Horizontal well delivery tractor perforating tool

A technology for tractors and horizontal wells, which is applied to drilling equipment, boreholes/well components, and production fluids, etc. It can solve the problems of heavy dismantling work, high requirements for transportation roads, and perforating equipment dropping wells, so as to prevent misfires The effects of reducing perforation accidents, improving perforation benefits, and reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

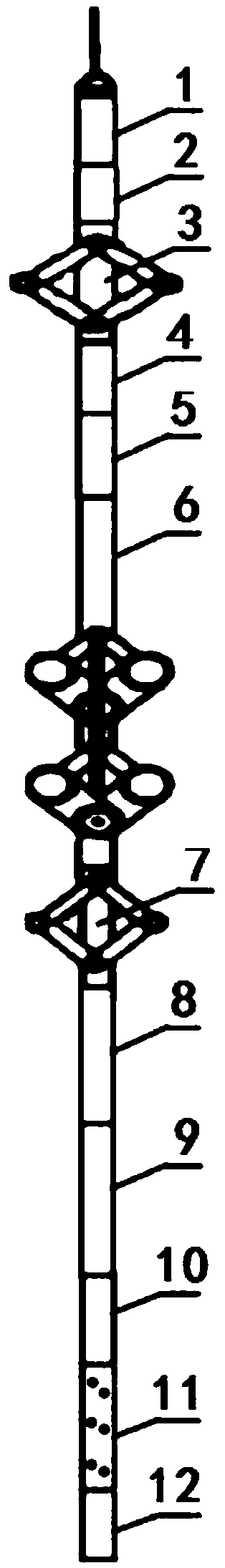

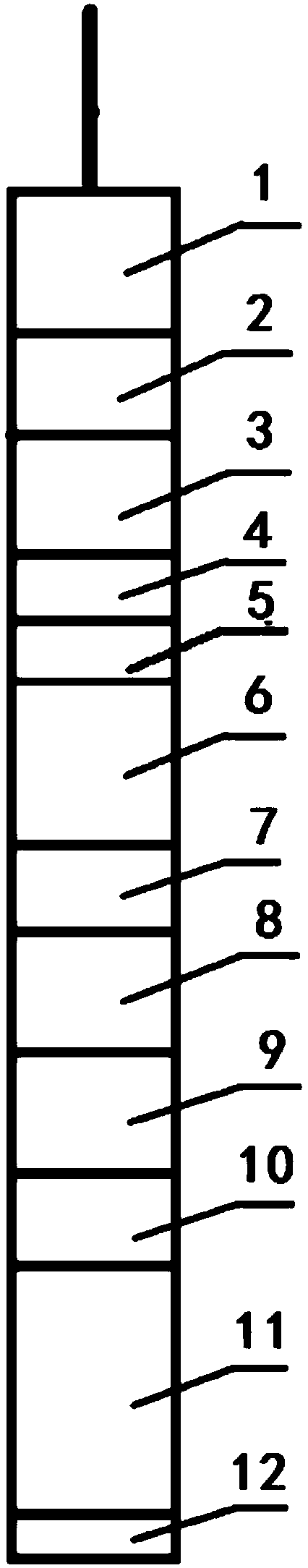

[0022] refer to figure 1 , 2 , the throwing short joint 1 of the present invention, the rotating joint 2, the upper centralizer 3, the braking joint 4, the magnetic positioning joint 5, the tractor 6, the lower centralizer 7, the flexible joint 8, the safety power supply joint 9, The shock absorber 10, the perforator 11 and the ball gun tail 12 are sequentially connected as a whole through threaded fasteners from top to bottom. The cable bridle is conveniently and quickly connected with the drop joint through a screw thread.

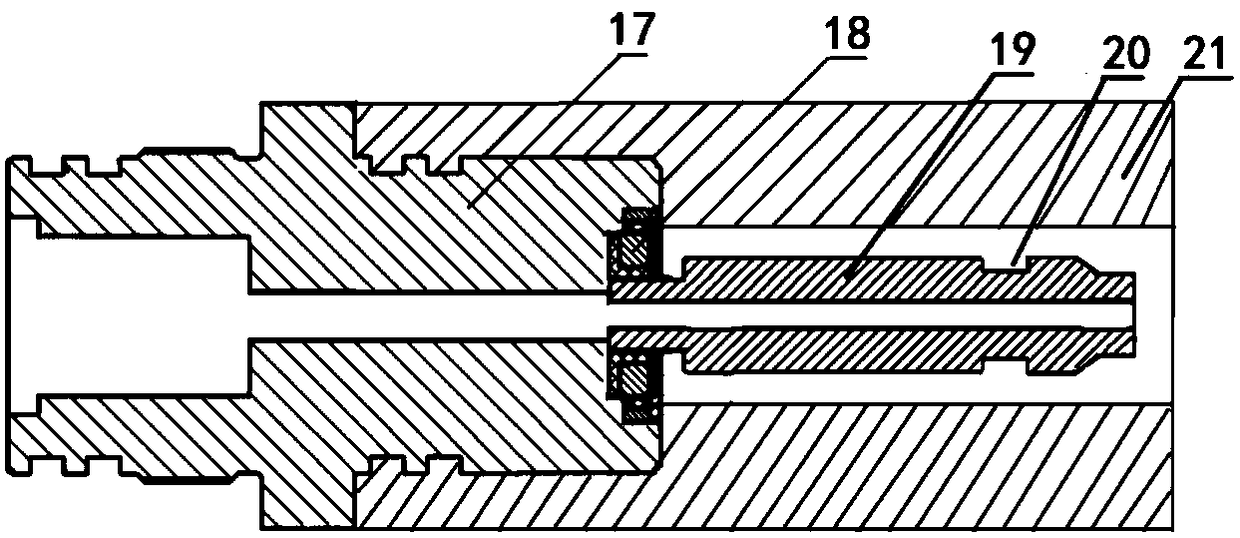

[0023] refer to image 3 , 4 , the drop-hand short joint 1 is composed of upper and lower joint components. The upper joint 17 of the upper joint assembly is screwed to the cable horse head, the lower joint one of the upper joint assembly is screwed to the outer tube 21, and the connecting sleeve 19 located in the outer tube is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com