Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Tight grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

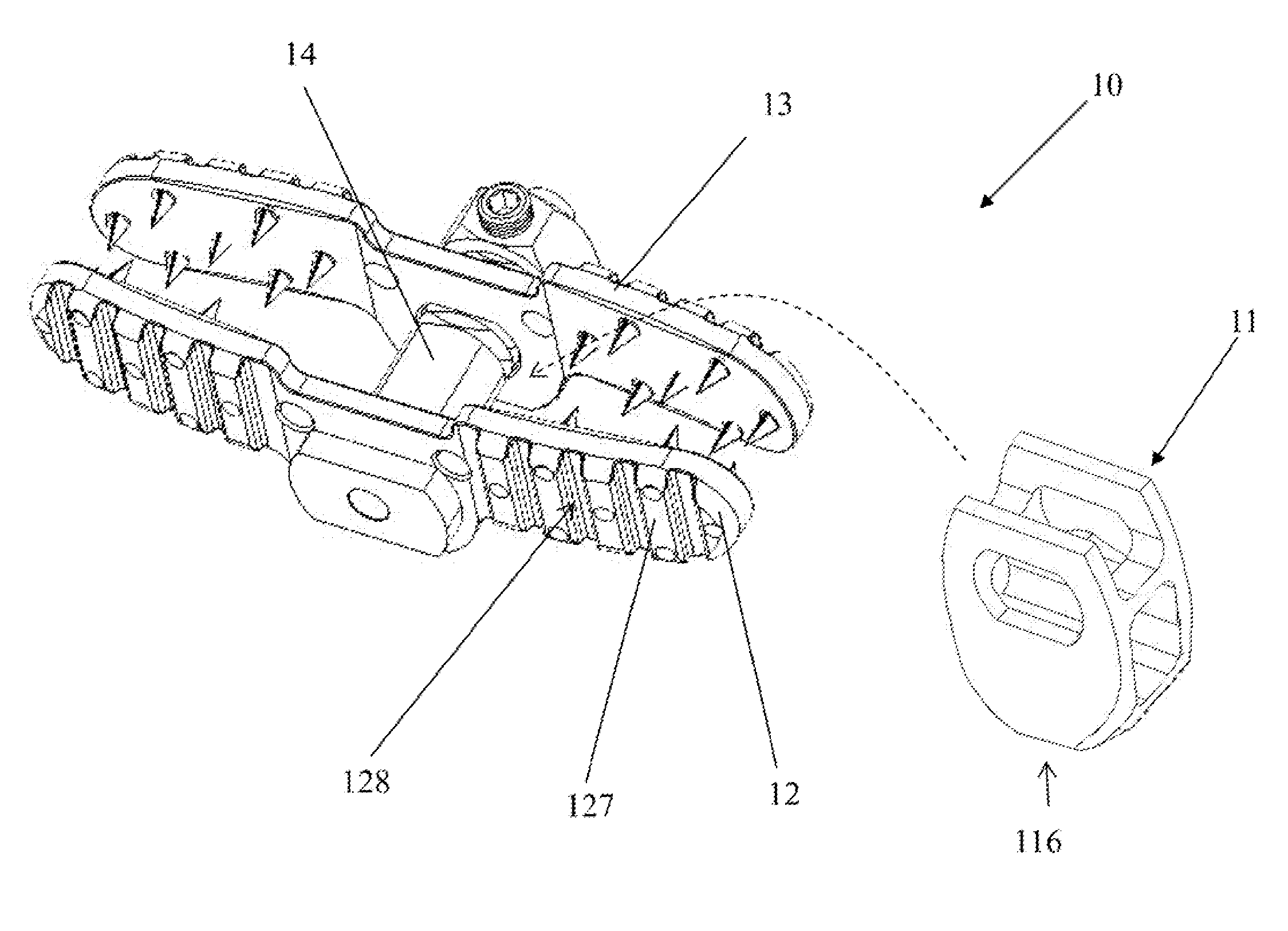

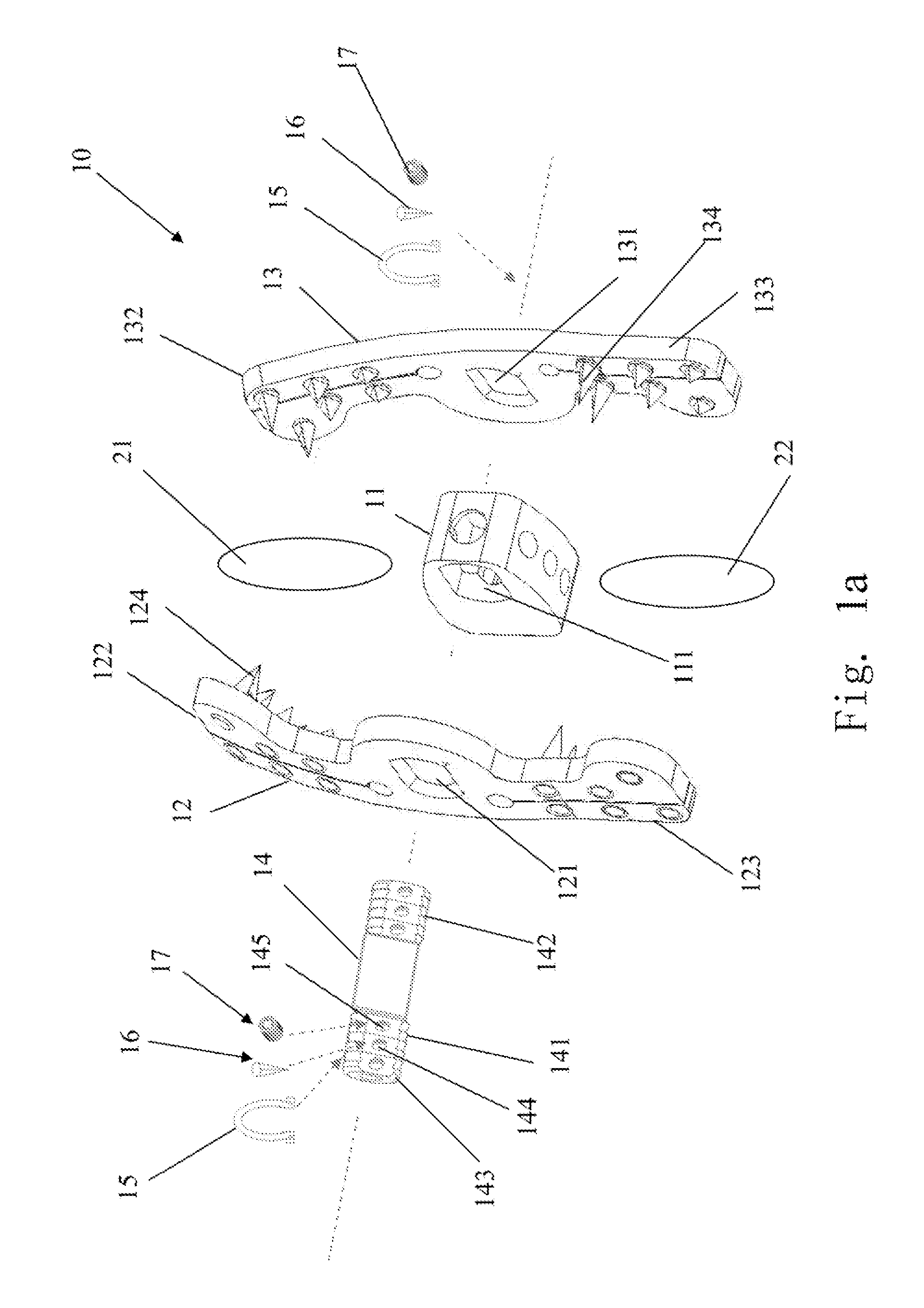

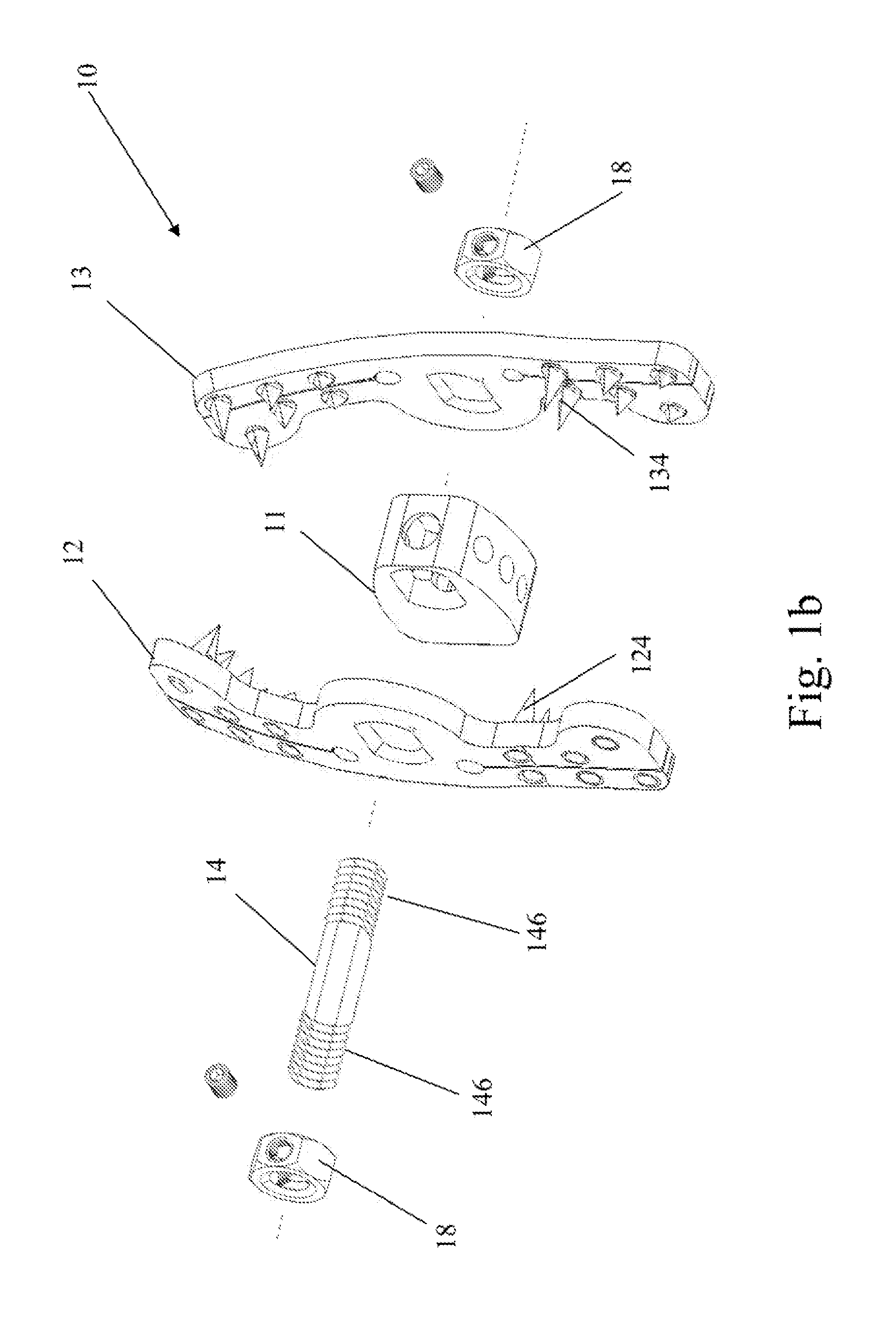

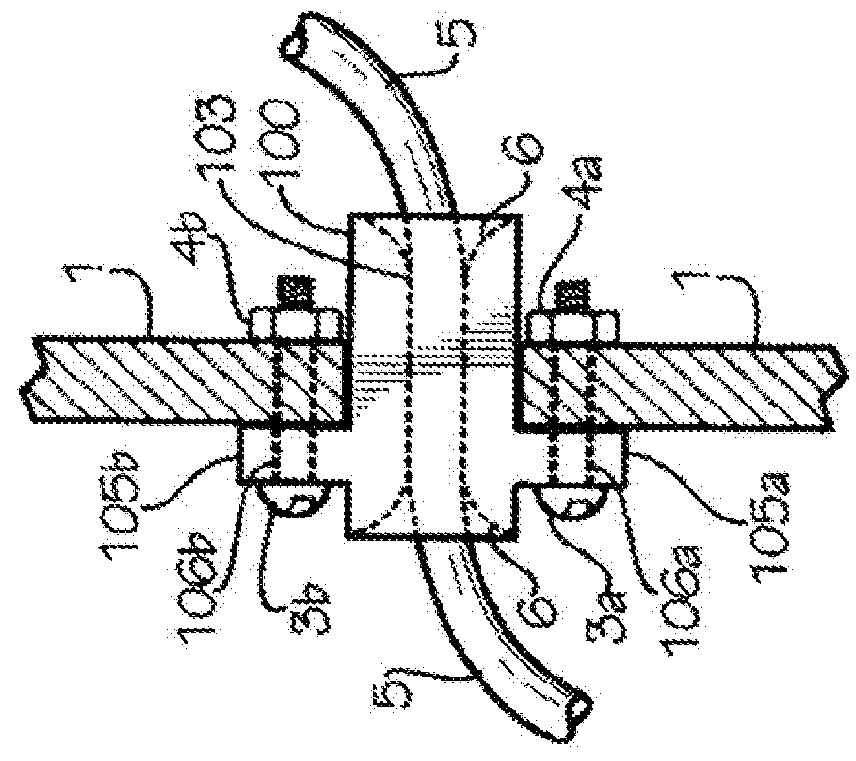

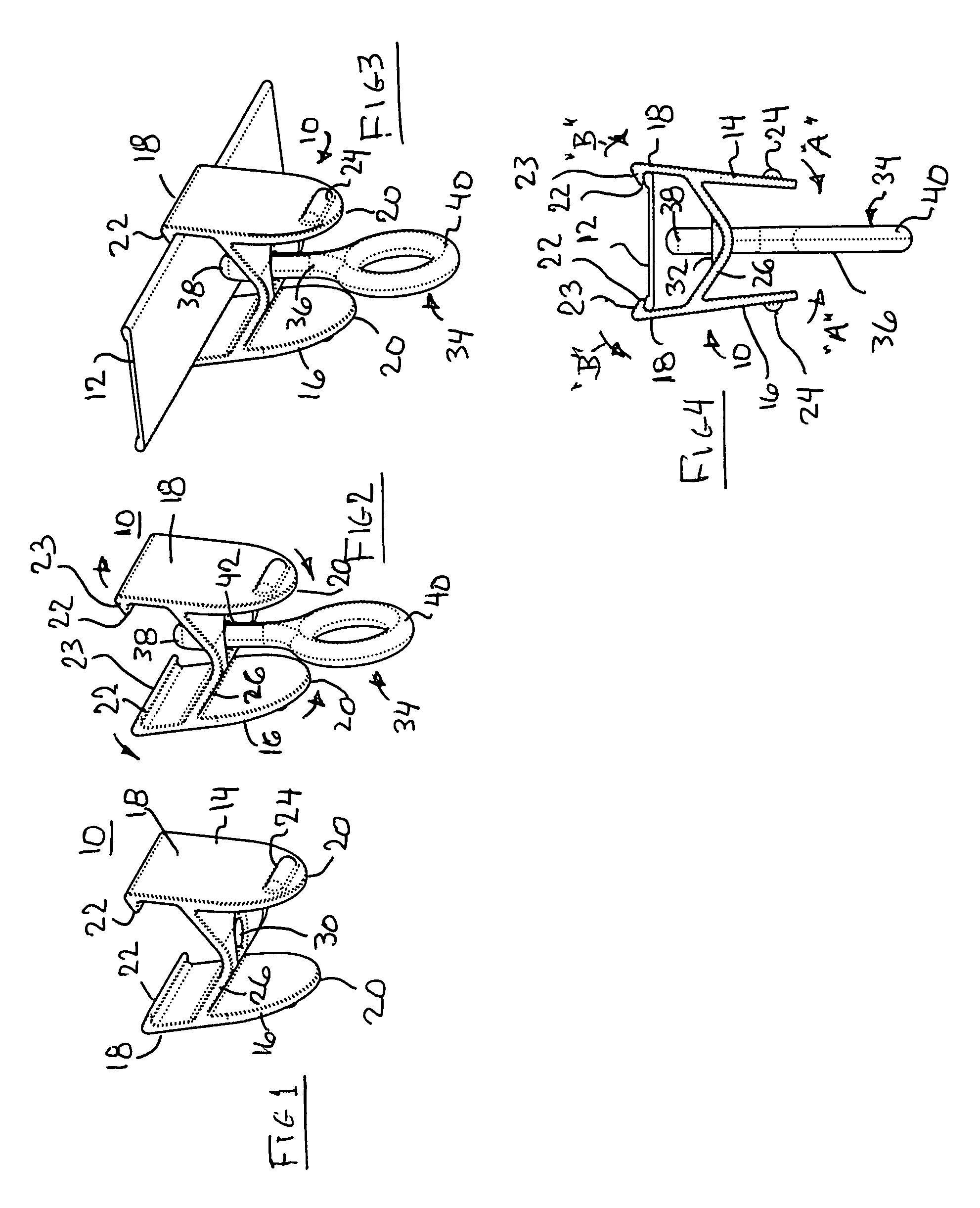

Device for tightly gripping on the spinous process of the spine

InactiveUS20120089184A1Tight gripPrevent revolutionInternal osteosythesisJoint implantsEngineeringSpinous process

Disclosed is a device for tightly gripping on the spinous process, installed between two spinous processes, with a horizontal hole through the main body, and two arc-shaped side plates connecting onto two ends of the main body, each plate having a through hole, and fastening on the spinous process, and a centrally placed item passing through a horizontal hole of the main body thereby connecting the main body and the two plates, and firmly fastened by a single or plurality of fastening items on one or two sides of the centrally placed item. Furthermore, the centrally placed item having at least one fixed hole section, and when the fastening items move toward the main body and tighten, the two plates change shape, putting pressure on the upper and lower gripping section of the two plates, this upper and lower gripping section therefore more firmly gripping on the spinous process.

Owner:YEH CHUNG CHUN

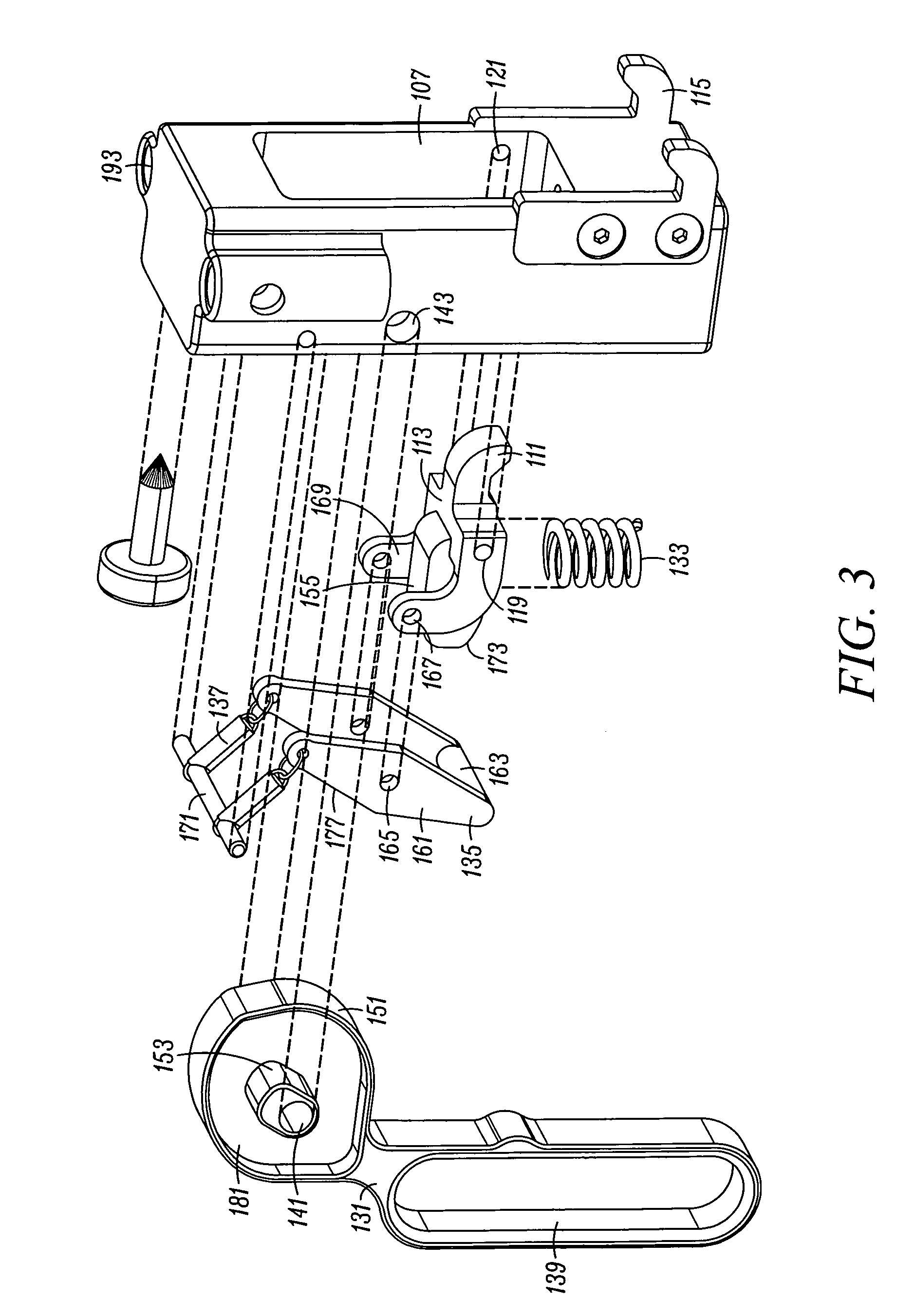

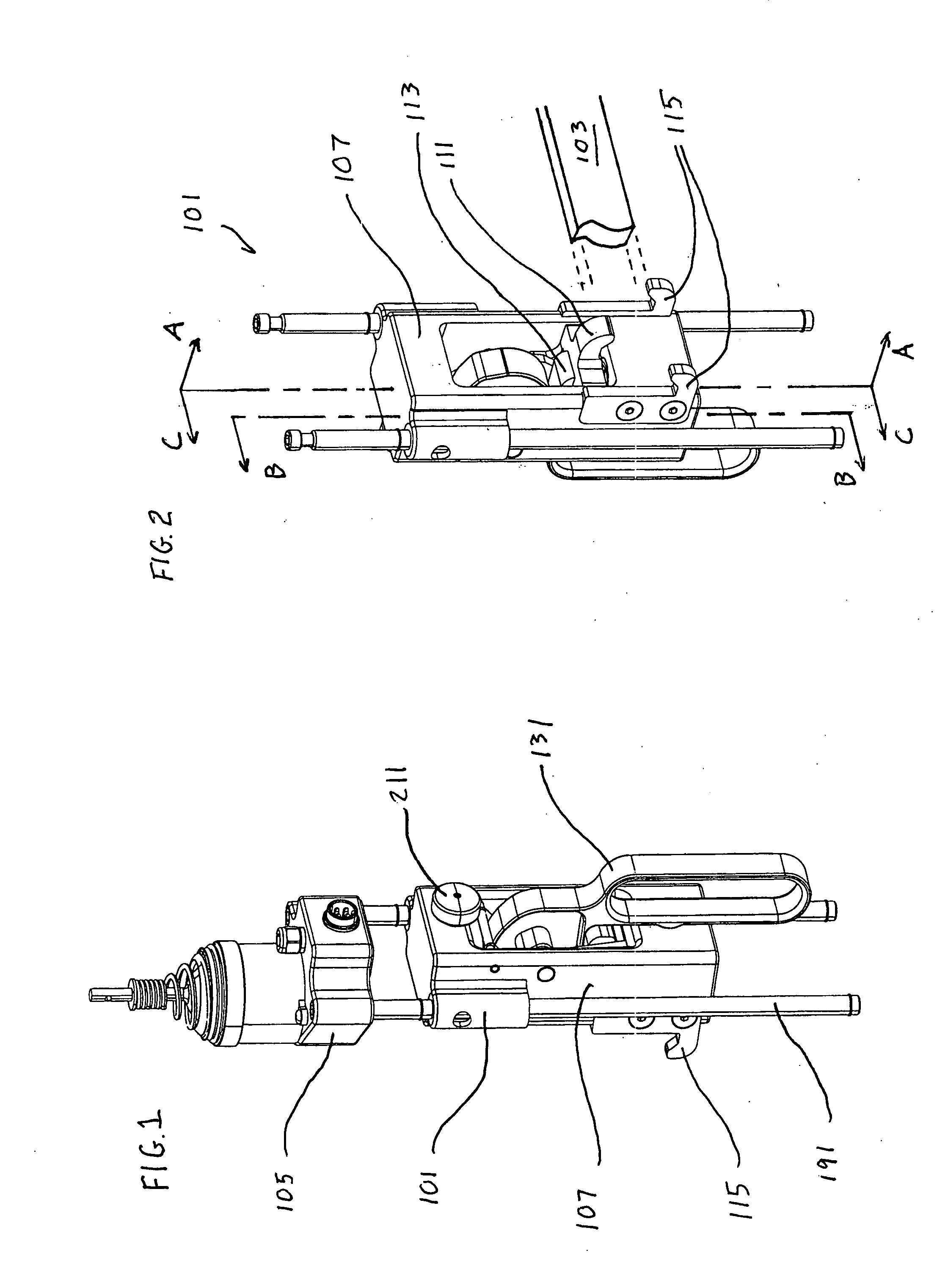

Rail clamp

A clamp for attaching a medical device to an OR table rail, including two closable clamp jaws that close to an extreme position that leaves inadequate room for the rail. A handle actuates the jaws apart, and a spring biases them together through a range of jaw positions. A lock member is biased to swing through a range of lock positions in which it progressively engages and locks the jaw mechanism through its range of jaw positions. A pair of bars carries the medical device on the clamp, and allows it to be adjustably positioned with respect to the rail.

Owner:SCOTT CHRISTOPHER P

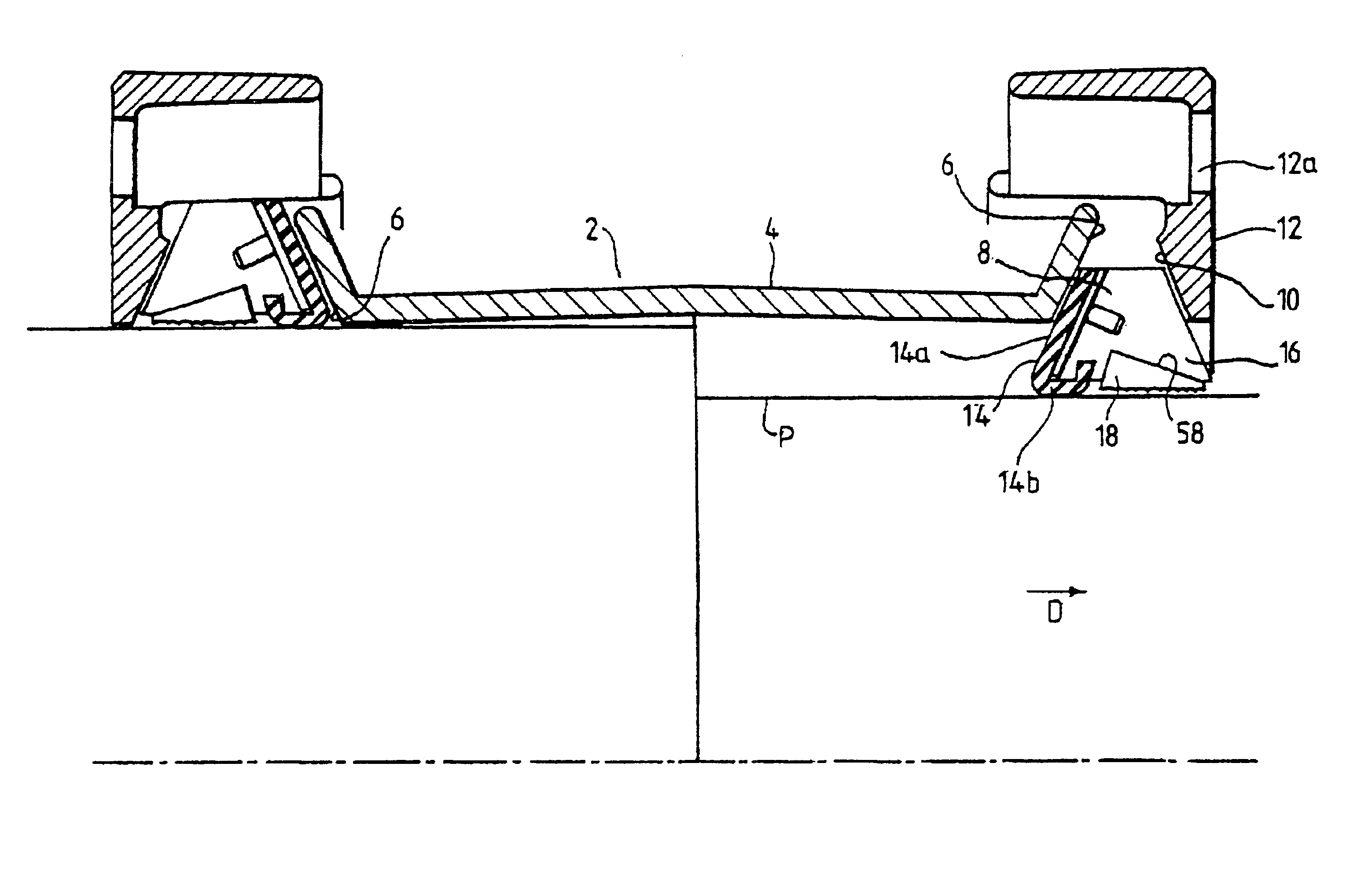

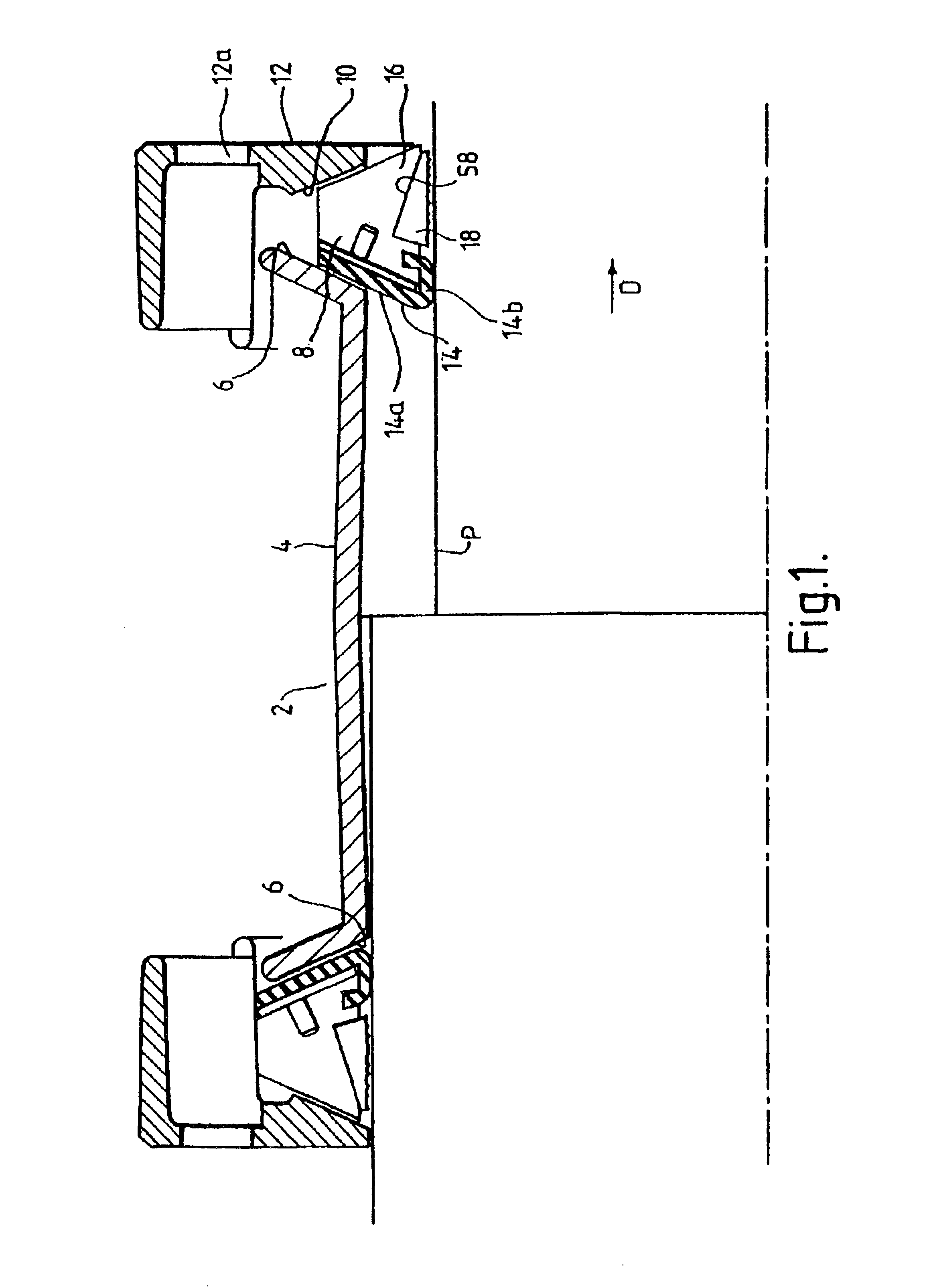

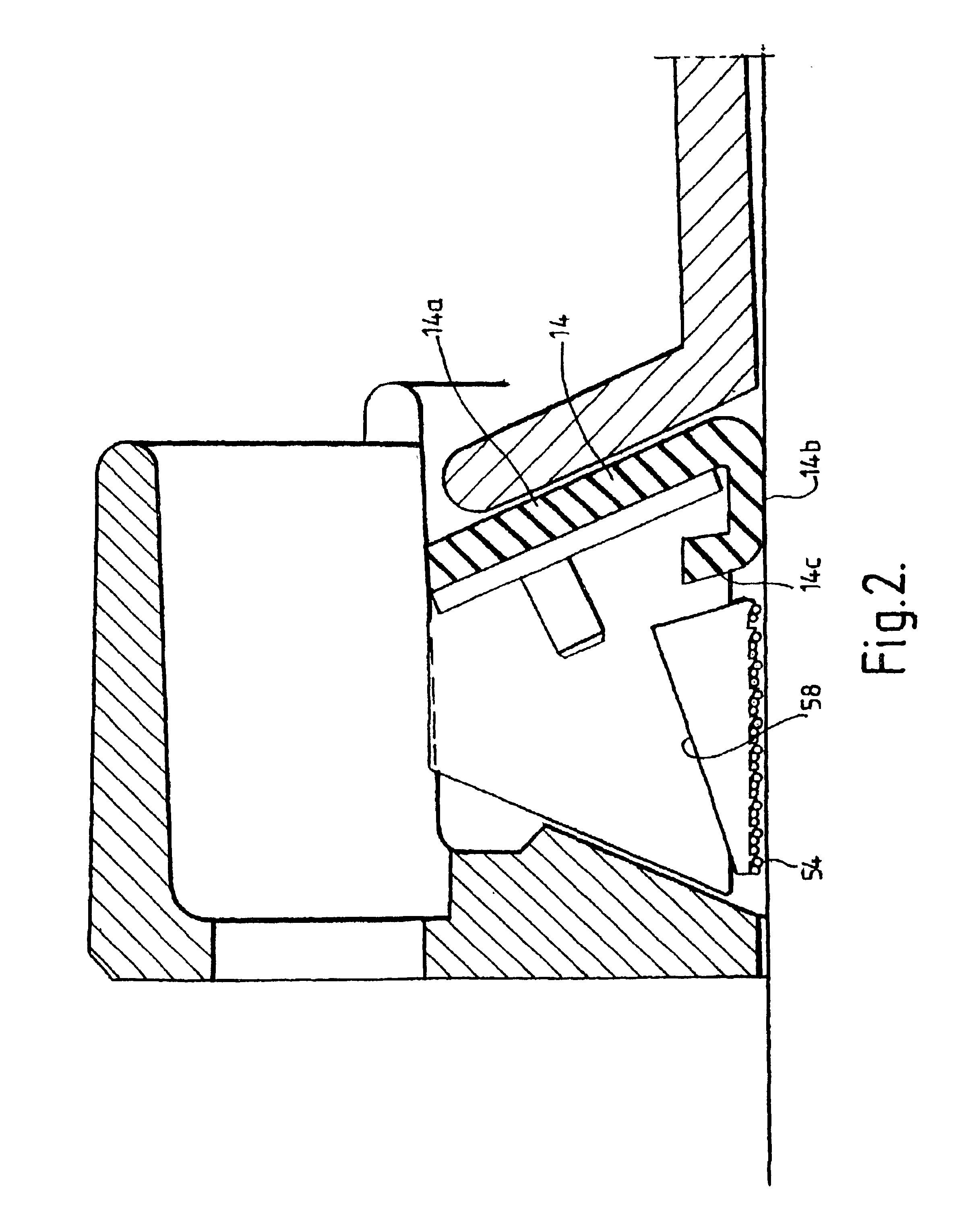

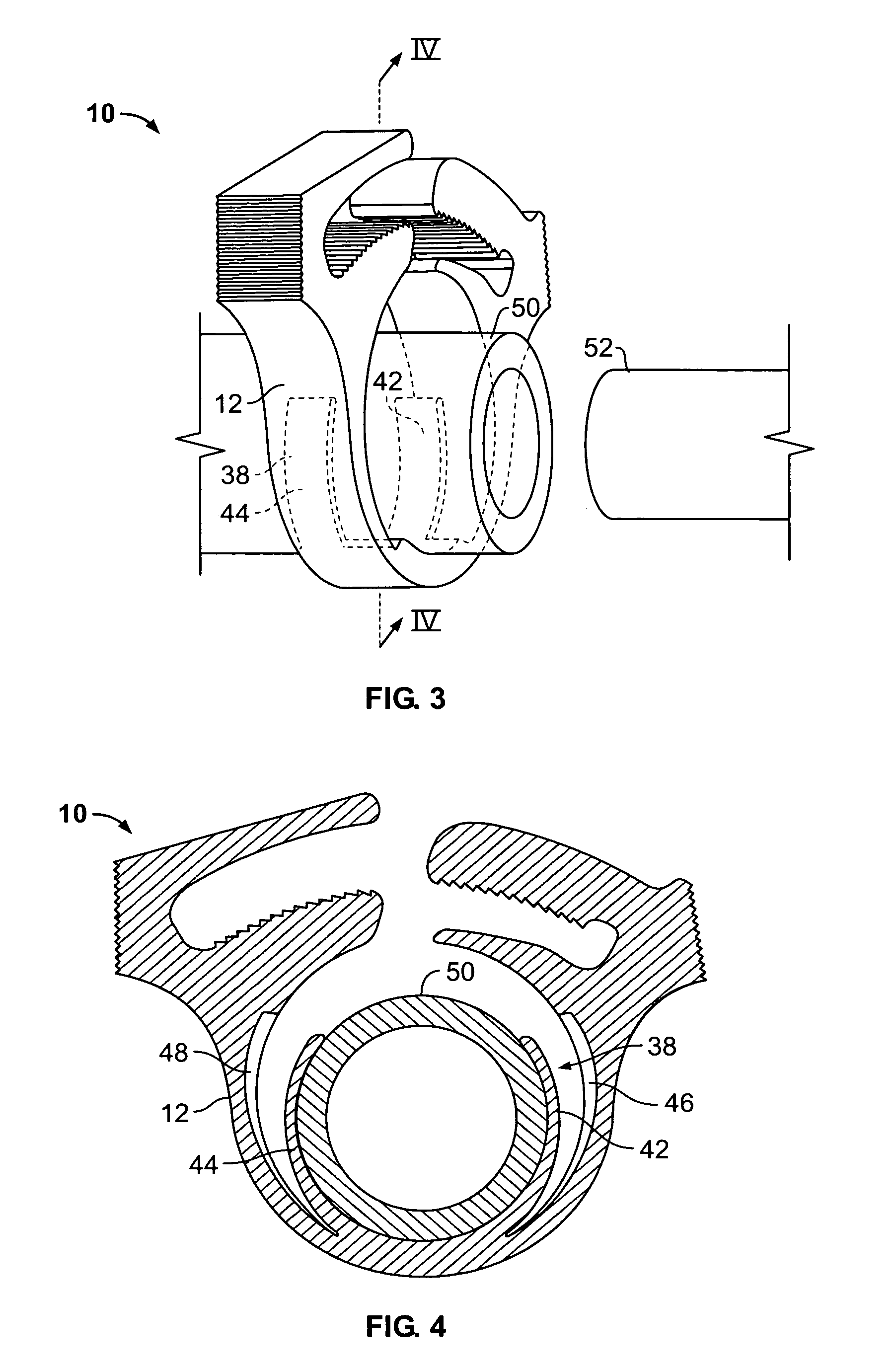

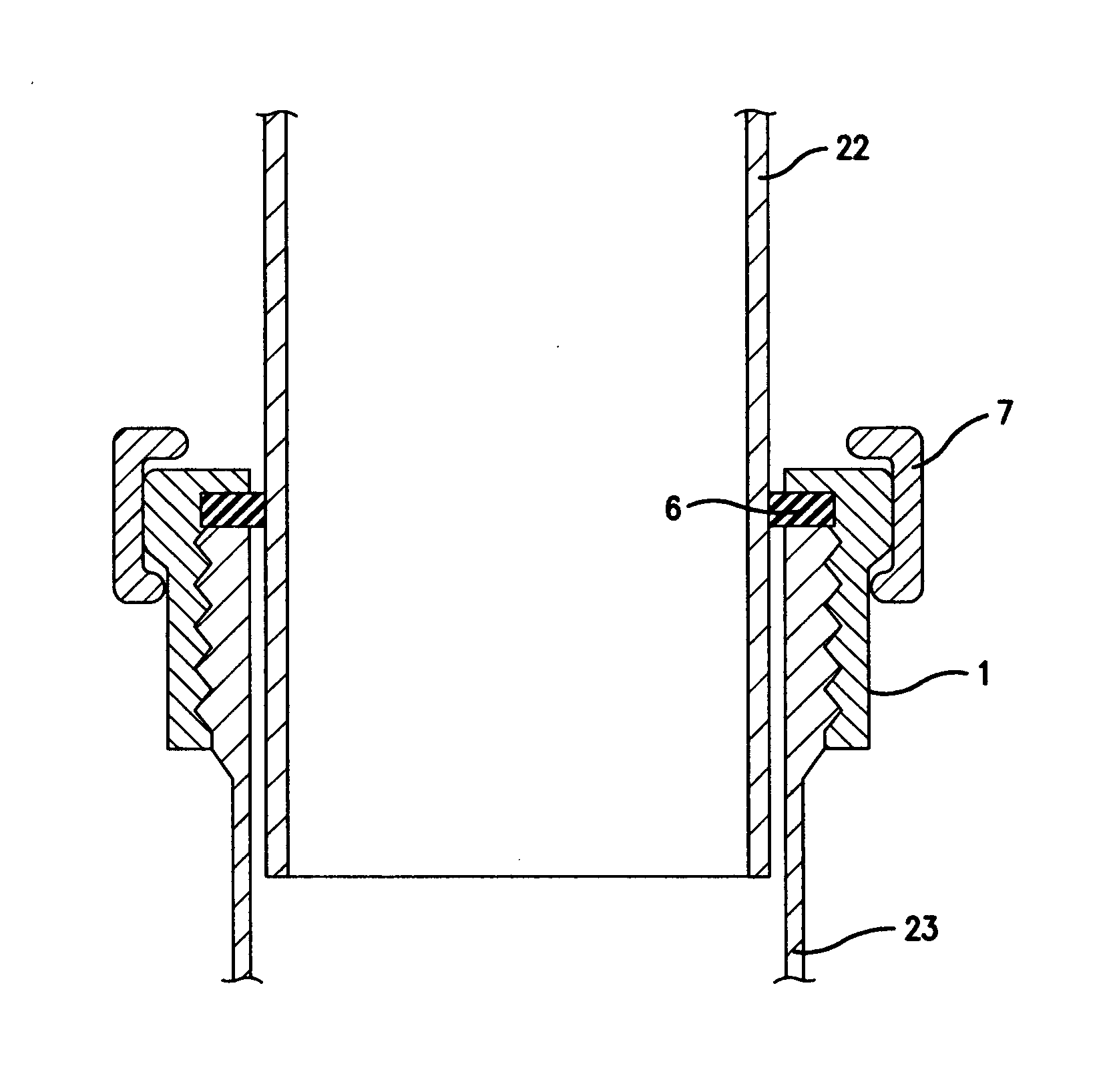

Pipe coupling device

A pipe coupling device (2) for joining the ends of two pipes is disclosed. The pipe coupling device (2) includes a sleeve (4) configured to receive an end of a pipe and having an annular first abutment surface (6); a compression member (12) having an annular second abutment surface (10); a sealing and gripping assembly (8) for sealing against and gripping the pipe; and threaded fasteners for drawing the compression member (12) and the sleeve (4) axially together so as to compress the sealing and gripping assembly (8) against the pipe. The sealing and gripping assembly (8) includes a sealing member (14) and a gripping device. The gripping device may include an annular carrier (16) having an annular recess for retaining a gripping member (18). The gripping surface of the gripping member (18) and the annular carrier (16) are adapted for relative axial movement wherein the gripping member (18) may be moved into tighter contact with the pipe.

Owner:CRANE CO

Clamp for clamping coaxial cable connectors to coaxial cables

InactiveUS6134774ASimple designLow costLine/current collector detailsClamped/spring connectionsCoaxial cableElectrical conductor

A coaxial cable connector includes a housing made from an electrically conductive material and a hollow, cylindrical sleeve extending from a first end of the housing. The sleeve is constructed from a material which is deformable onto a coaxial cable. An inner conductor connector projects from the first end of the housing at a point centrally positioned within the hollow, cylindrical sleeve. Insulation is positioned between the housing and the inner conductor connector from the housing, and an outer conductor connector projects from the first end of the housing at a point positioned with the hollow, cylindrical sleeve between the inner conductor connector and the hollow, cylindrical sleeve.

Owner:WILLIAMS DEBORAH +1

Band clamp

Owner:HEYCO

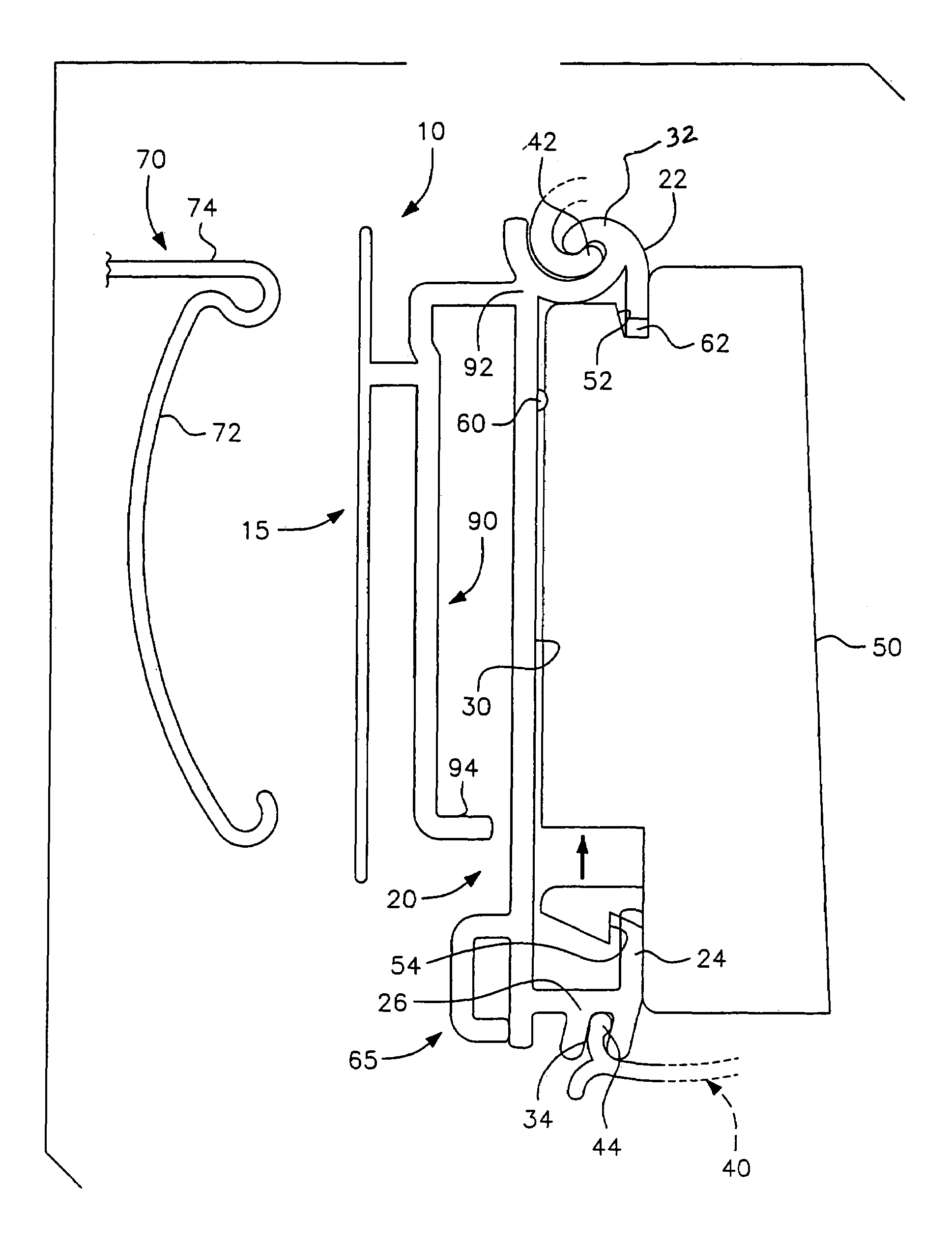

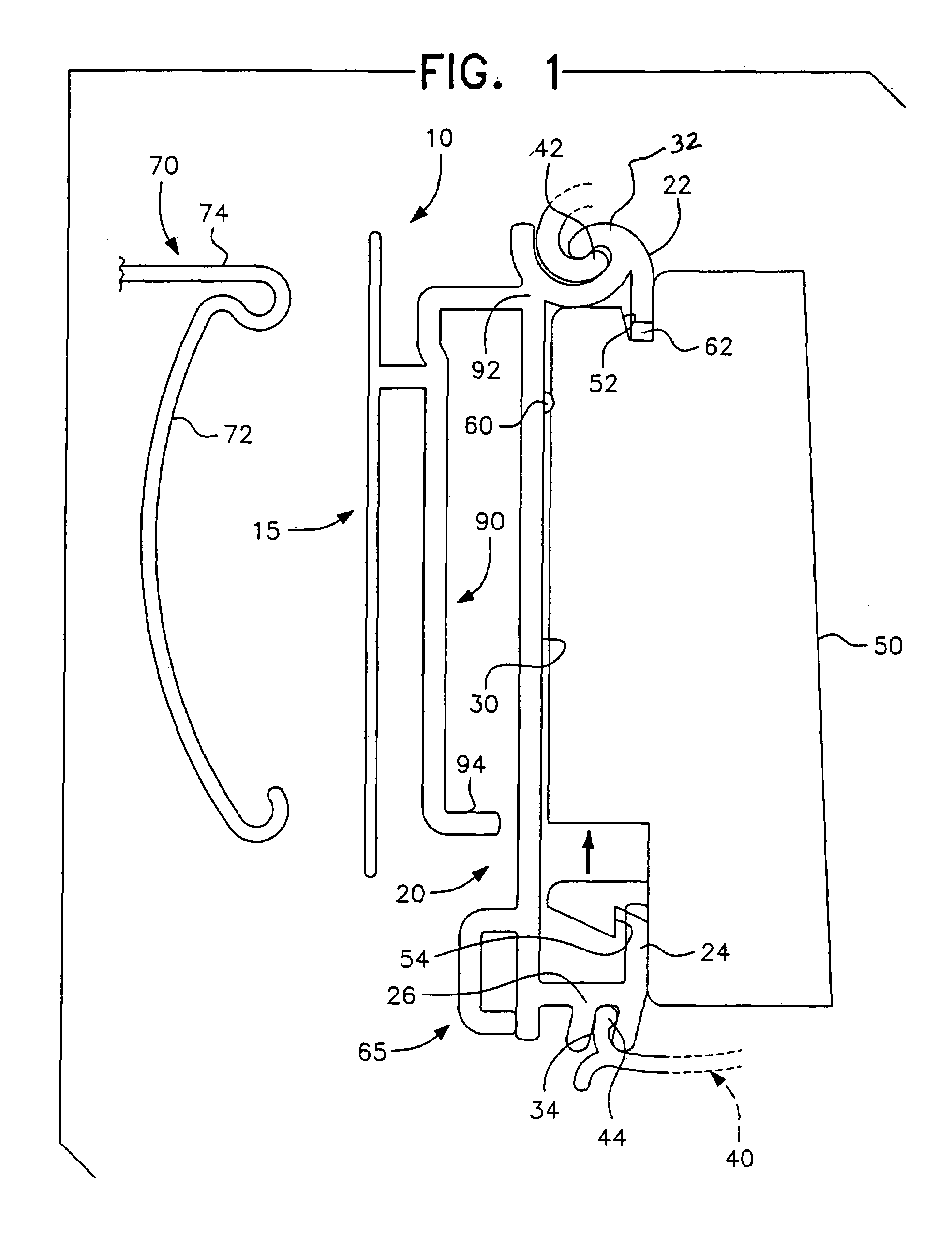

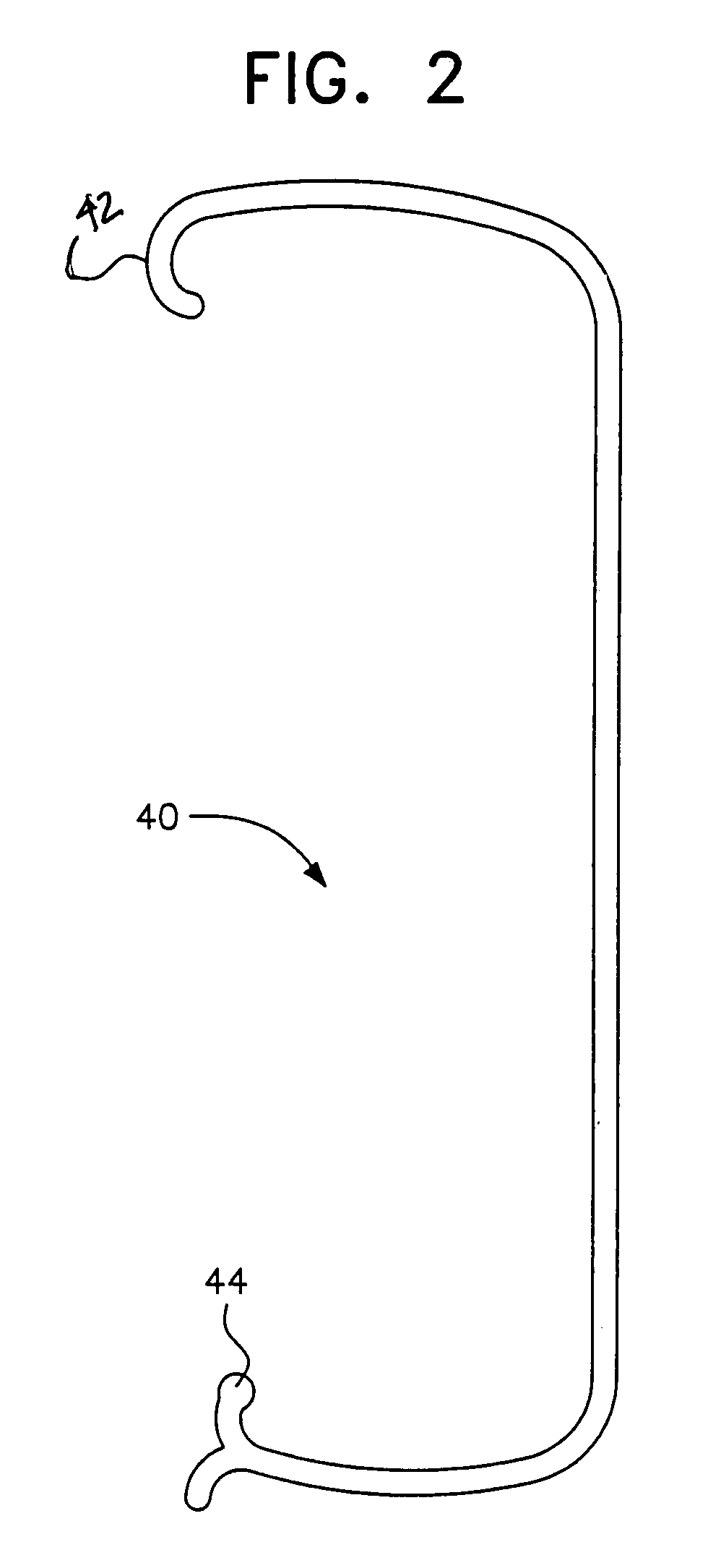

Rail clamp

InactiveUS20090013507A1Loose dimensional toleranceEasy to browseSnap fastenersCandle holdersEngineeringExtreme position

A clamp for attaching a medical device to an OR table rail, including two closable clamp jaws that close to an extreme position that leaves inadequate room for the rail. A handle actuates the jaws apart, and a spring biases them together through a range of jaw positions. A lock member is biased to swing through a range of lock positions in which it progressively engages and locks the jaw mechanism through its range of jaw positions. A pair of bars carries the medical device on the clamp, and allows it to be adjustably positioned with respect to the rail.

Owner:SCOTT CHRISTOPHER P

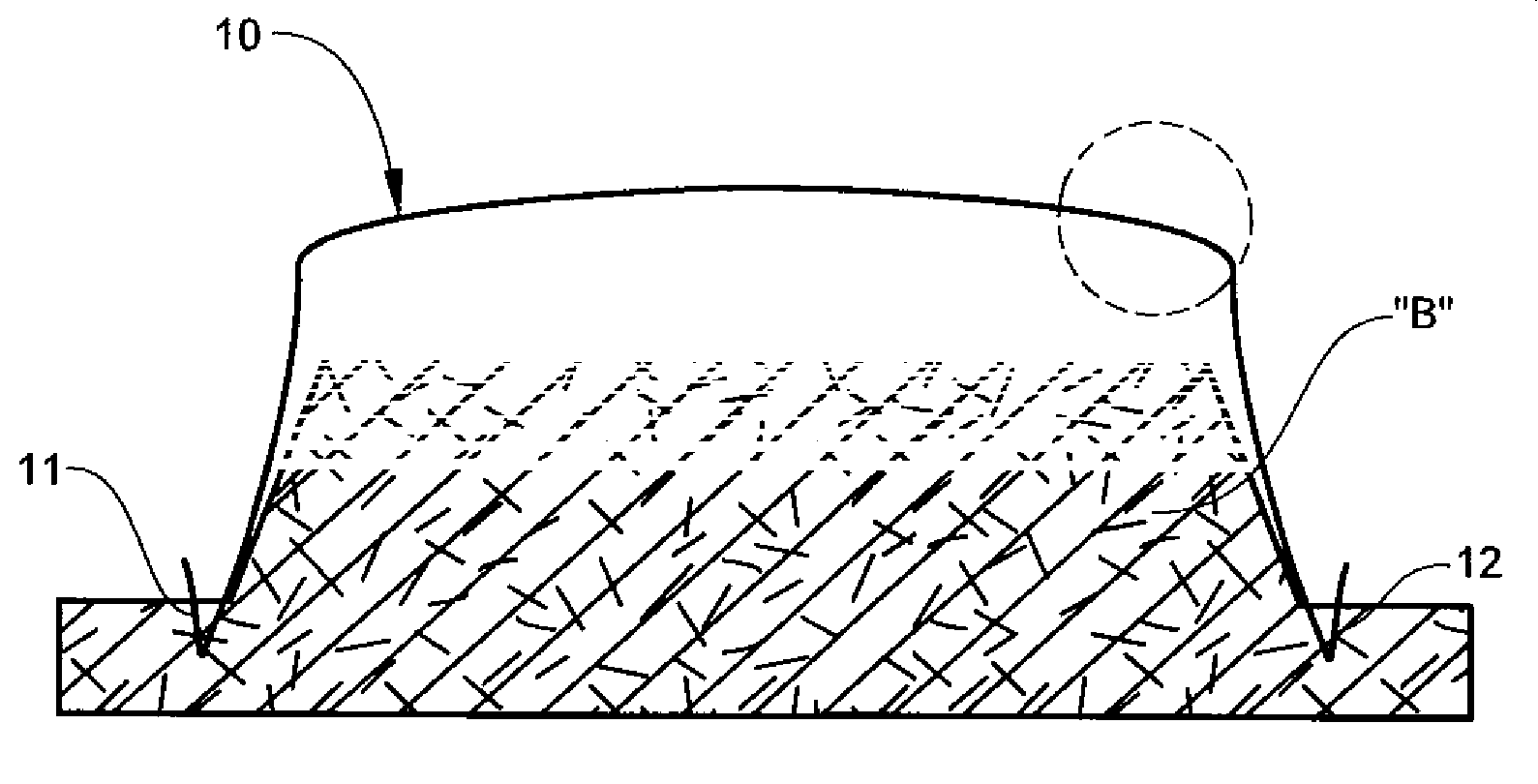

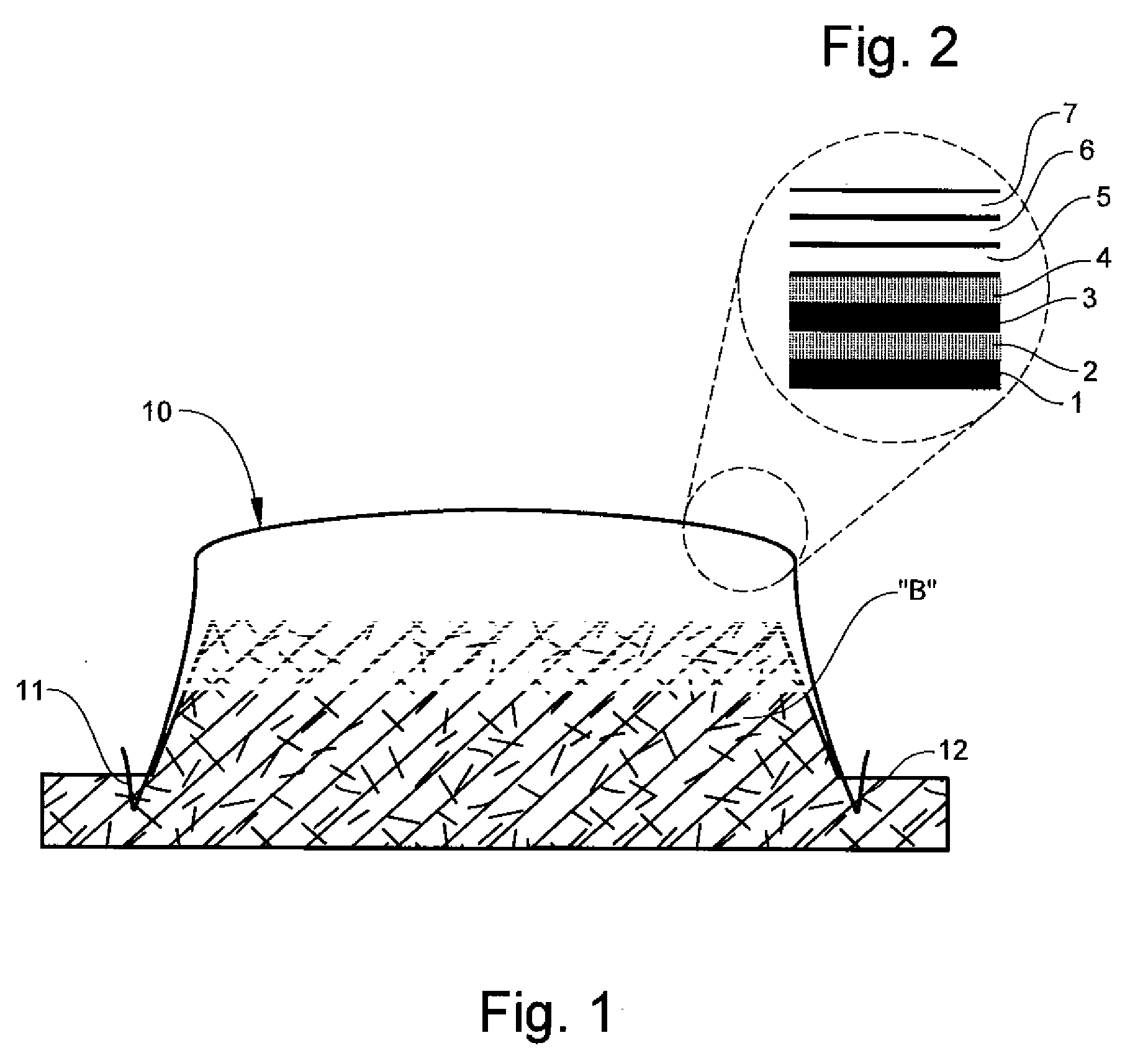

Barrier Agricultural Fumigation Film

InactiveUS20070298197A1Slowing down escapeTight gripWrappers shrinkageShrinkage connectionsLow-density polyethyleneLinear low-density polyethylene

A film that provides a fumigant barrier on a raised crop bed includes a barrier material for restricting the flow of a fluid fumigant, and an elastic polymer material for providing elasticity in the film so that the film can be stretched around the crop bed. The barrier material can be a combination of a polyamide, such as copolyamide 6 / 66, and an amorphous nylon resin. The elastic polymer can be a plastomer, such as an ethylene based octene plastomer or a polyolefin plastomer. The film can also include a polyethylene resin, such as a linear low density polyethylene, to provide strength to the film. The film can be made utilizing a blown film extrusion process.

Owner:RIJNLANDSE PLASTICS GROEP

Automotive door with repositionable immobilizer

InactiveUS20080309120A1Freedom of movementTight gripBuilding braking devicesWing accessoriesMobile vehicleMotorized vehicle

An automotive vehicle includes one or more swinging doors which may be immobilized in a number of positions, so as to allow the door to be used, for example, to assist passengers in entering and leaving the vehicle.

Owner:FORD GLOBAL TECH LLC

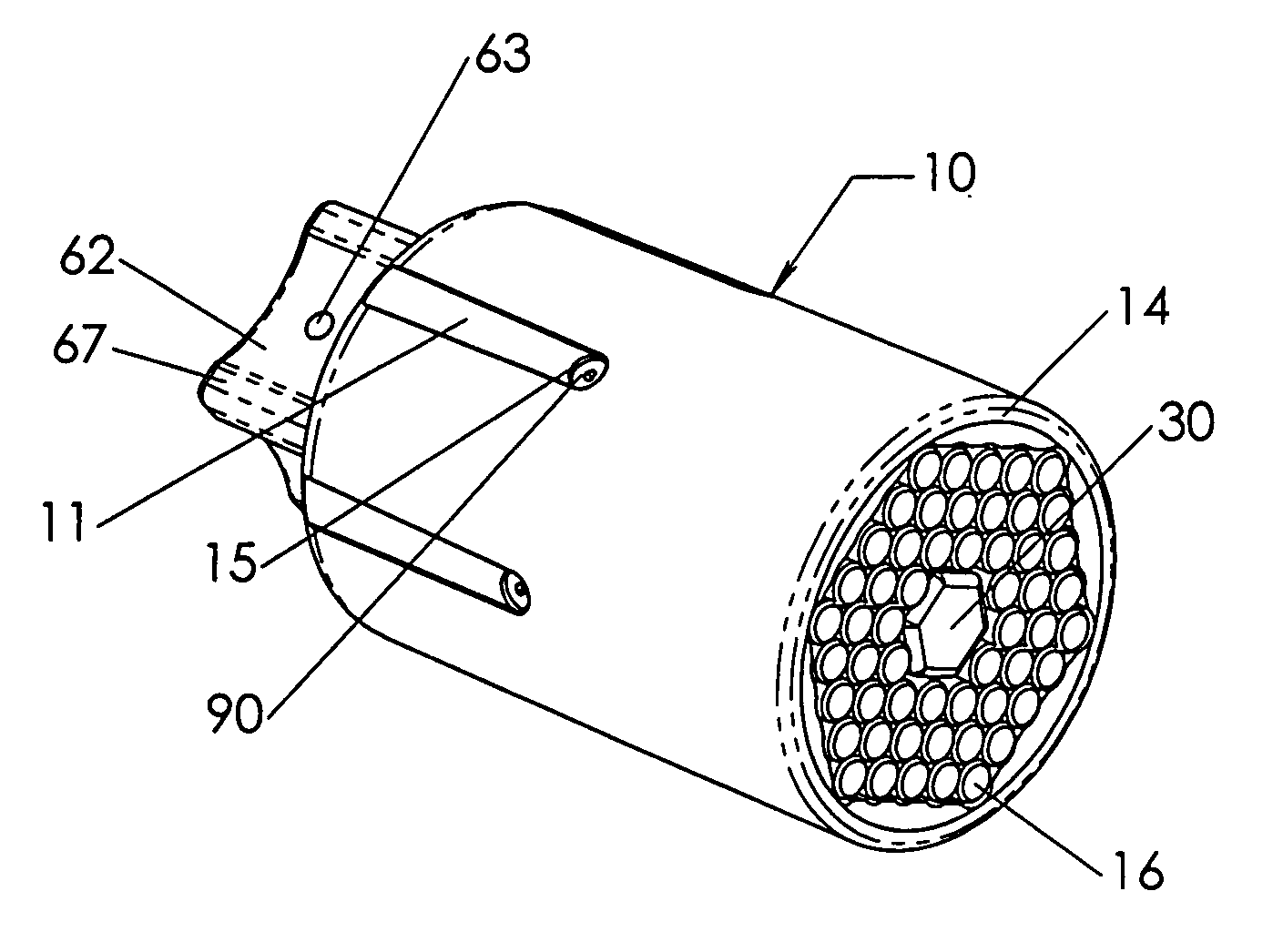

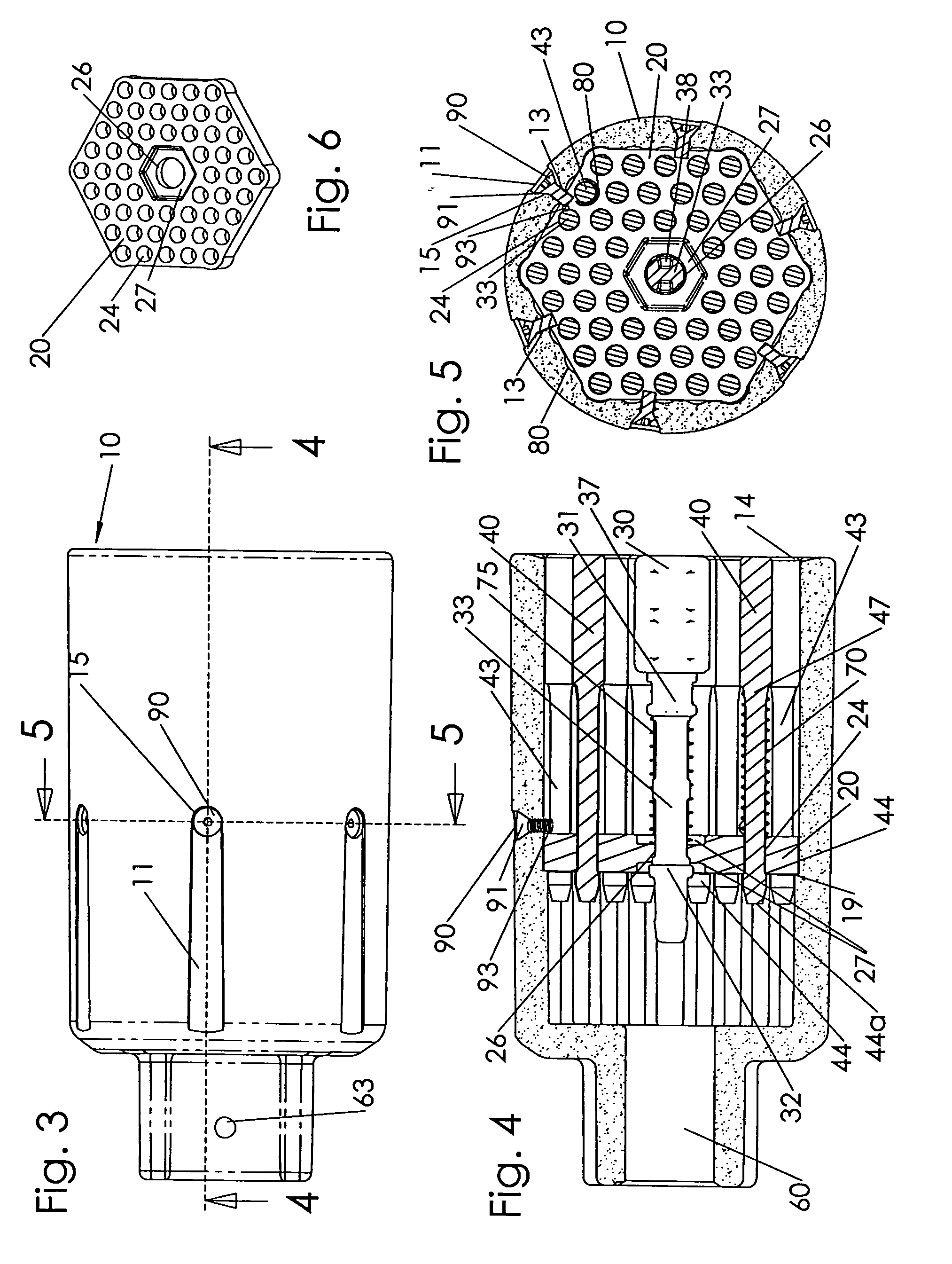

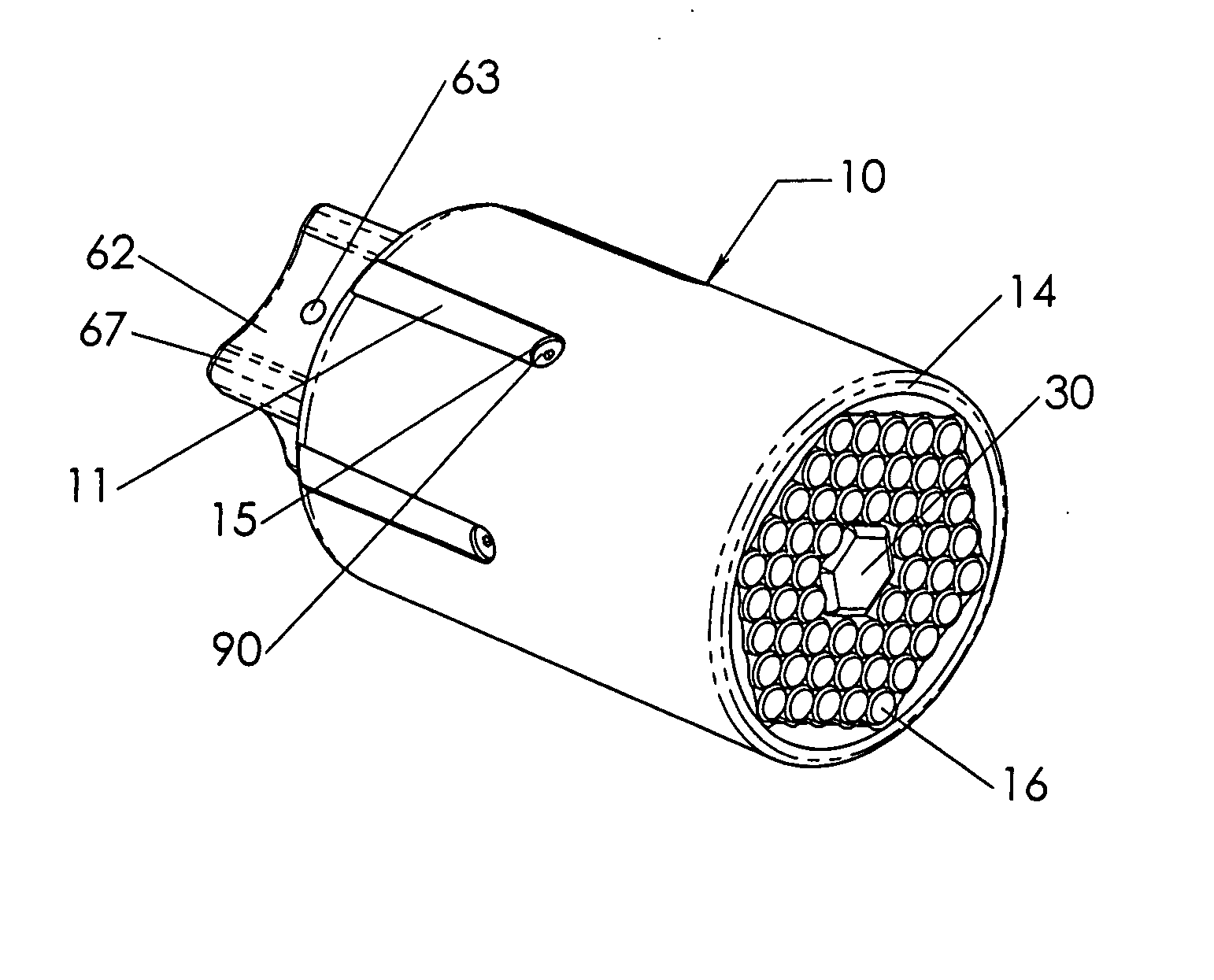

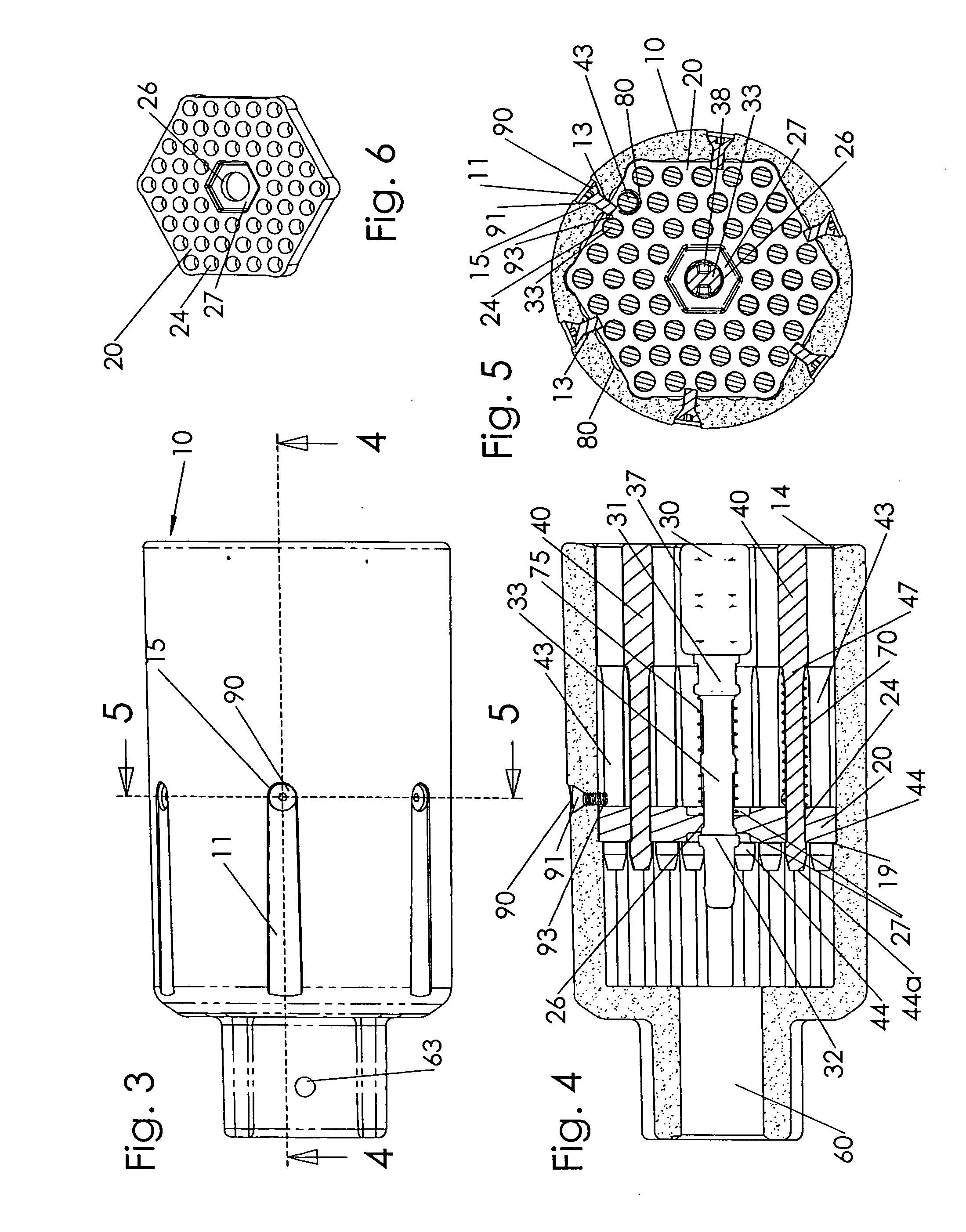

Large self-forming socket

A heavy duty, large self-forming socket having a plurality of retractable gripping pins bundled in parallel and held in a frame within a housing is disclosed. The frame is positioned axially within the housing by radially extending, elongated hold elements that are positioned circumferentially around the housing. Slots in the housing exterior allow efficient inspection of the position of holes into which the hold elements are installed. A collar with shelf around the center pin protects the bias spring for the pin from over-compression. The gripping pins may be held to the frame by spring clips. An adaptor is attached wherein a secondary operation is used to remove the adaptor from the square end of the socket. The self-forming socket is well suited for use with valves and controls for water, gas, sewage conduits and piping.

Owner:WORKTOOLS

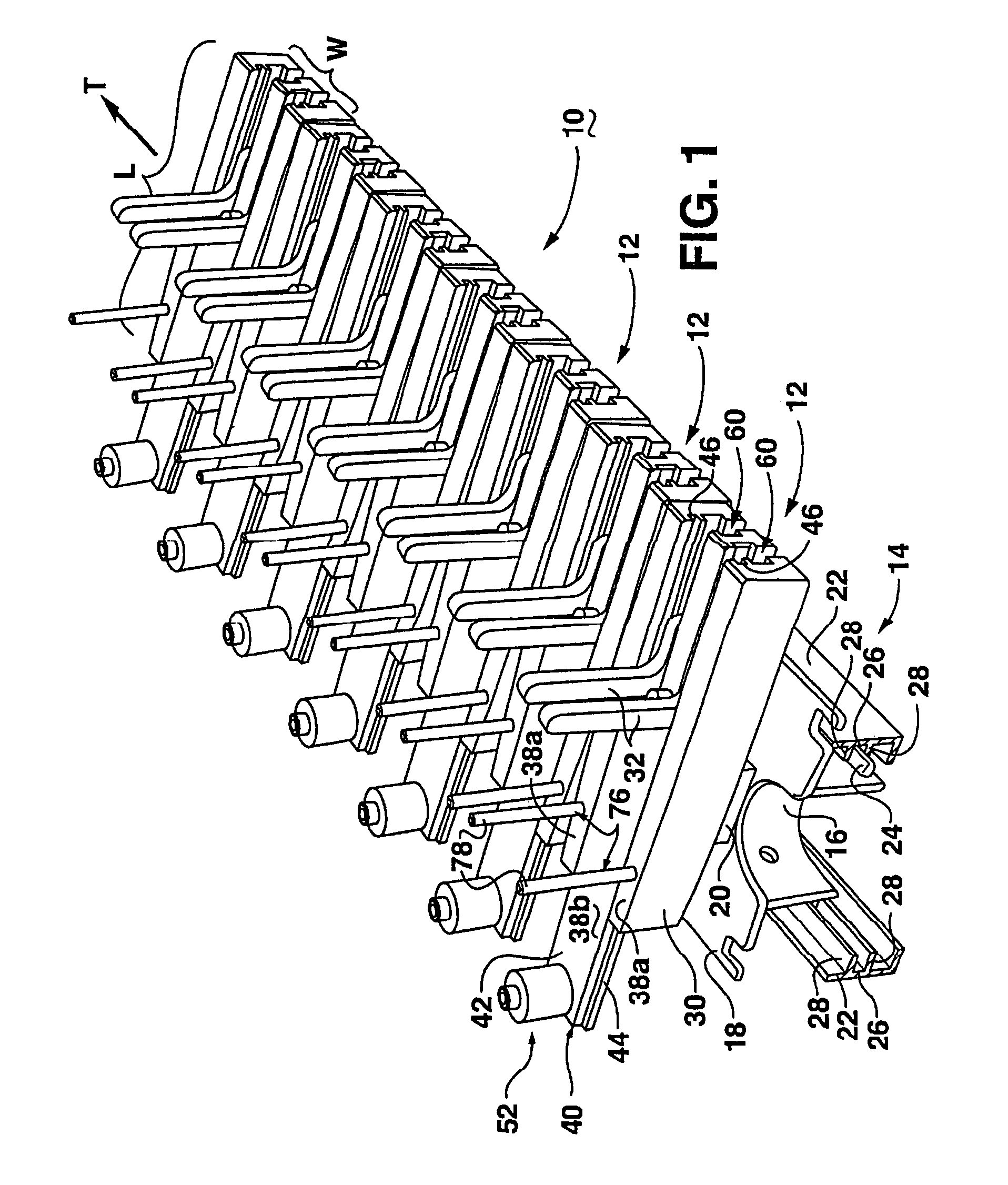

Conveyor with movable grippers, and related conveyor link

A conveyor suitable for conveying objects along a transport direction, and related links, are disclosed. The conveyor includes a plurality of connected links, each link having a length extending across the direction of transport and a width extending along the direction of transport. Each link also has a body, a cam follower member, and at least one gripping member. A gear drive mechanism may be used to interconnect the cam follower member and the gripping member. The cam follower member is movable to selectively move the gripping member between a first position and a second position. The gripping member when in first position is disposed in an open position, and the gripping member when in the second position is disposed in a gripping position for contacting one of the objects to hold the object during transport. Gear-drive mechanisms of various designs may be used to interconnect the cam follower member and gripping member. A releasable holding member, such as a spring-loaded ratchet member, may be used to secure the gripping member in the second position. Multiple opposed gripping members may be used. Various modifications and options are possible.

Owner:ILLINOIS TOOL WORKS INC

Slip joint with clamp

InactiveUS20110272888A1Reduce the overall diameterHighly resistant to being putSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

The present invention provides an improved slip joint pipe coupling, which is reinforced by the mechanical compression of a split collar and sealing ring.

Owner:IRIZZARY ARMANDO +1

Self-adjusting variable grip locking plier for gripping a workpiece

A self-adjusting variable grip locking plier for gripping a workpiece. The plier includes a body, a handle, and a wedge. The plier is designed for extremely fast set up and for easily gripping and holding the workpiece with one hand with absolutely no adjustments ever to make, and provides a larger than ordinary jaw capacity in a very compact design. The plier grips and holds the workpiece with a light or tremendous gripping force with no adjustments ever to make, and with an extremely fast unlocking system, while at the same time fitting into the palm of one hand. When the workpiece is grasped, one simply ratchets the handle until the desired grip is obtained. The more times one squeezes the handle the tighter the grip. This automatically locks the plier at the desired grip. To release the plier one simply pushes the wedge back into the body with the palm of one hand.

Owner:MCNATT STANLEY L

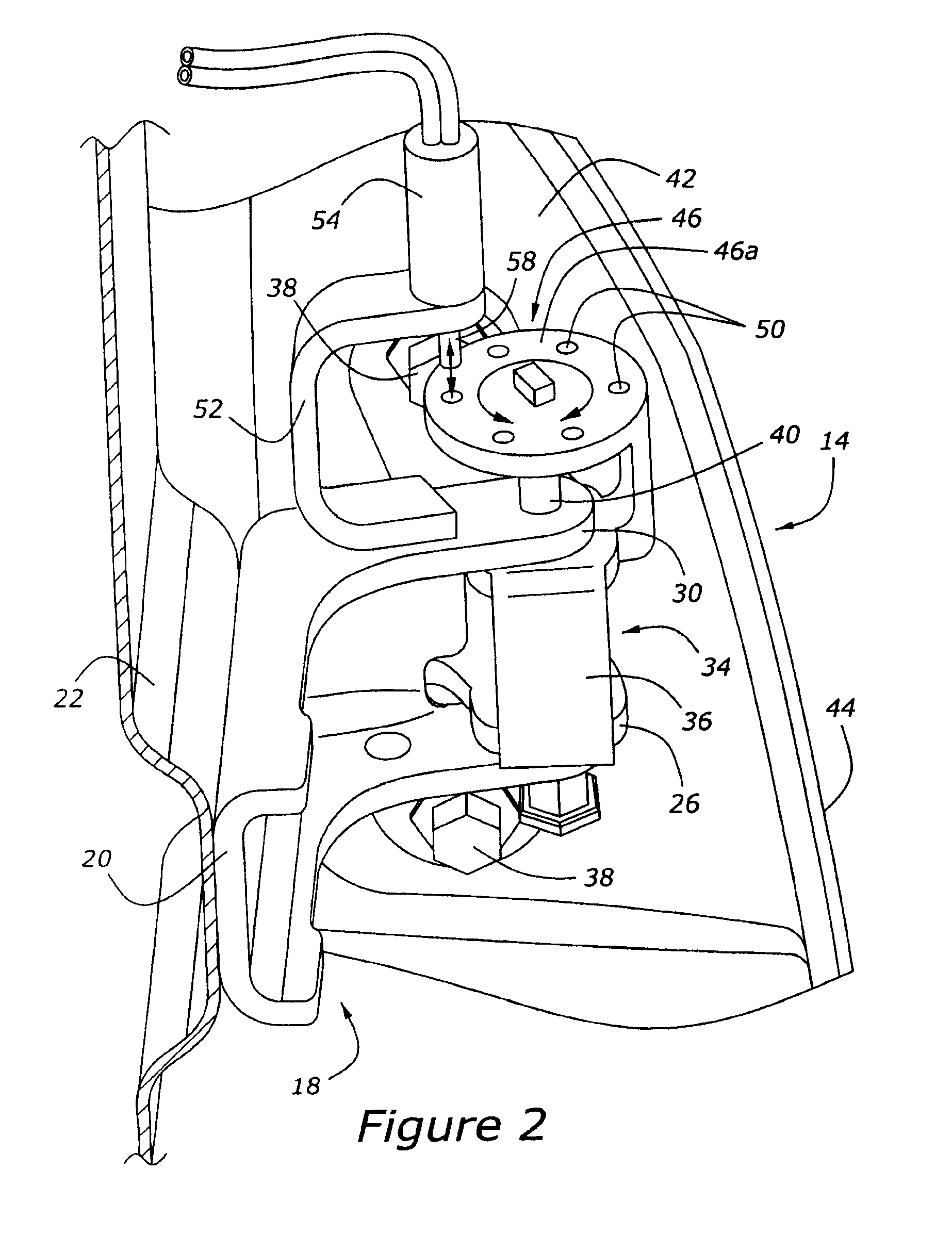

Syringe/plunger coupling

A medical fluid injector, replaceable syringe, and coupling mechanism to engage the syringe plunger to the plunger drive ram of the injector are provided wherein coupling involves a cam cleat-like mechanism, thereby allowing for cooperative movement between the plunger drive ram and syringe plunger. The coupling mechanism of the plunger drive ram is provided with first and second movable members, each having toothed, arcuate surfaces, while the coupling mechanism of the syringe plunger is provided with a knurled extension. Disengagement of the coupling mechanism is facilitated by translational movement of a face plate located on the forward end of the injector housing.

Owner:LIEBEL FLARSHEIM CO

Fixed angle ESL label holder with flex grip and moisture seal

InactiveUS7287350B2Simple and inexpensive mannerTight gripStampsLayered productsElectronic shelf labelCombined use

An electronic shelf label (ESL) holder, including an attachment member portion to be secured to a supporting surface, such as a C-channel, a holder member with protrusions for removably receiving and supporting the ESLs and, optionally, a cover member pivotally carried by the holder member to overly and protect the ESLs. The holder member includes a lip extending from at least one of the top or bottom fingers of the holder formed of flexible PVC material that is flexible relative to the remaining portion of the holder and is compressible for providing a tight fit of the ESL to the holder. The flexible lip is utilized in combination with a backing member which, in one embodiment, is a flexible PVC bead that extends along the length of the holder and, in a second embodiment, includes a relatively broad or wide pad of flexible PVC material that further provides a seal against the battery or other electronics of the ESL.

Owner:FAST JACOB +1

Handlebar accessory mount

ActiveUS20180001950A1Inhibition releaseHigh strengthArticle supporting devicesCycle containersCamScrew thread

A cam lever operated accessory gripping mechanism the gripping mechanism includes a cam lever, a threaded stud, a dowel fixed to a first end of the threaded stud, first and second relatively movable main body sections, the first of the main body sections including a handlebar bracket extension, a first clamping jaw for engaging a first side of the accessory, and an opening shaped to slidably receive the second main body section, and the second main body section including a bore and a slot for receiving a fastening member into which the threaded stud is threaded, and a second clamping jaw for engaging a second side of the accessory. The dowel is rotatably mounted in the camming lever, which has at least one overcenter camming surface that engages a cam-engaging surface of the first main body section, such that pivoting of the camming lever about the dowel in a first direction causes the dowel holding section of the camming level to move in an axial direction of the threaded stud, pulling the second main body section against a biasing force provided by a biasing spring extending between the first and second main body sections, in a direction that causes the second clamping jaw to move towards the first clamping jaw and thereby grip the accessory. Adjustment of the gripping mechanism to fit different accessories is accomplished by turning the threaded stud to cause axial movement of the follower insert and corresponding movement of the second main body section is a desired direction, to adjust the initial spacing of the first and second clamping jaws.

Owner:ALLEN JEFFREY M

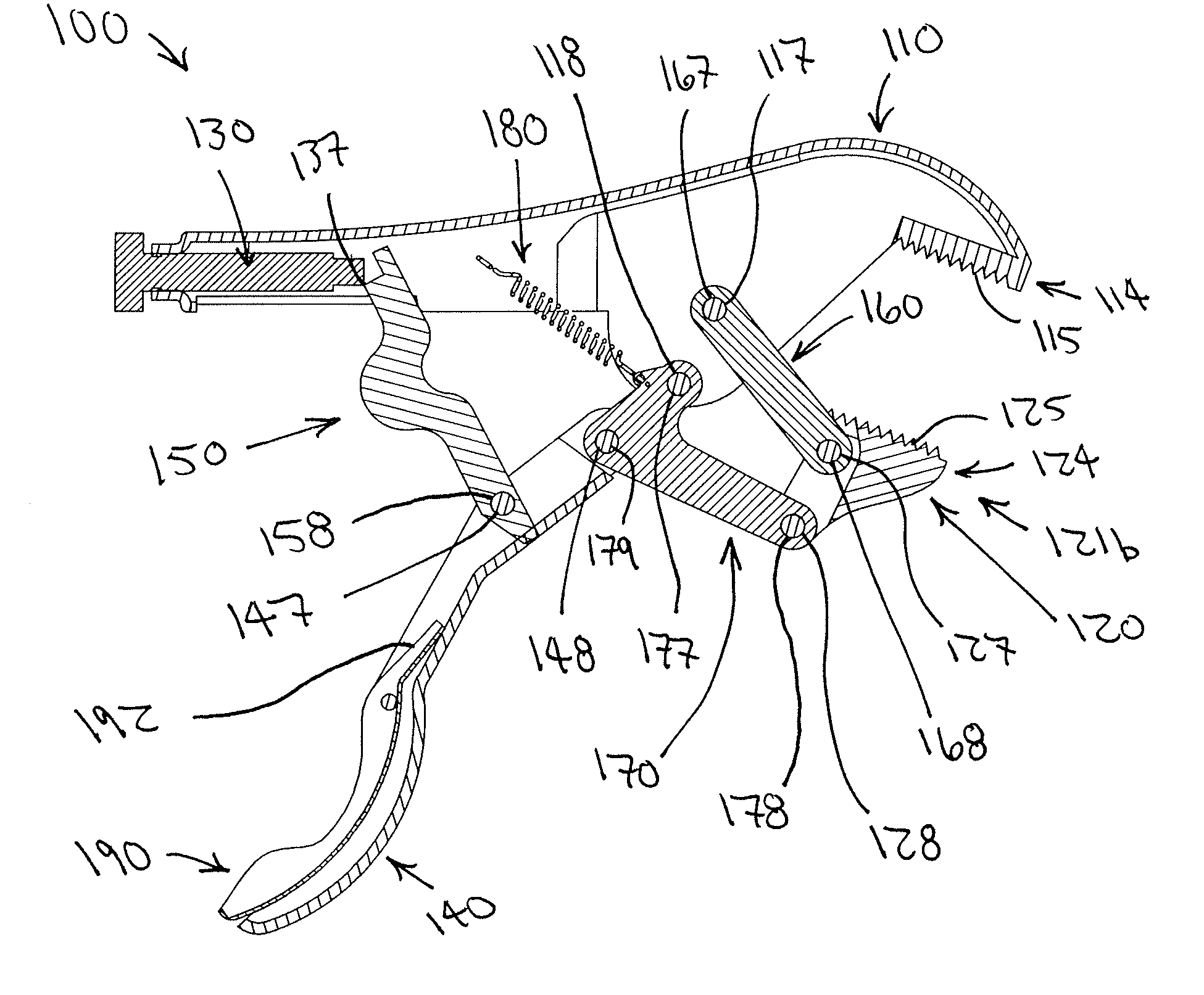

Pliers Having Generally Parallel Jaws

Pliers with parallel jaws include an upper portion having an upper jaw of upper teeth, a lower jaw portion having a lower jaw of lower teeth. The lower jaw portion includes first and second pivot points. An adjustment portion is non-pivotably coupled to the upper portion and selectively movable relative thereto and includes a first pivot point. A lower handle includes first and second pivot points. A break over link includes first and second pivot points pivotably coupled to the adjustment portion and lower handle's first pivot points, respectively. A two-point link includes first and second pivot points pivotably coupled to the upper portion's and lower jaw portion's first pivot points, respectively. A three-point link includes first and second pivot points pivotably coupled to upper and lower jaw portions' first and second pivot points, respectively, and a third pivot point pivotably coupled to the lower handle's second pivot point.

Owner:STUCKY ANDREW C

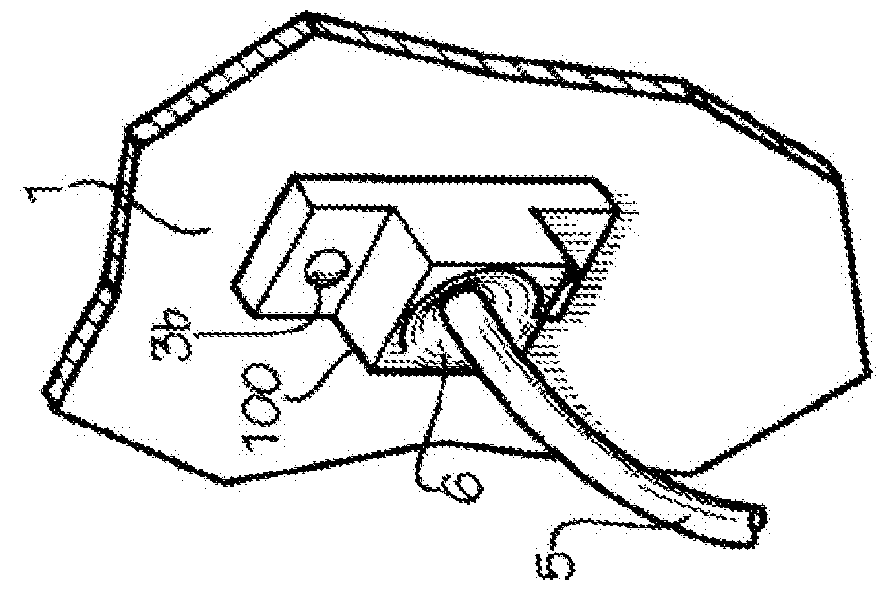

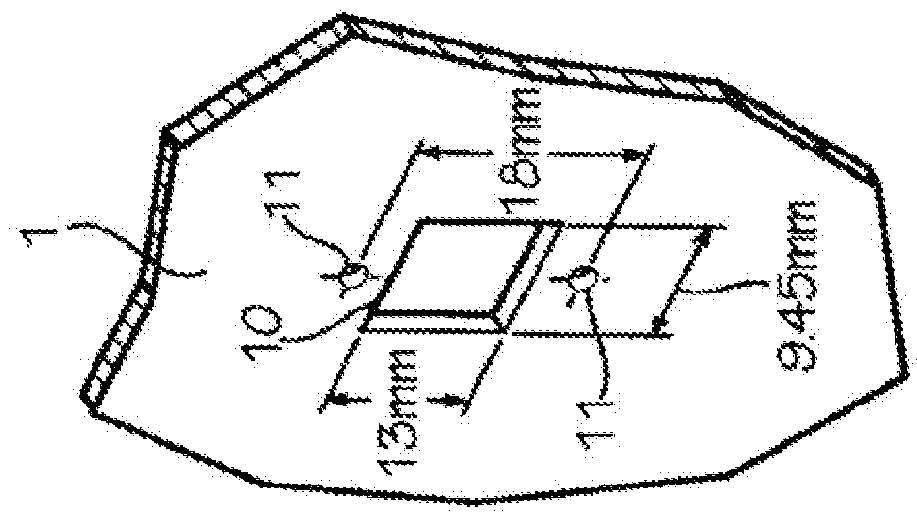

Panel-mountable fiber optic cable feedthrough

InactiveUS20170269319A1Minimal effortRemove complicationsFibre mechanical structuresFiberPlastic injection molding

A novel panel-mountable fiber optic cable feedthrough is described that has two main body parts that can be brought together around single or multiple fiber optic cables and secured in place to prevent slippage of the cable(s). Use of two such main body parts that split along a plane that passes through the axis of the fiber optic cable(s) allows joining the two main parts at any position along the cable(s) without the need to thread the cable(s) through a one or more pre-formed cylindrical cavities in the body of the feedthrough. The main parts for this fiber optic feedthrough can be made by plastic injection molding suitably shaped to relieve bending strain in the glass optical fiber(s) within the cable(s). The foot-print for mounting such a feedthrough can be made compatible with that of a number of popular fiber optic connector mounts, including the SC-connector.

Owner:M2 OPTICS

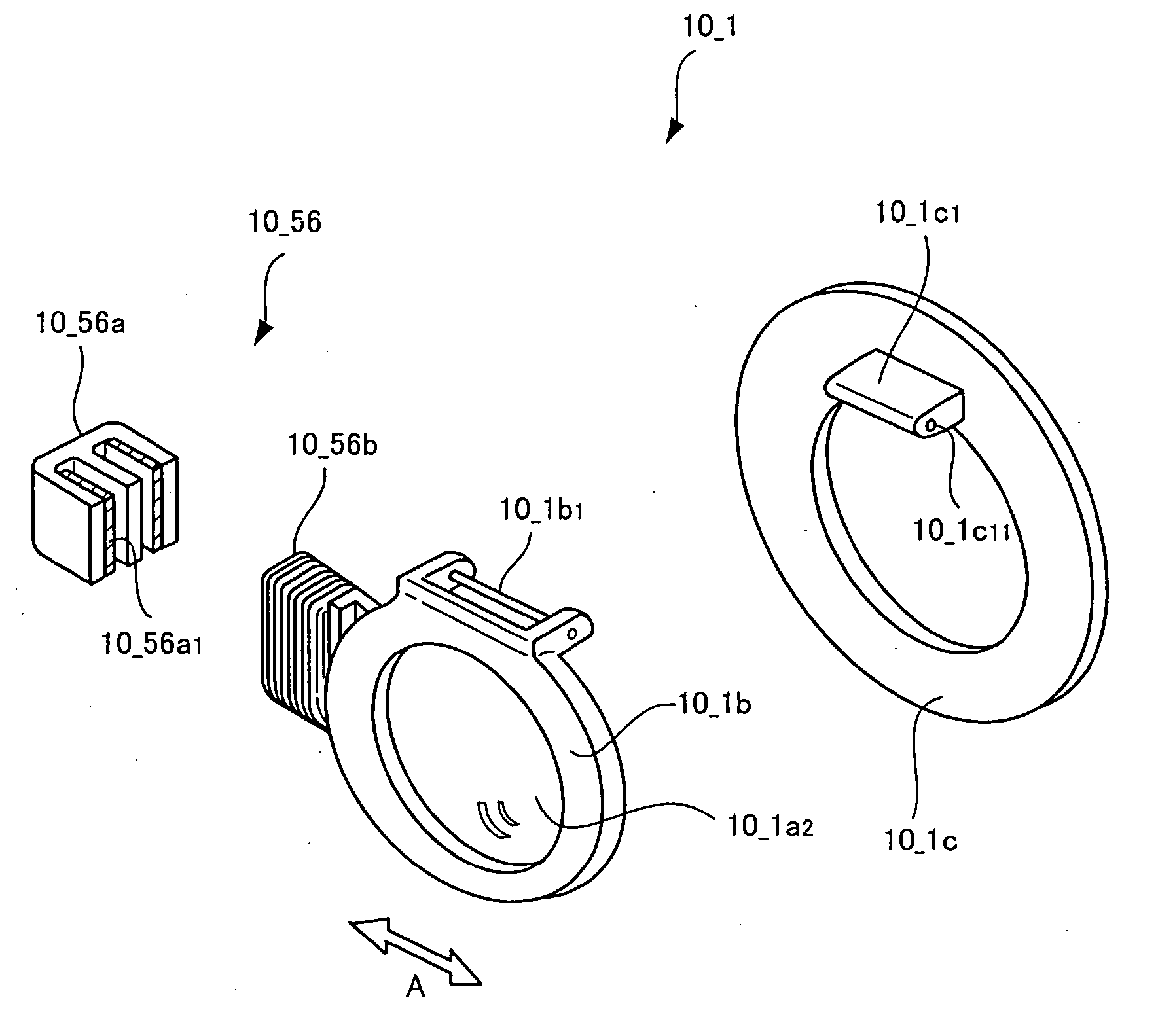

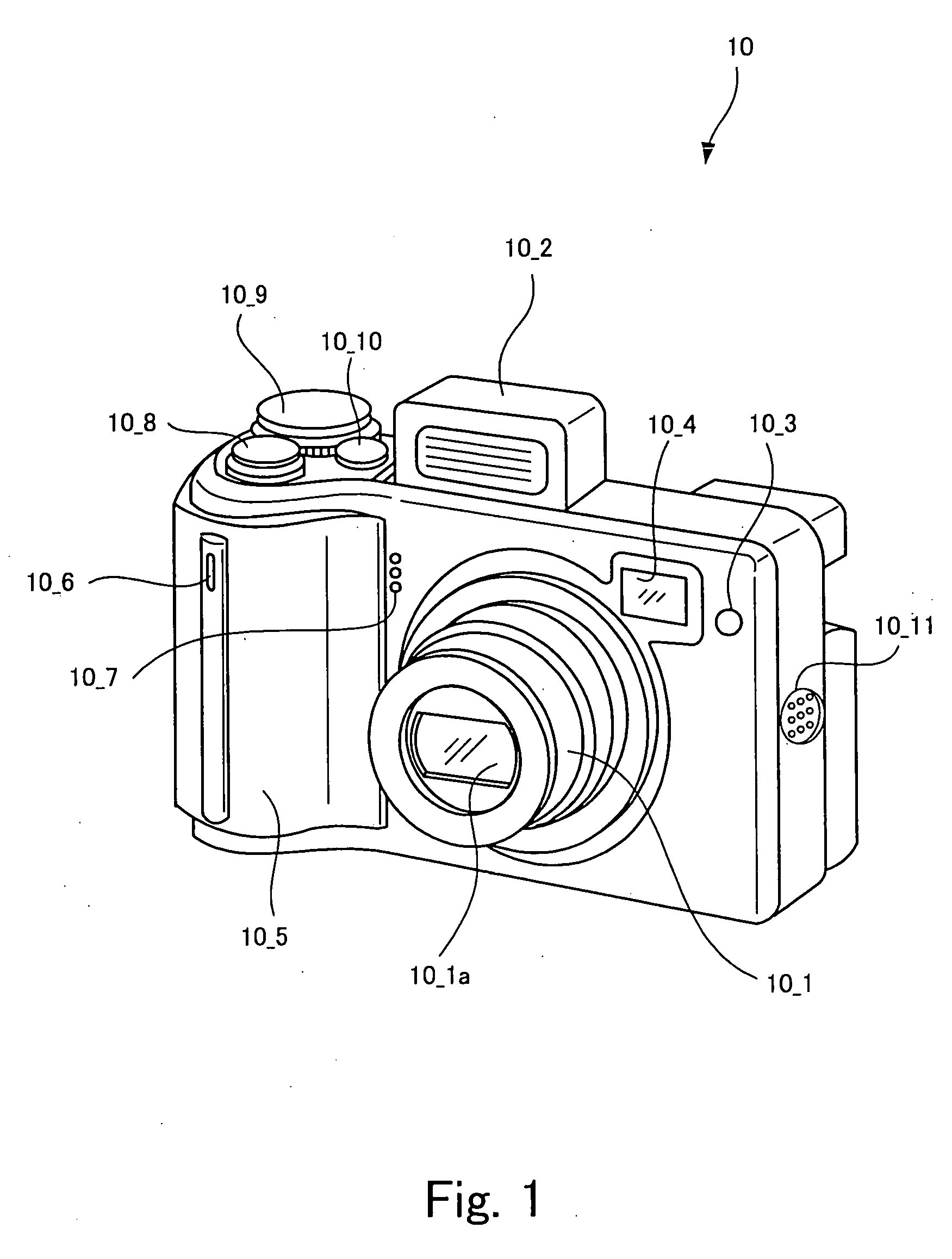

Image-taking device

InactiveUS20060153554A1Easy to useImage is often very smallPrintersProjectorsLiquid-crystal displayAngular rate sensor

An image-taking device is capable of effectively utilizing a shake correcting section and thereby shooting an image with little blur. The image-taking device includes: an angular rate sensor which detects a shake; a shift lens which travels within a predetermined moving range to correct the shake; a shift lens driving section which pulls the shift lens, which has moved to a biased position from a predetermined center, back to the center; a central processing unit which calculates a correction effect for the shake; and a liquid crystal monitor. The central processing unit calculates the correction effect based on a distance between the position of the moved shift lens and the center, and displays the correction effect on the liquid crystal monitor.

Owner:FUJIFILM HLDG CORP +1

Panel-mountable fiber optic cable feedthrough

ActiveUS9696512B2Relieve stressAvoid strainFibre mechanical structuresPlastic injection moldingEngineering

A novel panel-mountable fiber optic cable feedthrough is described that has two main body parts that can be brought together around a fiber optic cable and secured in place to prevent slippage of the cable. Use of two such main body parts that split along a plane that passes through the axis of the fiber optic cable allows joining the two main parts at any position along the cable without the need to thread the cable through a pre-formed cylindrical cavity in the body of the feedthrough. The main parts for this fiber optic feedthrough can be made by plastic injection molding suitably shaped to relieve bending strain in the glass optical fiber(s) within the cable. The foot-print for mounting such a feedthrough can be made compatible with that of a number of popular fiber optic connector mounts, including the SC-connector.

Owner:M2 OPTICS

Large self-forming socket

A heavy duty, large self-forming socket having a plurality of retractable gripping pins bundled in parallel and held in a frame within a housing is disclosed. The frame is positioned axially within the housing by radially extending, elongated hold elements that are positioned circumferentially around the housing. Slots in the housing exterior allow efficient inspection of the position of holes into which the hold elements are installed. A collar with shelf around the center pin protects the bias spring for the pin from over-compression. The gripping pins may be held to the frame by spring clips and / or a resilient O-ring. An adaptor is attached wherein a secondary operation is used to remove the adaptor from the square end of the socket. The self-forming socket is well suited for use with valves and controls for water, gas, sewage conduits and piping.

Owner:WORKTOOLS

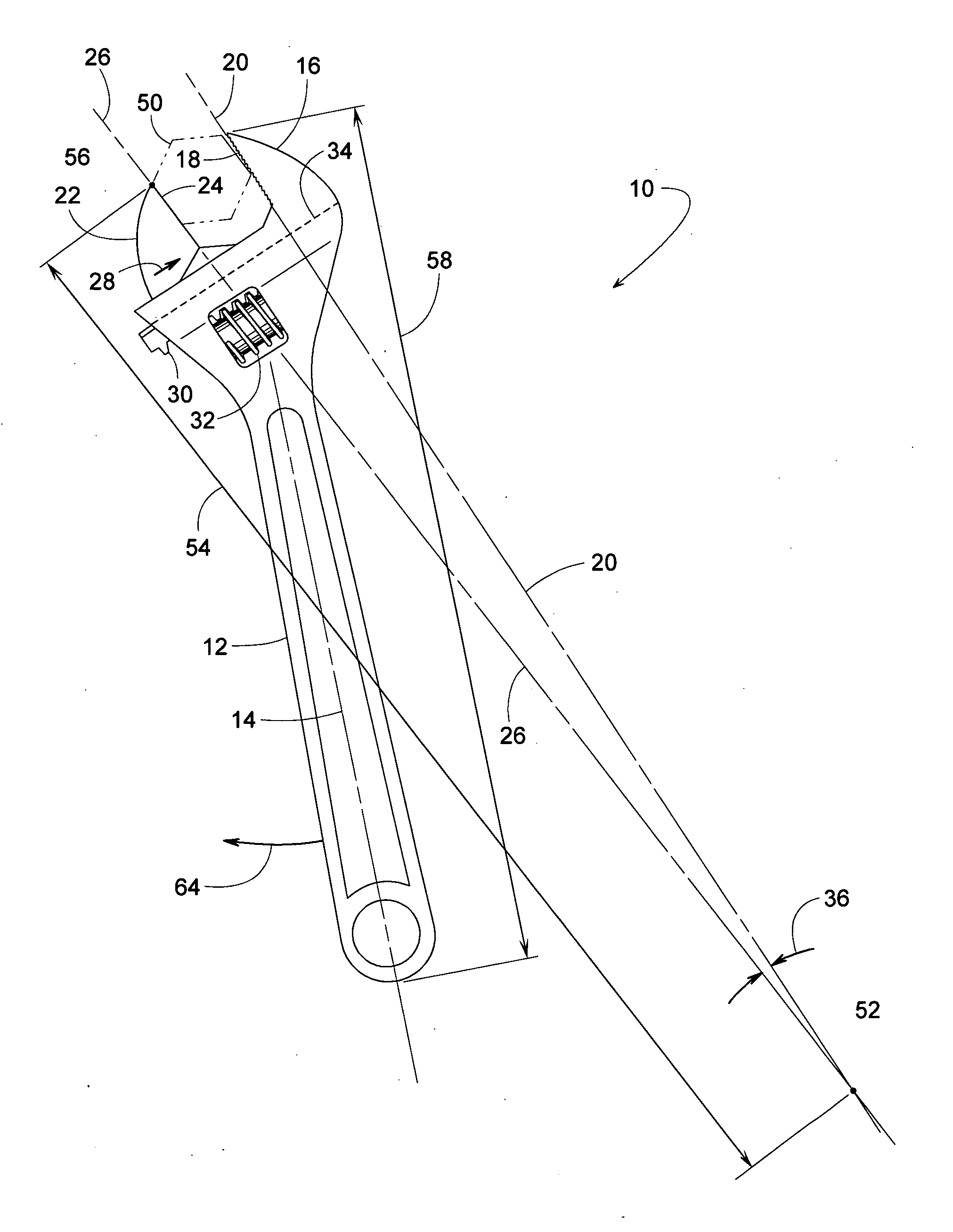

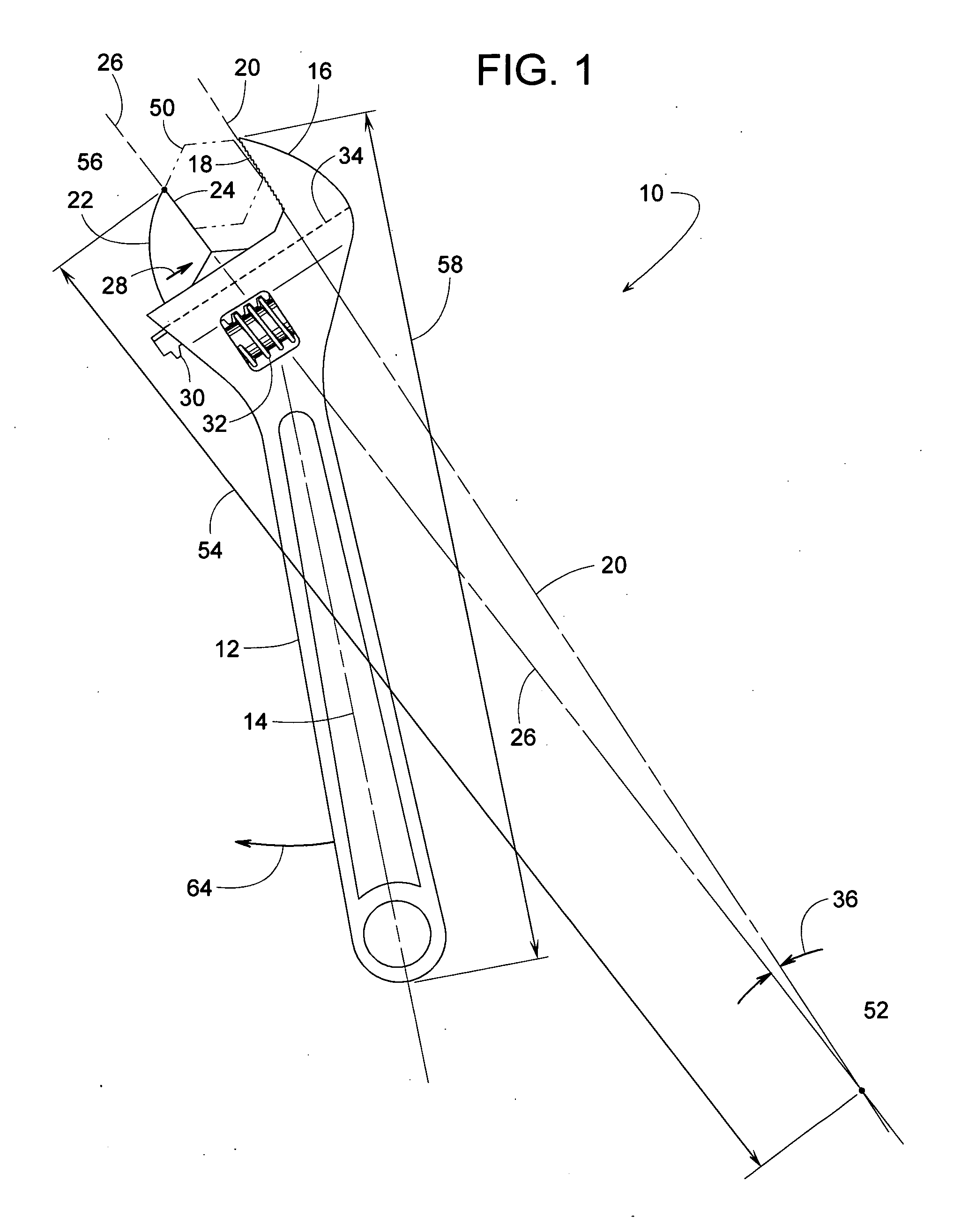

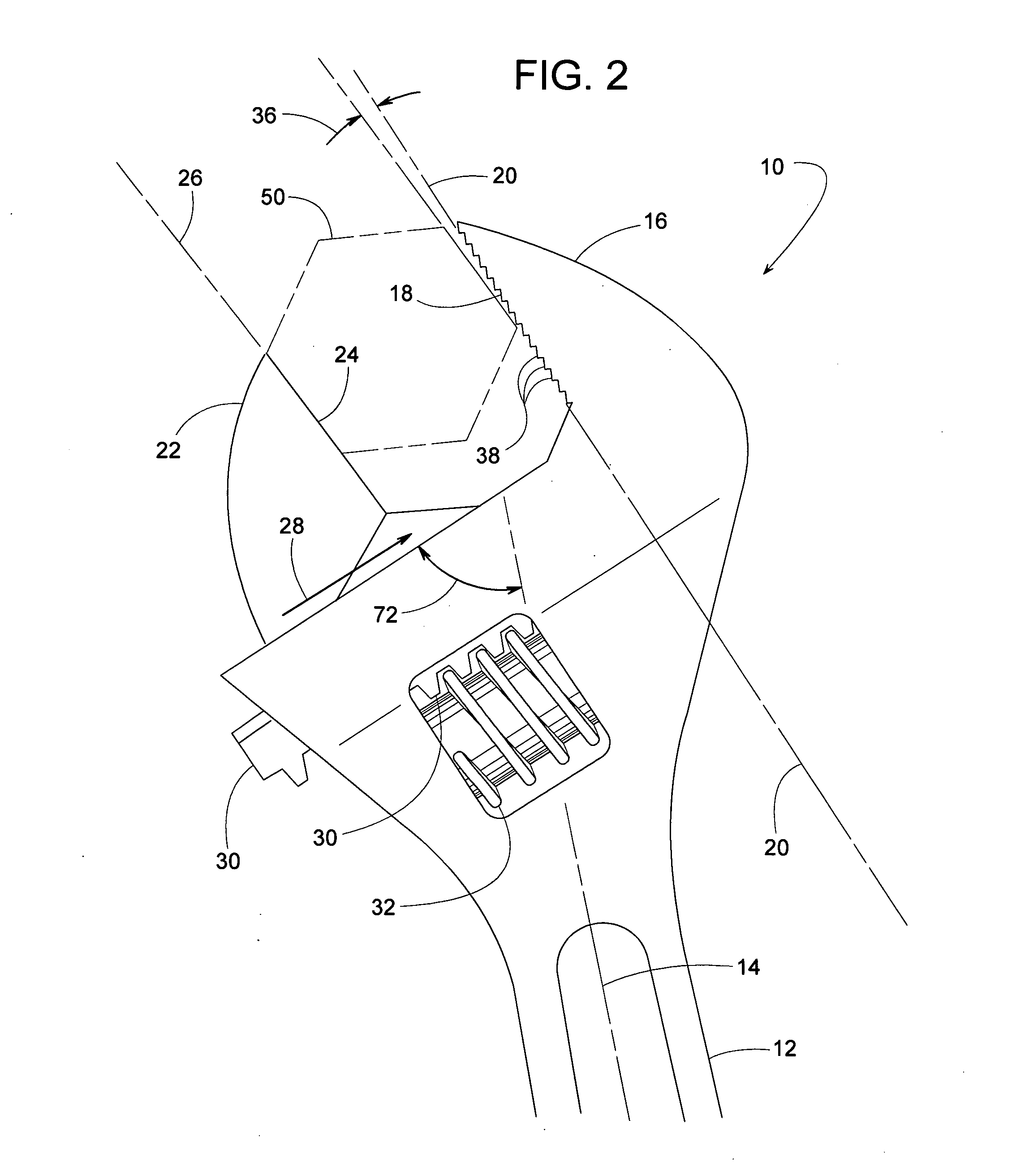

Universal adjustable wrench with tactile snap action

An adjustable wrench for gripping hexagonal and other shaped heads includes two slightly non-parallel jaw faces, wherein one face is smoother than the other. The angle between the two jaw faces is extremely shallow to create a “snap-action” geometry. Combining that geometry with jaw faces of unequal roughness can result in a desirable binding action that causes the wrench to tightly grip the head. In some cases, the wrench will continue clinging to the head even after the user releases the handle of the wrench.

Owner:HARTER ROBERT J

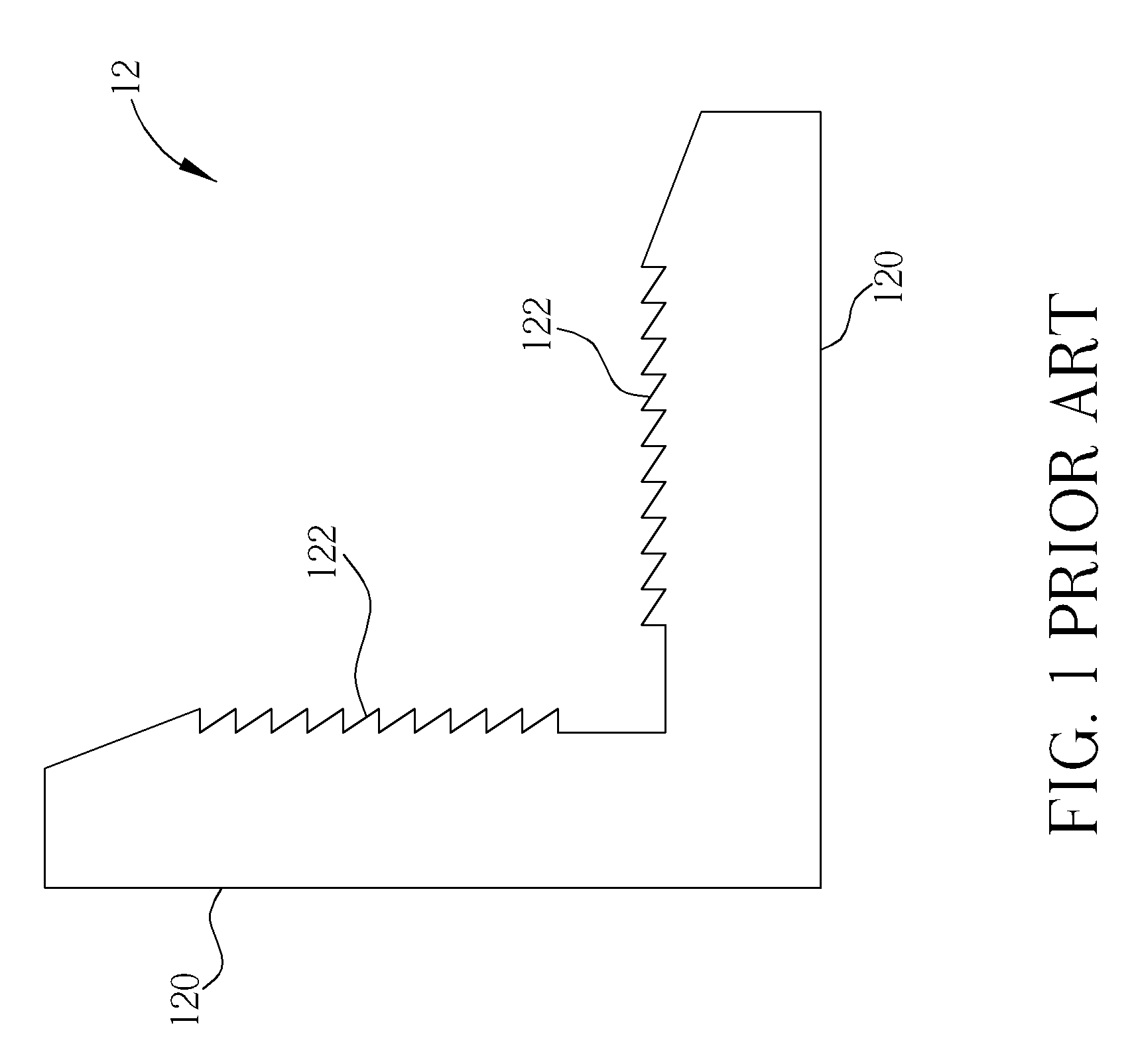

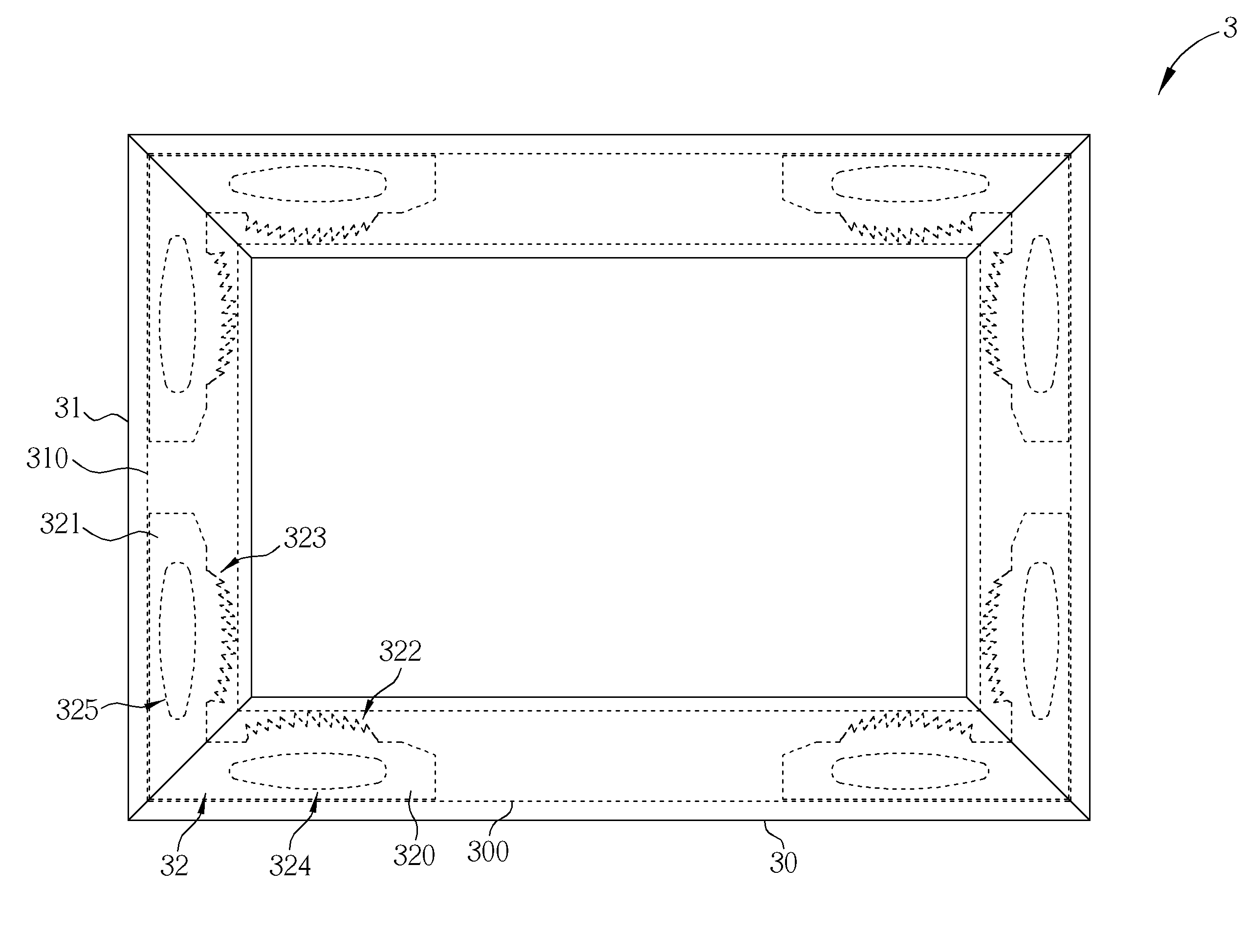

Corner key and frame assembly

ActiveUS8763342B2Sufficient space for deformationTight gripScaffold connectionsPicture framesEngineeringElectrical and Electronics engineering

Owner:AU OPTRONICS CORP

Corner key and frame assembly

ActiveUS20130019558A1Sufficient space for deformationTight gripDoors/windowsKey type connectionsElectrical and Electronics engineeringStructural engineering

Owner:AU OPTRONICS CORP

Fastener for garment drawstrings, laces, and the like

InactiveUS20160025186A1Prevent looseningIncrease coefficient of frictionSnap fastenersRopes and cables for vehicles/pulleyShoe lacesEngineering

A fastener connects two strings together, such as the drawstring of sweatpants or the two shoe lace strings ends of respective shoe lace strings in a pair of sneakers. The body of the fastener is made out of a material, such as highly dense polyurethane foam, that is strong, yet flexible, or of a rigid plastic, that is strong, yet flexible. The two strings to be fastened pass through one or more gripping and / or locking holes in the fastener body. When the shoelace is passed through the gripping and / or locking holes, the dense polyurethane foam grips the lace tightly. The free ends are pulled through one or more peripheral slits extending towards, but not all the way to, the gripping and / or locking holes and then bent against the upper outer surface of the disk and locked in place in the respective one or more peripheral locking slits.

Owner:DELUCA CHARLES

Winding method of cable winding and wrapping belt

The invention discloses a winding method of a cable winding and wrapping belt. A cable winding and wrapping machine is used for winding a cable. The method comprises the following operation steps that A, two annular lining plates of the cable winding and wrapping machine are arranged on the cable in a penetrating manner through central holes of the lining plates, each adjusting shaft is adjusted, and a roller is connected with the outer edge of the cable in an abutting manner; B, the position of a shifting rod in an arc-shaped groove of a fixed plate is adjusted, and a walking rolling angle b of the roller is set; C, a flexible protection belt is wound on a core shaft with a tensioning device, the position of a sliding block in a sliding groove of the adjusting plate is adjusted, and the swing angle a of a rolling shaft is set; D, a tensioning nut is adjusted to extrude a second friction piece through a damping spring, an inner blocking piece enables a flexible protection belt roll to extrude one side of a first friction piece, and tensioning force is applied to the flexible protection belt roll; and E, the flexible protection belt released out of the core shaft winds the cable. Compared with the prior art, the method has the beneficial effect that the problems that existing cable winding packaging is poor in stability and high in cost are solved.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD +1

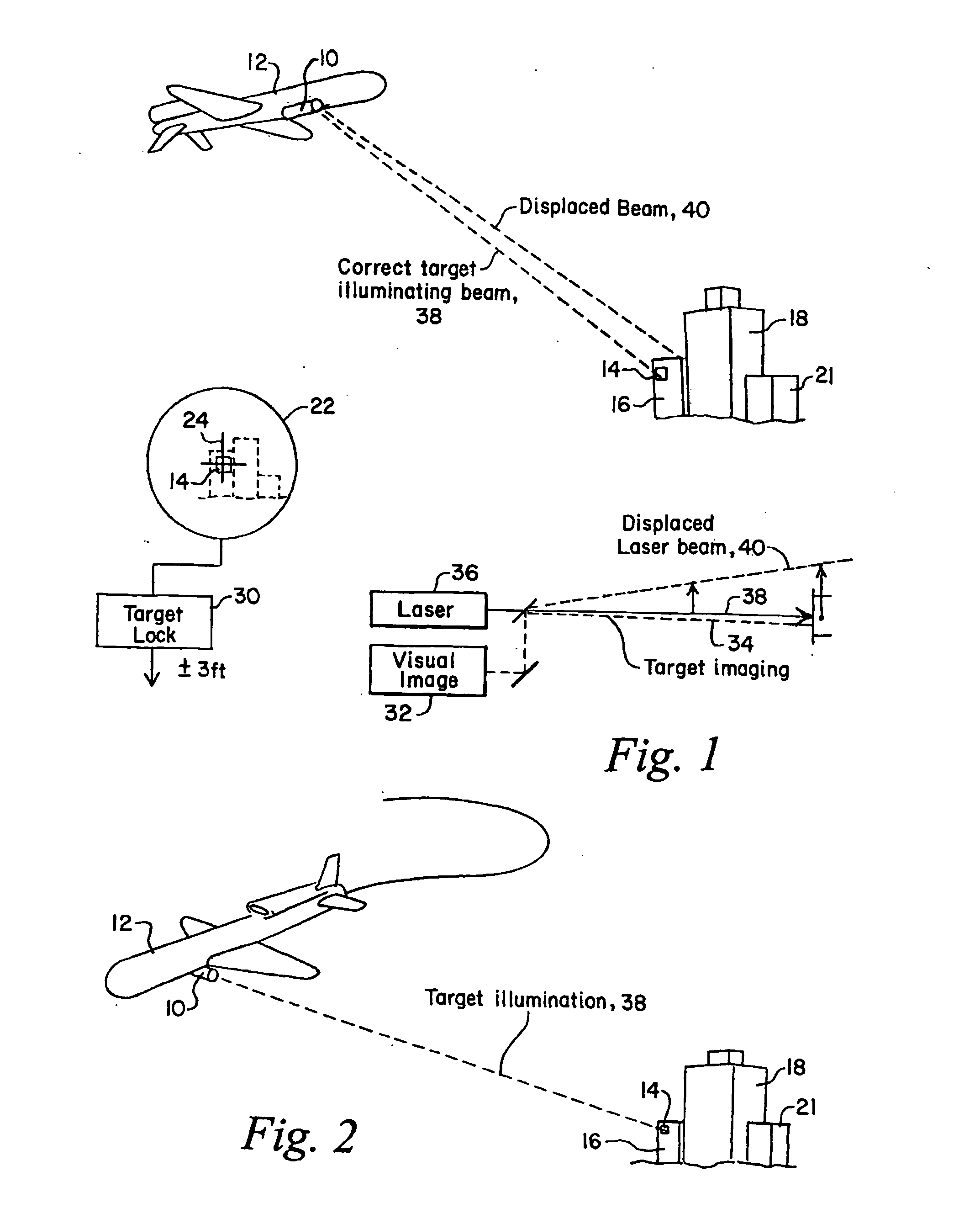

Ultra stable optical element x,y, positioning unit for use in harsh environments

InactiveUS20060093269A1Reduce thermal resistanceReduce generationCoupling light guidesMountingsSet screwLaser target

An X, Y positioning unit, mount or fixture is designed to adjust the position of an optical element mounted in the fixture so as to move it laterally and vertically with respect to the optical axis of the element, such that, once adjusted, the position is maintained through the clamping of plates about the positioning fixture to lock the hinges against movement. In this manner the adjusted position of the optical element is locked with high forces exerted by the plates on the fixture, with the locking technique not affecting the alignment. In one embodiment, the fixture includes live hinges which join an optical element holder to a fixed plate and pivot the holder about orthogonal axes crossing at the center of an optical element holder such that small movements of the hinged holder about the hinges adjusts the position of the center of the optical element holder and thus the optical element. The fixture in a preferred embodiment includes a milled block of metal having slots Electric Discharged Machined or High Speed Machined therein to leave thin flexible hinges, with positioning screws utilized to move the optical element holder about the hinges. When the appropriate adjustment has been made, the holder is clamped in the adjusted position to the fixed plate through the use of the clamping plates to provide a rigid structure capable of withstanding high static and dynamic loading. For laser target designator applications, positioning unit tolerance is less than one half micron, resulting in target designation boresight alignment errors less than 500 microradians.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Snap-on securement clip for hanging objects from ceiling rails

InactiveUS7065912B2Tight gripNone of methods is secureStampsFurniture partsEngineeringFlexible cable

Owner:VISUAL CREATIONS INC

Fixed angle ESL label holder with flex grip and moisture seal

InactiveUS20060143962A1Simple and inexpensive mannerTight gripStampsLayered productsElectronic shelf labelCombined use

An electronic shelf label (ESL) holder, including an attachment member portion to be secured to a supporting surface, such as a C-channel, a holder member with protrusions for removably receiving and supporting the ESLs and, optionally, a cover member pivotally carried by the holder member to overly and protect the ESLs. The holder member includes a lip extending from at least one of the top or bottom fingers of the holder formed of flexible PVC material that is flexible relative to the remaining portion of the holder and is compressible for providing a tight fit of the ESL to the holder. The flexible lip is utilized in combination with a backing member which, in one embodiment, is a flexible PVC bead that extends along the length of the holder and, in a second embodiment, includes a relatively broad or wide pad of flexible PVC material that further provides a seal against the battery or other electronics of the ESL.

Owner:FAST JACOB +1

Large self-forming socket

A heavy duty, large self-forming socket having a plurality of retractable gripping pins bundled in parallel and held in a frame within a housing is disclosed. The frame is positioned axially within the housing by radially extending, elongated hold elements that are positioned circumferentially around the housing. Slots in the housing exterior allow efficient inspection of the position of holes into which the hold elements are installed. A collar with shelf around the center pin protects the bias spring for the pin from over-compression. The gripping pins may be held to the frame by spring clips and / or a resilient O-ring. An adaptor is attached wherein a secondary operation is used to remove the adaptor from the square end of the socket. The self-forming socket is well suited for use with valves and controls for water, gas, sewage conduits and piping.

Owner:WORKTOOLS

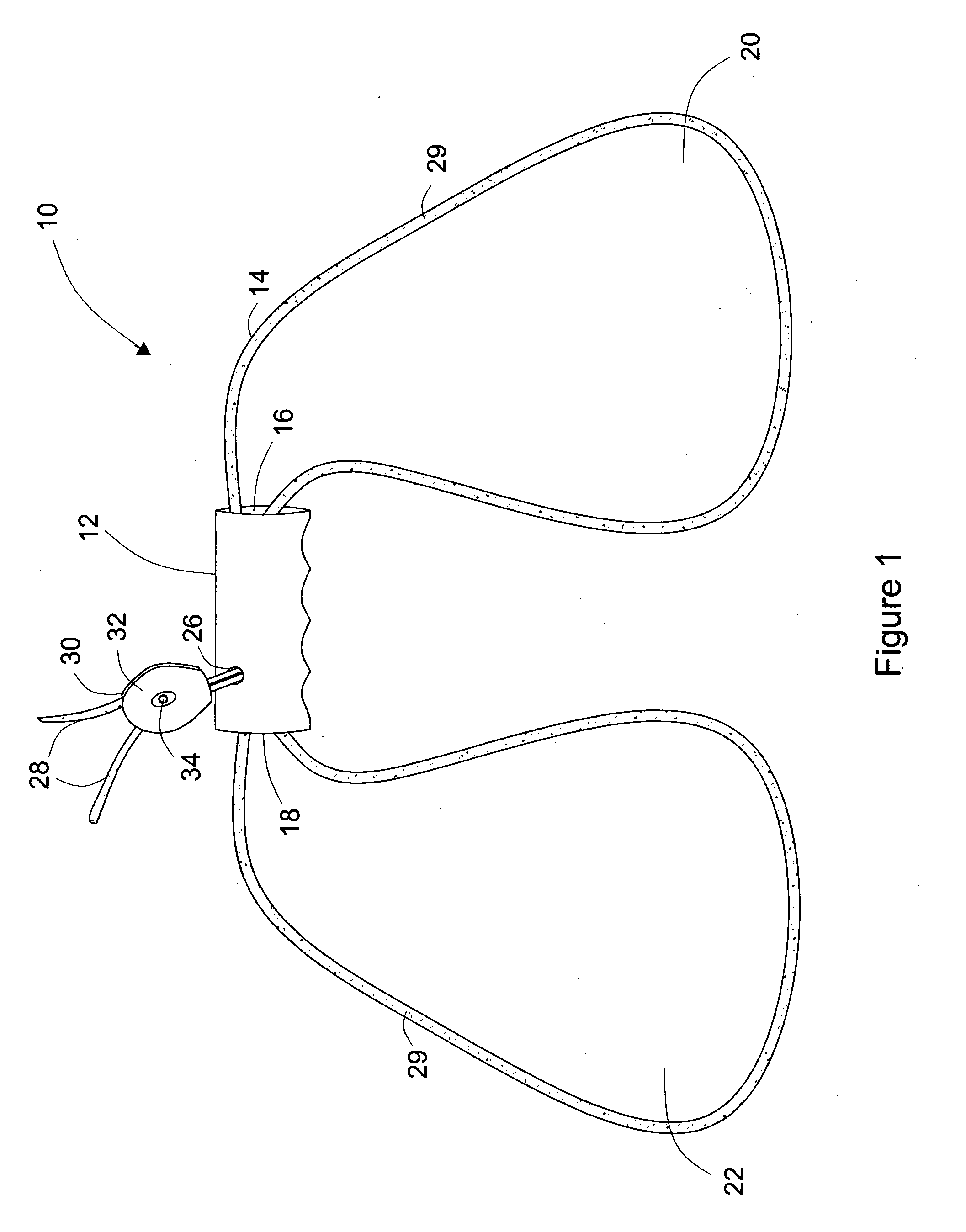

Apparatus and method for facilitating the lifting and carrying of objects without handles

InactiveUS20060085950A1Promote sportsTight gripTravelling sacksTravelling carriersFastenerEngineering

There is a gripping section with first and second open ends, a ductile member, such as a strap, forming first and second hoops extending from the first and second open ends. The hoops and wrap and tighten around the object. Ends of the ductile member protrude through a hole in the handle. A fastener receives the ends of the ductile member to allow a user to tighten the hoops. There may be a plurality of ductile members. There may be a slot in the gripping section.

Owner:DAMAR ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com