Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Middle state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

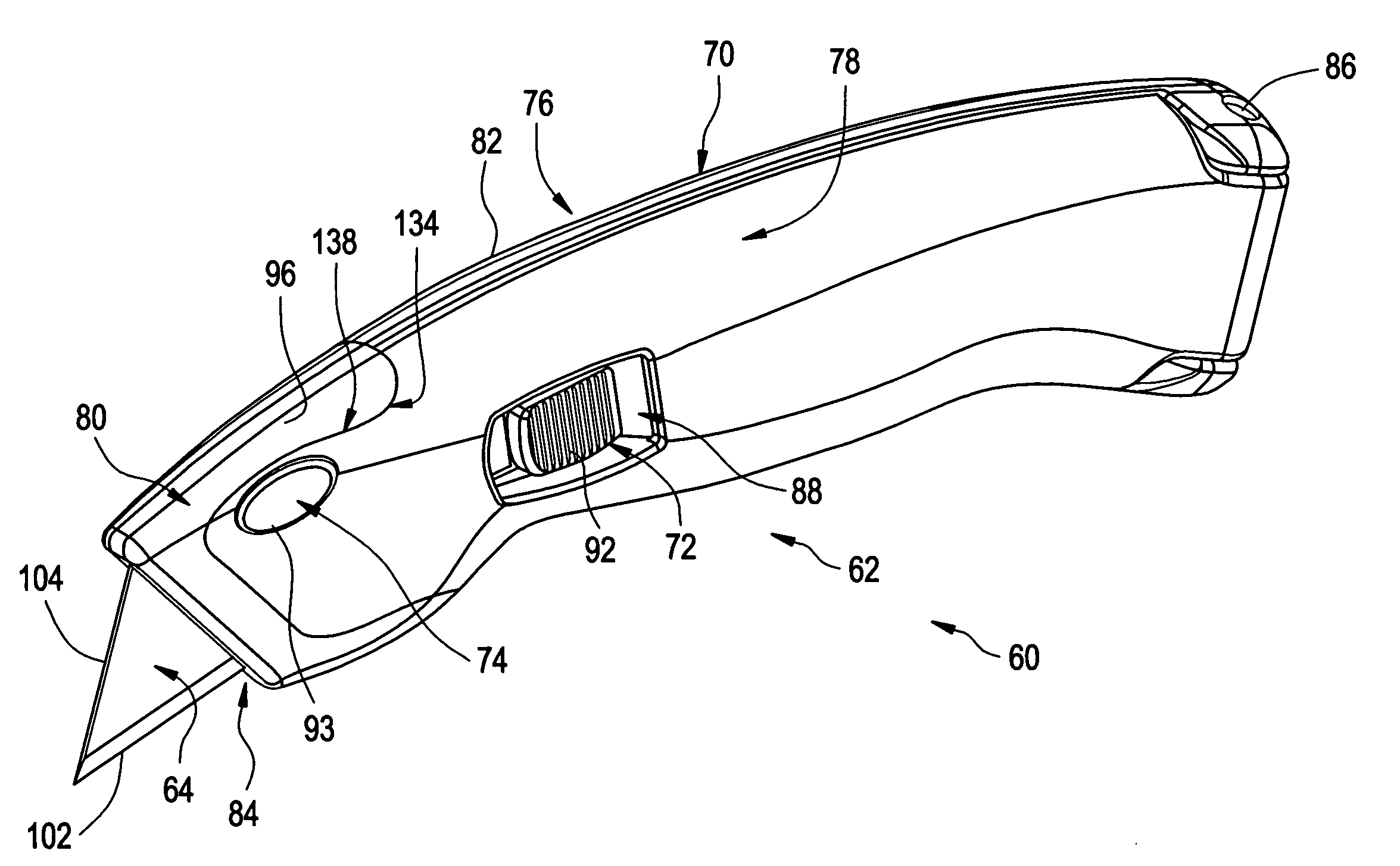

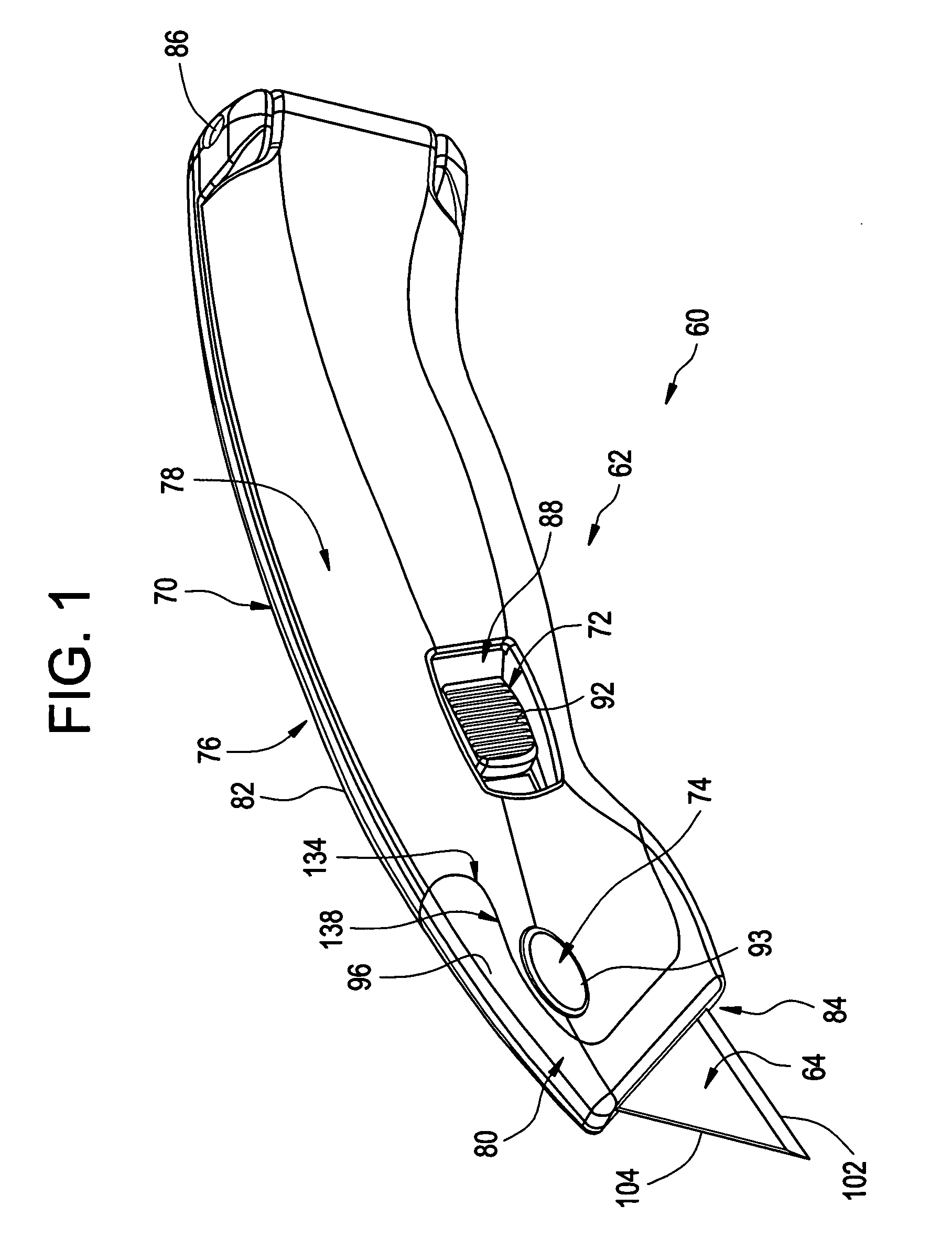

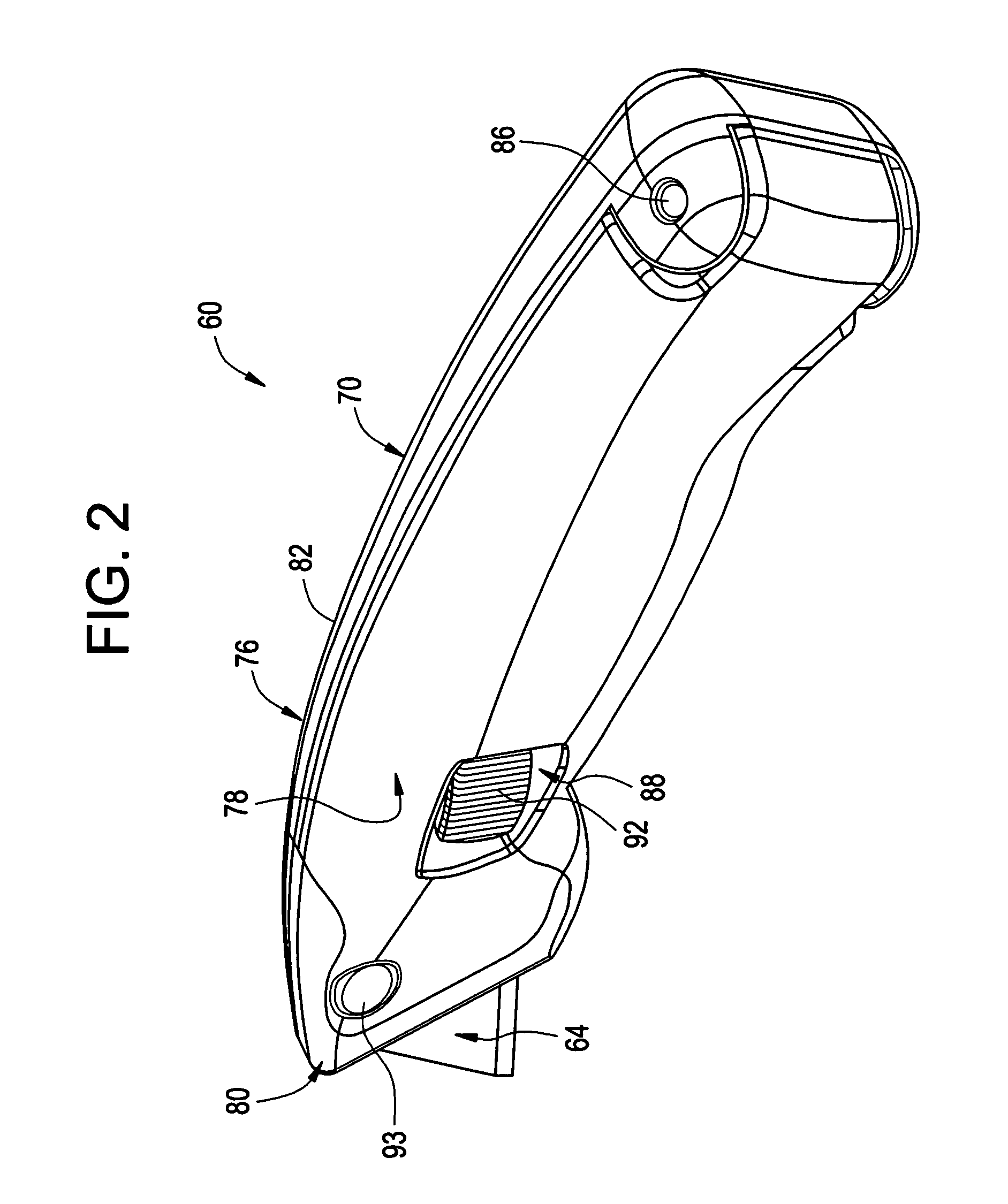

Utility knife

InactiveUS20050193566A1Increased durabilityLow costThrusting weaponsWeapon componentsWear resistantKnife blades

A handle for a utility knife includes a housing made up of two or more portions. In one embodiment, a manually operable member for use in releasing the blade is retained to at least one portion of the housing and does not become separated from the housing when the housing is in an open state. In another embodiment, a catch for engaging the blade extends from a support member that is slidably movable within the housing. In another embodiment, the housing is formed of metal and a nose portion is formed of a metal that is more wear resistant than the rest of the housing, in order to improve the durability of the nose portion. In another embodiment, a bail screw is captured on a first housing portion and threadedly engageable with a second housing portion for (i) releasably securing the first and second housing portions in a fully closed state and, in turn, releasably securing a blade within the blade opening, and (ii) manually positioning at least one of the first and second housing portions in at least one intermediate state between the fully closed state and a fully opened state to, in turn, permit the blade to be manually moved through the blade opening.

Owner:BLACK & DECKER INC

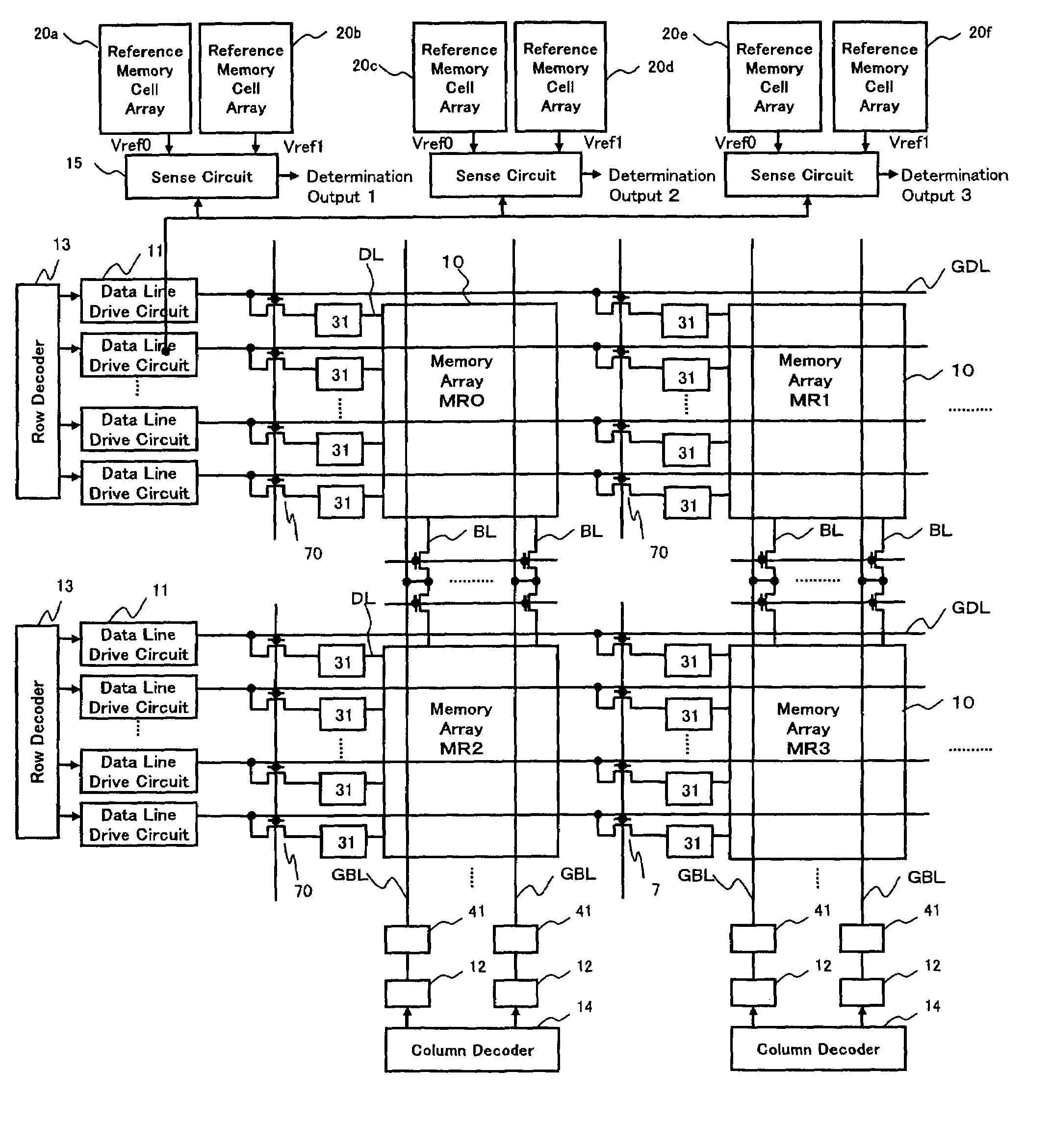

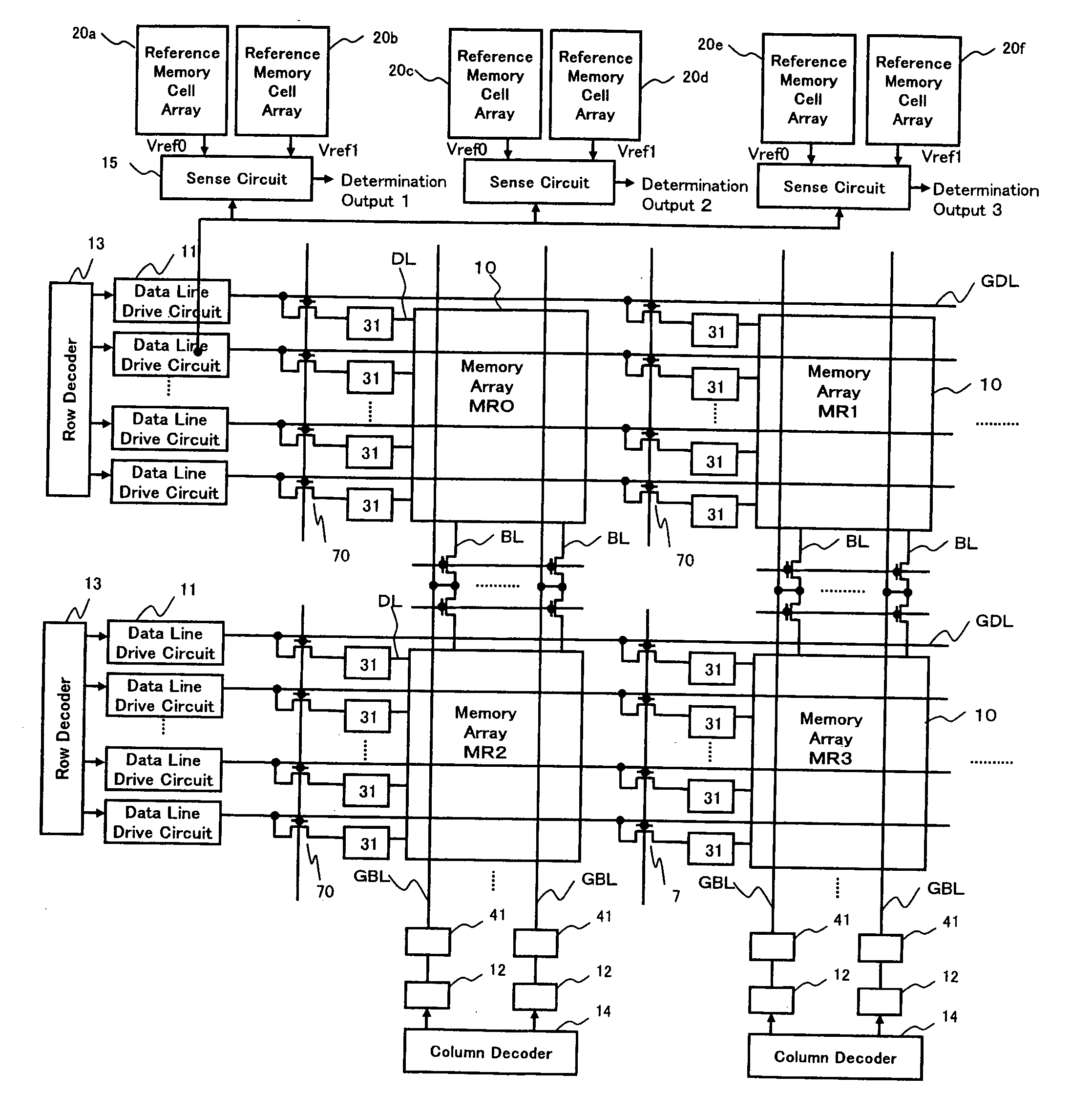

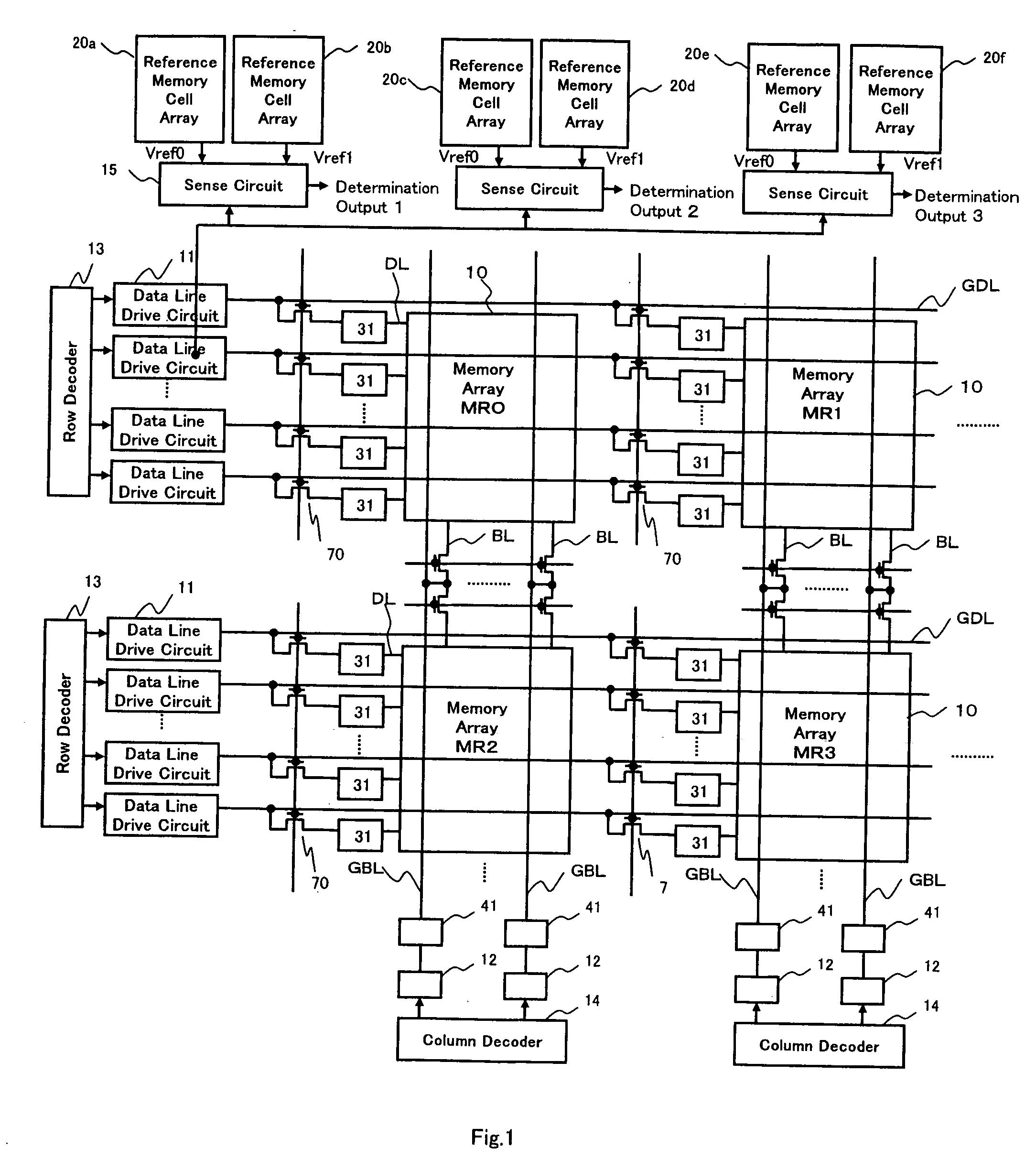

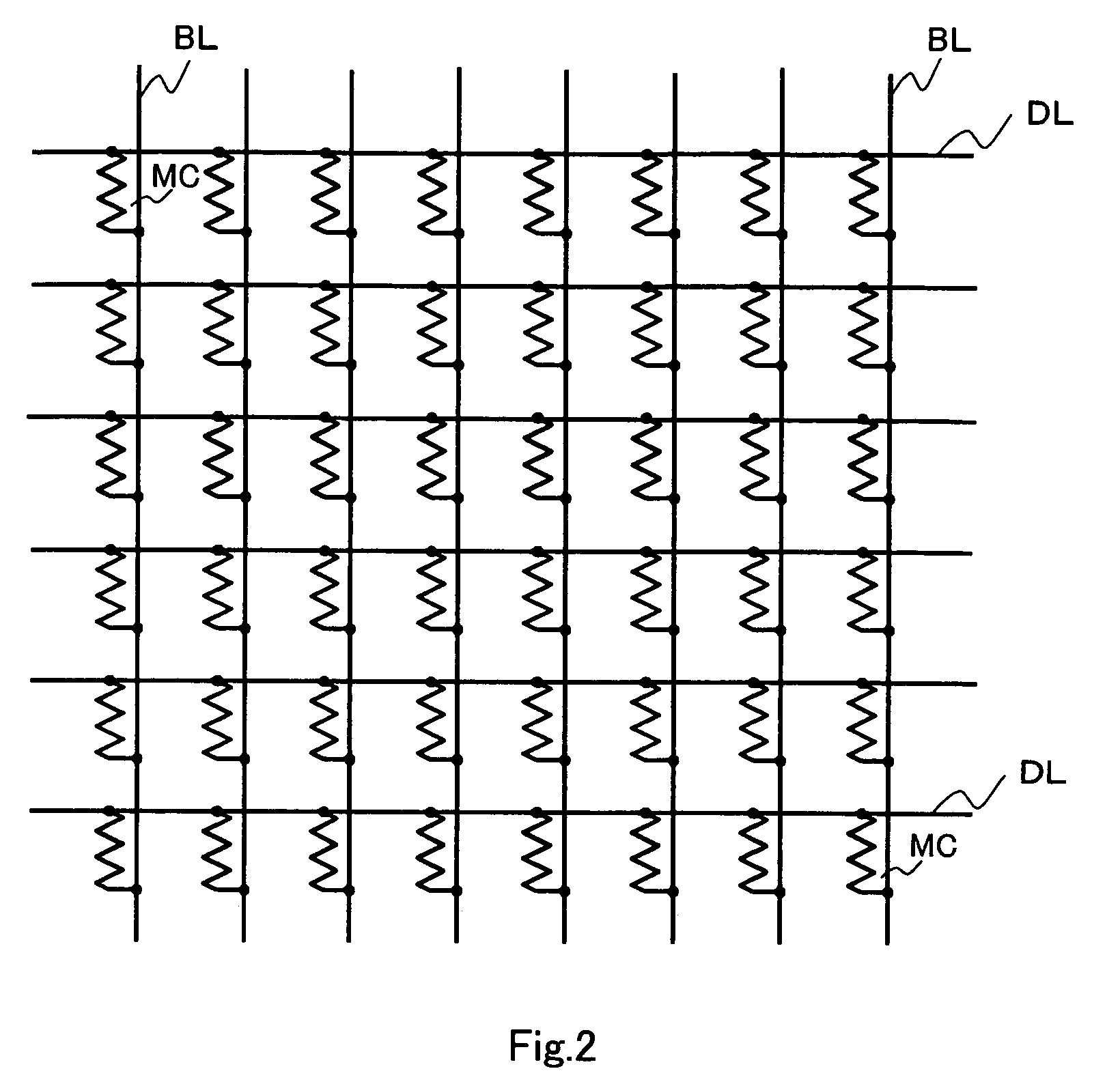

Semiconductor memory device

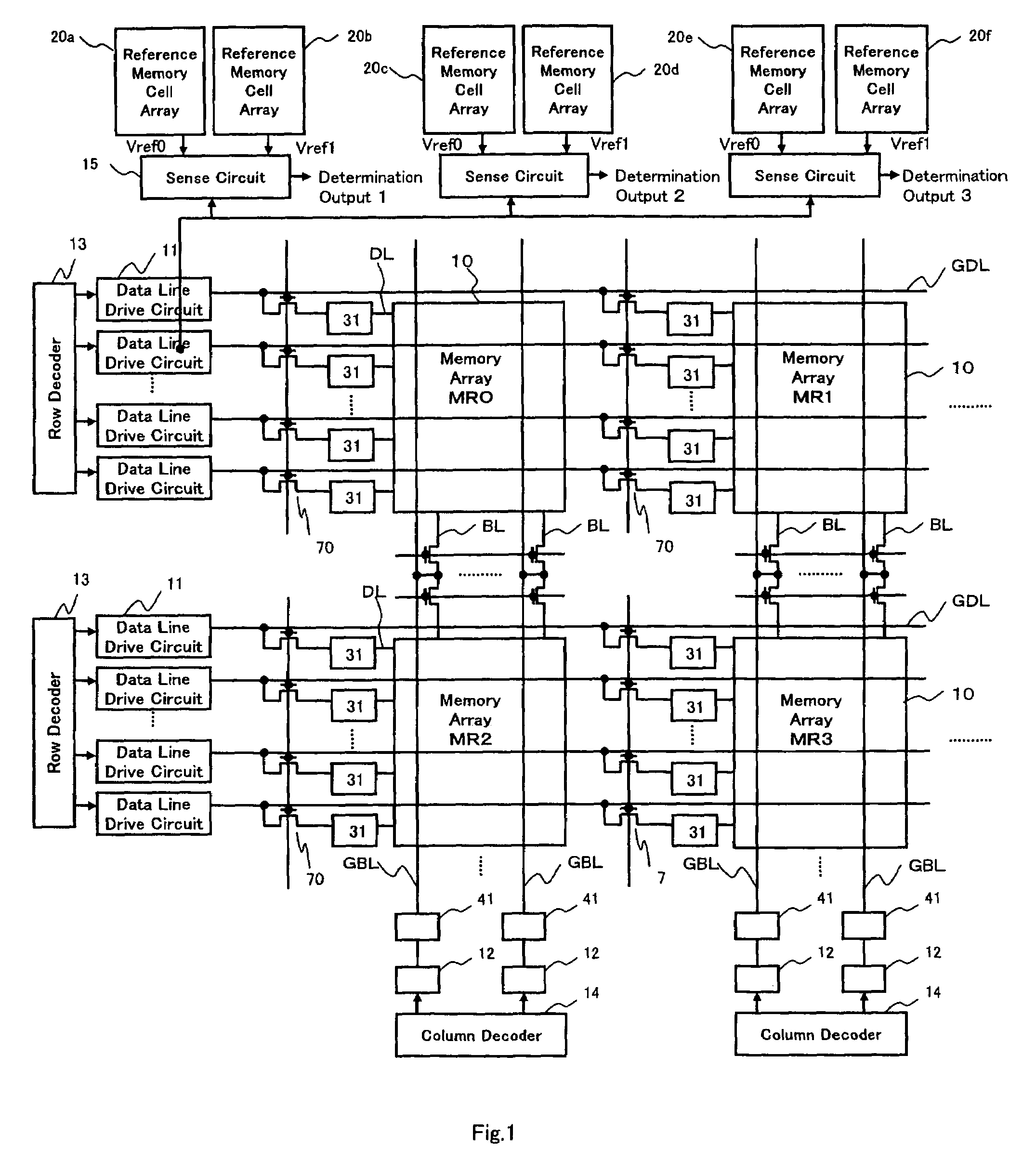

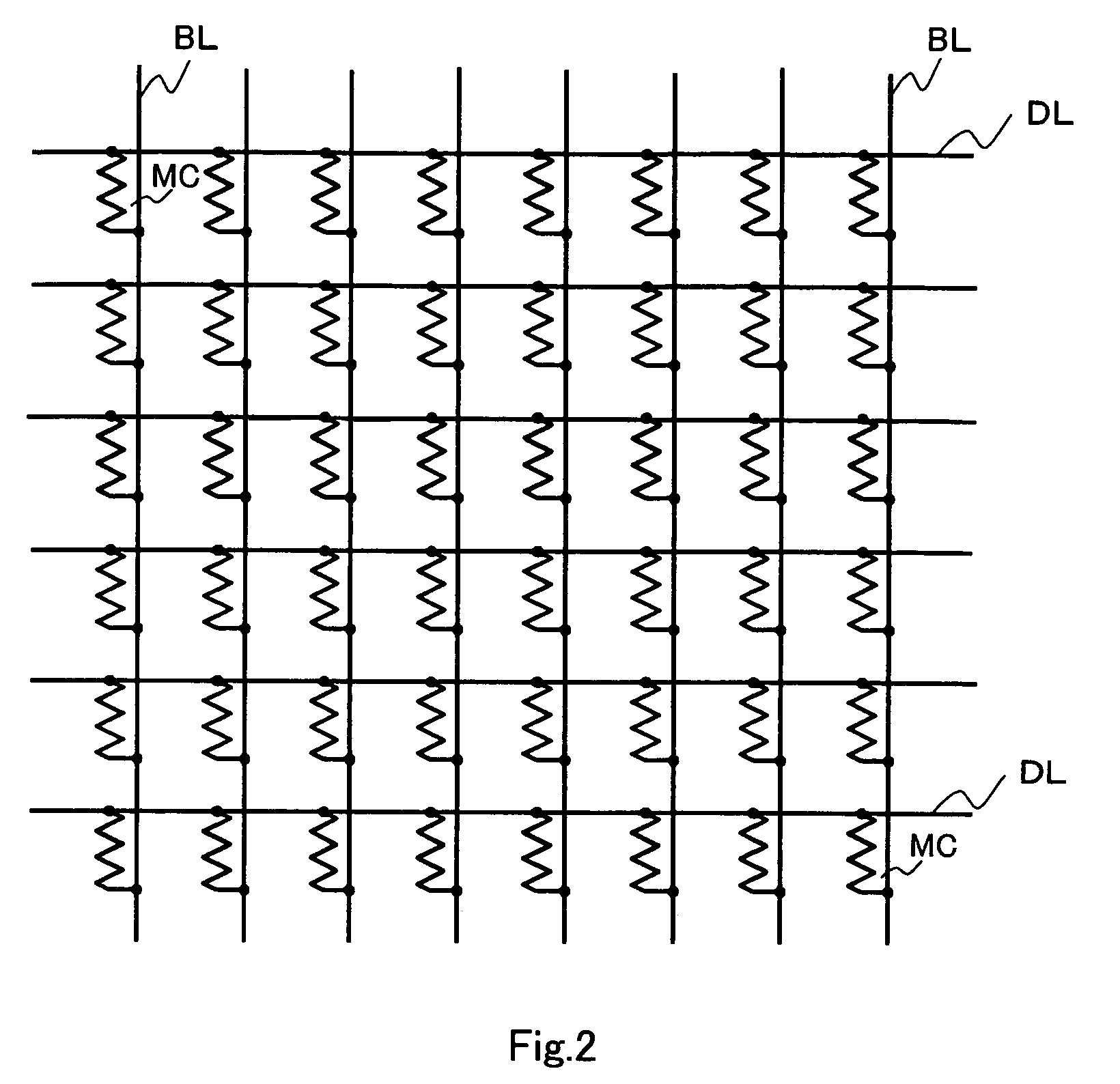

InactiveUS7027342B2Improve a readout marginReadout margin can be improvedRead-only memoriesDigital storageHigh resistanceReference current

In a semiconductor memory device having a crosspoint-type memory cell array, each reference level between two adjacent memory levels when memory levels of multi-level information stored in a memory cell are arranged in order of size of resistance values of a corresponding variable resistive element is defined by a reference current in a middle state between a first and a second current states. In the first current state, a readout current of high resistance selected cell in which the resistance is higher in the two adjacent memory levels becomes the largest state depending on a distribution pattern of a resistance state of the other unselected cell. In the second current state, a readout current of low resistance selected cell in which the resistance is lower in the two adjacent memory levels becomes a smallest state depending on a distribution pattern of a resistance state of the other unselected memory cell.

Owner:XENOGENIC DEV LLC

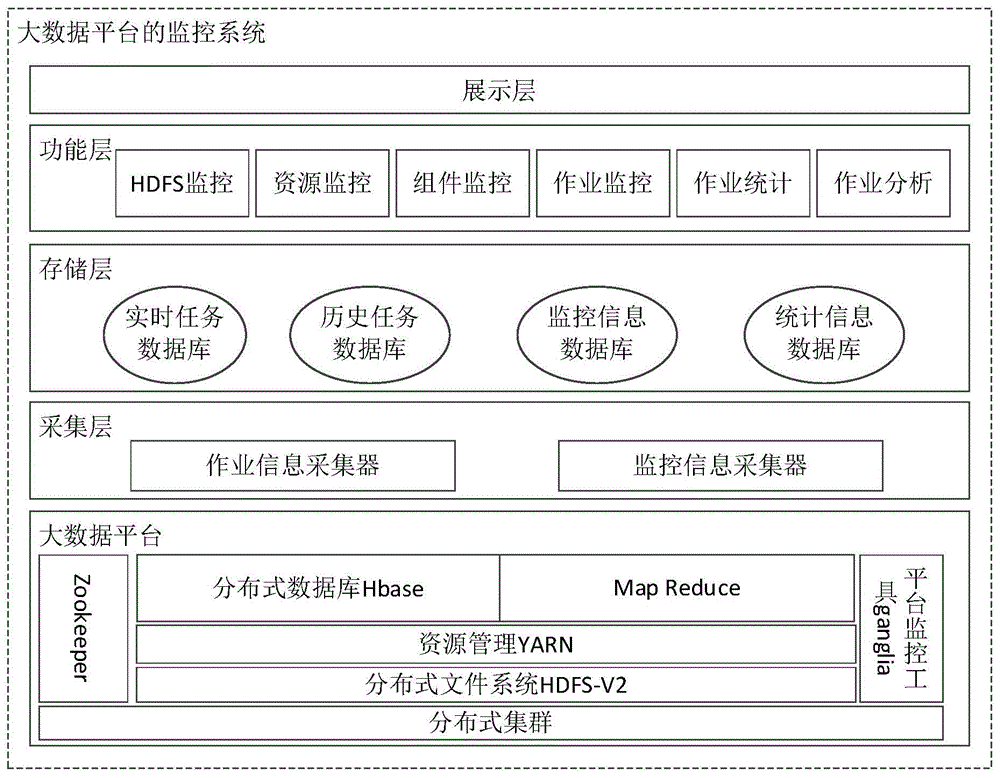

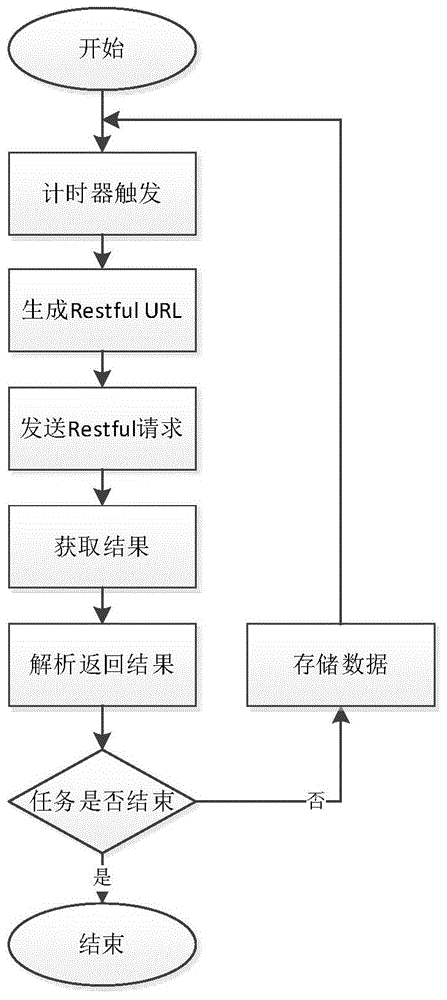

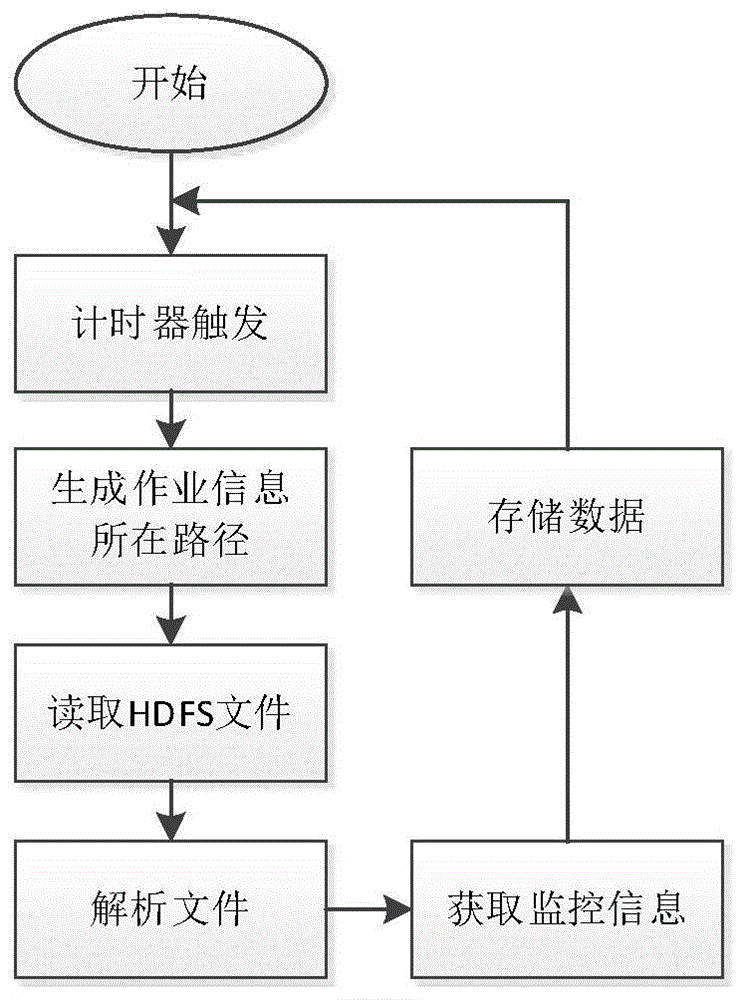

Monitoring system of large data platform

InactiveCN104615526AHardware monitoringSpecial data processing applicationsData platformStatistical analysis

The invention relates to a monitoring system of a large data platform. The monitoring system of the large data platform comprises a large data platform operation information statistic module, a large data platform operation monitoring module and a large data platform operation statistic analysis module. The monitoring system of the large data platform resolves the following problems that firstly, the large data platform uses the Hadoop to store and manage data; secondly, for operation on the platform, the large data platform only stores the final state of operation, the middle state of operation is not recorded, and operation analysis is not facilitated; thirdly, the large data platform is lack of statistics and analysis of the operation state and trend, and only the current operation information can be obtained. The monitoring of assemblies in the platform is realized and displayed on an interface. The monitoring system of the large data platform realizes operation middle process monitoring, and collects and stores the input and output data amount and dependence information of operation. Through statistics and analysis of data in the operation process, the monitoring system of the large data platform realizes statistics and analysis of the operation trend in the large data platform.

Owner:BEIHANG UNIV

Semiconductor memory device

InactiveUS20050276138A1Low costLow cost manufacturingRead-only memoriesDigital storageHigh resistanceReference current

Owner:XENOGENIC DEV LLC

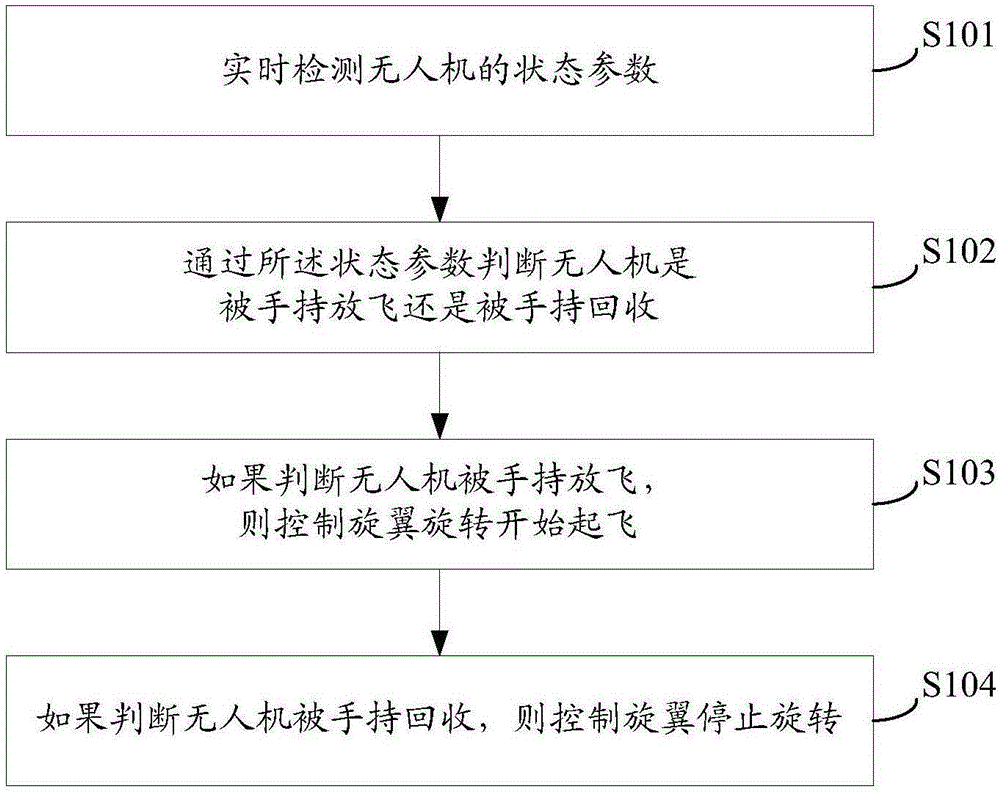

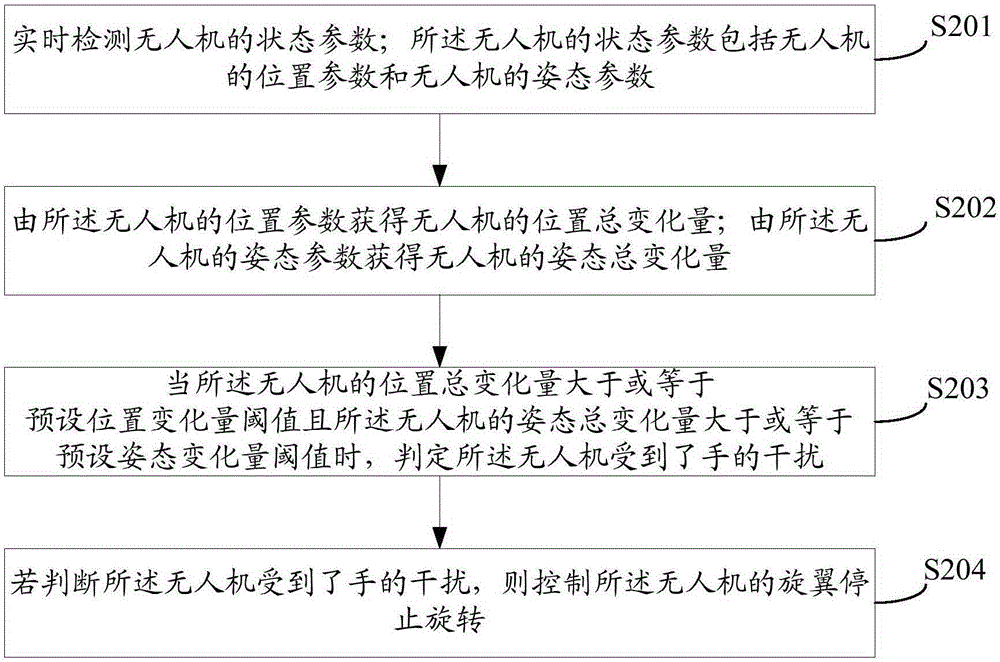

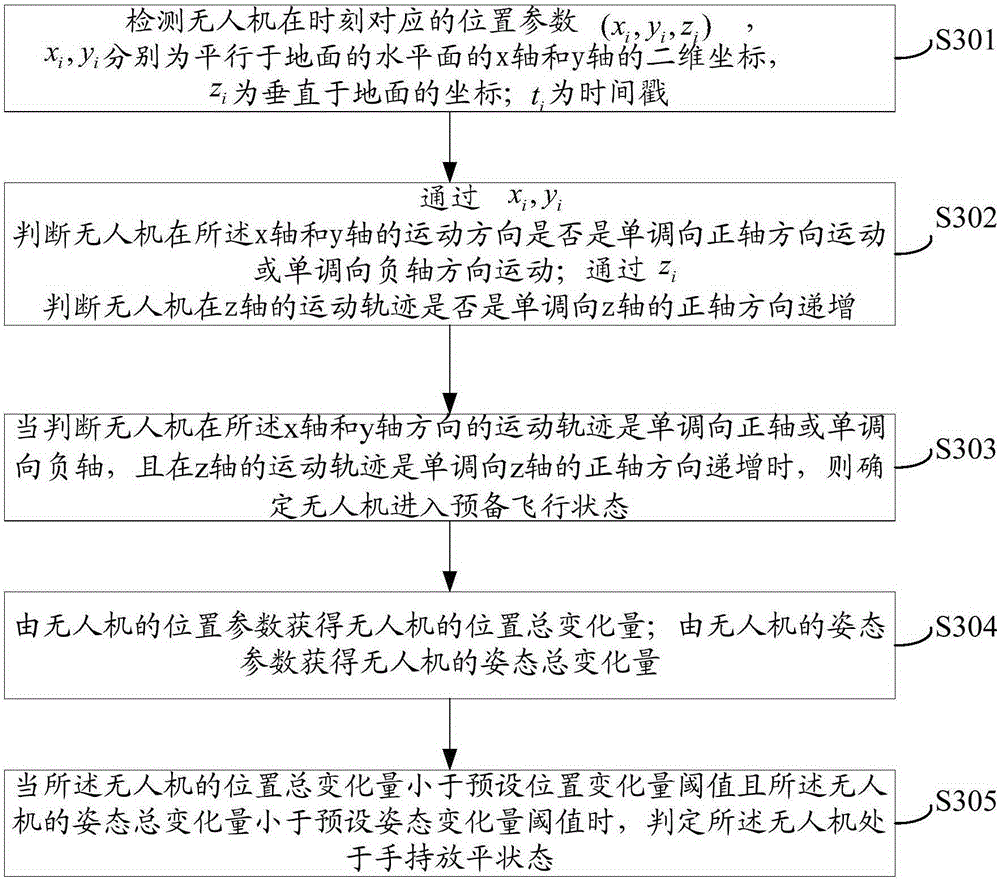

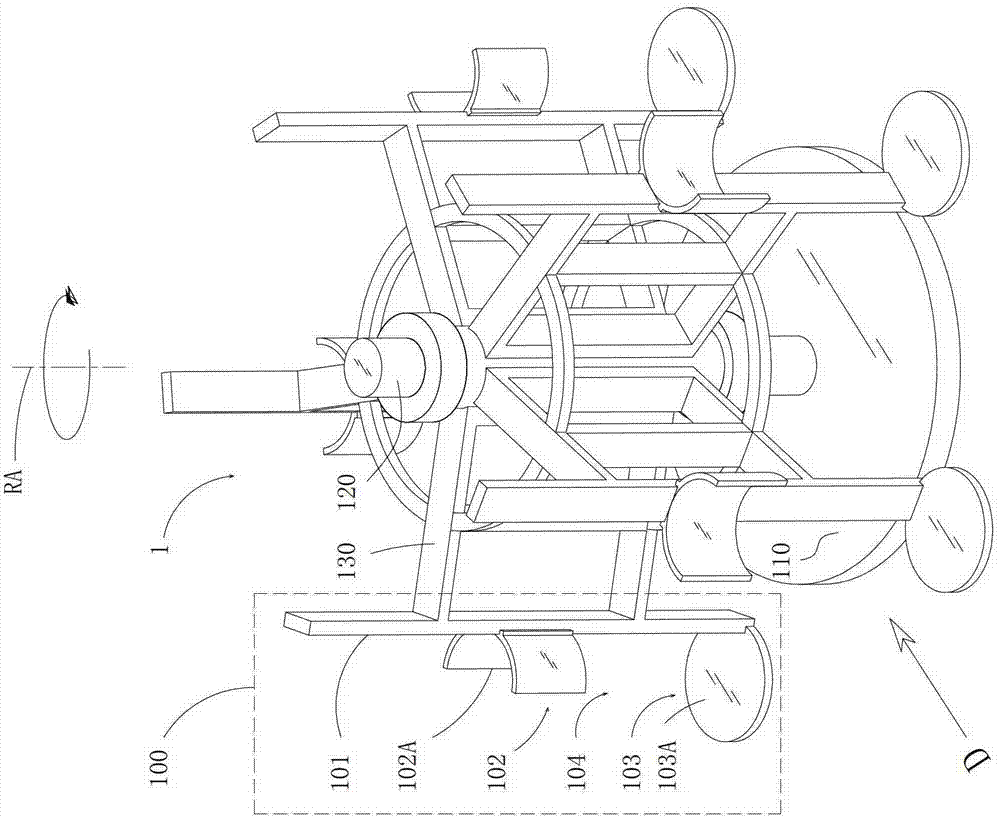

Method of retrieving and releasing unmanned aerial vehicle in hand-held mode and apparatus thereof

InactiveCN105182986AOmit flyingOmit recyclingRemote controlled aircraftAttitude controlState parameterRemote control

The invention provides a method of retrieving and releasing an unmanned aerial vehicle in a hand-held mode and an apparatus thereof. The method comprises the following steps of detecting a state parameter of an unmanned aerial vehicle in real time; through the state parameter, determining whether the unmanned aerial vehicle is released in the hand-held mode or is retrieved in the hand-held mode; if the unmanned aerial vehicle is determined to be released in the hand-held mode, making a rotor wing rotate so as to begin to take off; if the unmanned aerial vehicle is determined to be retrieved in the hand-held mode, making the rotor wing stop rotating. When being retrieved in the hand-held mode, the unmanned aerial vehicle receives a resistance of hands so that the state parameter of the unmanned aerial vehicle during a flight process changes obviously when being affected by the resistance of hands in short time. When the unmanned aerial vehicle takes off in the hand-held mode from a stop state, a middle state parameter changes because the unmanned aerial vehicle is lifted. Therefore, through the change of the state parameter, whether the unmanned aerial vehicle is released in the hand-held mode can be determined. By using the method provided in the invention, a user does not need to control remote control equipment so as to carry out releasing and retrieving of the unmanned aerial vehicle. For the user, a technology of operating a remote controller is omitted. For the unmanned aerial vehicle, the vehicle is free and is not controlled by other equipment.

Owner:BEIJING ZERO ZERO INFINITY TECH

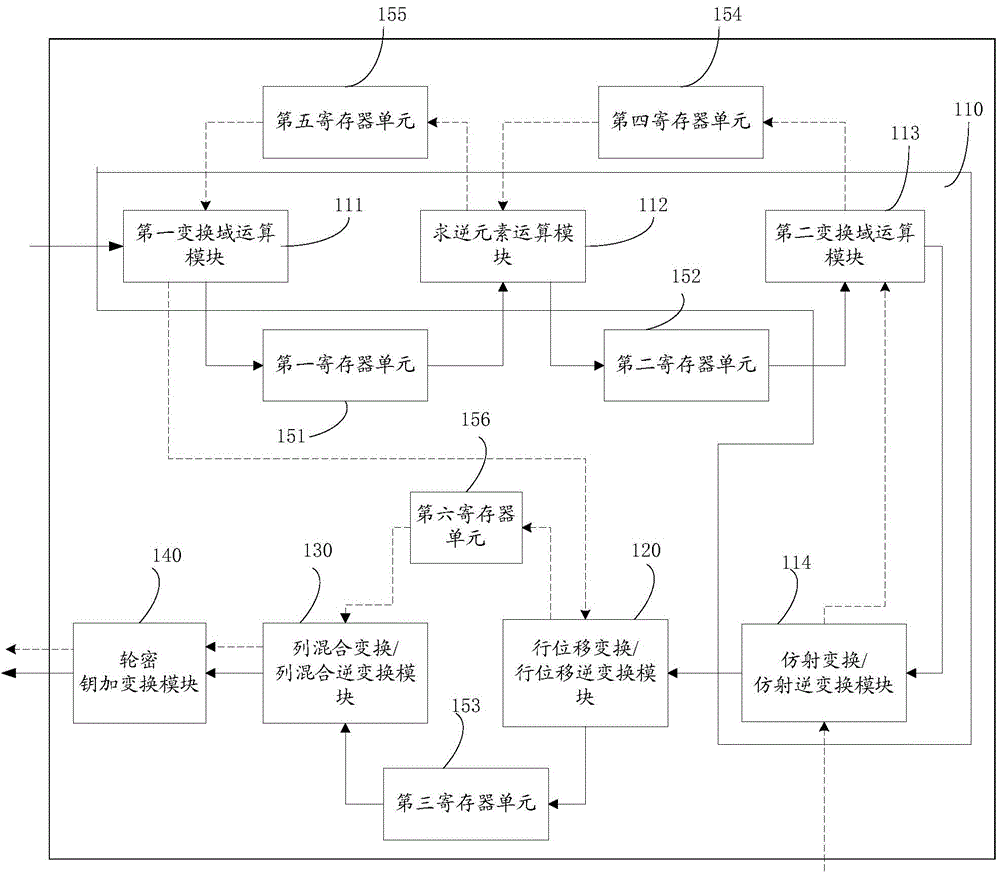

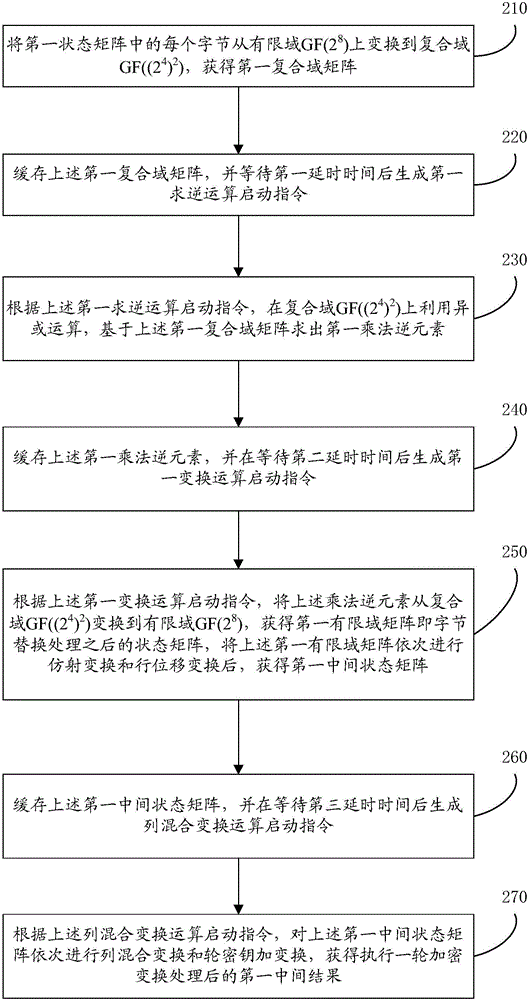

Device based on AES (advanced encryption standard) encryption/decryption algorithm and pipelining control method

InactiveCN104639314AAvoid duplicationImprove design efficiencyEncryption apparatus with shift registers/memoriesExclusive orAdvanced Encryption Standard

The invention provides a device based on AES (advanced encryption standard) encryption / decryption algorithm and a pipelining control method. The method comprises the following steps that a first composite domain matrix is buffered, and in addition, a first inversion operation starting instruction is generated after the waiting for the first delay time; exclusive-or operation is utilized in a composite domain GF((2<4>)<2>) according to the first inversion operation starting instruction, and a first multiplicative inverse element is solved on the basis of the first composite domain matrix; the first multiplicative inverse element is cached, and in addition, a first transform operation starting instruction is generated after the waiting for the second delay time; according to the first transform operation starting instruction, the first multiplicative inverse element is transformed into a finite domain GF(2<8>) from the composite domain GF((2<4>)<2>), and a first finite domain matrix is obtained; the first finite domain matrix is sequentially subjected to affine transformation and line shift transformation, and a first middle state matrix is obtained. The device and the method solve the problem that the defects in the aspects of area, power consumption and velocity exist when the existing hardware is used for realizing an AES algorithm.

Owner:SHENZHEN INST OF ADVANCED TECH

Online detecting method of numerical control machining middle state of plane structural member

ActiveCN102866672AAvoid influenceGuarantee processing qualityProgramme controlComputer controlNumerical controlComputer Aided Design

The invention discloses an online detecting method of a numerical control machining middle state of a plane structural member. First, a theoretical face of a middle machining state is established, for a three-axis face of finish machining, a face requiring detecting is selected according to the final state of a part computer-aided design (CAD) model, and a theoretical face of the middle machining state is formed by offsetting a working allowance value along the normal direction of the selected face. For a five-axis face of the finish machining, a face formed by scanning of an operation tool in the last step is used as the theoretical face of the middle machining state, a series of points are dispersed along a finish machining tool path and projected on the theoretical face of the middle state, detecting points of the middle state are formed, finally a detecting path is planned, and a numerical control (NC) program is formed to conduct online detecting. Theoretical thickness and theoretical distance are calculated according to the theoretical face of the middle machining state and form detecting result evaluation basis with a detecting point theoretical position. The online detecting method effectively solves the part quality problem caused by deformation of a large-scale part middle machining state and machining errors, and machining quality is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

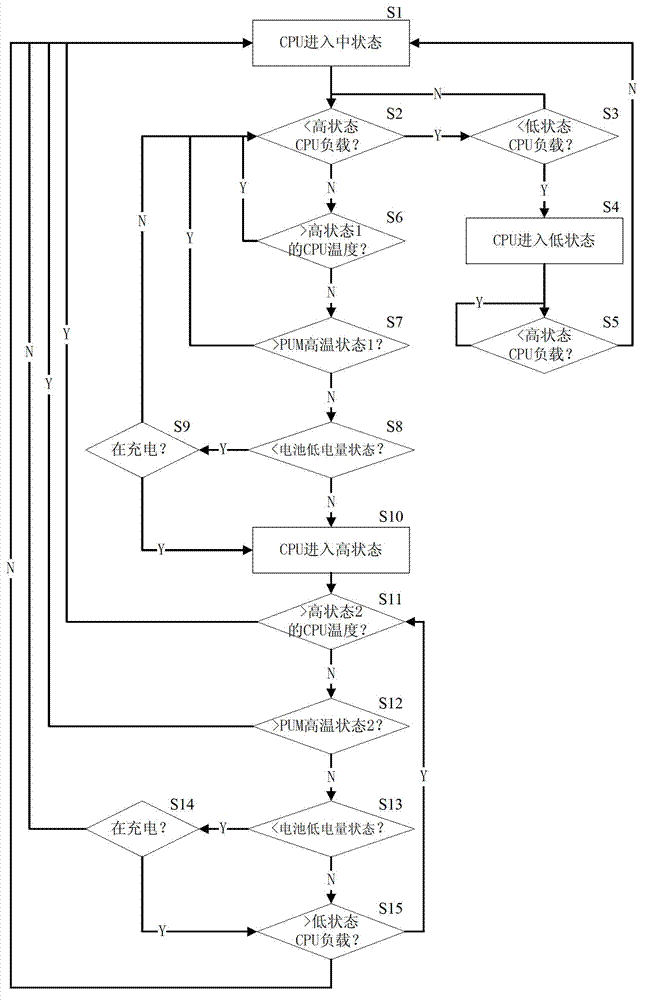

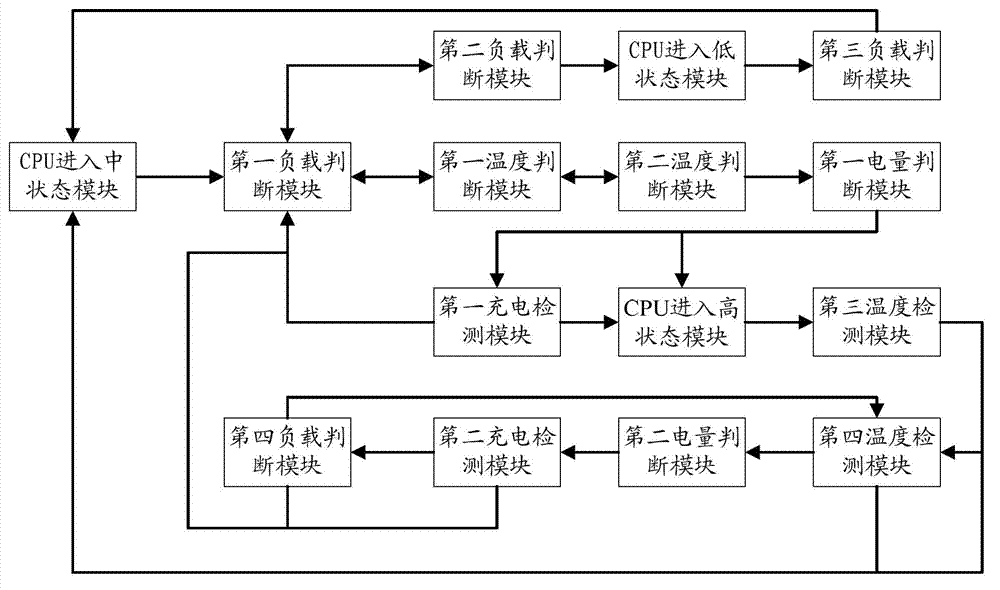

Power consumption self adjusting system of intelligent system and method thereof

ActiveCN102902348AReduce power consumptionReduce system heatEnergy efficient ICTResource allocationPower Management UnitSmart system

The invention provides a power consumption self adjusting method of an intelligent system. According to the method, when the intelligent system is started and any program is not started or operated, a CPU (Central Processing Unit) is defaulted to be operate in a middle state. Subsequently, one or more programs are used or closed one by one in the process of use. The programs which are currently used need to be supported by corresponding CPU resources, for example, if more programs are currently operated, more CPU resources are needed and vice versa. By using the method, the load and temperature of the CPU, the temperature of a power management unit and the battery power are detected to be compared with all set states, thereby controlling the CPU to intelligently enter the most suitable state of three operating states with high, middle and low power consumption, and power consumption and system heat are reduced on the basis that the best effect is achieved.

Owner:SHENZHEN SIECOM COMM TECH DEV CO LTD

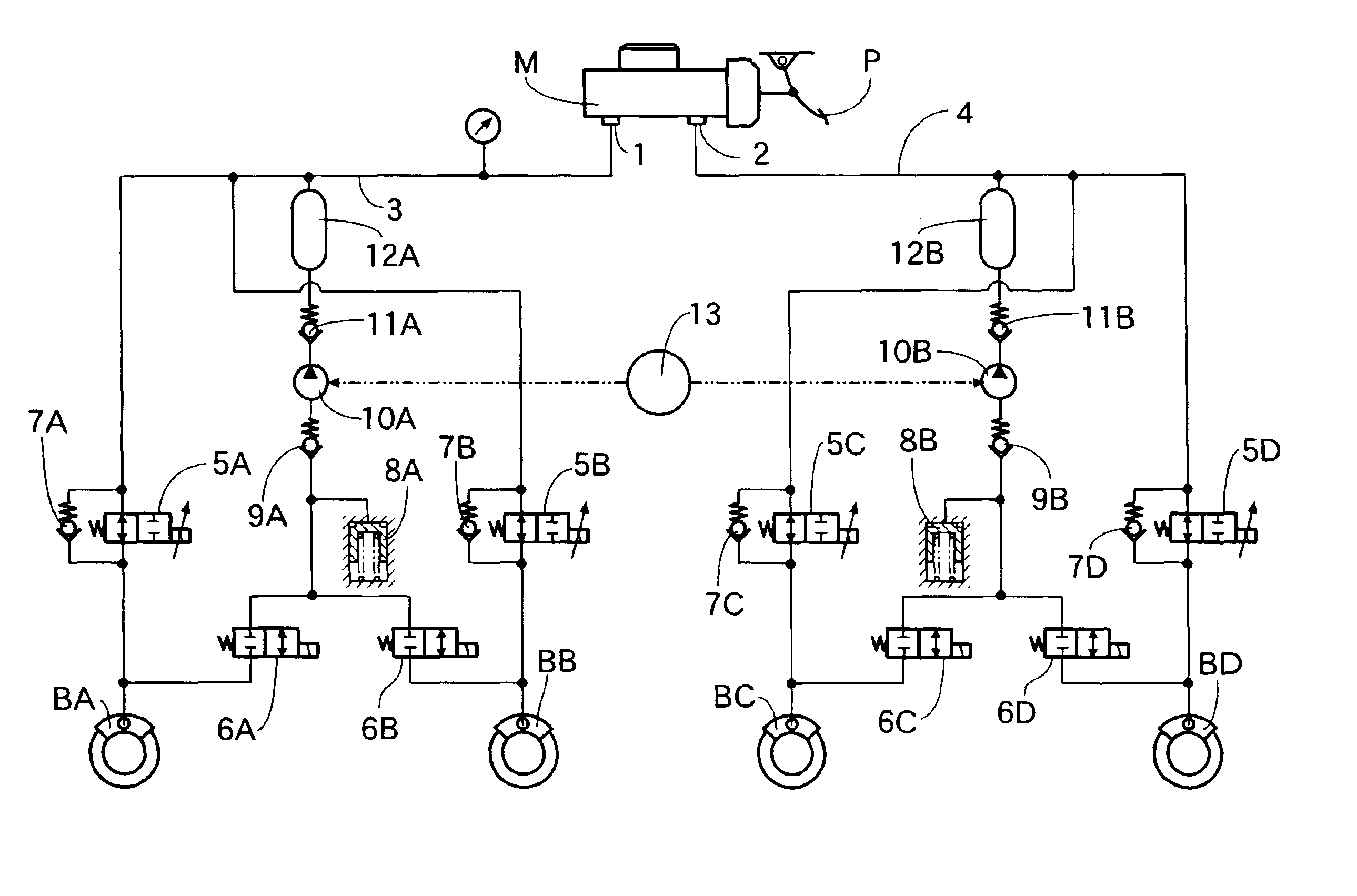

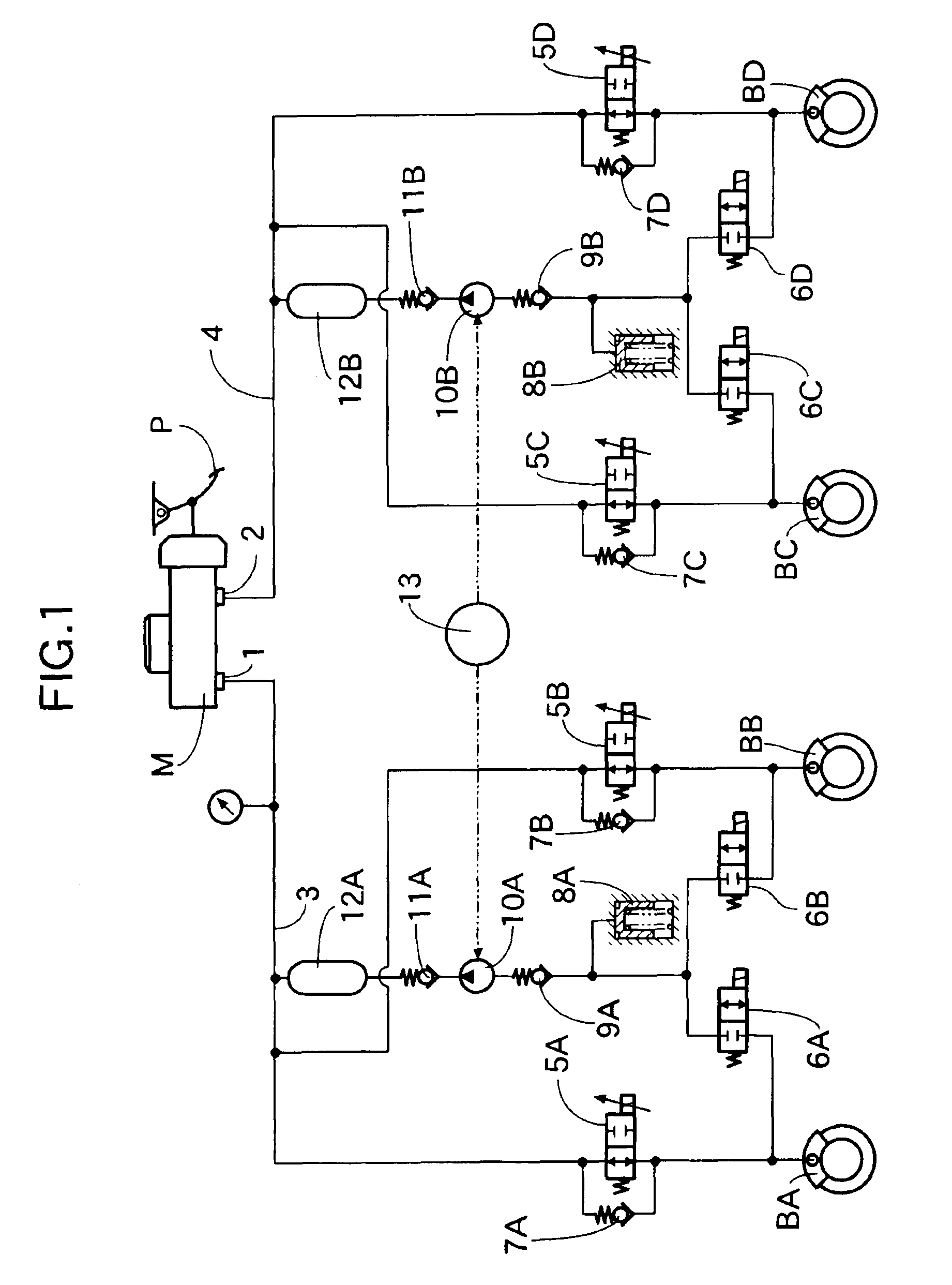

Antilock brake control system for vehicle

InactiveUS6908161B2Decreasing rate is highSuppress generationBraking action transmissionApplication and release valvesElectricityControl system

An antilock brake control system for a vehicle including normally-opened solenoid valves, normally-closed solenoid valves, and diodes. Each of the normally-opened solenoid valves is switched over among a turned-on state in which a predetermined first electric current is permitted to flow through the coil, a turned-off state in which the supply of the electric current to the coil is topped, and a middle state in which a second electric current lower than the first electric current is permitted to flow. In addition, the system includes a switch that is maintained in an electrically disconnecting state during shifting of each of the normally-opened solenoid valves from the turned-on state to the middle state, until the shifting is completed.

Owner:HONDA MOTOR CO LTD

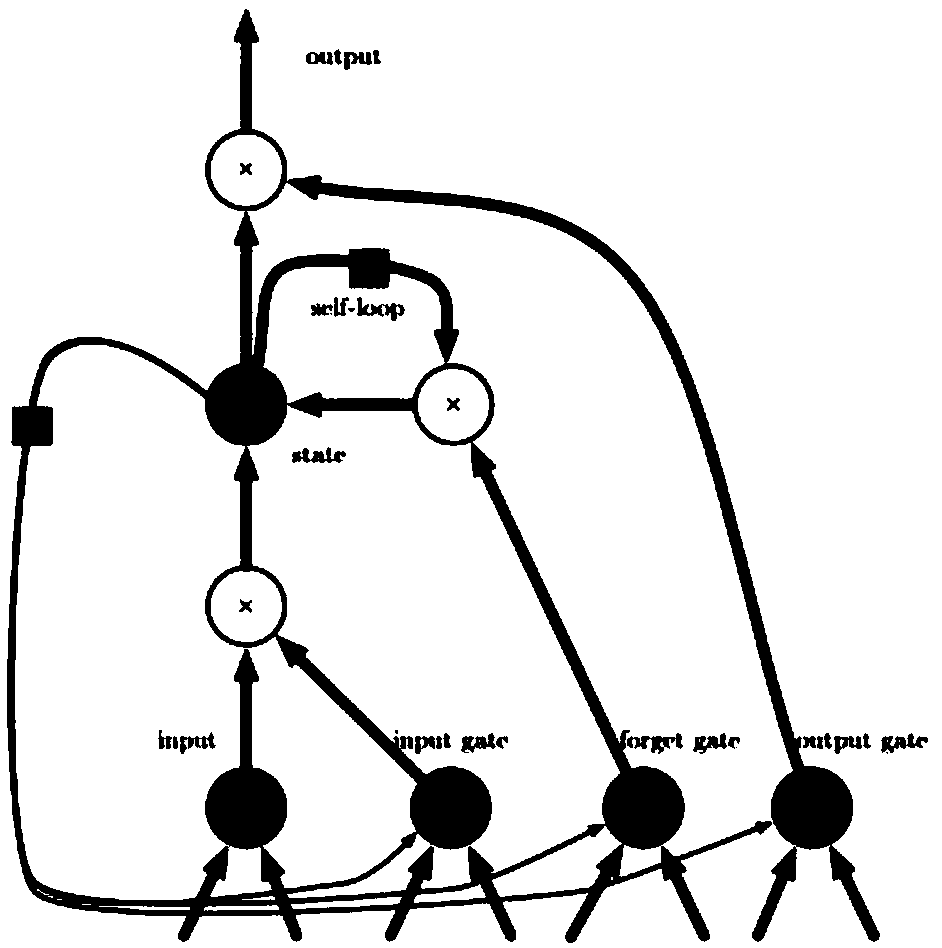

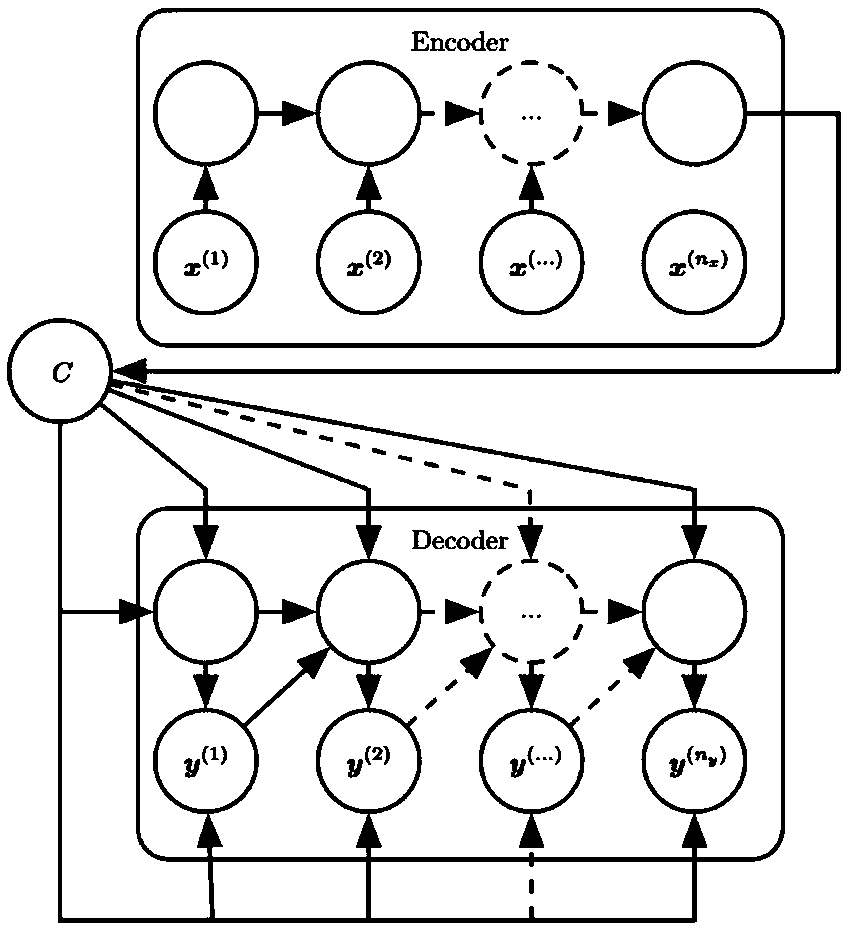

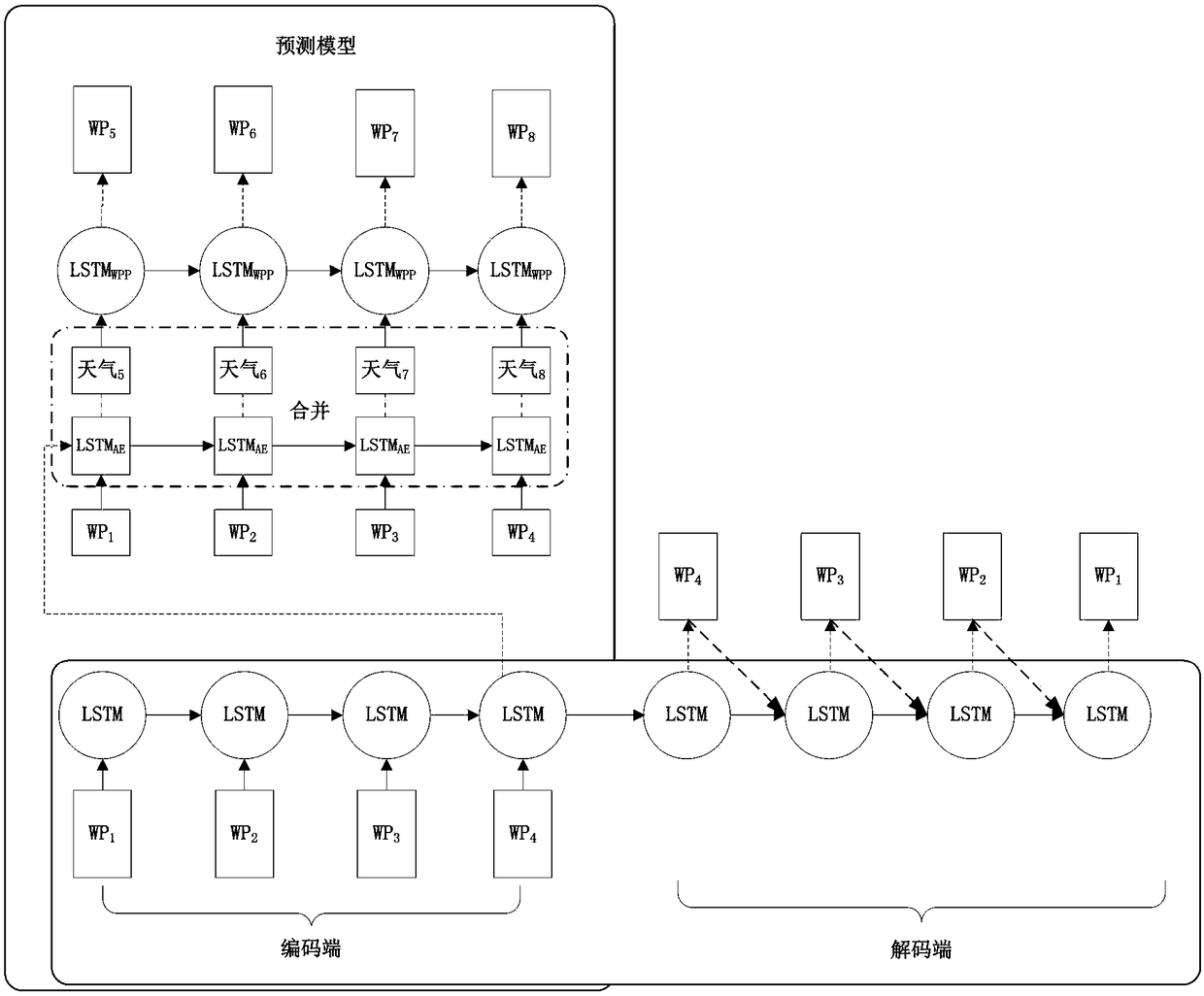

Short-term wind-power power forecasting method based on coding/decoding long-short term memory network

ActiveCN108711847AEfficient miningReduce the risk of misidentificationClimate change adaptationSingle network parallel feeding arrangementsElectricityAlgorithm

The invention discloses a short-term wind-power power forecasting method based on a coding / decoding long-short term memory network. The method comprises steps of firstly, using an E-D based LSTM network to carry out AE processing on power, and extracting a trained network middle state as abstract expression of a time sequence relation in WP data; then, combining the network middle state extractedin the first step with weather data in a prediction period, and inputting the result into a new LSTM network, thereby finishing prediction of wind-power power. Compared with a multi-layer LSTM networkmethod where AE preprocessing is not used, according to the invention, by use of the WP time frequency relation information extracted in the AE process, the model misspecification risk of a model isreduced; the generalization ability is improved; and by combining the time sequence characteristic and the weather prediction information, the prediction precision is further improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +3

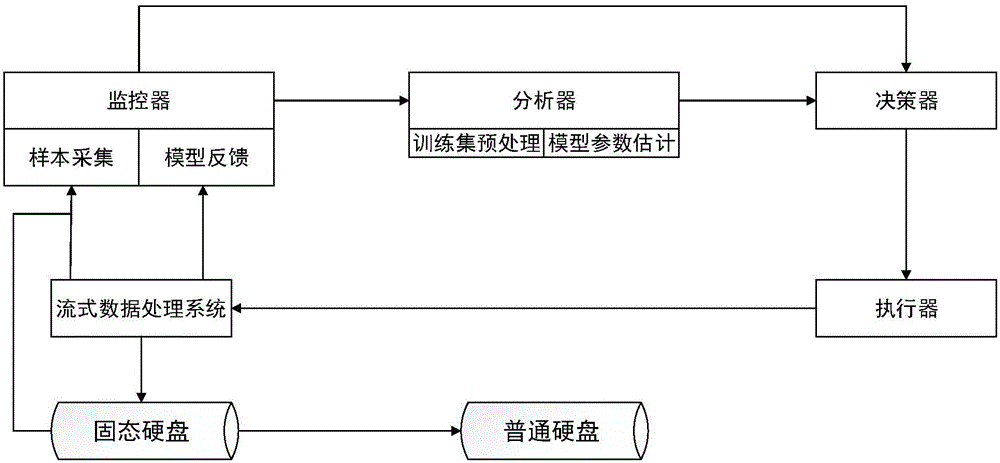

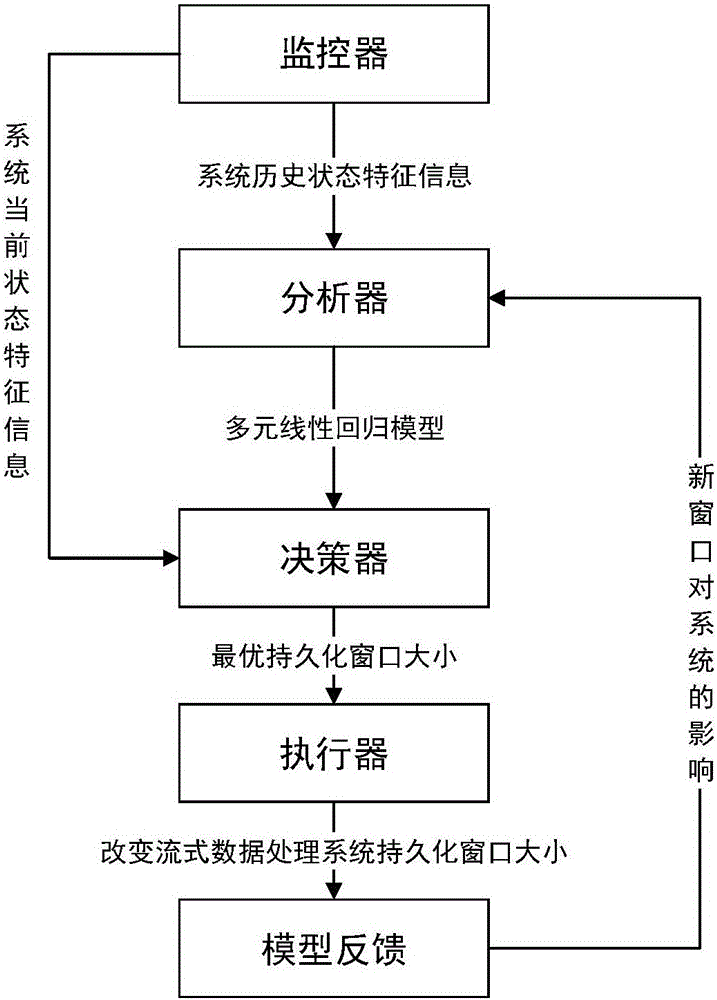

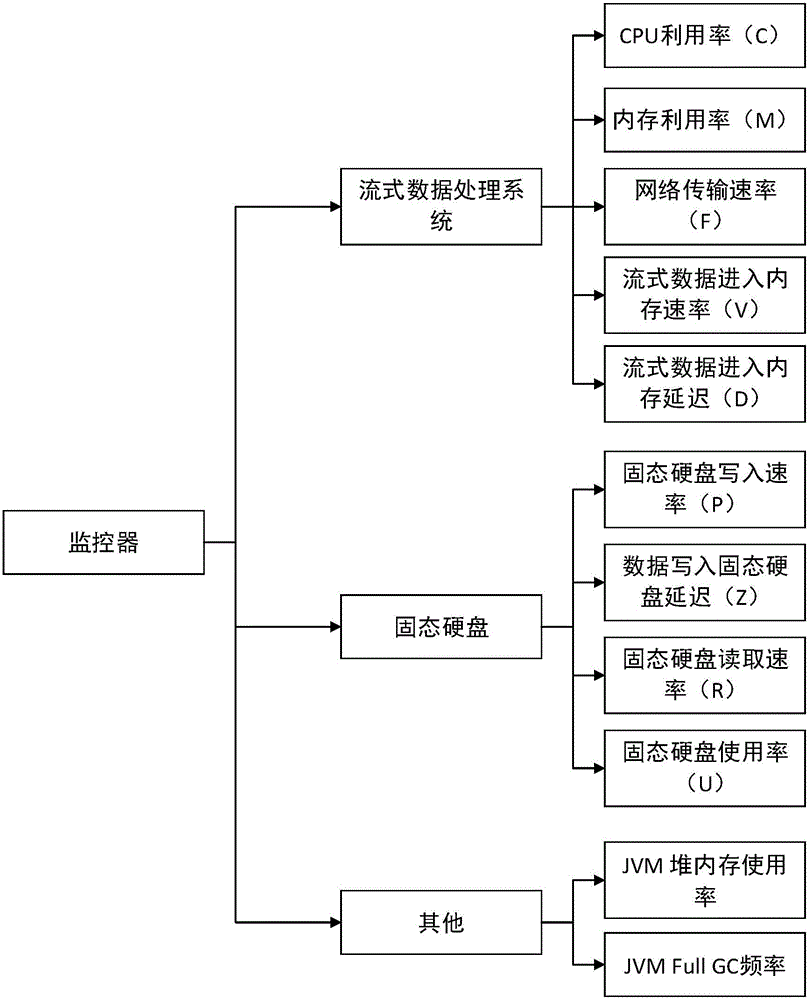

Streaming data self-adaption persistence method and system based on mixed storage

ActiveCN105893541ASolve fixed problemsEnsure balanceInput/output to record carriersSpecial data processing applicationsStreaming dataUsability

The invention provides a streaming data self-adaption persistence method and system based on mixed storage. The method includes the steps that state feature information of a streaming data processing system is collected in real time; a multiple linear regression model based on machine learning is established, and model parameters are estimated according to the collected state feature information; the optimal persistent window size of the streaming data processing system under the current state is calculated and obtained according to the state feature information of the current streaming data processing system and the established regression model; the streaming data processing system changes the current persistent window according to the obtained persistent window size, and the middle state or the calculation result in the streaming data processing process is stored in a solid state disk; when data capacity in the solid state disk reaches a certain degree, data in the solid state disk are stored in an ordinary hard disk. By means of the method and system, the persistent window size at the moment can be calculated according to the current and historical state information, accordingly the situation that the streaming data rate is unstable is dynamically adapted, and balance between usability and consistency of the system is guaranteed.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

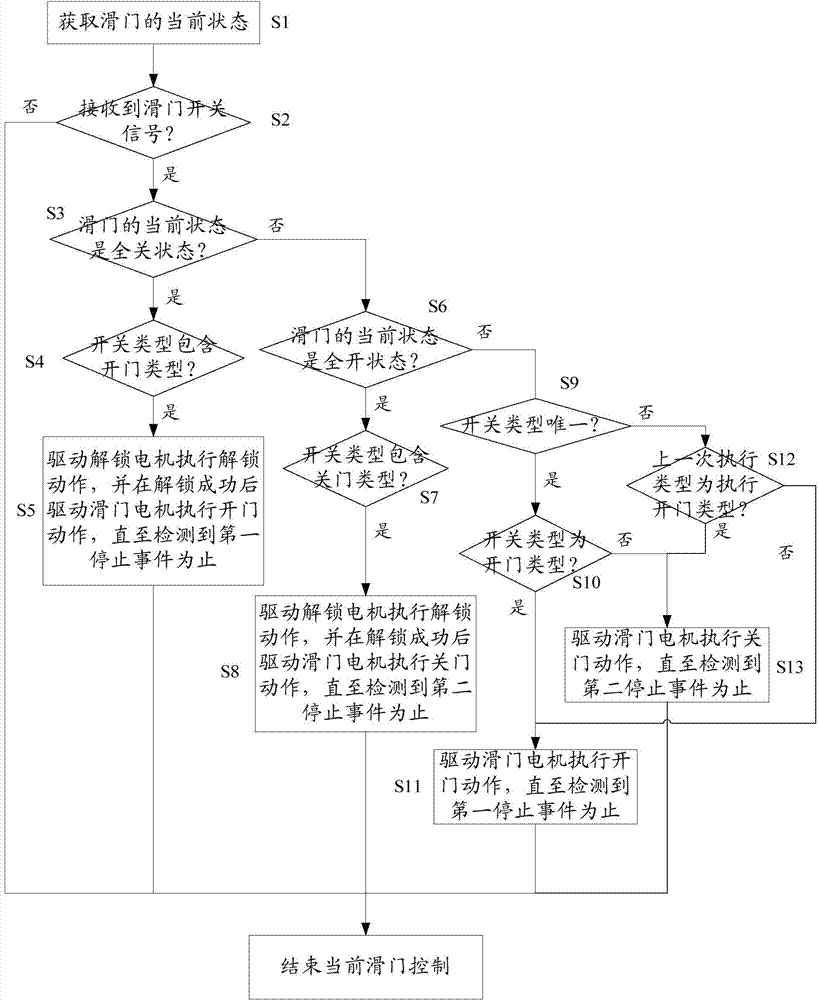

Electric slide door control method

InactiveCN104775706APower-operated mechanismElectrical locking actuatorsMiddle stateOpening - action

The invention discloses an electric slide door control method. According to the method, the slide door action is controlled according to the opening and closing type of slide door opening and closing signals and the current state of a slide door. The method concretely comprises the following steps that a slide door motor is driven to execute the door opening action respectively when the current state is a fully closed state and the opening and closing type includes the door opening type, the current state is a middle state and the opening and closing type is only the door opening type, when the current state is the middle state and the opening and closing type is not unique, and when the last executing type is the door closing action execution; the slide door motor is driven to execute the door closing action respectively when the current state is the fully open state and the opening and closing type include the door closing type, when the current state is the middle state and the opening and closing type is only the door closing type, when the current state is the middle state and the opening and closing type is not unique, and the last execution type is the door opening action execution; the action of driving the slide door motor to execute the door opening action and the door closing action is respectively stopped when the slide door opening and closing signals are received. The method provided by the invention has the advantage that the control freedom degree is high.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

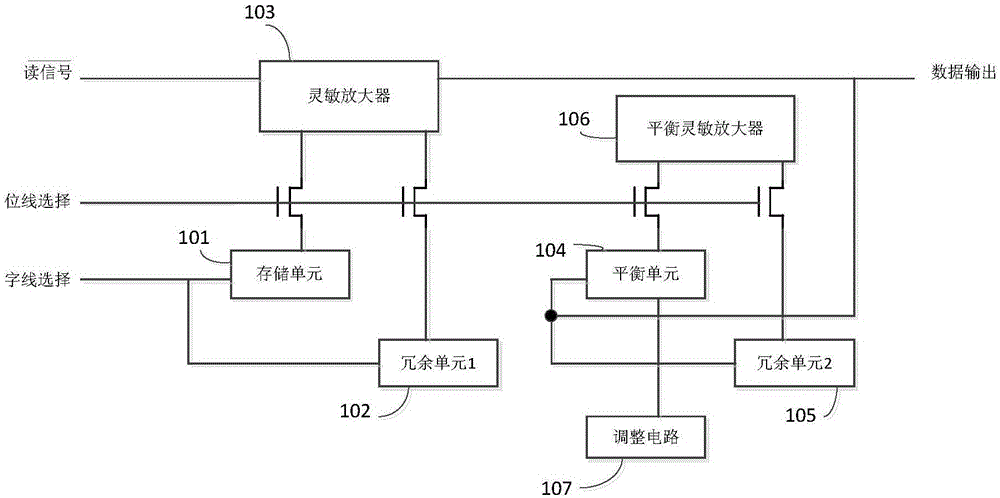

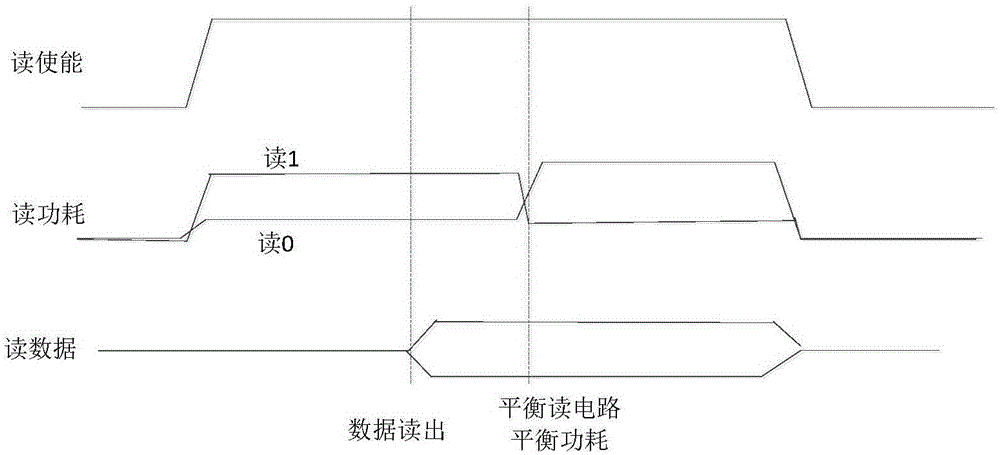

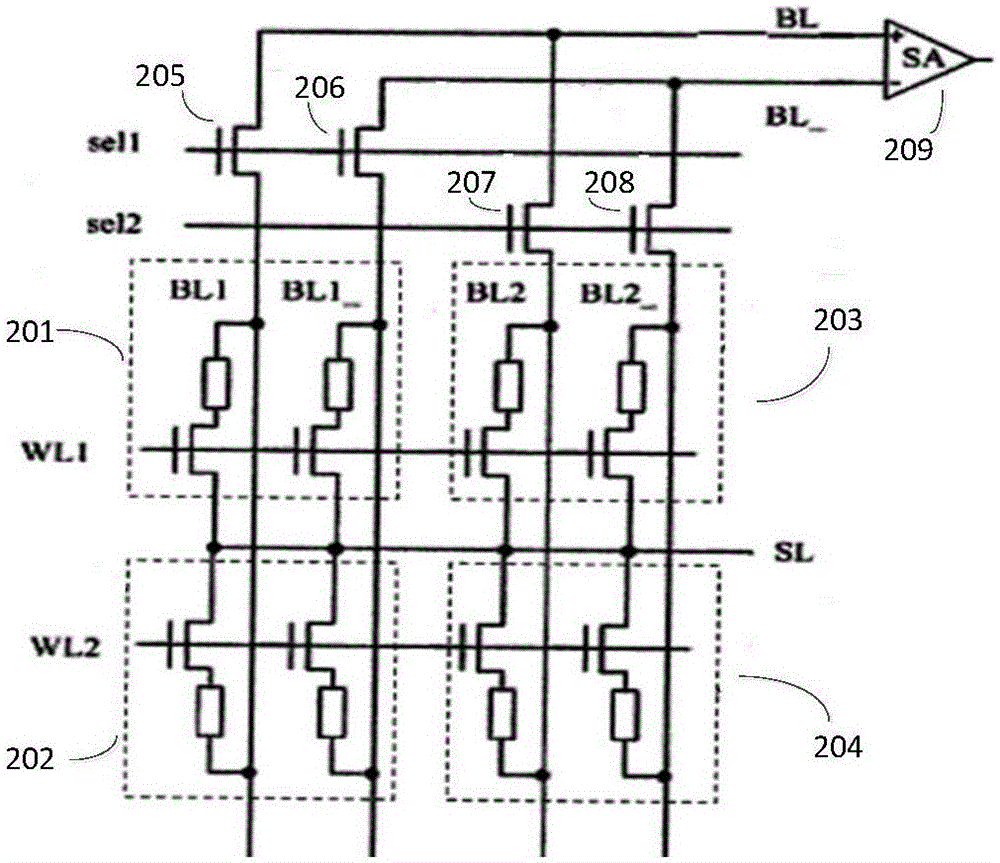

Reading circuit of non-volatile memory capable of preventing side channel attack

ActiveCN105023615AImproving the ability to resist power analysis attacksRead-only memoriesEngineeringMiddle state

The invention belongs to the technical field of a semiconductor memory, and particularly relates to a reading circuit structure of a non-volatile memory capable of preventing side channel attack. The structure comprises a storage unit, a first reference unit, a second reference unit, a voltage difference amplification circuit, a sensitivity amplifier, a current source, a column selection transistor, two reference unit column selection transistors, two reading enabling control transistors and two gates, wherein the storage unit is in a conduction state or non-conduction state; the conduction state represents 1 data storage; the non-conduction state represents 0 data storage; the first reference unit and the second reference unit have the same structure as the storage unit; the first reference unit is pre-programmed into the non-conduction state; and the second reference unit is pre-programmed into the conduction state. In the structure, a path of complementary reference unit columns can be opened at the same time in the reading process, so that a reading power consumption curve is balanced; therefore the side channel attack of the power consumption analysis can be prevented. According to another circuit structure, on the basis of the structure, the reference units in a middle state are used for performing reading operation; the reference units are used as redundancy units for balancing the reading power consumption; a 0 reading power consumption curve and a 1 reading power consumption curve can be further balanced; and the resistance on the power consumption analysis type side channel attack is facilitated.

Owner:FUDAN UNIV

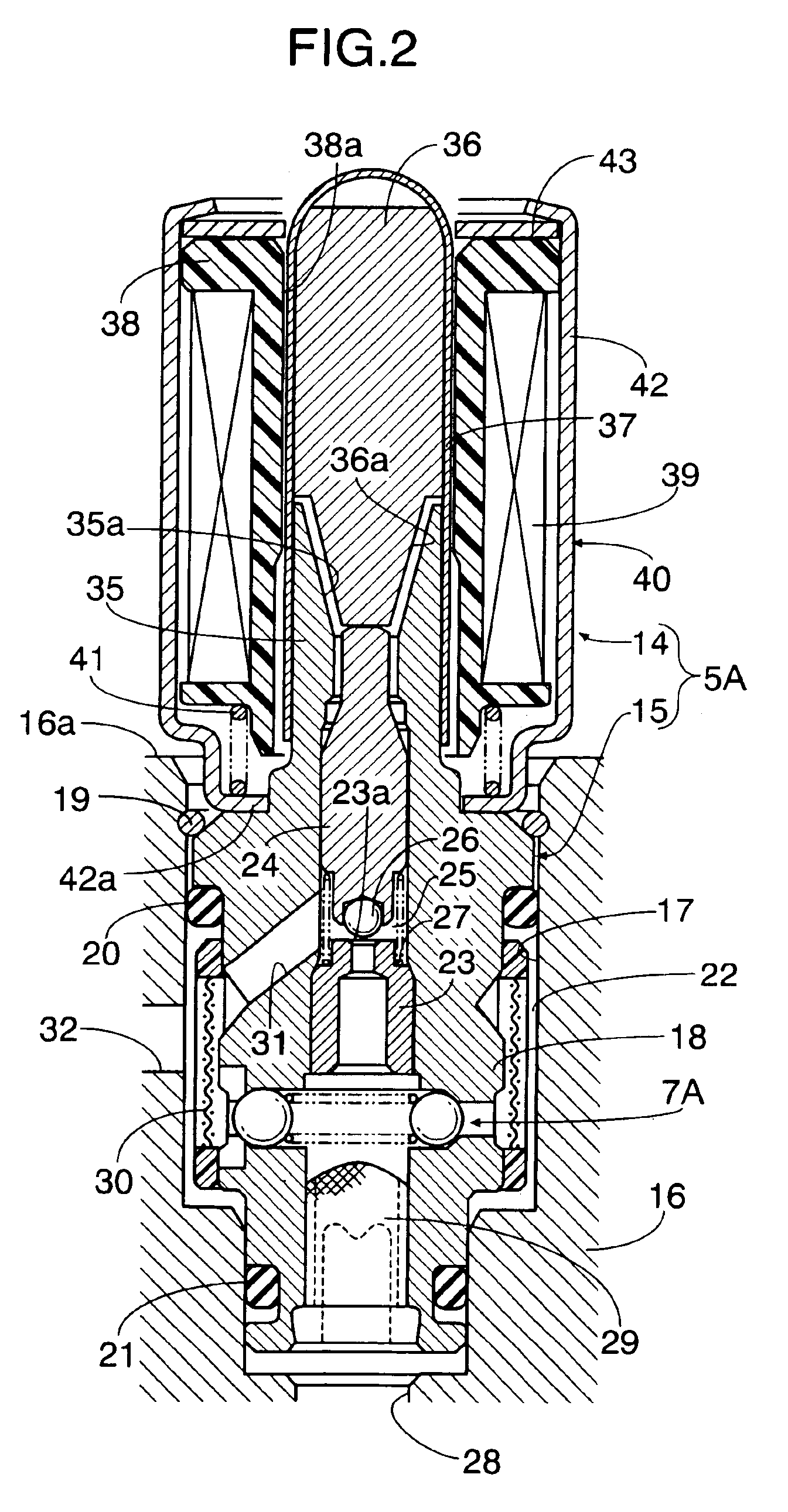

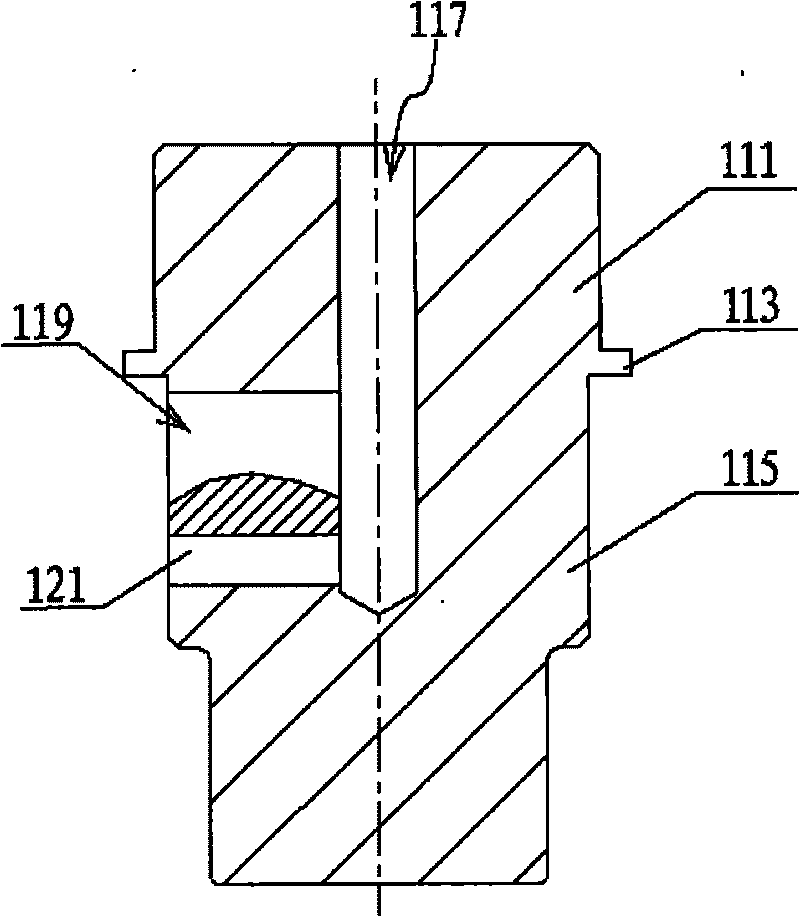

Horizontal well delivery tractor perforating tool

PendingCN109113685AStable jobAvoid damageDrilling rodsConstructionsUltimate tensile strengthScrew thread

Owner:中石化石油工程技术服务有限公司 +2

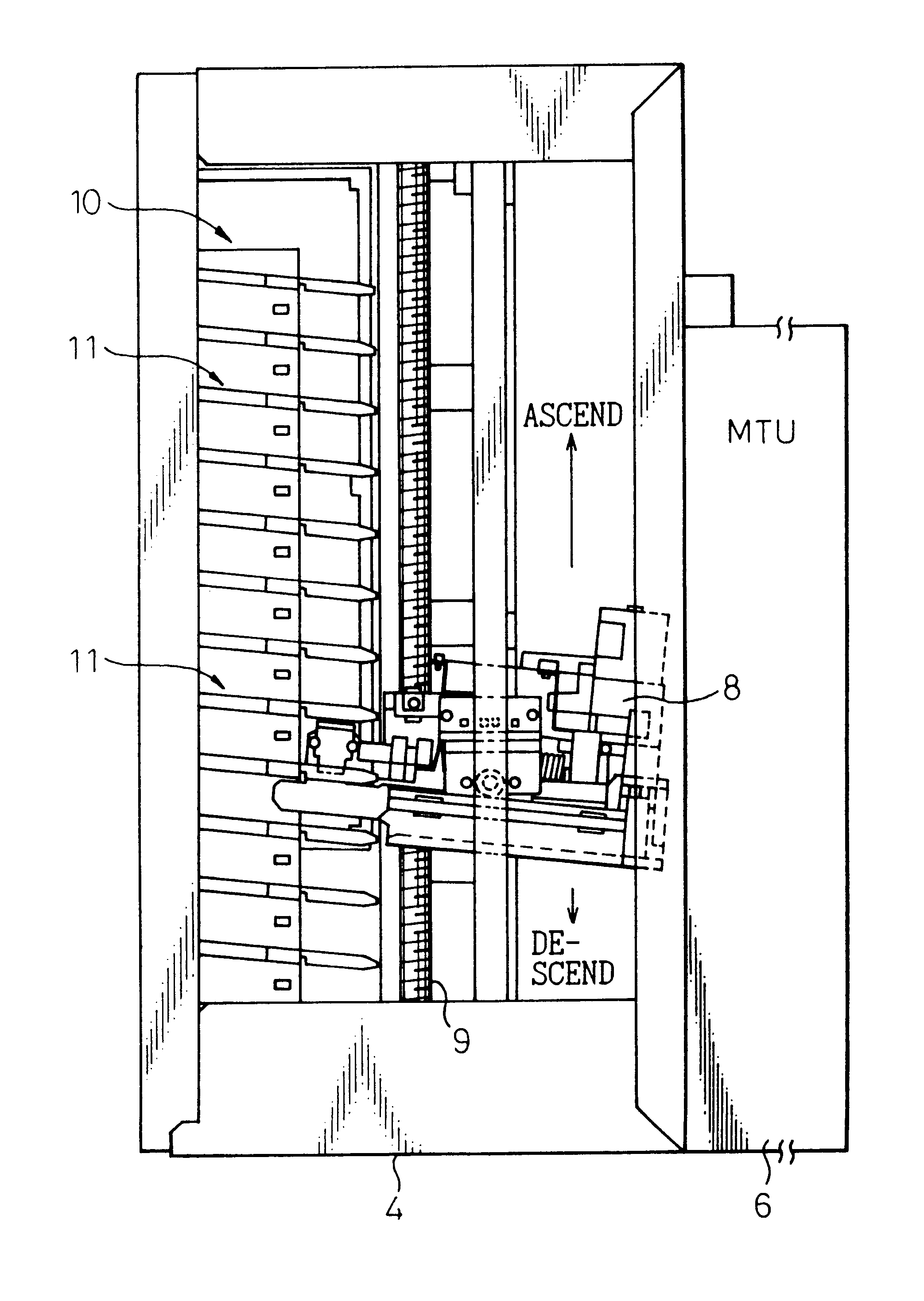

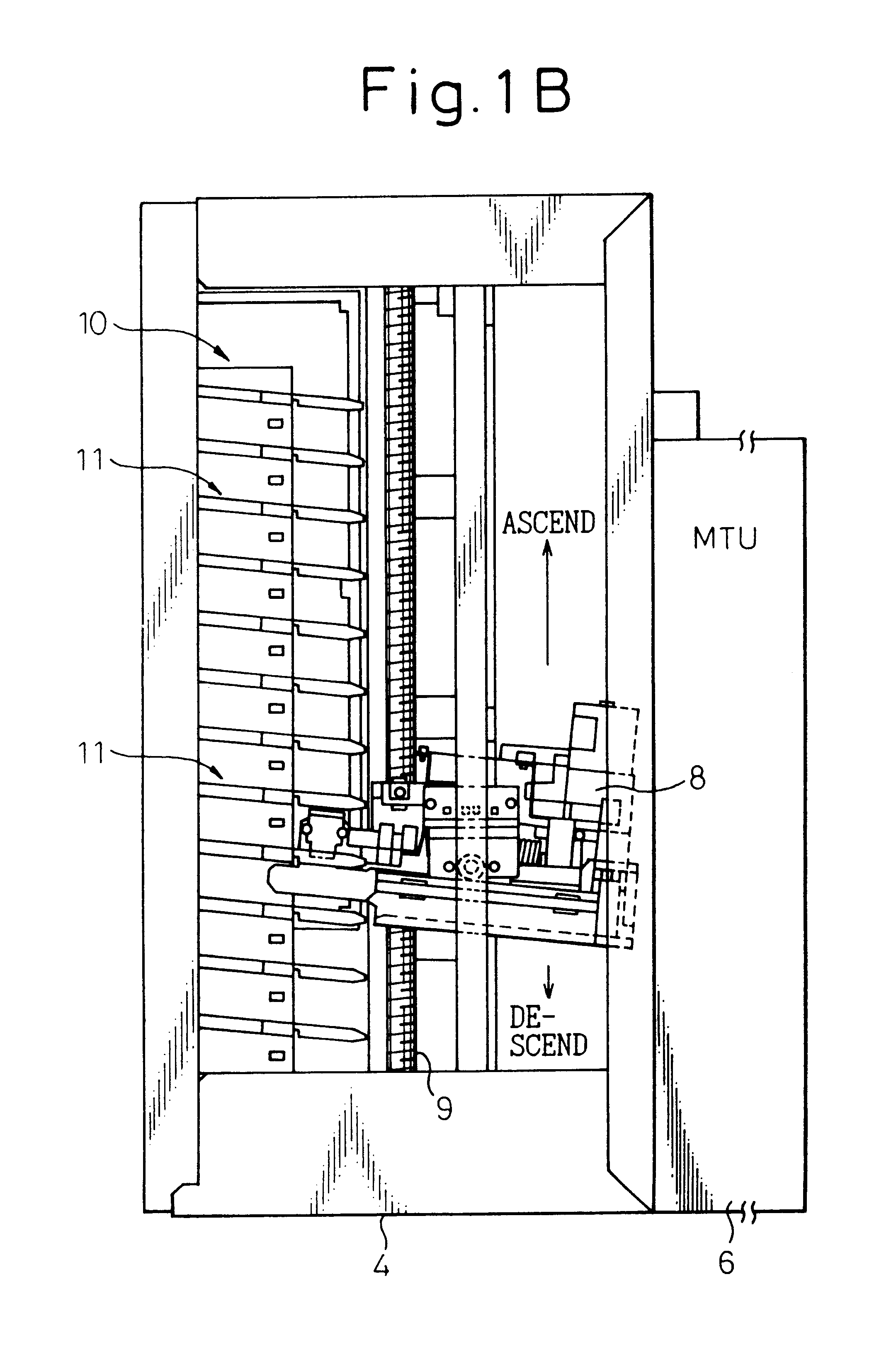

Apparatus for automatically conveying cartridges

An apparatus is automatically conveying cartridges reliably and correctly without causing errors, making it possible to enhance the operation efficiency and performance of the apparatus. The apparatus is automatically conveying cartridges disposed adjacent to a recording / reproducing apparatus, and is comprised of a cell mechanism having racks, an accessor mechanism having an accessor, and a conveyance control unit for controlling the conveyance of the cartridges by controlling the accessor mechanism, wherein the accessor is provided with catcher hands, a catcher hand drive mechanism, an open detector mechanism for detecting the open state of said catcher hands, and a closed detector mechanism for detecting the closed state of said catcher hand. The conveyance control unit is equipped with a catcher hand controller which controls the catcher hands to assume an open state, a closed state or a middle state which is an intermediate state relying upon the data detected by the open detector mechanism and the closure detector mechanism.

Owner:FUJITSU LTD

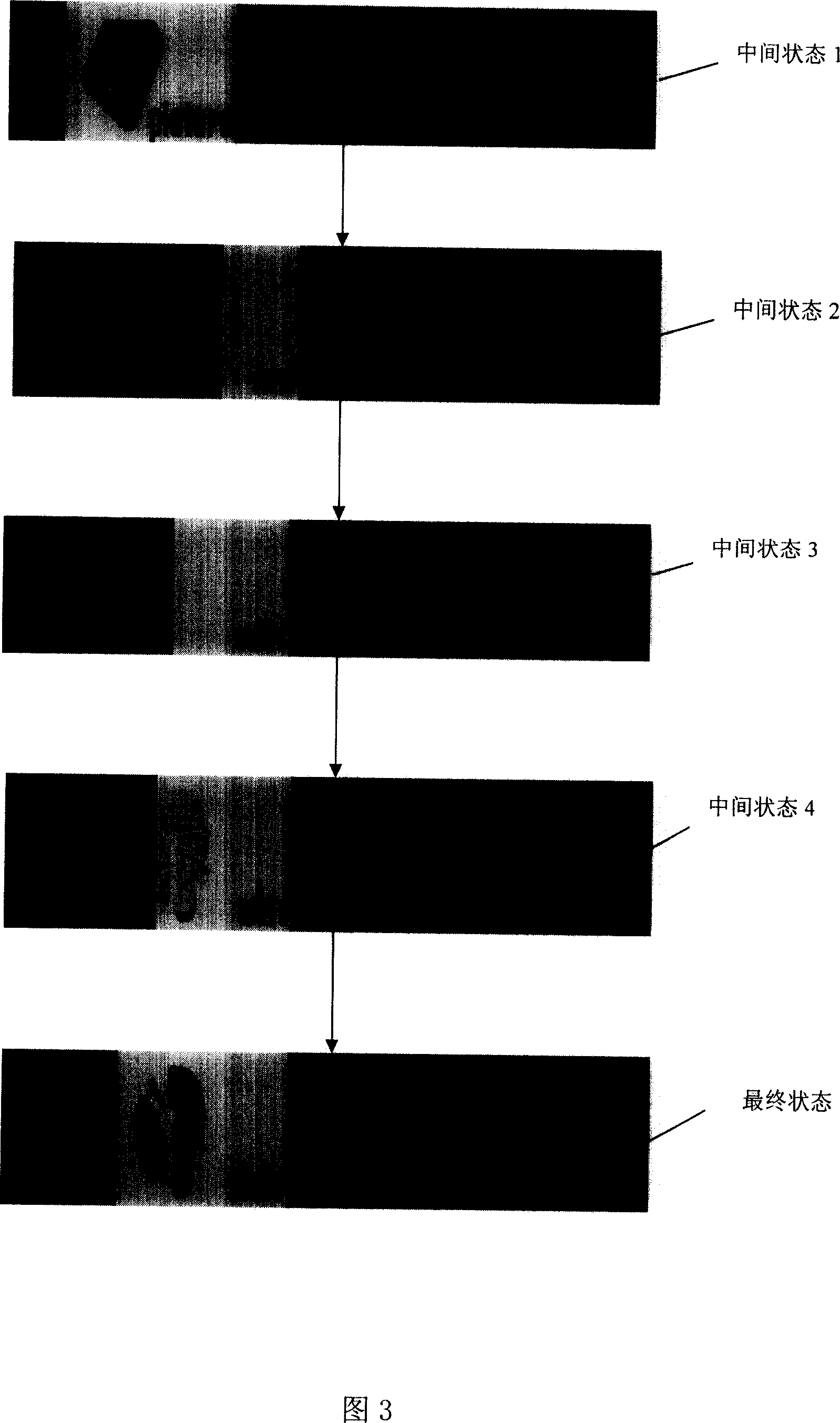

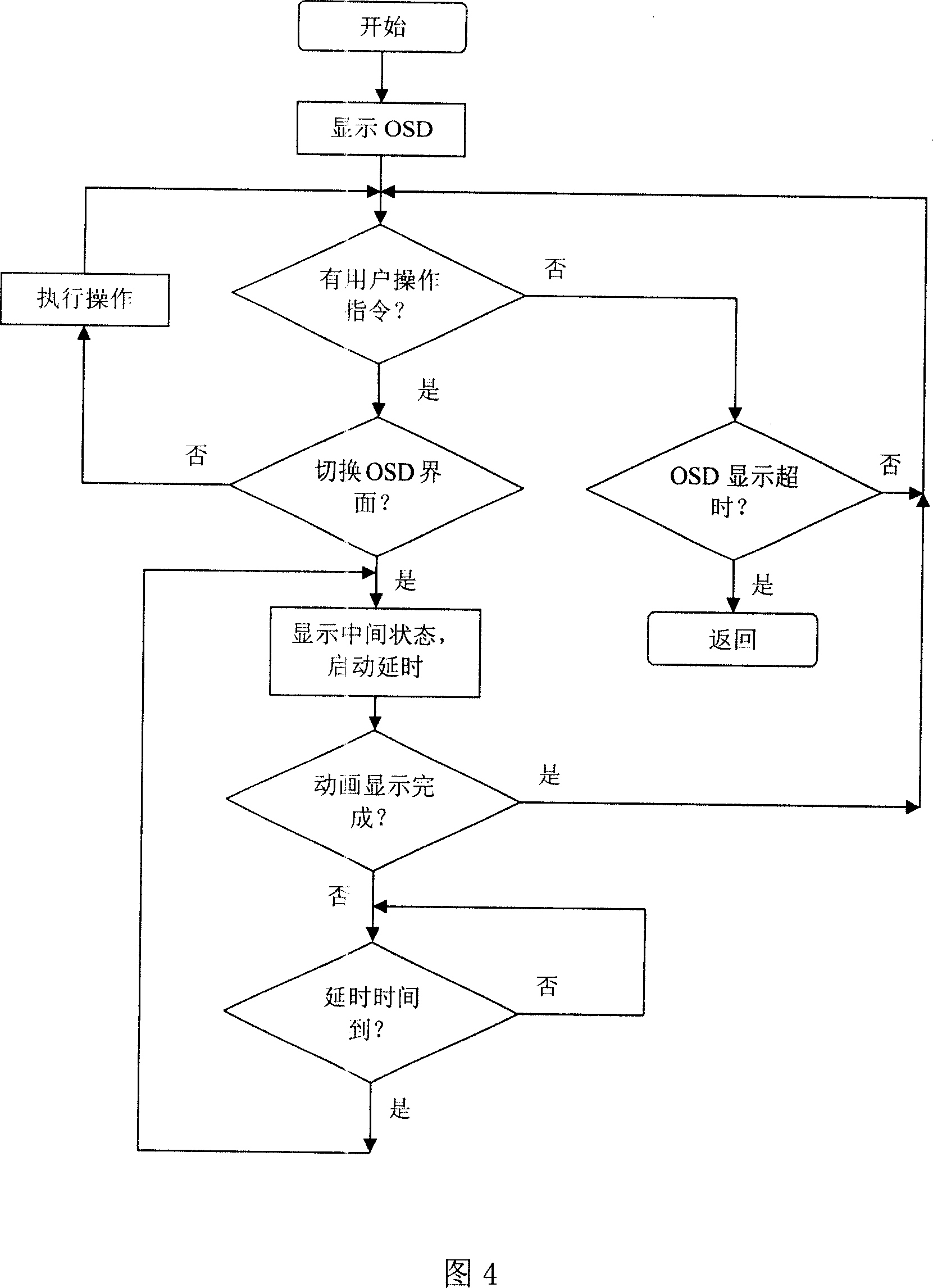

Display device for function menu dynamic switch and its implementing method

InactiveCN101155276AVivid dynamic menu effectSmooth dynamic menu effectTelevision system detailsColor television detailsAnimationDisplay device

The present invention discloses a display device for functional menu dynamic switch as well as its implementing method. The method includes the following steps: a. after receiving command for switching to new functional menu from user, the microprocessor MCU of the display device calls corresponding middle state pictures of the new functional menu from the memory in order, and transmits the pictures one by one to the display screen of the display device to display; b. after all the picture of middle state are displayed in the display screen of the display device, the MCU calls corresponding final state picture of the new functional menu, and output to the screen of the display device to display. The present invention implements lifelike fluent dynamic menu effect using cartoon shooting principium, and ensures the seeing art of the TV menu display field reach a new administrative level.

Owner:SHENZHEN TCL NEW-TECH CO LTD

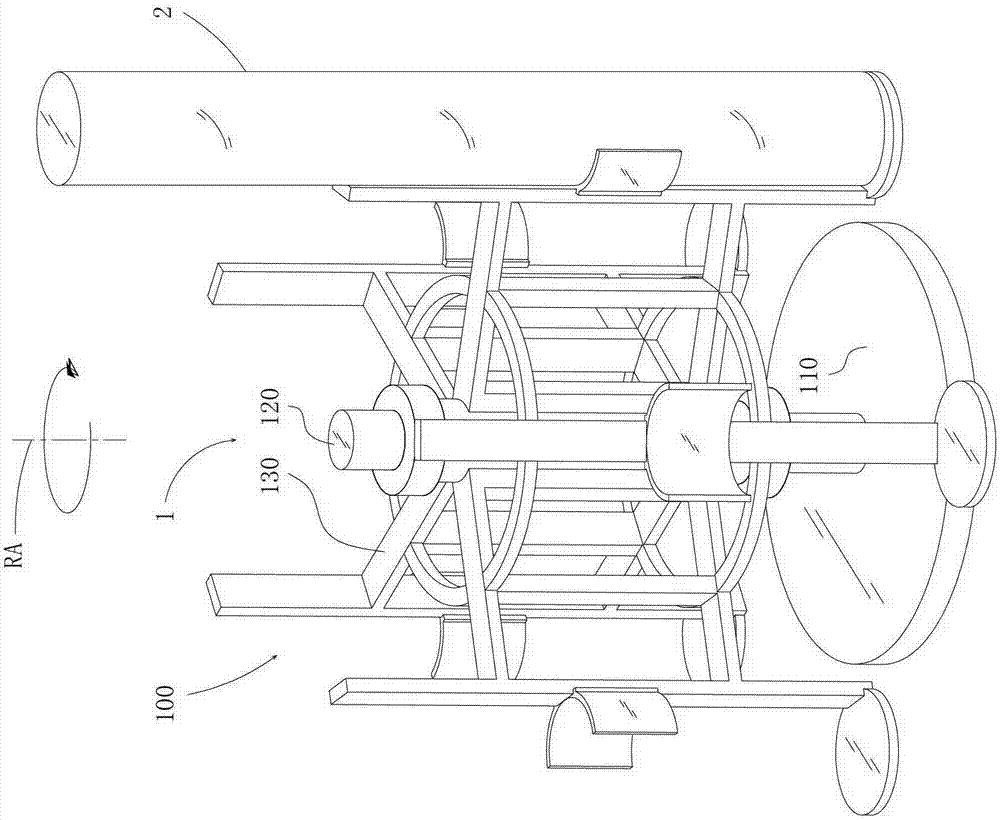

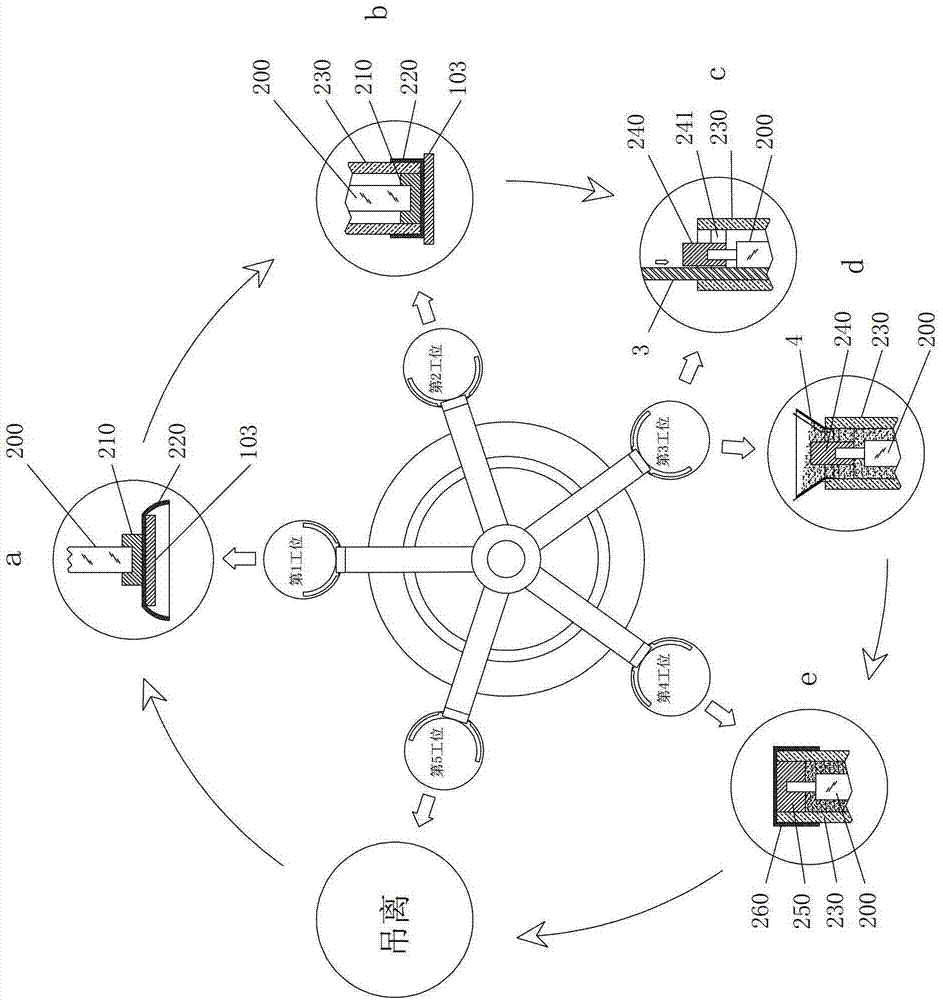

Production line type assembling method of isostatic pressing filter element forming die

The invention discloses an efficient production line type assembling method of an isostatic pressing filter element forming die. The efficient production line type assembling method adopts a die filling system comprising at least one die filling and transporting unit, and the at least one die filling and transporting unit can respectively move to different work positions under the guide of the die filling system in sequence; and if a process of a middle state of a container which is just provided with an opening at the upper end and is assembled on the same die filling and transporting unit is defined as a pre-half process and a process that a die which is positioned on the die filling and transporting unit in the middle state is subjected to material filling until the assembling is completed is defined as a post-half process, the pre-half process is completed on at least one work position, and the post-half process is completed on the other at least one work position. According to the efficient production line type assembling method disclosed by the invention, the die filling and transporting unit is used as a carrier for assembling and transporting the die, the labor transporting is saved, the work of repositioning the die on an assembling platform is saved, and the assembling efficiency is increased.

Owner:CHENGDU INTERMENT TECH

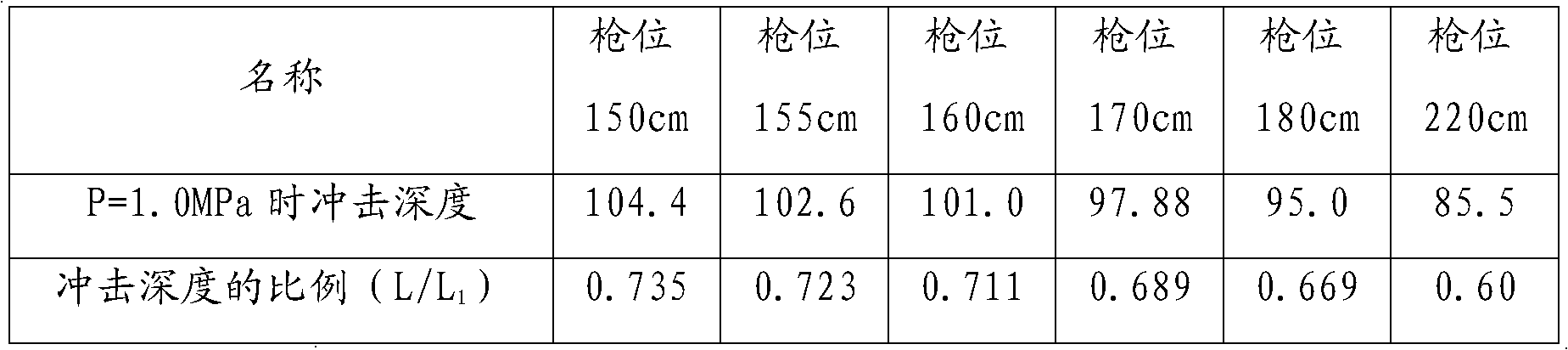

Converter steelmaking phosphorus reservation smelting method

ActiveCN103131817AIncrease residual manganese contentReduce consumptionManufacturing convertersSteelmakingOxygen

The invention relates to a converter steelmaking phosphorus reservation smelting method and belongs to the technical field of metallurgy. According to the converter steelmaking phosphorus reservation smelting method, a smelting period is divided into a front state, a middle state and a late stage. By controlling an addition amount of lime, R binary basicity of cinders is constantly kept between 2.0 and 2.8. By adjusting the flow and a gun position of an oxygen ejecting gun, the weight ratios between ejected oxygen amounts of the front state, the middle state and the late stage and the total oxygen ejecting amount are respectively controlled at 18%-22%, 55%-65% and 18%-22%. Impact depths of oxygen ejecting currents of the early stage and the middle stage are controlled to be 60%-70% of the depth of melted steel. The impact depth of an oxygen ejecting current of the late stage is controlled to be 70%-80% of the melted steel. Residual carbon content of terminal point smelted steel is controlled between 0.05% to 0.1%. According to the converter steelmaking phosphorus reservation smelting method, peaks of the early smelting stage and the late smelting stage are reasonably controlled with balance. Thus, the reservation rate of the phosphorus in melted iron can be 30% to 70% without addition of phosphorus-included ore so as to achieve demanded phosphorus reservation smelting.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

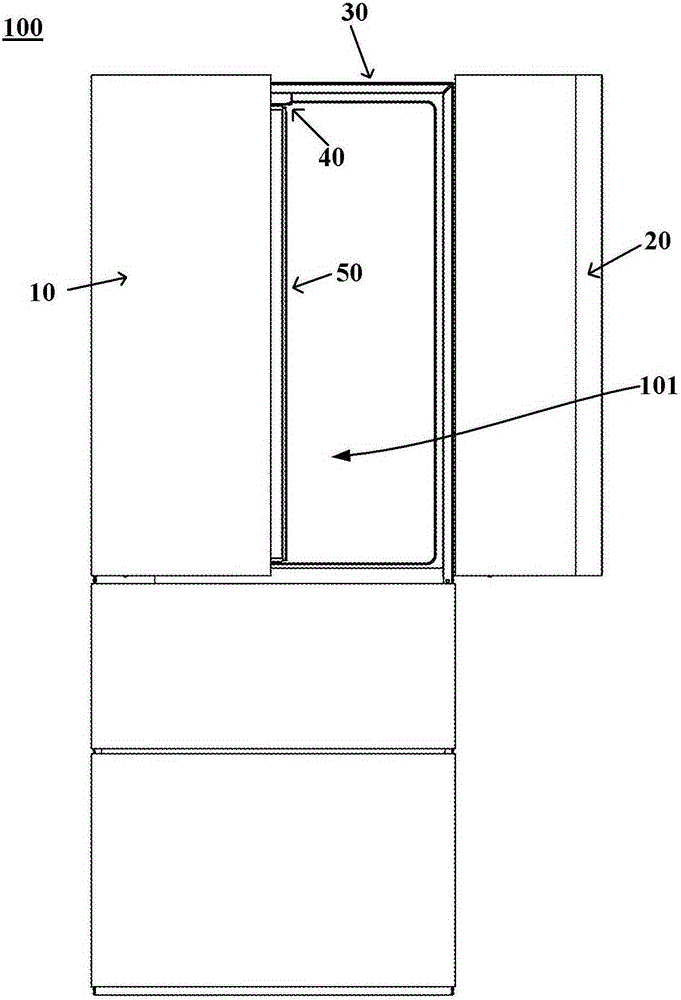

Refrigerator

InactiveCN105333668AAvoid noiseAvoid offsetLighting and heating apparatusDomestic refrigeratorsEngineeringMiddle state

The invention provides a refrigerator which comprises storage chambers, a first door body and a second door body which are pivotally arranged on the two horizontal sides of the storage chambers respectively, a vertical beam rotatably mounted at the opening end of the first door body, and a guiding element arranged at the top of the vertical beam in a vertically telescopic manner, and further comprises a front baffle plate, a back baffle plate, a first magnetic part and a second magnetic part, wherein the front baffle plate and the back baffle plate are arranged on the top walls of the storage chambers, and limit a guiding groove of which the gas faces forwards to guide the vertical beam to rotate relative to the first door body; the first magnetic part is fixed to the guiding element; the second magnetic part is fixed below the first magnetic part; and the first magnetic part and the second magnetic part are arranged in a mutual repulsion manner. According to the refrigerator, when the guiding element is positioned in front of the front baffle plate and when the first door body is closed, the guiding element retracts downwards after being in contact with the front baffle plate, and moves upwards to enter the guiding groove under the action of the repulsive force between the first magnetic part and the second magnetic part after crossing the front baffle plate; the first door body can be successfully closed when the vertical beam is in a fully expanded state or a middle state.

Owner:HAIER SMART HOME CO LTD

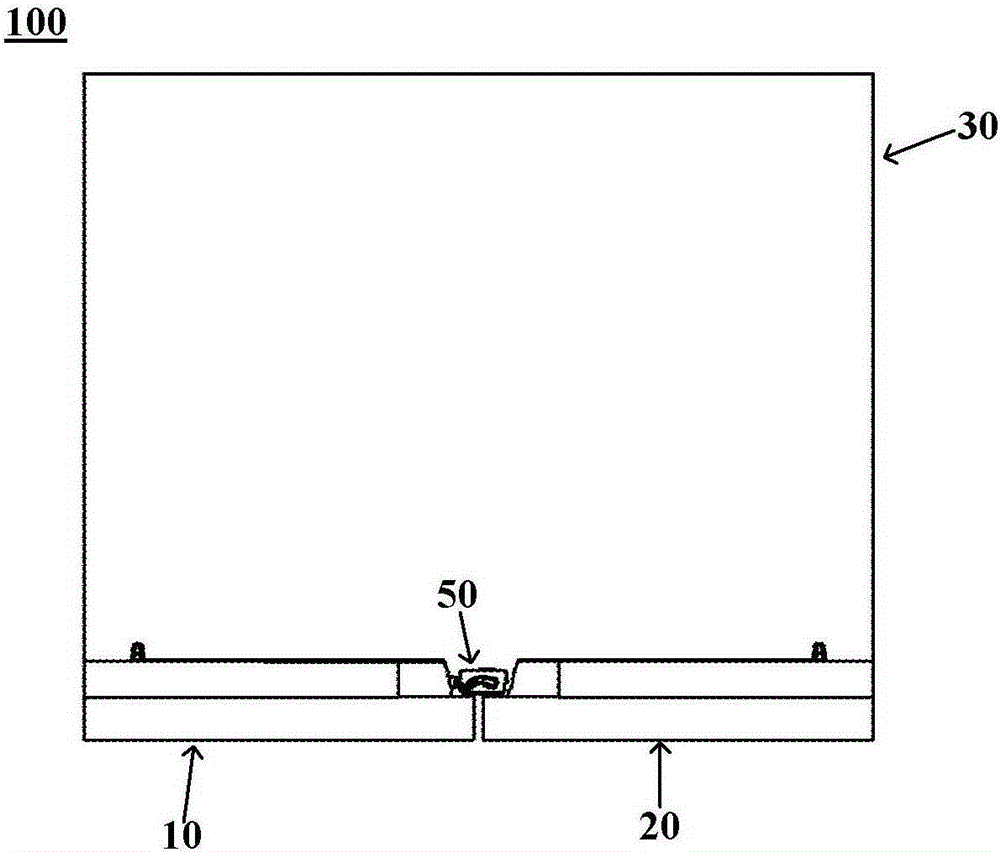

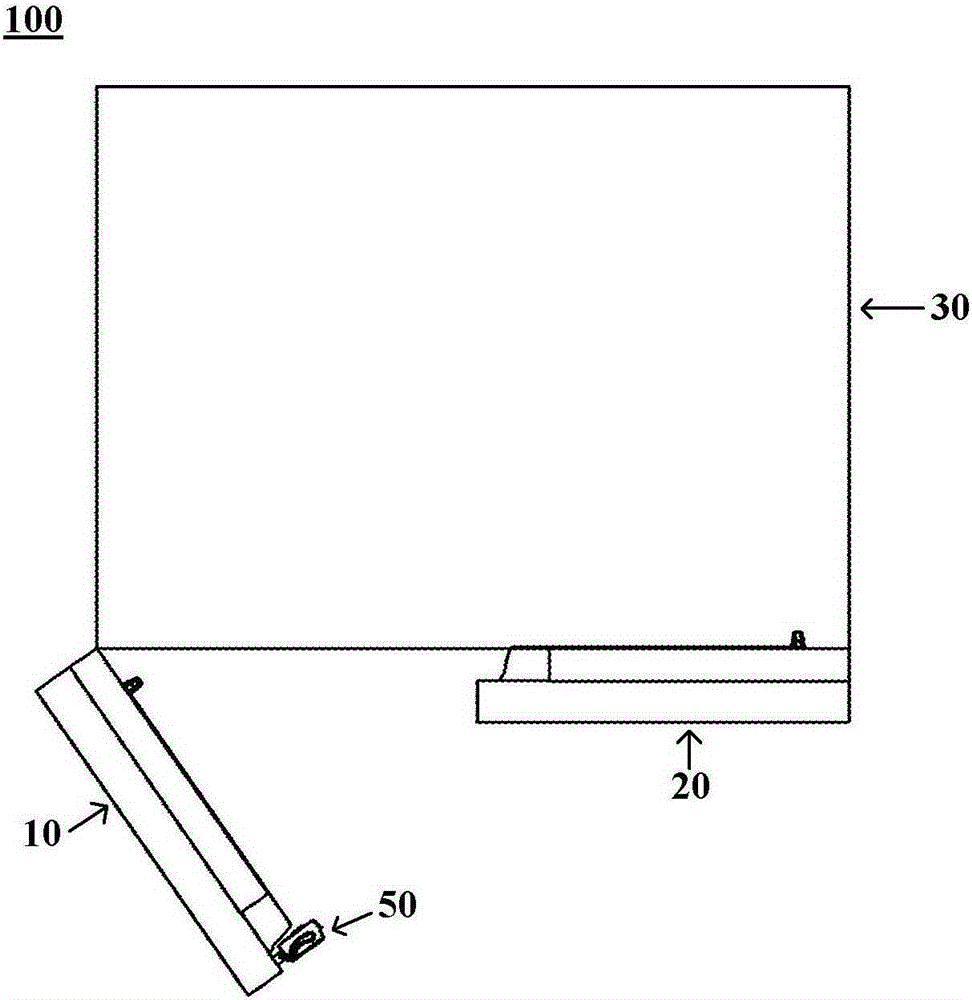

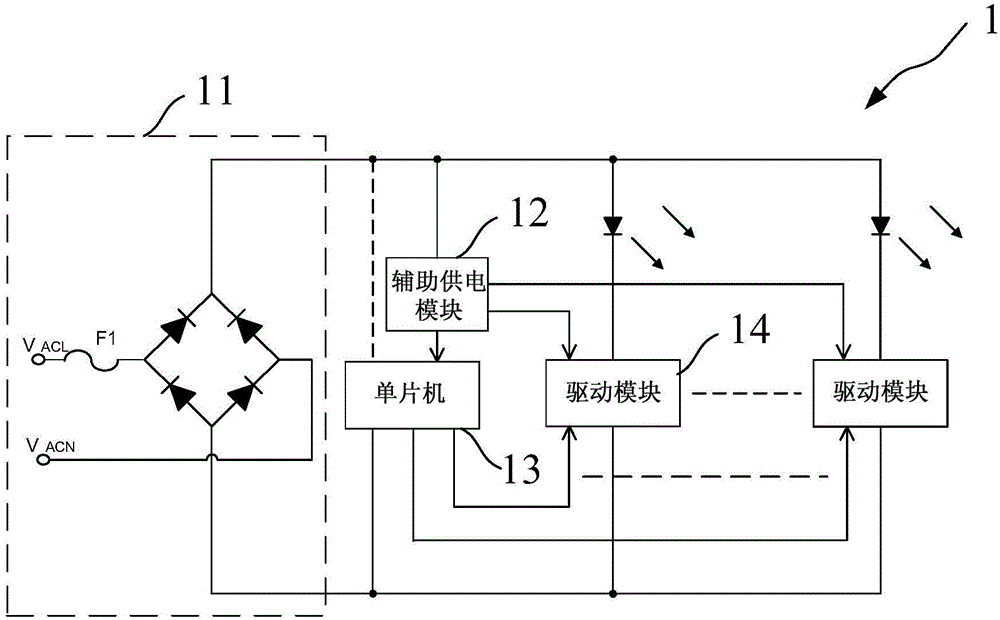

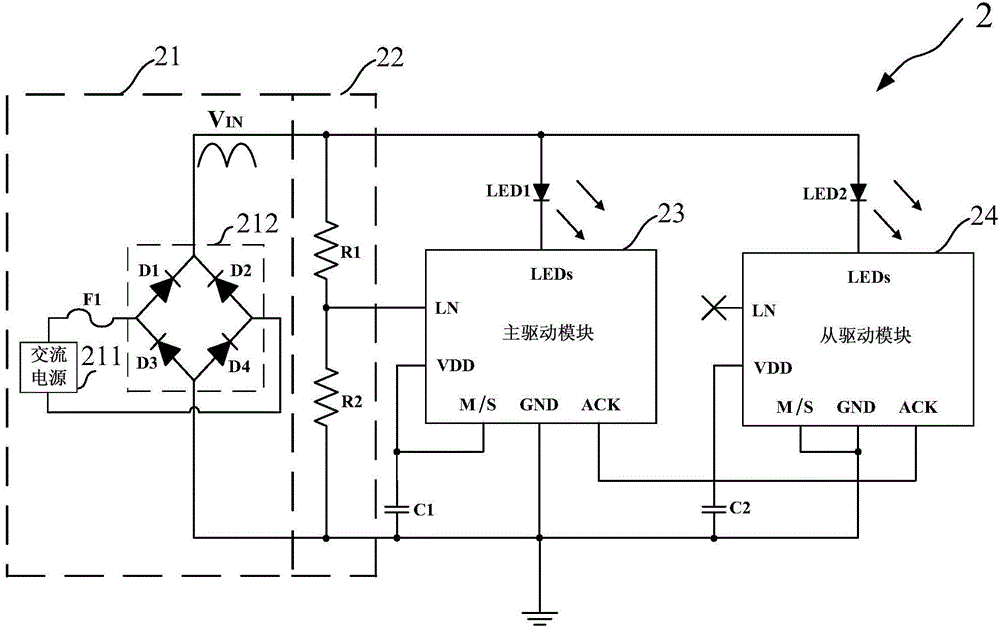

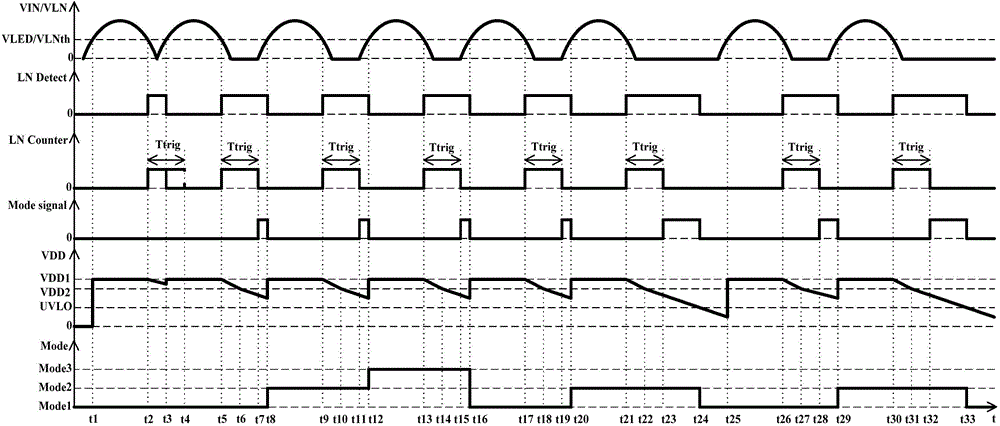

Control circuit and method for regulating color temperature or luminance of LED

ActiveCN106304518AReliable implementation of switch detection functionAvoid interferenceElectric light circuit arrangementControl circuitComputer science

The invention provides a control circuit and method for regulating a color temperature or luminance of an LED. The control circuit at least comprises a power supply module for providing an input voltage, a sampling module for sampling the input voltage, a primary driving module for regulating the color temperature or the luminance of a primary LED module according to a sampling value output by the sampling module, and multiple secondary driving modules for regulating the color temperatures or the luminance of multiple secondary LED modules according to a state control signal output by the primary driving module. According to the control circuit, the input voltage is directly sampled; when the sampling voltage is less than a set value for a certain time, the color temperature or the luminance state is changed, and each temperature or the luminance state is changed circularly; and after the switched-off driving module is re-started, it defaults that the state is changed circularly. The power supply switch is reliable in the detection function; an extra control and auxiliary power supply unit is not required; the control method is simple and efficient; the state control signal uses a middle state of high and low electric levels, so that a complex digital logic circuit can be avoided; and in addition, a low-power-consumption mode is designed for each driving module.

Owner:CRM ICBG (WUXI) CO LTD

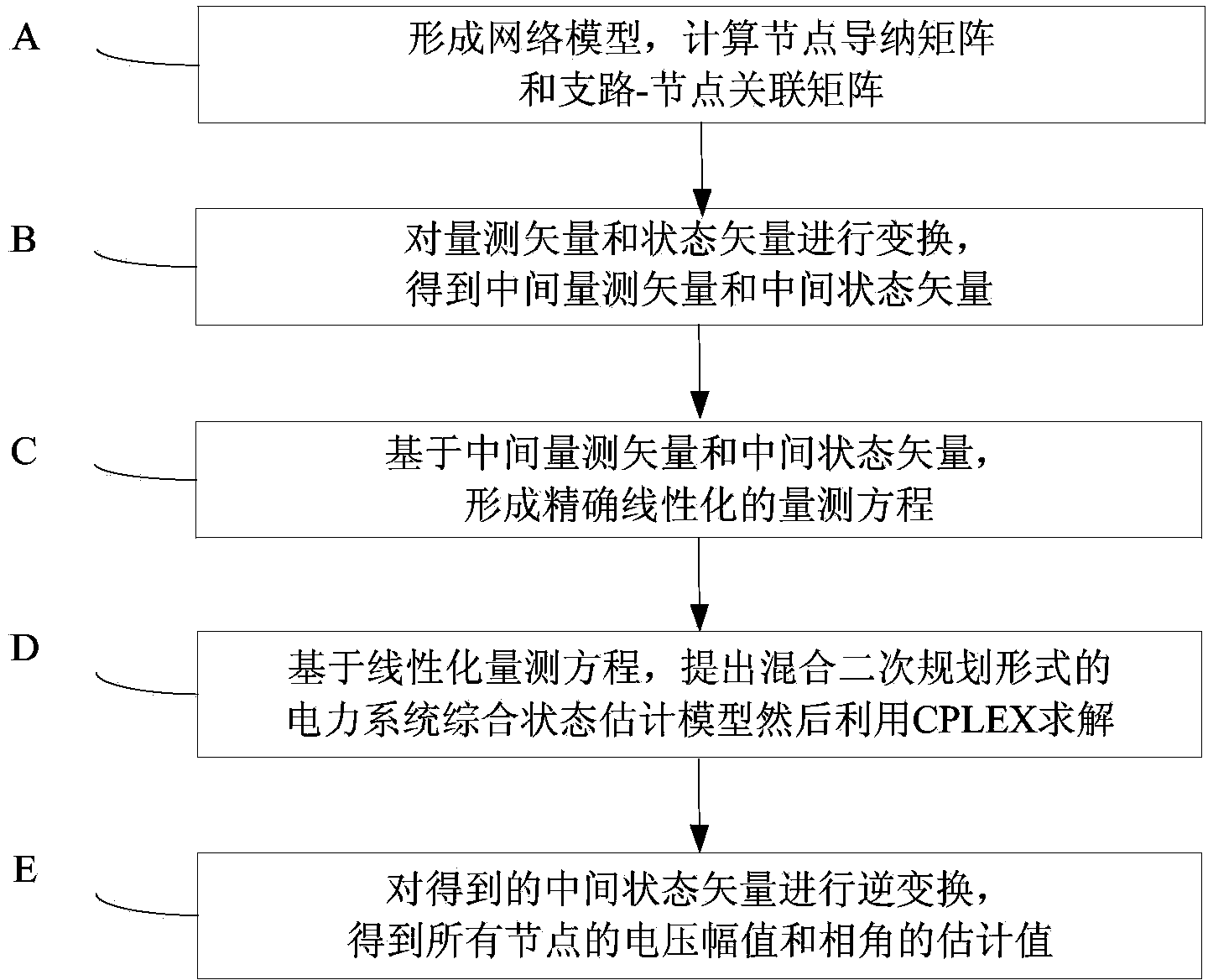

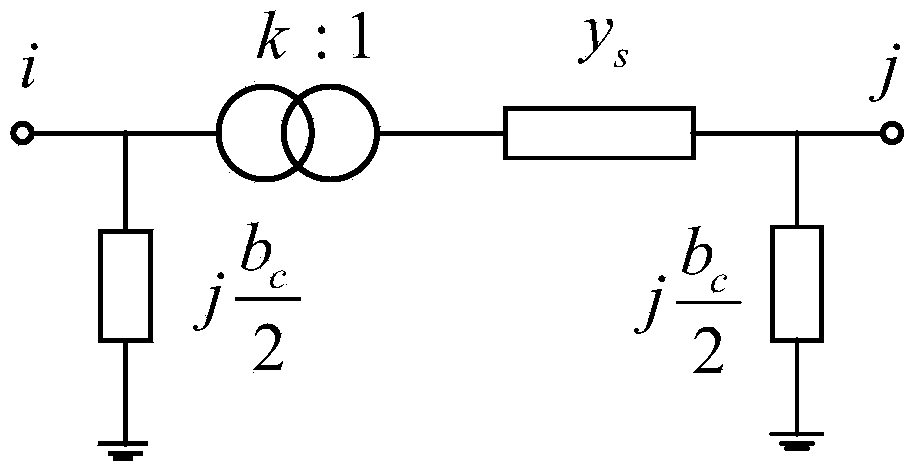

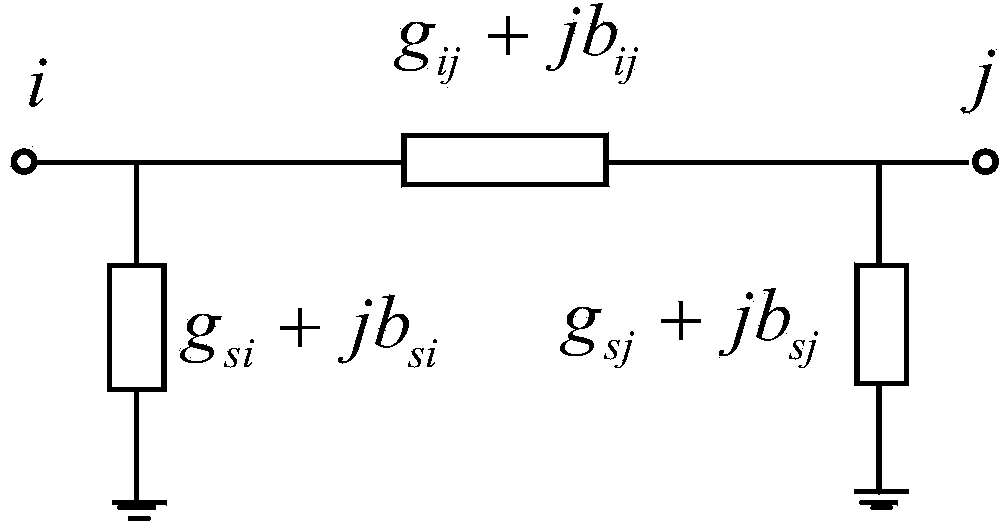

Mixing-quadratic-programming-form electrical power system synthesis state estimation method

InactiveCN103593566AImprove solution efficiencySuitable for online applicationSpecial data processing applicationsVoltage amplitudeElectric power system

The invention discloses a mixing-quadratic-programming-form electrical power system synthesis state estimation method which can comprises the following steps that a network model is formed, a node admittance matrix and a branch-node incidence matrix are computed; a measurement vector and a state vector are converted, a middle measurement vector and a middle state vector are obtained; based on the middle measurement vector and the middle state vector, a precision linearized measurement equation is formed; based on the obtained linearized measurement equation, a mixing-quadratic-programming-form electrical power system synthesis state estimation model is provided, then CPLEX software is used for solving, an estimation value of the middle state vector is obtained, bad data, topology errors and parameter errors are identified during the process; the obtained middle state vector is subjected to inverse transformation, and voltage amplitude values of all nodes and estimation values of phase angles are obtained. The method has the advantages of being accurate, reliable and high in solving efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

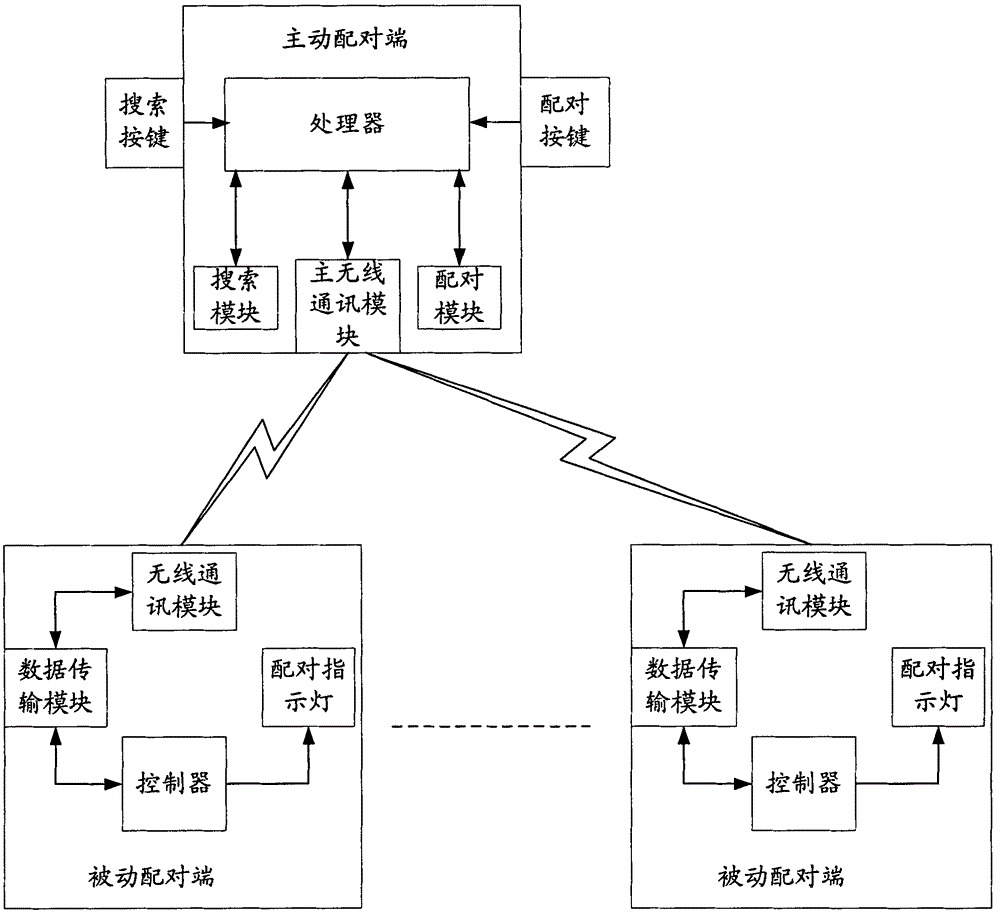

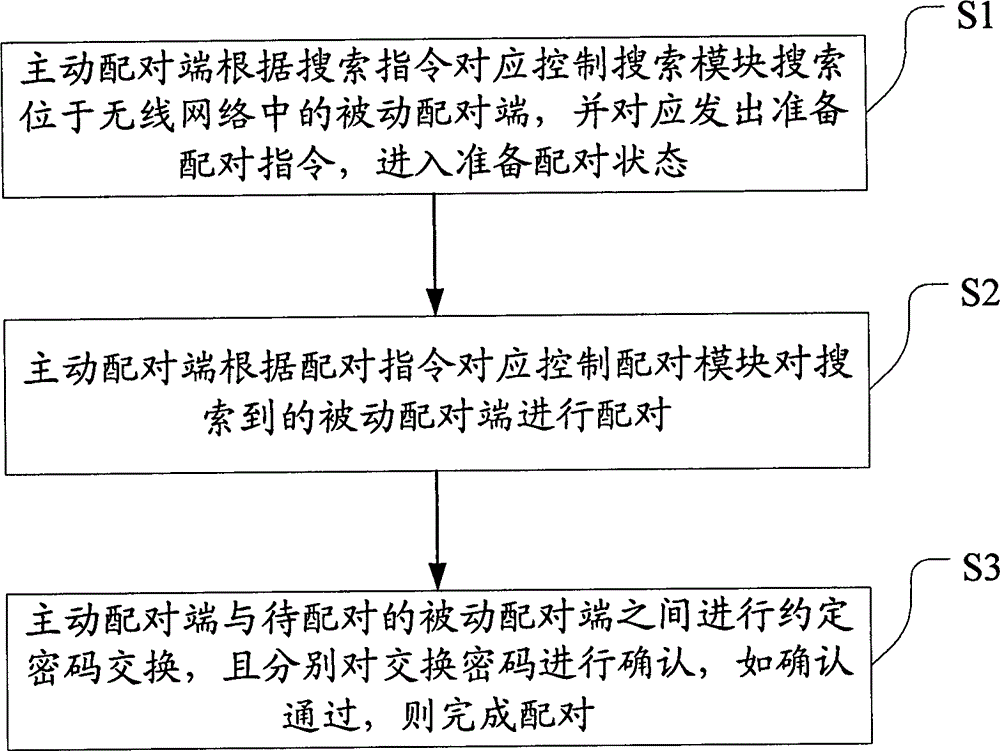

System and method for quickly pairing industrial wireless communication equipment

InactiveCN103152839AMeet special requirements for pairing methodsImprove application efficiencyConnection managementSecurity arrangementPasswordMiddle state

The invention discloses a system and a method for quickly pairing industrial wireless communication equipment. The method comprises the following steps of searching and pairing passive pairing terminals in a wireless network by active pairing terminals, and identifying passwords, so as to realize pairing. The system and the method have the advantages that the accuracy, the safety, the high speed, the automation and the non-contacting are ensured; the application efficiency of the equipment is furthest improved only by changing the equipment a little, so the quick, safe and reliable industrial wireless communication equipment is established, and the special requirement on the pairing method of the industrial wireless communication equipment by a user is greatly met; the requirement is met by increasing a middle state of a wireless communication pairing process, and the technical problem that the prior industrial wireless communication pairing method cannot simultaneously ensure the accuracy, the safety, the high speed, the automation and the non-contacting is solved.

Owner:LAUNCH SOFTWARE DEV

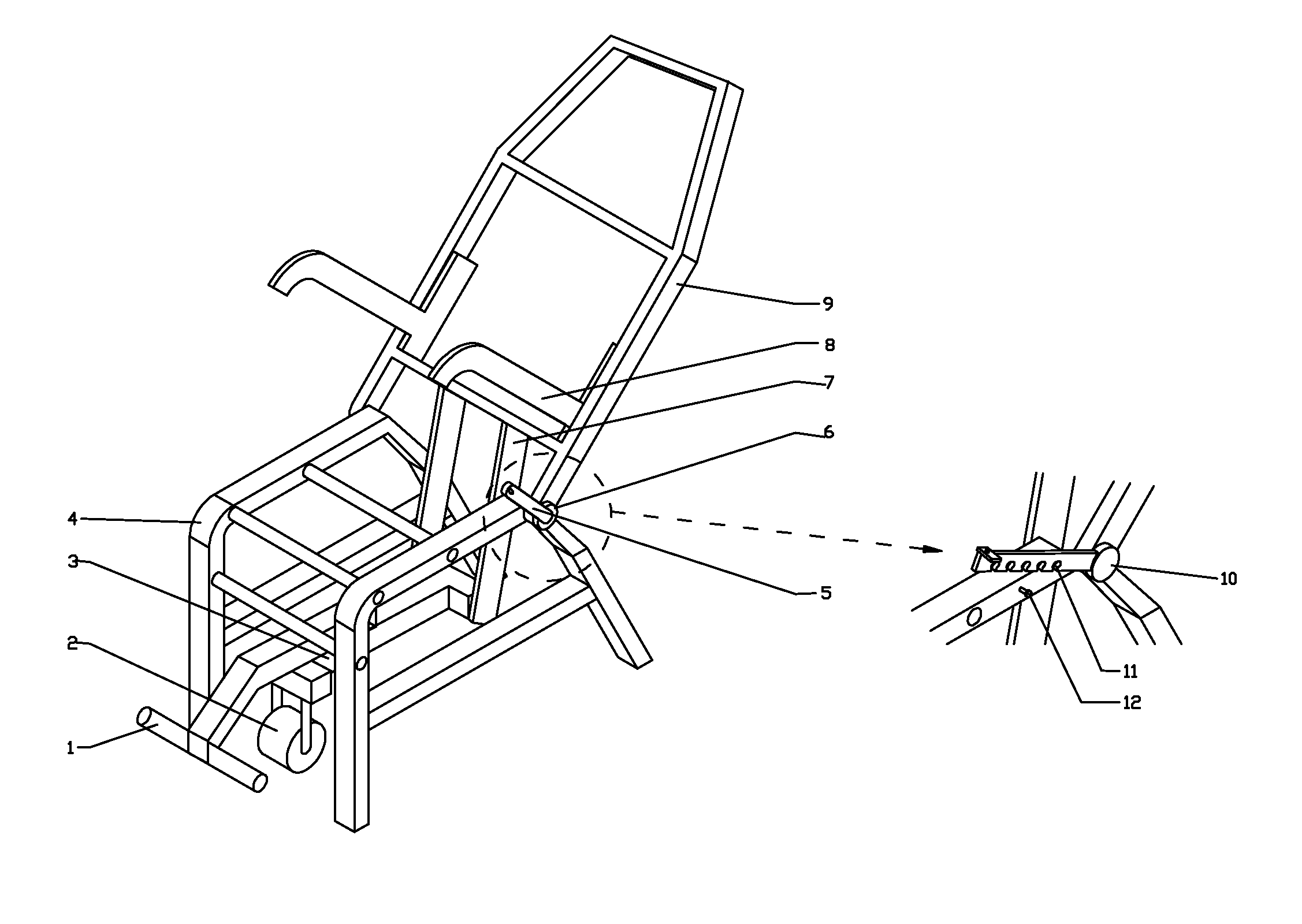

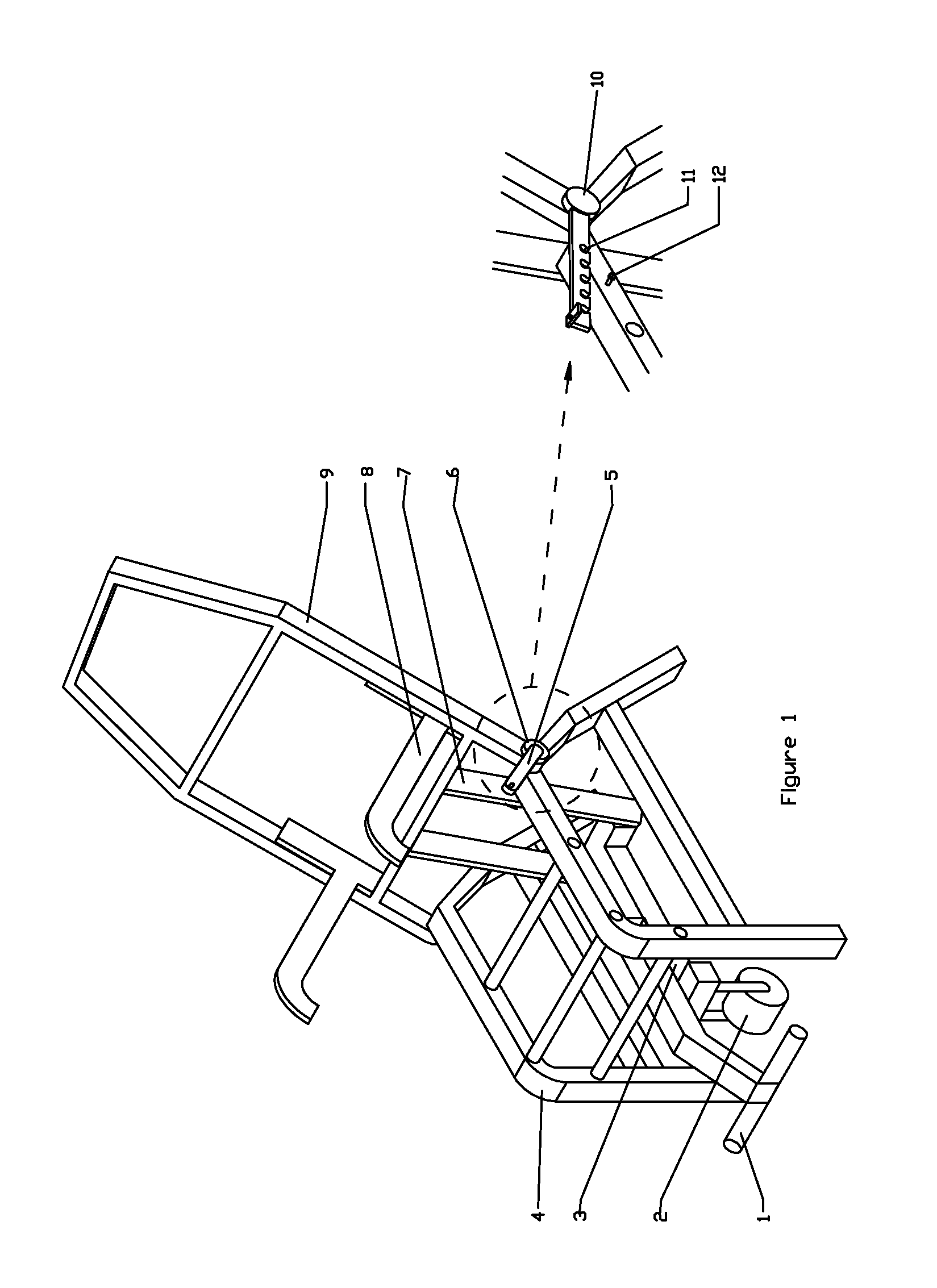

Chair with multiple exercising functions

A multifunction office / fitness chair includes a backrest with an armrest and a seat connected with the backrest through a pivot. The backrest is also connected with a footrest through a footrest connection device. The backrest is able to rotate 90 degrees around the pivot, so that the chair can be switched among an office-chair state for work, a recliner state for exercise and a middle state for rest. A user can use the chair of the invention for work and for exercise in a bedroom or an office without limitations to access to equipment, location and time. Using the chair to exercise three to five minutes per day can help lose weight effectively.

Owner:MAN YAN GAO +1

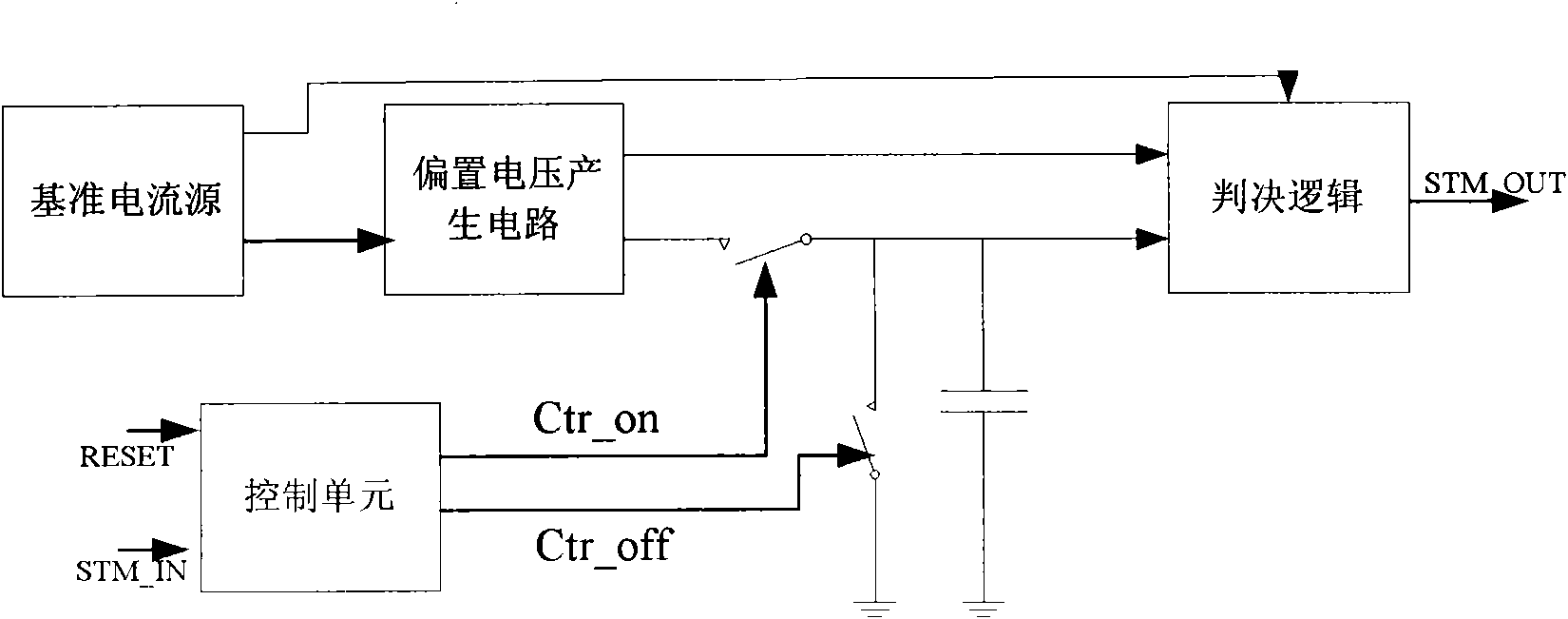

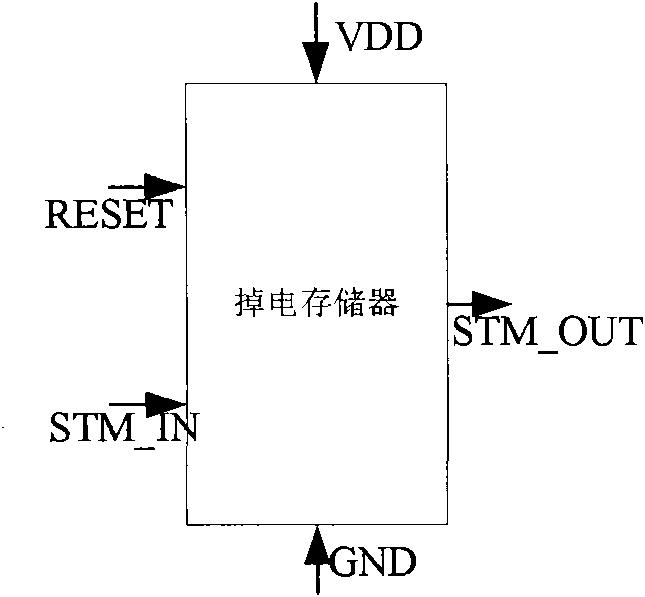

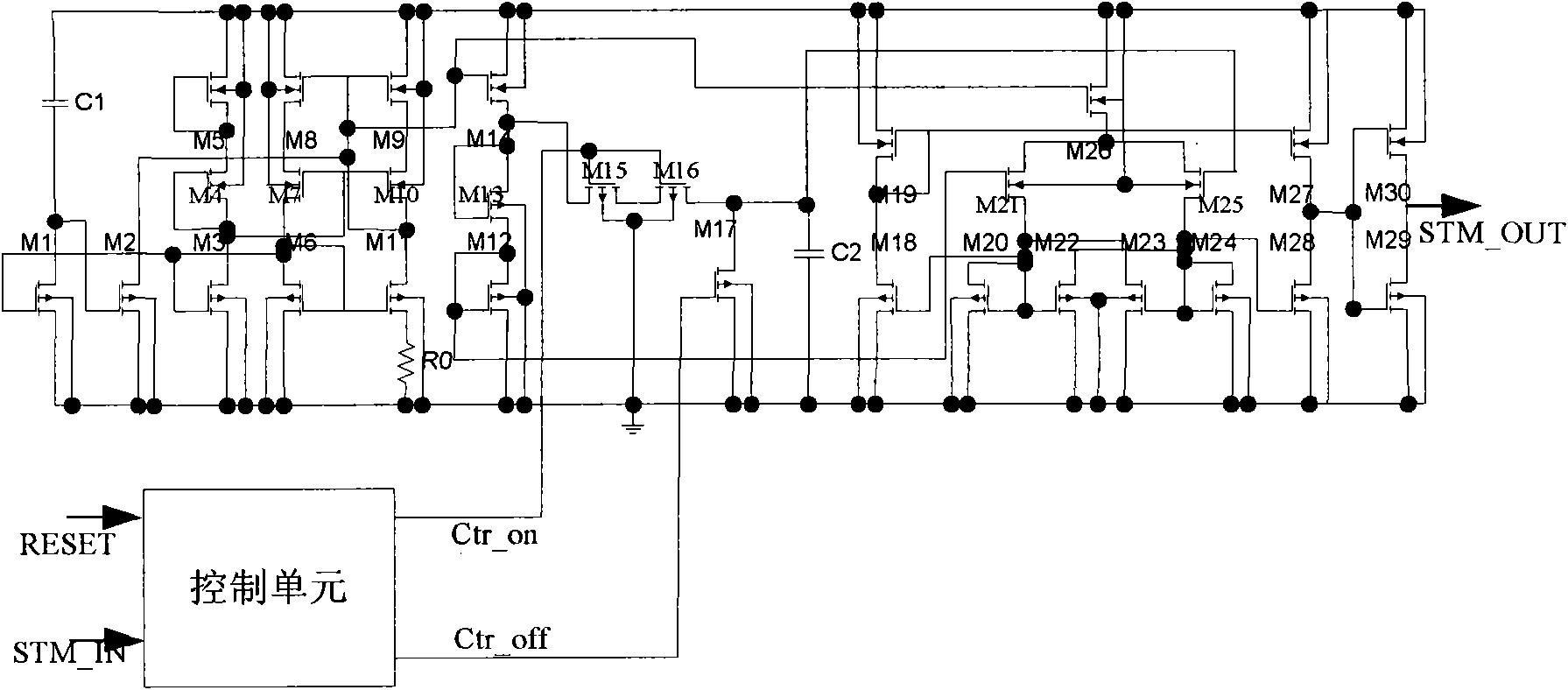

Power-failure transient memory used for passive radio-frequency identification labeled chip

ActiveCN101587743ADigital storageRecord carriers used with machinesReference currentShortest distance

The invention discloses a power-failure transient memory used for a passive radio-frequency identification labeled chip, and relates to memory technology in the field of circuits. The power-failure transient memory is supplied with power by a power supply voltage VDD and comprises a reference current source, a control unit, a bias voltage generating circuit, a storage unit and a judgment logic, wherein the reference current source supplies bias current for the storage unit and the judgment logic; the control unit generates a control signal according to a reset signal RESET provided by a digital circuit and information STM-IN to be stored to operate the storage unit; the bias voltage generating circuit converts reference current generated by the reference current source into reference voltage as a reference signal of the judgment logic; the storage unit carries out transient storage on the information to be stored according to the instruction of the control unit; and the judgment logic compares the relation of the storage content of the storage unit and the reference voltage, converts an analog signal into a digital signal STM-OUT and outputs the digital signal into the digital circuit. The power-failure transient memory can store state information of the labeled chip before power failure or a middle state of the digital circuit for short time, and improve the efficiency and stability of short-distance wireless communication.

Owner:BEIJING TONGFANG MICROELECTRONICS

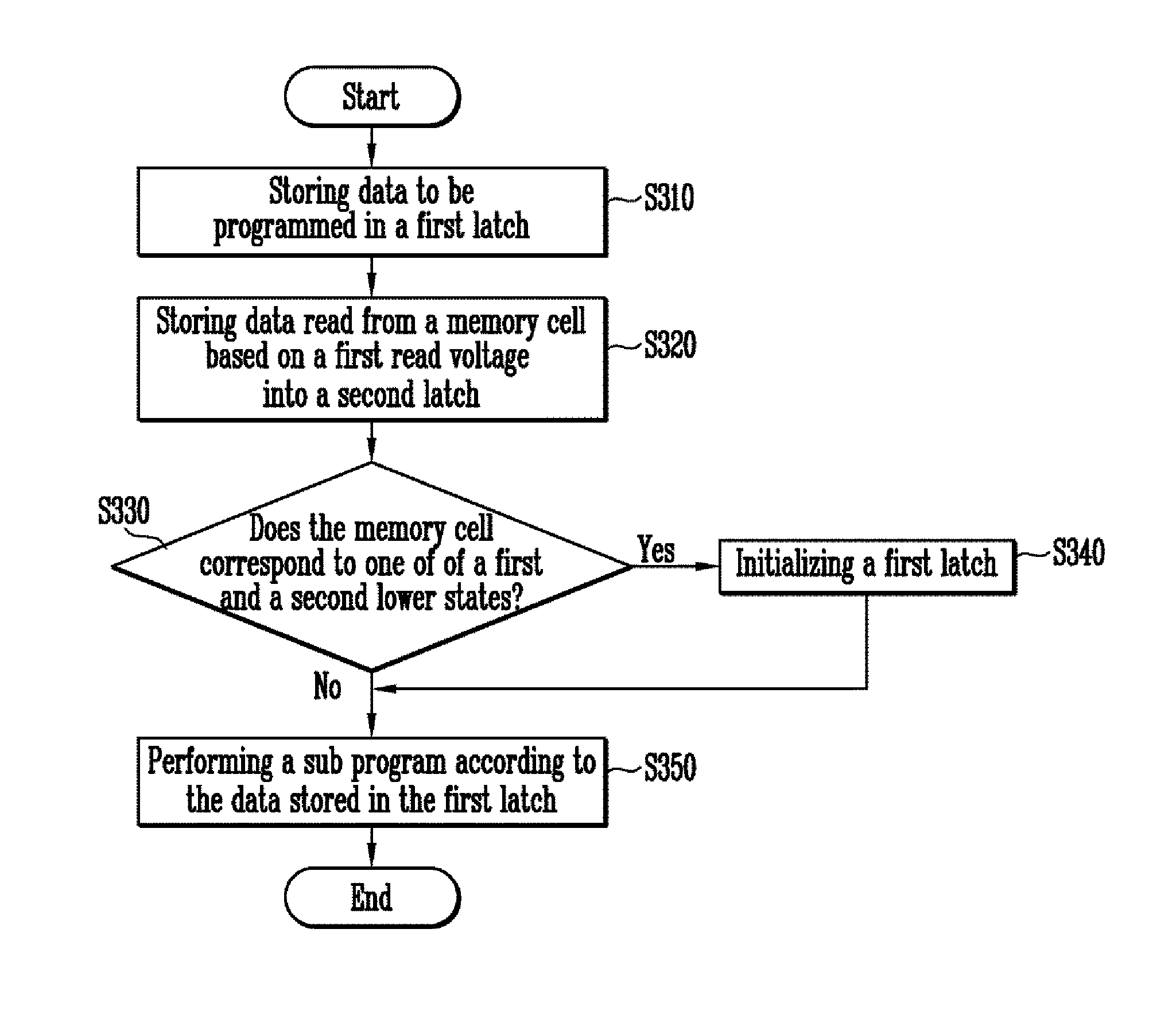

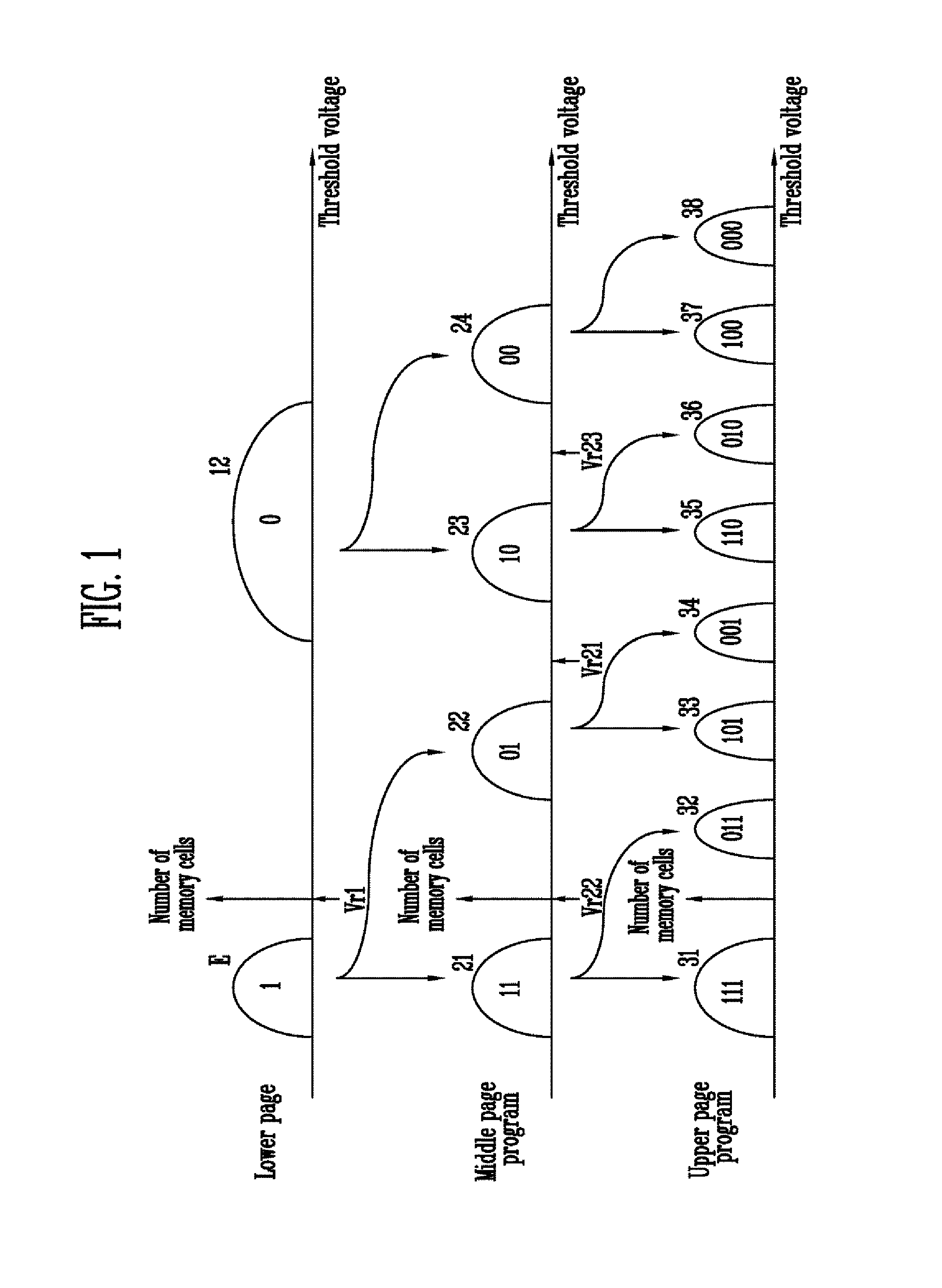

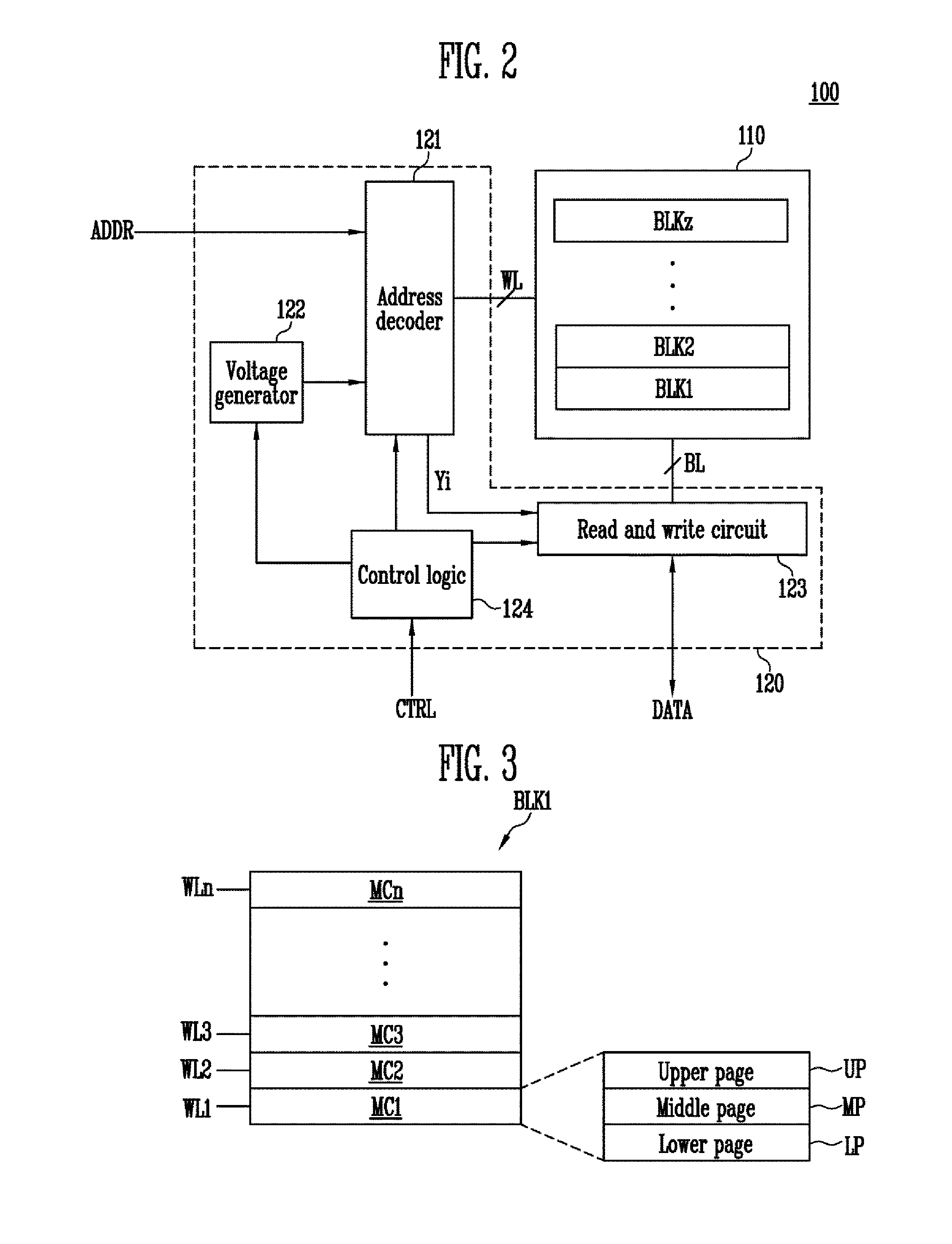

Semiconductor memory device and method of operating the same

A semiconductor memory device is provided. The semiconductor memory device includes memory cells having first to fourth middle states corresponding to different threshold voltage distributions. The semiconductor memory device also includes a peripheral circuit configured to perform a first program operation to program memory cells having the third and the fourth middle states to have four upper states and perform a second program operation to program memory cells having the first and the second middle states to have another four upper states.

Owner:SK HYNIX INC

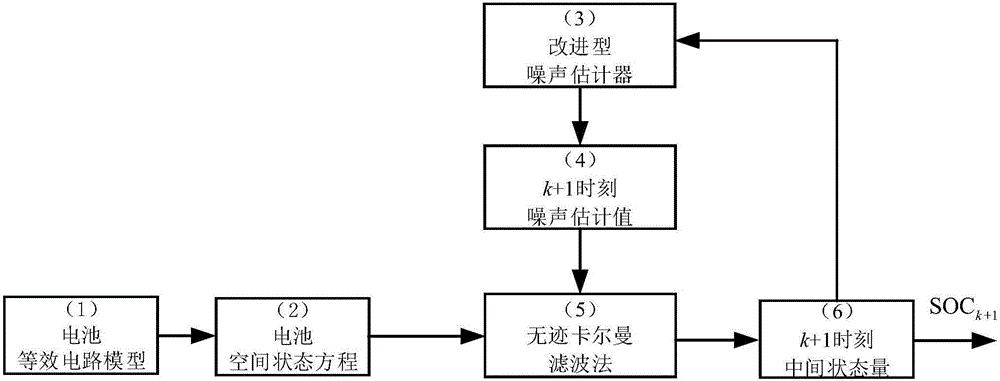

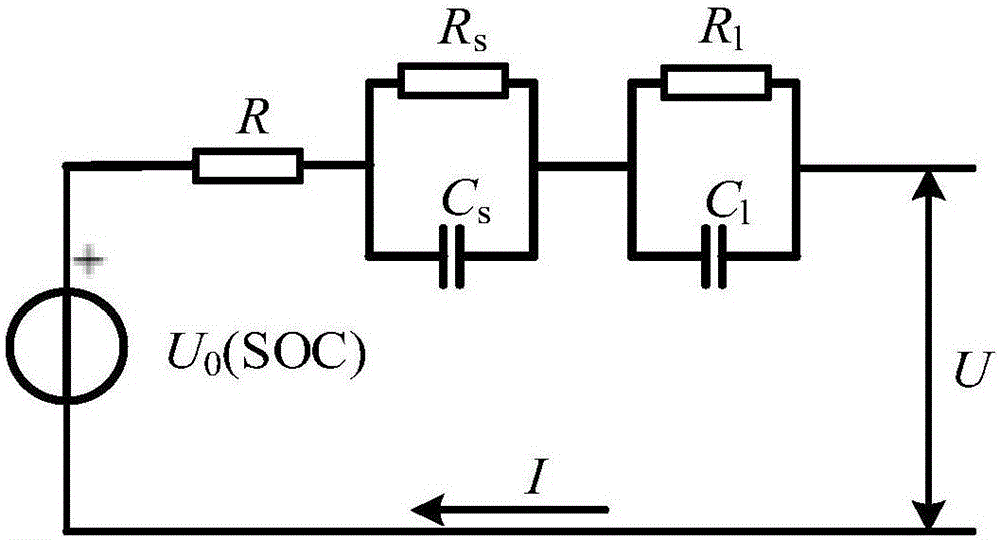

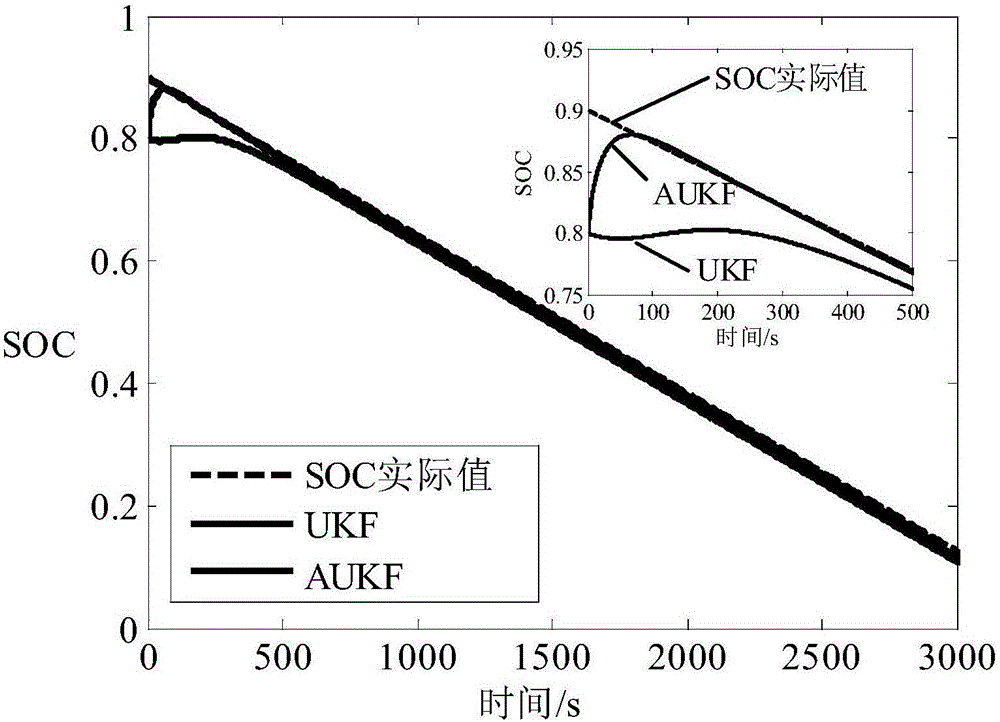

Battery charge state estimation method with improved noise estimator

InactiveCN106443496AHigh precisionFast convergenceElectrical testingBattery chargeEstimation methods

The invention discloses a battery charge state estimation method with an improved noise estimator. The method comprises the following steps of: according to an equivalent circuit model of a battery, establishing a spatial state equation of the battery, and acquiring a noise estimation value as shown in the specification at a moment K by using the improved noise estimator; furthermore, by taking the noise estimation value as noise counting information of a self-adaptive unscented Kalman filter method, with the combination of the spatial state equation of the battery, performing battery charge state estimation by using the self-adaptive unscented Kalman filter method so as to obtain a middle state amount as shown in the specification at the moment k, and by taking the middle state amount as the input amount of the improved noise estimator at the moment k+1, performing circulation recursion, thereby obtaining a battery charge state estimation value. The battery charge state estimation method with the improved noise estimator, which is disclosed by the invention, is relatively high in estimation precision and relatively good in robustness when compared with a standard unscented Kalman filter method.

Owner:YANCHENG INST OF TECH

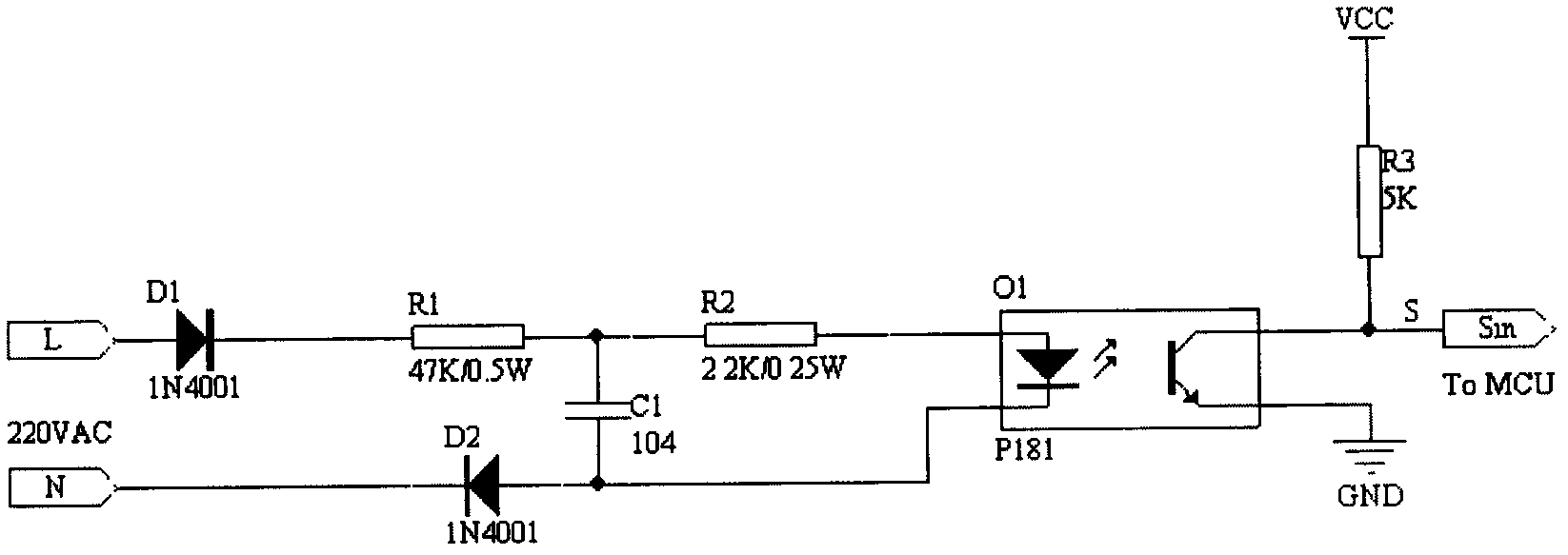

Alternating-current 220V input signal acquisition circuit

InactiveCN103076490ASafe collectionImprove securityMeasurement using ac-dc conversionElectrical resistance and conductanceDistributed filtering

The invention discloses an alternating-current 220V input signal acquisition circuit. The alternating-current 220V input signal acquisition circuit is characterized in that one end of an alternating-current 220V input signal is connected with a semiwave rectifying module which is connected with a voltage-distributing filtering module; the voltage-distributing filtering module is connected with one end of the input of a photoelectric isolating module, and the other end of the input of the photoelectric isolating module is connected with a protection module; the protection module is connected with the other end of the alternating-current 220V input signal; one end of the output end of the photoelectric isolating module is grounded, and the other end of the output end of the photoelectric isolating module is connected with a pull-up resistor and then is connected with an IO pin of an acquired MCU (Micro Controller Unit) so as to realize the circuit for directly isolating and acquiring the 220V input signal. Compared with the prior art, the alternating-current 220V input signal acquisition circuit disclosed by the invention has the advantages that any MCU can realize safe and reliable acquisition of the alternating-current 220V input by the circuit; and the middle state-quantity conversion device is reduced, the system is optimized, the system security is improved, the cost is saved and the safe operation is effectively ensured.

Owner:SHANGHAI HUAJIAN ELECTRICAL EQUIP

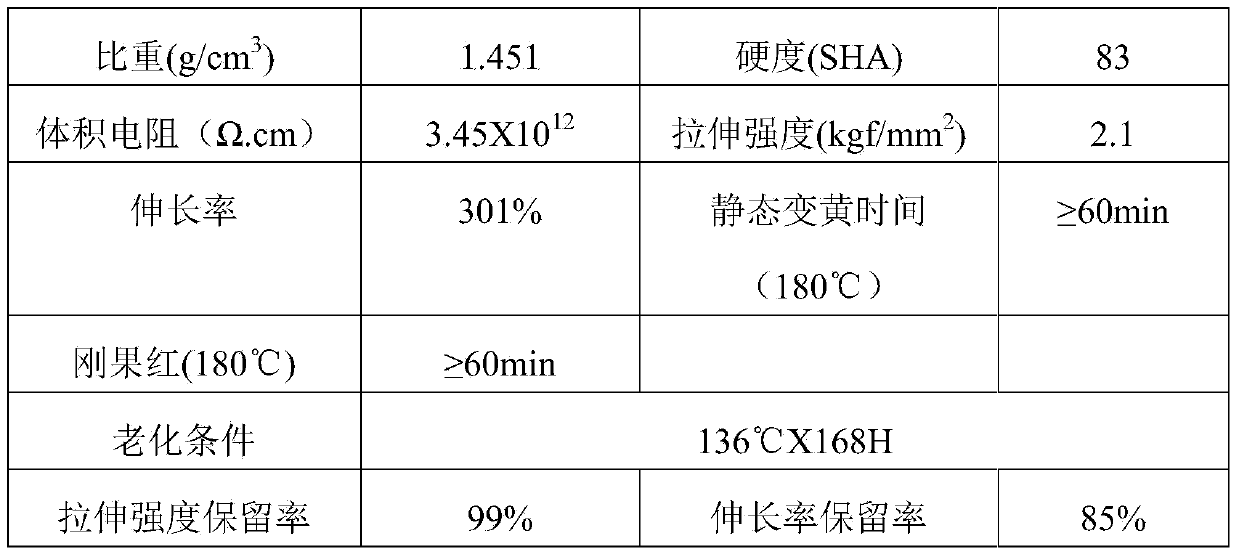

Environmental protection and high temperature resistant PVC (polyvinyl chloride) compound calcium-zinc stabilizer

InactiveCN104194221AImprove mid-late aging effectSolve the defect of insufficient coloring stabilityPolyvinyl chlorideFatty acid

The invention discloses an environmental protection and high temperature resistant PVC (polyvinyl chloride) compound calcium-zinc stabilizer. The stabilizer comprises the following components in percentage by weight: 10 to 20% of fatty acid zinc, 10 to 40% of fatty acid calcium, 10 to 20% of beta-diketone, 20 to 40% of zeolite, 5 to 15% of THEIC (trihydroxyethyl isocyanurate) and 5 to 10% of sodium perchlorate. The environmental protection and high temperature resistant PVC compound calcium-zinc stabilizer disclosed by the invention has good stability in the earlier stage, the middle state and the later stage, and can protect PVC from aging comprehensively in a three-dimensional manner, so that the integrated heat-proof stabilizing effect of the product far exceeds the effect of the ordinary monomer calcium-zinc stabilizer, product performances are completely in conformity with a standard requirement of 105 DEG C of UL62, and the product has an excellent appearance, furthermore, the product does not contain heavy metals, such as lead and cadmium, and completely does not contain substances in SVHC (Substances of Very High Concern) in the latest EU (European Union) REACH instruction, thereby meeting the new development trend in the world today, and being a material with wide application prospects.

Owner:湘乡市贝特尔塑胶有限公司

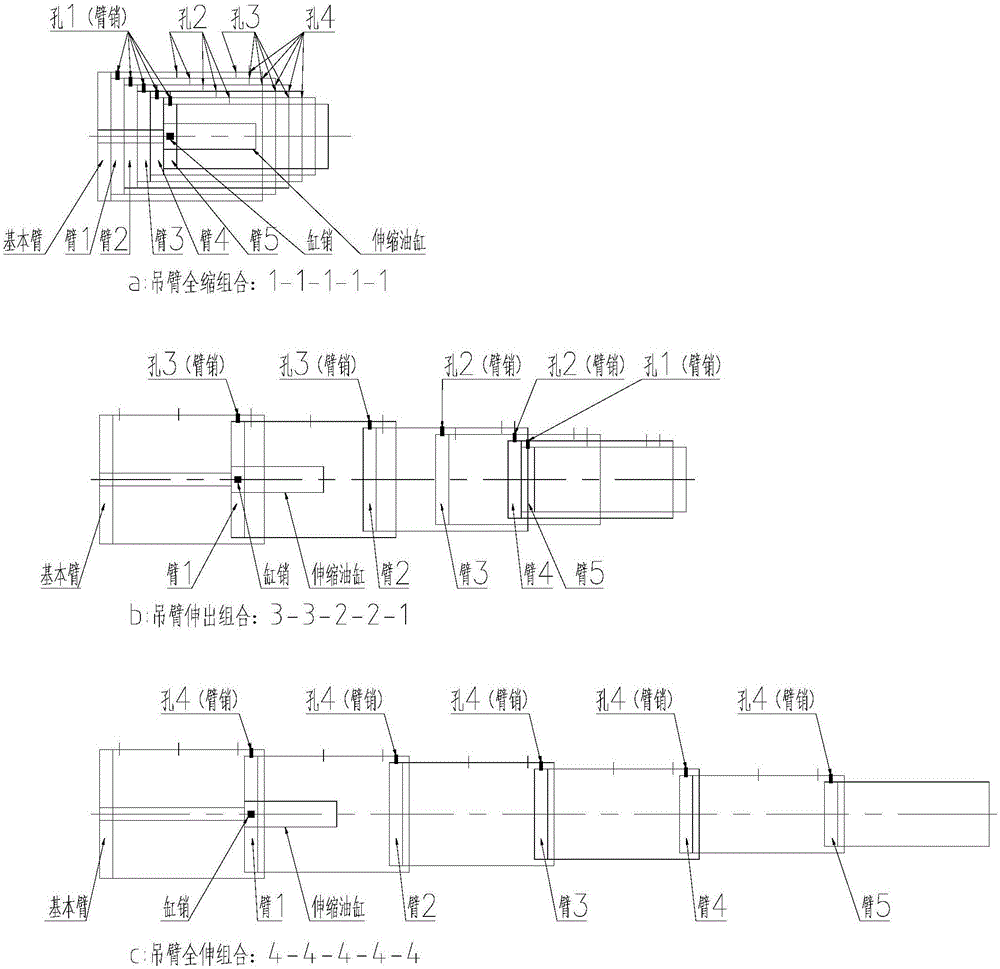

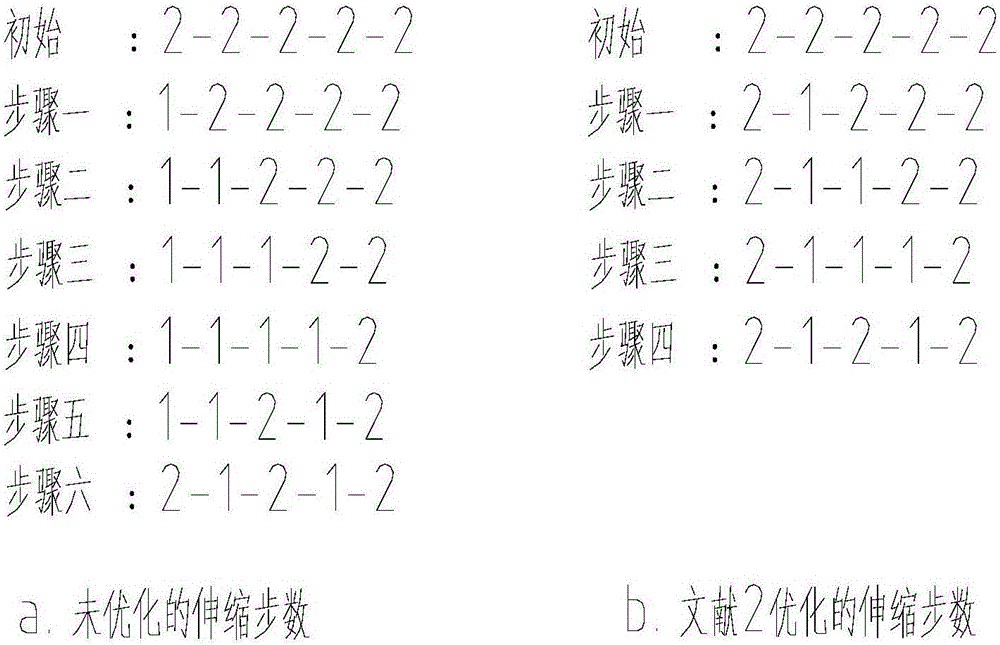

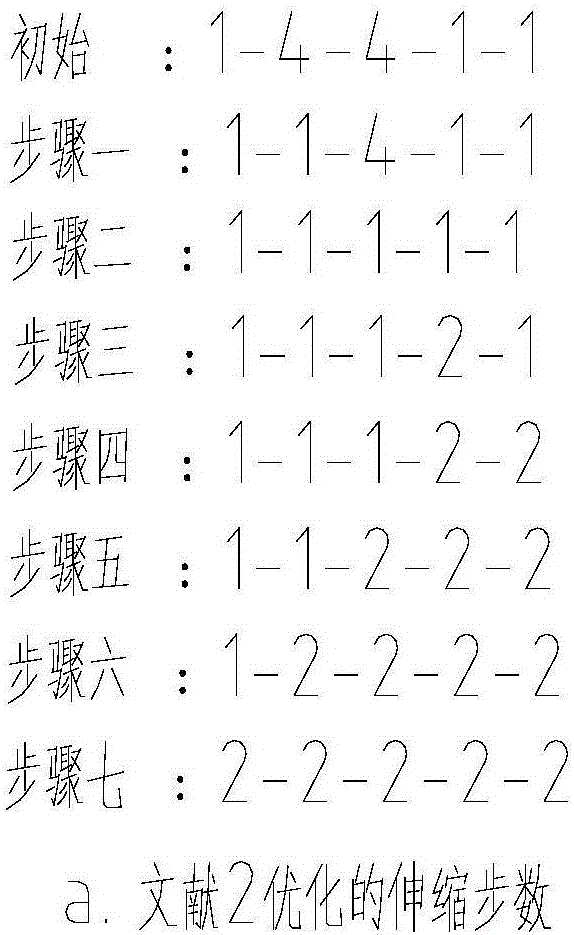

Single-cylinder bolt multistage sequential extension path optimization method

ActiveCN106744386AReduce the number of telescopic stepsImprove scaling efficiencyCranesComputer scienceMiddle state

The invention relates to a single-cylinder bolt multistage sequential extension path optimization method, and belongs to the single-cylinder bolt multistage sequential extension path optimization method. Middle states of all arc sections are extracted according to three states for arrangement and combination to generate multiple middle state sets tM{}; and a shrinkage arm limit combination to be searched is searched from the generated middle state sets. The middle state sets are sent to an estimation formula series in sequence; and the state sets satisfied by all estimation formulas are the shrinkage arm limit state sets. The method is simple and clear in flow, and in particular, is suitable for program realization; and in particular, when the arm section number n and the pin hole number m are increased, the program can be conveniently performed.

Owner:JILIN UNIV

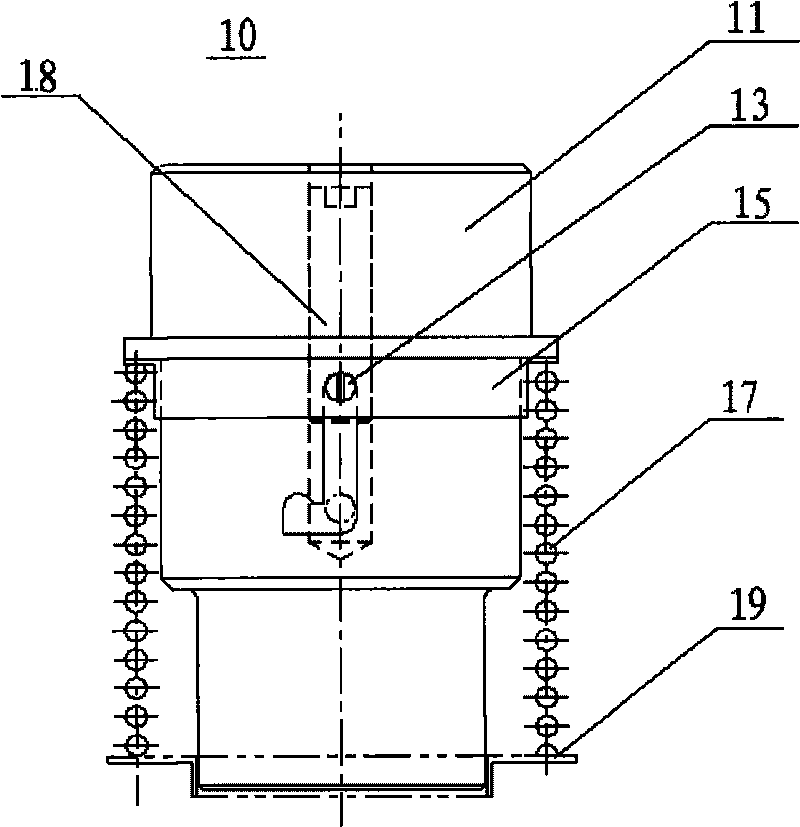

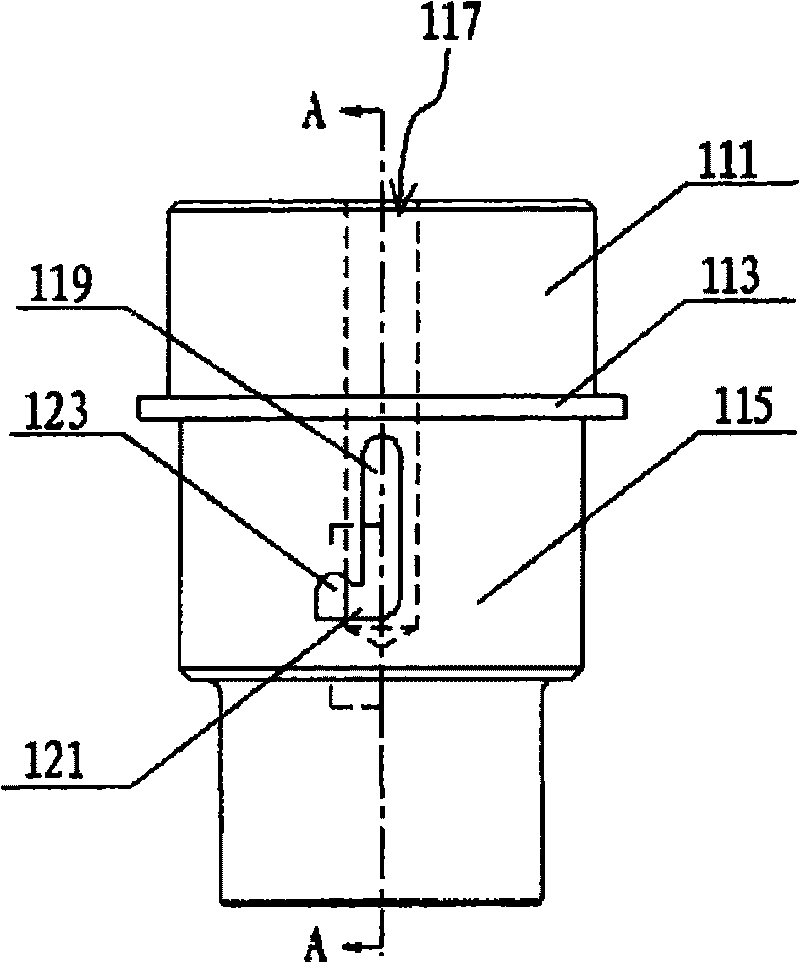

Arm pin structure of suspension arm and arm pin assembly and disassembly mechanism thereof

ActiveCN101734561AAvoid being in the middle of such a situationGuaranteed reliabilityMetal-working hand toolsCranesEngineeringExtreme position

The invention discloses an arm pin structure of a suspension arm. The arm pin structure comprises an arm pin, a spacer sleeve, a spring, a guide rod and a pin, wherein the arm pin is provided with a centre hole, the wall of the arm pin is provided with a groove penetrating the centre hole; the spacer sleeve is sheathed on the arm pin; one end of the spring is butted with the spacer sleeve; the guide rod is rotatablely arranged in the centre hole of the arm pin; the pin is arranged in the groove of the arm pin and is used to fixedly connect the guide rod and the spacer sleeve; the groove is provided with a positioning part for limiting the extreme position of the pin, and the extreme position of the pin corresponds to the upper extreme position or lower extreme position of the arm pin. The invention has the advantages of high efficiency, low labor strength and the like; in addition, the arm pin only can be in a working state or a compressed state so as to avoid the situation that the arm pin is in a middle state, caused by an accidental operation and safety hazard is caused to affect stability of the axial orientation of the suspension arm. The invention also discloses an arm pin assembly and disassembly mechanism which adopts the lever principle to compress the arm pin spring, thus the time for completing the compression of the arm pin spring is shorter.

Owner:ZOOMLION HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com