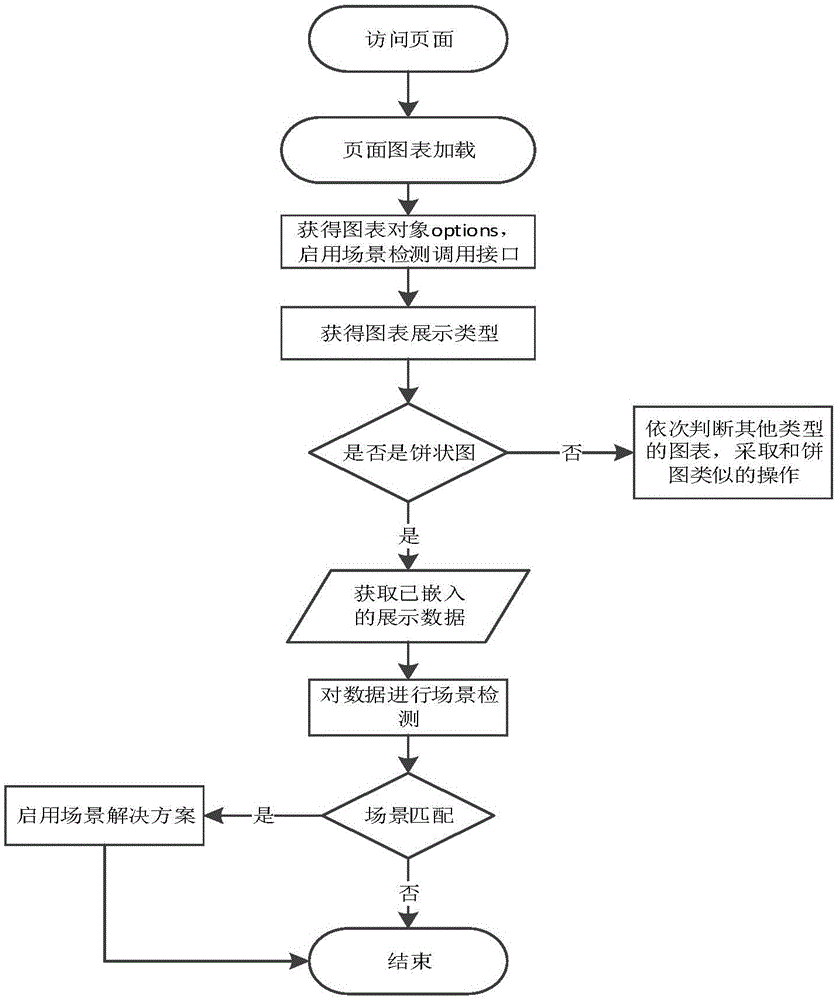

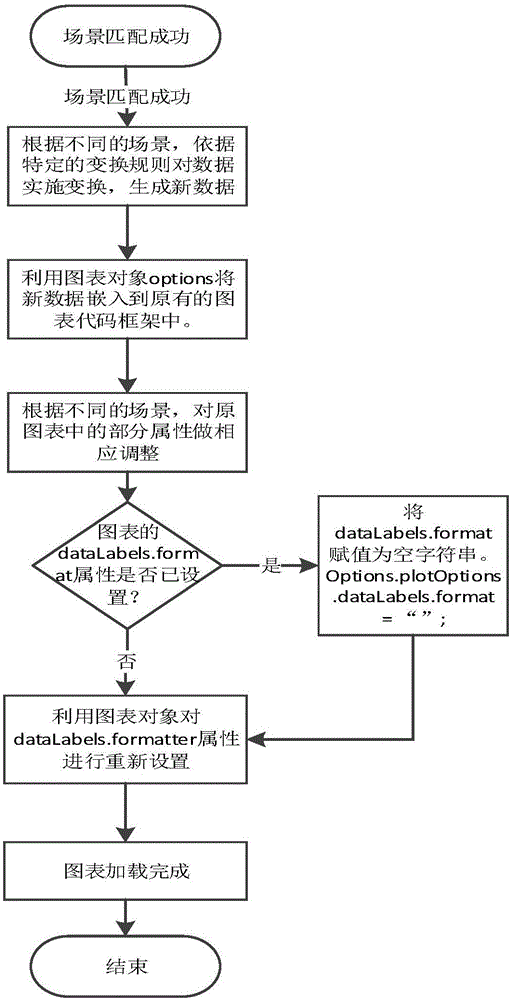

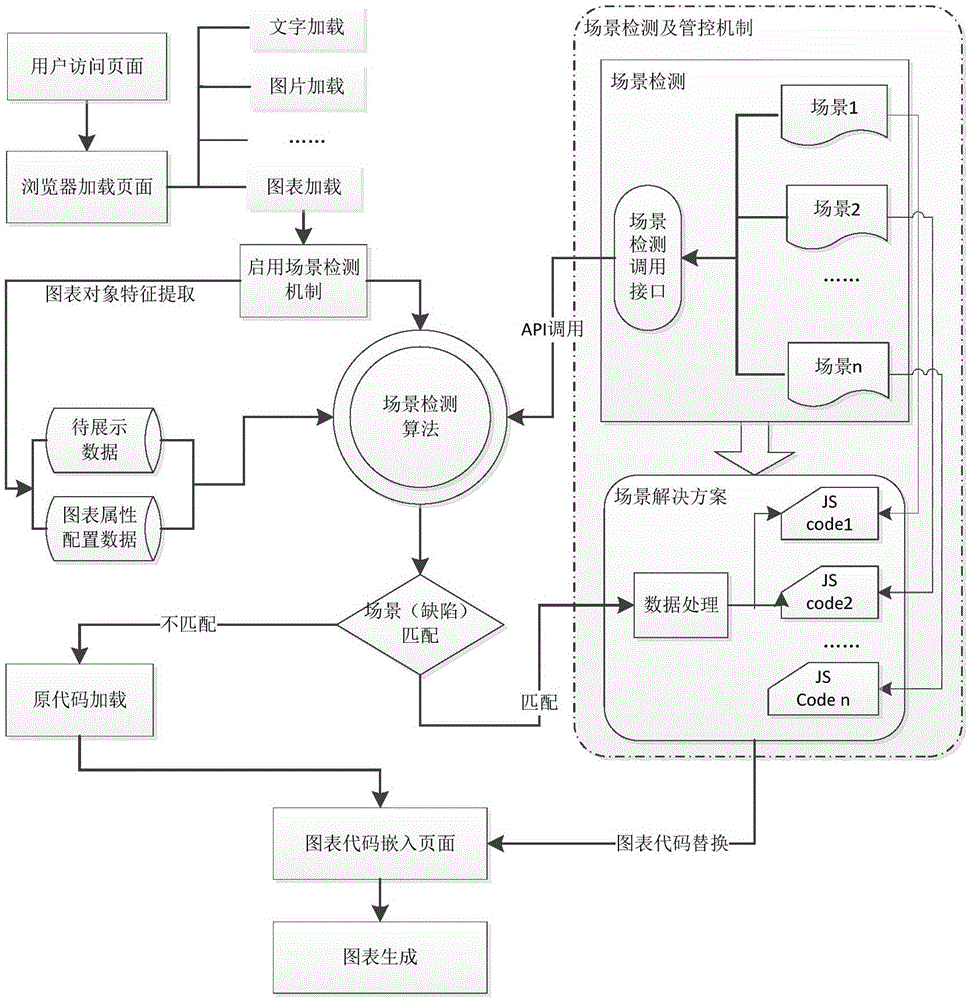

Chart display defect optimization method based on chart types and data feature scenes

ActiveCN105117404AImprove display defectsThe generated interface displays wellOther databases browsing/visualisationSpecial data processing applicationsAlgorithm

Owner:NANJING UNIV

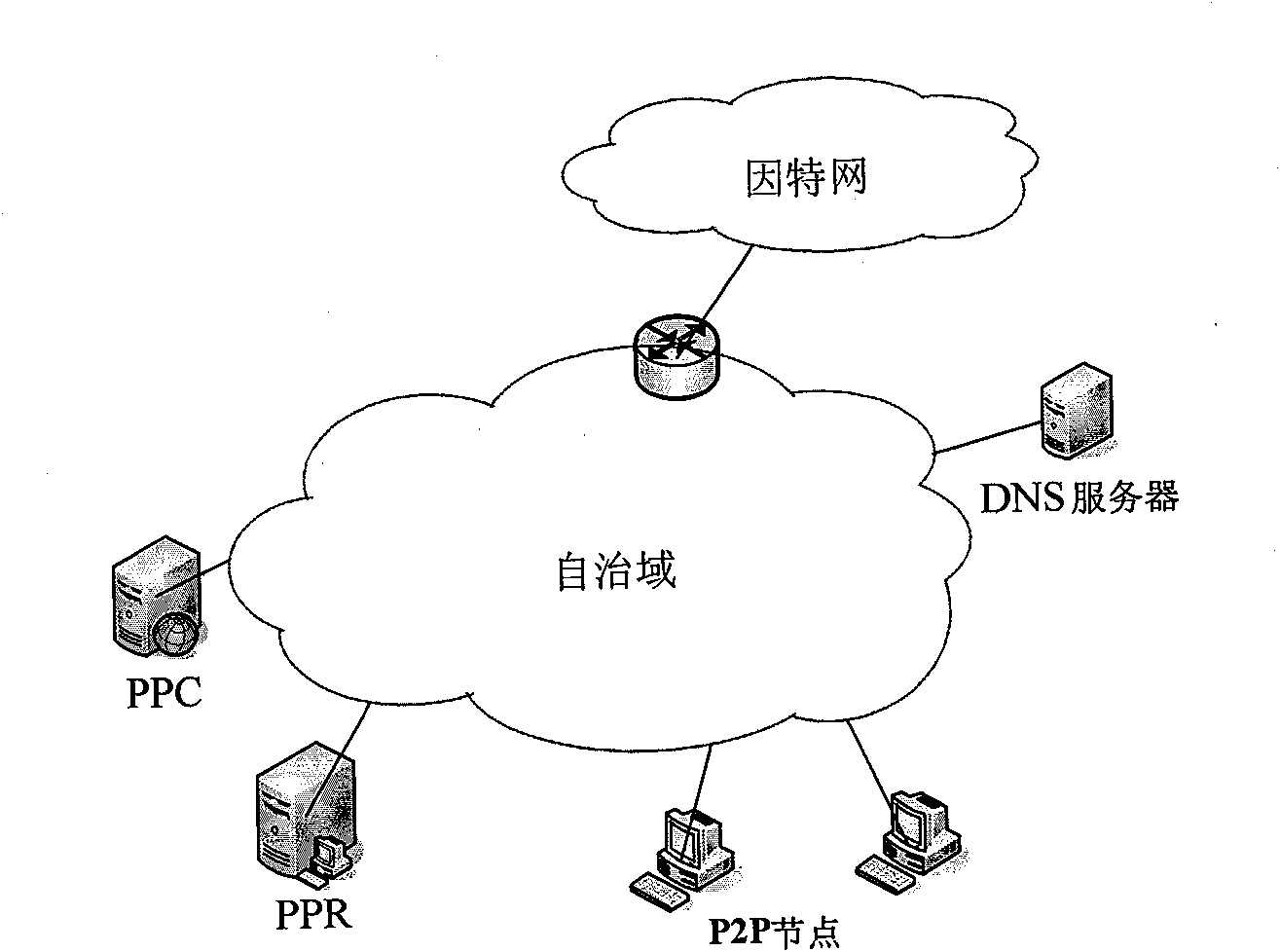

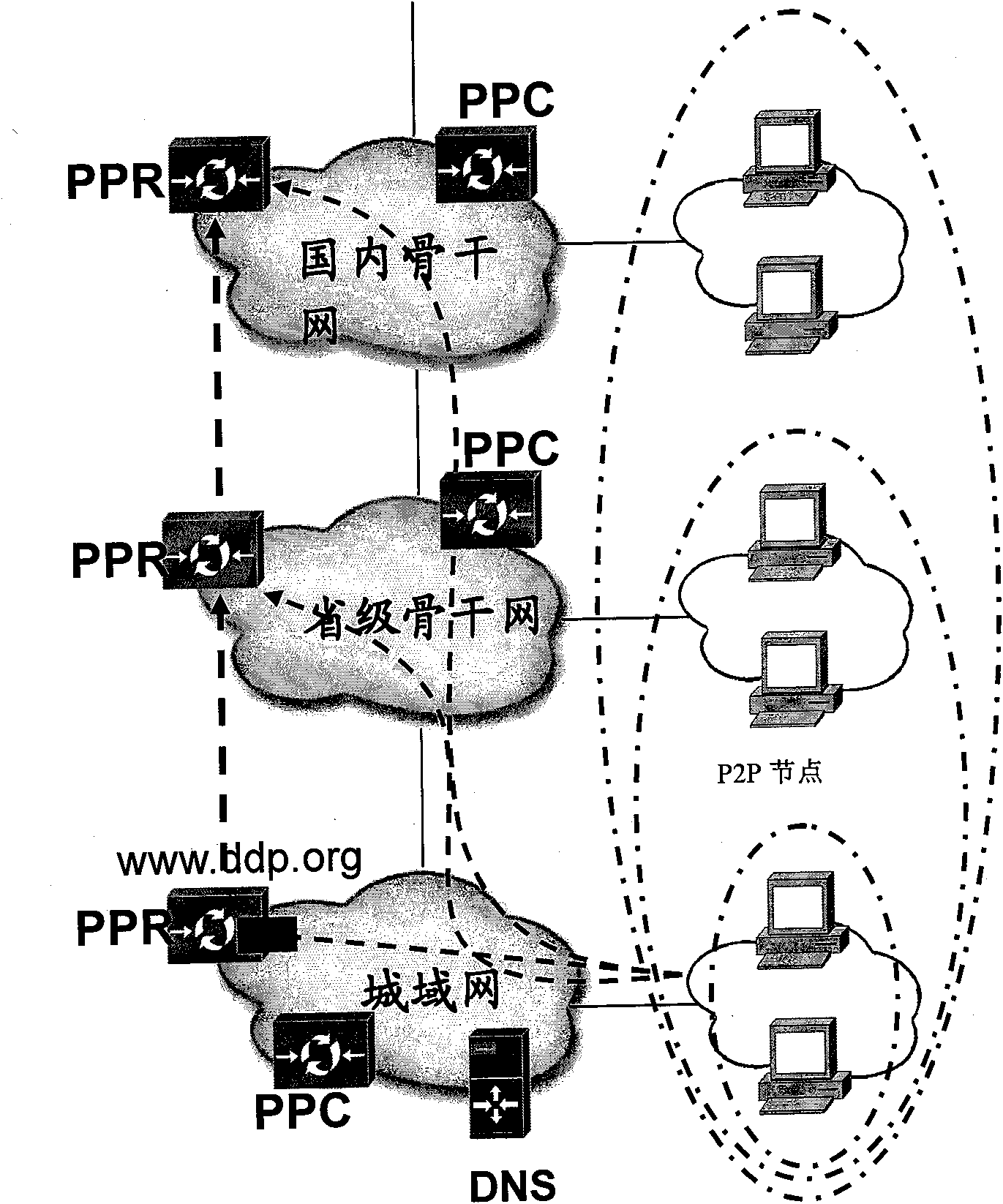

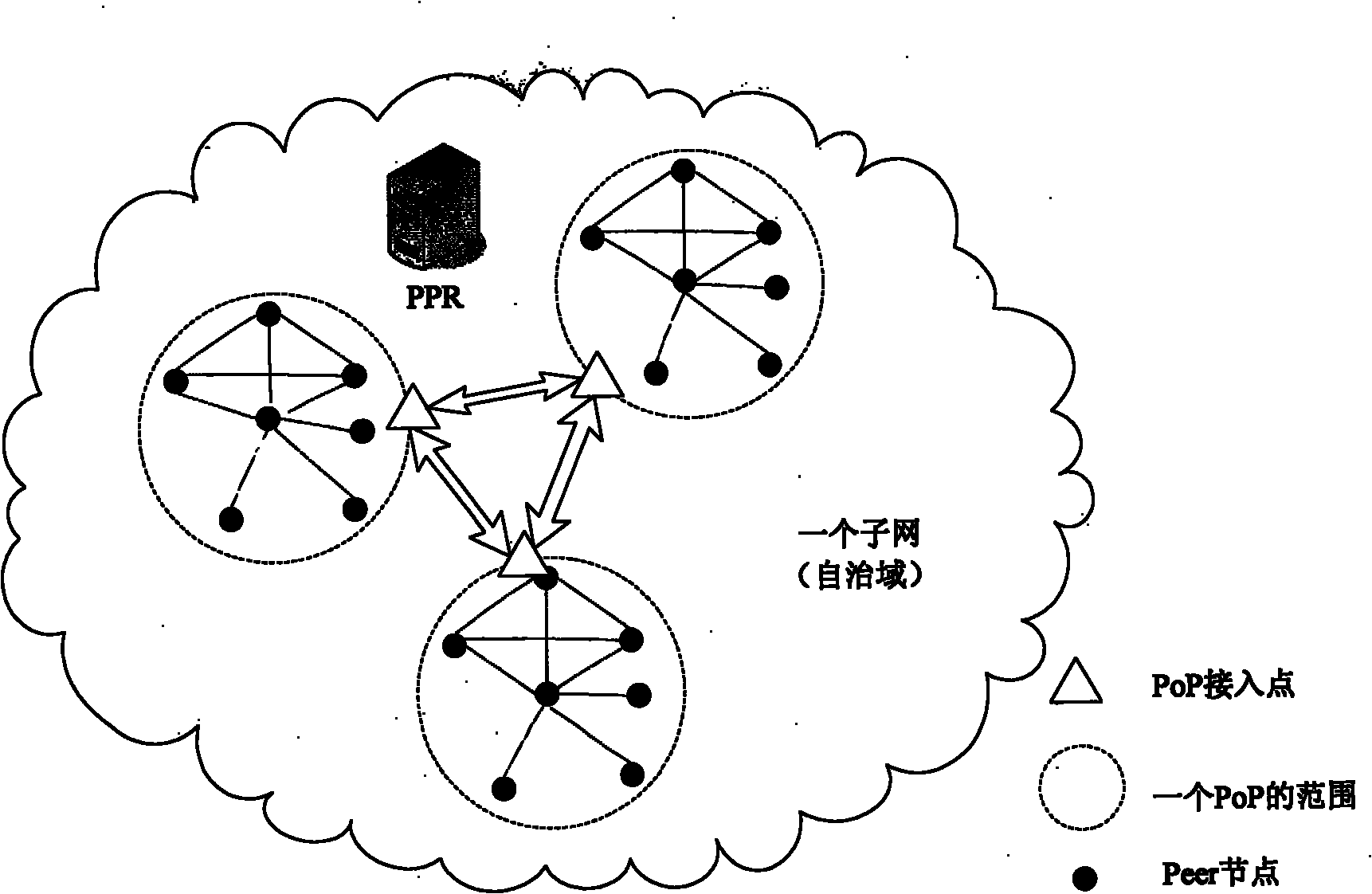

P2P traffic-optimized network system

InactiveCN101958827AAvoid mismatchReduce deploymentData switching networksTraffic capacityNetworked system

The invention provides a P2P traffic-optimized network system which comprises a plurality of levels of autonomous domains, and also comprises a plurality of P2P traffic-optimized domains, wherein each autonomous domain comprises a plurality of P2P nodes, and each P2P traffic-optimized domain comprises an autonomous domain and a P2P redirection device deployed in the autonomous domain; the P2P node is used for sending a resource request to the P2P redirection device of the P2P traffic-optimized domain, and the P2P redirection device is used for receiving the resource request of the P2P node of the P2P traffic-optimized domain, finding target P2P nodes containing target resources within the traffic-optimized domain and returning a target P2P node list to the P2P node sending the resource request; and the P2P redirection device is also used for refusing the resource request of the P2P node of the P2P traffic optimized domain. In the invention, the traffic-optimized domains are built based on the autonomous domains, thereby avoiding the problem that an idealized model is not matched with an actual network environment in the prior art. The invention has the advantages of few devices needing to be deployed, simple deployment and low cost.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Method for surface treatment by developing machine after electronic circuit board anti-soldering process

ActiveCN102281719AImprove process capabilityAchieve optimal resultsPrinted circuit secondary treatmentWater usePrinting ink

The invention relates to a method for carrying out surface processing on an electronic circuit board (PCB) by a developing machine after welding prevention processing, which comprises the following procedures of processing by a first developing trough, primary wind pressure tube water prevention, processing by a second developing trough, secondary wind pressure tube water prevention, processing by a third developing trough, tertiary wind pressure tube water prevention, medium pressure washing, processing by a punching water jet scalpel, composite washing, processing by a sponge roller, cold air drying, hot air drying, inspection and the like. In the invention, after spray disks of the developing troughs are structurally regulated and the punching water jet scalpel is added, no residual ink is generated at the bottom of a blink hole and no phenomenon of poor hole blockage of a through hole is generated; by a wind pressure water prevention mode, the defect that after the ink is rolled by the roller, the copper surface of the PCB is stained with the ink can be improved and the amount of printing ink on pad can be reduced; the water using amount can be saved; the speed of the developing machine can be improved, the production efficiency is promoted, the scrappage is reduced and the yield rate of the PCB can be promoted.

Owner:GULTECH WUXI ELECTRONICS CO LTD

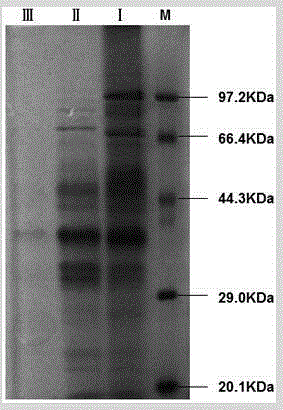

Method for separating and purifying xylanase from waste flammulina velutiper cultivation material

The invention provides a method for separating and purifying xylanase from waste flammulina velutiper cultivation materials. According to the method, digestion conditions of xylanase left in the waste flammulina velutiper cultivation materials are optimized, and methods such as ammonium sulfate precipitation, dialysis, SephadexG-100 sephadex chromatography and DEAEC-52 ion-exchange chromatography are adopted to separate and purify cellulose, and the purity of protein achieves electrophoresis purity by virtue of SDS-PAGE identification. The xylanase is extracted from the waste flammulina velutiper cultivation materials and is effectively separated and purified, the structure and the function of xylanase can be deeply studied, and the scientific reference is provided for production and application of xylanase.

Owner:FUJIAN AGRI & FORESTRY UNIV

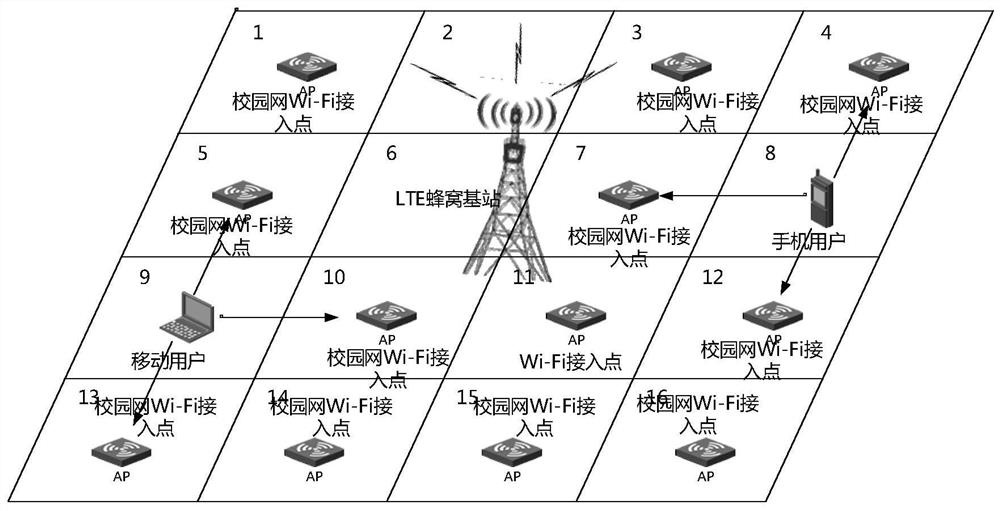

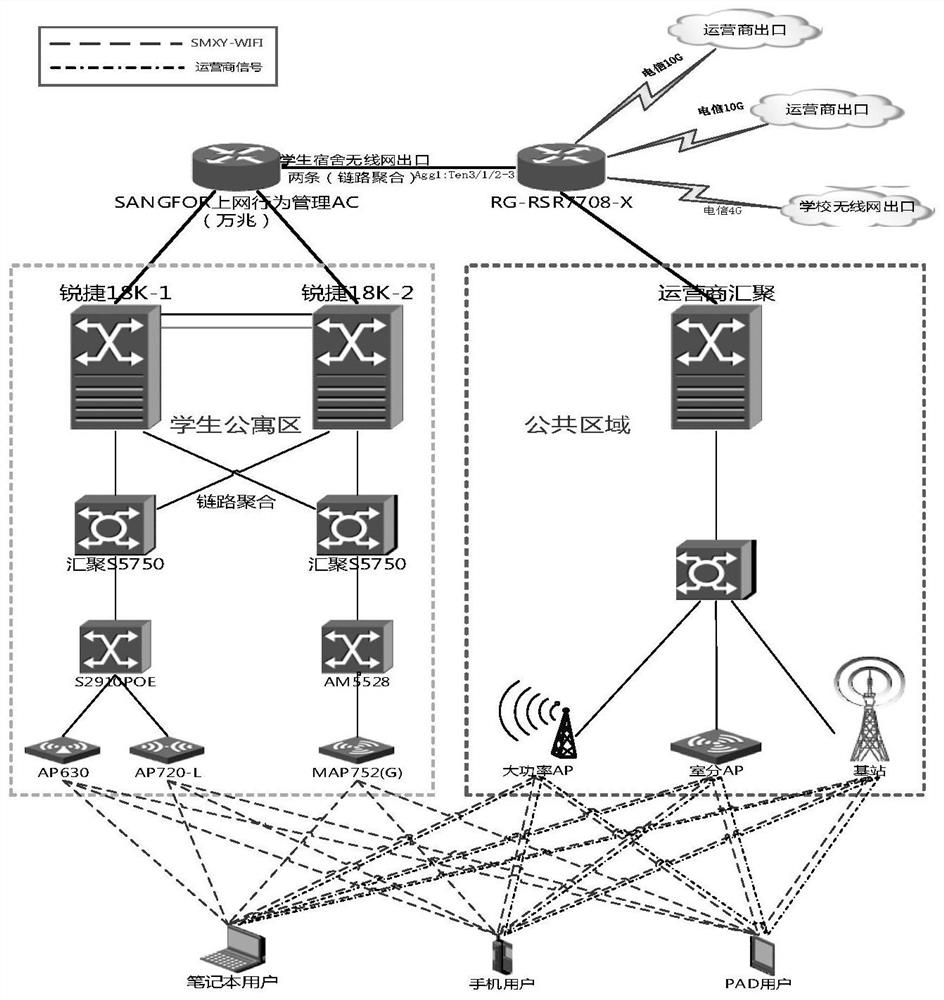

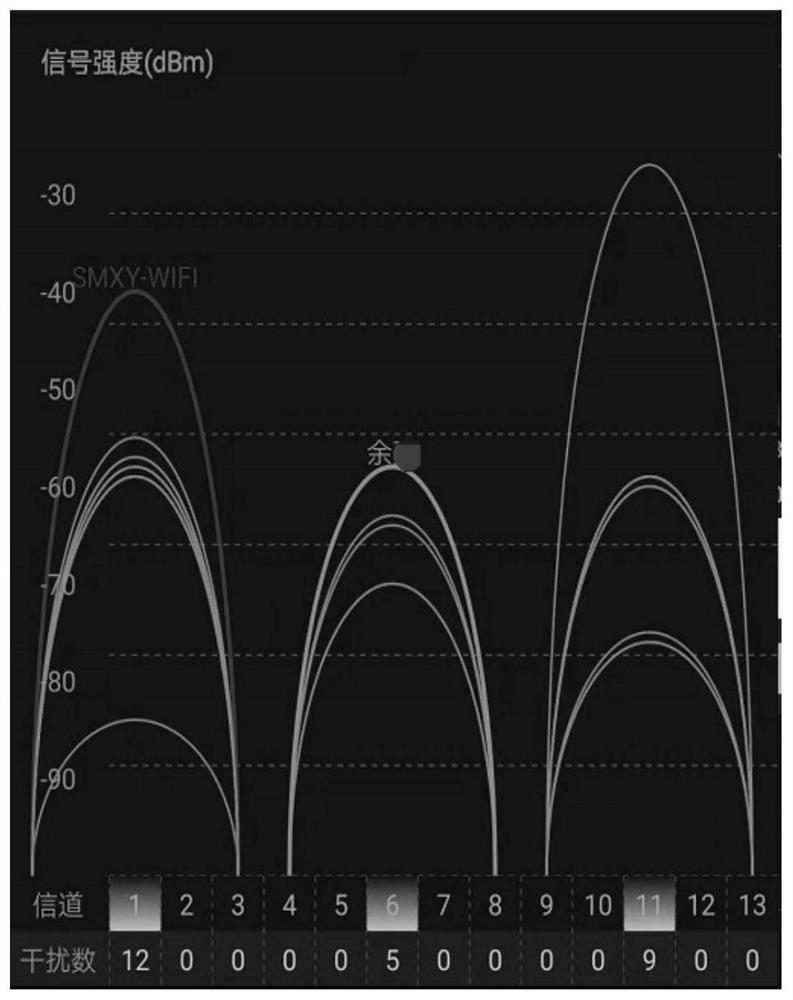

Mobile data distribution method of heterogeneous wireless network based on campus network

ActiveCN111669785AAchieve optimal resultsNetwork traffic/resource managementAssess restrictionEngineeringNetwork management

The method is suitable for the technical field of network management, and provides a mobile data distribution method of a heterogeneous wireless network based on a campus network. Firstly, a campus network and mobile data traffic are optimized; the mobile bandwidth is combined with the Wi-Fi bandwidth of the campus network; internet surfing of campus network users in colleges and universities is taken as a scene, the constructed multi-objective optimization problem is converted into a maximization problem and a data distribution method of a general delay-aware Wi-Fi distribution and network selection algorithm for calculating an optimal strategy by considering a user service satisfaction return rate. In different positions, a user can automatically select the network connection of the userby presetting a threshold strategy, so as to achieve a network optimization effect.

Owner:SANMING UNIV

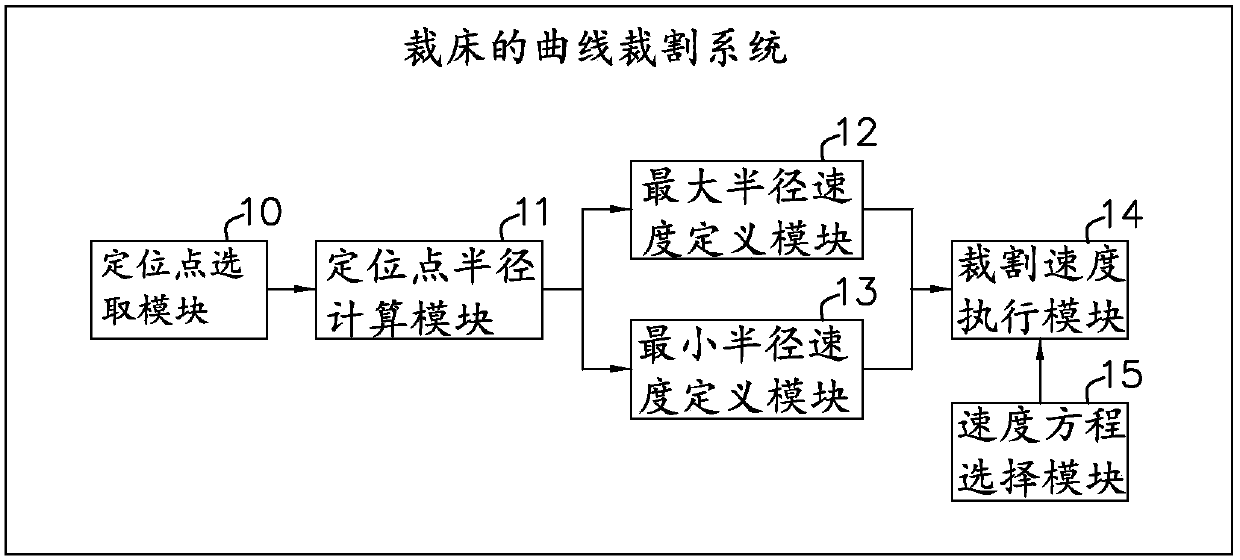

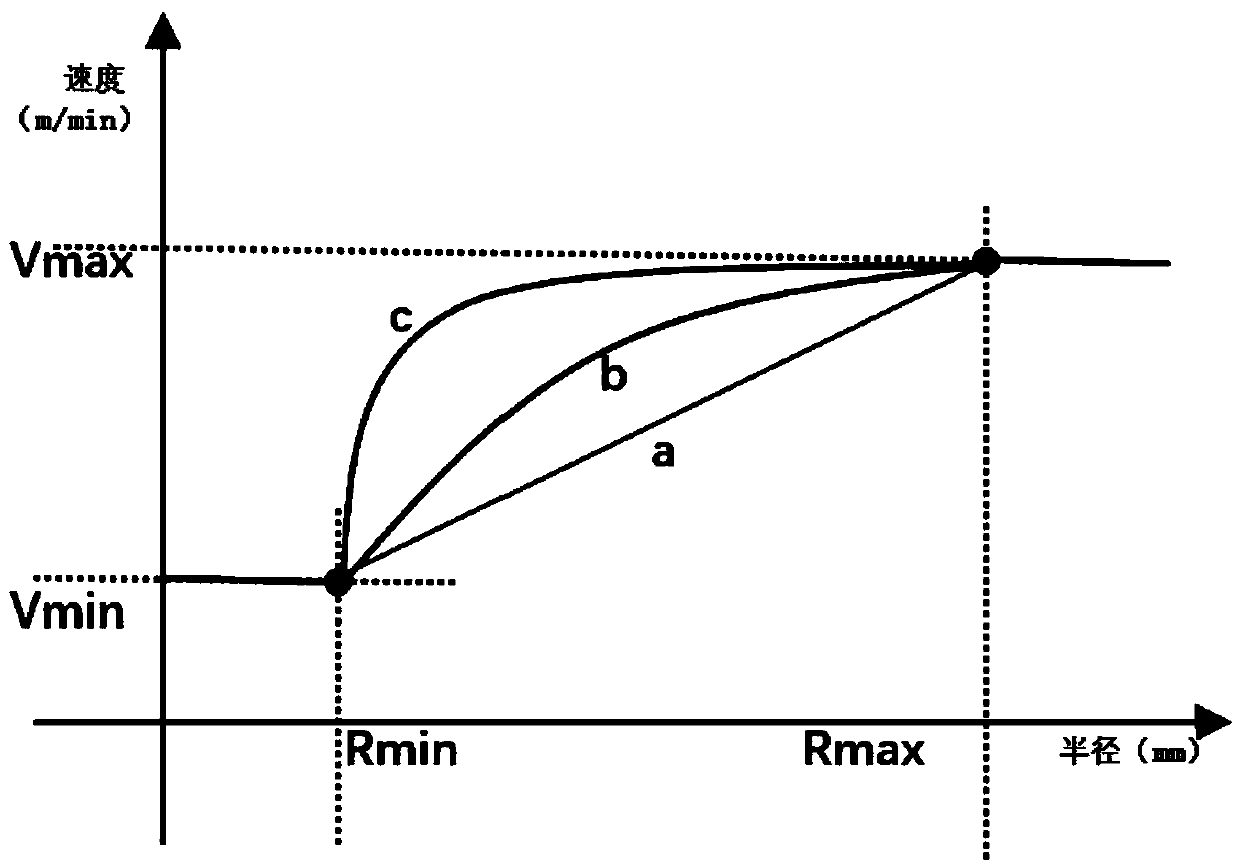

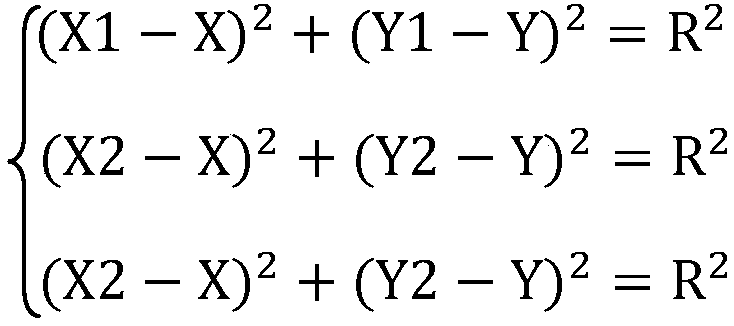

Curve cutting system of cutting bed

InactiveCN108021103AFor the purpose of simplifyingAchieve optimal resultsNumerical controlComputer moduleMinimum cut

The invention provides a curve cutting system of a cutting bed. The curve cutting system of the cutting bed comprises one locating point selection module, one locating point radius computation module,one maximum radius speed definition module, one minimum radius speed definition module and one cutting speed execution module. The cutting speed execution module is used for selecting a continuouslyvariable speed value in a range of a maximum cutting speed value and a minimum cutting speed value and cutting the cloth, and the continuously variable speed value follows an equation that V is equalto KRf+d, wherein V is corresponding speed when radius is R, and K, f and d are variables. The curve cutting system of the cutting bed has the advantages that various curve speed optimization schemescan be designed according to actual requirements and are converted into mathematical formulas, so that only an appropriate speed scheme needs to be selected when the cloth is cut, and further the aimof simplification is achieved; meanwhile, cutting can be carried out at different speeds according to curves with different radians, and the effect of optimization is achieved, so that cutting qualitycan be improved.

Owner:BULLMER ELECTROMECHANICAL TECH

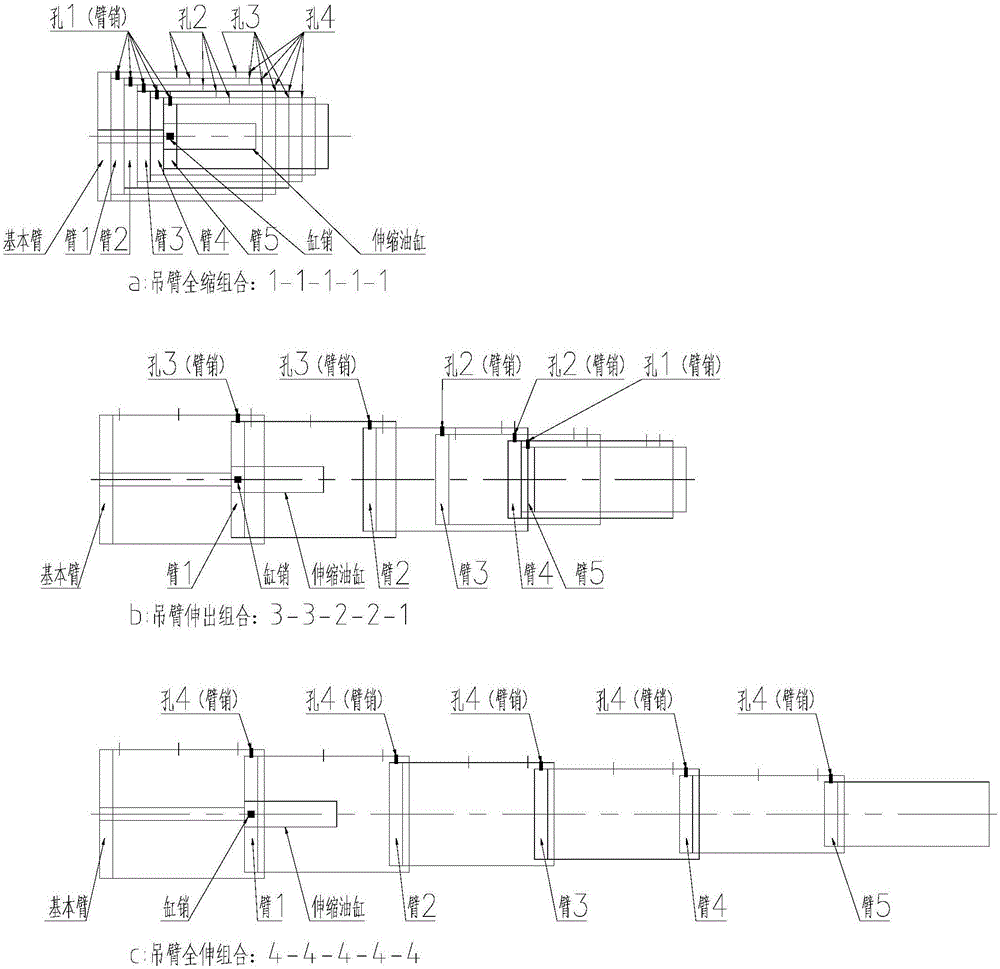

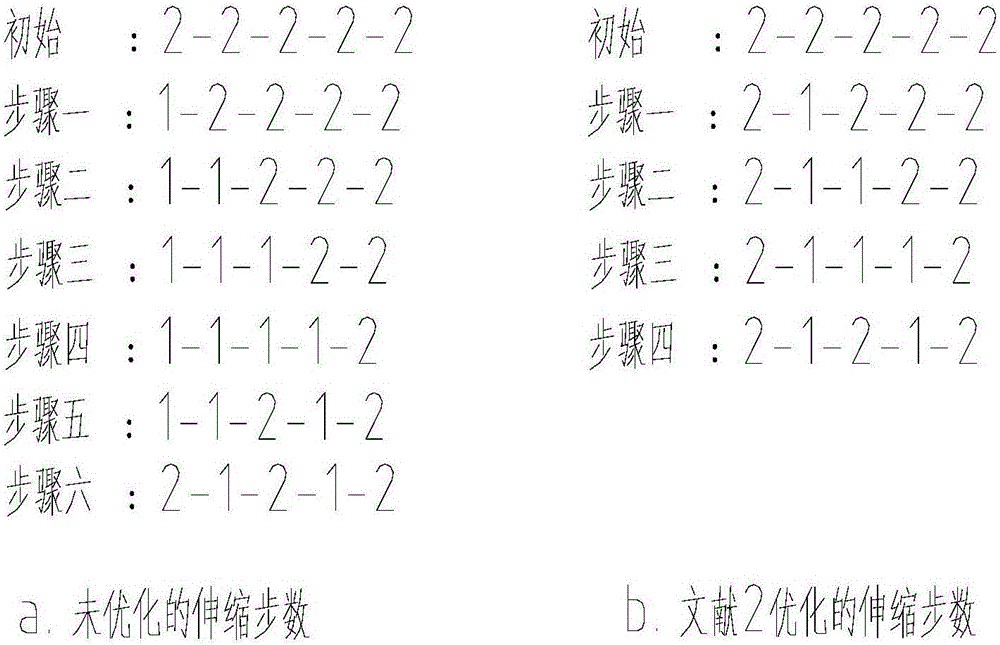

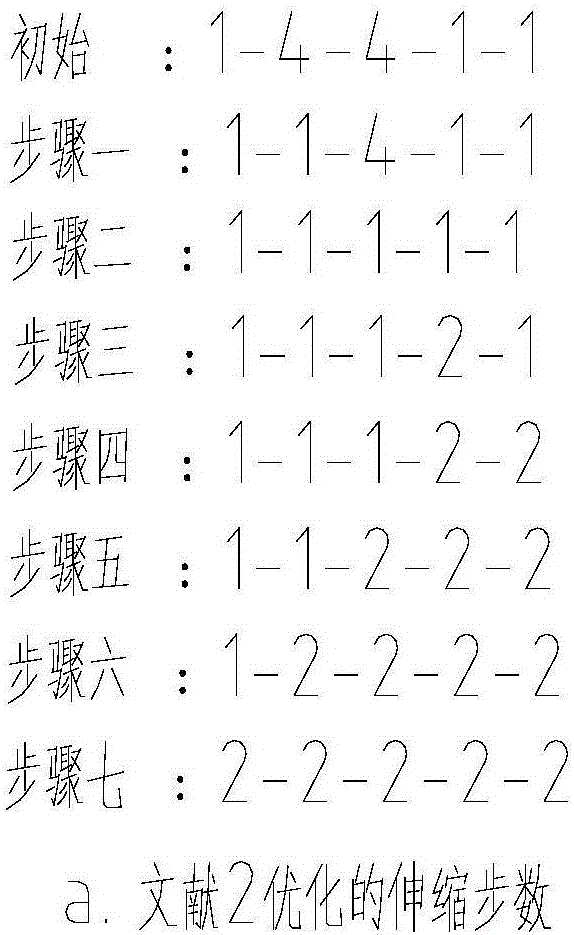

Single-cylinder bolt multistage sequential extension path optimization method

ActiveCN106744386AReduce the number of telescopic stepsImprove scaling efficiencyCranesComputer scienceMiddle state

The invention relates to a single-cylinder bolt multistage sequential extension path optimization method, and belongs to the single-cylinder bolt multistage sequential extension path optimization method. Middle states of all arc sections are extracted according to three states for arrangement and combination to generate multiple middle state sets tM{}; and a shrinkage arm limit combination to be searched is searched from the generated middle state sets. The middle state sets are sent to an estimation formula series in sequence; and the state sets satisfied by all estimation formulas are the shrinkage arm limit state sets. The method is simple and clear in flow, and in particular, is suitable for program realization; and in particular, when the arm section number n and the pin hole number m are increased, the program can be conveniently performed.

Owner:JILIN UNIV

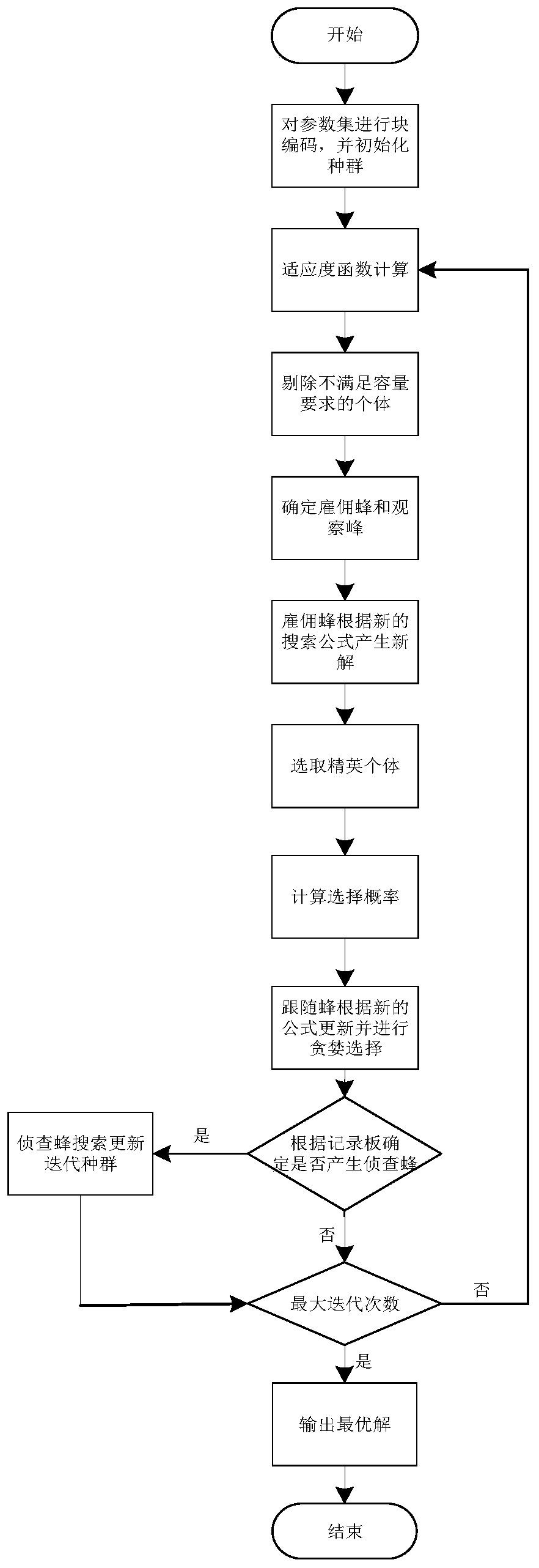

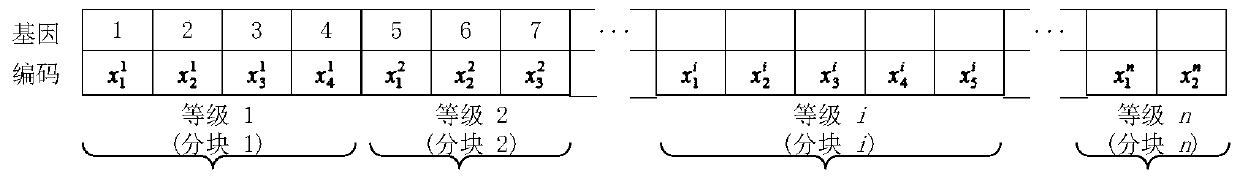

Optimization method of artificial bee colony algorithm based on multiple improvement strategies

InactiveCN111291854ARobustFast convergenceArtificial lifeManufacturing computing systemsEvolution strategyDifferential evolution

The invention relates to an optimization method of an artificial bee colony algorithm based on multiple improved strategies. According to the invention, a differential evolution strategy (DES), a trigonometric factor oscillation strategy (TFOS), a heterogeneous learning strategy (DDVLS) and a Gaussian distribution strategy (GDS) are improved, the global search capability of the algorithm is enhanced, the understanding precision is improved, and finally, a global optimal solution is obtained, so that the defects of the ABC algorithm are effectively overcome, the accuracy is improved, the convergence speed is increased, and the effect of optimizing the classical ABC algorithm is achieved.

Owner:ZHEJIANG UNIV OF TECH

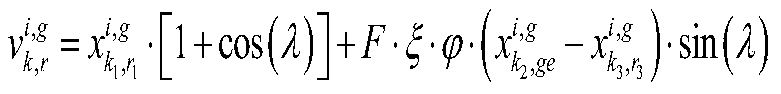

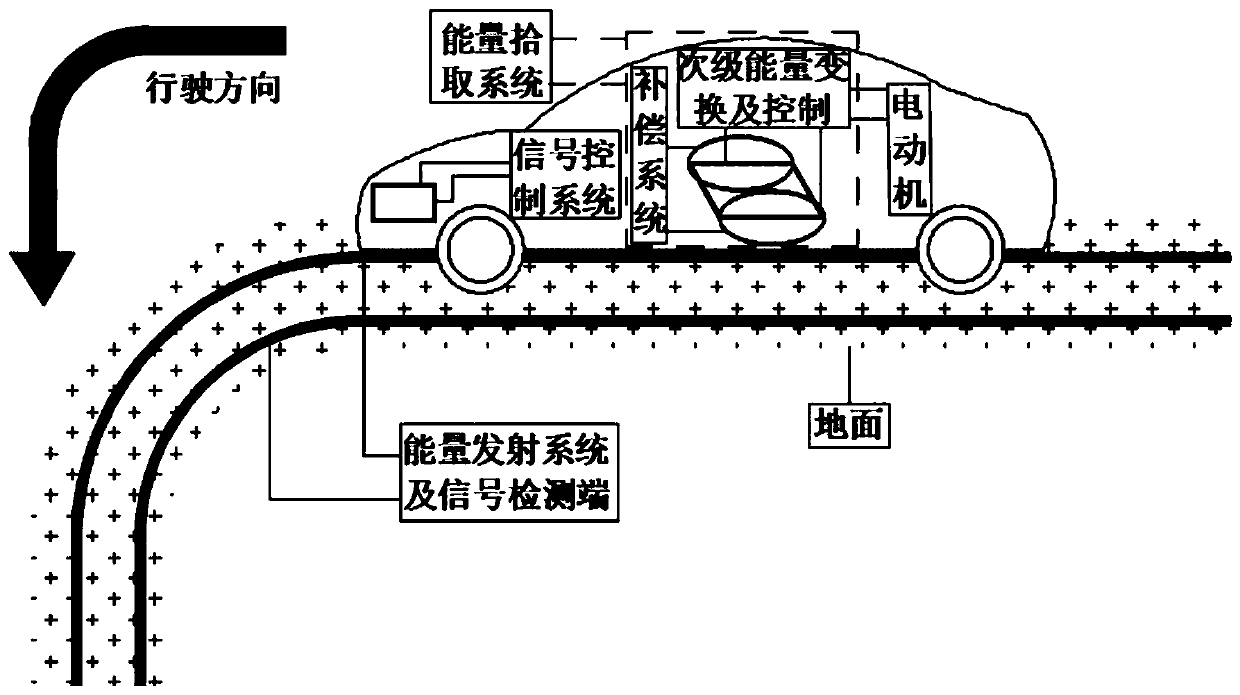

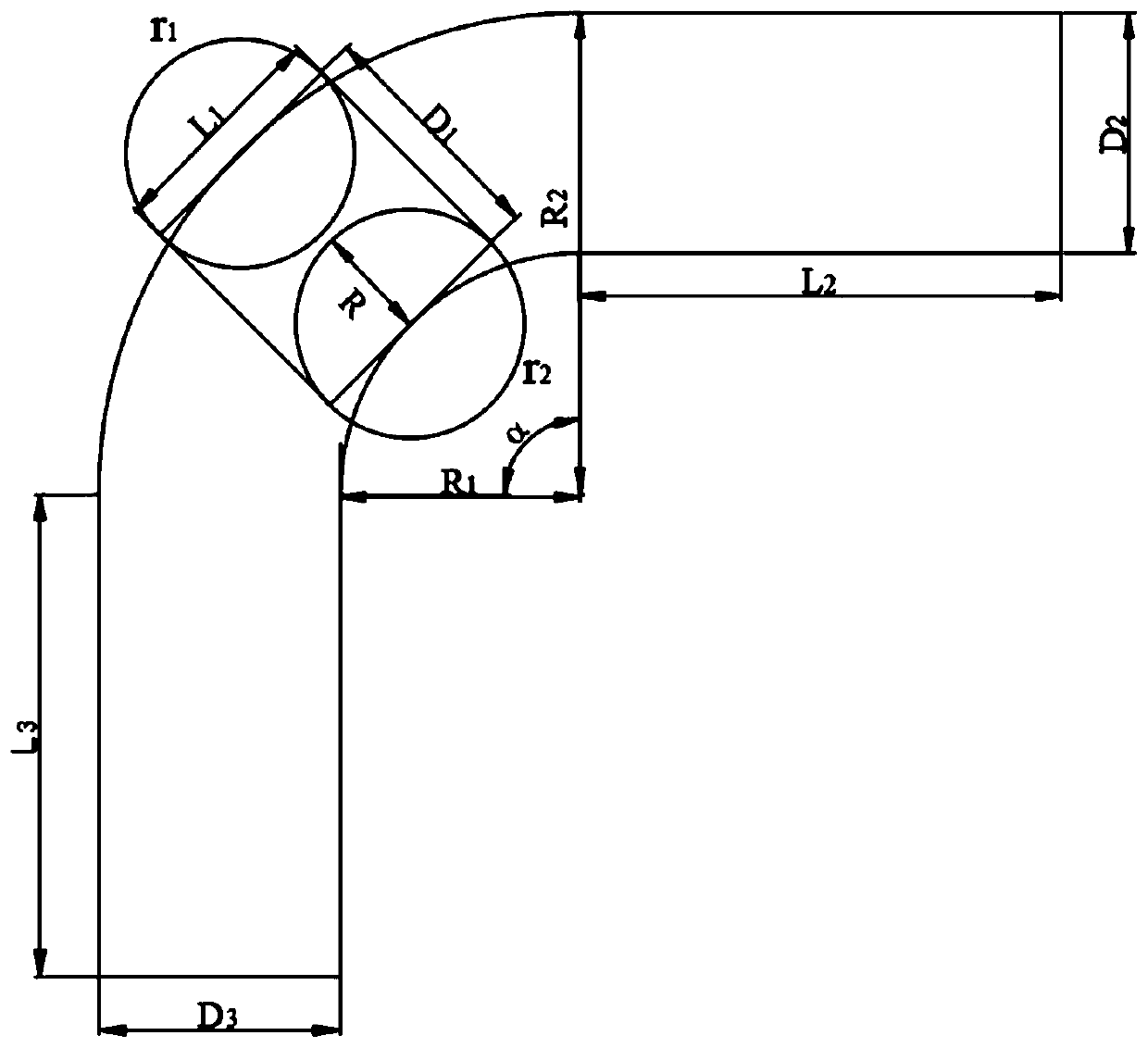

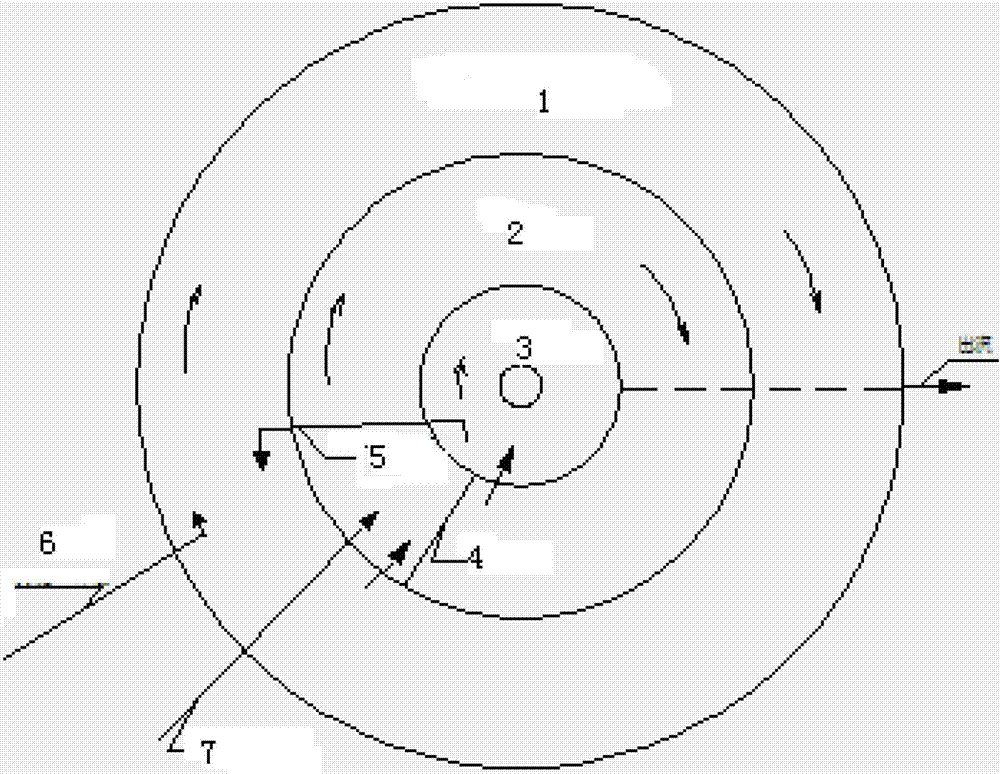

Electric automobile wireless charging system suitable for multi-angle curve

ActiveCN111016693AAchieve optimal resultsCharging stationsCircuit arrangementsTransmitter coilRoad surface

The invention relates to an electric automobile wireless charging system suitable for a multi-angle curve, which is used for maintaining the stability of mutual inductance and voltage stability and increasing the mutual inductance and pickup voltage when an electric automobile makes a turn. The system comprises a transmitting coil turning along with the road surface, a rectangular pickup coil mounted on a chassis of the electric automobile, and a compensation coil arranged right above the rectangular pickup coil in parallel, wherein the electric automobile runs right above the transmitting coil, and the rectangular pickup coil and the compensation coil are connected in parallel to drive the electric automobile. Compared with the prior art, the wireless charging system has the advantages ofreducing fluctuation, improving pickup voltage and the like.

Owner:SHANGHAI DIANJI UNIV

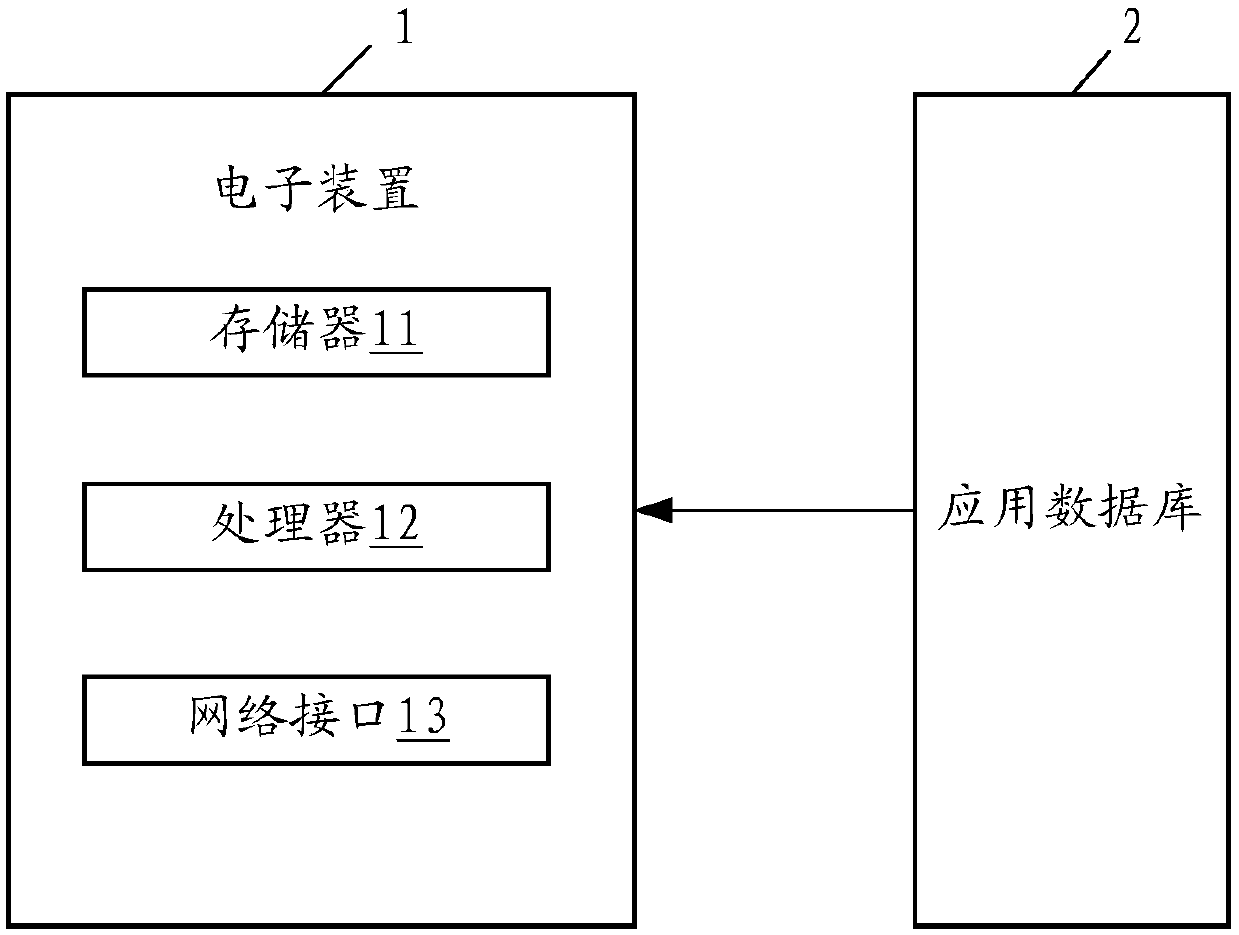

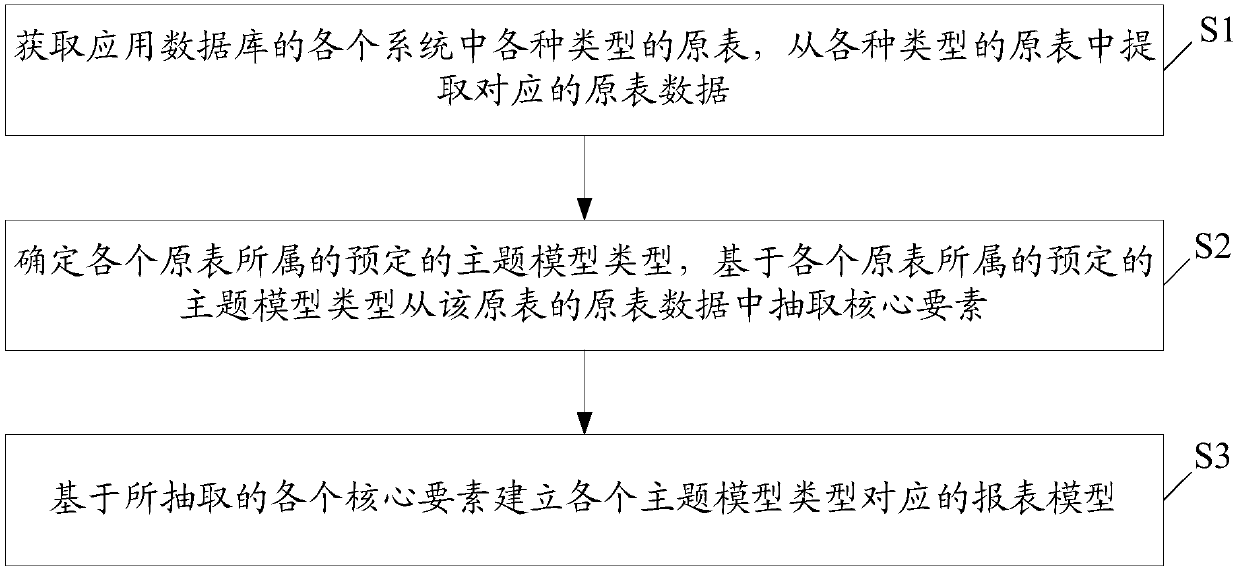

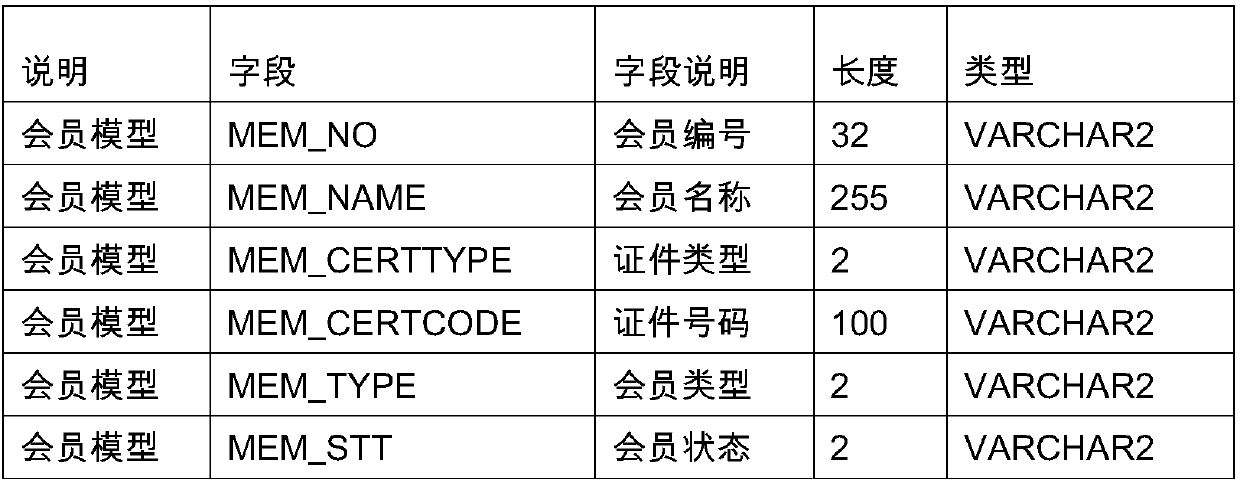

Electronic device, report database optimization method and storage medium

InactiveCN107871010AReliable structureReduced development effortSpecial data processing applicationsTopic modelDatabase optimization

The invention relates to an electronic device, a report database optimization method and a storage medium. The method comprises the following steps of: obtaining various types of original reports in each system of an application database and extracting corresponding original report data from the various types of original reports; determining a predetermined topic model type, to which each originalreport belongs, and extracting core elements from original report data of each original report on the basis of the predetermined topic model type, to which the original report belongs; and establishing a report model corresponding to each topic model type on the basis of the extracted core elements. According to the report database optimization method, relatively stable and reliable structures ofreport databases can be kept so as to achieve the effect of optimization.

Owner:重庆金融资产交易所有限责任公司

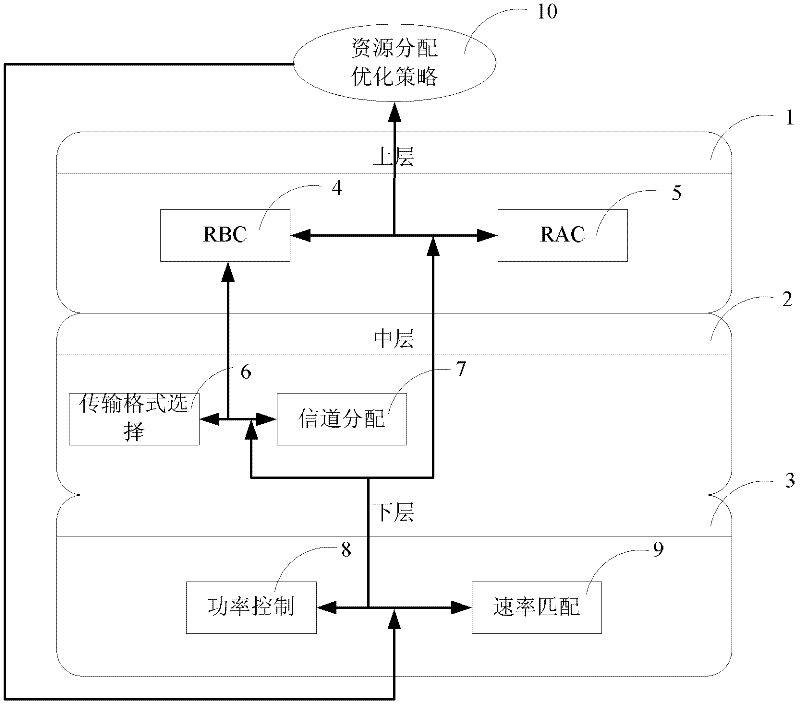

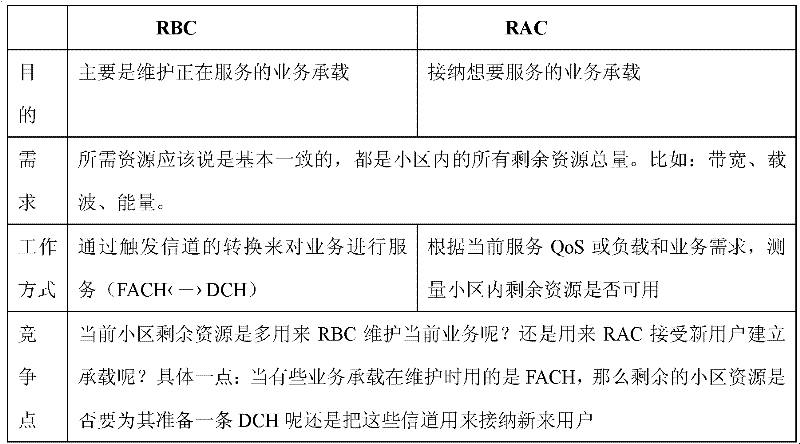

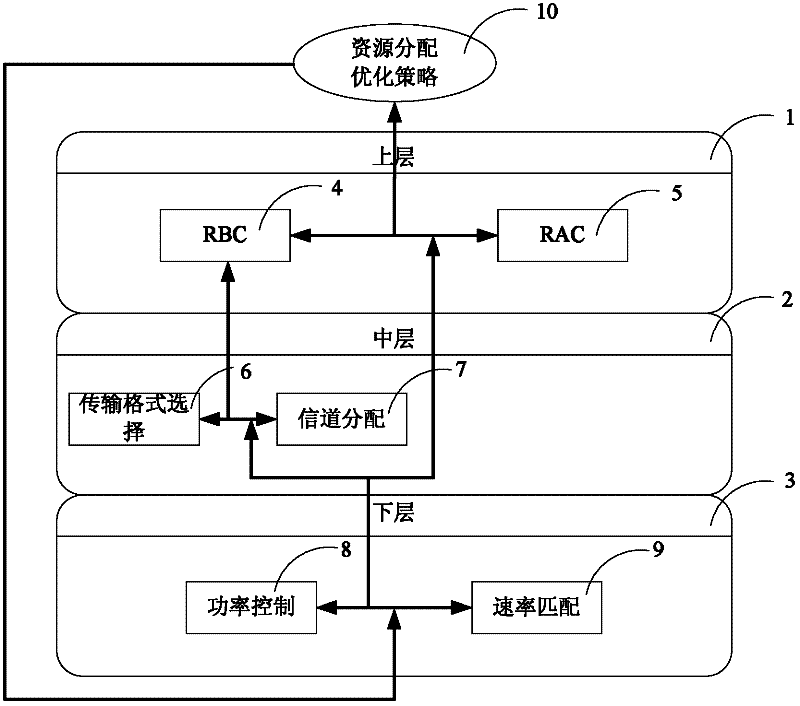

Cross-layer optimization method for radio network resource management based on joint game

InactiveCN102238590ARealize managementAchieve optimal resultsNetwork traffic/resource managementCross-layer optimizationRadio networks

The invention discloses a cross-layer optimization method for radio network resource management based on joint game. The method is applied in the radio network, aims at multiple radio network resources and multiple protocol stack layers, takes the correlation between the radio network resources and the protocol stack layers into consideration, and is used for integrally and reasonably optimizing the resources in radio network cells and achieving the needed optimization objective. In the involved radio network protocol stack layers, a corresponding game model is built in each layer according to the function characteristics of each layer in the involved protocol stack, the game strategy space and results in other protocol stack layers are taken into consideration when the game model in each protocol stack layer is built, the game objective of the upper protocol stack layer is set as the overall objective of the system according to the needs, and game in other protocol stack layers serves the game in the upper protocol stack layer to mainly enlarge the strategy space for the objective protocol stack layer or optimize the game objectives, thereby finally achieving the required overall optimization objective.

Owner:曲桦 +1

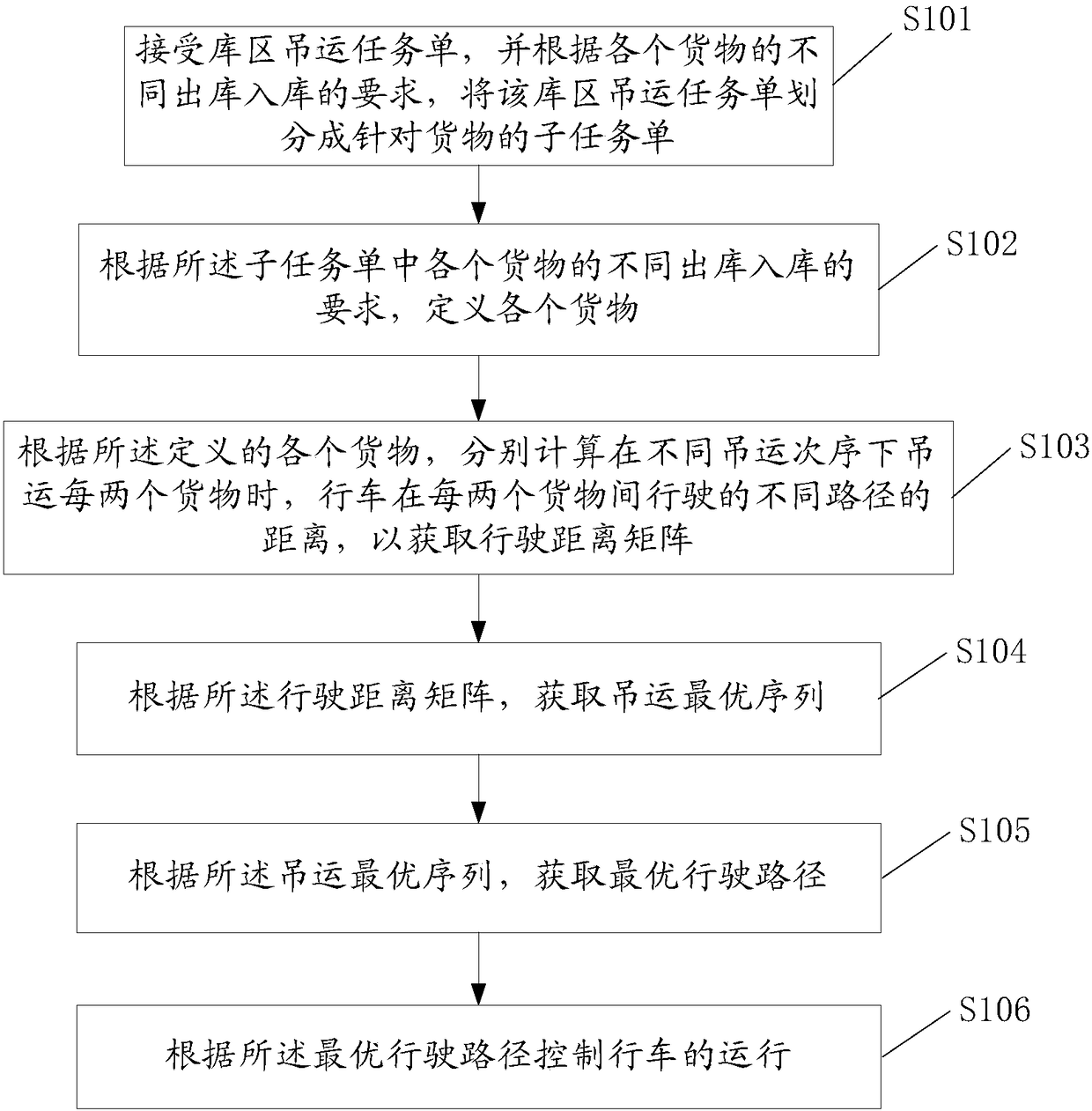

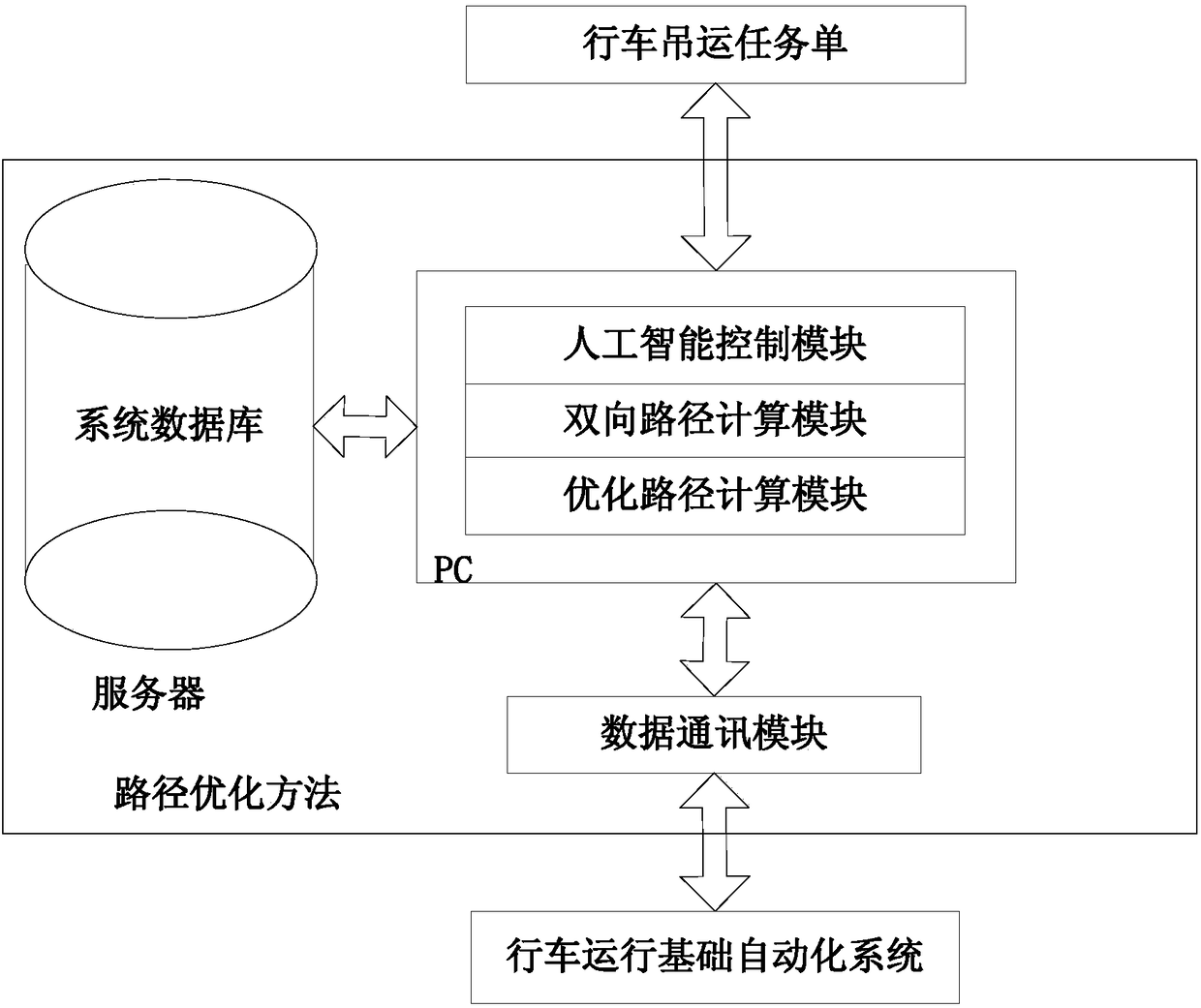

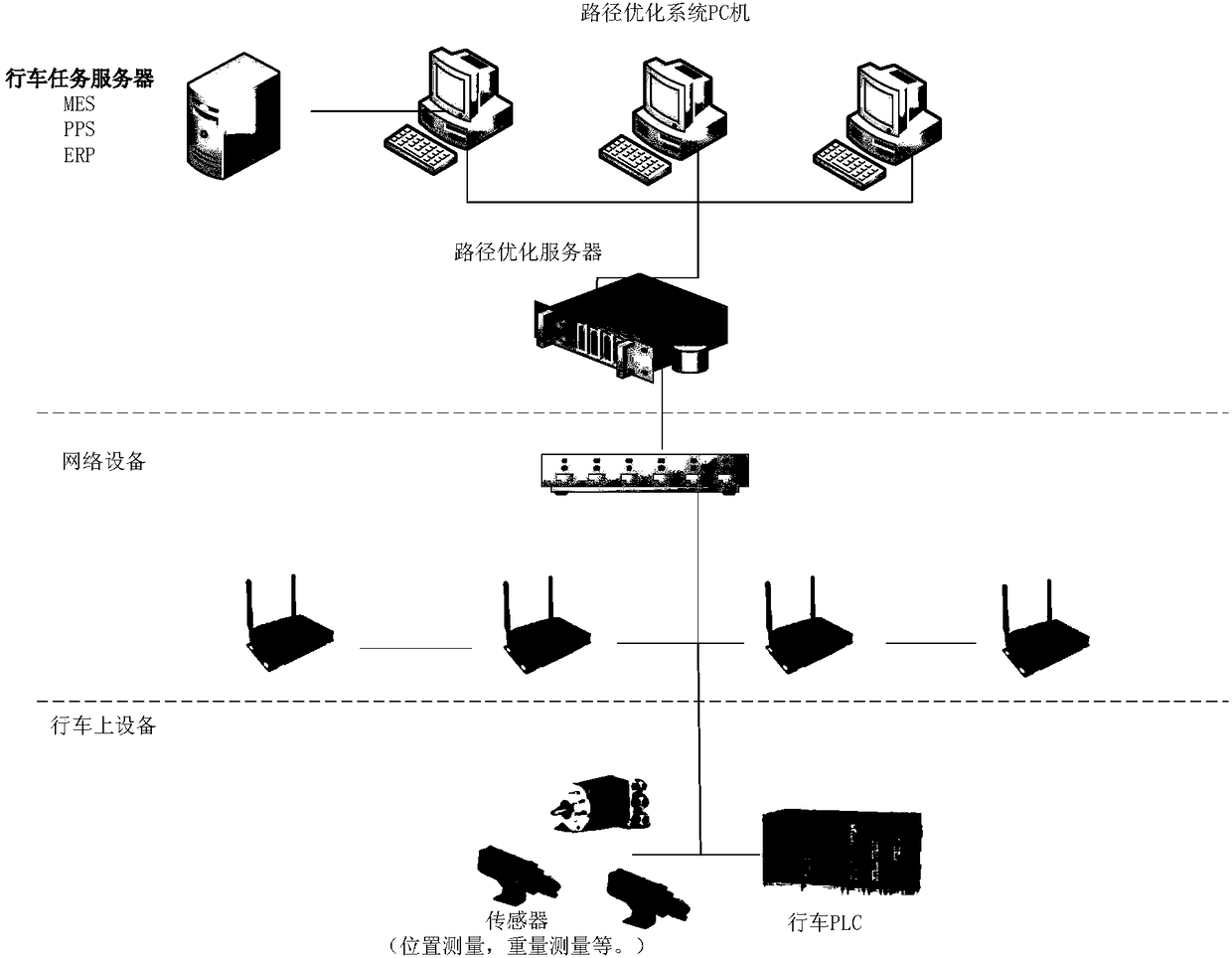

Method and system for optimizing unmanned travelling crane lifting path of warehouse area in two-way path asymmetrical state

An embodiment of the invention discloses a method for optimizing an unmanned travelling crane lifting path of a warehouse area in a two-way path asymmetrical state. The method comprises the steps of A, receiving a lifting task order of the warehouse area, and dividing the lifting task order of the warehouse area into sub-task orders for cargos according to different output and input requirements of the cargos; B, according to the different output and input requirements of the cargos in the sub-task orders, defining positions and output and input gate numbers of the cargos; C, according to position coordinates and the output and input gate numbers of the cargos, calculating a driving distance, between every two cargos, of a traveling crane under different lifting sequences to obtain a driving distance matrix; D, according to the driving distance matrix, calculating an optimal lifting sequence; E, according to the optimal lifting sequence, calculating an optimal driving path; and F, according to the optimal driving path, controlling the running of the traveling crane. Therefore, the driving distance of the traveling crane can be shortened and the utilization rate of the traveling crane can be increased.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

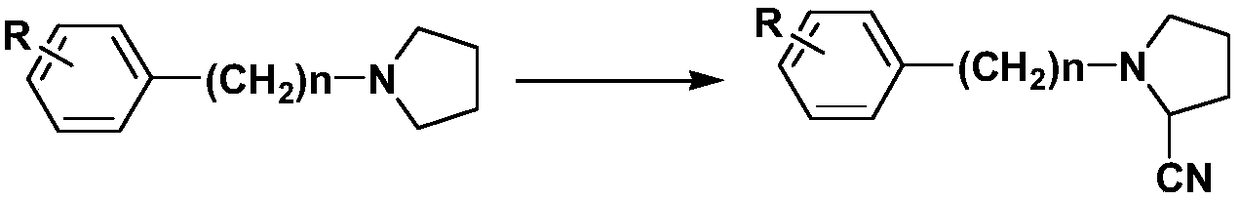

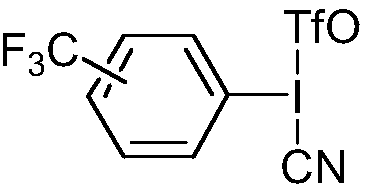

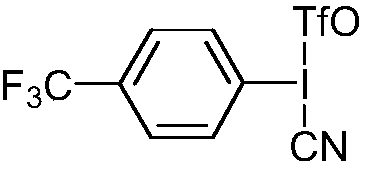

Preparation method of alpha-amino-nitrile compound taking pyrrolidine tertiary amine as primer

InactiveCN109134338AIncrease productionLow pricePhysical/chemical process catalystsOrganic chemistrySolventPotassium ferrocyanide

The invention provides a preparation method of an alpha-amino-nitrile compound taking pyrrolidine tertiary amine as a primer. The preparation method comprises the following step of green synthesis ofalpha-amino-nitrile through a one-pot process by taking potassium ferrocyanide as a cyaniding reagent and an iodine phenyl compound as a reaction accelerant under the condition of a compound solvent containing trifluoroethanol and a catalyst. The invention provides the safer cyaniding reagent and an efficient synthetic method of alpha-amino-nitrile with mild reaction conditions. The preparation method is simple in post treatment, mild in reaction condition and short in reaction time, and develops a simple and efficient synthetic route for cyaniding synthesis of pyrrolidine tertiary amine.

Owner:求秋平

Classroom environment control system

InactiveCN106500237AEasy to moveGood for physical and mental healthSpace heating and ventilation safety systemsLighting and heating apparatusAlarm stateEngineering

A classroom environment control system relates to the technical field of environment monitoring. A temperature sensor, a carbon dioxide concentration sensor, an illumination intensity sensor, a liquid crystal screen, a fluorescent lamp, a buzzer, a relay, an infrared diode, and a light emitting diode are connected to a logic control circuit; a power source supplys electricity to the logic control circuit; the logic control circuit reads a temperature value of the temperature sensor, compares the temperature value with a preset value, controls starting or stopping of an indoor air conditioner through the infrared diode, or controls starting or stopping of an indoor fan through the relay; when the logic control circuit detects the fact that the carbon dioxide concentration is higher than a preset value, the buzzer is started, the liquid crystal screen displays an alarm state so as to prompt windowing and air-exchange; and the illumination intensity sensor detects the current illumination intensity, and controls the brightness of the fluorescent lamp in real time. The classroom environment control system can intelligently control a classroom environment, can achieve an optimized effect of the classroom environment, is beneficial to physical and mental health of students, can improve the leaning efficiency of the students, and can save energy and protect an environment.

Owner:王梦舟

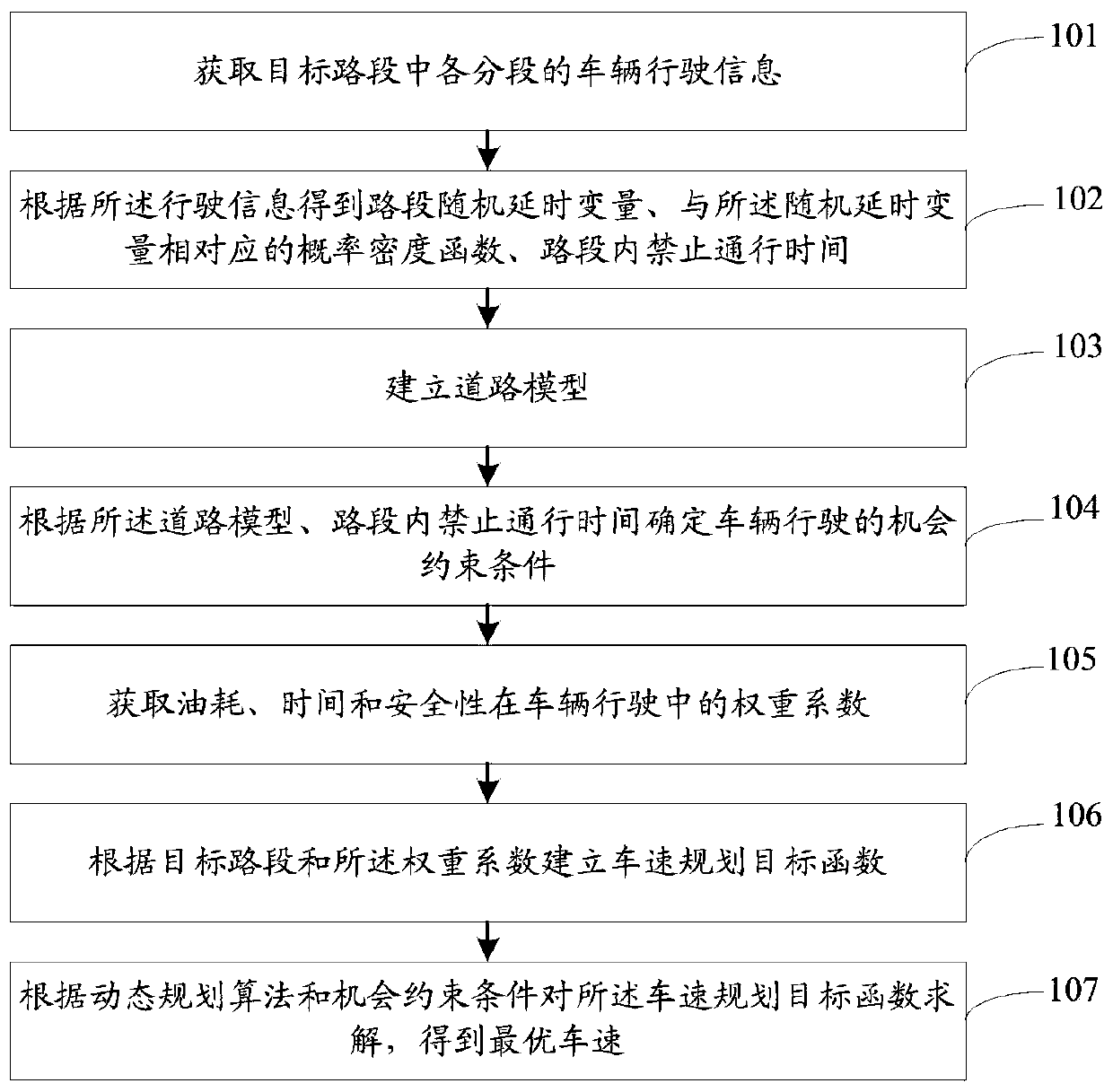

A data-driven intelligent and robust vehicle speed real-time planning method and system

ActiveCN109064760BImprove traffic flow efficiencyAchieve optimal resultsControlling traffic signalsRegistering/indicating working of vehiclesDynamic planningVehicle driving

The invention discloses a data-driven intelligent and robust vehicle speed real-time planning method and system. The data-driven intelligent and robust vehicle speed real-time planning method comprises the steps that vehicle driving information of all segments in an objective road segment is obtained; road segment random delay variables, probability density function corresponding to the random delay variables and no passing time in the road segment are obtained according to the driving information; a road model is established; a constraint condition of opportunity of the vehicle driving is determined according to the road model and the no passing time in the road segment; weight coefficients of fuel consumption, time and safety in the vehicle driving are obtained; a vehicle speed planningobjective function is established according to the objective road segment and the weight coefficients; and the vehicle speed planning objective function is solved according to a dynamic planning algorithm and the constraint condition of opportunity, and the optimal vehicle speed is obtained. According to the data-driven intelligent and robust vehicle speed real-time planning method and system, thecorresponding objective function can be established according to the requirement, and the corresponding vehicle speed optimized effect is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

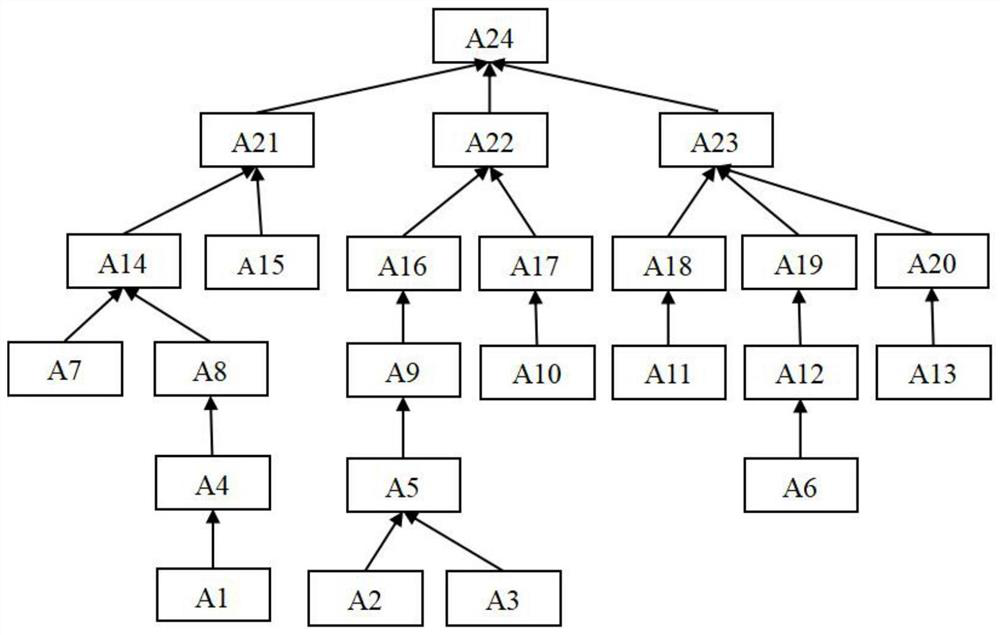

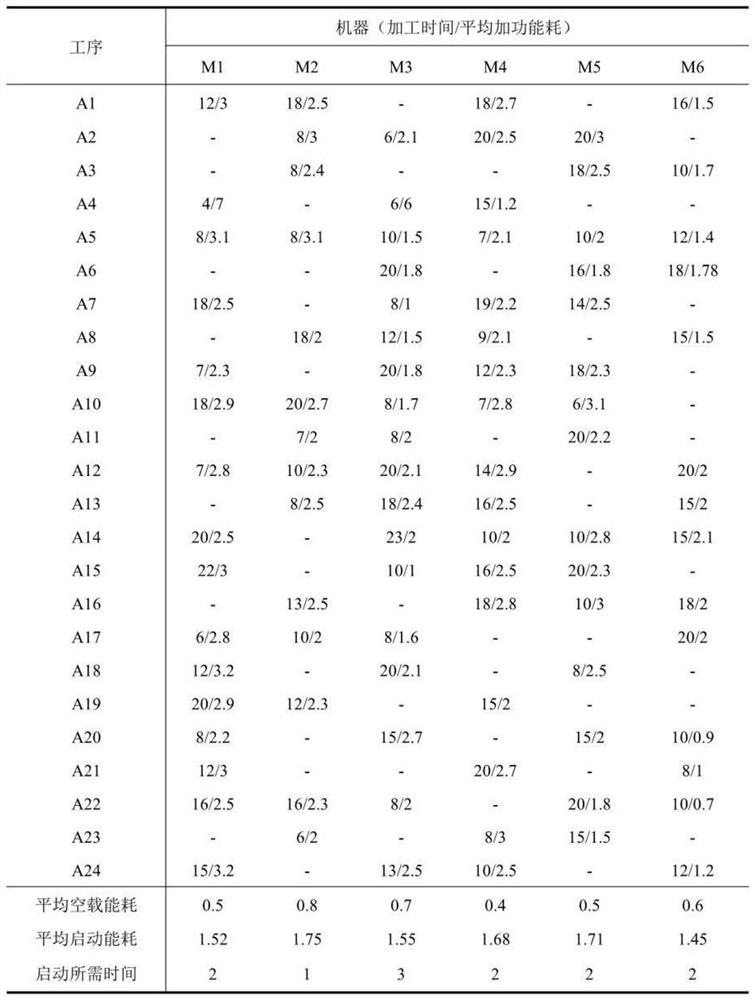

Comprehensive scheduling method considering on-time completion and energy consumption

PendingCN114819515ATime equalizationBalanced energy consumptionResourcesProcess equipmentProcess engineering

The invention discloses a comprehensive scheduling algorithm considering on-time completion and energy consumption. The method comprises the following steps: determining a scheduling sequence of processes by adopting an energy consumption priority strategy; for a non-subtree key energy consumption process, determining processing equipment by adopting an equipment time consumption distribution strategy; for the key energy consumption process of the sub-tree, determining initial processing equipment by adopting a process time consumption balancing strategy; when the sub-tree key energy consumption process does not meet the time constraint after being scheduled on the initial processing equipment, re-determining the process processing equipment by adopting a process equipment adjustment strategy; and carrying out final equipment adjustment on the working procedures which do not meet the requirement of finishing on time by adopting a delivery time backtracking adjustment strategy.

Owner:HARBIN UNIV OF SCI & TECH

Emergency situation handling dynamic route monthly planning method for security system

InactiveCN108303104AAccurate and reliable alarm timePolice route scienceInstruments for road network navigationTime informationShortest distance

The invention discloses an emergency situation handling dynamic route monthly planning method for a security system. The method comprises the following steps: obtaining geographical location information and time information, determining all possible paths, determining the concrete roads of every path, determining the traffic time tij of every road, determining the traffic time T1, T2, ..., Tn of every path, and calculating the sum of all the traffic times of the roads of every path i according to the following formula: Ti = ti1 + ti2 + ... + tim; and taking the minimum value Ta from the T1, T2, ..., Tn, and determining the route a as the target route, that is a vehicle selects the path a as the final driving path, and selects a corresponding speed as a driving speed. Newest calculated traffic time data of the front road is especially timely used, so the time selection of the roads is dynamic; and a security service station having a shortest distance to emergency situation point and a corresponding route are found, so the uncertainty of the time of the security vehicle running to a fire scene is greatly reduced.

Owner:东莞产权投资有限公司

Figure optimization method of surface acoustic wave filter chip after lift-off process

The present invention discloses a figure optimization method of a surface acoustic wave filter chip after a lift-off process. The method comprises the concrete steps: corrosive liquid is uniformly distributed at the surface of a wafer and is configured to corrode the wafer figure, wherein the temperature of the corrosive liquid is maintained in the range of 22 DEG C to 24 DEG C and the rotation speed of a clamp is 1500 rpm+_ 50 rpm; the corrosive liquid or deionized water are configured to scour the surface of the chip through adoption of a centrifugal force generated by rotation of the clamp; the corrosion time is in the range of 60s to 90s, the corrosive liquid is configured to clean the chip, and when the corrosion time is up, the corrosive liquid is closed and the deionized water is opened to clean the chip; and the cleaning and the drying are performed after the corrosion is end, and the figure optimization of the surface acoustic wave filter chip after the lift-off process is completed. According to the invention, the center frequency of a surface acoustic wave filter chip is enhanced, and the reverse offset, of uniform line width caused in the process of photoetching development, is performed; and moreover, the reliability of surface acoustic wave filter products is improved.

Owner:北京航天微电科技有限公司

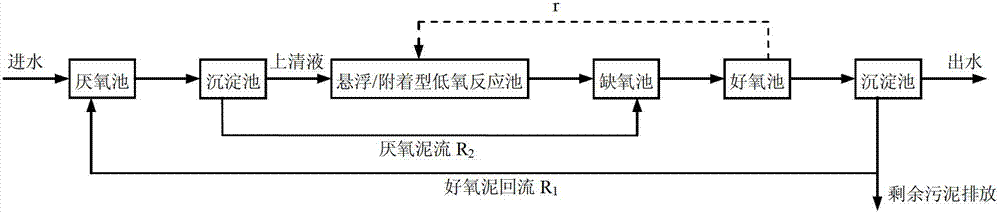

ALOAO double-sludge circulation synchronic denitrification and phosphorus removing process, operation method thereof, and employed biological reaction tank

ActiveCN102730832BReduce demandImprove nitrogen and phosphorus removal efficiencyTreatment with aerobic and anaerobic processesSludgeSewage

The invention relates to an ALOAO double-sludge circulation synchronic denitrification and phosphorus removing process. According to the invention, first, pre-treated sludge is delivered into an anaerobic tank; sludge-water separation is carried out in a first sedimentation tank; an obtained supernatant is delivered into a hypoxic reaction tank; sludge obtained by sedimentation in the first sedimentation tank is directly delivered into an anoxic tank, and is mixed with the liquid discharged from the hypoxic reaction tank; the mixture is delivered into a short-time aerobic tank, and is than delivered into a second sedimentation tank; an obtained supernatant is discharged, and a part of the sludge obtained by sedimentation is delivered back to the anaerobic tank; and the rest of the sludge is discharged as residual waste sludge. According to the invention, mixed liquid reflux is designed on the path from the short-time aerobic tank to the hypoxic reaction tank, and the reflux ratio is set according to requirements. The process and the operation control method provided by the invention have relatively broad adaptability to sewage qualities. The method can be used for removing nitrogen and phosphorus with low carbon source and low consumption on oxygen. Therefore, the method is suitable for the reformation and construction of municipal wastewater treatment plants with requirements on nitrogen and phosphorus removing.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

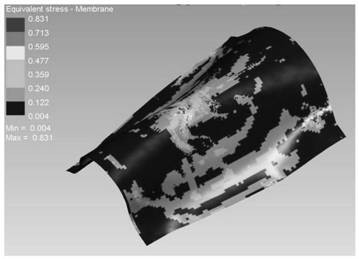

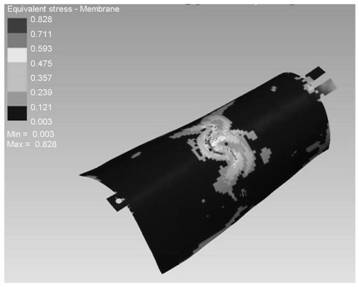

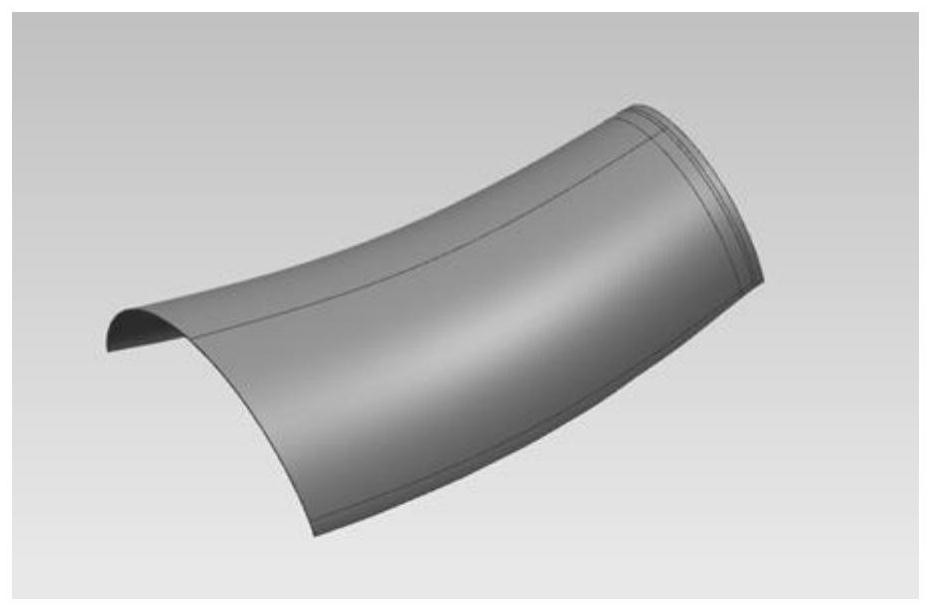

Hot forming method for variable-curvature skin sheet metal part

PendingCN112792200AAchieve optimal resultsSolve the local wrinkle problemShaping toolsThermoformingElement analysis

The invention discloses a hot forming method for a variable-curvature skin sheet metal part, and belongs to the technical field of sheet metal and thermoforming. The problems that wrinkles, cracks and the like are prone to occurring in hot forming of existing variable-curvature skin sheet metal parts, and the forming period is long are solved. According to the method, the unfolding size of the part is calculated through a finite element analysis method, and the problem of local wrinkles after part forming is effectively solved by optimizing the mold structure and changing the part hot-pressing mode. The changed contour of an unfolded material effectively gets rid of the complex stress influence of excessive process allowance on the position where the hot formed wrinkles are prone to occurring, and profile-followed attachment of a plate in the thermoforming process is facilitated; plate positioning holes are designed in the two ends of the unfolded material and serve as fixing holes of the hot formed plate, and the plate positioning holes also server as positioning holes for subsequent laser cutting of the part, so that the working efficiency of laser cutting of the part is greatly improved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com