Hot forming method for variable-curvature skin sheet metal part

A technology for hot press forming and sheet metal parts, applied in the field of sheet metal and hot forming, can solve the problems that materials cannot be discharged in a limited space, it is difficult to meet the shape requirements of skin parts, and the wall thickness of air pressure control parts is uneven. To achieve the effect of saving the time cost of hot pressing, saving the cost of hot pressing, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

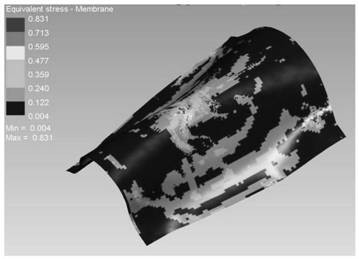

[0030] Skin Ⅰ is a sheet metal part with variable curvature, the structure is as follows figure 1 As shown, the middle part is concave and the two ends are upturned. The total length of the part exceeds 700mm, and the maximum depth along the direction of hot pressing is nearly 200mm.

[0031] 1. Determine the profile of the expanded material;

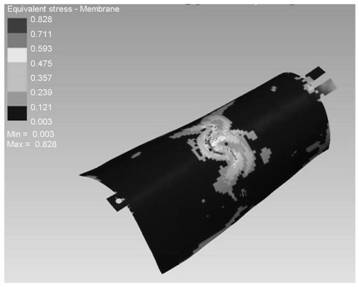

[0032] Calculate the expanded material size of the part according to the external dimensions of the final formed part, determine the expanded material outline of the part, reserve positioning surfaces at both ends of the expanded part, and design positioning holes on the positioning surface, such as figure 2 As shown, the modified profile of the unfolded material effectively gets rid of the complex force influence of excessive process allowance on the position where the wrinkles are easy to appear in thermoforming, which is conducive to the conformal bonding of the sheet during the thermoforming process, and between the two sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com