Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

896 results about "Extreme position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

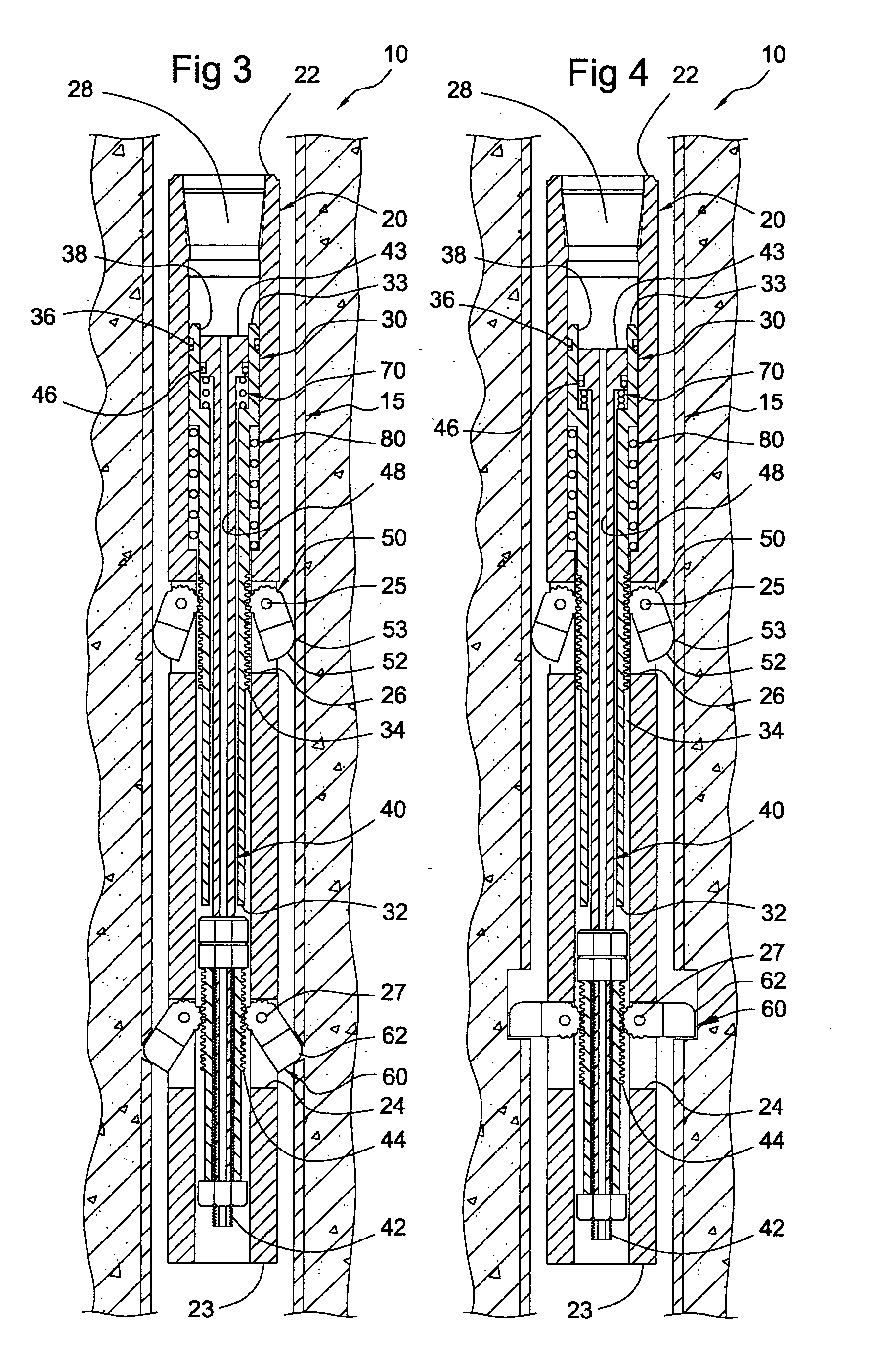

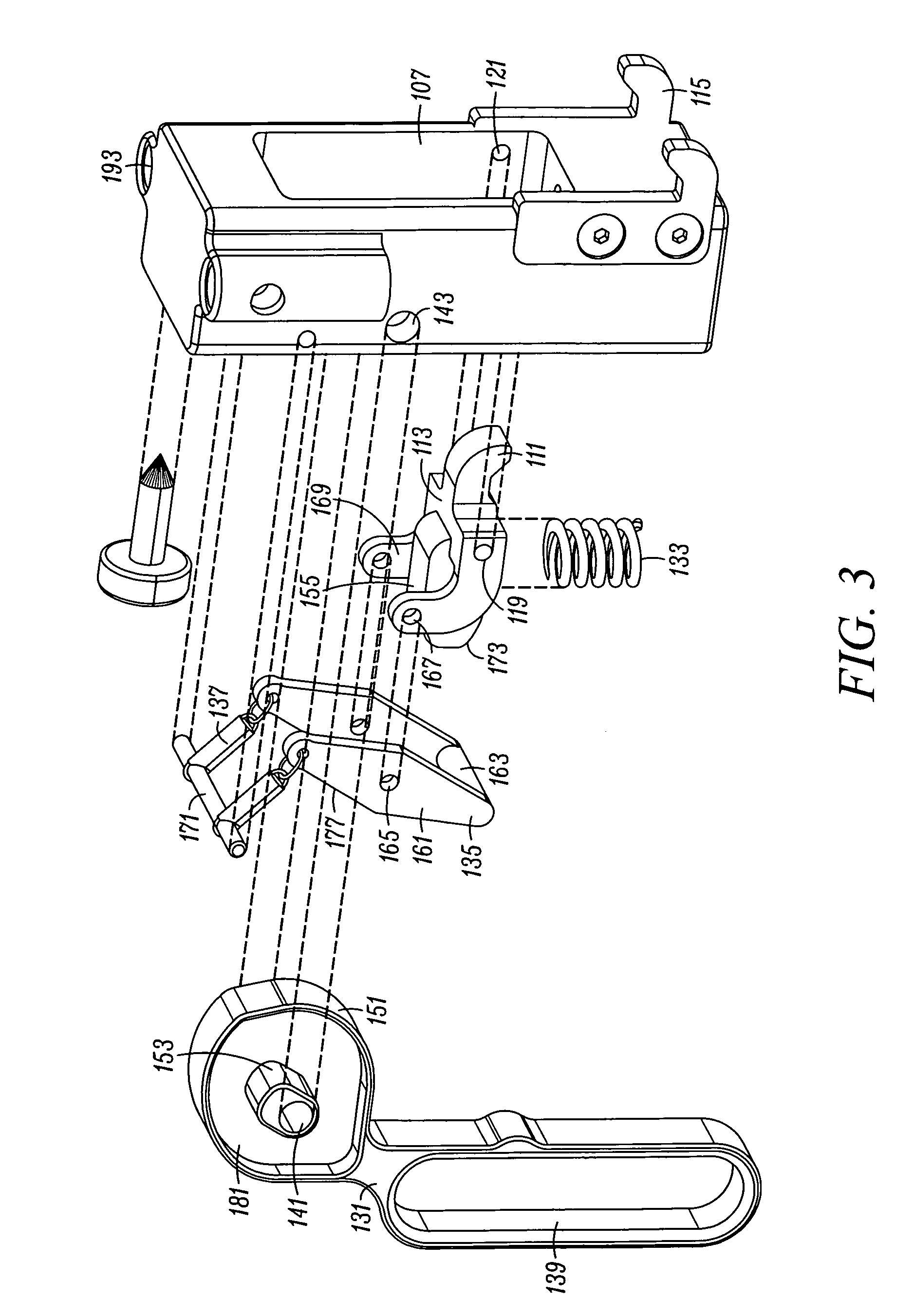

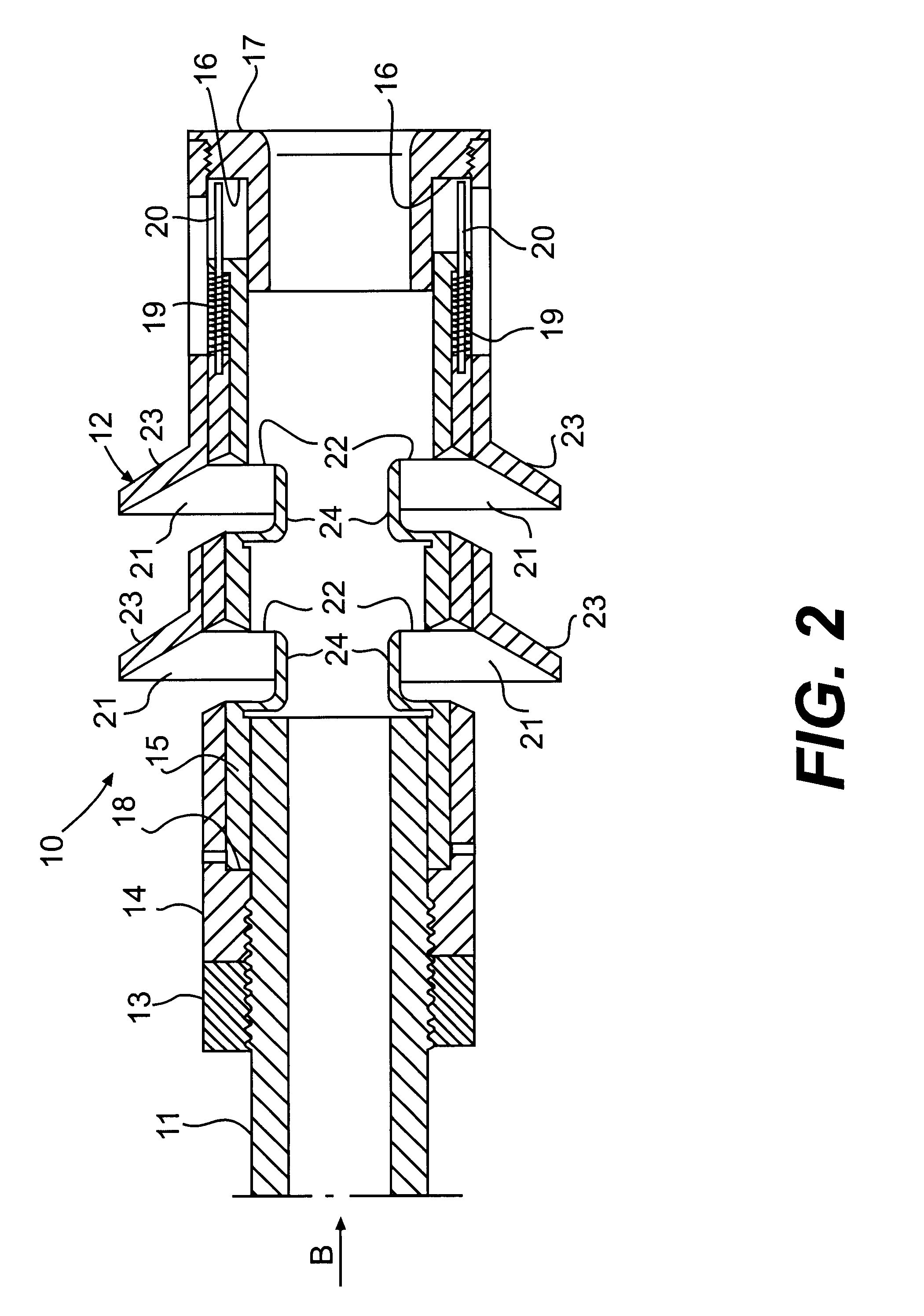

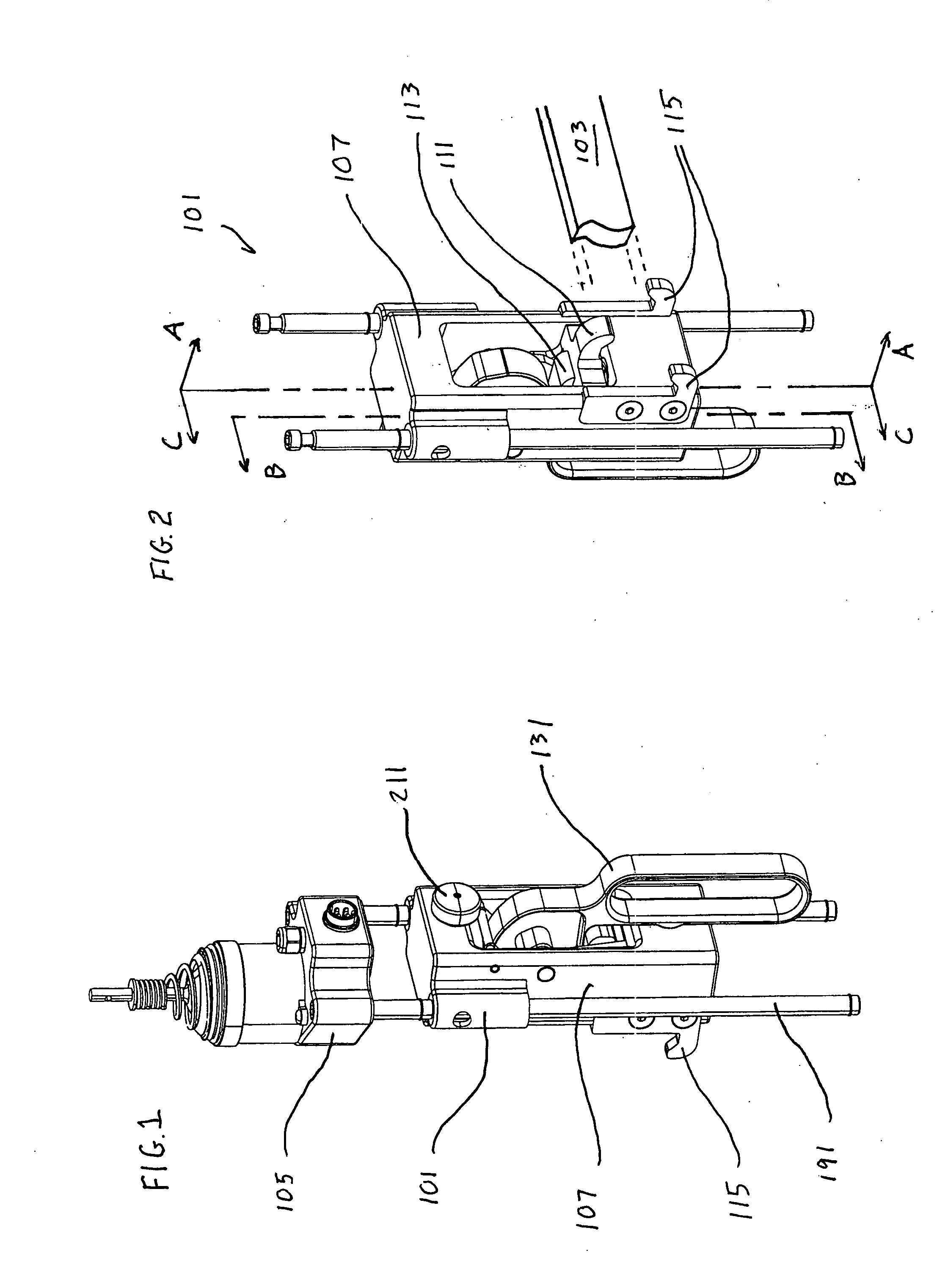

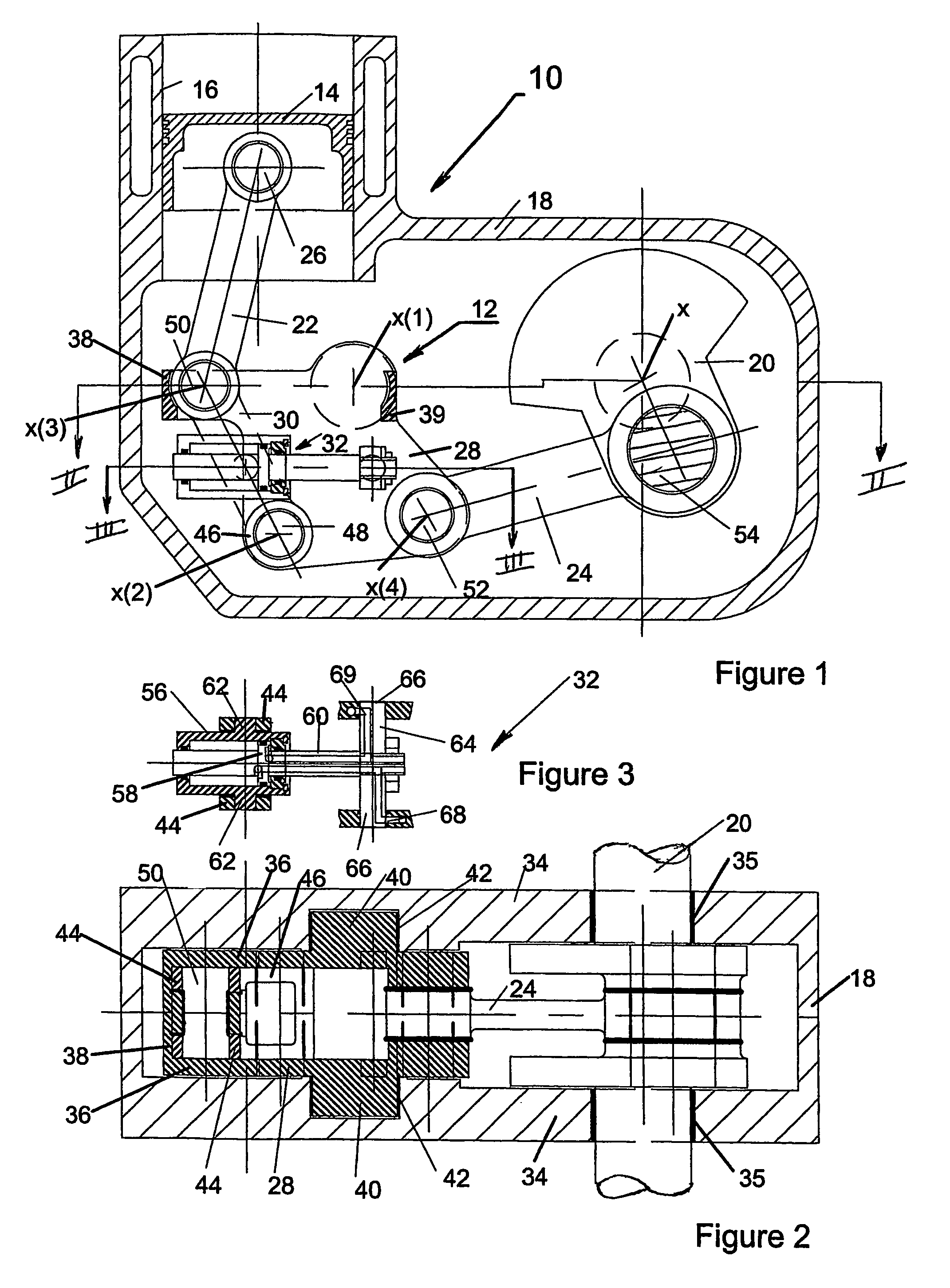

Section mill for wells

ActiveUS6920923B1Improve cutting performanceEasy to installDrill bitsFluid removalExtreme positionOil well

A section mill for casings used in oil wells to cut predetermined portions for repair purposes. An elongated cylindrical assembly is inserted through the casing and it includes at least two spaced apart apertures with one blade member pivotally mounted within each aperture. First and second coaxially disposed tubular shaft assemblies with teethed portions to coact with the blades to selectively move them between two extreme position upon the application of a pressurized fluid. The fluid needs to overcome the spring biased applied to the shaft assemblies. The first set of blades is stopped and slidably rotates in contact with the internal surface of the casing. The second set cuts through the casing with one end and sections the casing with the other end. After wearing off, the first set of blades continues the sectioning work.

Owner:MECOL OIL TOOLS

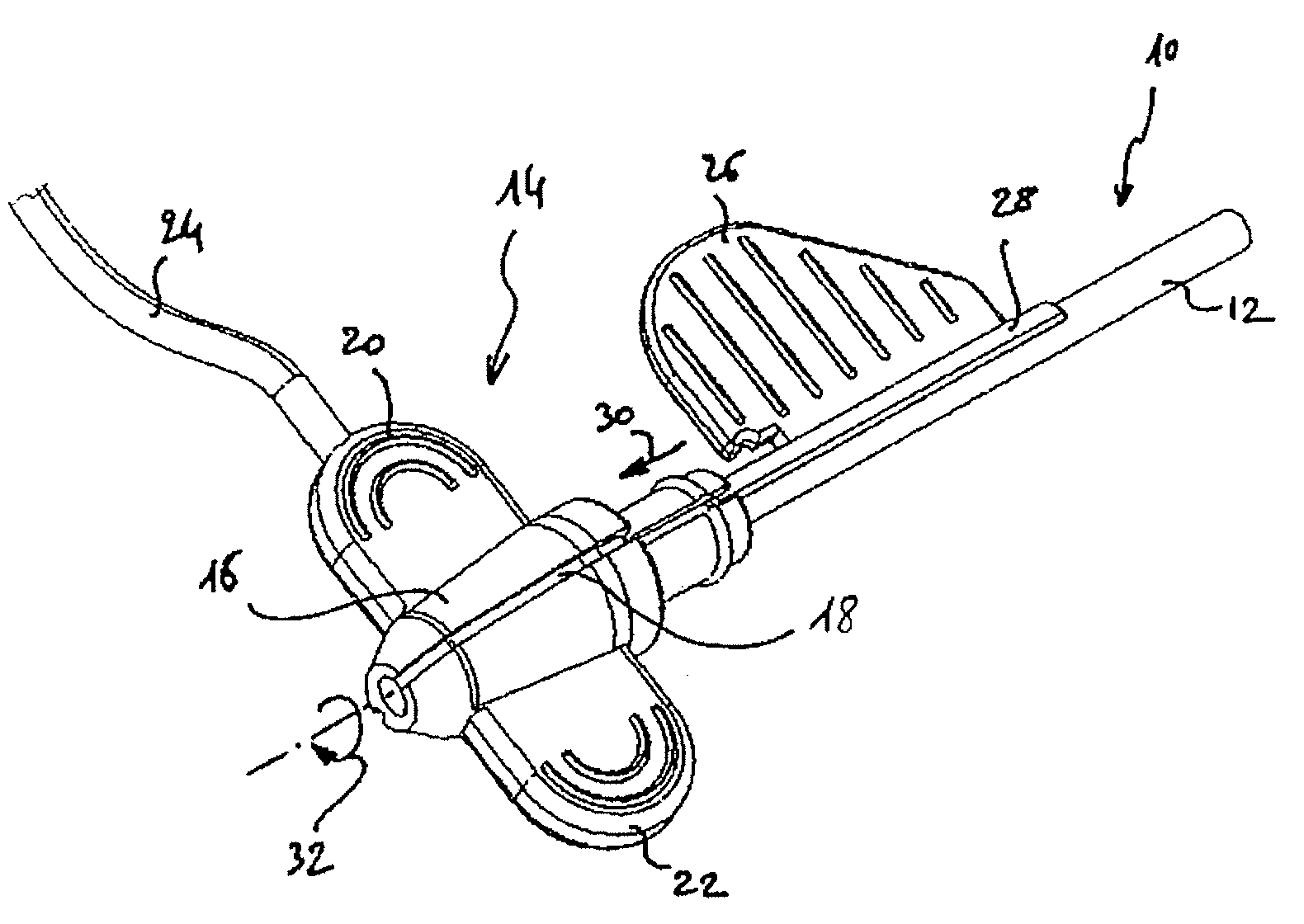

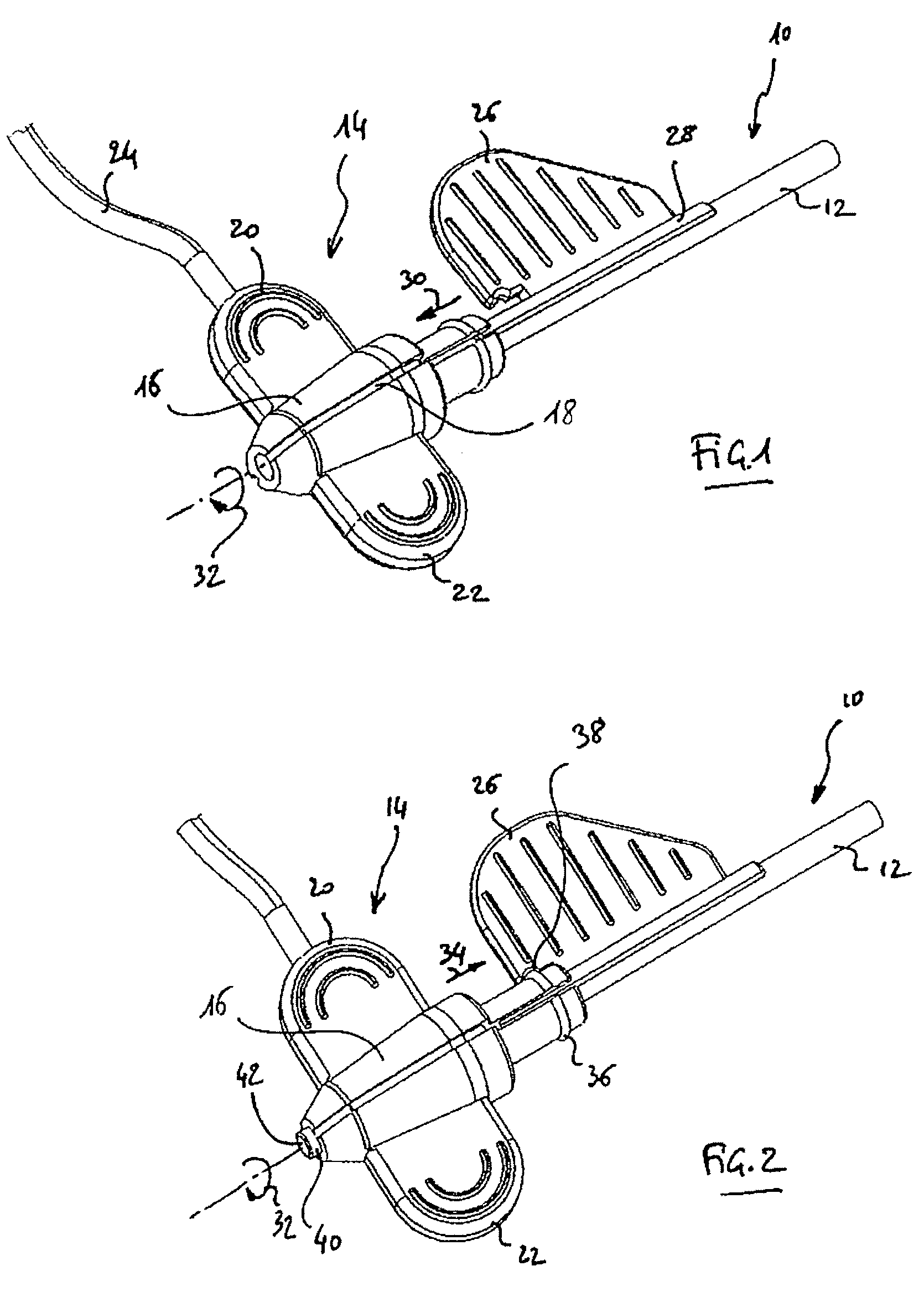

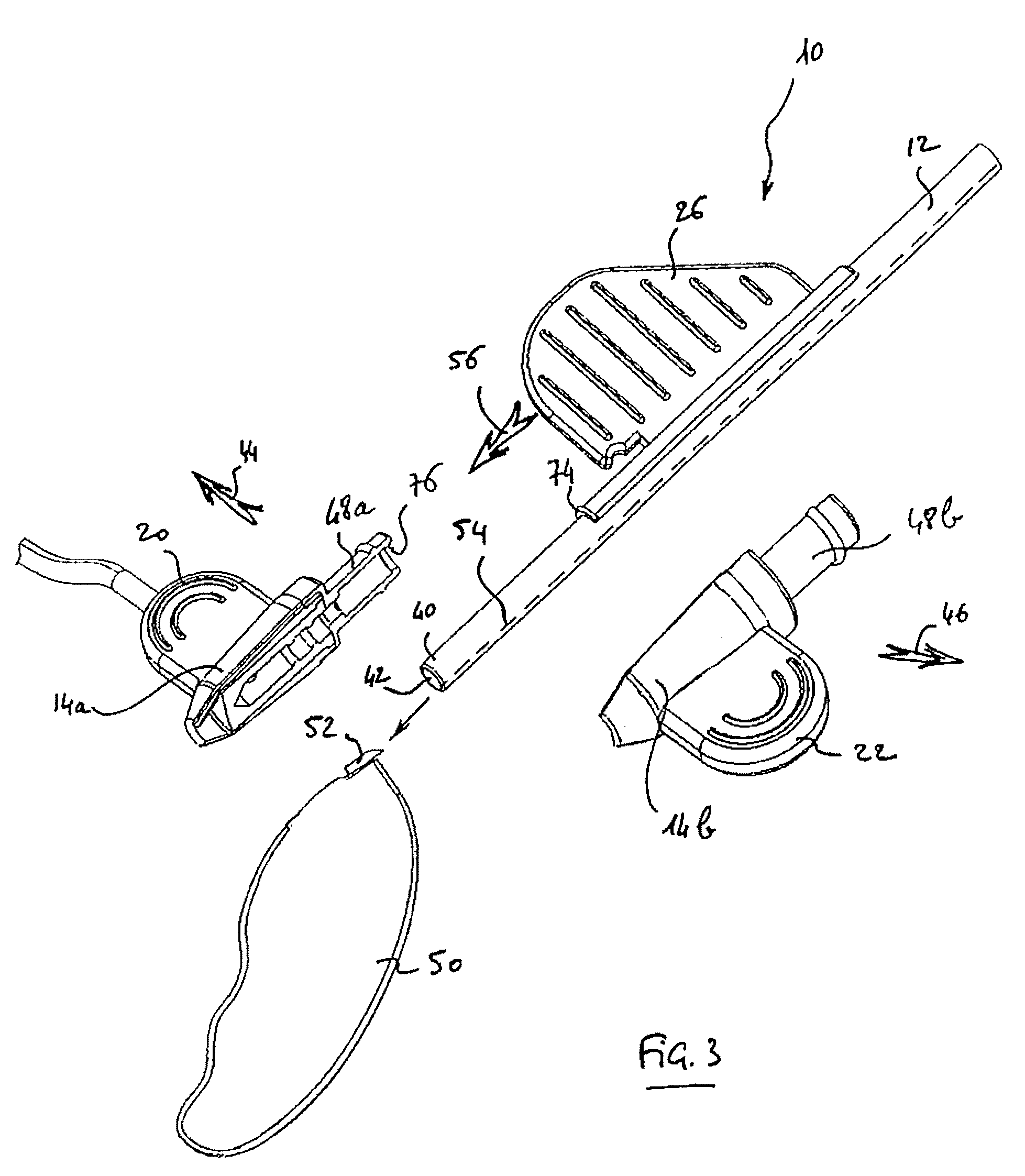

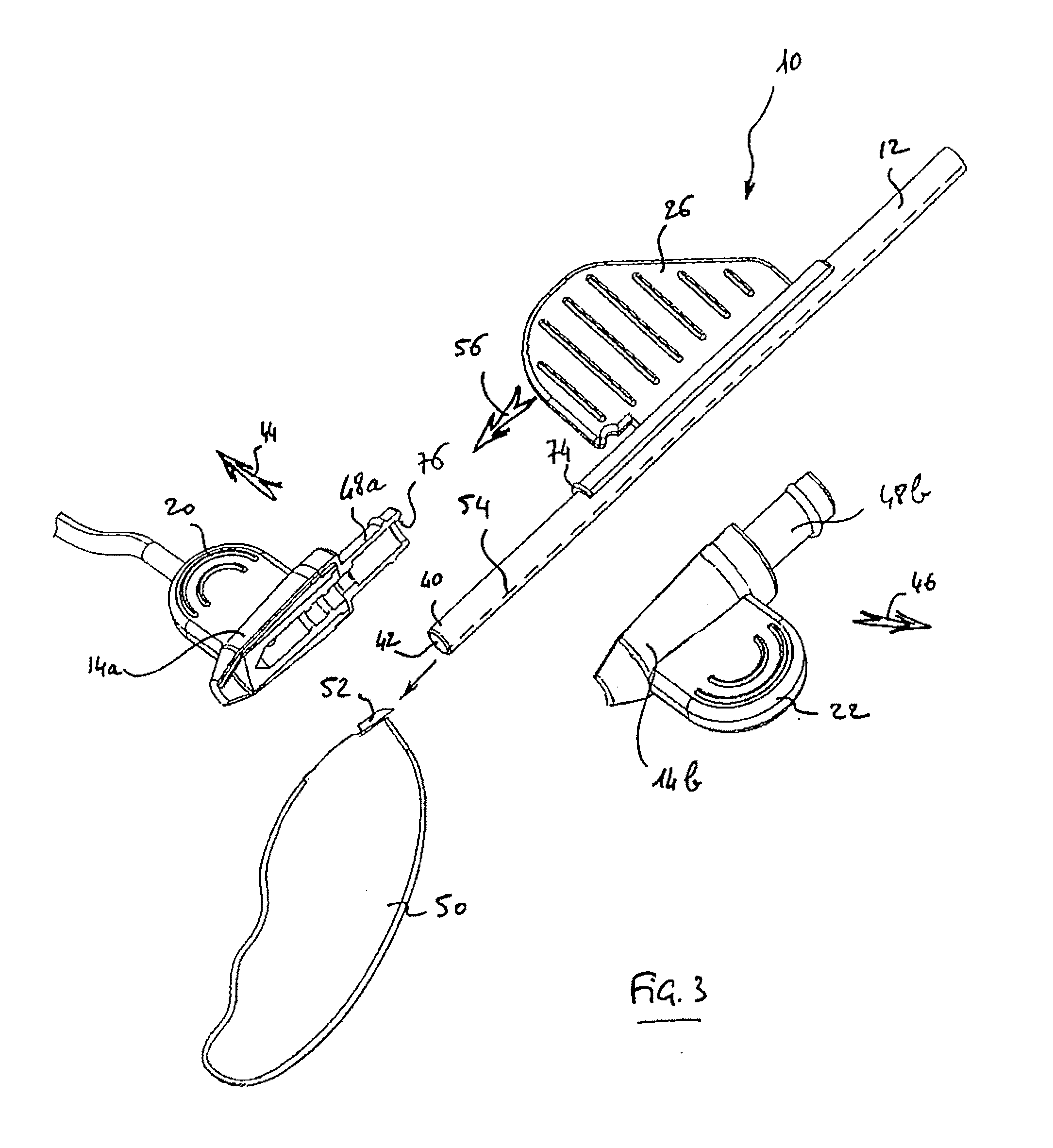

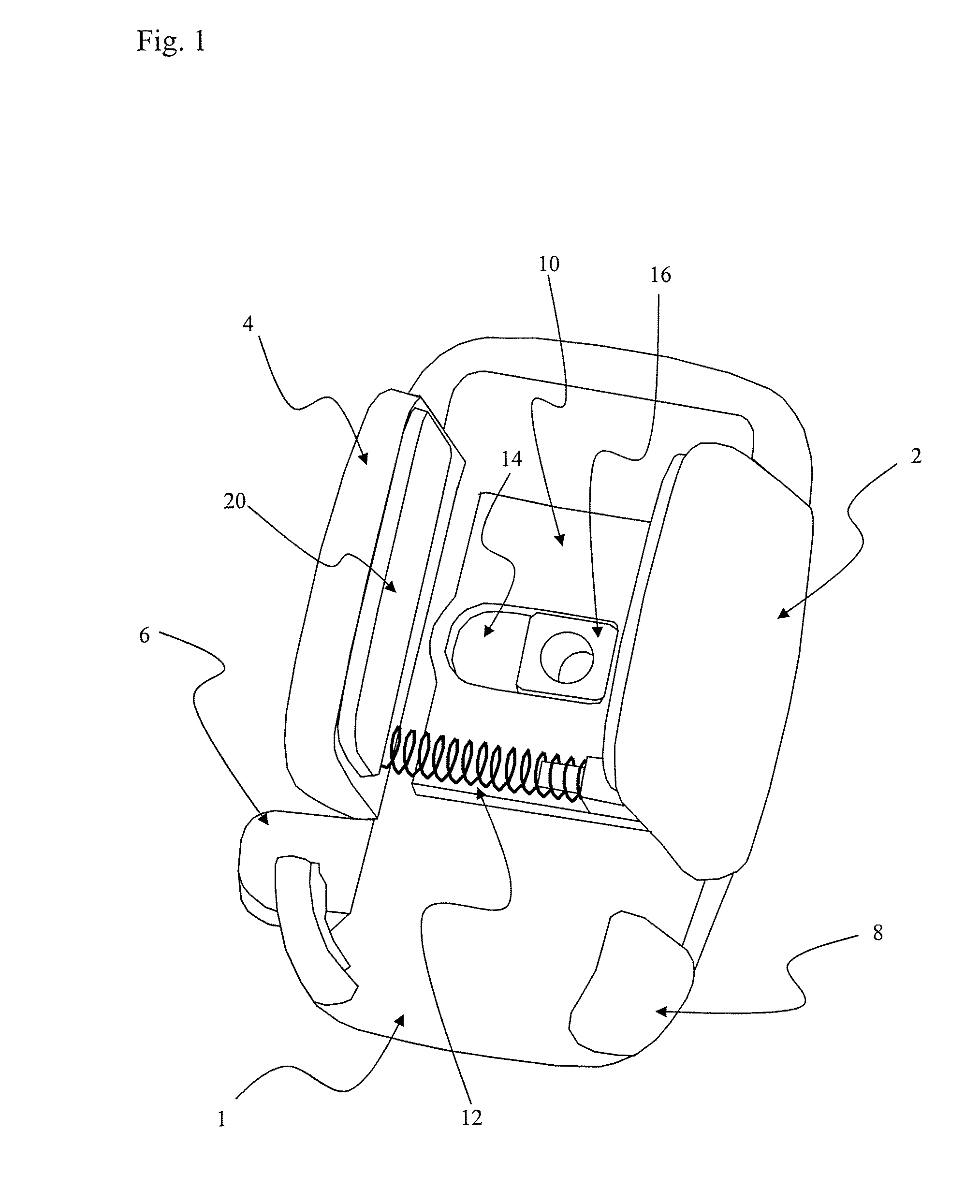

Toolkit for implanting an intracorporeal lead such as for cardiac pacing or sensing

ActiveUS8142446B2Reduce riskRisk minimizationElectrotherapyInfusion syringesExtreme positionAtrial pacing

A toolkit for implanting an intracorporal lead, preferably a cardiac sensing / pacing lead. This toolkit includes a guide-catheter (10), having a sheath (12) with an internal lumen (42) opened at its distal and proximal ends, and cuttable along a generatrix in order to allow extracting of the guide-catheter after use. A hemostatic valve (14) is mounted at the proximal end (40) of the guide-catheter, for selectively filling, or not, the internal lumen of the guide-catheter at its input end. The valve is frangible in at least two parts, each dissociable from the guide-catheter at both sides around a median axial plane. The valve comprising a mobile element sliding on the guide-catheter between two extreme positions, with an opened position where the proximal end (40) of the guide-catheter (10) freely emerges out of the valve so as to allow access to said internal lumen, and a closed position where this proximal end of the guide-catheter is filled in a tight manner.

Owner:SORIN CRM

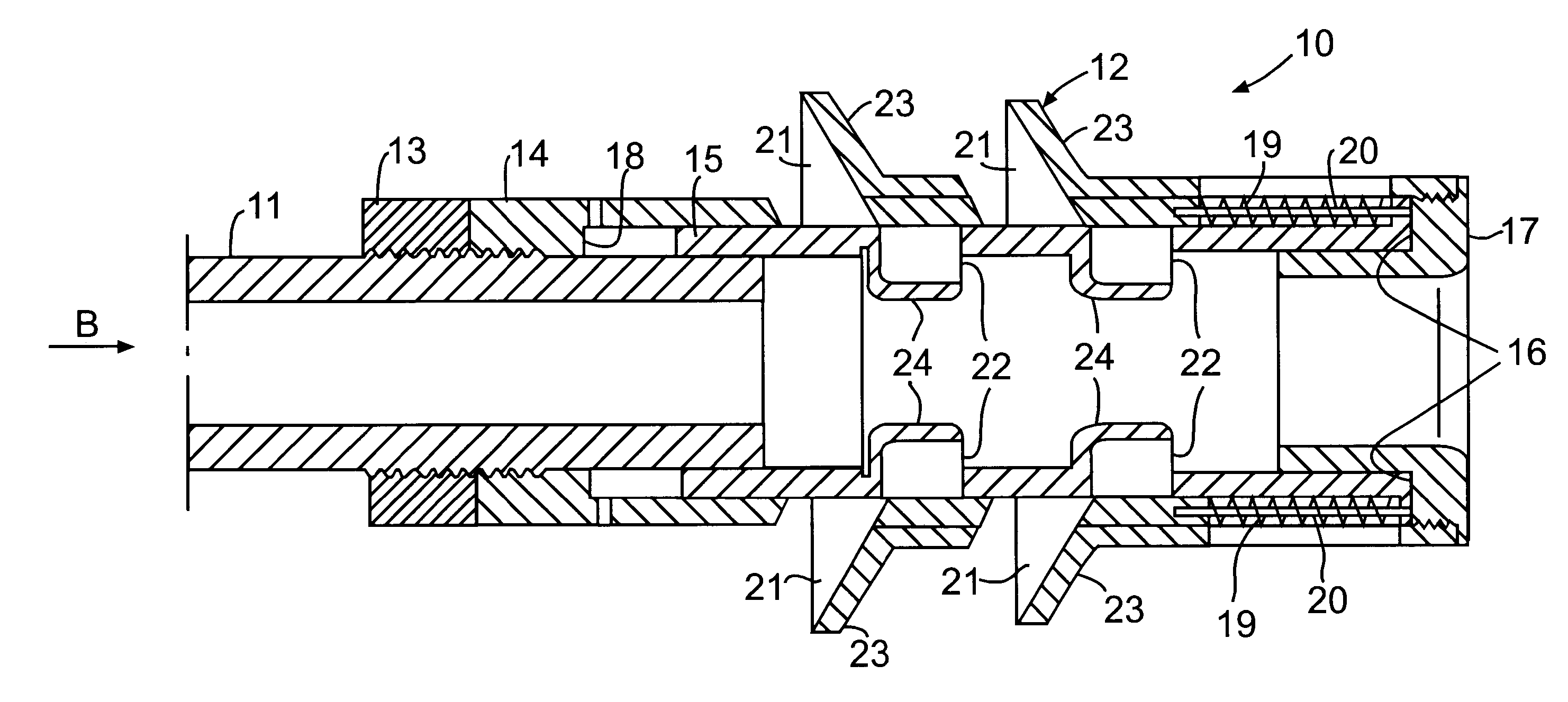

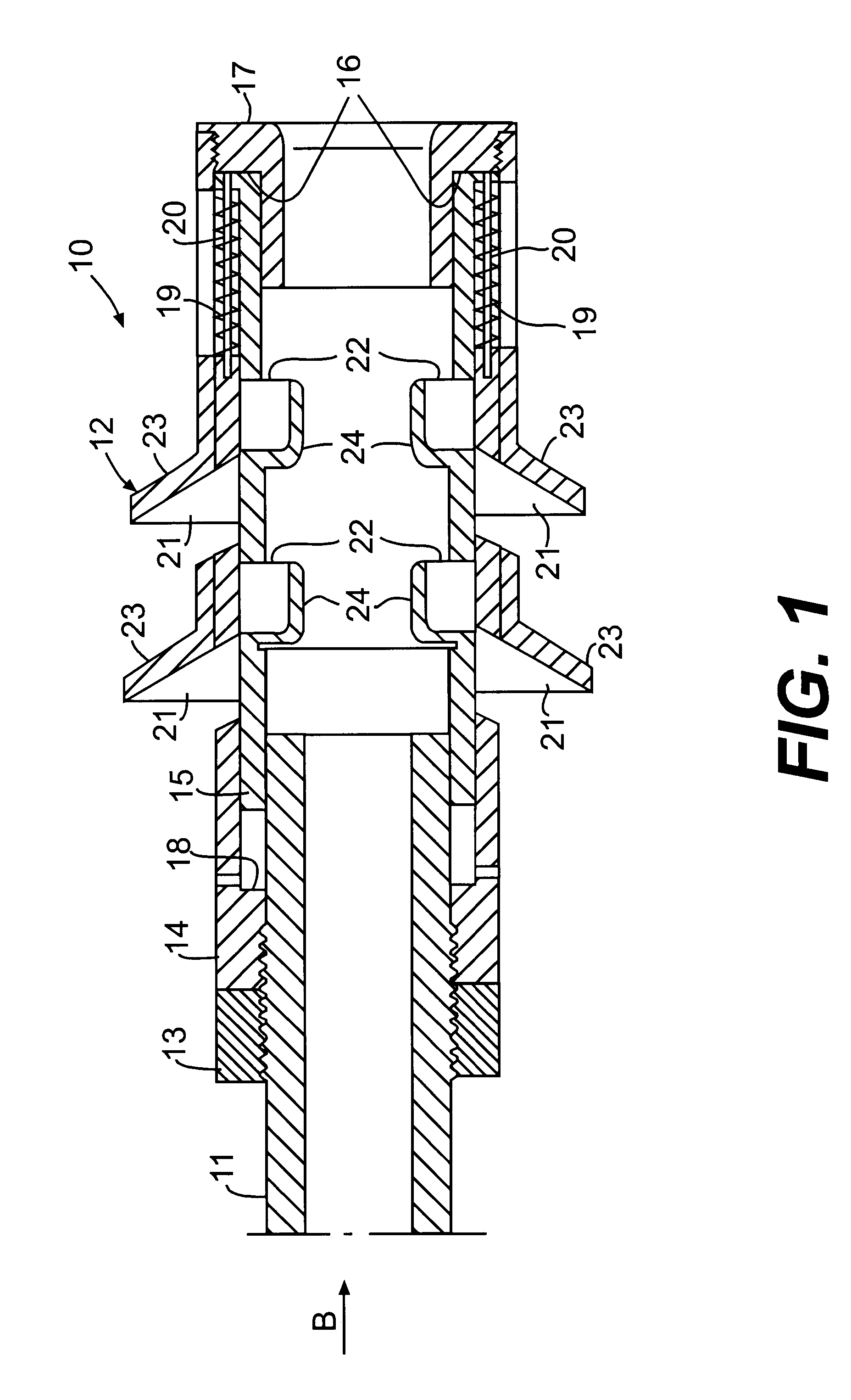

Rail clamp

A clamp for attaching a medical device to an OR table rail, including two closable clamp jaws that close to an extreme position that leaves inadequate room for the rail. A handle actuates the jaws apart, and a spring biases them together through a range of jaw positions. A lock member is biased to swing through a range of lock positions in which it progressively engages and locks the jaw mechanism through its range of jaw positions. A pair of bars carries the medical device on the clamp, and allows it to be adjustably positioned with respect to the rail.

Owner:SCOTT CHRISTOPHER P

Toolkit for implanting an intracorporeal lead such as for cardiac pacing or sensing

ActiveUS20090076522A1Simple and effective driving (openingSimple and effective and closing)ElectrotherapyDiagnosticsExtreme positionCardiac pacing

A toolkit for implanting an intracorporal lead, preferably a cardiac sensing / pacing lead. This toolkit includes a guide-catheter (10), having a sheath (12) with an internal lumen (42) opened at its distal and proximal ends, and cuttable along a generatrix in order to allow extracting of the guide-catheter after use. A hemostatic valve (14) is mounted at the proximal end (40) of the guide-catheter, for selectively filling, or not, the internal lumen of the guide-catheter at its input end. The valve is frangible in at least two parts, each dissociable from the guide-catheter at both sides around a median axial plane. The valve comprising a mobile element sliding on the guide-catheter between two extreme positions, with an opened position where the proximal end (40) of the guide-catheter (10) freely emerges out of the valve so as to allow access to said internal lumen, and a closed position where this proximal end of the guide-catheter is filled in a tight manner.

Owner:SORIN CRM

Muzzle brake

A muzzle brake for a gun which comprises an annular member mountable on the firing end of the muzzle of the gun, which member comprises a pair of concentrically located annular elements of which the first one is mounted stationary relative to the muzzle of the gun and the second one is slidably movable against the biasing action of a spring relative to said first element in a direction opposite the firing direction of the gun, said movement taking place under the influence of the exhaust gas resulting from the firing of a projectile by the gun, and said movement being from a first extreme position into which said spring forces said second element, in which position the brake is in the "off' position, to a second extreme position where the brake is in the fully "on' position, in which position said exhaust gas can force the first element, and hence the muzzle of the gun, to move in the firing direction, and so counteract the recoil action of the gun.

Owner:DANEL

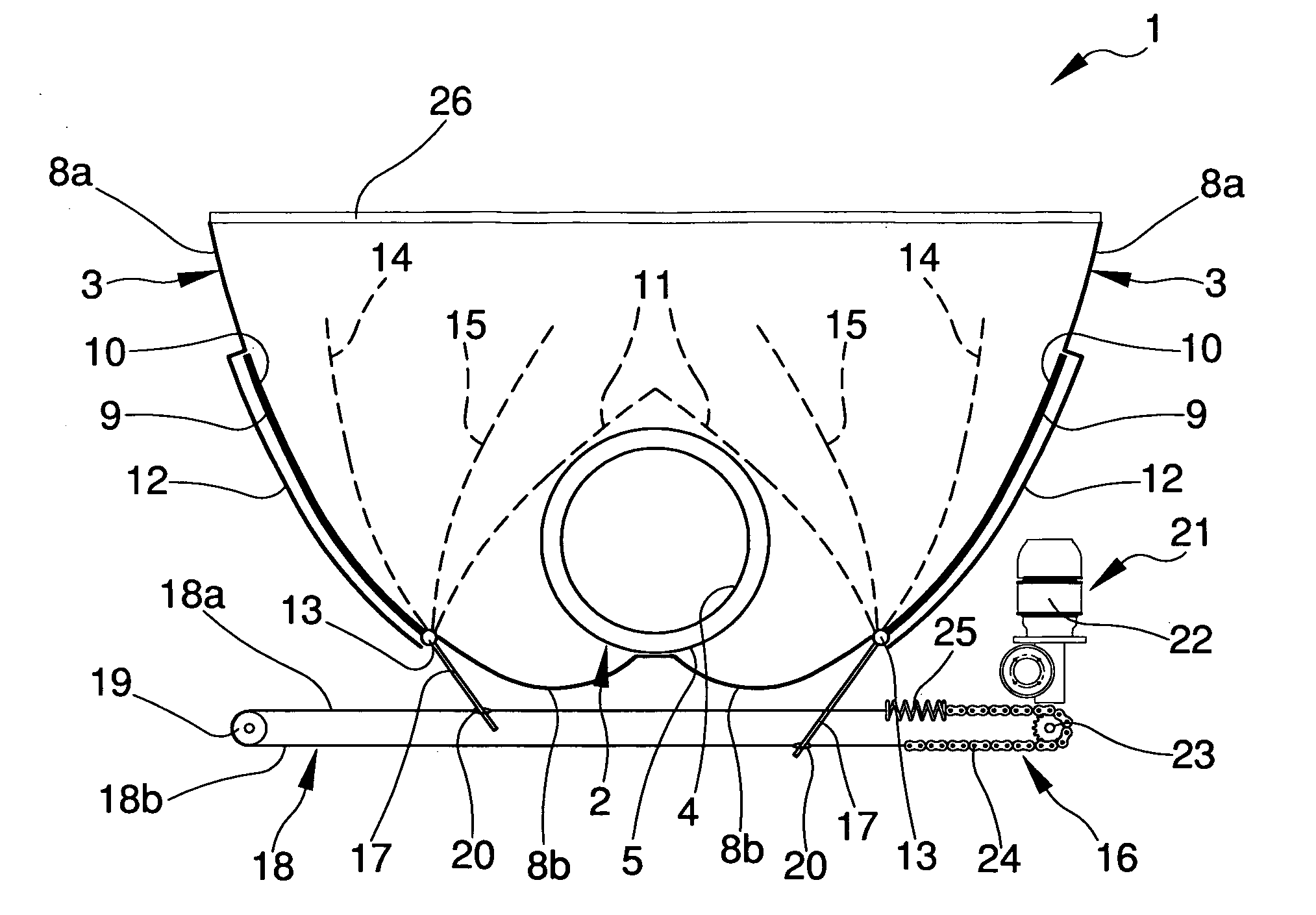

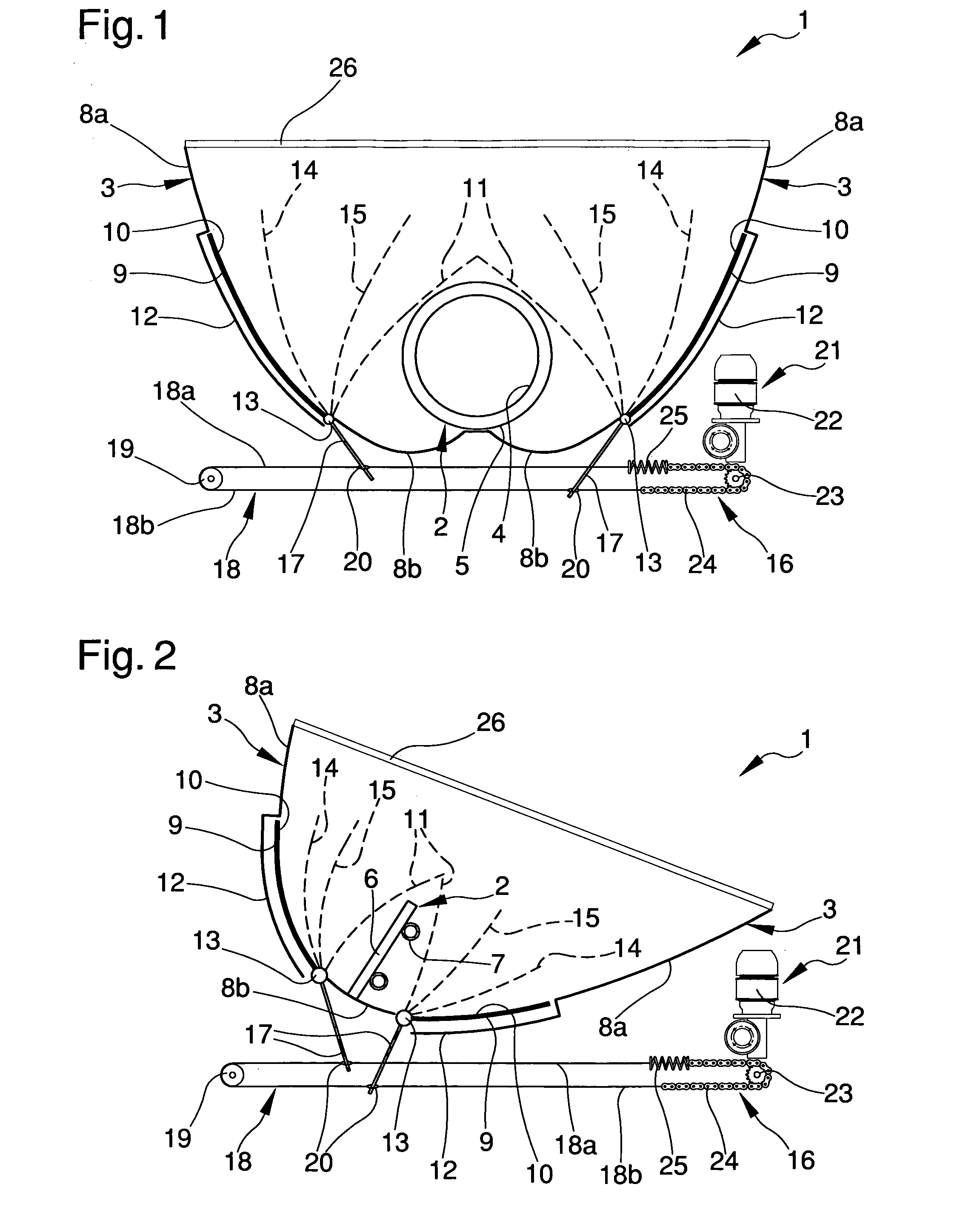

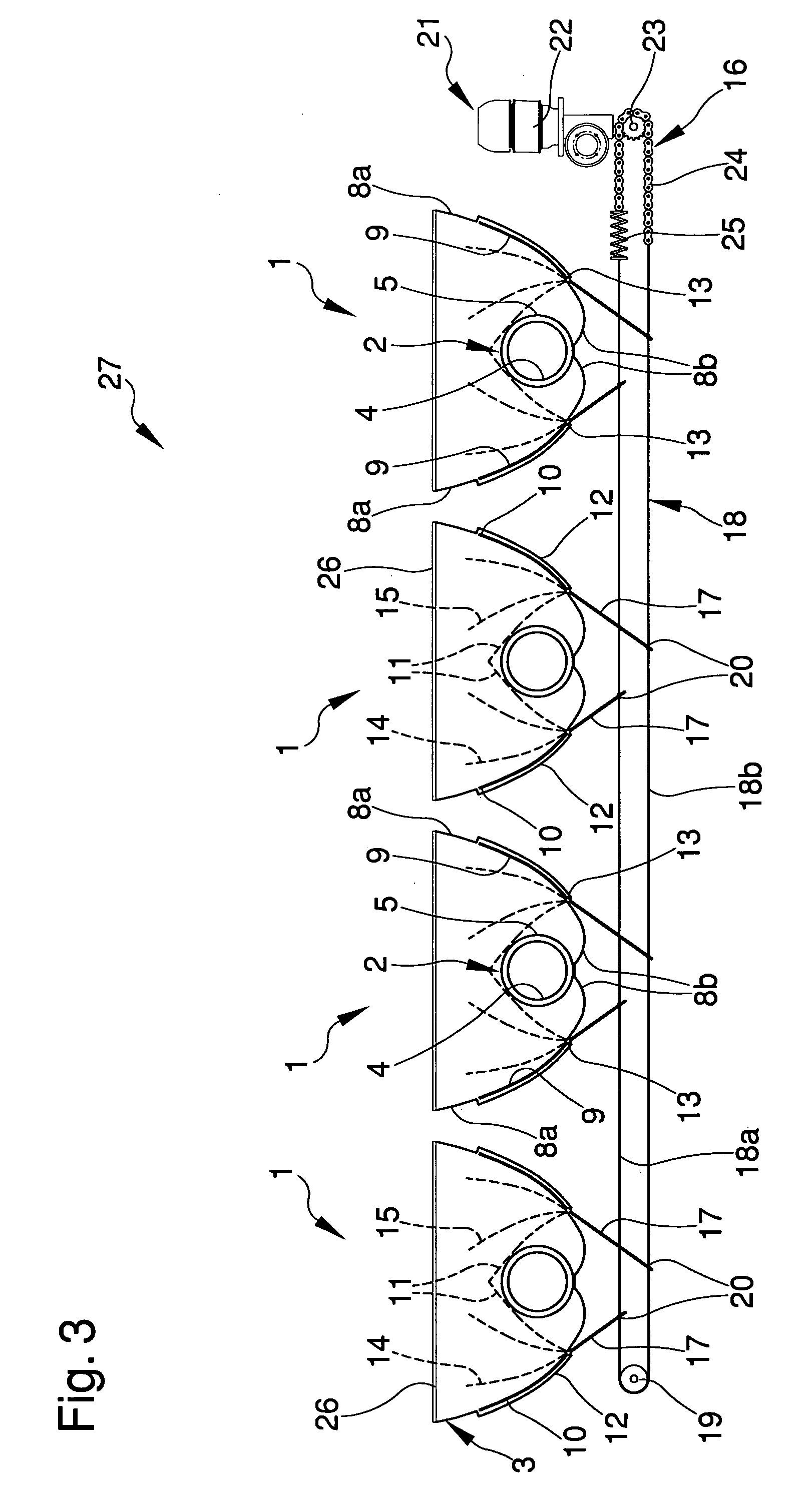

Non-tracking solar collector device

InactiveUS20110203574A1Avoid overall overheatingPrevent overheating of the absorber element more efficientlySolar heating energySolar heat collector controllersCollector deviceEngineering

Non-tracking solar collector device (1) comprising at least an absorber element (2), at least a couple of reflector elements (3) disposed on opposite sides of the absorber element (2) for conveying the solar radiation onto the absorber element itself and said reflector elements (3) comprising at least one fixed portion (8a,8b) and at least one rotating portion (9); the rotating portions (9) being movable between at least a first extreme position (10), in which the rotating portions are moved away from each other and the entire surface of said reflector elements (3) is substantially continuous, and a second extreme position (11), in which the rotating portions are moved close to each other in order to substantially obscure said absorber element (2).

Owner:KLOBEN S A S DI TURCO ADELINO E C

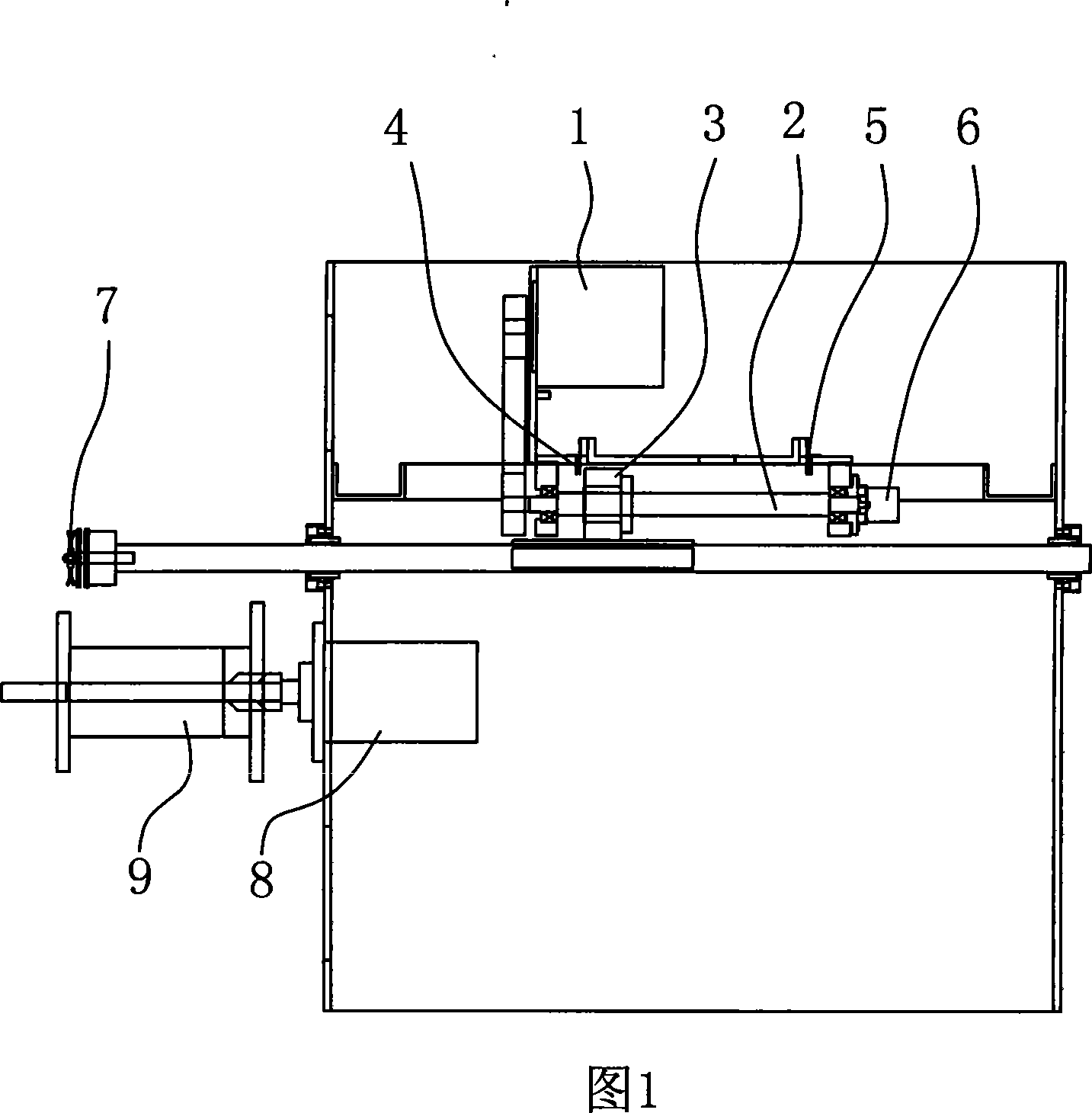

Numerical control wire ranging device and method thereof

InactiveCN101249911AAdapt to wiring requirementsSimple structureFilament handlingNumerical controlRange of motion

The invention provides a numerical control wire arranging device adaptable to occasions of drawing machines, enameling machines, tin machines, bare wire rewinder and the like and a wire arranging method thereof. The numerical control wire arranging device comprises a motor, a lead screw, a master screw, a forward rotating limit device, a counter-rotating limit device and an encoder, and thereby the numerical control wire arranging device has the advantages of simple structure, hard breakage and easy overhaul. In the wire arranging method, counting value of the encoder connected to the lead screw reflects angles of rotation and numbers of revolution of the lead screw, thereby reflecting straight-line motion distance of the master screw, and the encoder controls the motion of the motor through programs, thereby controlling range of motion and mode of motion of the master screw. Extreme position of the linear motion of the mater screw is limited by the forward rotating limit device and the counter-rotating limit device. After an input device of a control system is controlled to input set value, a combination of subprograms of system initiation, fixed distance wire arrangement, variable distance wire arrangement, variable speed wire arrangement and stop wire arrangement is operated for meeting requirements of wire arrangement of different take-up reels.

Owner:周开勇

Mobile device clamp holder with damped release mechanism

ActiveUS20070045495A1Eliminate disadvantagesExtended service lifePicture framesDomestic mirrorsEngineeringExtreme position

A holder for a mobile electronic device includes first and second clamping jaws, at least the first clamping jaw being displaceable toward the second clamping jaw to clamp the mobile electronic device. The holder also includes a stop element and an entraining element connected to the first clamping jaw, the entraining element being shaped so that it is displaceable with respect to the stop element, namely jointly with the damping jaw connected to it, in which case at least one extreme position corresponding to the maximum opening of the clamping jaw is defined in the displacement path by the impact of the stop element against the entraining element. The holder includes a damper element, which is mounted on the stop element and damps the stopping of the stop element against the entraining element.

Owner:III HLDG 3

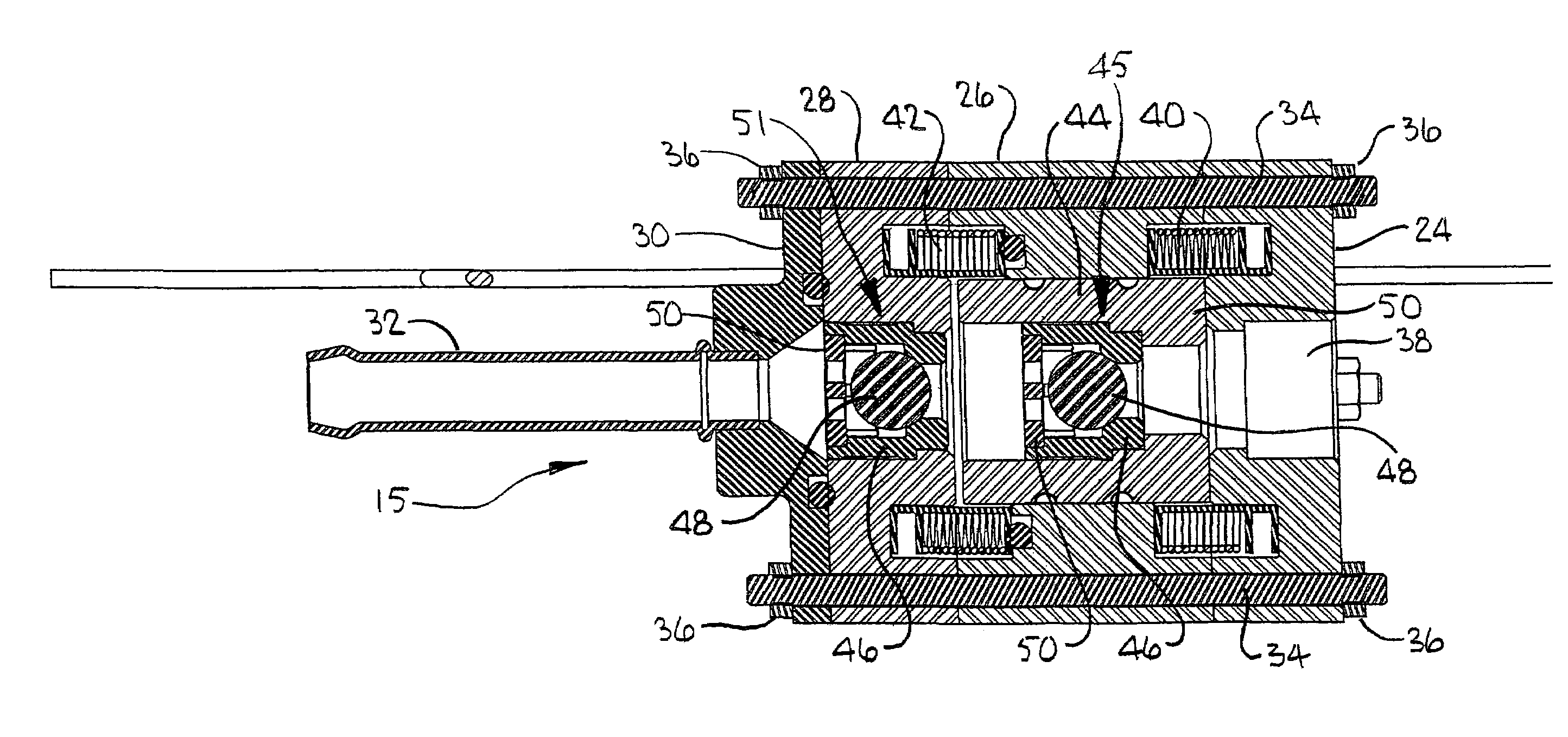

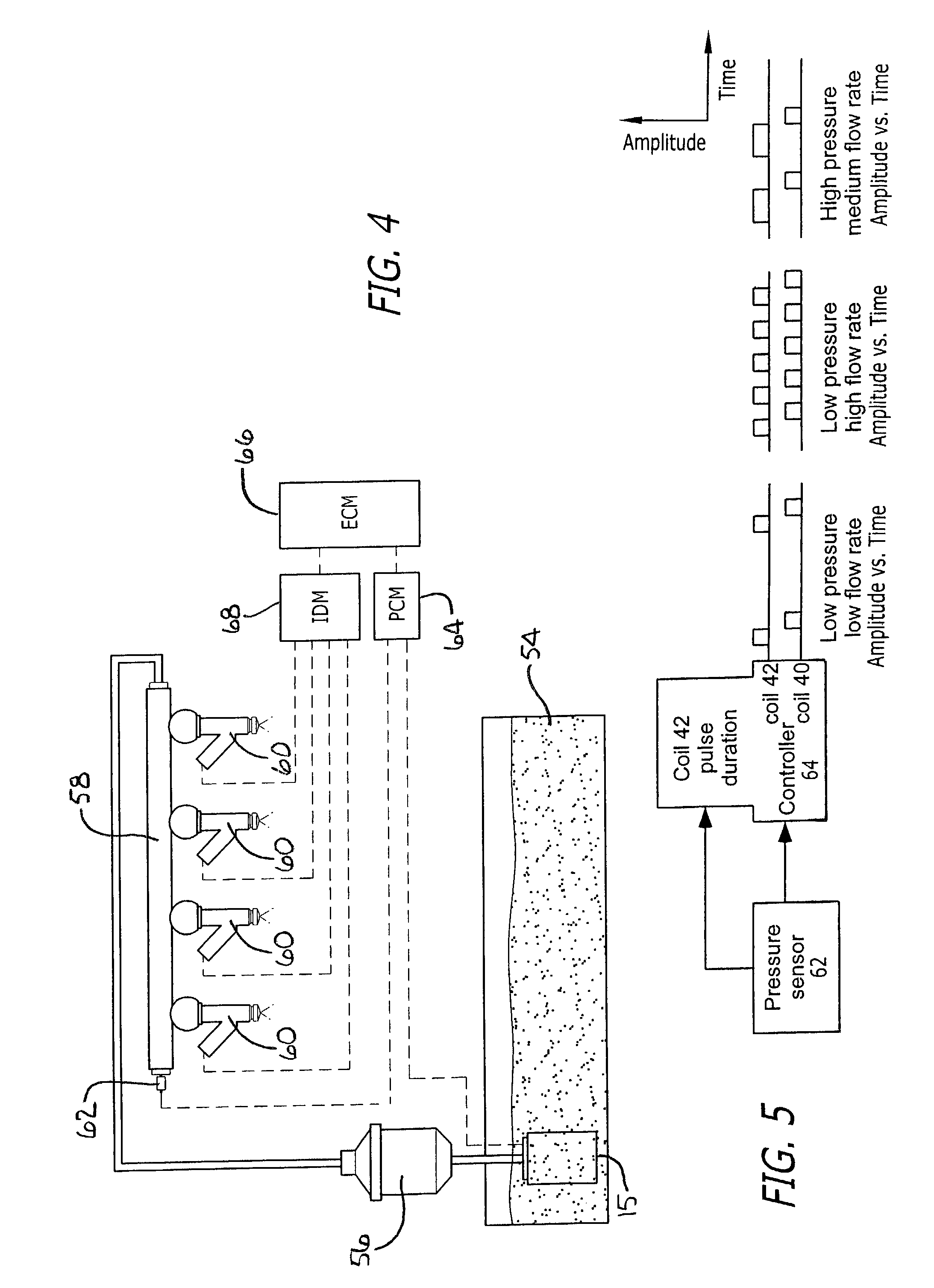

Digital fluid pump

ActiveUS7001158B2Limit motionIncrease flux densityPositive displacement pump componentsPump parameterHigh fluxElectrical impulse

Digital fluid pumps having first and second electromagnetic actuators formed in part by a piston to alternately drive the piston in opposite directions for pumping purposes. The piston motion is intentionally limited so that the electromagnetic actuators may operate with a high flux density to provide an output pressure higher than that obtained with conventional solenoid actuated pumps. The electromagnetic actuator coils are electrically pulsed for each pumping cycle as required to maintain the desired fluid flow and output pressure, with the piston being magnetically latchable at one or both extreme positions between pulses. Alternate embodiments and control methods and systems are disclosed.

Owner:STURMAN INDS

Mobile device clamp holder with damped release mechanism

ActiveUS7540459B2Product's lifetimeExtended service lifePicture framesDomestic mirrorsEngineeringMobile device

Owner:III HLDG 3

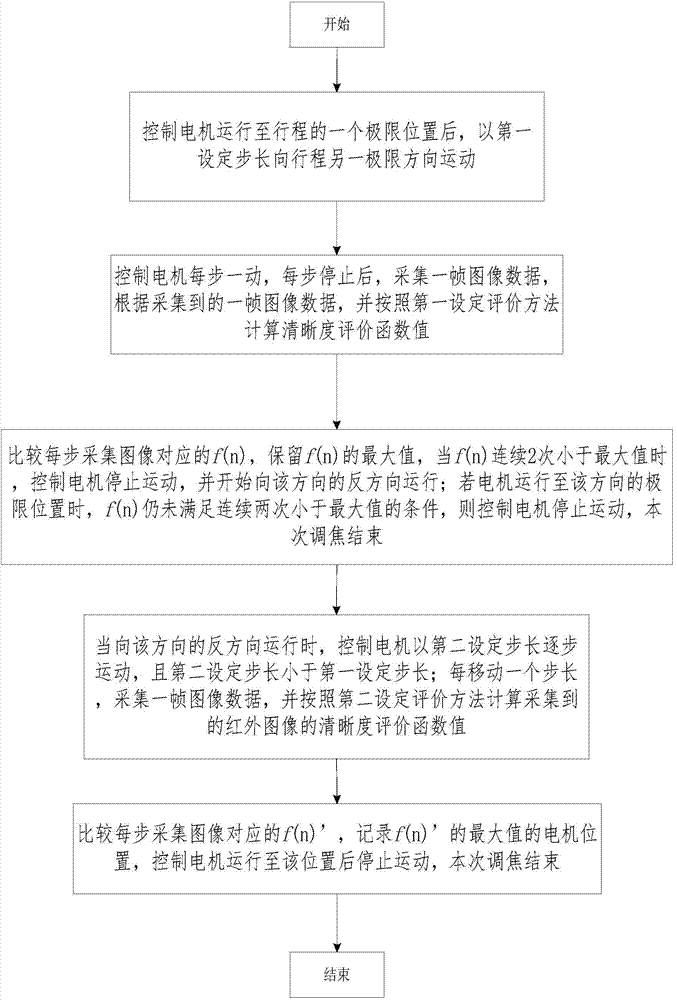

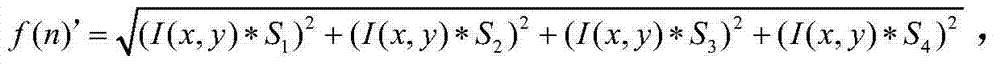

Coarse tuning and fine tuning combined infrared image automatic focusing method

ActiveCN104301601AMeet clarity requirementsEasy to adjustTelevision system detailsColor television detailsExtreme positionComputer science

The invention discloses a coarse tuning and fine tuning combined infrared image automatic focusing method which is characterized by controlling a motor to operate positively and negatively according to an automatic focusing command; controlling the motor to move to the negative direction with a relatively-large step length from the extreme position; in the moving process, calculating definition evaluation function value in real time; and when the function value reaches maximum value, controlling the motor to move to the negative direction again with a relatively-small step length and calculating definition evaluation function value in real time, and the maximum value place is the clearest imaging place. According to the method, combination of coarse tuning and fine tuning is realized through different motor movement step lengths, and automatic focusing calculation is carried out through two image definition evaluation functions, thereby guaranteeing an infrared imaging system to enable the focal length to be adjusted to the clearest imaging place quickly and realizing the optimum focusing effect; and the method is less in computation burden, high in real-time performance, beneficial to engineering application, and capable of meeting the definition requirement of the infrared imaging system.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Electrical protection method and device during frequency-changing elevator mechanical brake disabling

InactiveCN101143670AEnsure safetyAvoid High Speed Collision AccidentsMotor/generator/converter stoppersAC motor controlLow speedFrequency conversion

An electric protective method and a device when a mechanical brake of a frequency conversion elevator fails is characterized in that an elevator controller real time monitors the displacement and the speed of an elevator car, and can immediately judge the mechanical brake of the elevator fails and the elevator slips if any unallowable displacement and certain moving speed are found to the elevator car before the elevator controller makes any direction and speed instruction. At this time, the invention can immediately send the zero-speed running signal to a frequency converter, and use the frequency converter to control the zero-speed torque moment produced by dragging a motor to brake the elevator car to stop, so as to ensure the safety of the people going in and out of the elevator car; meanwhile, gives out the alarm signal to notify the people in the elevator car to quickly leave, and then controls to close the door. In case of any irreversible failure to the mechanical brake, the invention controls the elevator car to run at lower speed in the slipping direction, until the elevator runs to an extreme position and stops. In this way, the invention can prevent severe accidents of shearing injury to people and high-speed crash because of high-speed slipping of the elevator.

Owner:上海三意楼宇实业有限公司 +1

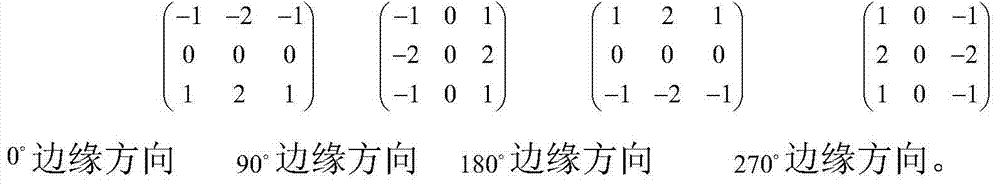

Detecting Method for Touch Panel

This invention provides a detecting method for a touch panel, comprising providing a sensing matrix having a plurality of sensing units, detecting sensing data generated from the sensing unit and defining the sensing unit as a touch point or a non-touch point based on the sensing data and group at least a portion of the touch points to form a touch point group. In the same touch point group, projection of a touch point overlaps a projection of at least one touch point of the touch point group in one of a row direction and a column direction while adjacent to a projection in the other direction of at least one touch point of the touch point group. Afterward, extreme positions of the touch point group in the row direction and the column direction is retrieved. Lastly, the detecting method includes determining a touch center position based on the extreme positions in the row direction and the column direction.

Owner:AU OPTRONICS CORP

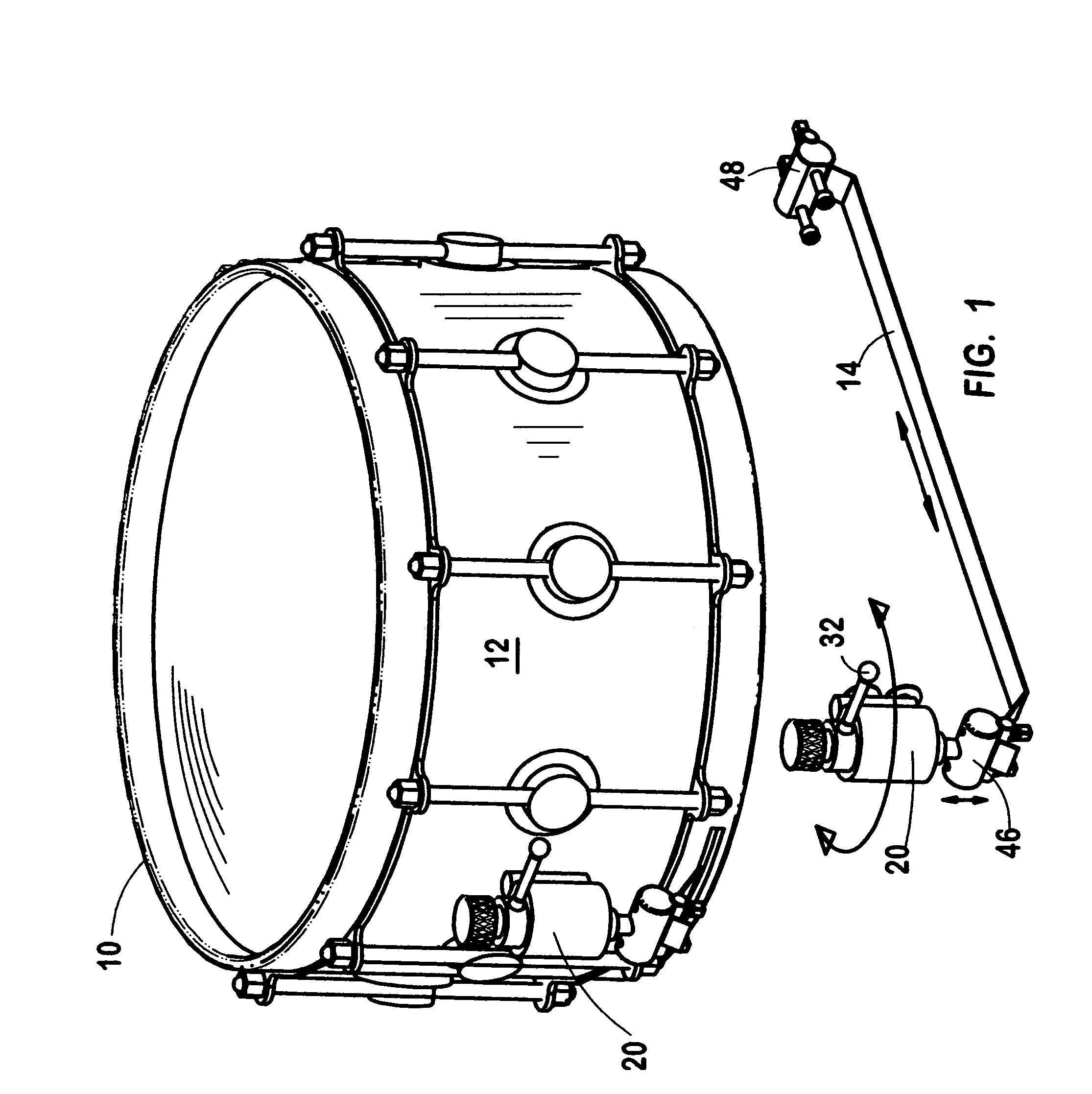

Snare drum accessory

InactiveUS20060266198A1Inherent level of frictionReliable settingsPercussion musical instrumentsEngineeringExtreme position

An adjustment mechanism for selectively tightening the snare wires of a snare drum, having a camming mechanism cooperatively formed by two concentric members with an inherent level of friction that allows it to be reliably set at either extreme position of adjustment of the tightness of the snare wires or at any desired intermediate position of adjustment, thus allowing the musician a full range of choice of the musical tones or effects to be produced by the snare wires.

Owner:JEFFRIES WALTER B +1

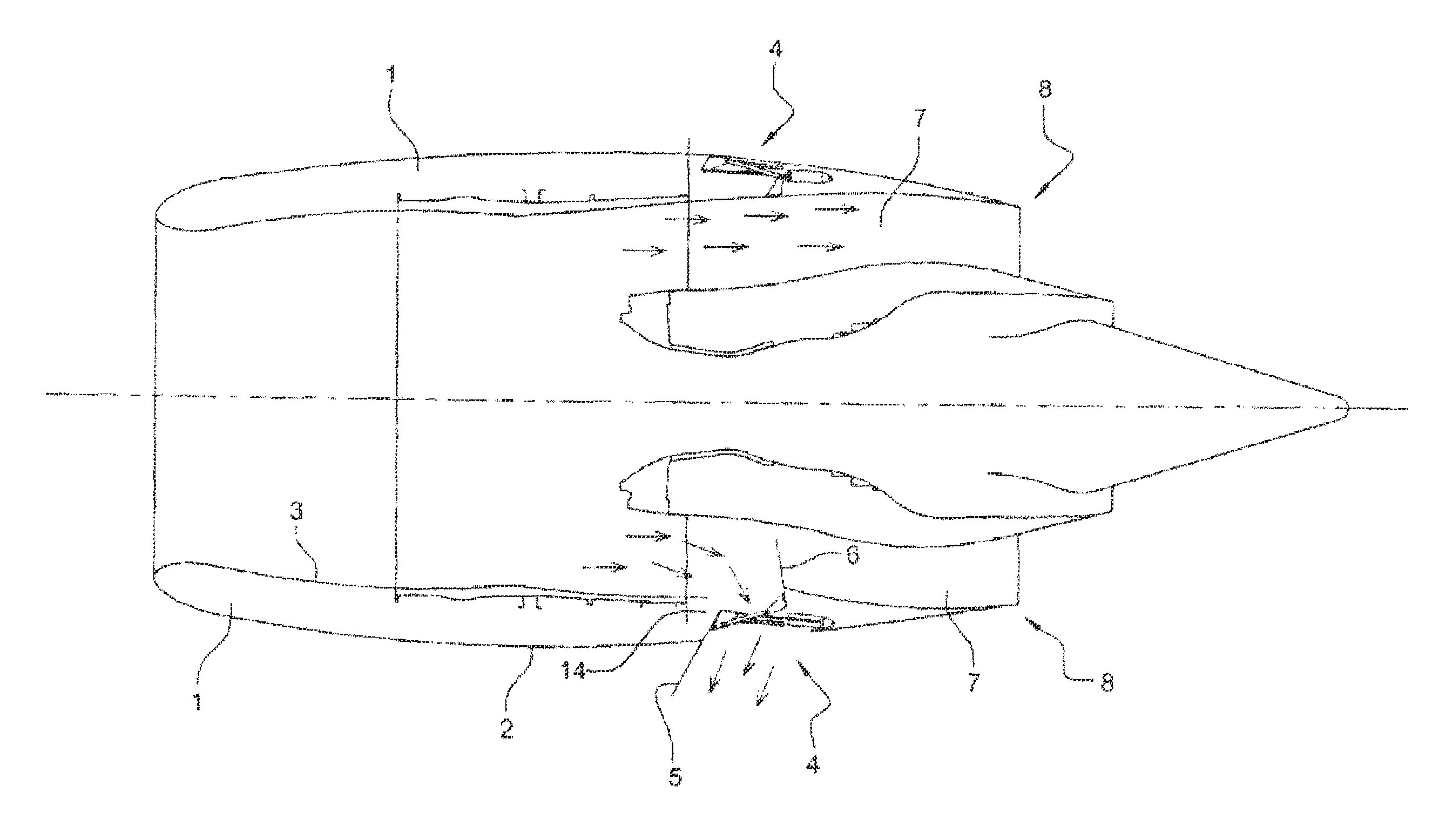

Nacelle for double flow engine

ActiveUS20100072324A1Simple designSimple in design and in its method of operationPower plant exhaust arrangementsEngine fuctionsNacelleActuator

A nacelle for double-flow engine with a cowling and at least one thrust reverser, the thrust reverser having an internal door and an external door arranged in the cowling, and means for simultaneously shifting these doors between a stable retracted position in which the doors are integrated in the cowling and a stable deployed position in which the internal and external doors are positioned at least partially inside and outside of the nacelle, respectively, to deflect the secondary flow and to generate a thrust reversal. The means for simultaneously shifting the doors comprise an actuator, one extremity of which is linked to one of the doors to shift this door between the extreme positions, and at least one linkage element linked to the doors to pivot by its extremities, so that the shifting of the door entails the shifting of the other door between these extreme positions.

Owner:AIRBUS OPERATIONS (SAS)

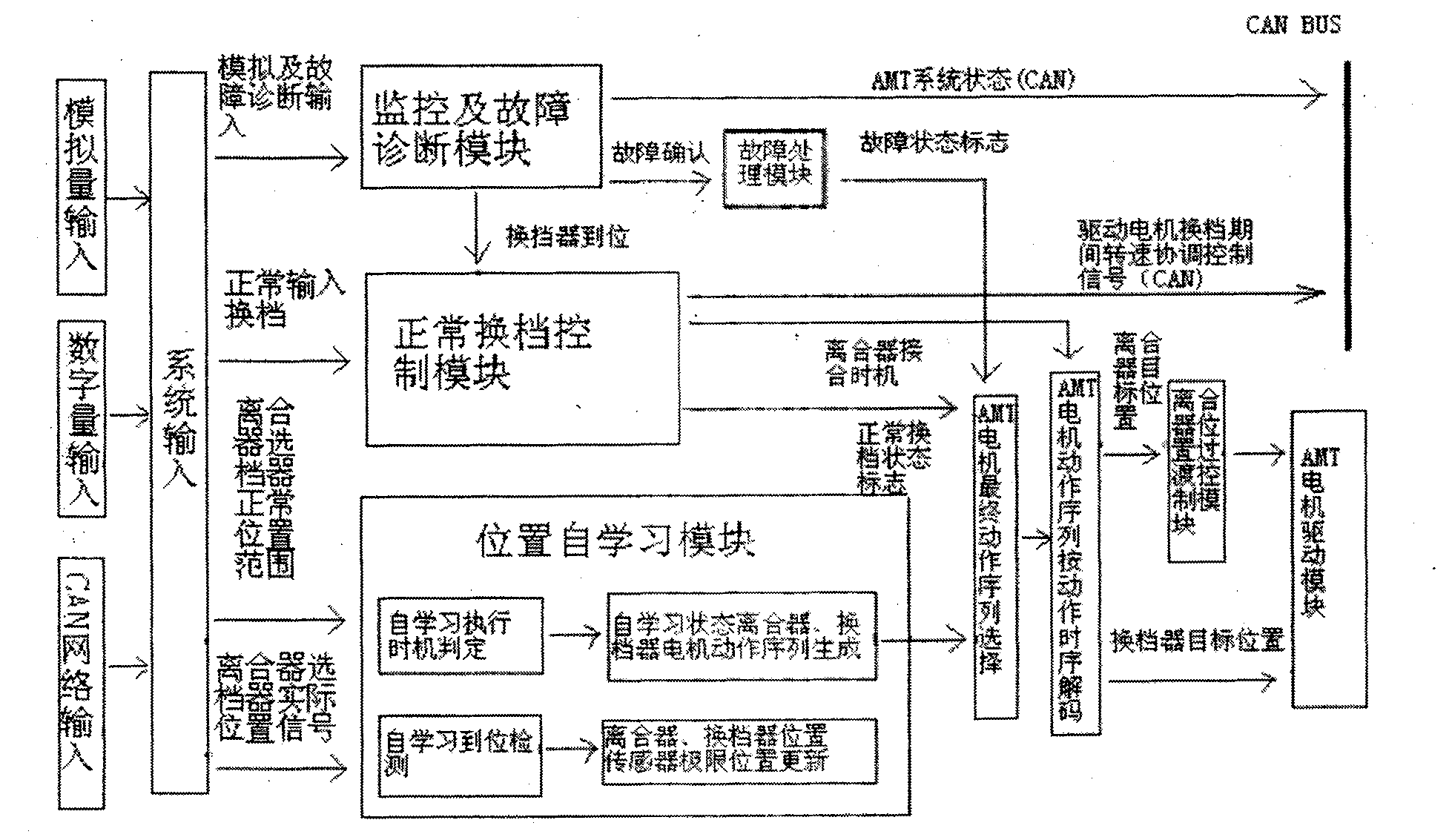

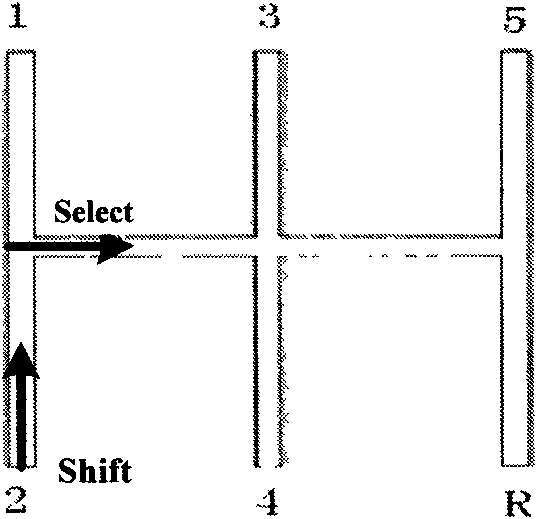

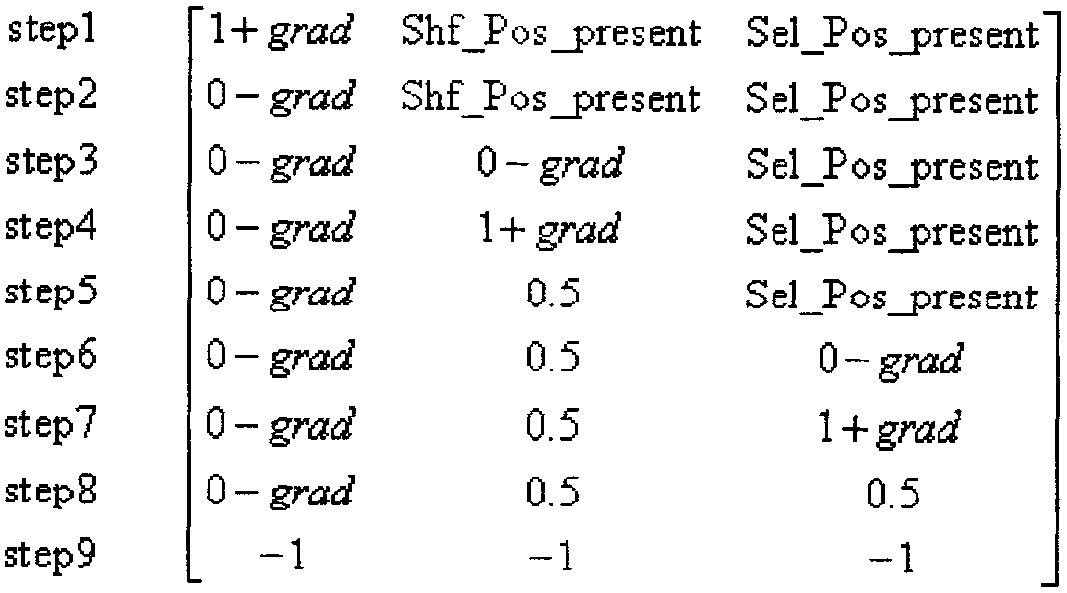

Gearshift mechanism extreme position self-learning control method for AMT system

InactiveCN102182821AMinor changesRealize automatic shiftingGearing controlMotor driveControl engineering

A gearshift mechanism extreme position self-learning control method for an AMT system is adopted for controlling the working sequence of the AMT system, and comprises the steps that firstly, an input signal of a self-learning module is acquired and input by a TCU (the control unit) and a self-learning bit zone is output to other subsequent modules of the AMT system; then an ATM action sequence module selects an action sequence matrix according the bit zone, and decoding is conducted according to action time sequence, so that the target position of each gearshift mechanism is obtained; and finally, the gearshift mechanism is driven to act by a motor driving module. The self-learning module conducts the in-place detection according to the actual position of the gearshift mechanism, and if the self learning process is completed, the extreme position parameter of a mechanical mechanism is updated and stored automatically. Therefore, when temperature is changed greatly or traveled distance is accumulated to a certain degree, the precision and the speed of motor driving can be guaranteed.

Owner:海博瑞德(北京)汽车技术有限公司

Fluid-responsive oscillation power generation method and apparatus

InactiveUS7989973B2Energy efficiencyEfficient use ofPropellersWind motor supports/mountsLeading edgeEngineering

Power generation apparatus includes a wing-shaped blade having opposite sides, opposite ends and leading and trailing edges extending between those ends. A lift differential producing device in the blade produces a lift differential at the opposite sides of the blade and that device is switched so that one blade side or the other produces the greater lift. A blade shaft extends along an axis in the blade that is in close parallel relation to the leading edge of the blade and that shaft is fixed to move with the blade. Supports support the blade shaft so that the blade can be positioned in a fluid stream with the leading edge facing upstream and swing about the axis between first and second extreme positions on opposite sides of a neutral position, the blade shaft oscillating with the blade. A coordinating device coordinates the switching of the lift differential producing device with the swinging of the blade so that the switching occurs at the extreme positions of the blade. A method of generating power using the apparatus is also disclosed.

Owner:BIRKESTRAND ORVILLE J

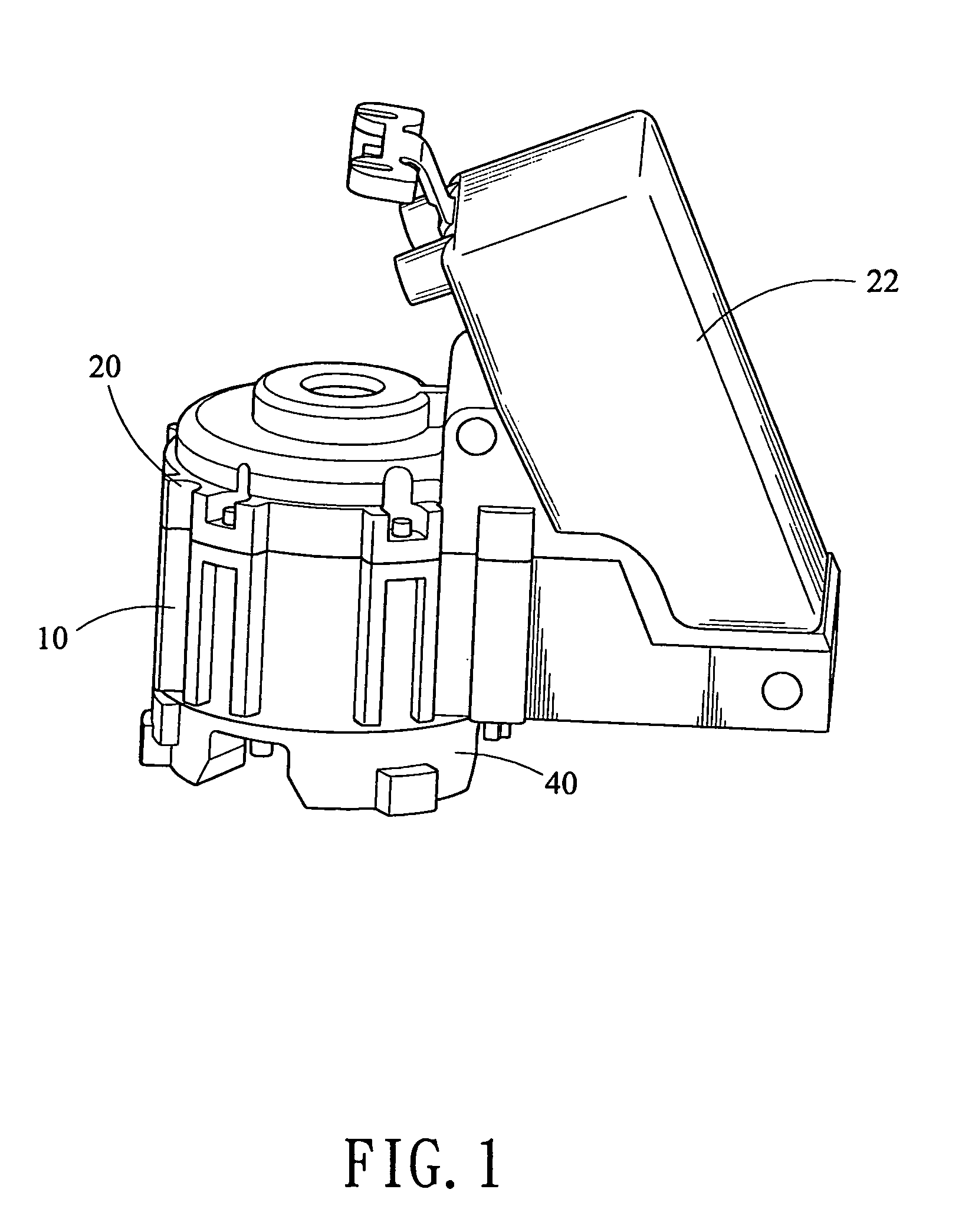

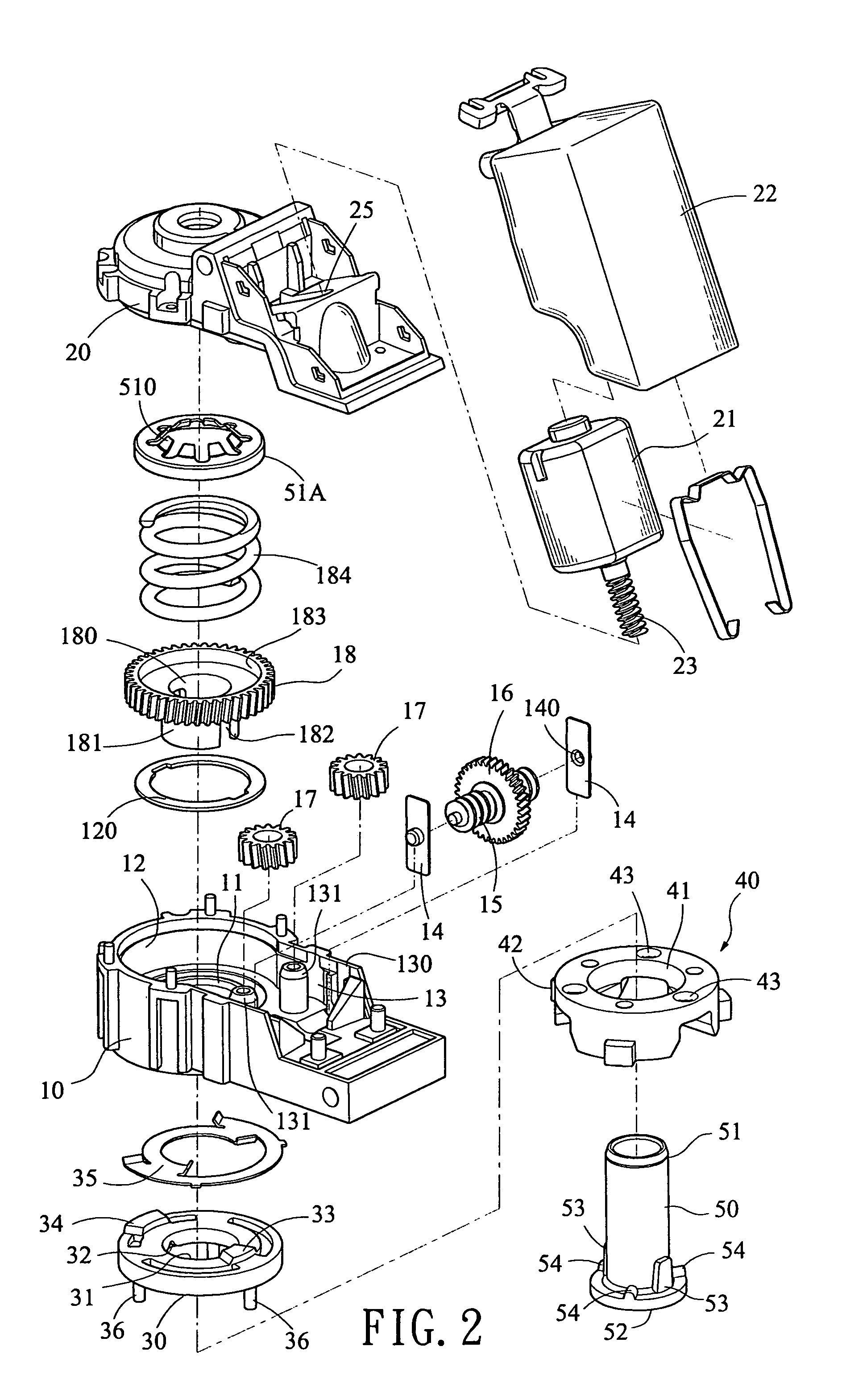

Electrically operable pivoting actuator for door mirror of motor vehicle

An electrically operable pivoting actuator for a door mirror is disclosed. The pivoting actuator comprises a frame, an electromotor, and an annular coupling member secured onto a horizontally extended support of the door mirror, the coupling member comprising two diametrically opposite protuberances wherein one protuberance is adapted to engage with a stop on the frame for stopping a clockwise or counterclockwise rotation of the coupling member relative to the frame so as to define a predetermined angle α of the fold-in door mirror as an angle between an extreme position of the stop engaged with one protuberance and another extreme position of the stop engaged with the other protuberance. The invention can be produced in a large scale for reducing the manufacturing cost and is adapted to install in any of a variety of door mirrors of motor vehicles without further modifications.

Owner:CHAW KHONG TECH

Miniature momentary contact sliding switch

Owner:BP HLDG

Rail clamp

InactiveUS20090013507A1Loose dimensional toleranceEasy to browseSnap fastenersCandle holdersEngineeringExtreme position

A clamp for attaching a medical device to an OR table rail, including two closable clamp jaws that close to an extreme position that leaves inadequate room for the rail. A handle actuates the jaws apart, and a spring biases them together through a range of jaw positions. A lock member is biased to swing through a range of lock positions in which it progressively engages and locks the jaw mechanism through its range of jaw positions. A pair of bars carries the medical device on the clamp, and allows it to be adjustably positioned with respect to the rail.

Owner:SCOTT CHRISTOPHER P

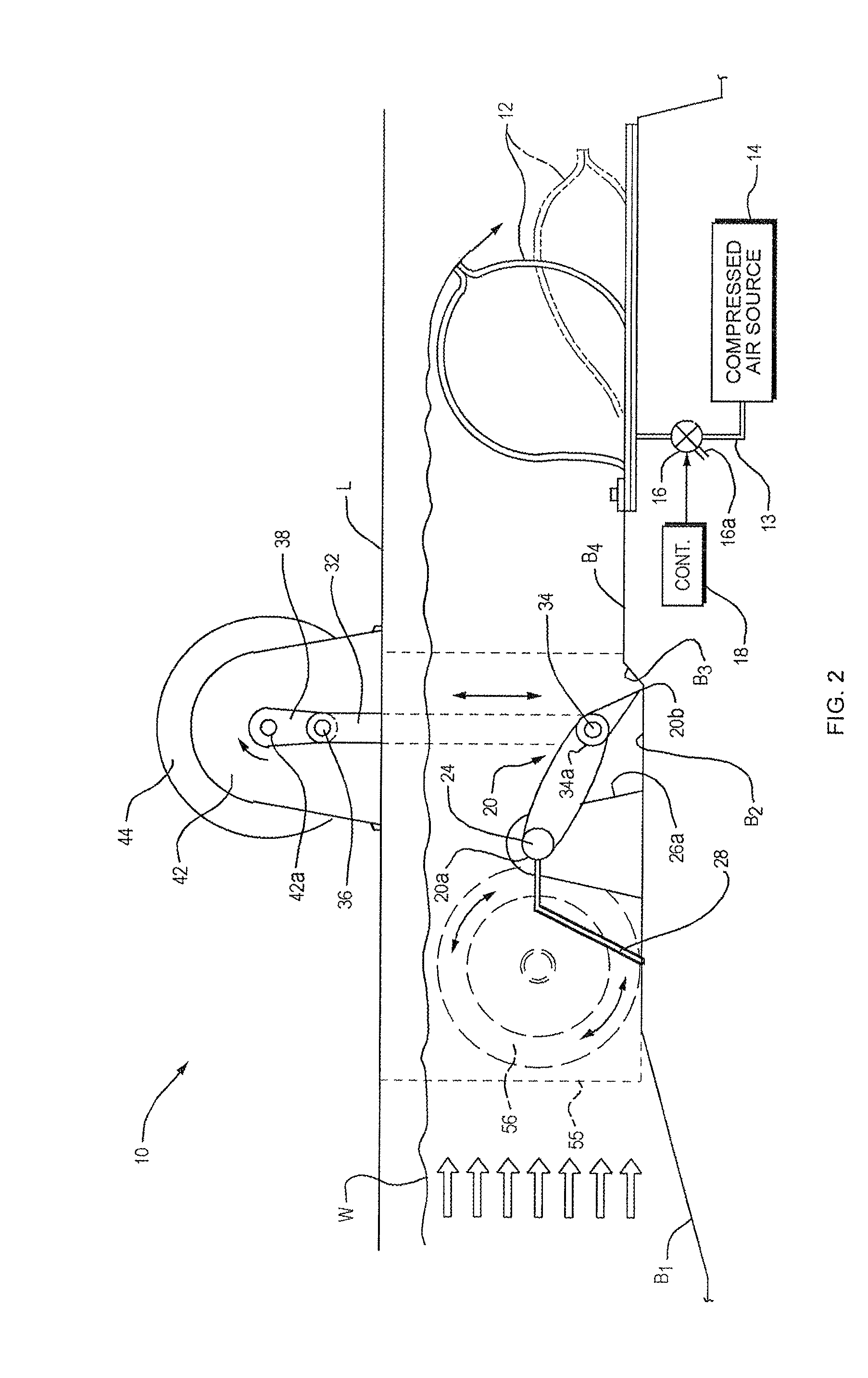

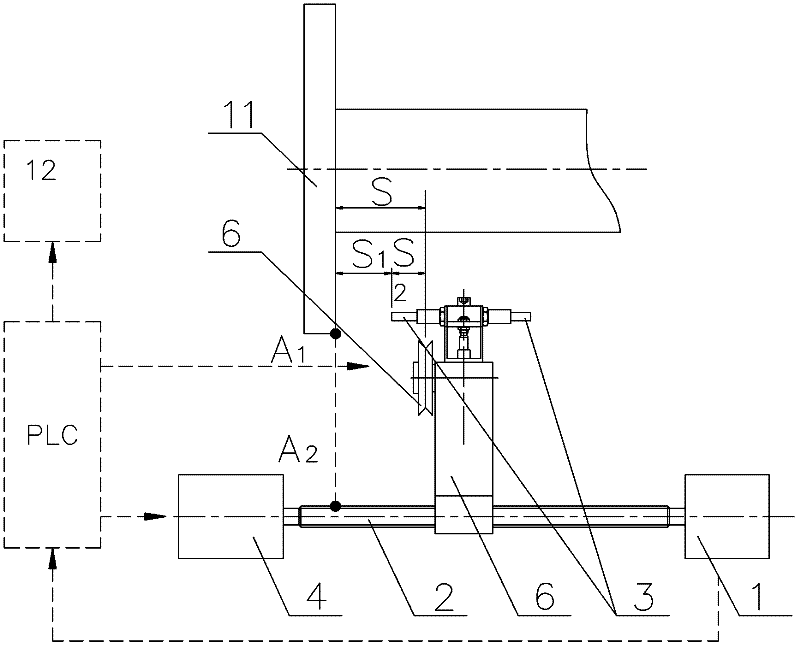

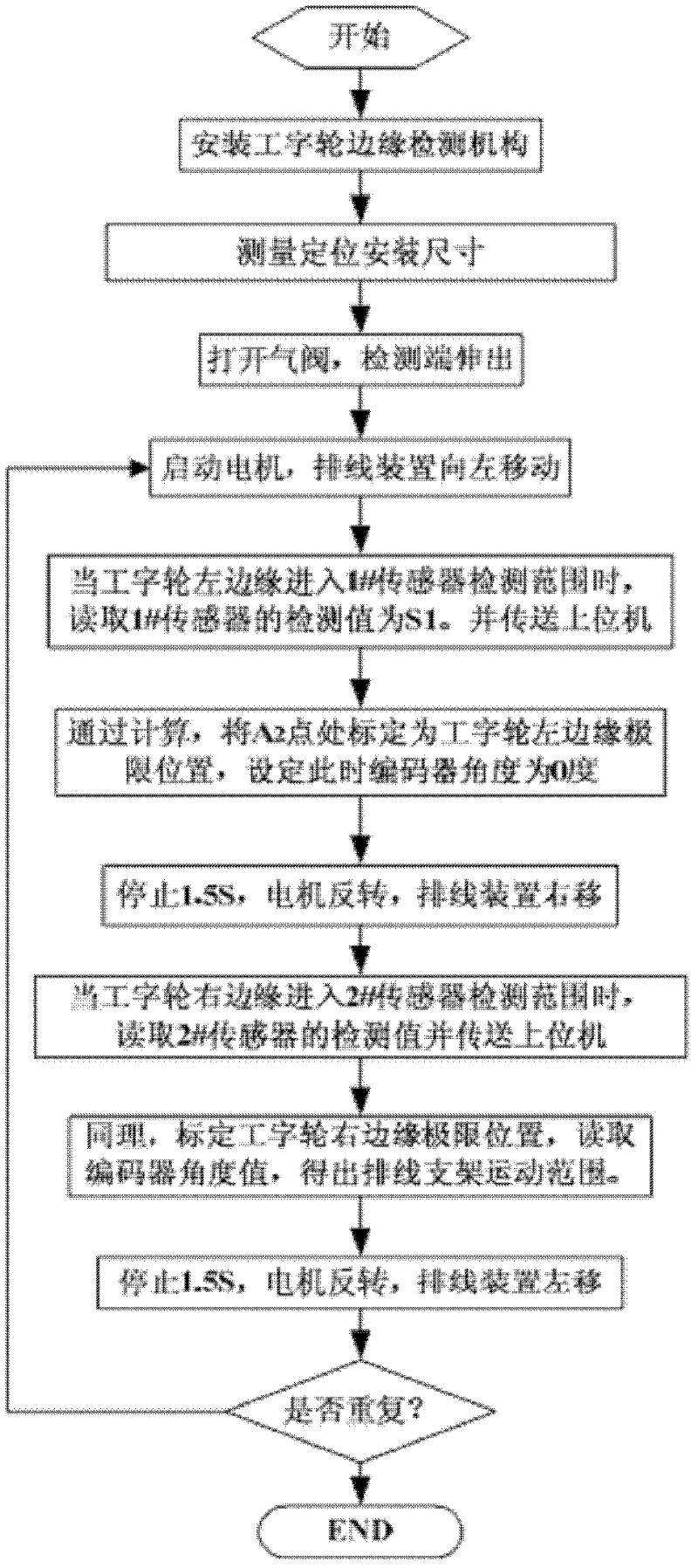

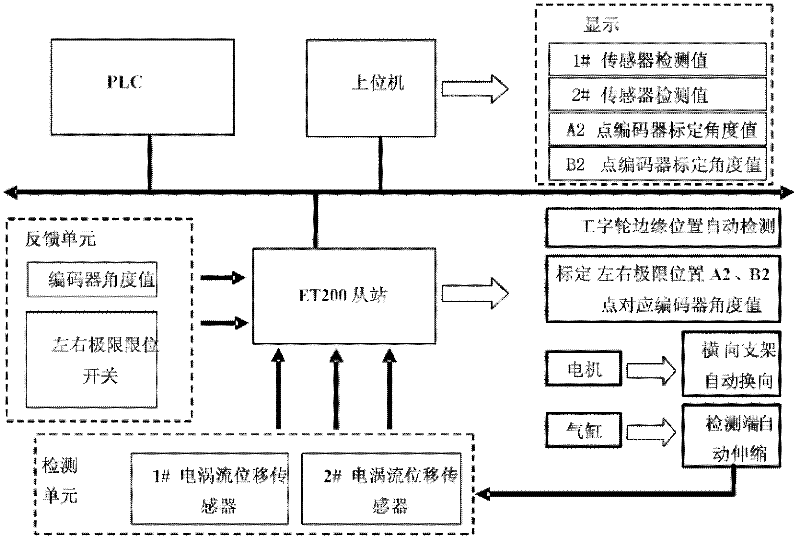

Position detecting system for edge of winding-up H-shaped wheel of wire drawing machine and control method thereof

ActiveCN102506678ASimple structureImprove detection accuracyUsing electrical meansProgramme control in sequence/logic controllersElectric machineEngineering

The invention discloses a position detecting system for the edge of a winding-up H-shaped wheel of a wire drawing machine and a control method thereof. The method comprises the following steps that: (1) two extreme positions are calibrated; in the process that a controller adopts a motor to drive a bracket to move on a lead screw, the controller acquires distances from displacement sensors to theinner edge of the H-shaped wheel by the two displacement sensors and calibrates the two extreme positions according to the distances; angle values of encoders corresponding to the two extreme positions are acquired; and (2) the bracket is controlled to do reciprocating movement between the two extreme positions, and the controller drives the bracket to move along the lead screw by the motor, and controls the motor to rotate reversely when the bracket reaches the extreme positions, so that the purpose that the bracket moves between the two extreme positions in a reciprocating manner till the wire arranging procedure on the H-shaped wheel is finished. The position detecting system has the characteristics of high detection accuracy and easiness in implementation and the like and can effectively avoid the phenomenon of wire stacking at the edge of the H-shaped wheel.

Owner:CENT SOUTH UNIV

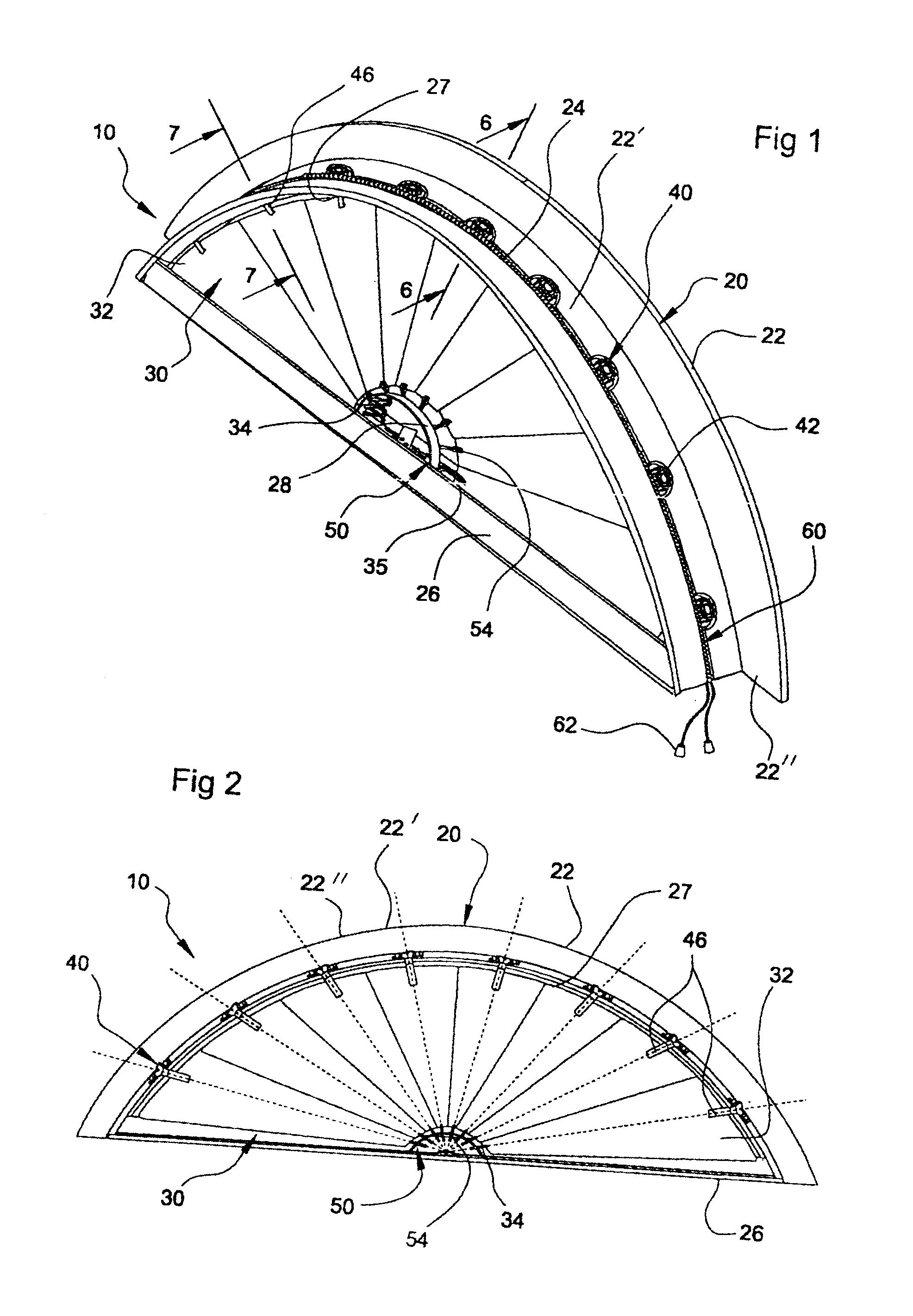

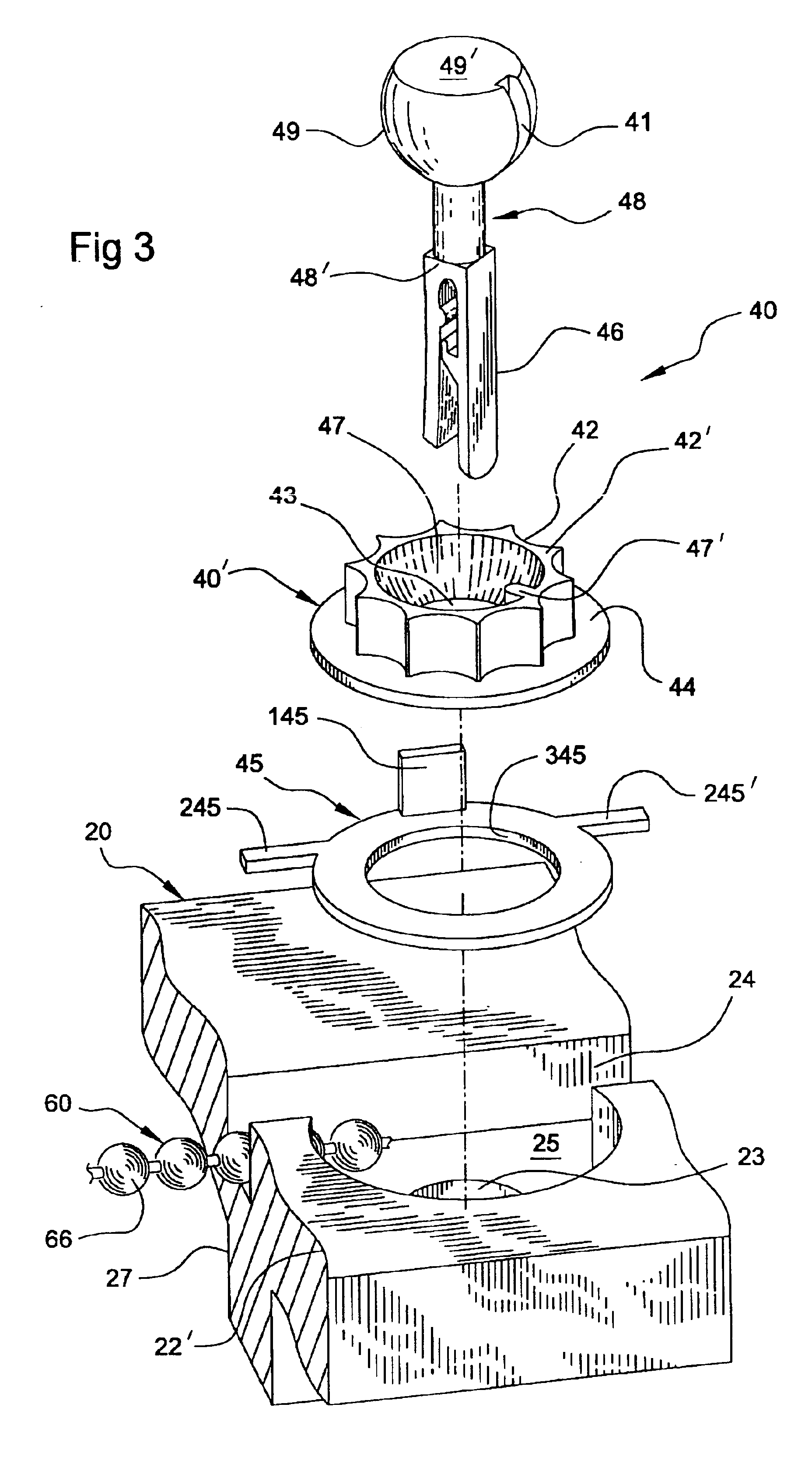

Sprocket assembly for louver arch mechanism

InactiveUS6877546B1Minimal effortVolumetrically efficientExtensible doors/windowsCurtain accessoriesEngineeringSprocket

A sprocket assembly for a louver arch assembly for semi-circular, non-perfect or imperfect arch frame assemblies with louvers rotably mounted therein. A tensioning mechanism keeps the louvers taut between an arched frame member and a smaller anchorage frame member. An actuating mechanism is used to rotate the louvers upon the application of a predetermined force to a chain that coacts with the sprocket assemblies coupled with hooked clip members that removably hold the louvers. The sprocket assembly includes a through opening and a socket with cooperative dimensions to receive the headed end of a pin, and an internal inwardly extending pin. A longitudinal channel is cooperatively disposed to receive the inwardly extending pin therein. In this manner, the louvers are rotated between two extreme positions.

Owner:GARCIA EDUARDO

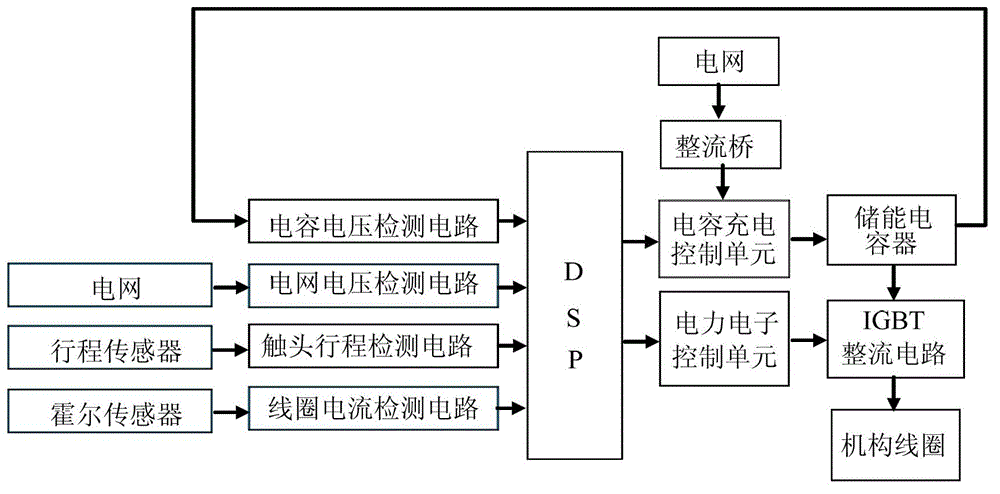

Control device and method for vacuum circuit breaker permanent magnetic mechanism based on double signal tracking

ActiveCN103336474AImprove reliabilityExtended service lifeProgramme controlComputer controlAutomatic controlElectric power system

The invention provides a control device and method for a vacuum circuit breaker permanent magnetic mechanism based on the double signal tracking, and belongs to the field of the automatic control of electrical equipment. According to the invention, a double closed-loop PID control algorithm is adopted to enable a vacuum circuit breaker permanent magnetic operating mechanism contact terminal with movement characteristics to be in a controlled state, so as to improve the robustness and control precision of a control system; field coil electric current of a current sensor measurement mechanism in the control device is utilized to enable the field coil electric current to be subjected to whole-course control, so as to avoid the possibility of coil burning down; a contact terminal journey dynamic curve is selected to reduce the impulsive force of a moving contact reaching an extreme position, so as to improve the reliability of the mechanism action and prolong the service life of the mechanism; the divide-shut brake voltage is improved, and the contact terminal journey curve is selected to reduce energy loss of the contact terminal caused by collision, so as to achieve the energy-saving effect, enable the circuit breaker to complete brake reclosing operation for more times under the same application condition, effectively prolong the service life of the circuit breaker, and improve the stability of an electric power system simultaneously.

Owner:SHENYANG POLYTECHNIC UNIV

Method for calibrating zeroing of servo mechanism

The invention relates to a method for calibrating the zeroing of a servo mechanism, which comprises the following steps: driving a servo motor in a low rotation speed mode to drive a moving part to move to a first extreme position and a second extreme position respectively; in the moving process of the moving part, continuing to detect whether the motor control energy of the servo motor exceeds afirst threshold value or a second threshold value; acquiring a motor coordinate value corresponding to the first or second extreme position when the motor control energy is increased to exceed the first threshold value or the second threshold value when the moving part reaches the first or second extreme position; and finally, calculating a conversion function of the motor coordinate and the actual coordinate by utilizing an actual coordinate value of the first extreme position, an actual coordinate value of the second extreme position, the motor coordinate value corresponding to the first extreme position and the motor coordinate value corresponding to the second extreme position. The method can simplify the structure of the servo mechanism and avoiding the use of an additional detectiondevice for determining whether the moving part reaches the extreme position.

Owner:MICRO-STAR INTERNATIONAL

Suction device with means for removing a replaceable tip

A method for removing a replaceable tip used with a suction device for dispensing a liquid removes the tip by bringing a removal device, arranged in an air space formed jointly by a sample space of a replaceable tip and a cylindrical space of an end part of a suction device, movable between its two extreme positions, namely an inner home position and an outer removal position, into cooperation with an inside surface of the replaceable tip mounted on the end part whereby the movement of the removal device into its removal position causes the replaceable tip to be detached from the end part. A suction device is provided for using the method.

Owner:SARTORIUS BIOHIT LIQUID HANDLING

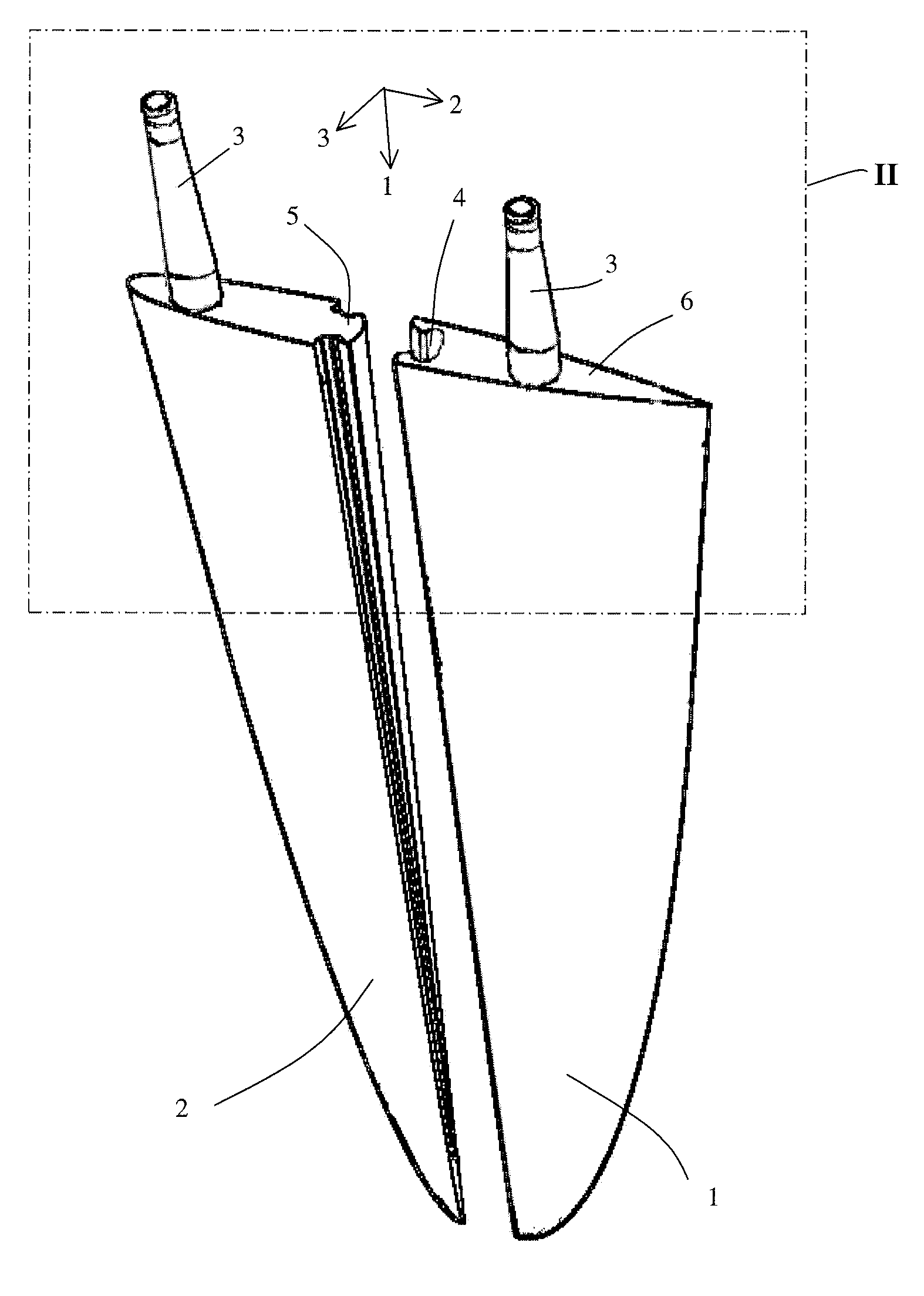

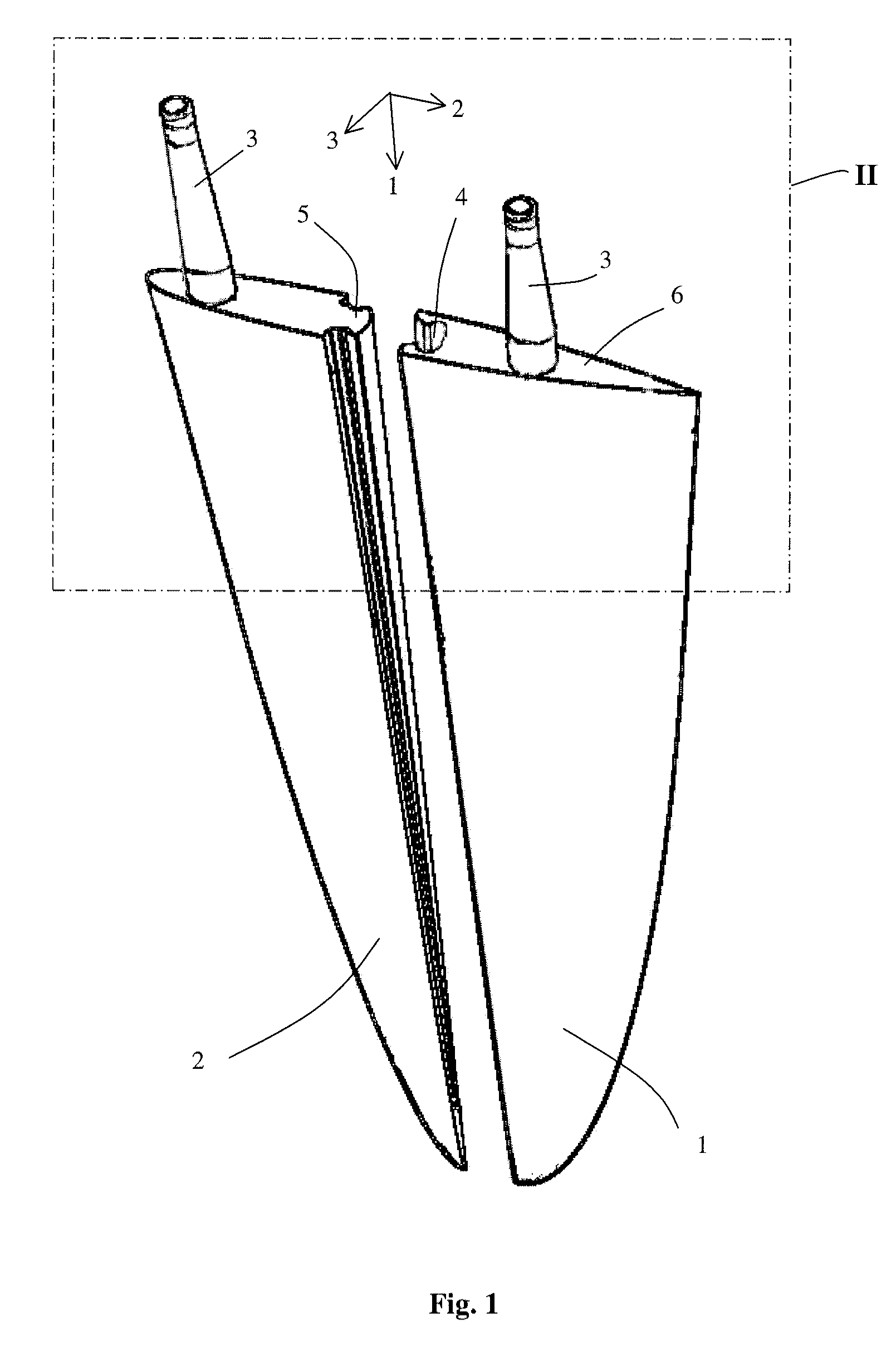

Dynamic fin comprising coupled fin sections

InactiveUS20110061579A1Improves hydro and aerodynamic propertySame effectPropellersWater sport boardsRotational axisCoupling

A dynamic or aerodynamic fin comprising at least two parallel arranged fin sections. At least one fin section comprises a rotational axis for installing the fin section by a rotation shaft. An end stop is provided for stopping the rotational movement of the fin section to define an extreme position. In the extreme position the fin sections provide a substantially cambered shape to the fin. The dynamic fin is improved in that it comprises a pair of coupling elements. A first fin section is coupled to a second adjacent fin section by a pair of a first and second coupling elements. The first coupling element is complementary to the second coupling element. The first coupling element is part of, preferably integral, with the first fin section and the second coupling element is part of, preferably integral, with the second fin section.

Owner:VAN GELDER KLAAS BOUDEWIJN

Method for determining local strength of bottom structure of ship launched from berth

The invention discloses a method for determining the local strength of a bottom structure of a ship launched from a berth. The method is characterized by comprising steps of firstly, simplifying the integral structure of the ship into a variable-cross-section thin-walled beam along the length direction of the ship, perpendicularly flexibly supporting buttresses, selecting a series of gliding positions as working conditions when the ship glides along the berth, acquiring values of buttress reaction force born by the ship structure corresponding to the various buttresses, and determining various stress extreme positions of the structure; secondly, analyzing the strength of the structure corresponding to the stress extreme positions by the aid of a local three-dimensional finite element model, and determining the structural strength of various regions. The method has the advantages that integral ship beam computation is combined with a local three-dimensional finite element model analysis process, so that modeling workload can be greatly reduced as compared with a whole-ship three-dimensional structural finite element modeling analysis process in the prior art, the computation time can be saved, and the analysis speed can be increased.

Owner:DALIAN SHIPBUILDING IND

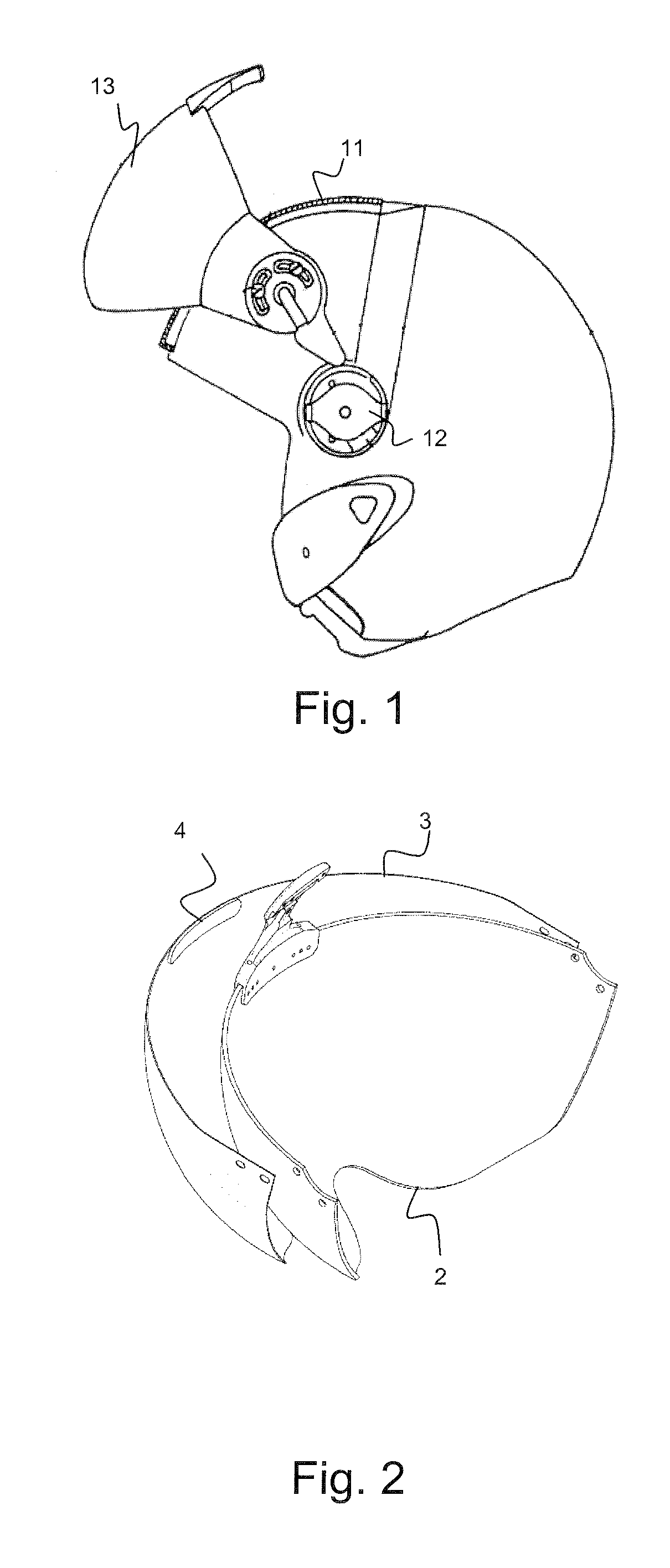

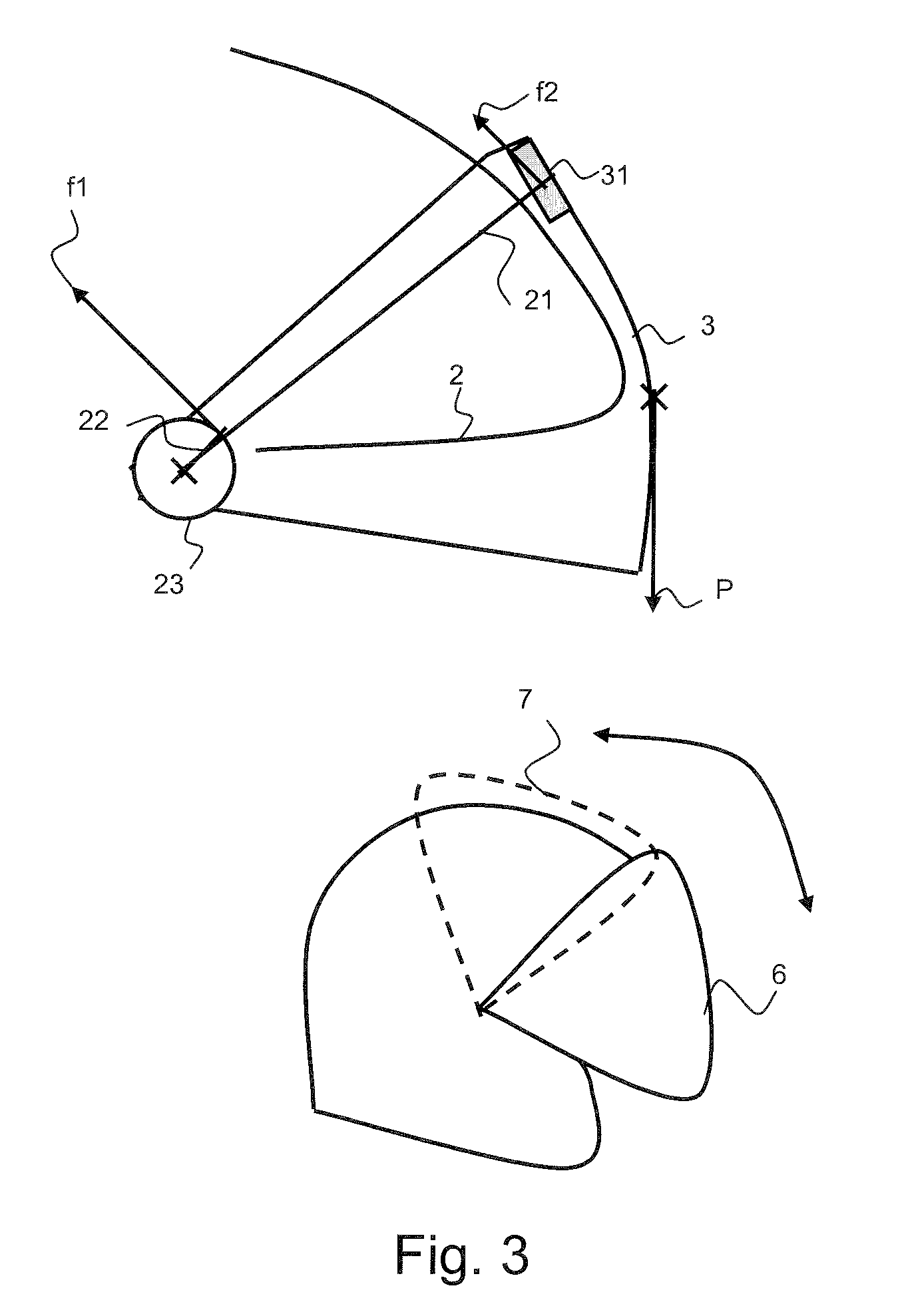

Headset Including a System for Securing the Visor by Microfibres

InactiveUS20100107292A1Produce friction resistanceImprove the resistance in piloting operationPersonal protection gearHelmetsFiberEngineering

The invention relates to headsets comprising at least a supporting shell and a moving visor that can be displaced between two extreme positions.The headset includes a system for securing the visor in any position between the two extreme positions by friction between the visor and the supporting shell, the friction being produced by at least one microfibre felt element.The invention applies to the field of headsets in general for users of motorized craft such as in aeronautics and automobiles for example.

Owner:THALES SA

Actuator mechanism and a shutter mechanism

ActiveUS20070242949A1Stable and controlled positionPrevent movementPermanent magnetsShuttersShape-memory alloyActuator

In one example, an actuator mechanism comprising: one or more coils for establishing a magnetic field; a rotating permanent magnet, which has at least one extreme position depending on the magnetic field; and driving members, which are coupled to the permanent magnet and by means of which the members coupled to the actuator mechanism are driven. In another example, an actuator mechanism comprising: one or more wires, which are manufactured of a shape memory alloy that shrinks when heated; and driving members, which are coupled to said wire and by means of which the members connected to the actuator mechanism are driven.

Owner:NOKIA CORP

Mechanism for internal combustion piston engines

InactiveUS7174863B2Precise positioningConnecting rodsInternal combustion piston enginesCombustionReciprocating motion

A rocking mechanism through which linear reciprocating movement of a piston of an internal combustion engine can be transferred, from the remote end of a connecting rod on which the piston is mounted, to a crankshaft. The mechanism includes a rocking member; mountings by which the rocking member is mountable in relation to the crankcase for the engine, for reversible rocking movement on a first axis (X1); a link member pivotally connected at one end to the rocking member so as to be pivotable relative to the rocking member on a second axis (X2) between two extreme positions; and a holding device.

Owner:SCALZO AUTOMOTIVE RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com