Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342 results about "Cam follower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cam follower, also known as a track follower, is a specialized type of roller or needle bearing designed to follow cam lobe profiles. Cam followers come in a vast array of different configurations, however the most defining characteristic is how the cam follower mounts to its mating part; stud style cam followers use a stud while the yoke style has a hole through the middle.

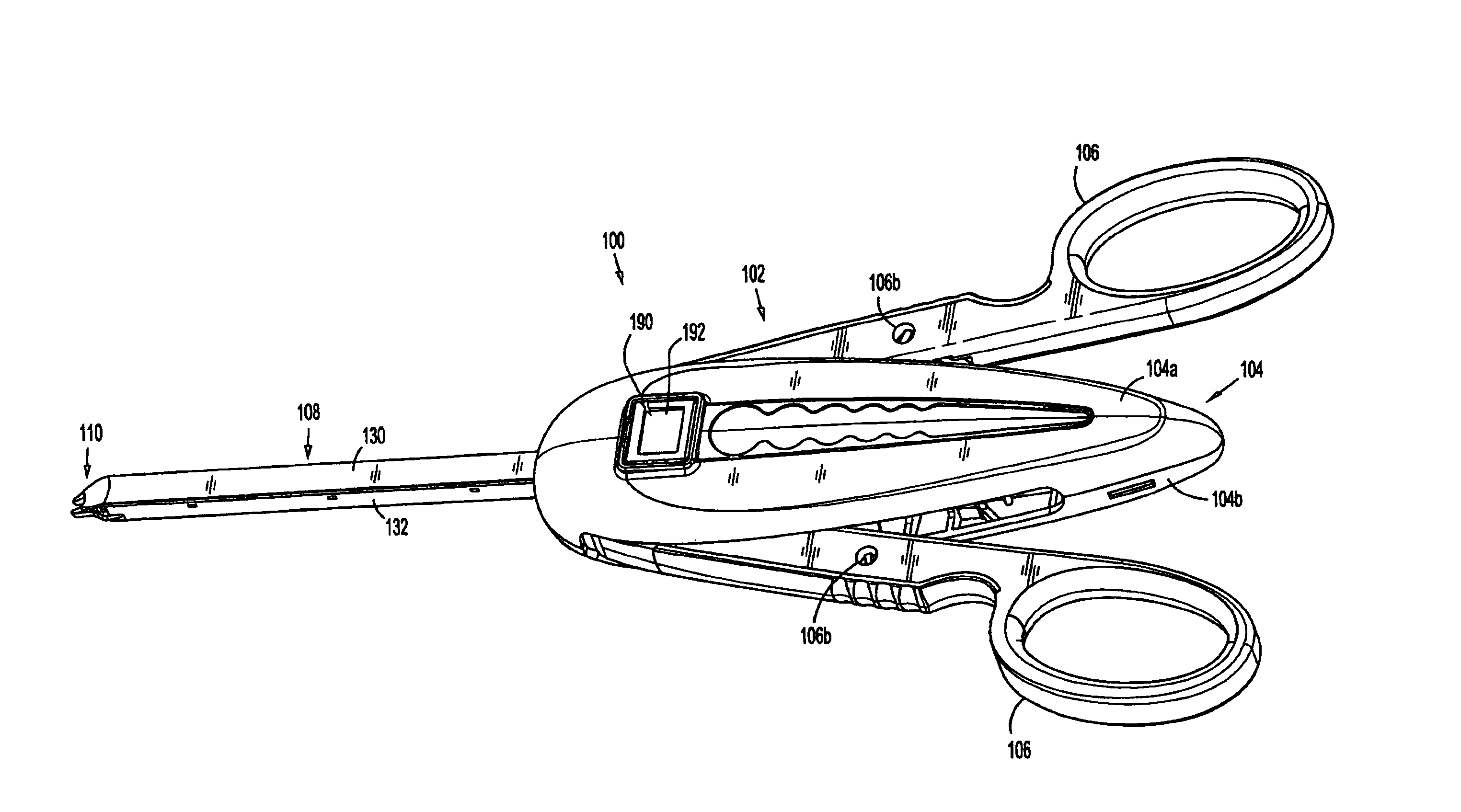

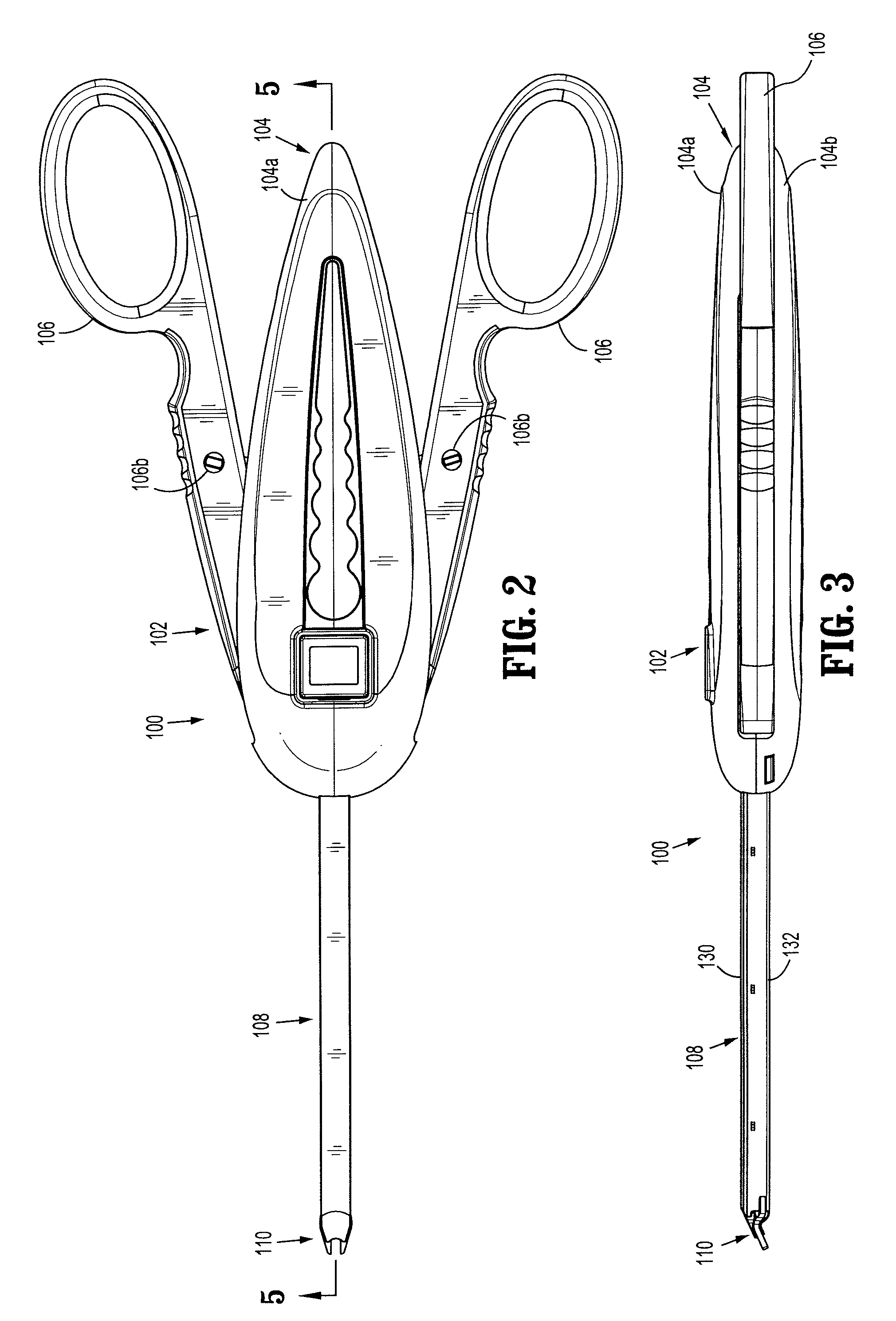

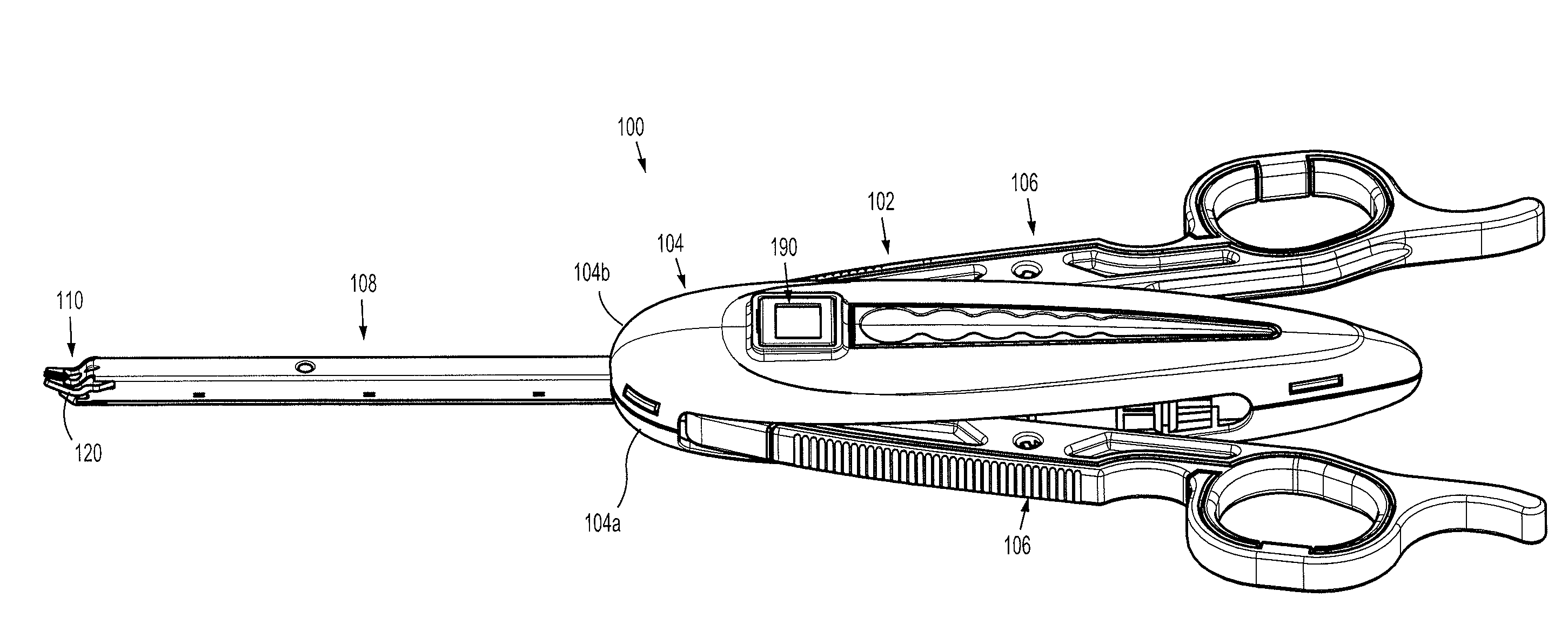

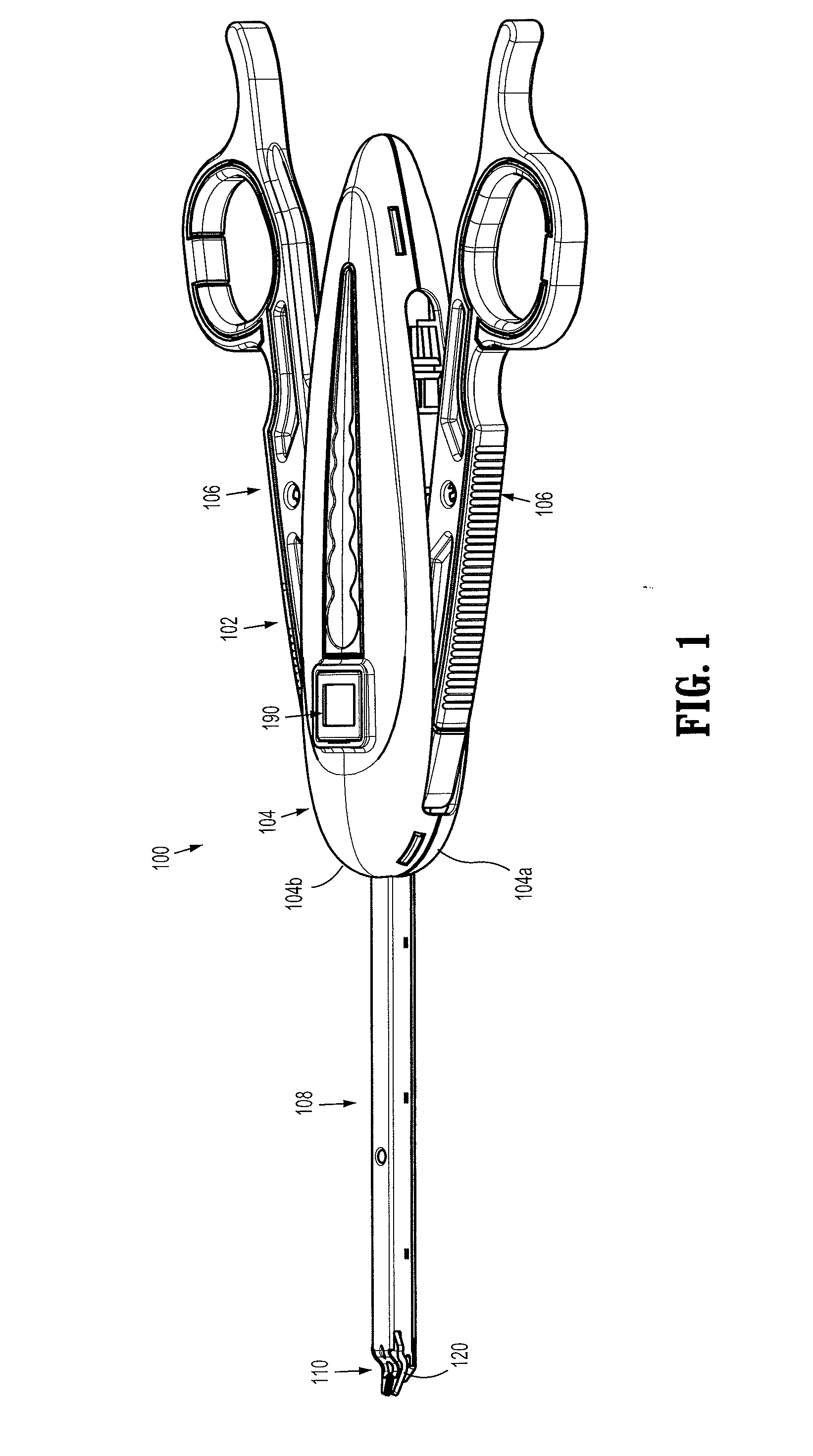

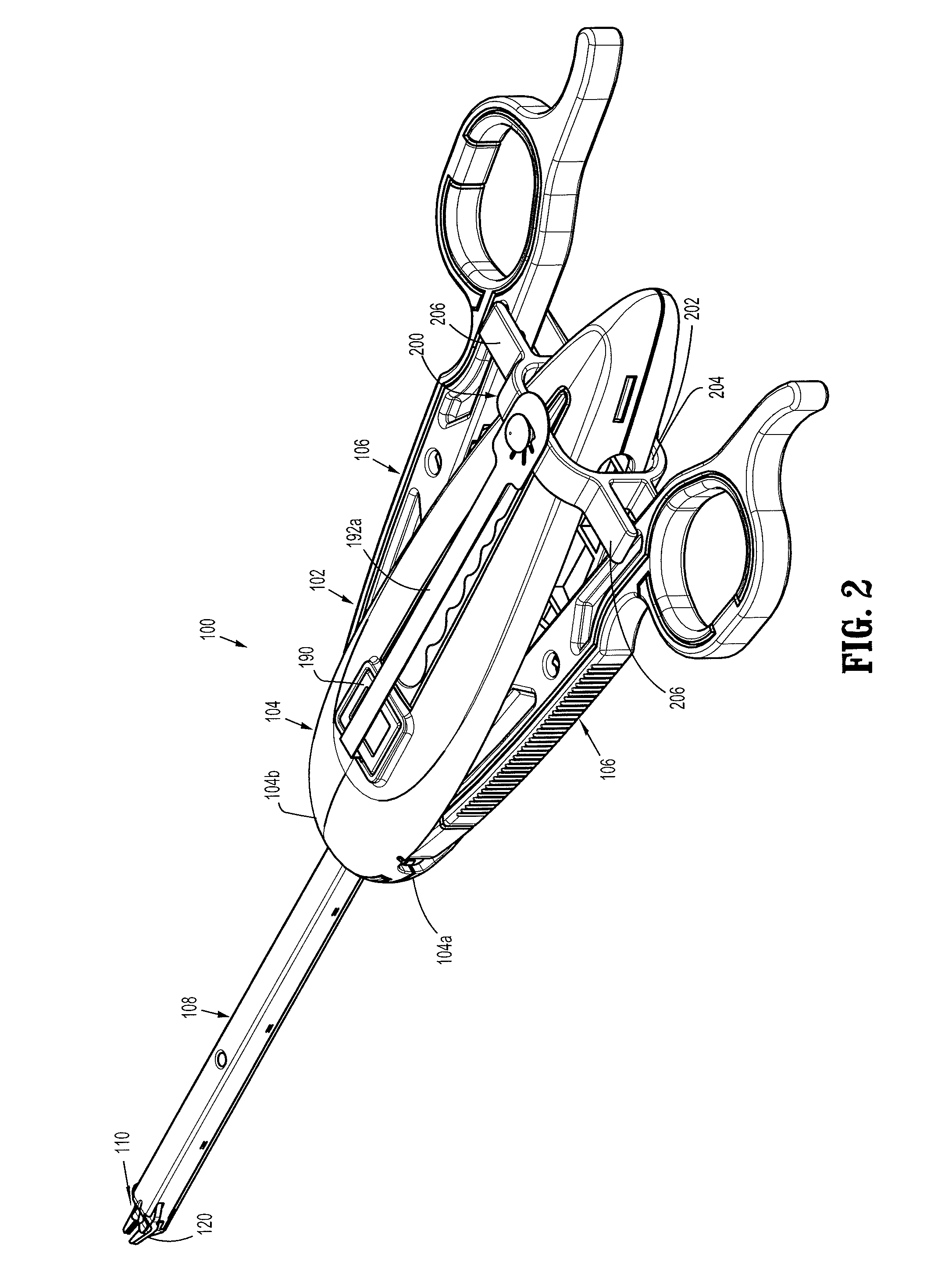

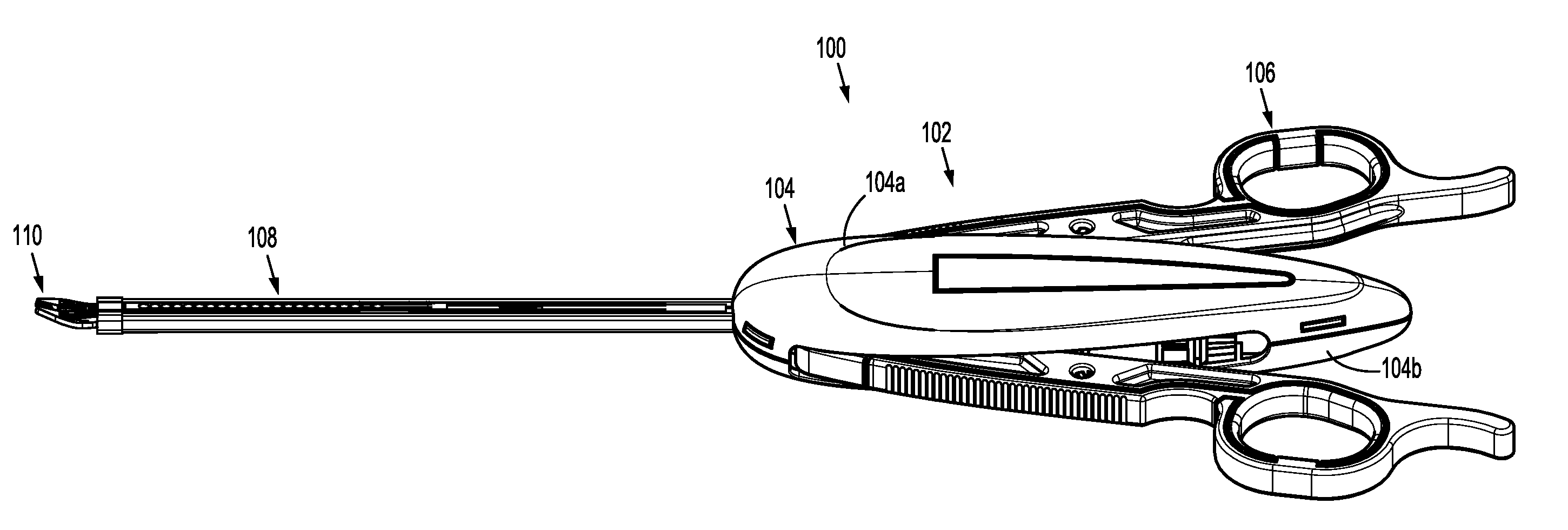

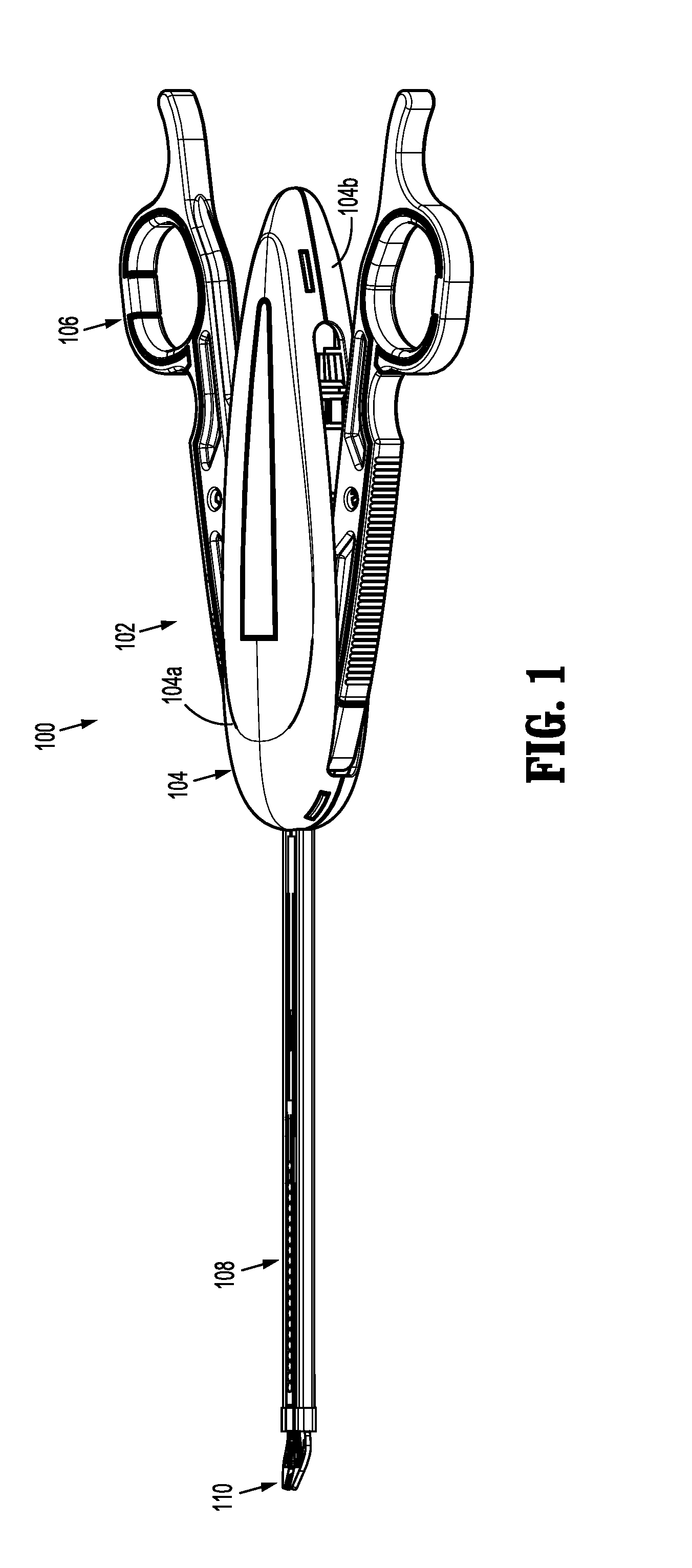

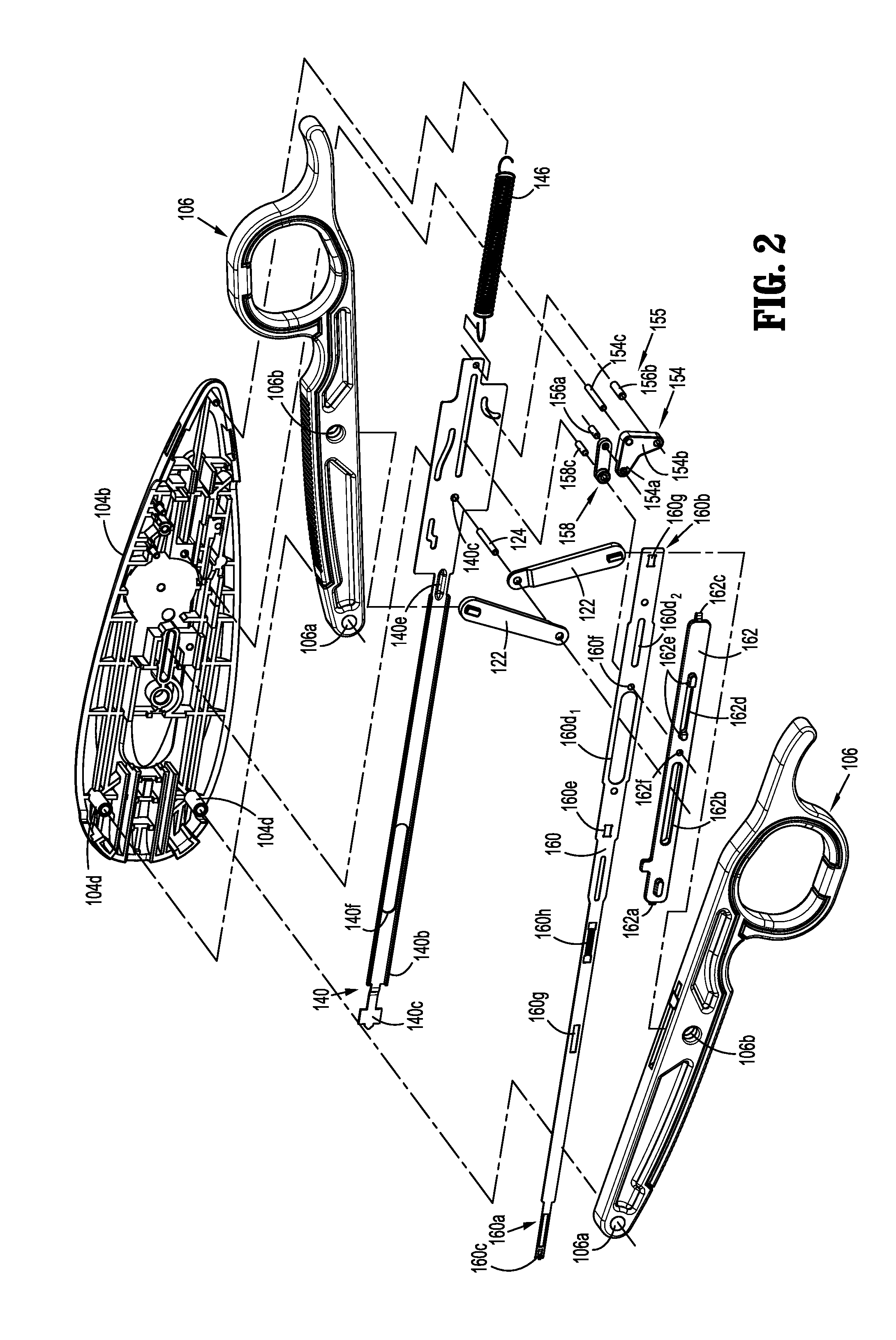

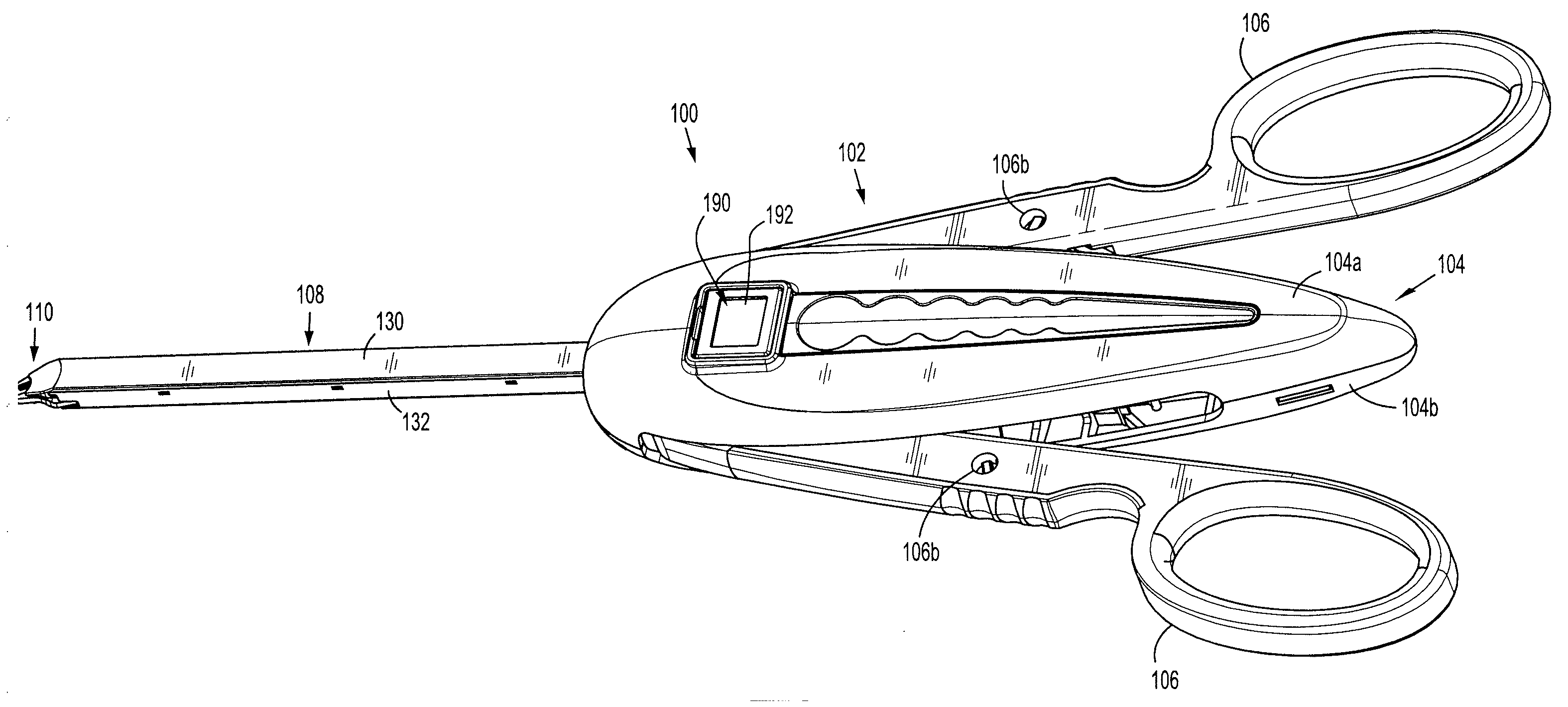

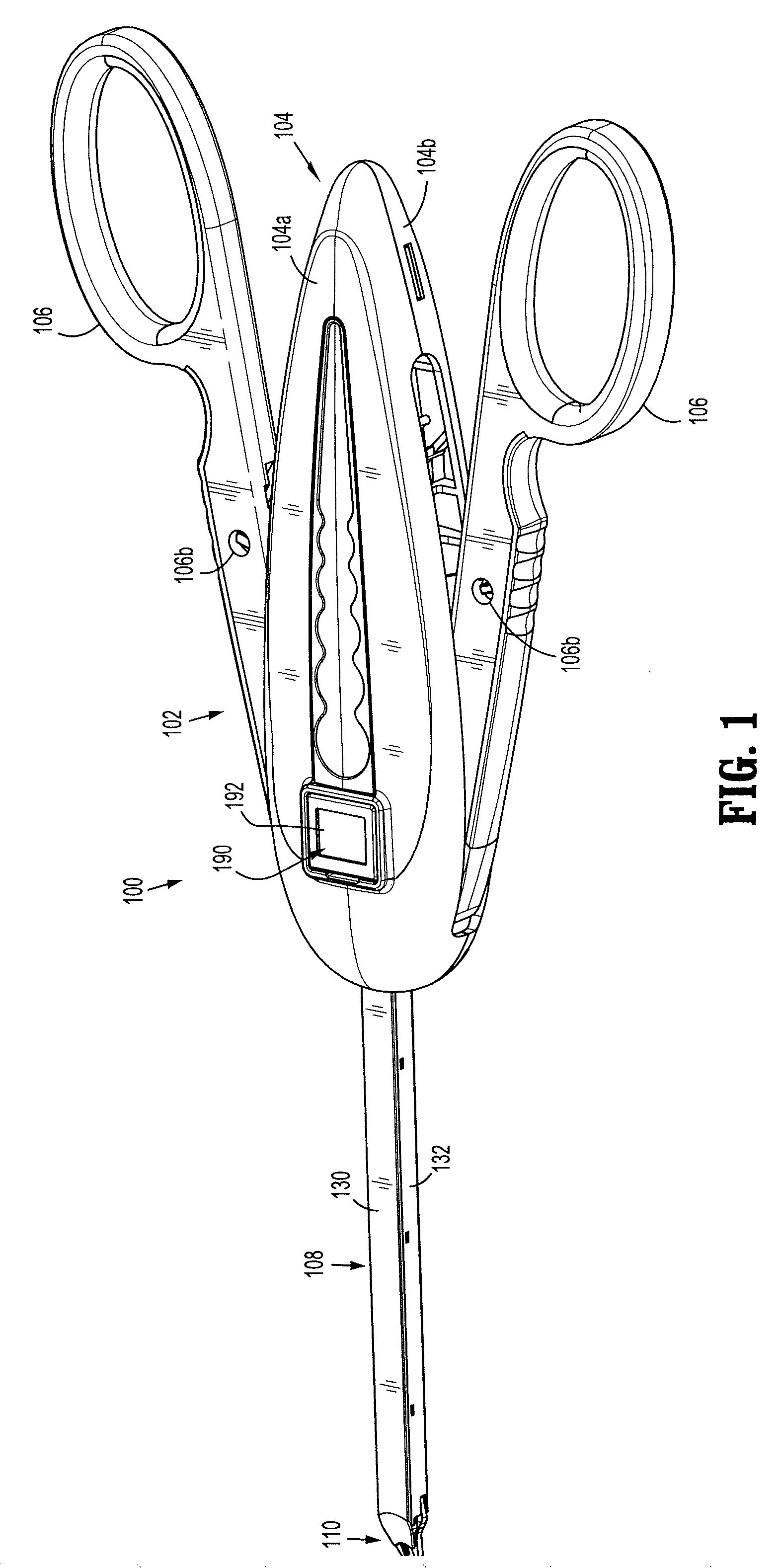

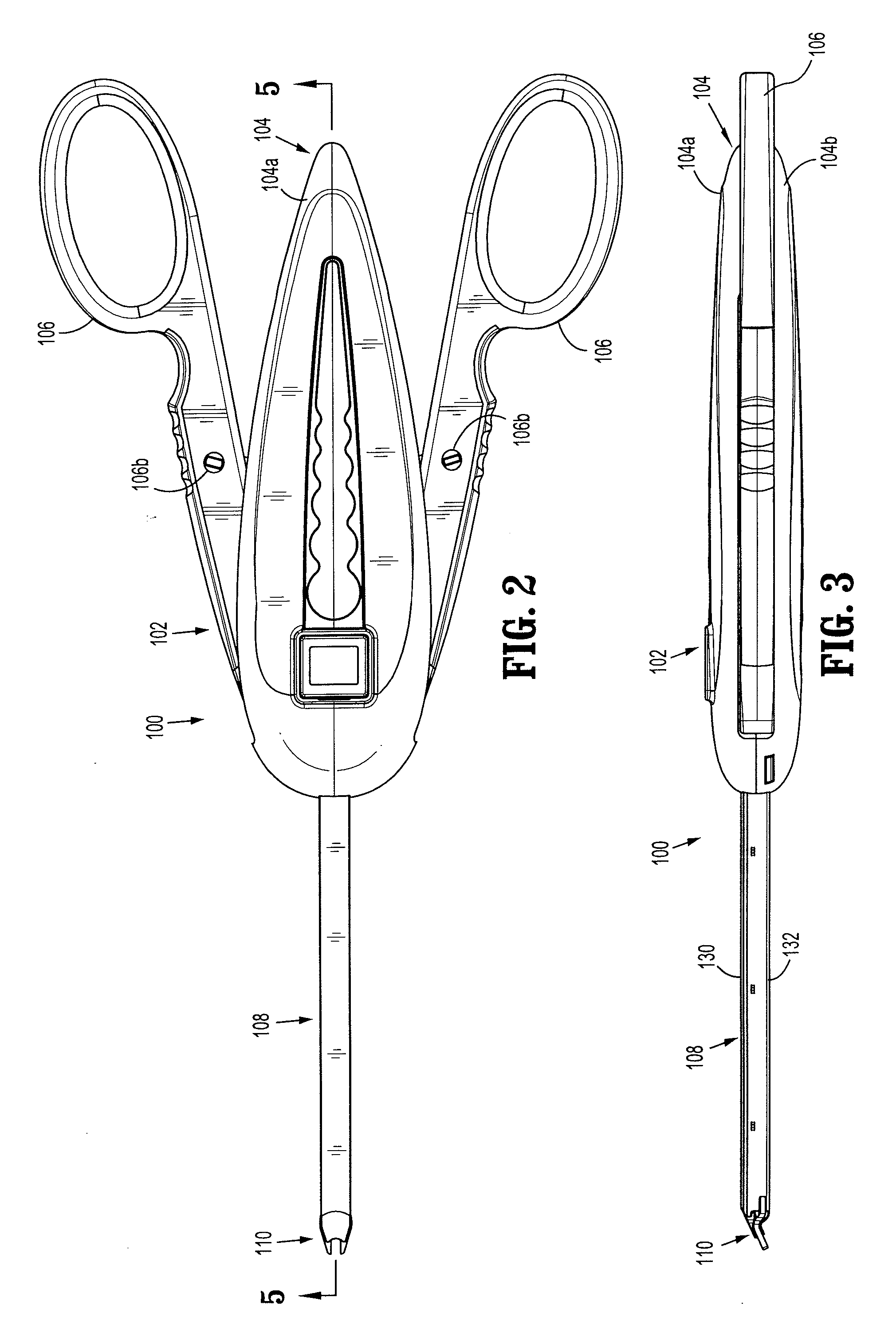

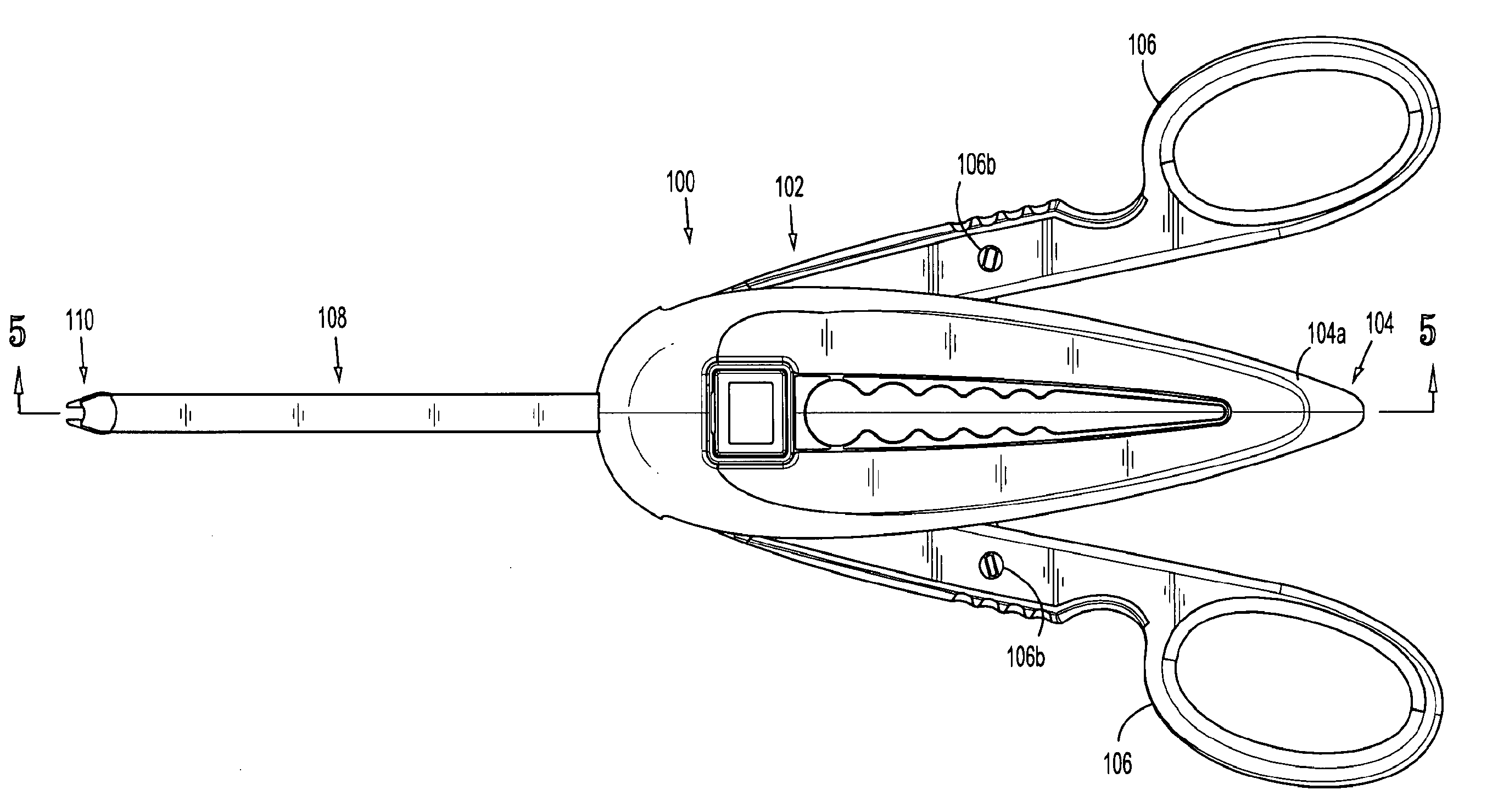

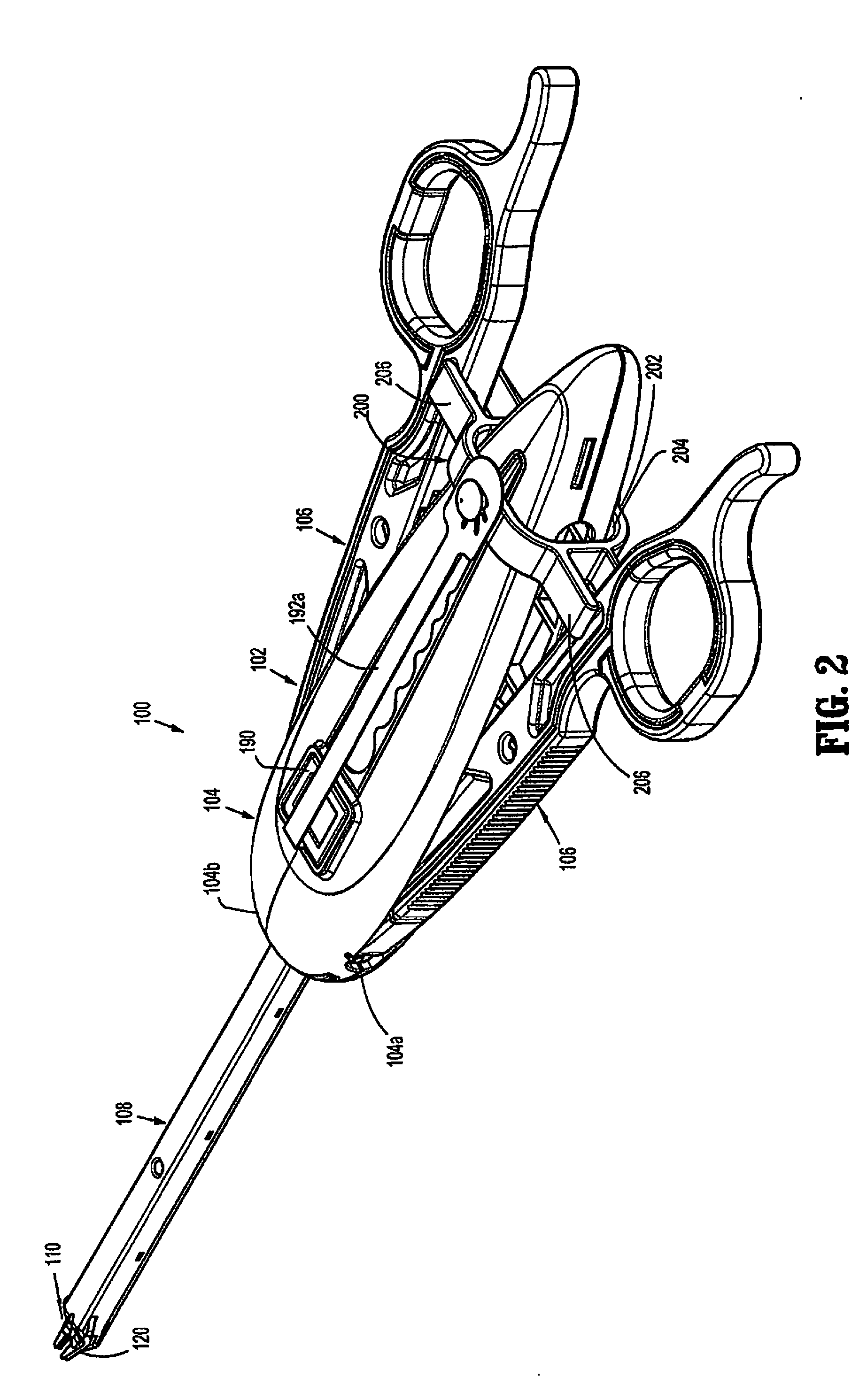

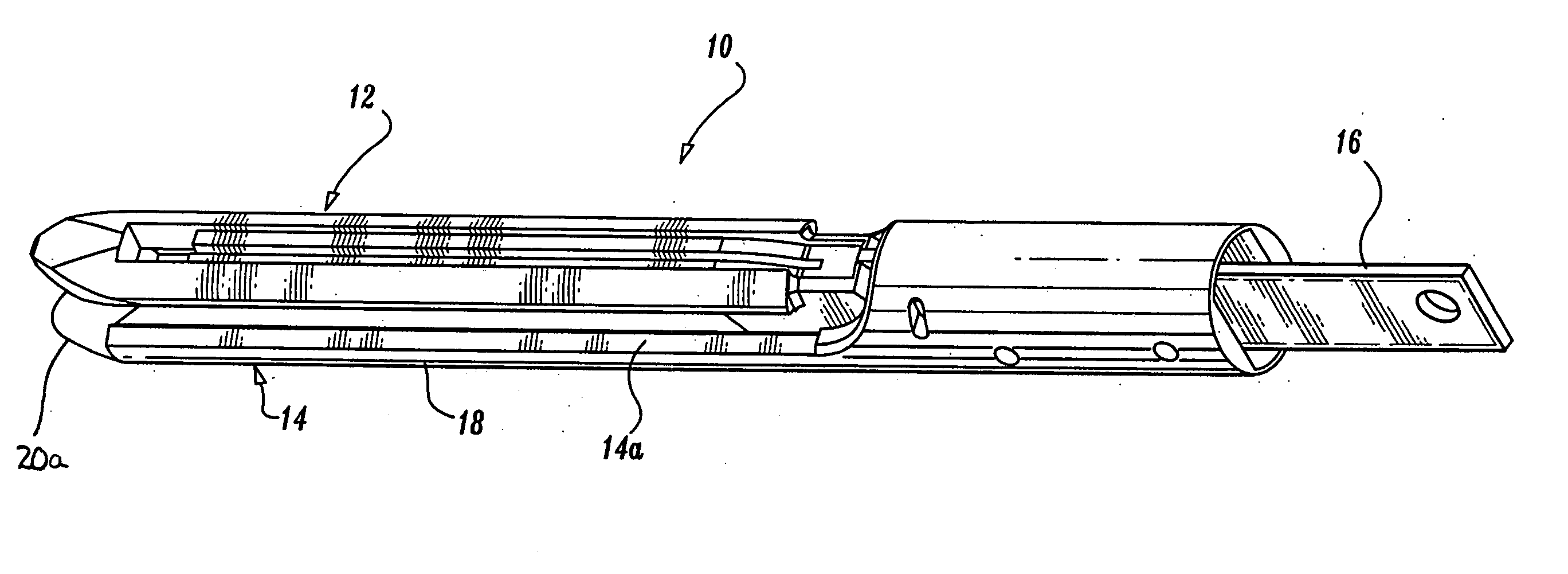

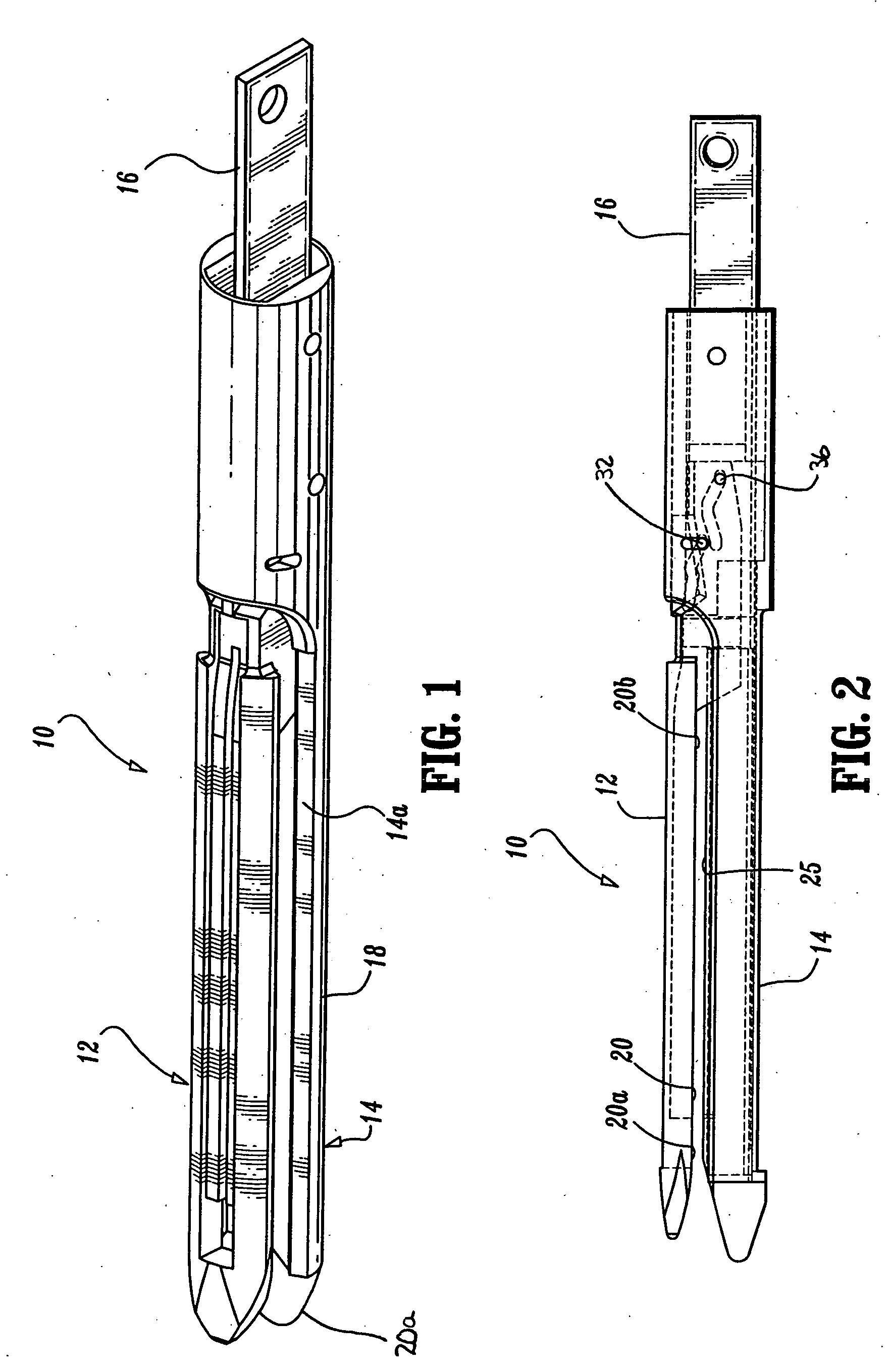

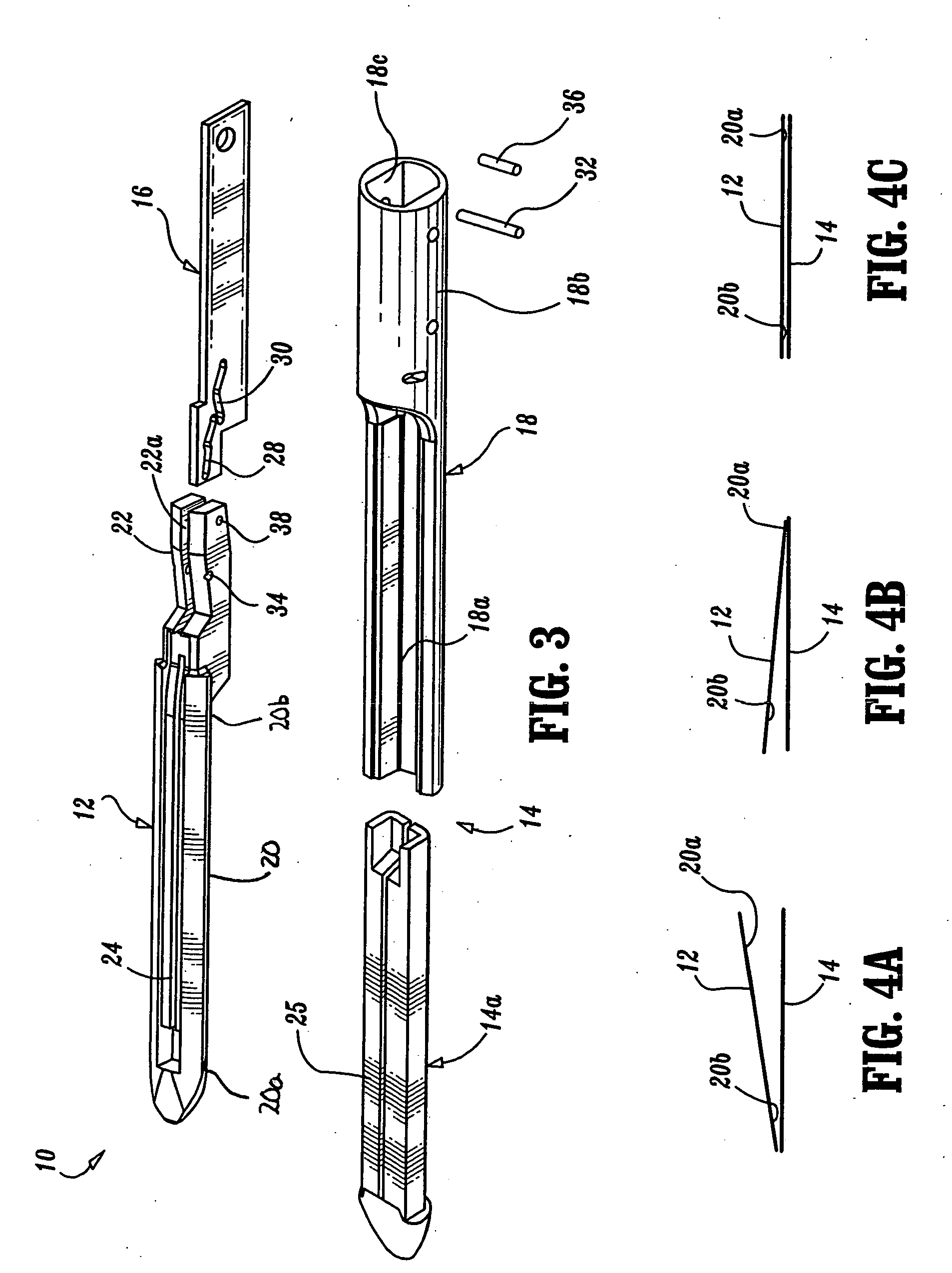

Surgical clip applier

A surgical clip applier is provided including a housing; a pair of handles; a channel assembly extending from the housing; a clip carrier disposed within said channel assembly and defining a channel and a plurality of windows; a wedge plate slidably disposed within said channel assembly and being operatively connected to said handles, said wedge plate including a plurality of apertures formed along a length thereof; a plurality of clips slidably disposed within said channel of said clip carrier; and a clip follower slidably disposed within said channel of said clip carrier at a location proximal of said plurality of clips. The clip follower is configured and adapted for selective engagement with said windows of said clip carrier and said apertures of said wedge plate to distally urge said plurality of clips relative to said clip carrier upon a distal advancement of said wedge plate.

Owner:TYCO HEALTHCARE GRP LP

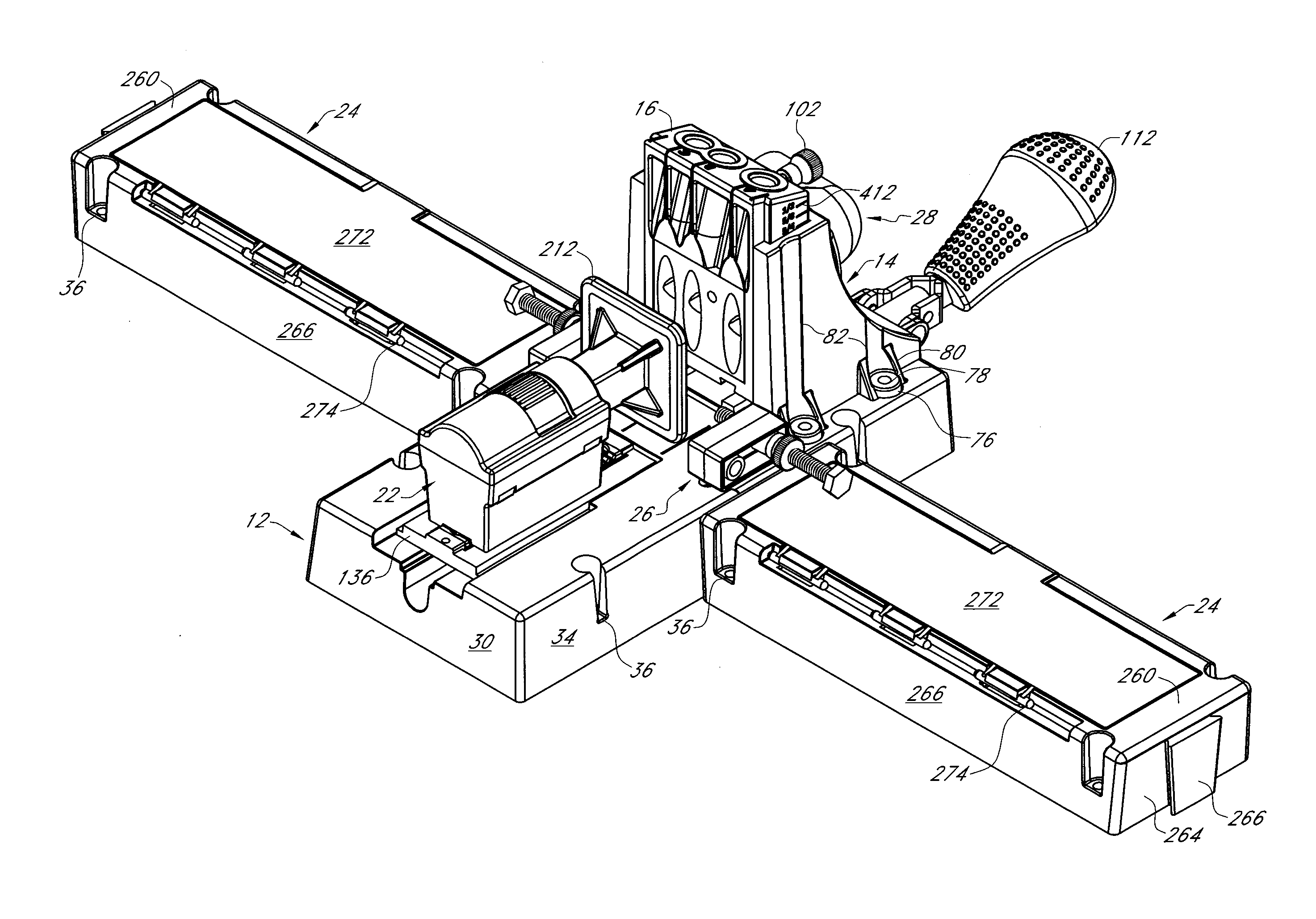

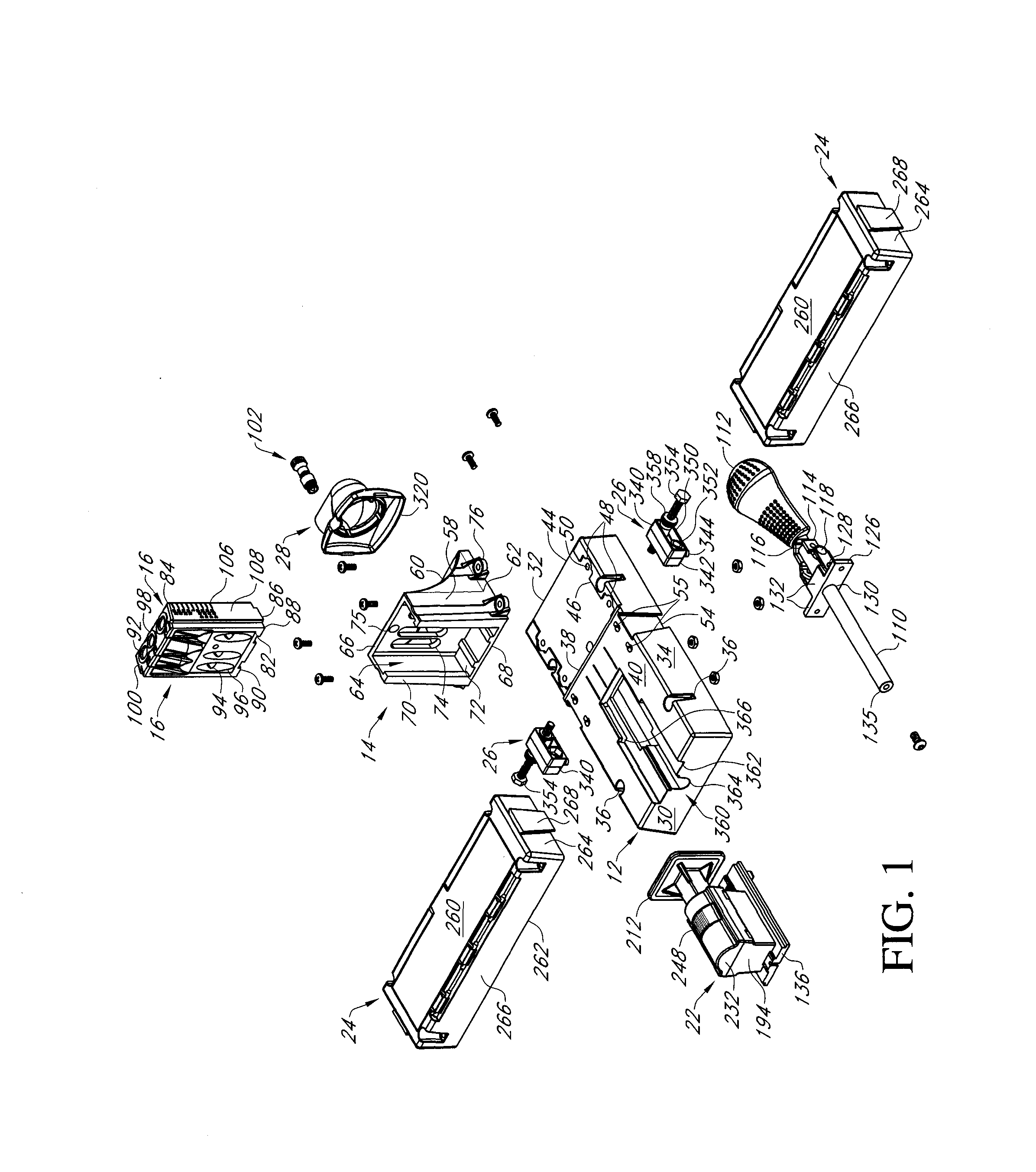

Surgical clip applier

Surgical clip appliers are provided and include a housing; at least one handle pivotably connected to the housing; a channel assembly extending distally from the housing; a clip carrier disposed within the channel assembly and defining a channel and a plurality of windows therein; a plurality of clips slidably disposed within the channel of the clip carrier; a wedge plate reciprocally disposed within the channel assembly; and a clip pusher bar reciprocally positioned within the housing and the channel assembly. A clip follower is slidably disposed within the channel of the clip carrier and disposed proximally of the plurality of clips. The clip follower is configured and dimensioned to lockout the clip applier after a last clip of the plurality of clips has been expelled by the surgical clip applier.

Owner:TYCO HEALTHCARE GRP LP

Surgical clip applier

A surgical clip applier is provided including a walking beam reciprocally disposed within a channel assembly and overlying a clip carrier, the walking beam being operatively connected to at least one handle for reciprocal movement upon actuation of the at least one handle, the walking beam including a plurality of distally oriented ramps extending into the clip channel; and a clip follower slidably disposed within the channel of the clip carrier and disposed proximally of the plurality of clips, the clip follower being configured and adapted for selective engagement with the distally oriented ramps of the clip carrier and the distally oriented ramps of the walking beam, wherein the clip follower is configured and adapted to urge the plurality of clips, in a distal direction relative to the clip carrier, upon reciprocal movement of the walking beam.

Owner:TYCO HEALTHCARE GRP LP

Surgical clip applier

A surgical clip applier is provided including a housing; a pair of handles; a channel assembly extending from the housing; a clip carrier disposed within said channel assembly and defining a channel and a plurality of windows; a wedge plate slidably disposed within said channel assembly and being operatively connected to said handles, said wedge plate including a plurality of apertures formed along a length thereof; a plurality of clips slidably disposed within said channel of said clip carrier; and a clip follower slidably disposed within said channel of said clip carrier at a location proximal of said plurality of clips. The clip follower is configured and adapted for selective engagement with said windows of said clip carrier and said apertures of said wedge plate to distally urge said plurality of clips relative to said clip carrier upon a distal advancement of said wedge plate.

Owner:TYCO HEALTHCARE GRP LP

Surgical clip applier

A surgical clip applier is provided including a housing; a pair of handles; a channel assembly extending from the housing; a clip carrier disposed within said channel assembly and defining a channel and a plurality of windows; a wedge plate slidably disposed within said channel assembly and being operatively connected to said handles, said wedge plate including a plurality of apertures formed along a length thereof; a plurality of clips slidably disposed within said channel of said clip carrier; and a clip follower slidably disposed within said channel of said clip carrier at a location proximal of said plurality of clips. The clip follower is configured and adapted for selective engagement with said windows of said clip carrier and said apertures of said wedge plate to distally urge said plurality of clips relative to said clip carrier upon a distal advancement of said wedge plate.

Owner:COVIDIEN LP

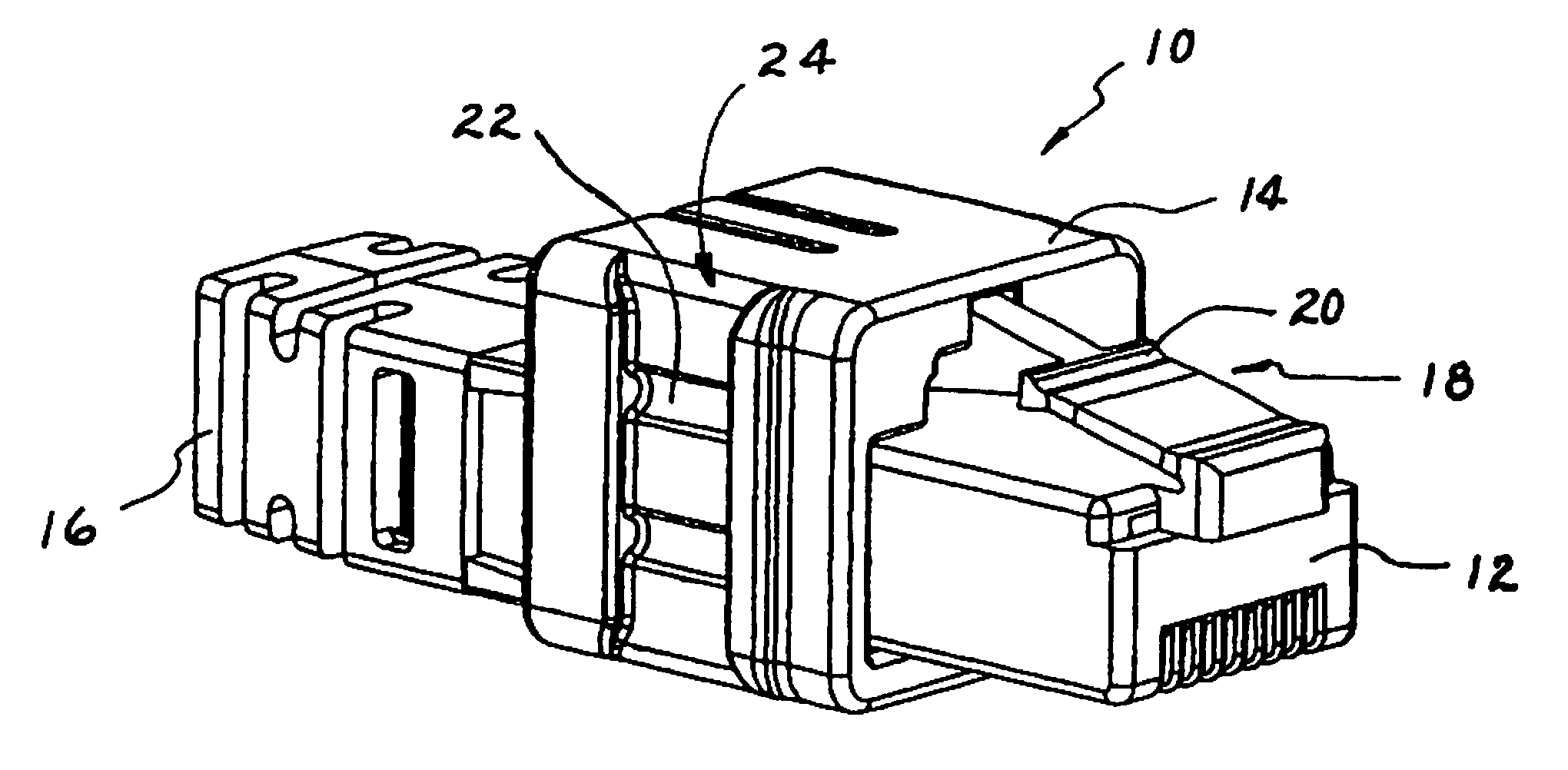

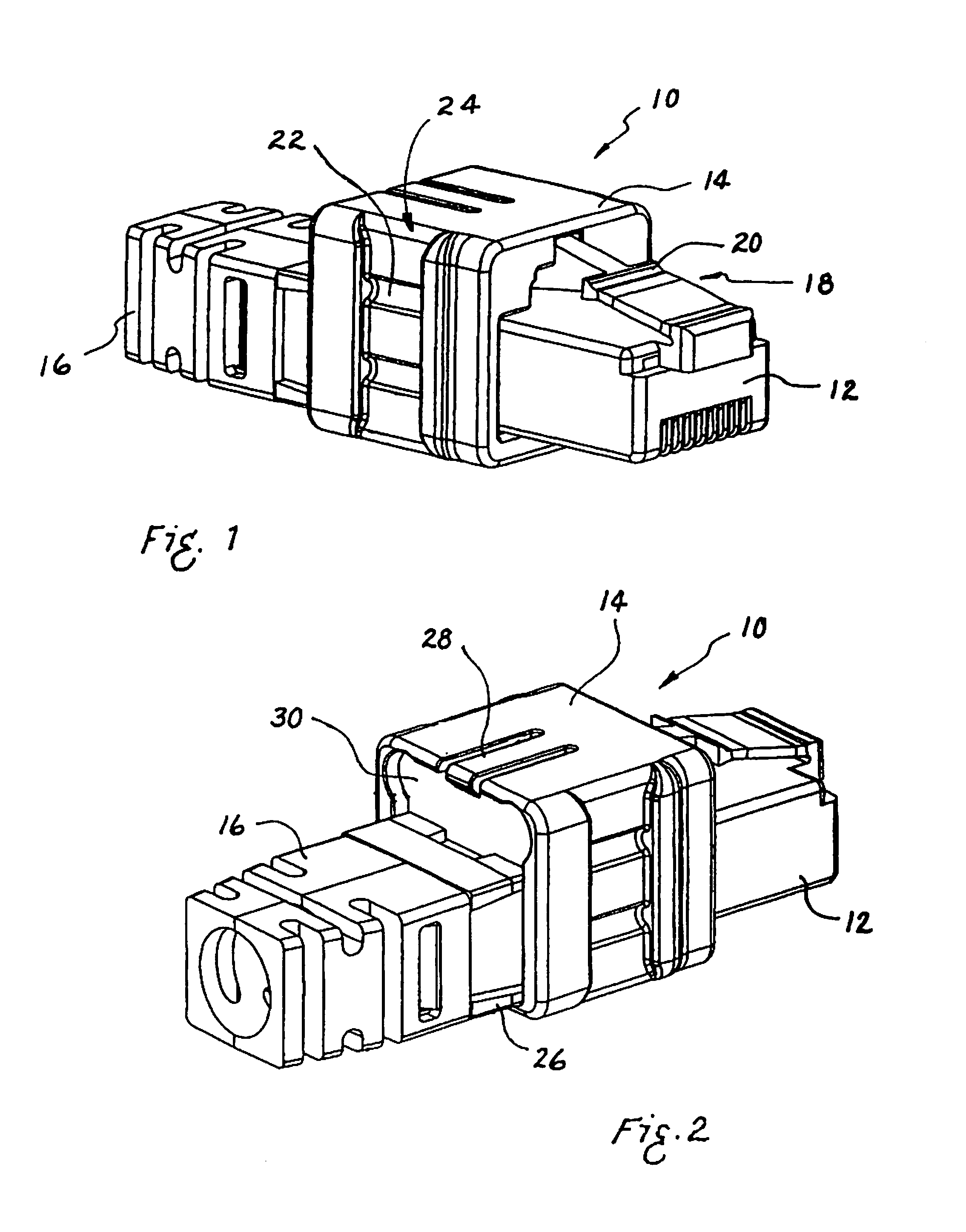

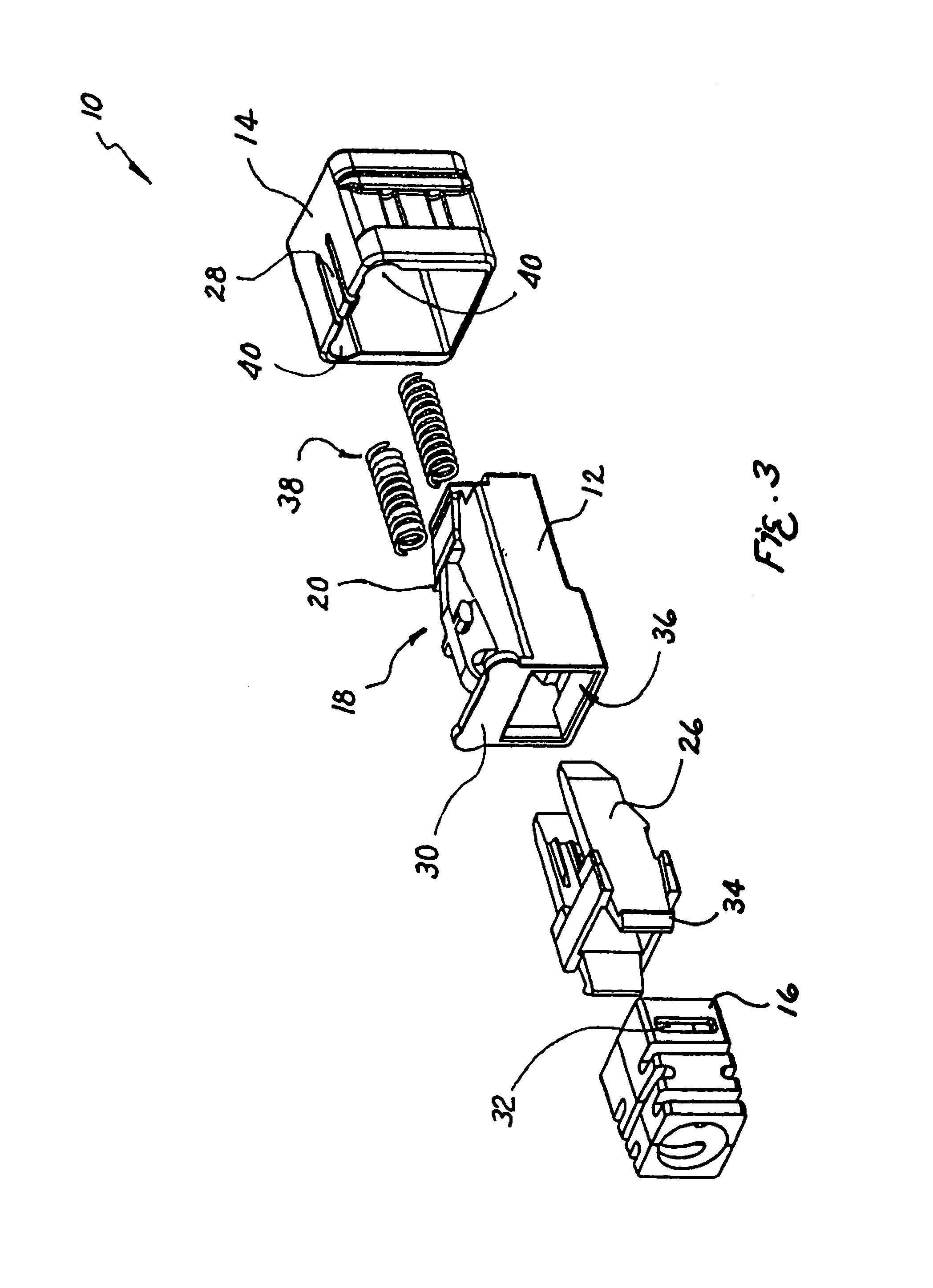

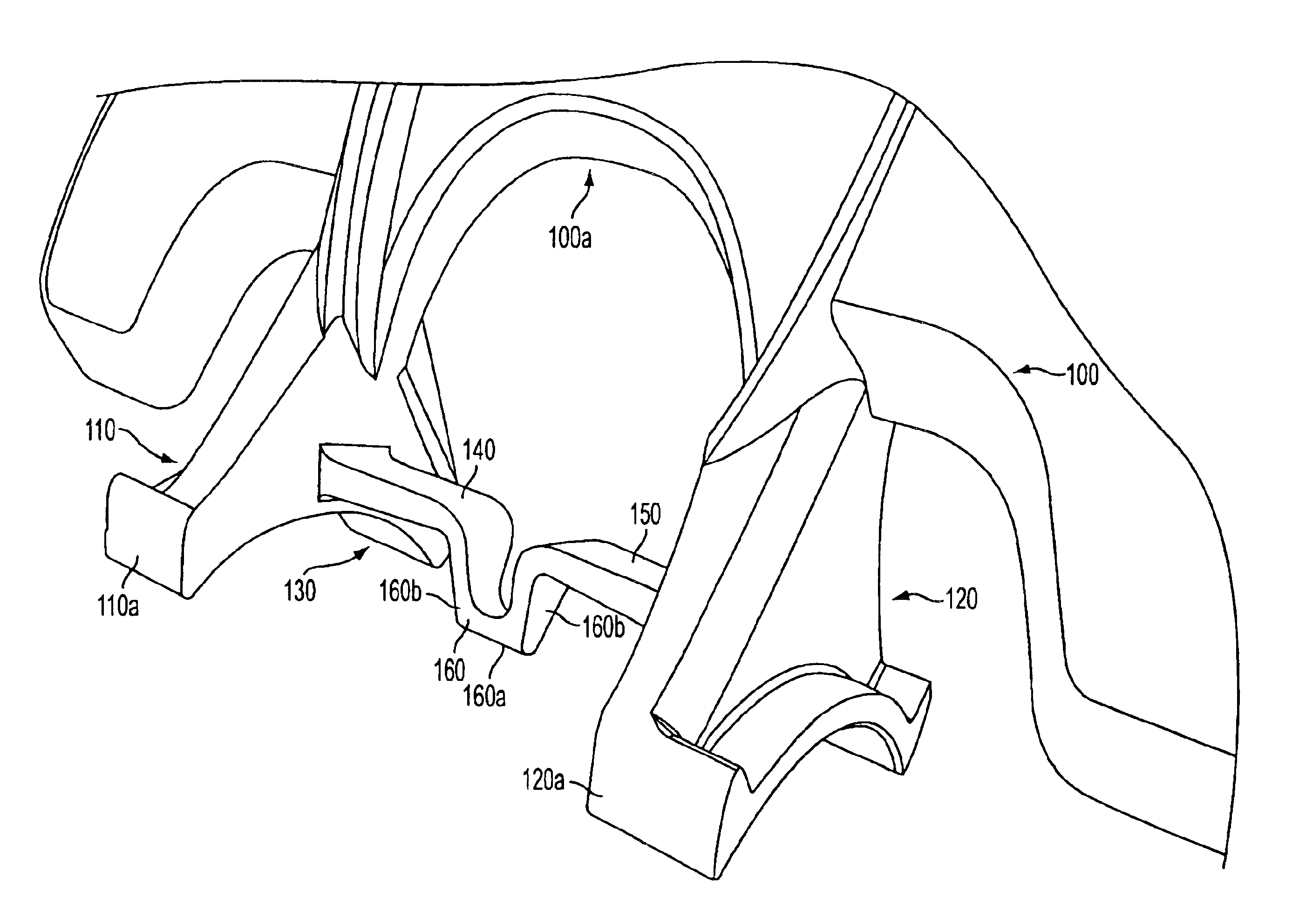

Push-pull plugs and tools

A push-pull plug has an outer housing that may be moved forwardly and backwardly along a plug housing. When the outer housing is in its forward position, a latch arm is in an upward or mated position and the plug will stay mated to a jack when the plug is inserted into the jack. When the outer housing is moved backwardly, cam surfaces on the outer housing push cam followers on the latch arm downwardly, moving the latch arm and latch to a downward or unmated position. The plug may then be removed from a jack as the outer housing is pulled. The plugs may be adapted for use with an insertion and removal tool. Corner finger grips may be formed on the outer housing and may be located in an alternating manner to facilitate use when plugs are closely positioned.

Owner:PANDUIT

One-piece spring for razor handle

A razor handle head is provided having a one-piece spring extending between and molded integrally with a pair of opposed arms that carry connectors to which a razor cartridge movably (e.g., pivotally) mounts. The single-piece spring has a pair of outer spring sections extending from the arms and a center portion with a cam follower which bears against a cam surface on the cartridge to bias the cartridge as it moves relative to the handle head. The one-piece spring also flexes with the arms during assembly of the cartridge to the handle head.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

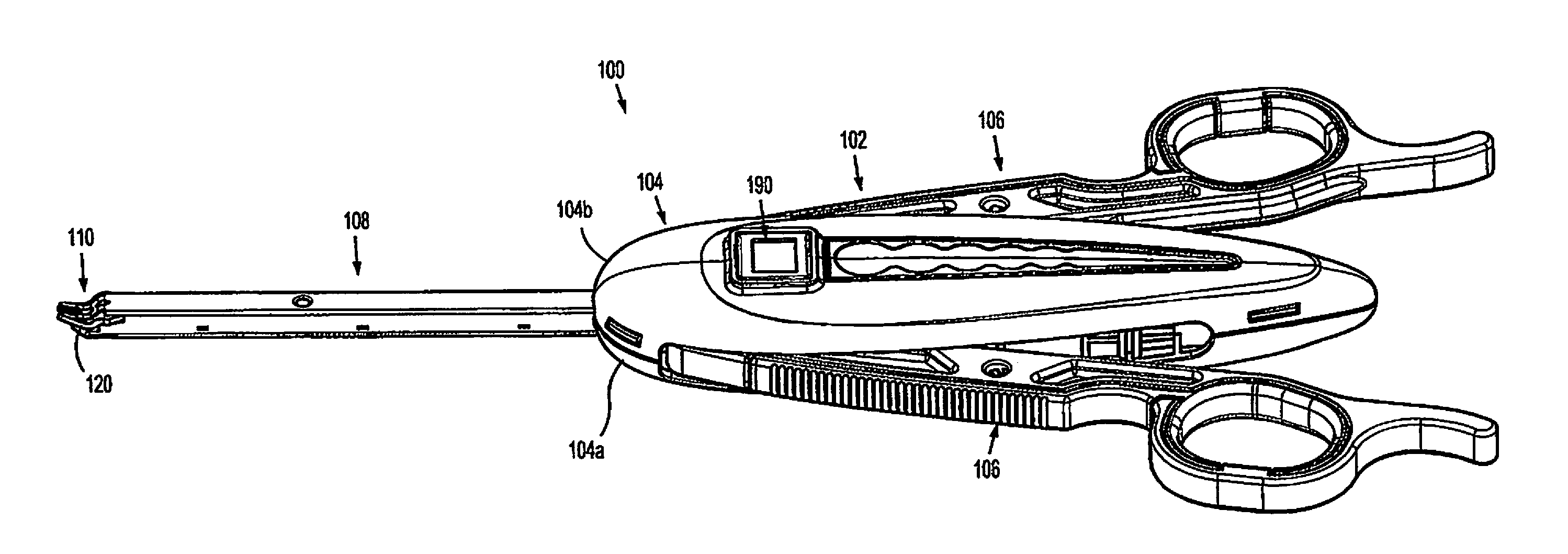

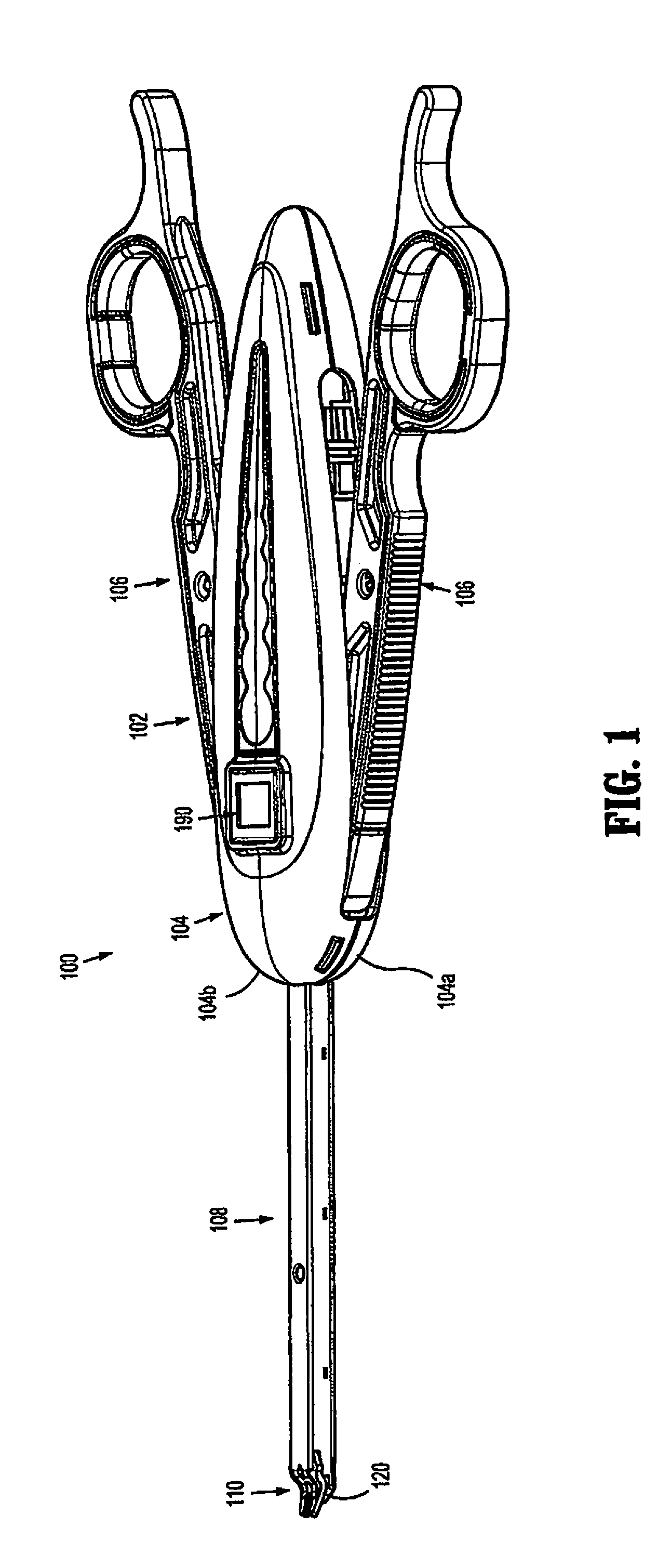

Surgical clip appliers

A surgical clip applier includes a housing, at least one handle, a channel assembly, a clip carrier, a wedge plate, a clip pusher bar, and a clip follower. The at least one handle is pivotably connected to the housing. The channel assembly extends distally from the housing. The clip carrier is disposed within the channel assembly and defines a channel and a plurality of windows. The wedge plate is reciprocally disposed within the channel assembly. The clip pusher bar is reciprocally positioned within the housing and the channel assembly. The clip follower is slidably disposed within the channel of the clip carrier and disposed proximally of a plurality of clips. The clip follower is configured and dimensioned to lockout the clip applier after a last clip of the plurality of clips has been expelled by the surgical clip applier.

Owner:TYCO HEALTHCARE GRP LP

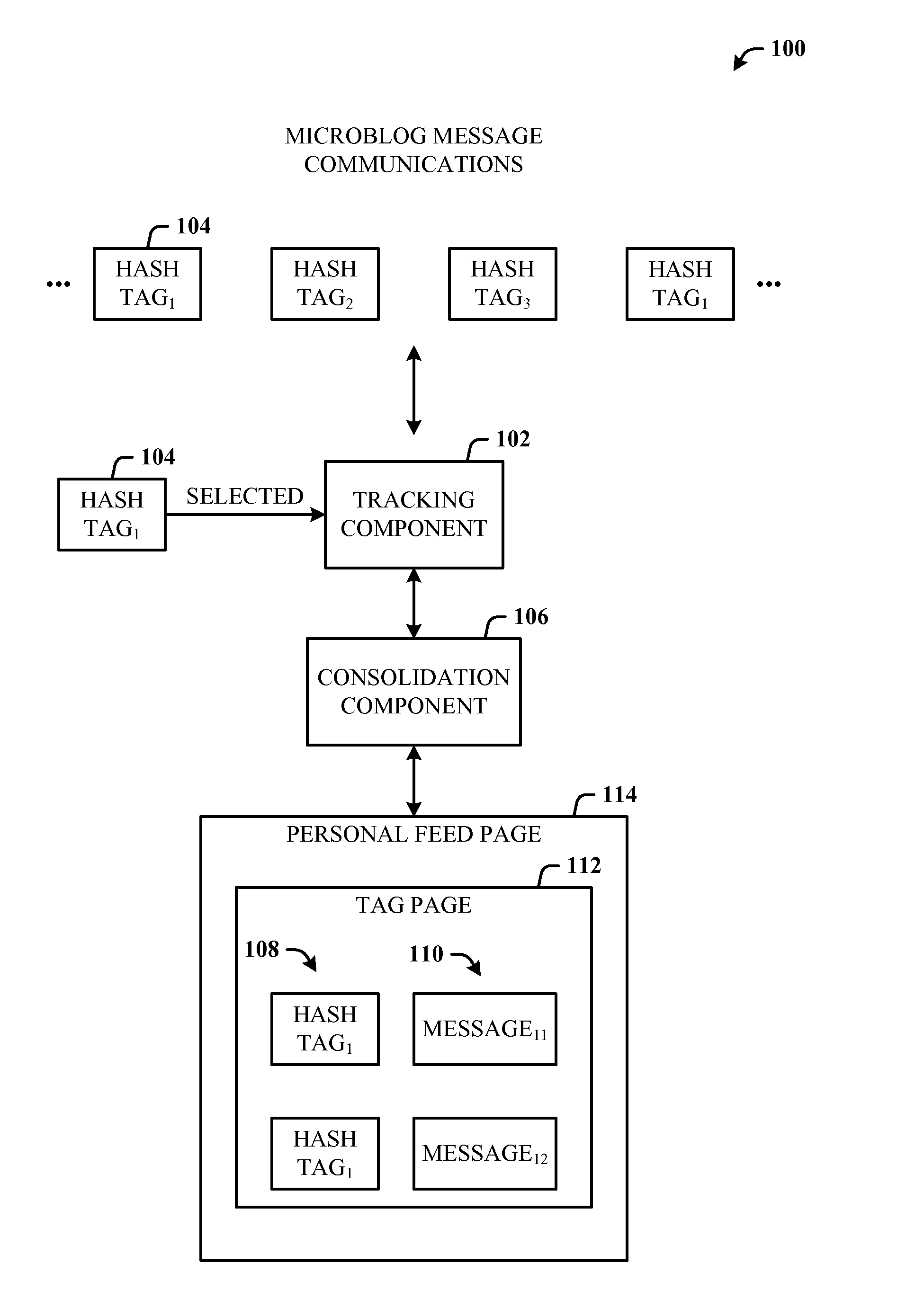

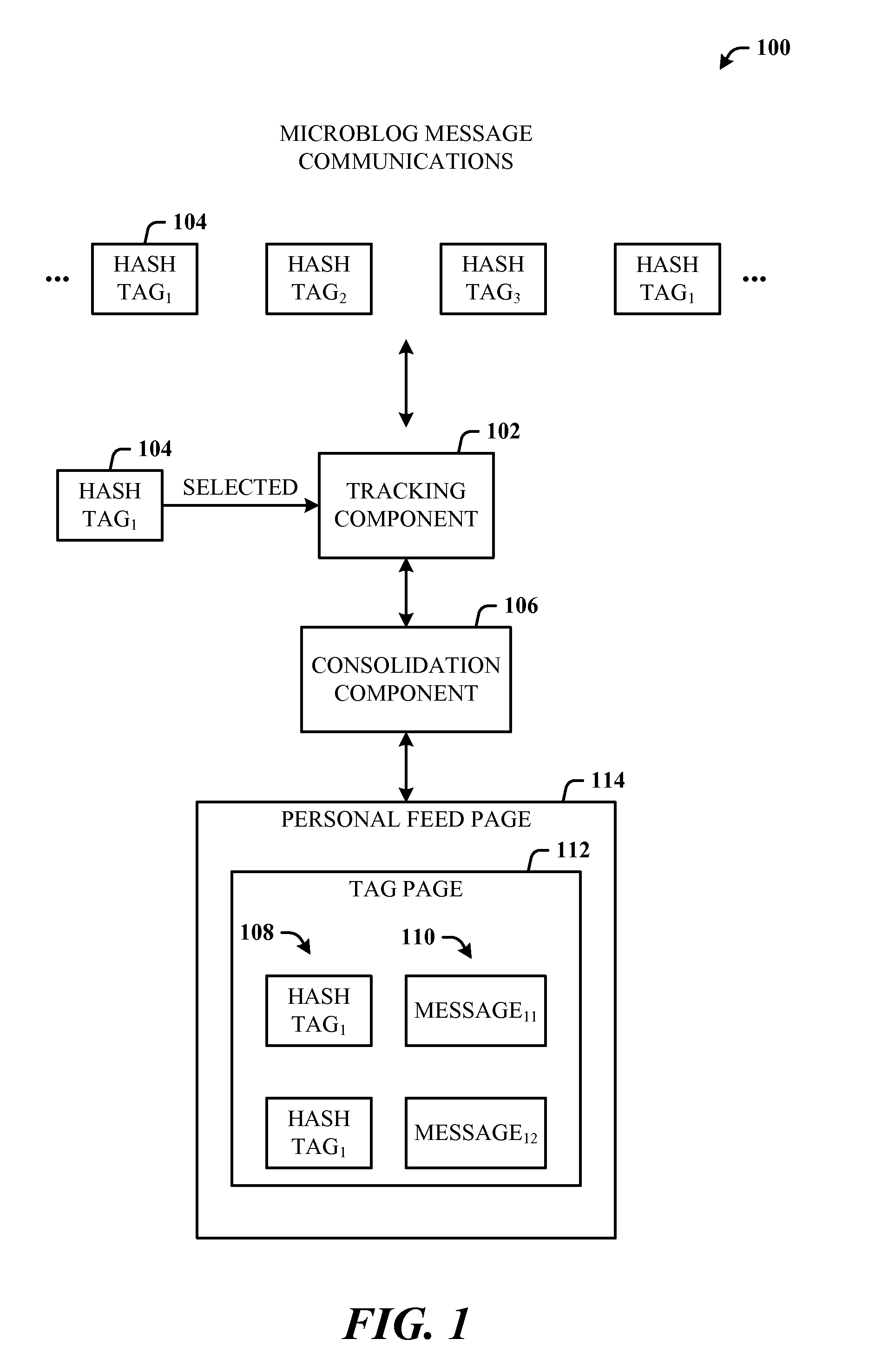

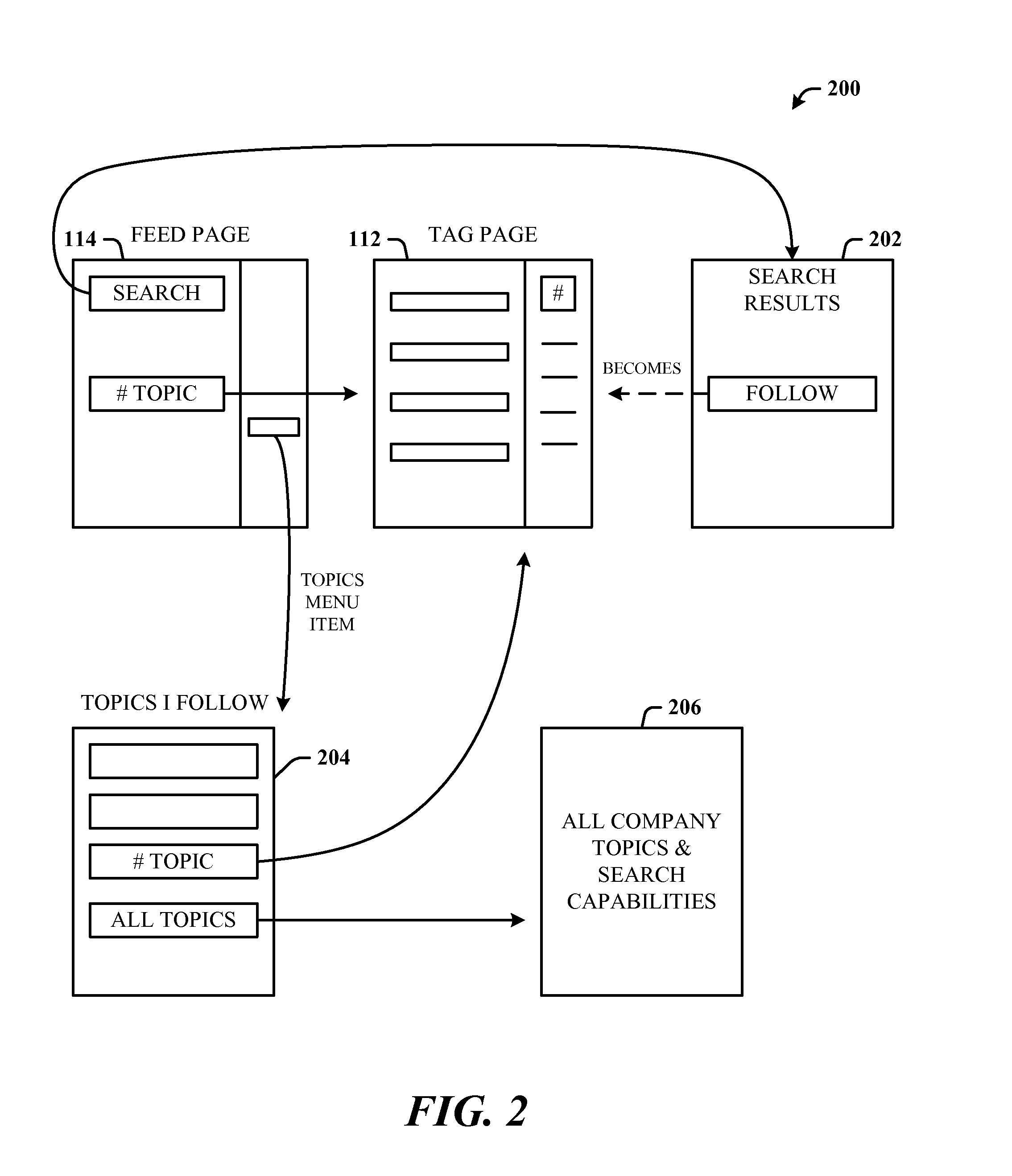

Hash tag management in a microblogging infrastructure

ActiveUS20120158863A1Enhanced tag managementEfficient discoveryDatabase updatingData processing applicationsMicrobloggingSpecific time

Architecture that provides enhanced tag telemetry in a microblogging communications infrastructure. The architecture provides efficient discovery and tracking of topics that are of interest to a specific user by enabling users to follow (track) hash tags (#tag) and to receive and view all messages tagged with the hash tag appear in the user's personal feed. Each hash tag has a persisted tag page that aggregates all the associated activity, and includes a list that includes, but is not limited to, the tag followers, the most frequent user (uses the tag the most often in a specific time frame), a description, related tags, for example. The user can receive all the updates in the user's personal feed, and see an aggregation of all the messages and conversations associated with the tag in single place. The user can also mute the tag to prevent the receiving of tag information.

Owner:MICROSOFT TECH LICENSING LLC

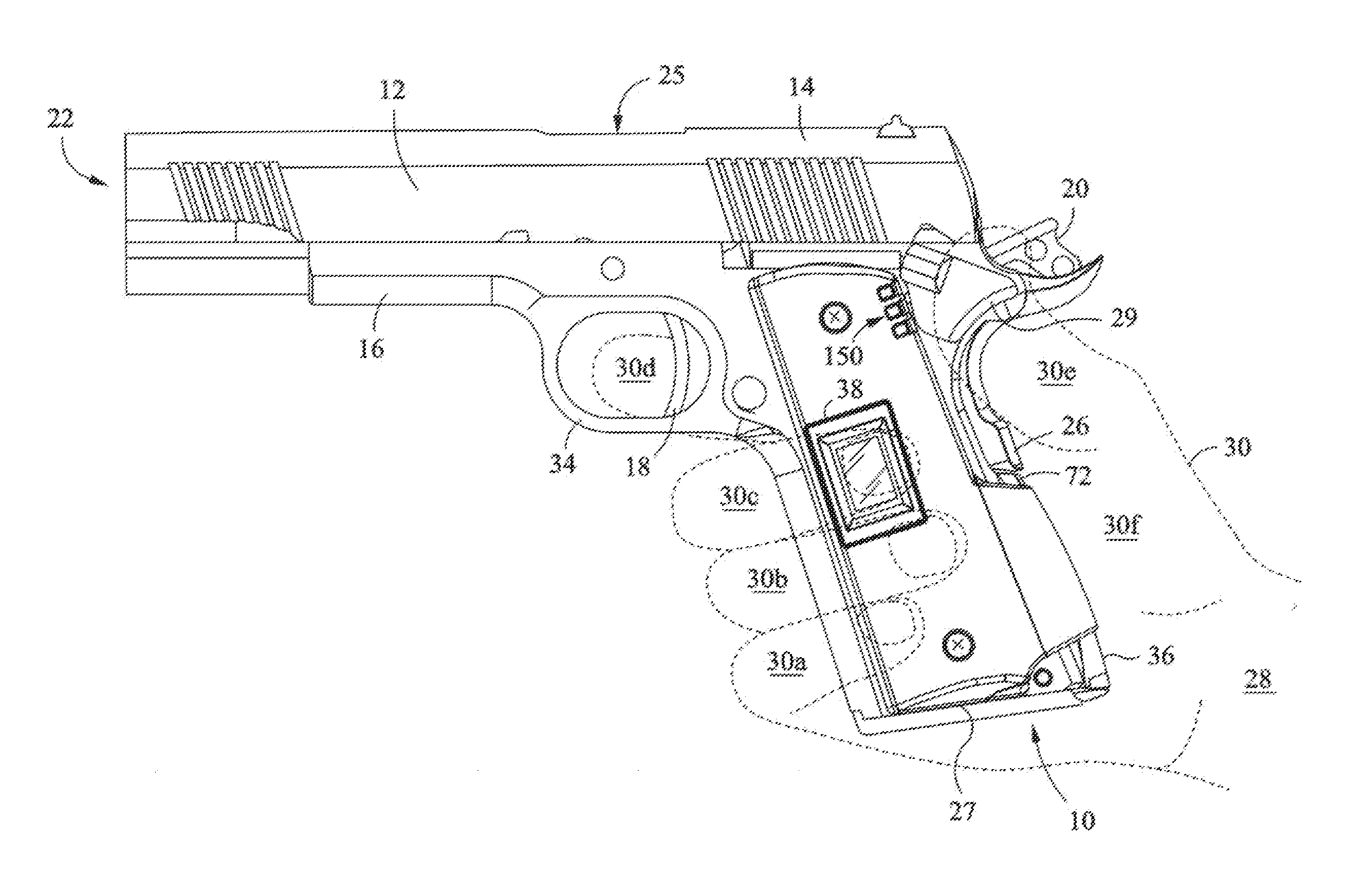

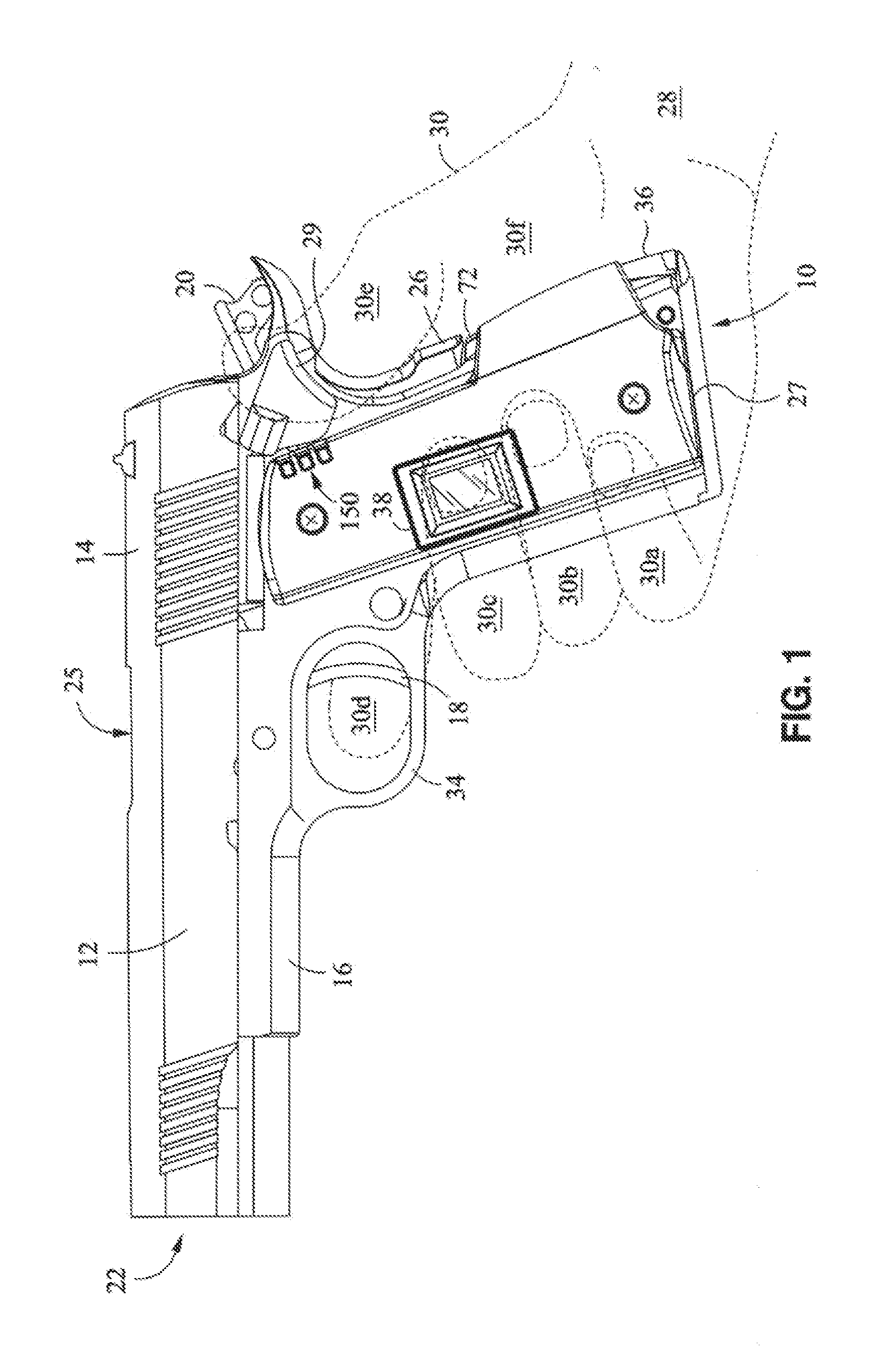

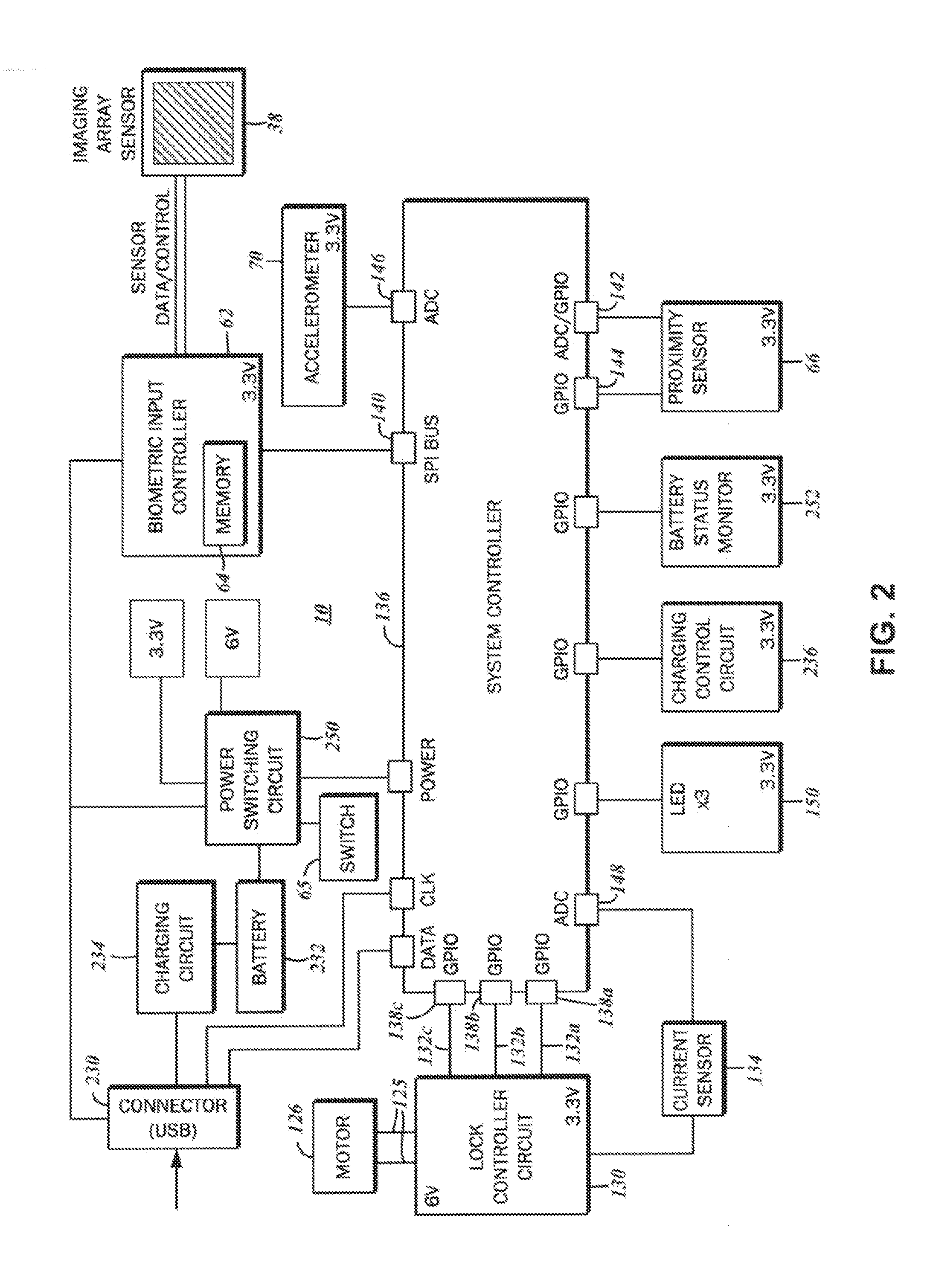

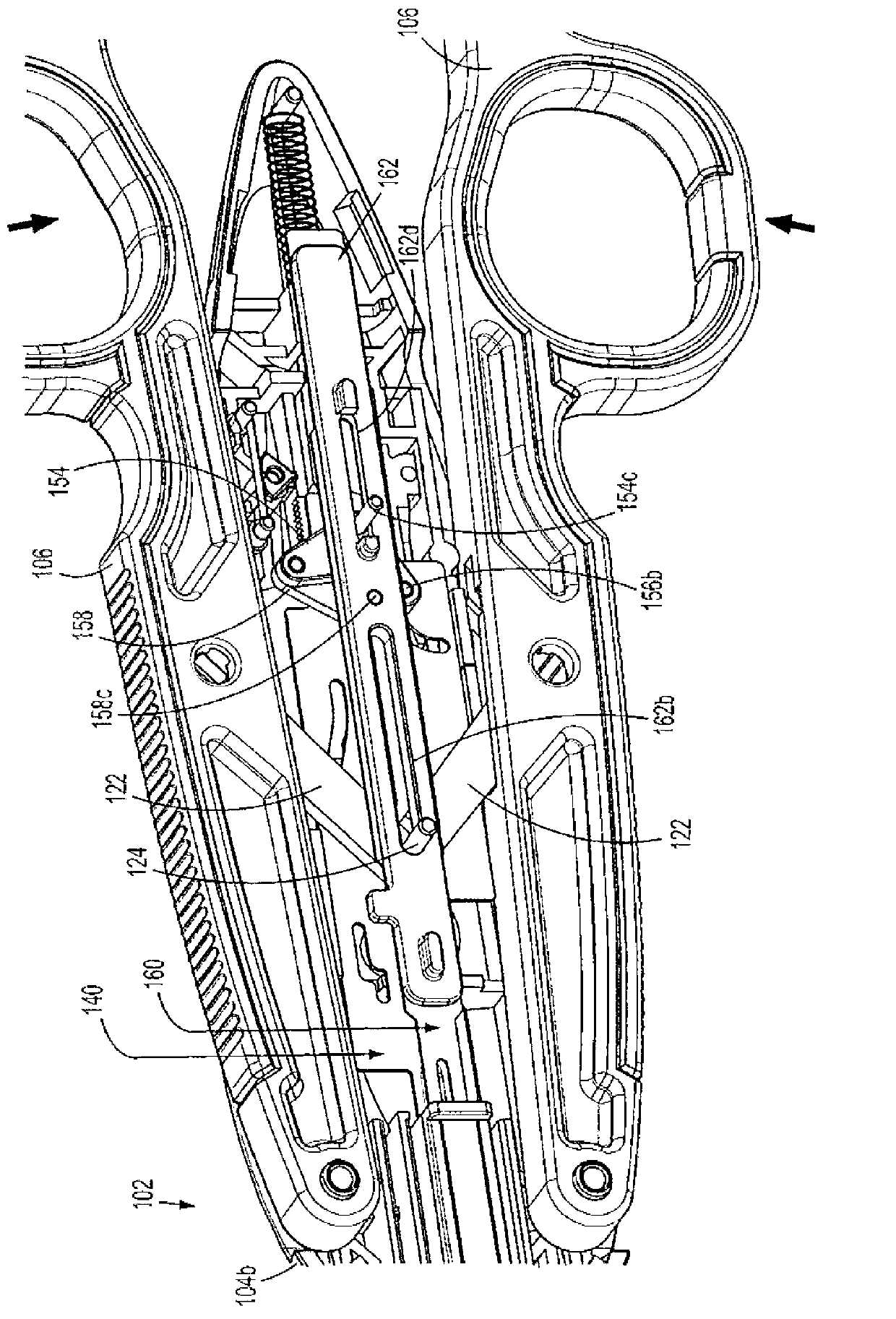

Firearm safety lock with key-based override

A lock for a firearm is disclosed. The firearm has a grip safety and a sear engageable to a biased hammer in a cocked position and releasable by a trigger. The lock includes a housing defining a bore within which a mainspring biasing the hammer is revived. A latch is rotatably mounted to the housing and has a grip safety arm and a cam follower, and has a first rotational excursion with the grip safety arm in engagement with and restricting the grip safety to block movement of the trigger, and an opposed second rotational excursion with the grip safety arm in disengagement from the grip safety to unblock depression of the grip safety and movement of the trigger. An actuator is mounted to the housing and cooperatively linked to the latch, and provides motive force for positioning the larch in the first rotational excursion and the second rotational excursion.

Owner:INTELLIGUN

Surgical clip applier

InactiveCN103181810AAct as a lockPrevent closed strokeDiagnosticsSurgical forcepsReciprocating motionEngineering

A surgical clip applier is provided including a walking beam reciprocally disposed within a channel assembly and overlying a clip carrier, the walking beam being operatively connected to at least one handle for reciprocal movement upon actuation of the at least one handle, the walking beam including a plurality of distally oriented ramps extending into the clip channel; and a clip follower slidably disposed within the channel of the clip carrier and disposed proximally of the plurality of clips, the clip follower being configured and adapted for selective engagement with the distally oriented ramps of the clip carrier and the distally oriented ramps of the walking beam, wherein the clip follower is configured and adapted to urge the plurality of clips, in a distal direction relative to the clip carrier, upon reciprocal movement of the walking beam.

Owner:TYCO HEALTHCARE GRP LP

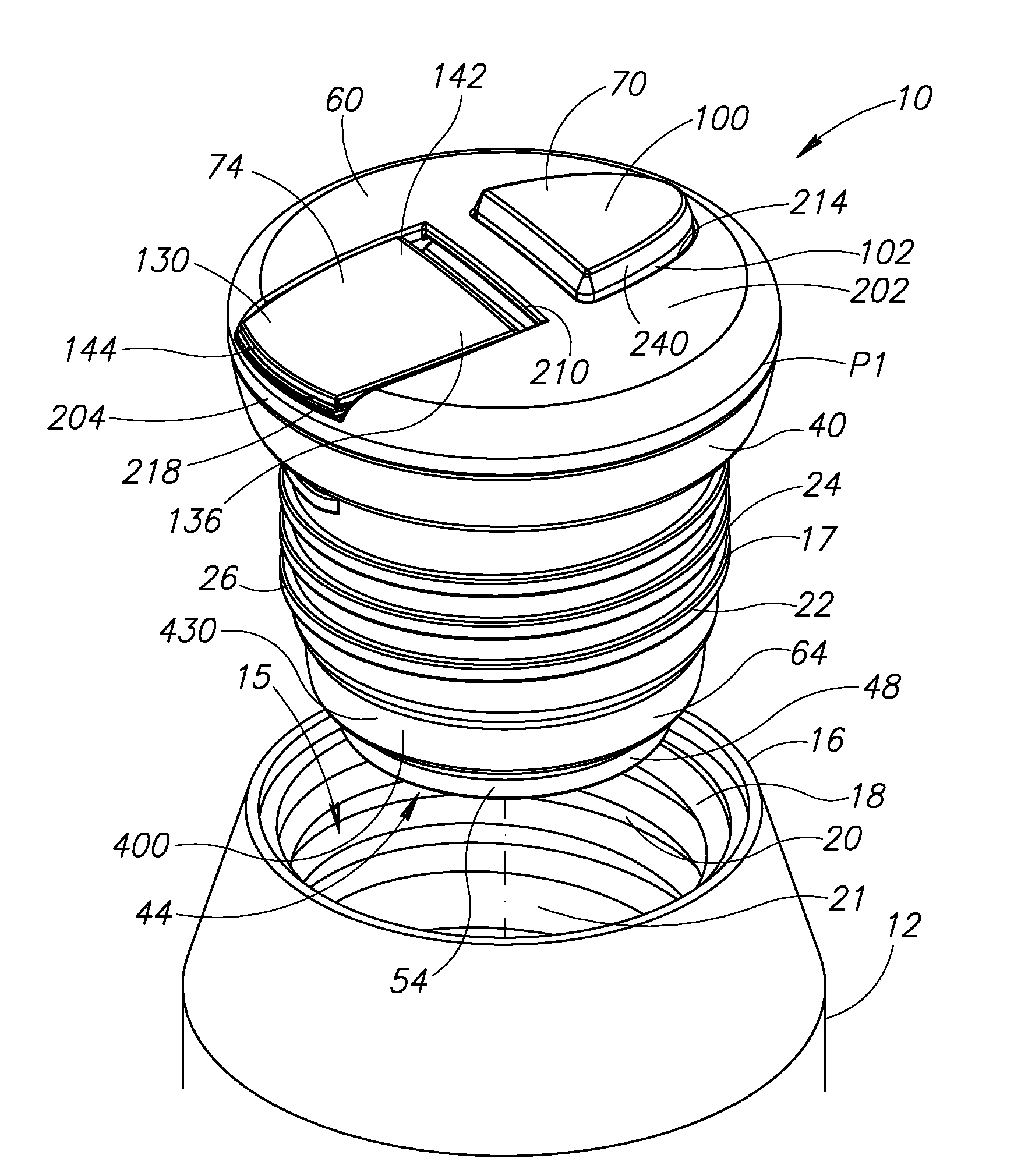

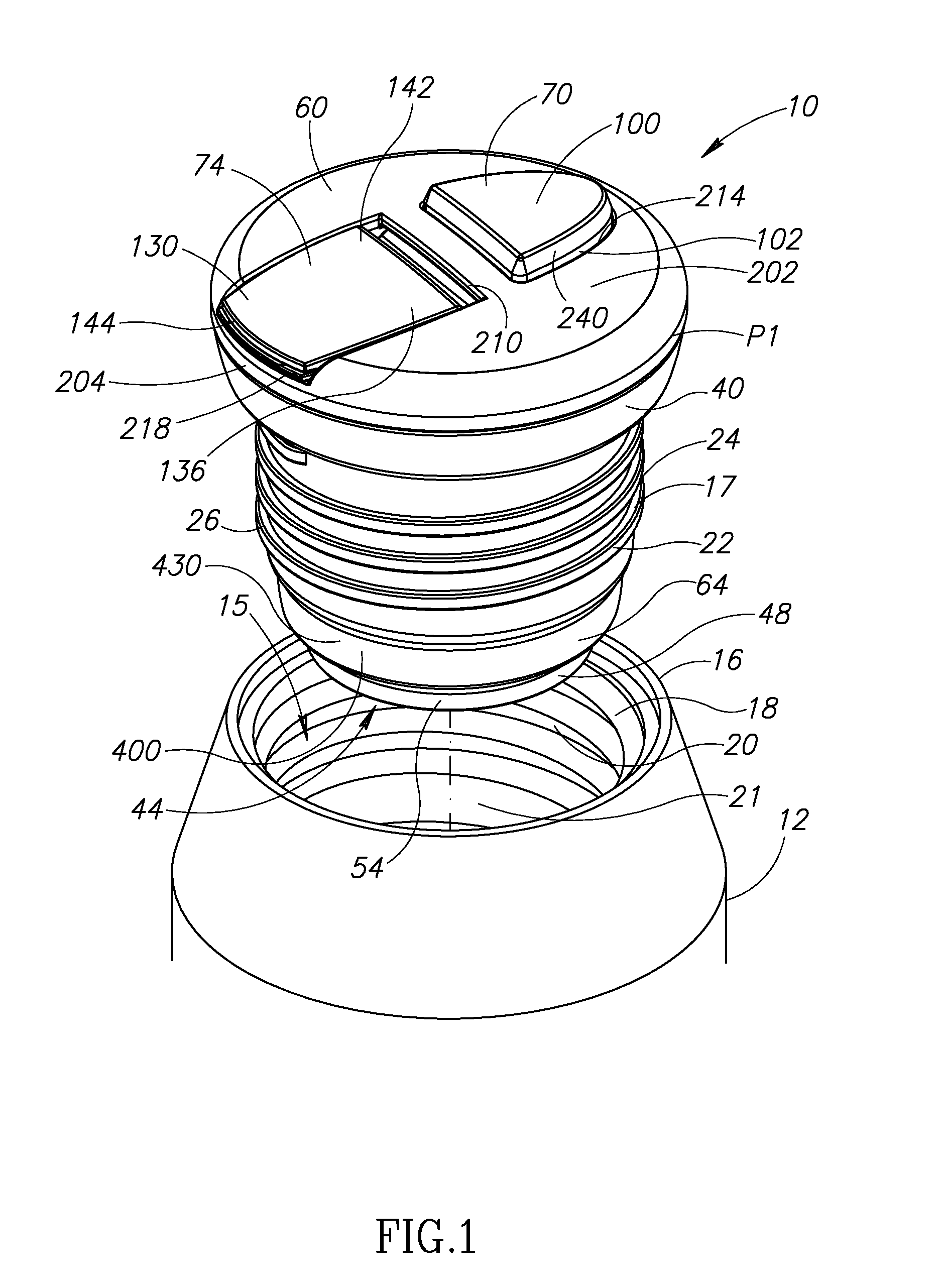

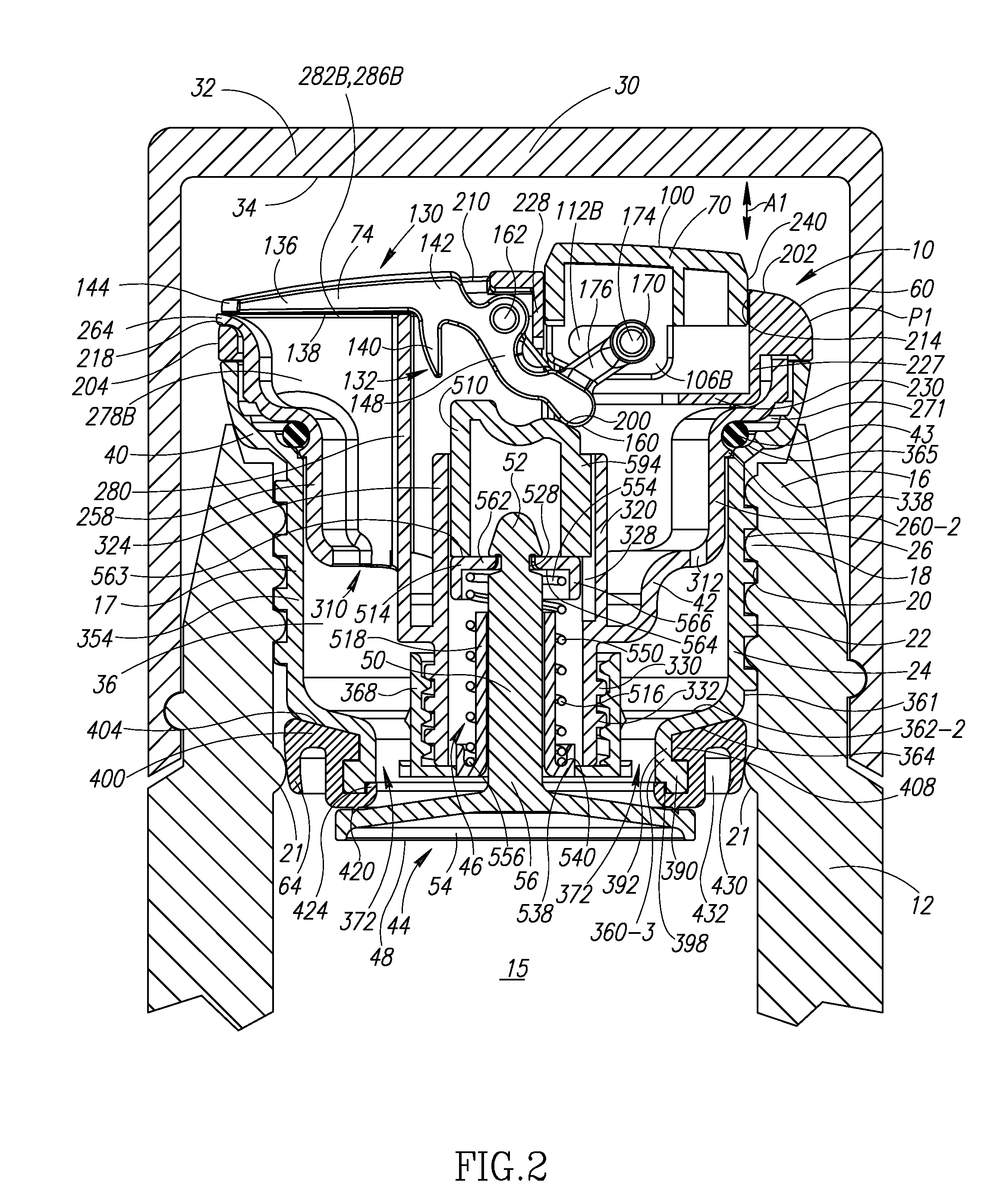

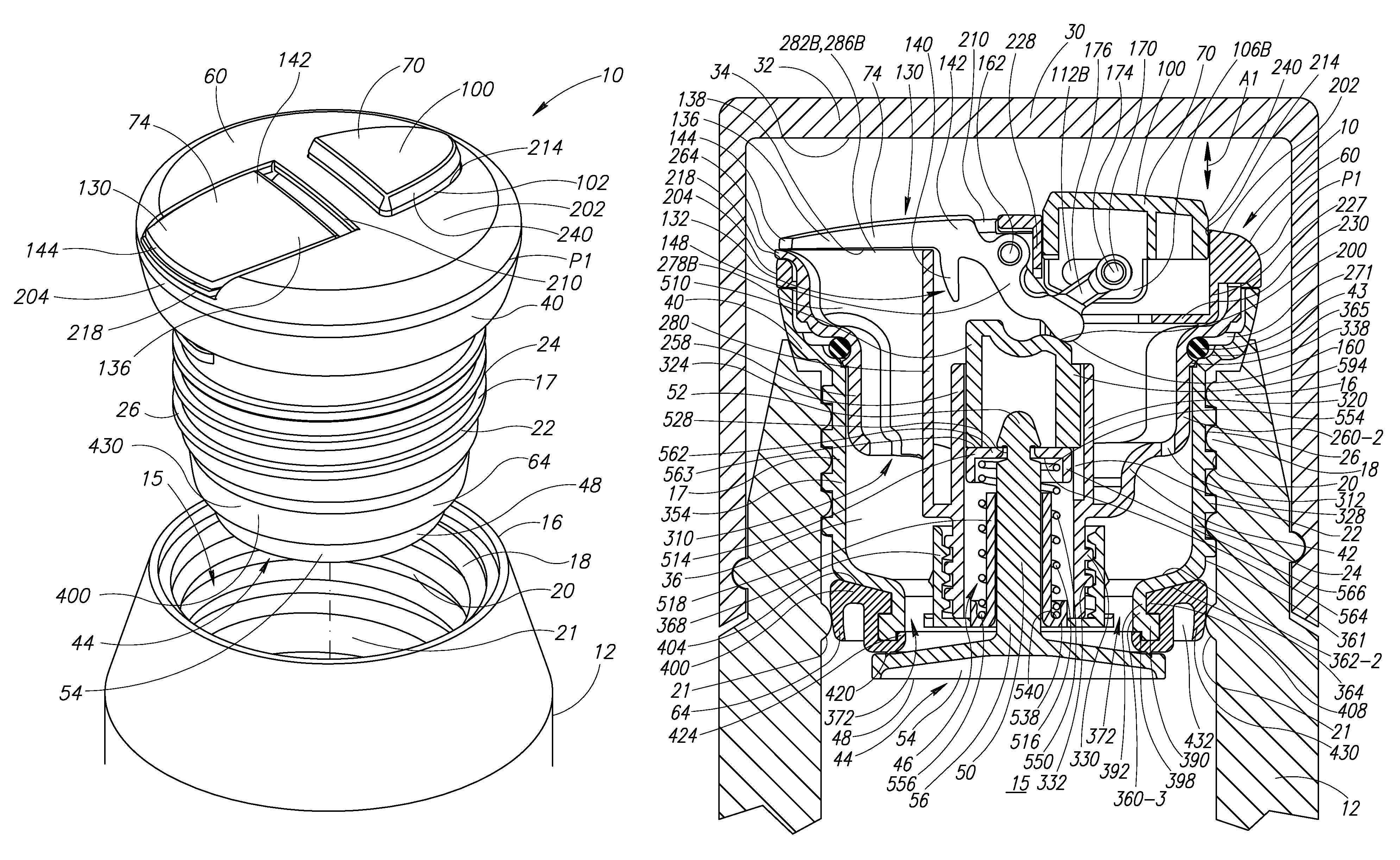

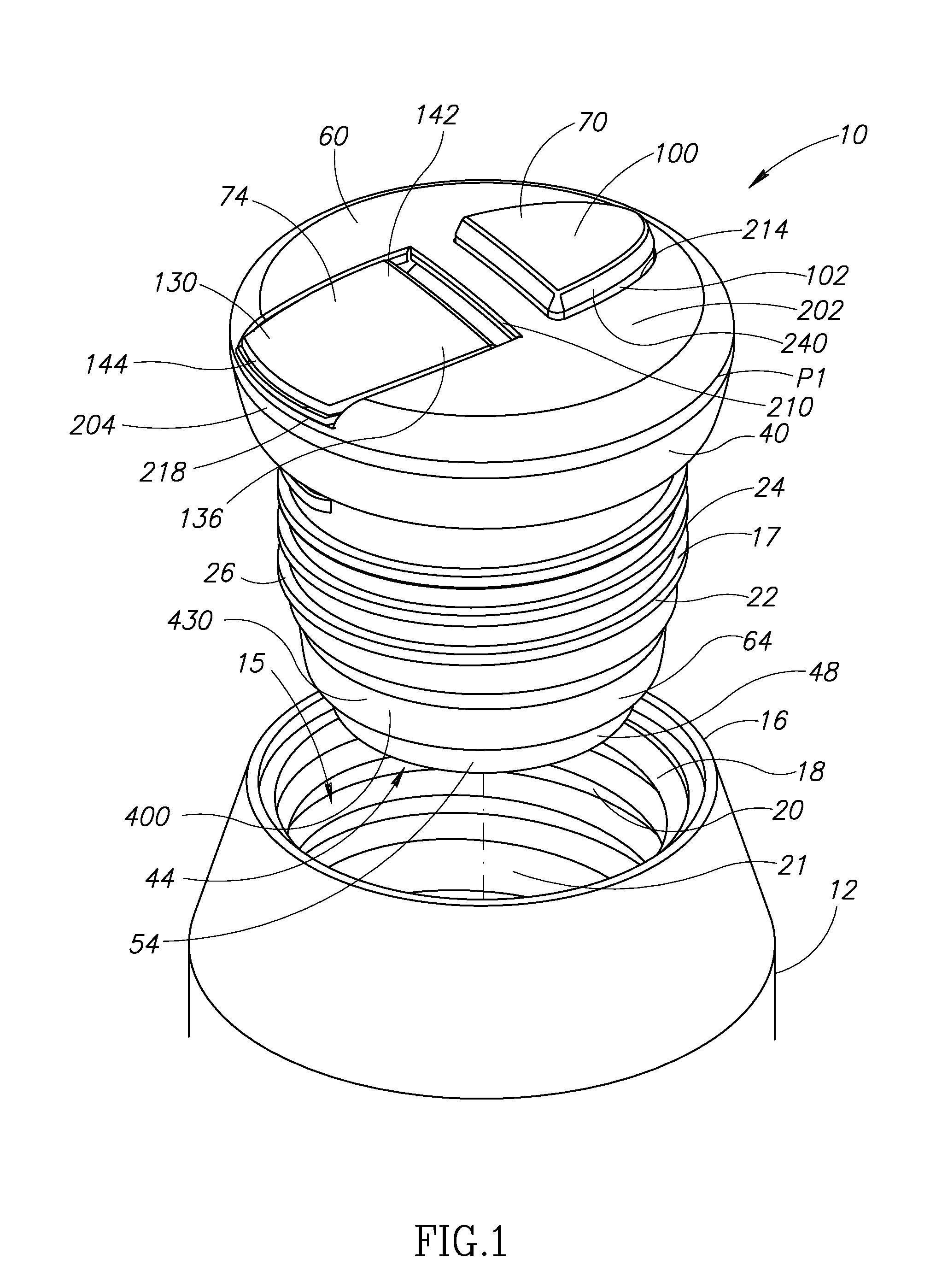

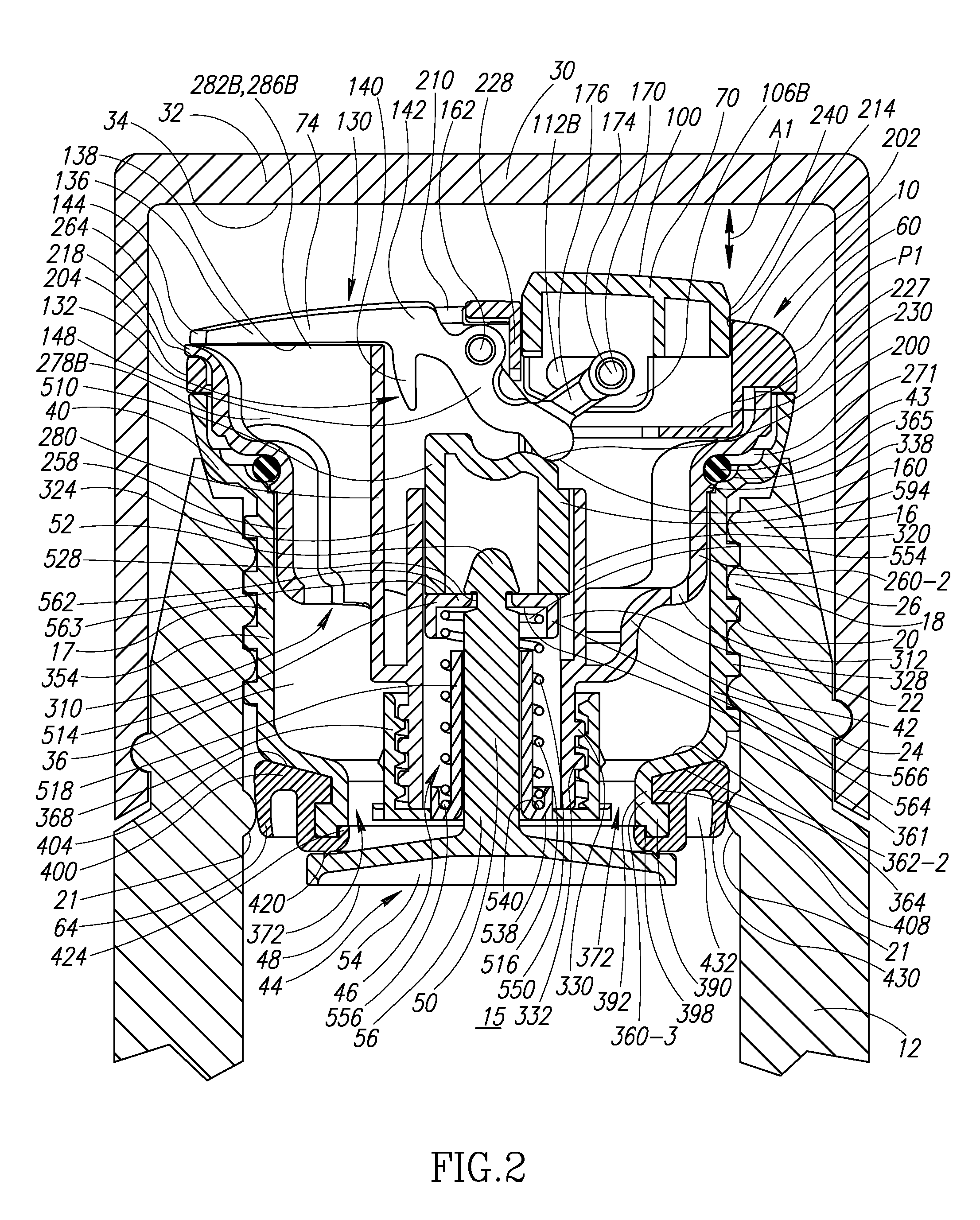

Bottle stopper

A stopper for an opening of a container such as a thermos. The stopper includes a pushbutton, a fluid flow channel extending between an inlet and an outlet, and a movable plug portion positioned adjacent the inlet. A biasing member biases the plug portion into sealing engagement with the inlet thereby preventing the contents of the container from flowing into the channel. A cam follower is disposed upon a cam surface opposing the biasing member. The cam follower is rotatable by the pushbutton relative to the cam surface from a closed position to an open position and when so rotated, exerts a biasing force on the cam surface sufficient to overcome the biasing force exerted by the biasing member on the plug portion and space the plug portion from the inlet allowing the contents of the container to flow into the channel and out the outlet.

Owner:PACIFIC MARKET INT

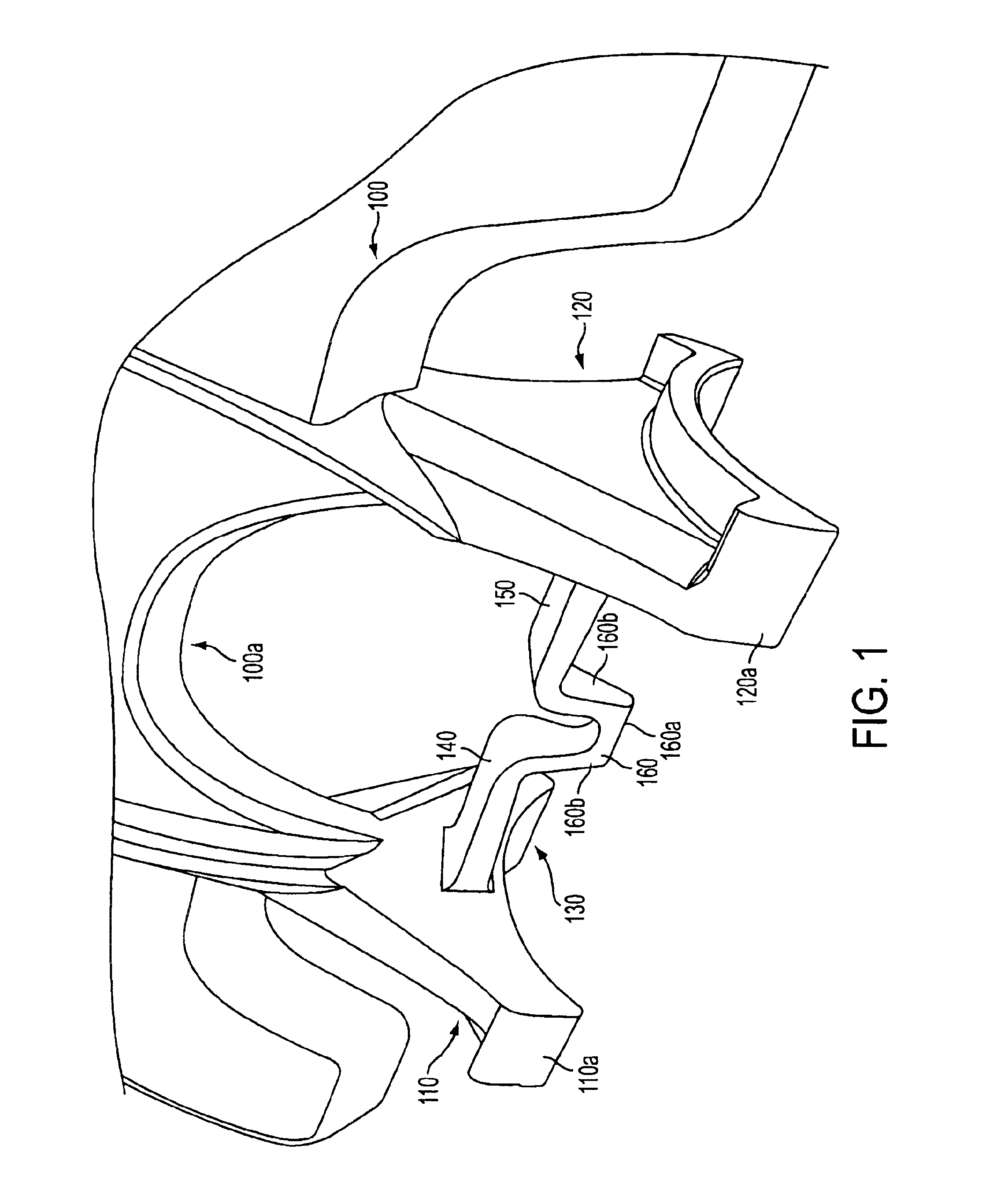

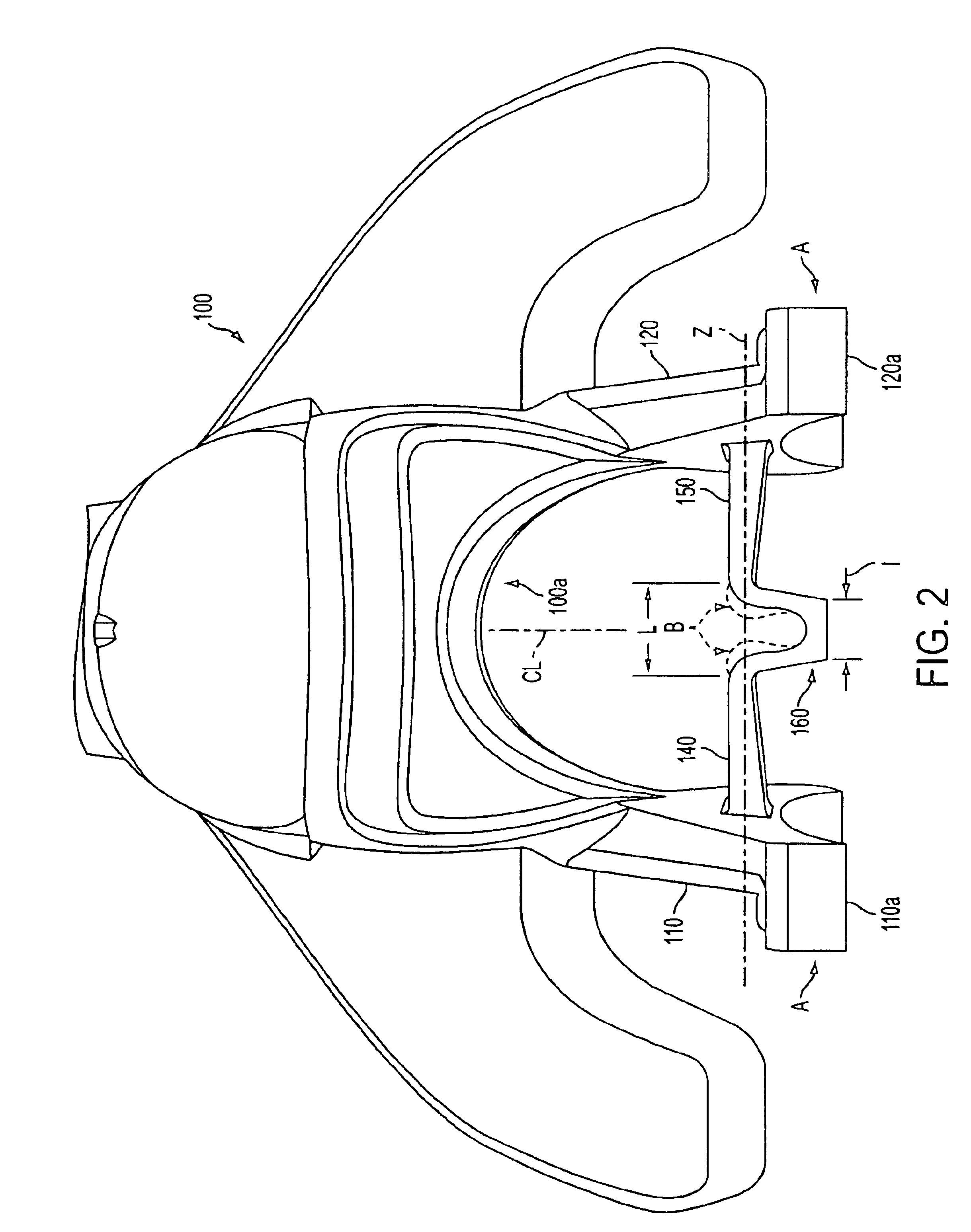

Tool assembly for surgical stapling device

ActiveUS20060100644A1Easy to holdConducive to manipulationSuture equipmentsStapling toolsEngineeringActuator

A tool assembly having a pair of jaws is disclosed. Each of the jaws has a proximal end and a distal end and the first jaw is movable in relation to the second jaw between a spaced position and an approximated position. First and second cam followers are supported on the first jaw. An approximation member is movable in relation to the first jaw and includes at least one cam surface positioned to engage the first and second cam followers. The approximation member is movable in relation to the first jaw to move the at least one cam surface in relation to the first and second cam followers to effect movement of the first and second jaws from the spaced position to the approximated position. The at least one cam channel is configured to approximate the distal ends of the first and second jaws prior to approximation of the proximal ends of the first and second jaws. In another preferred embodiment, the tool assembly includes an articulation and firing actuator. The articulation and firing actuator includes a flexible band having a first end portion extending at least partially through the body portion and through the cartridge assembly, a central portion extending from the first end portion operably associated with the dynamic clamping member and a second end portion extending from the central portion through the cartridge assembly and at least partially through the body portion to a position adjacent the first end. The articulation and firing actuator is operably associated with the tool assembly such that movement of either the first end portion or the second end portion of the flexible band proximally and independently of the other end portion effects pivoting of the tool assembly in relation to the body portion, and movement of both the first and second end portions of the flexible band simultaneously effects movement of the dynamic clamping member to eject the staples from the cartridge assembly.

Owner:TYCO HEALTHCARE GRP LP

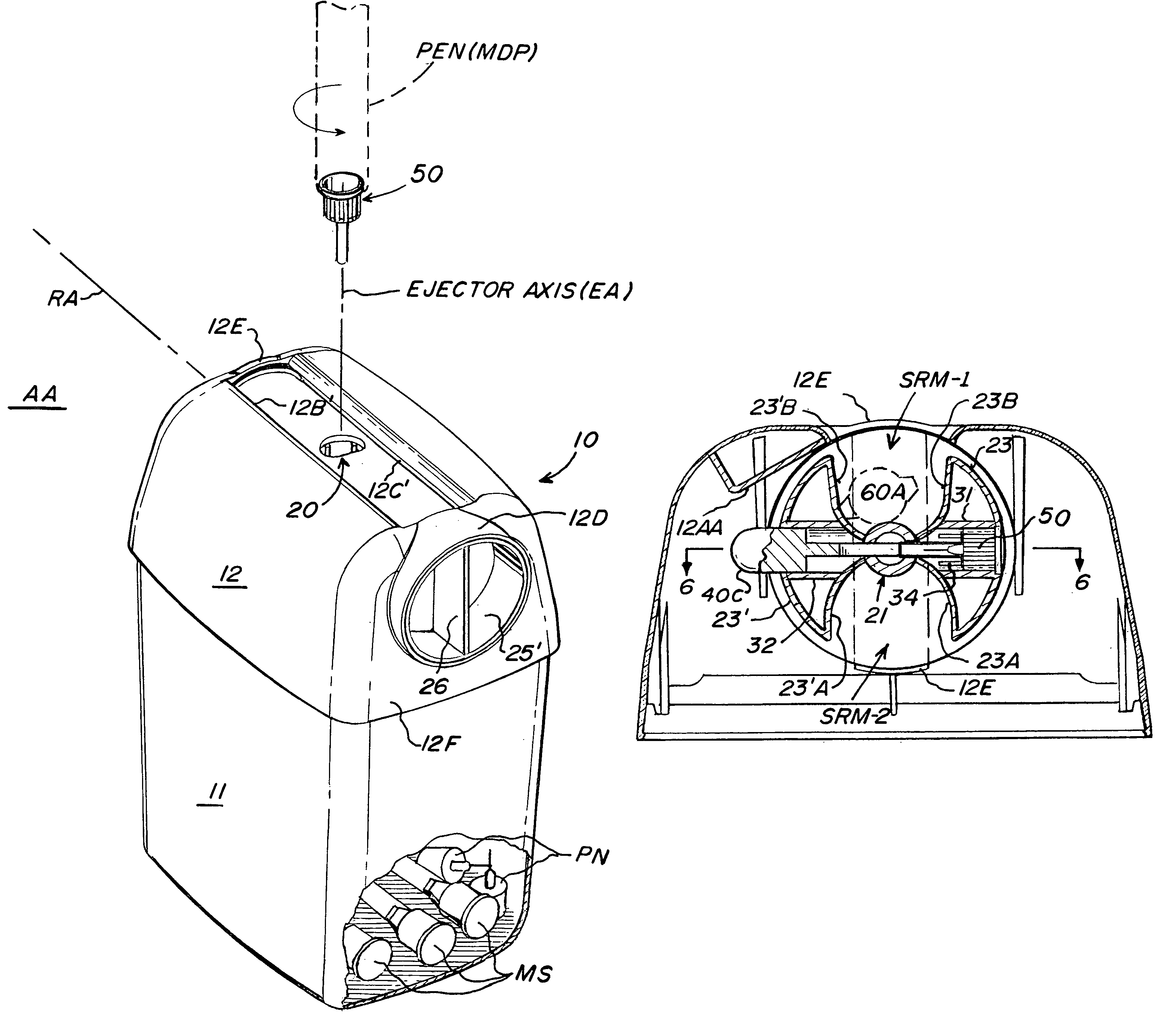

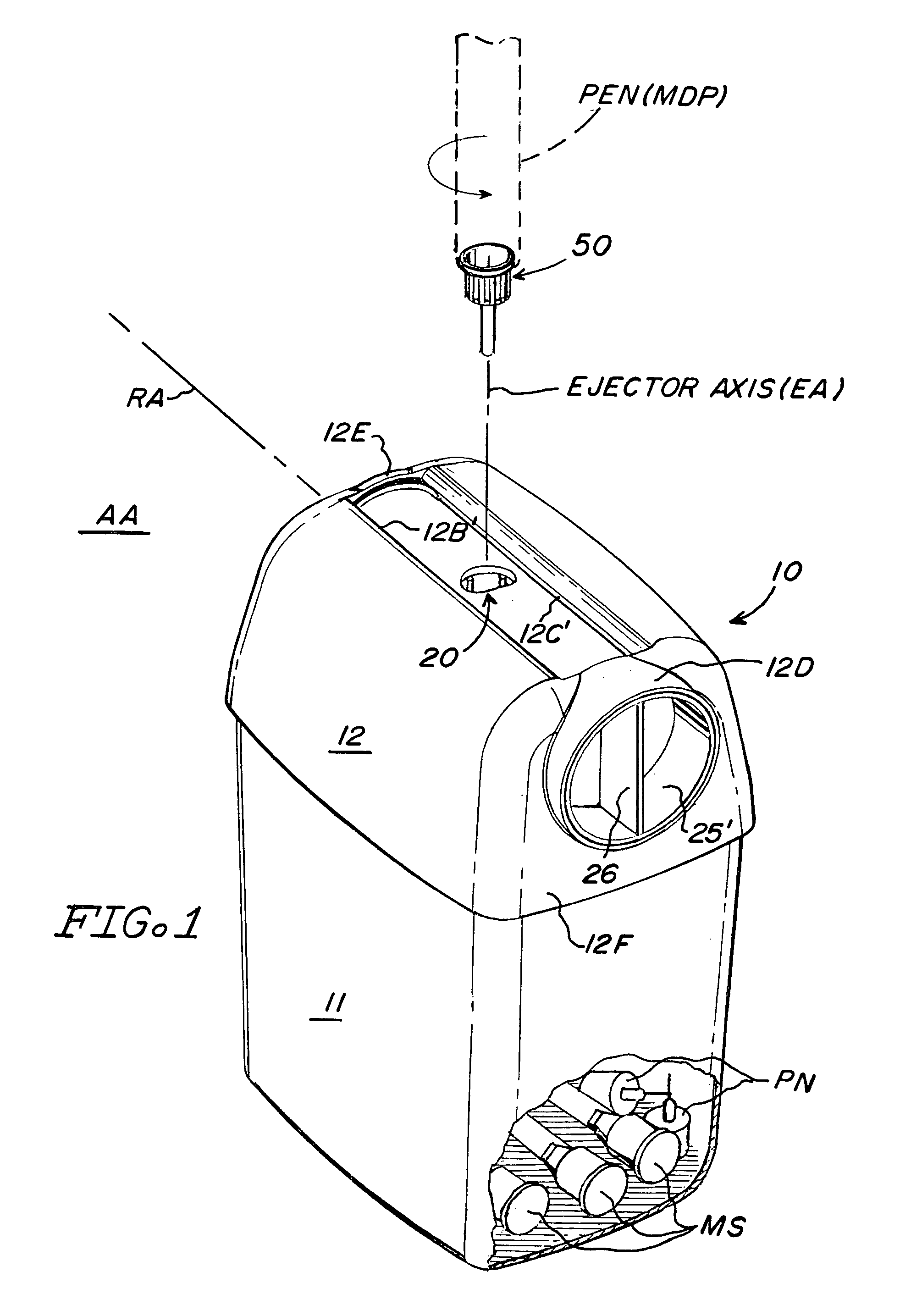

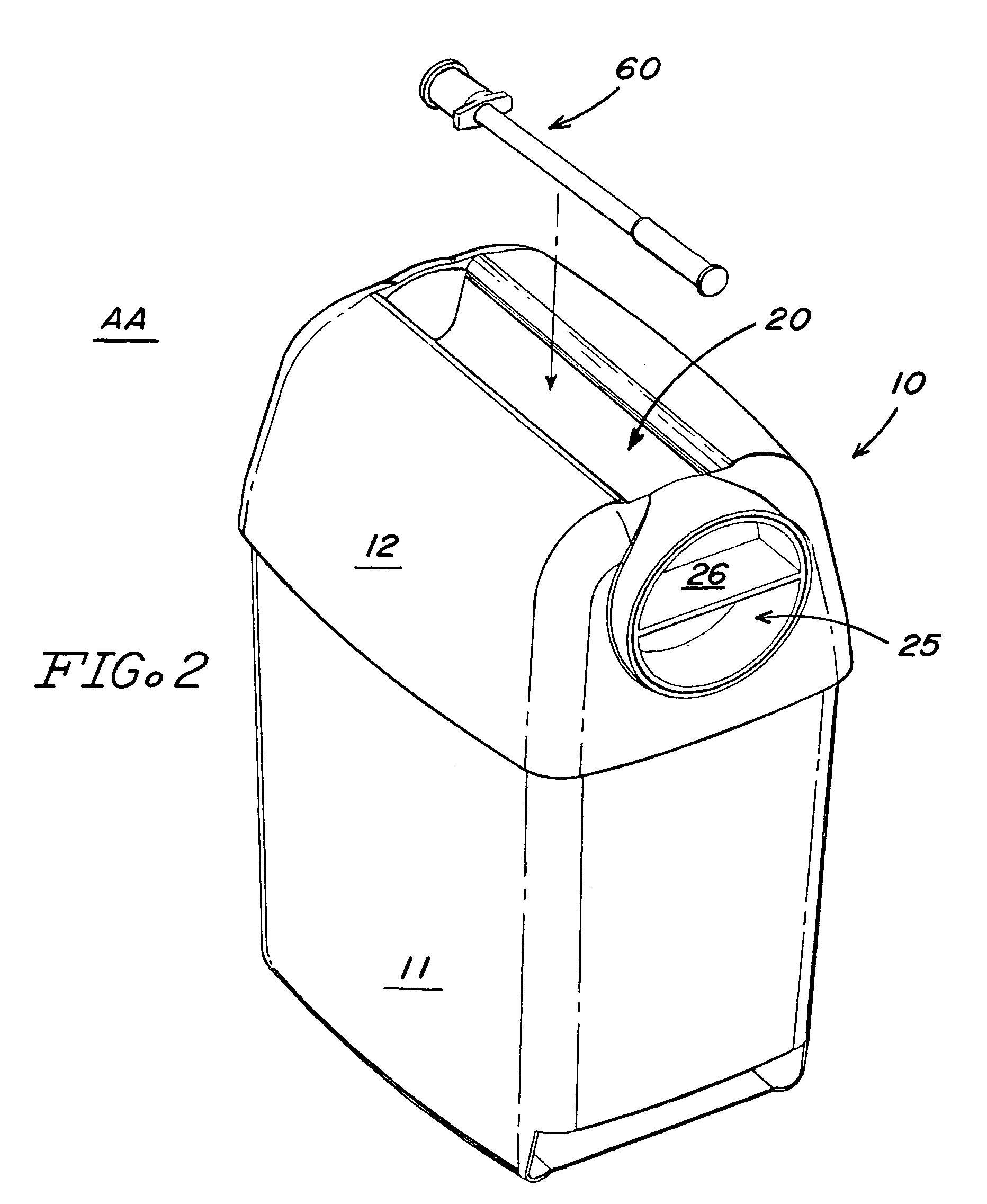

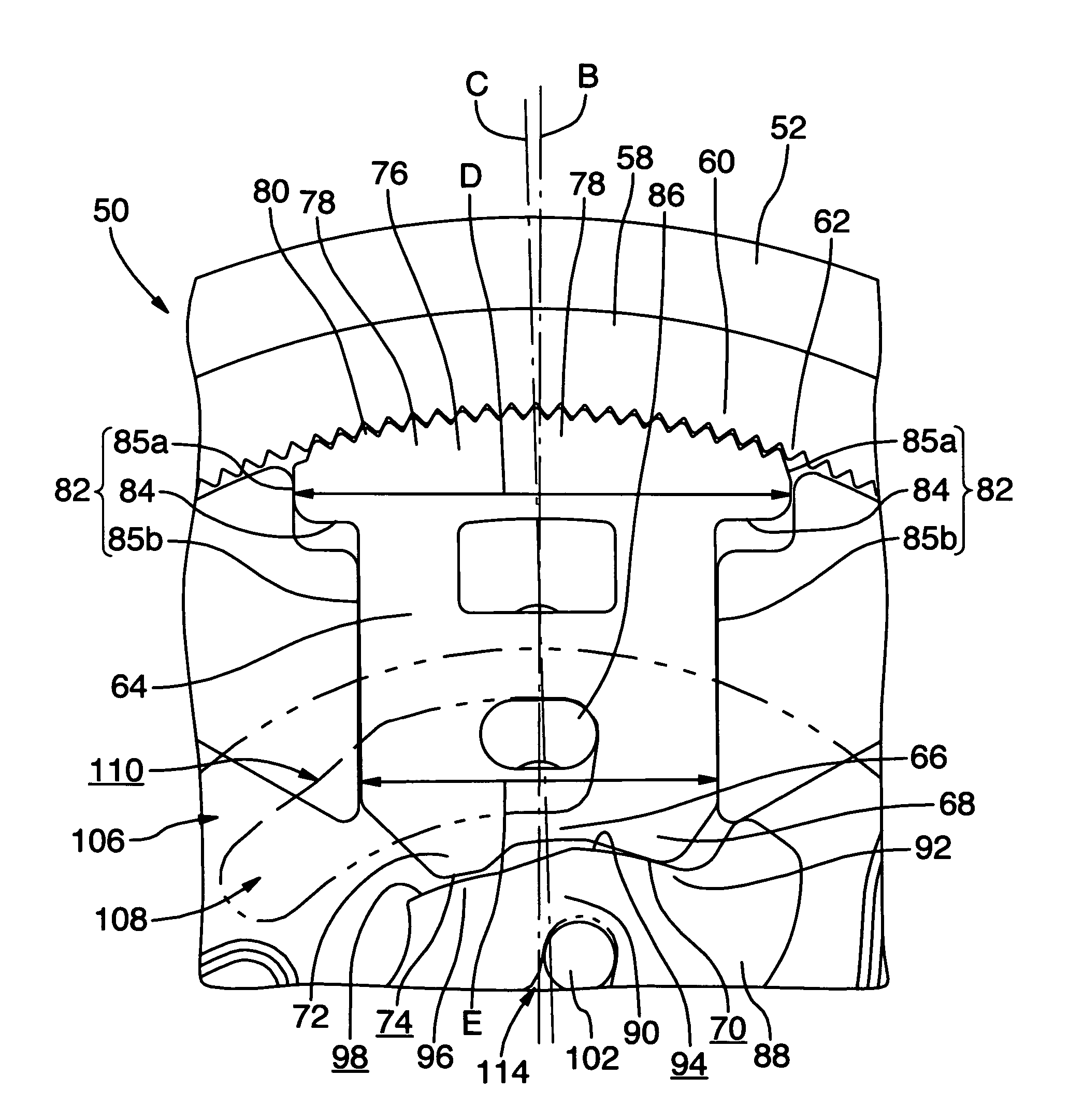

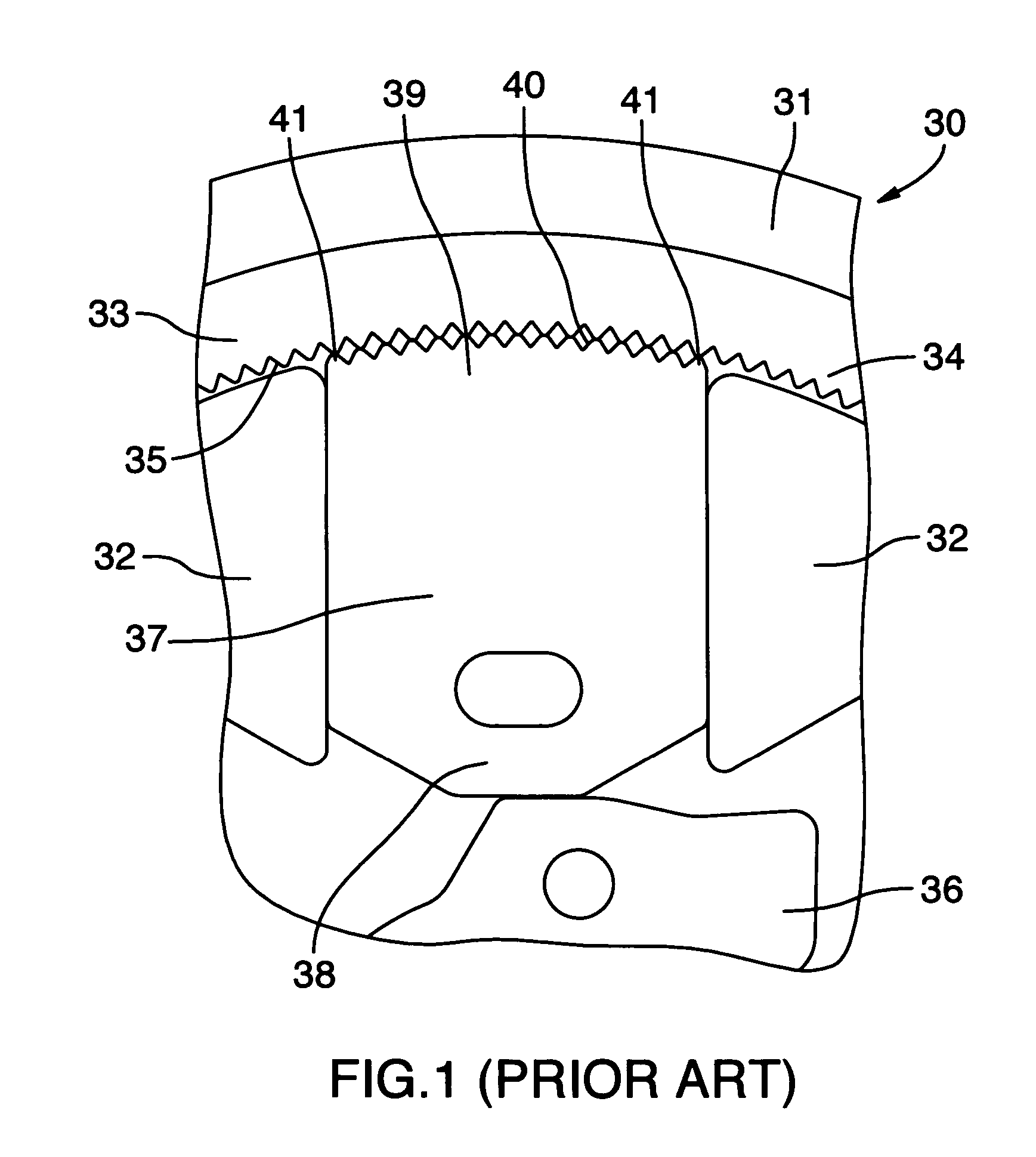

Sharps container for safe storage of used pen needles and used medical syringes

A sharps container for safe reception and storage of used pen needles and used medical syringes comprises a housing which supports a manually rotatable member. A used pen needle receiving and ejecting apparatus is connected to the rotatable member. Used pen needles are inserted into the receiving apparatus. As the receiving and ejecting apparatus is rotated, a cam follower connected to the ejecting apparatus engages a cam within the housing to cause the ejection of the used pen needle from the receiving apparatus into the housing. The rotatable member also has an elongated recess sized to receive a medical syringe. Manual rotation of the rotatable member rotates the elongated recess to drop the medical syringe into the housing.

Owner:ULTIMED INC

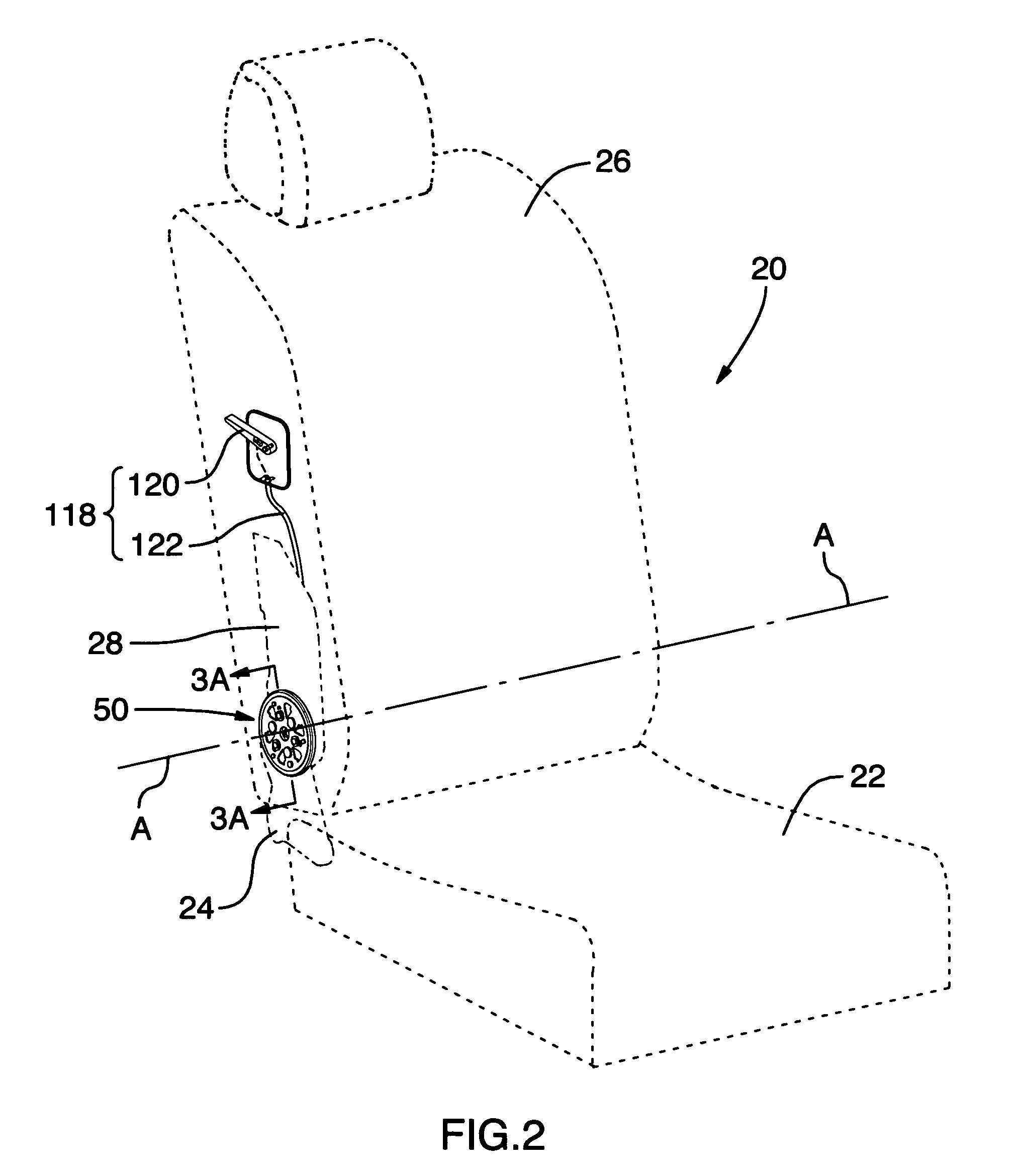

Rotary recliner mechanism for use with a vehicle seat assembly

A rotary recliner includes rotatable plate members that pivotally interconnect a vehicle seat back and cushion. A pawl defines a pawl axis and slides between a guide pair on one plate member. An outer end of the pawl includes a gear segment that is lockable with a ring gear on the other plate member. A cam rotates between locked and unlocked positions, and has a camming surface eccentric of the pivot axis. When locked, the camming surface engages a cam-follower surface on the pawl, with the pawl being engaged by the cam solely at the cam-follower surface, and with the pawl axis being askew of a radial axis, such that the gear segment locks with the ring gear, and such that the plate members are restrained from rotating. When unlocked, the gear segment is removed from the ring gear, such that the plate members may be rotated.

Owner:FAURECIA AUTOMOTIVE SEATING CANADA

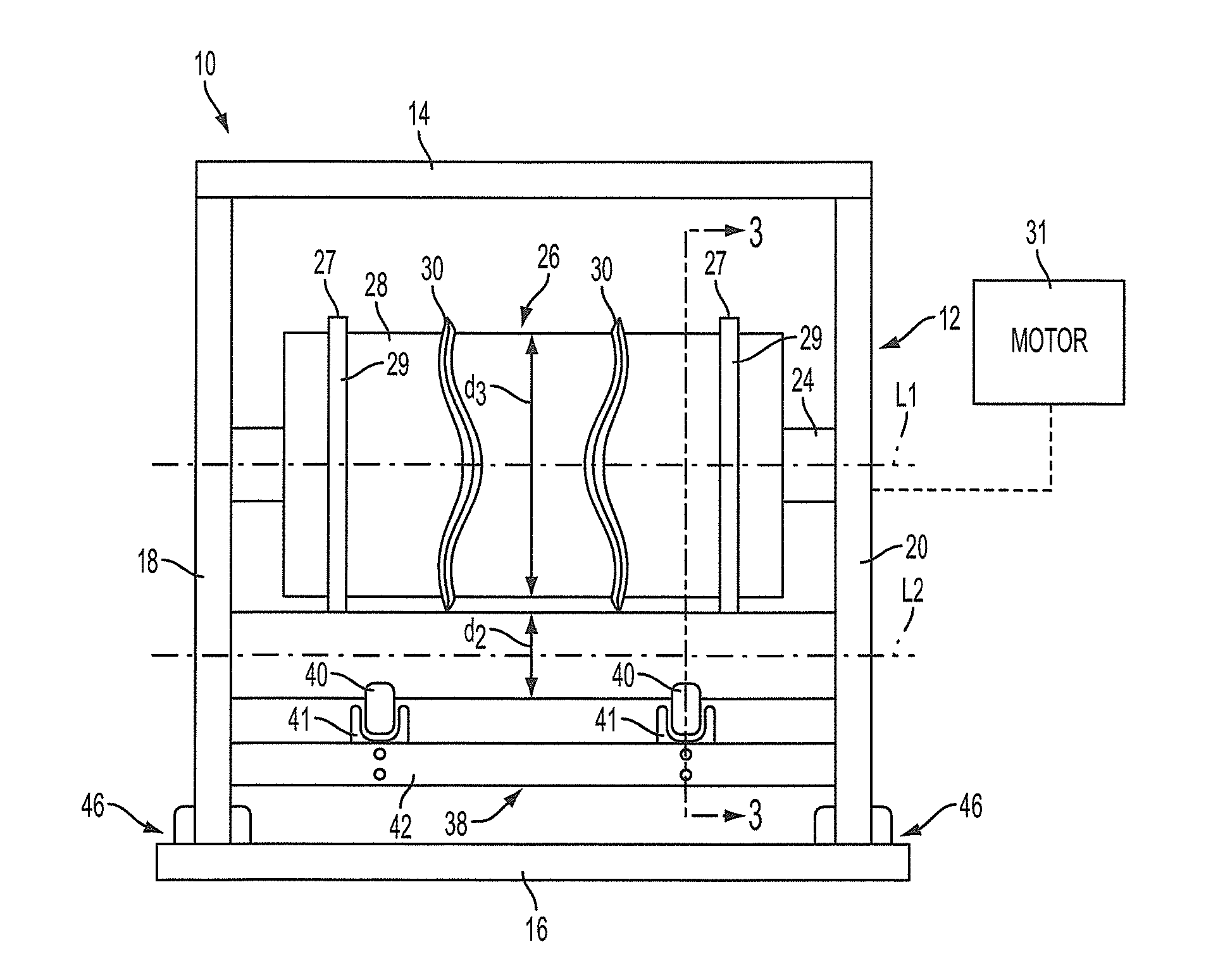

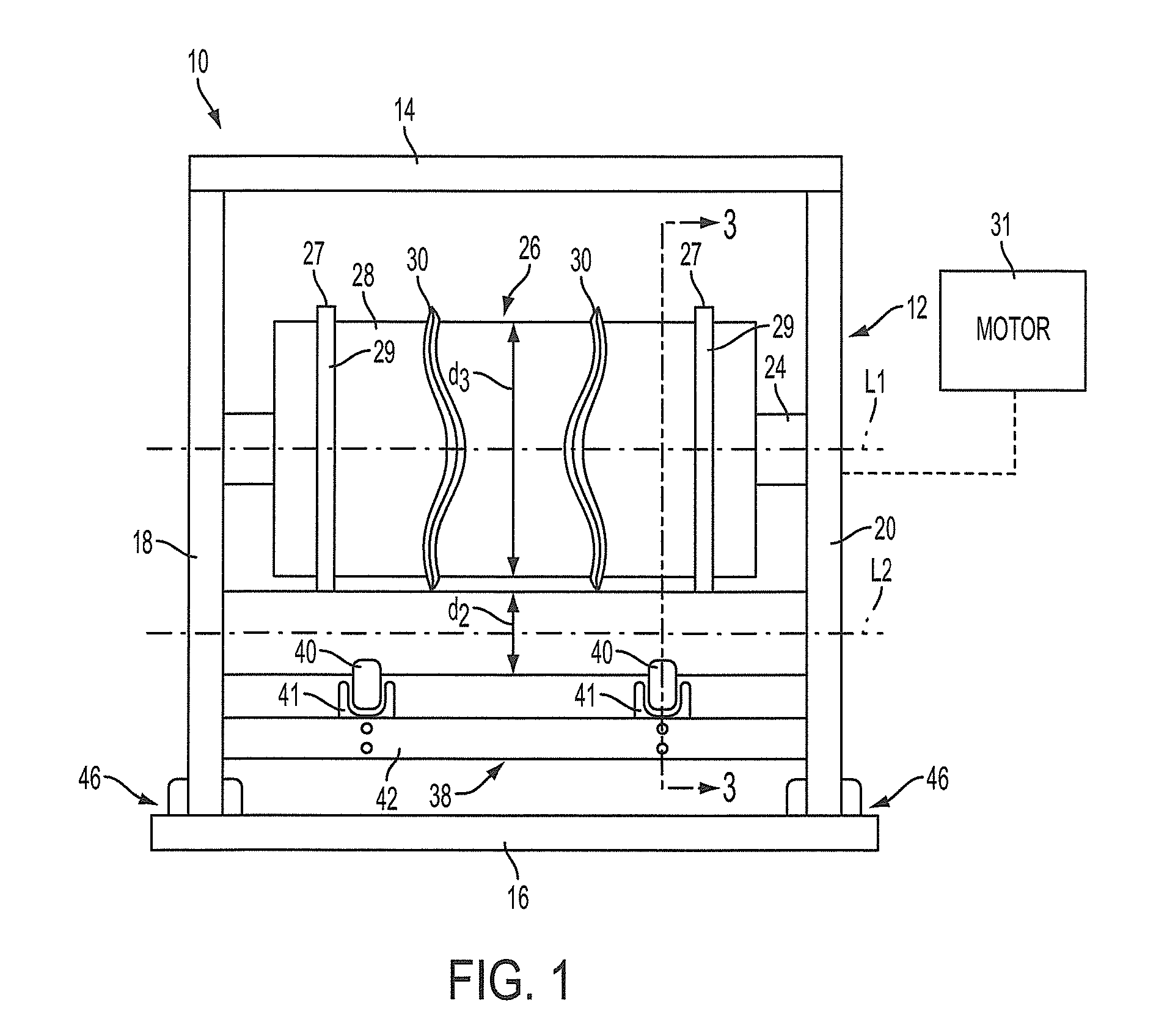

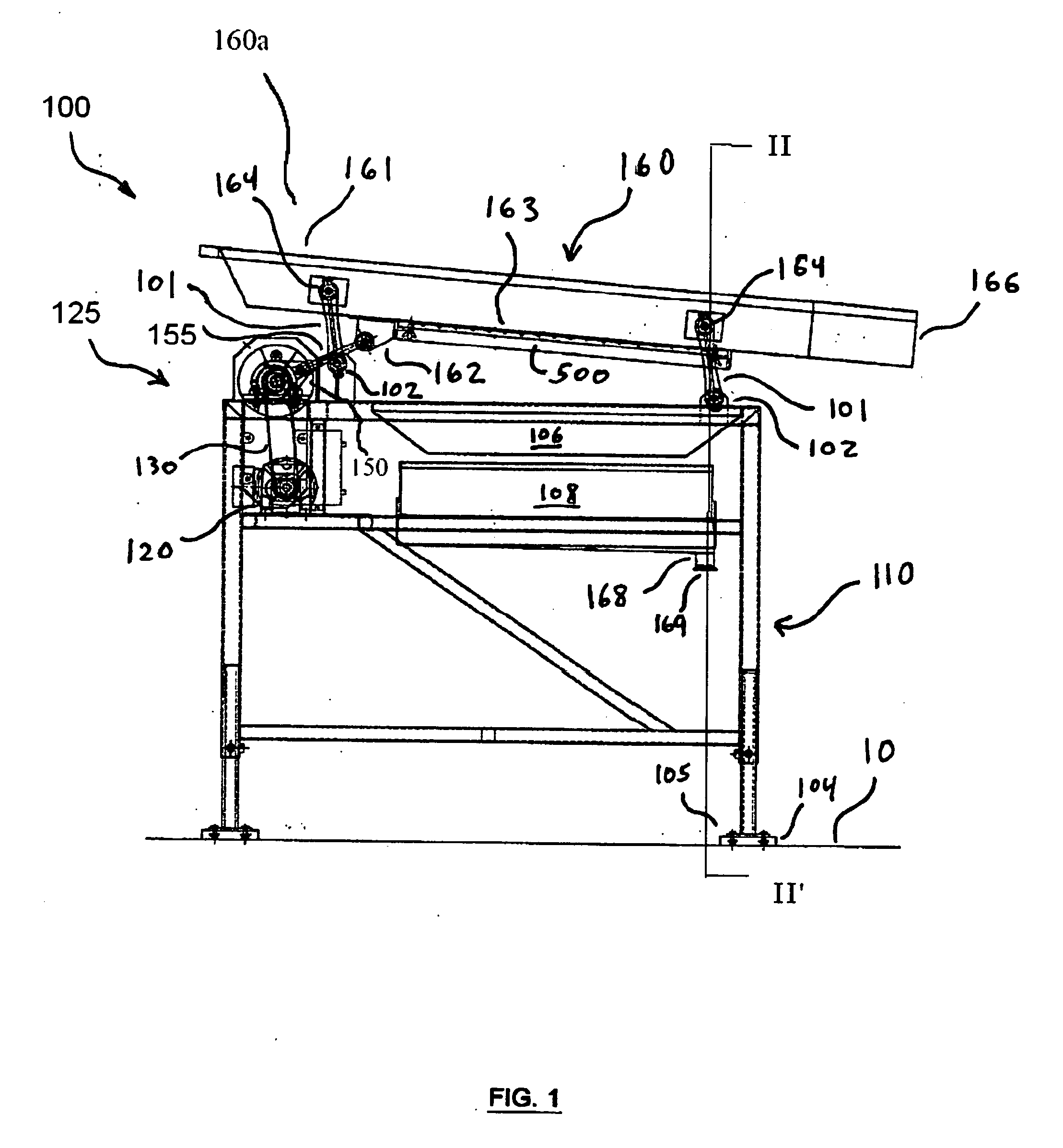

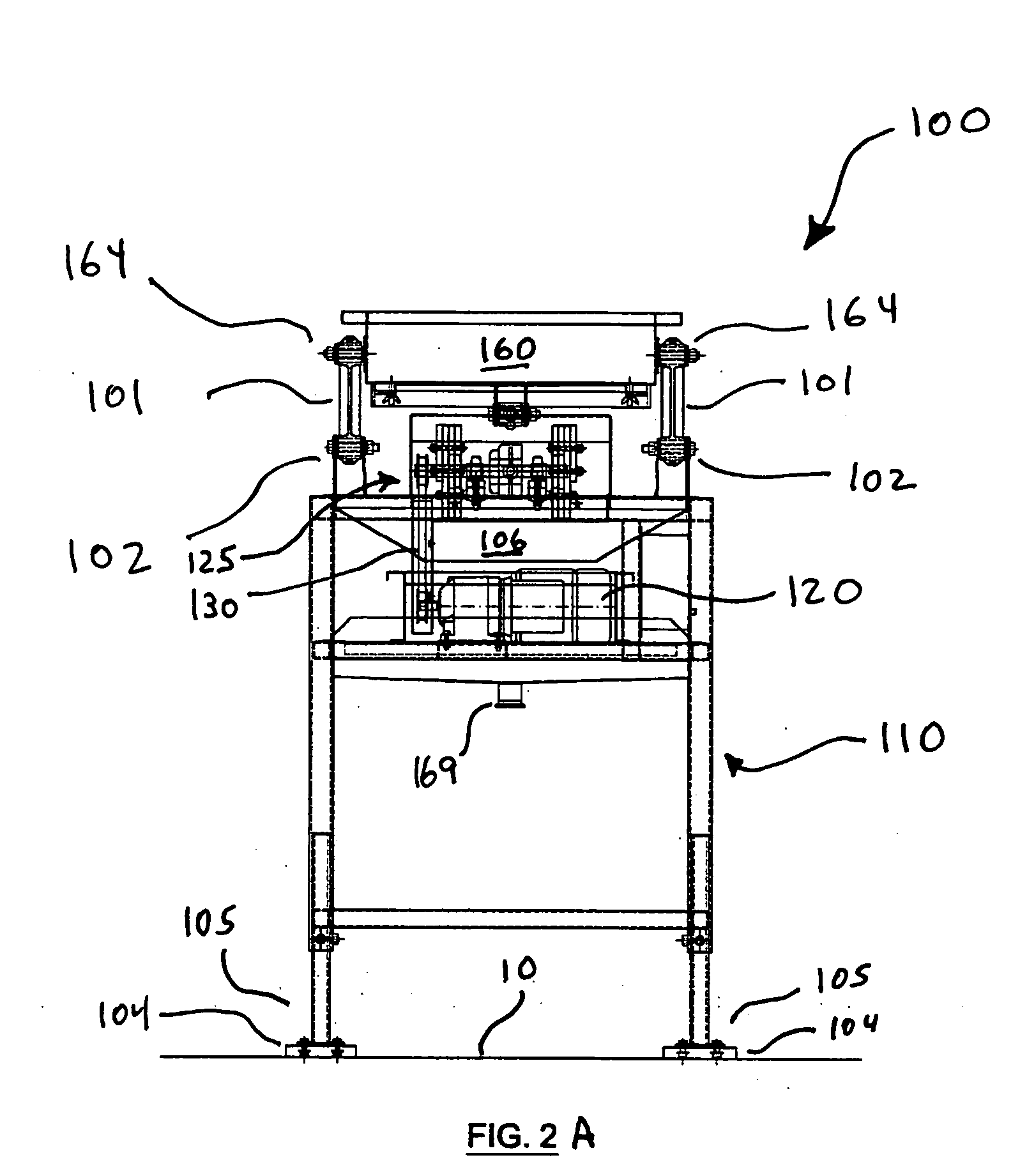

Anvil Roll System and Method

A rotary cutting apparatus comprising a frame and a die roll defining a first longitudinal axis and comprising a cutting member. The die roll is rotatably connected with the frame and configured to rotate about the first longitudinal axis. The rotary cutting apparatus further comprises a bearer ring connected with the die roll and an anvil roll defining a second longitudinal axis and comprising an outer radial surface. The anvil roll is rotatably connected with the frame and is configured to rotate about the second longitudinal axis. The bearer ring of the die roll is in contact with the outer radial surface. The anvil roll may be supported by at least one cam follower. The anvil roll may be axially removable from the frame via lateral translation along the second longitudinal axis.

Owner:THE PROCTER & GAMBLE COMPANY

Bottle stopper having pushbutton and movable plug

A stopper for an opening of a container such as a thermos. The stopper includes a pushbutton, a fluid flow channel extending between an inlet and an outlet, and a movable plug portion positioned adjacent the inlet. A biasing member biases the plug portion into sealing engagement with the inlet thereby preventing the contents of the container from flowing into the channel. A cam follower is disposed upon a cam surface opposing the biasing member. The cam follower is rotatable by the pushbutton relative to the cam surface from a closed position to an open position and when so rotated, exerts a biasing force on the cam surface sufficient to overcome the biasing force exerted by the biasing member on the plug portion and space the plug portion from the inlet allowing the contents of the container to flow into the channel and out the outlet.

Owner:PACIFIC MARKET INT

Printhead Carrier For An Imaging Apparatus

An imaging apparatus includes a printhead carrier for mounting a printhead cartridge. The printhead carrier includes a carrier back wall having an upper portion. A back portion of a printhead cartridge cradle is connected to the carrier back wall. A first proximal end of a latch lever is pivotably attached to a front portion of the printhead cartridge cradle. The latch lever has at least one cam follower, with each cam follower being located near the first distal end of the latch lever. A second proximal end of a carrier lid is pivotably attached to the upper portion of the carrier back wall. Each cam of the carrier lid is formed near a second distal end of the carrier lid, and each cam is positioned for progressive engagement by a corresponding cam follower as the latch lever is moved from an open position toward a latched position.

Owner:FUNAI ELECTRIC CO LTD

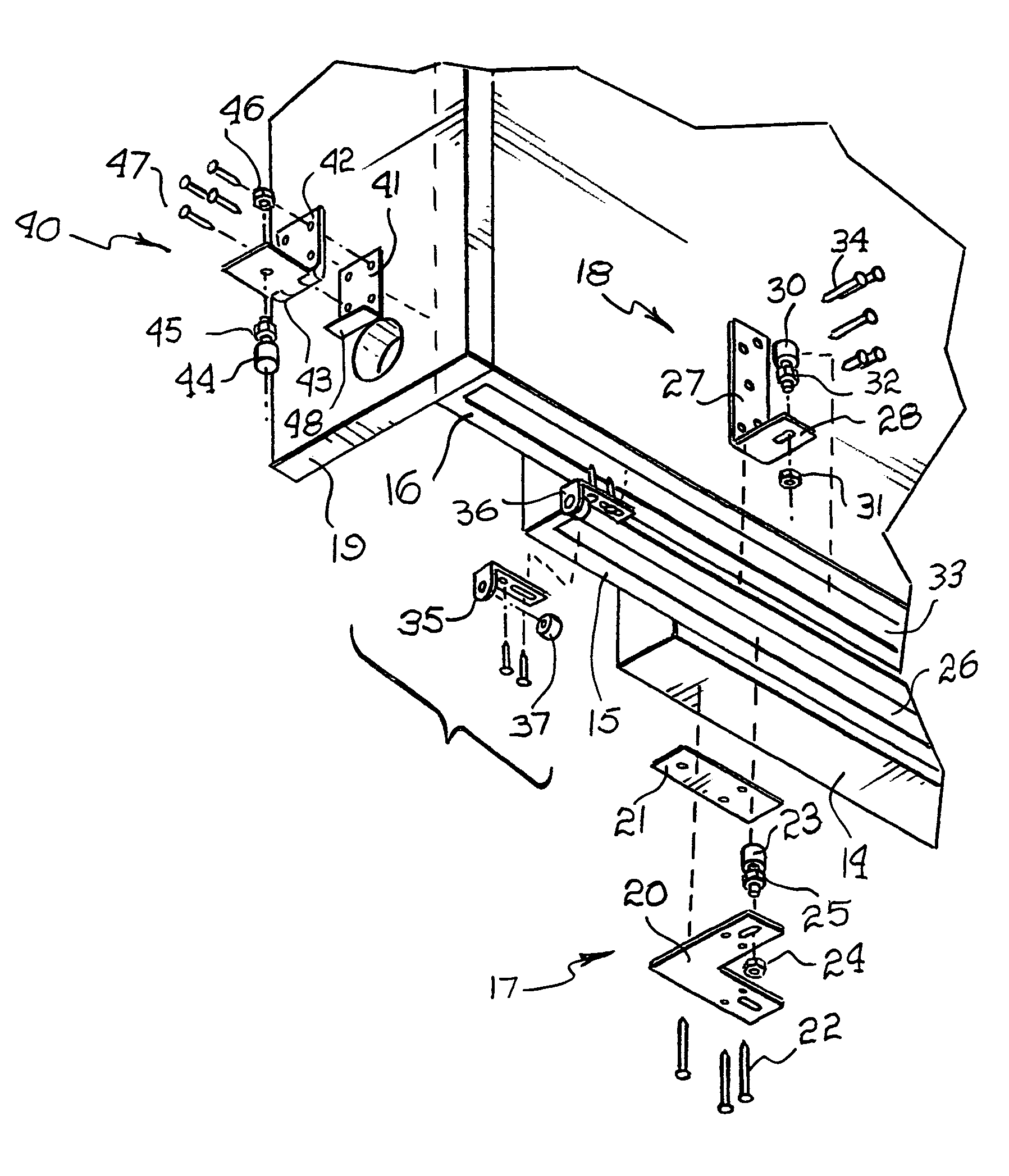

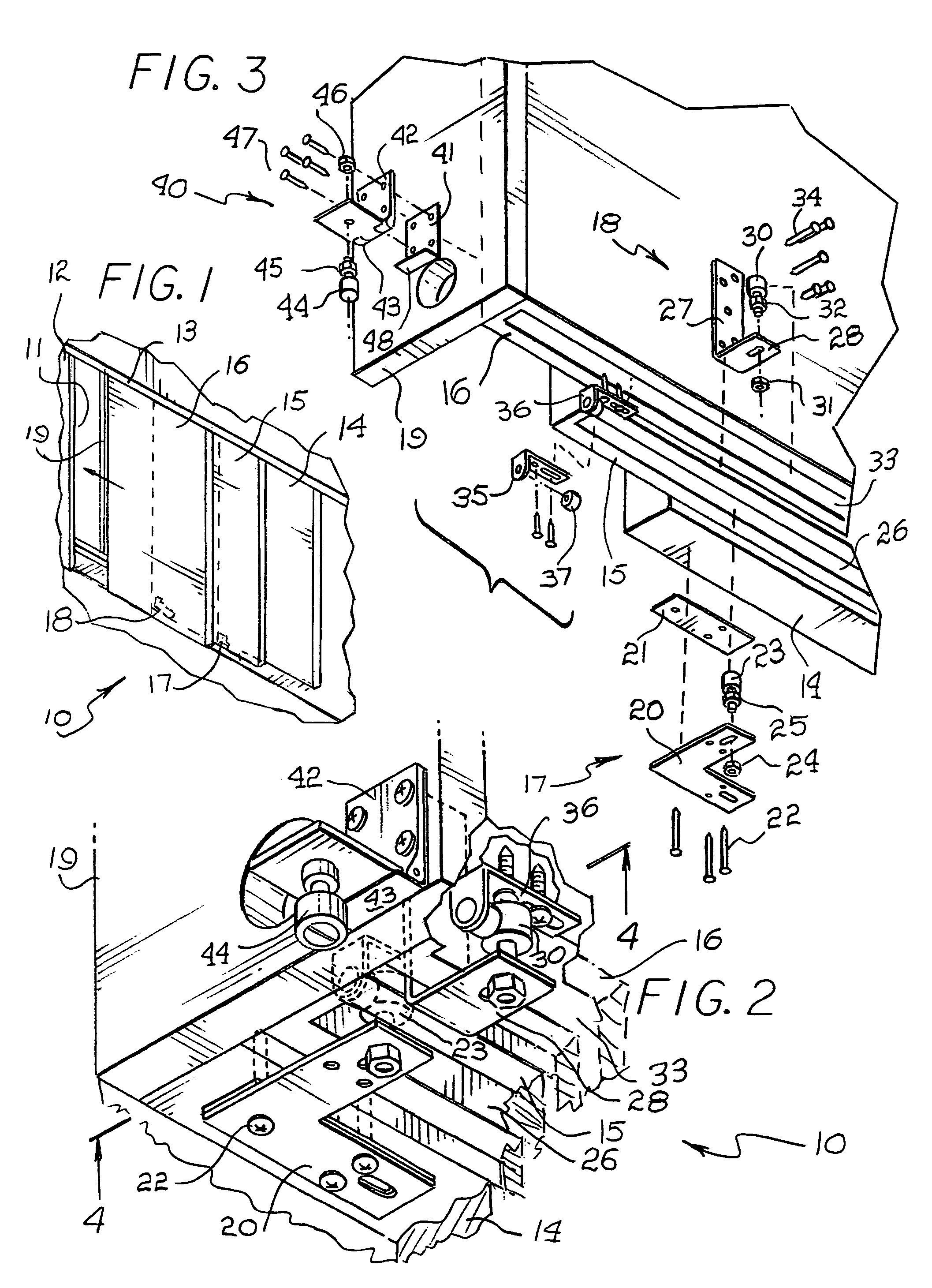

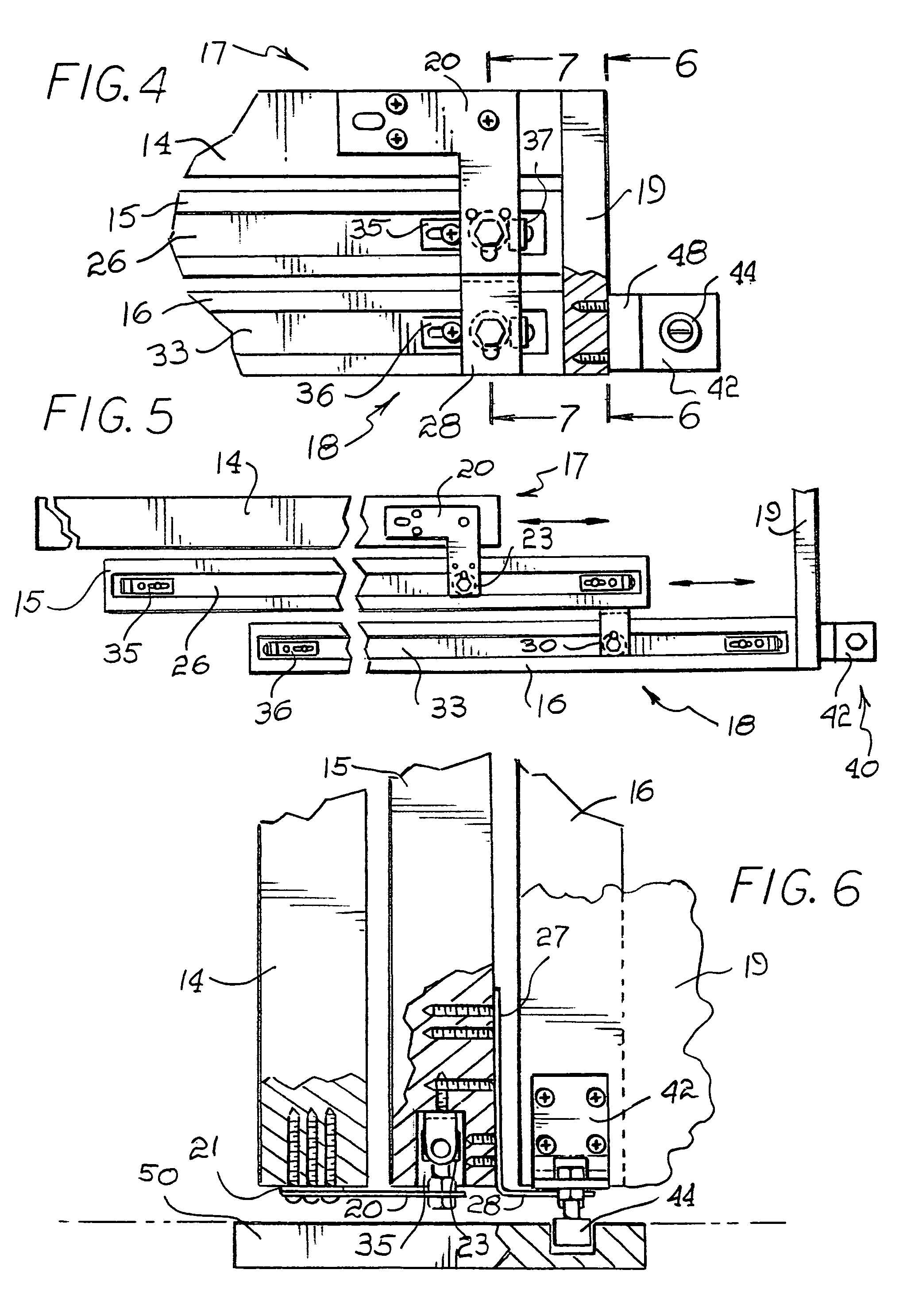

Multiple door joining assembly

InactiveUS7458410B1Avoid problemsWing operation mechanismsWing suspension devicesEngineeringCam follower

A joining assembly for “ganging” respective doors together such that by movement of one door causes the other doors to follow. A connecting plate and a spacer plate is screwed to the bottom of a primary door while the connecting plate includes a cam follower to ride in a groove in the bottom of a first secondary door. In this manner, both doors are “ganged” together. If other secondary doors are required to be joined with the previous two doors, a connecting angle plate is employed for securing to the secondary door so as to guide the third, fourth, etc. doors. A guide stop, hinge floor guide, and cam follower assembly is mounted to the last door in the multi-door series and the cam follower “tracks” in a floor guide hidden in a “pocket” when a storage pocket is employed in the installation. By ganging these doors, stability is imparted by the weight and mass of the doors.

Owner:BRONNER DAN

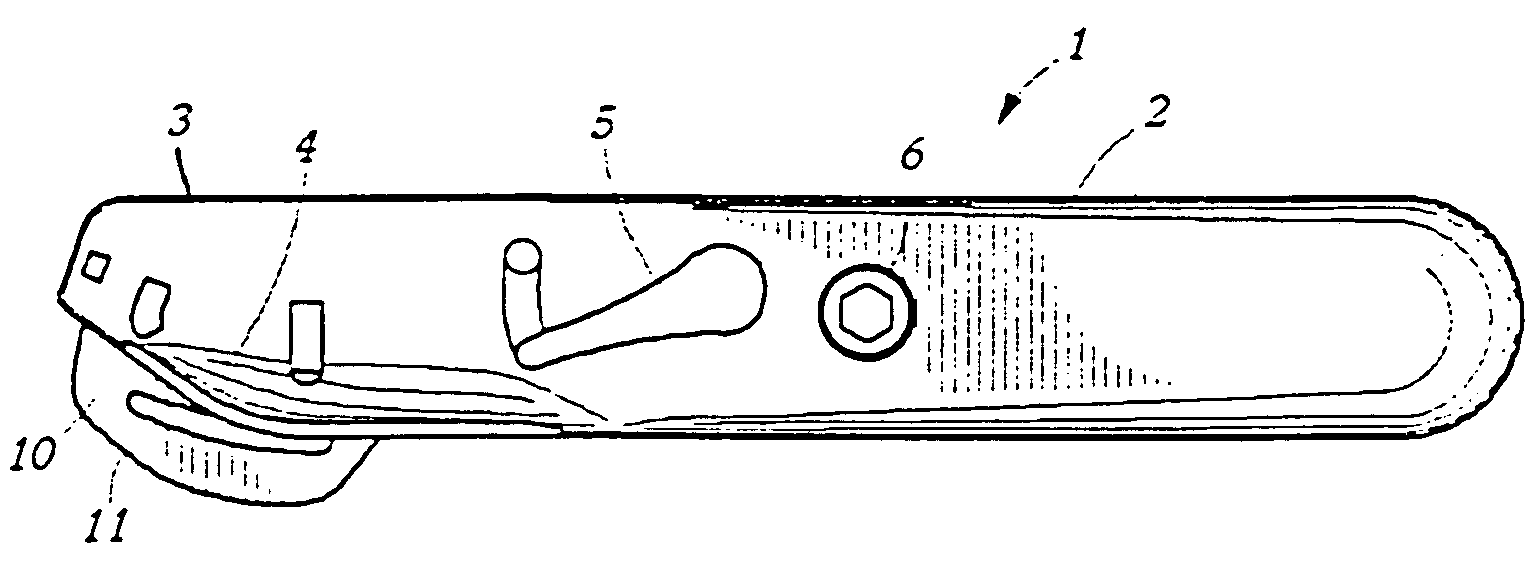

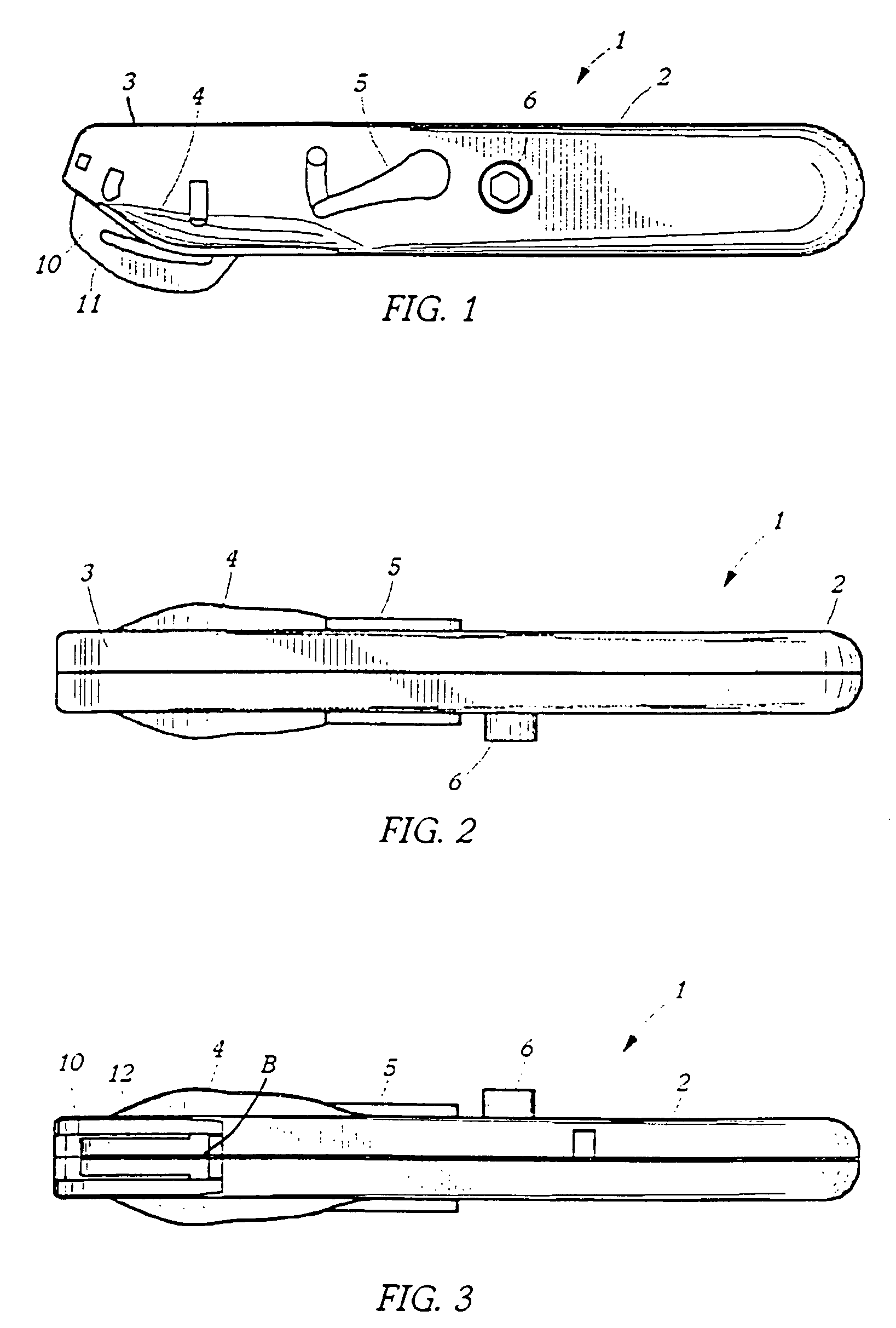

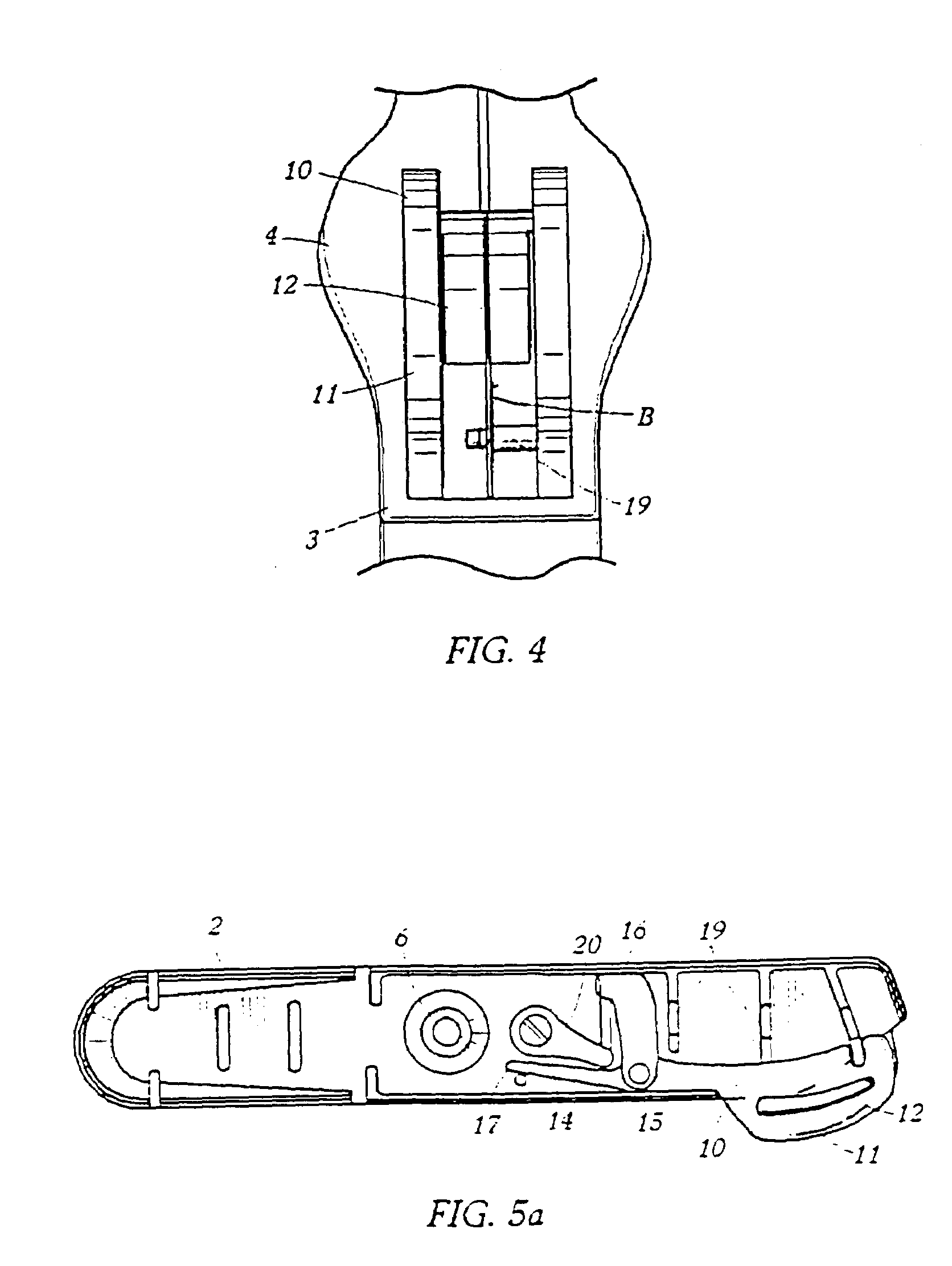

Case knife with multiple position blade guards

InactiveUS7024772B1Easy to operateOperational securityOpening closed containersBottle/container closureEngineeringKnife blades

A case knife (1, 101), generally consists of a pair of substantially symmetrical handle shells (13, 112). A single edge razor blade B is removably supported in one end of the handle formed by these handle shells. Each handle shell includes two moving parts—a guard (10, 110) and a thumb or finger operable button (5, 105). Each such guard, when paired with a substantially identical guard of the other handle half shell, flanks the otherwise protruding sharp edge of the razor blade. Each guard can move independently to expose a protruding corner of the razor blade. The operable button is mounted on an axle or lug (14, 103) that passes from the inside of a handle shell, through to its outside surface. This axle is in turn fixed to a cam follower (20, 120) mounted on the inside of each shell.

Owner:SPECMASTER

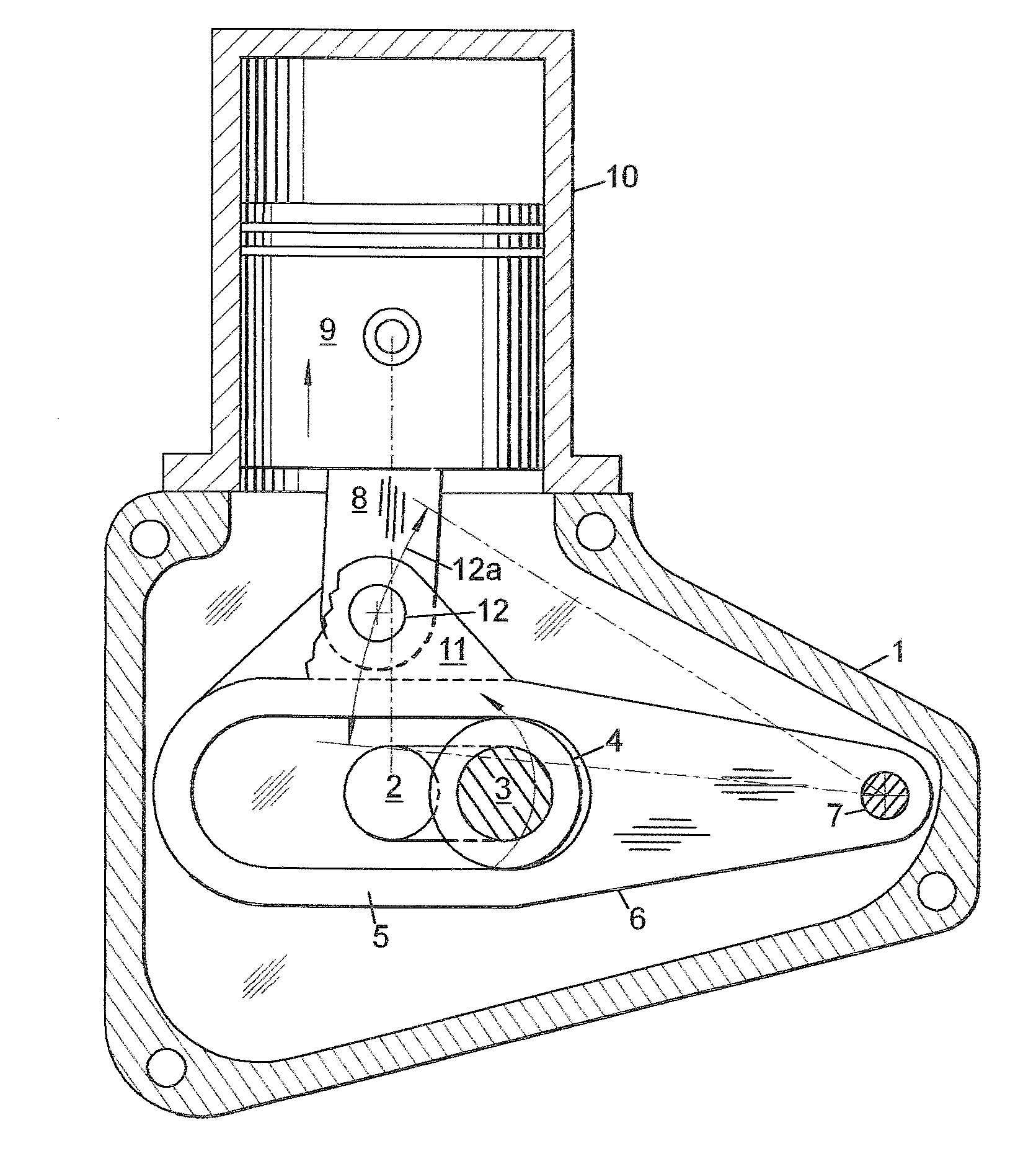

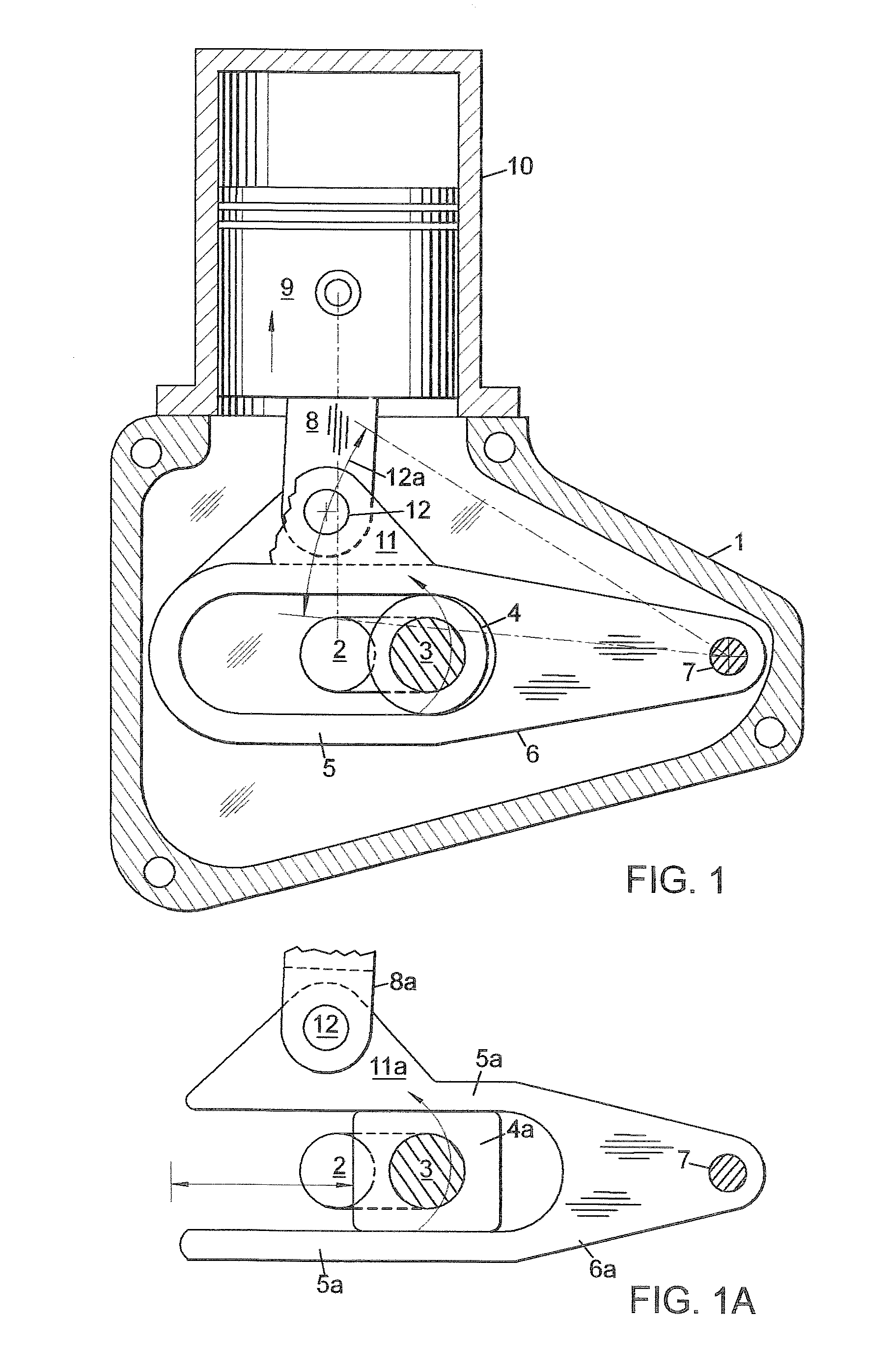

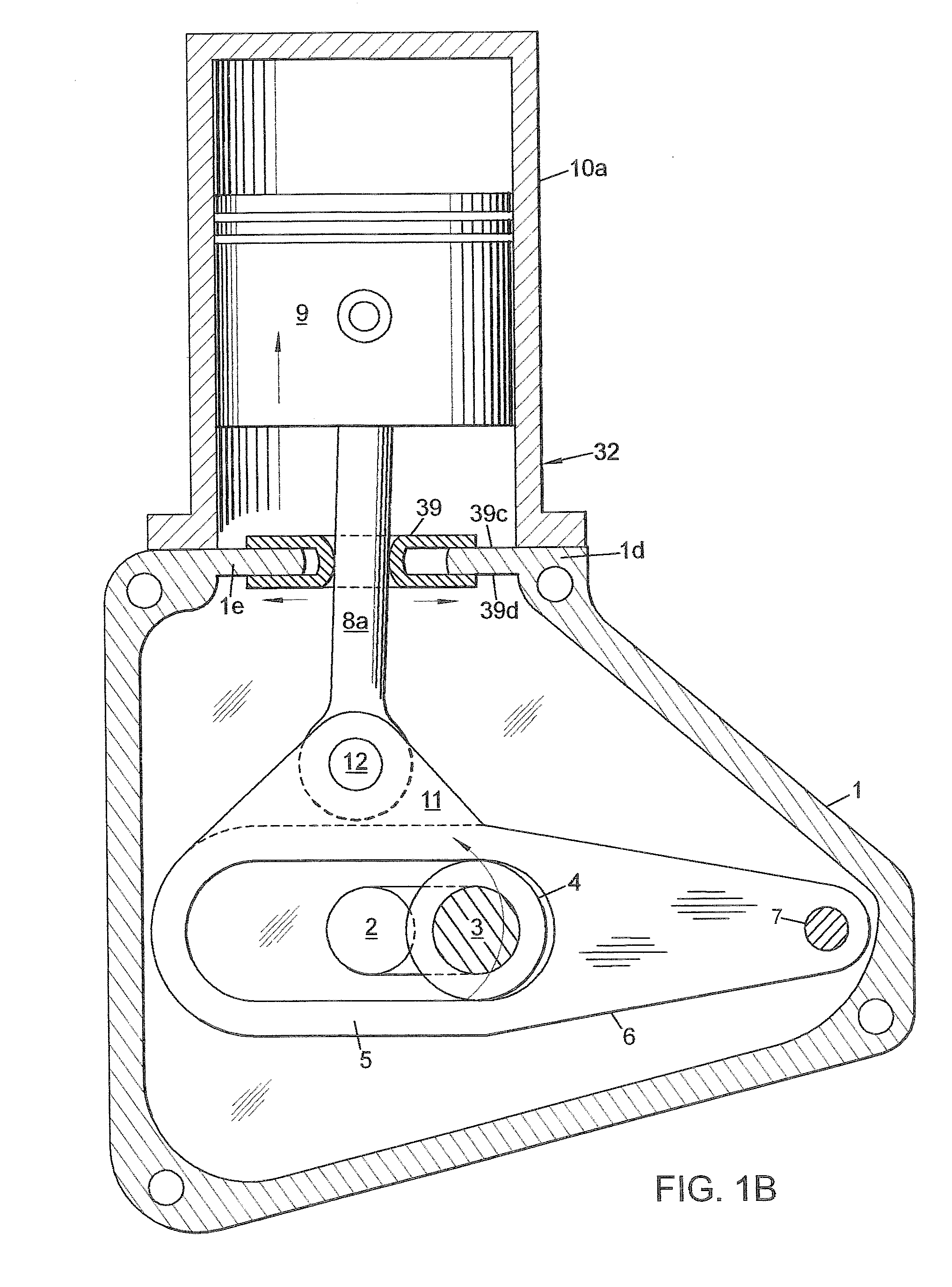

Self-Aspirated Reciprocating Internal Combustion Engine

InactiveUS20110146601A1Eliminating shaft counter weightExcessive vibrationConnecting rodsSealing arrangements for enginesSingle plateInternal combustion engine

Disclosed are crankshaft, single-plate cam and beam mechanisms that provide significant improvements in performance for 2- & 4-stroke engines, compressors and pumps. These cost effective mechanisms include linkages with the new and improved use of pivoting arms that operate with a variety of cylinder arrangements. One embodiment of the crankshaft mechanism has its crankpin roller positioned within a novel yoke-arm. The cam mechanism uses a pair of centrally positioned parallel links that are connected to roller cam followers and single or diametrically-opposed pistons. A pair of laterally extending follower arms connects to the ends of the links to provide support and alignment for the piston rods. Between the reciprocating links, cam followers and follower arms is a rotating odd-lobe plate cam. A beam mechanism uses opposite-direction extending balancing beams that are connected to links, cam followers and piston rods.

Owner:FISHER PATRICK T

Ratcheting quick-adjust drilling jig

ActiveUS20140341665A1Easy to adjustQuicklyDrilling/boring measurement devicesThread cutting feeding devicesEngineeringPlunger

A quick adjust ratcheting pocket hole jig is presented. The pocket hole jig has a base with a removable upright connected thereto. A guide assembly is slidably received within the upright. Removable and replaceable side supports are connected to the base by way of a dove tail joint. Removable and replaceable adjustable stops are connected to the base by way of key holes. A clamp assembly is connected to the base having a handle portion and a clamp follower. The clamp follower has a ratcheting mechanism and a compressible plunger assembly. The clamp follower can quickly be adjusted using a button on the clamp follower that disengages the ratcheting member such that it can be quickly adjusted. When the handle is operated, it draws the clamp follower towards the upright and guide assembly compressing the spring loaded plunger assembly thereby quickly and tightly and adjustably holding a workpiece therebetween.

Owner:KREG ENTERPRISES

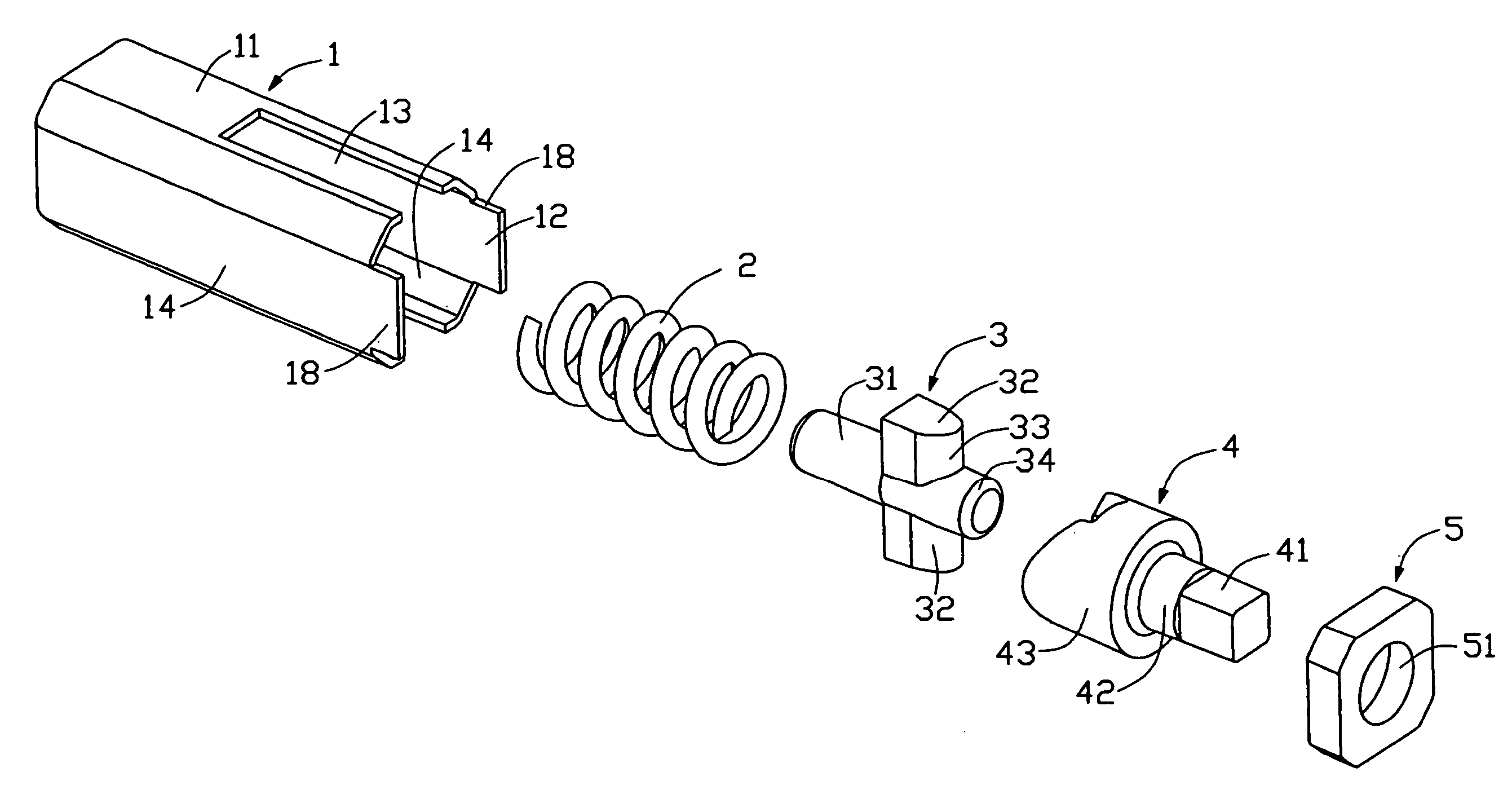

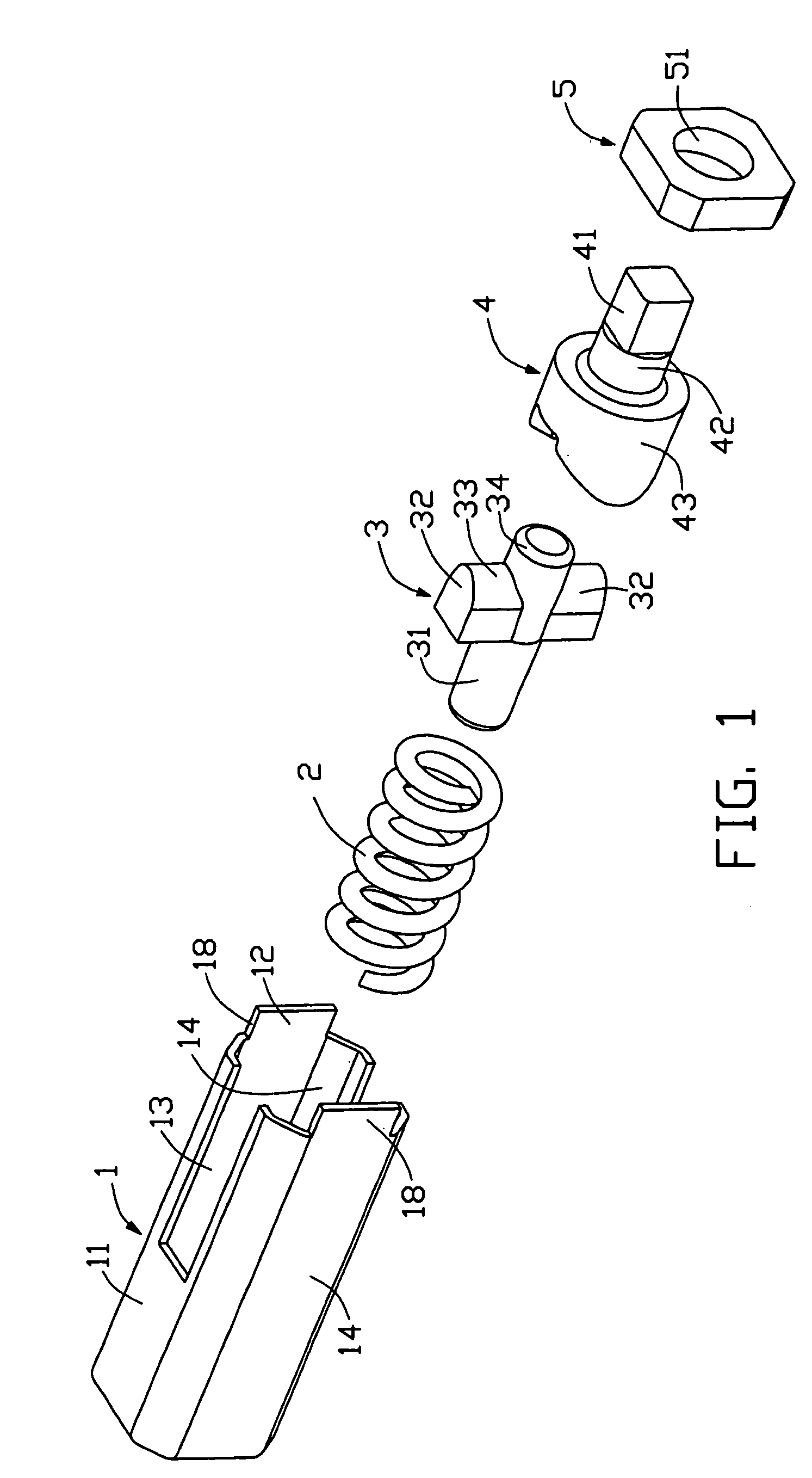

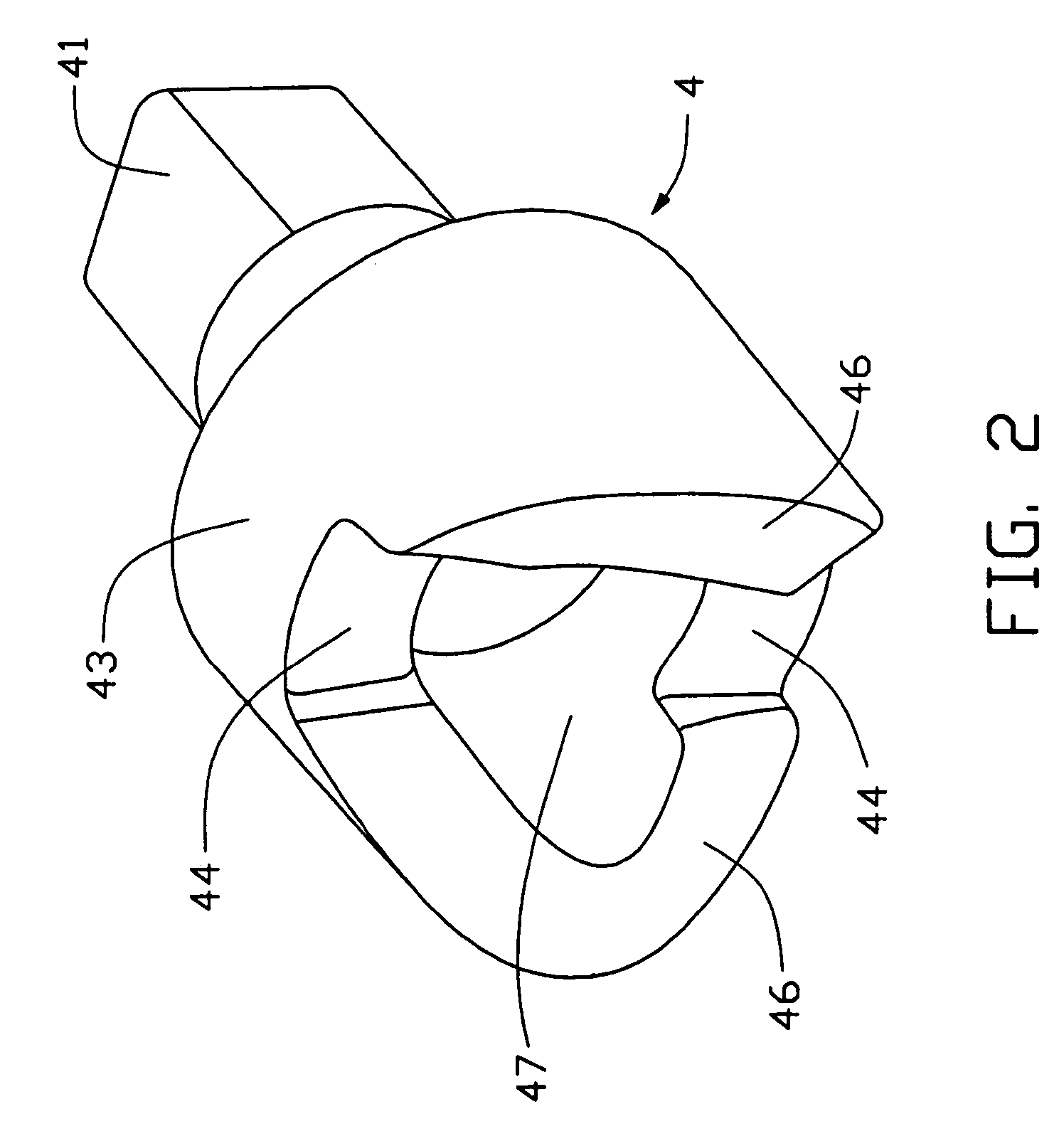

Hinge assembly

A hinge assembly includes a housing (1) encasing a spring (2), a cam follower (3), a cam member (4) and a washer (5) therein. The cam follower has a shaft (31), and a pair of tabs (32) perpendicularly formed on the shaft. The spring is coiled over the shaft, and is compressively engaged in the housing. The tabs of the cam follower slide in grooves (13) of the housing. The cam member includes a cam portion (43) and a connector (41). The cam portion forms a pair of peaks (46) and a pair of valleys (44), being engaged with the tabs of the cam follower. The connector extends outside of the housing. The washer is rotatably inserted over the connector, and is fitted in the housing for fixing the hinge components in the housing.

Owner:FIH (HONG KONG) LTD +1

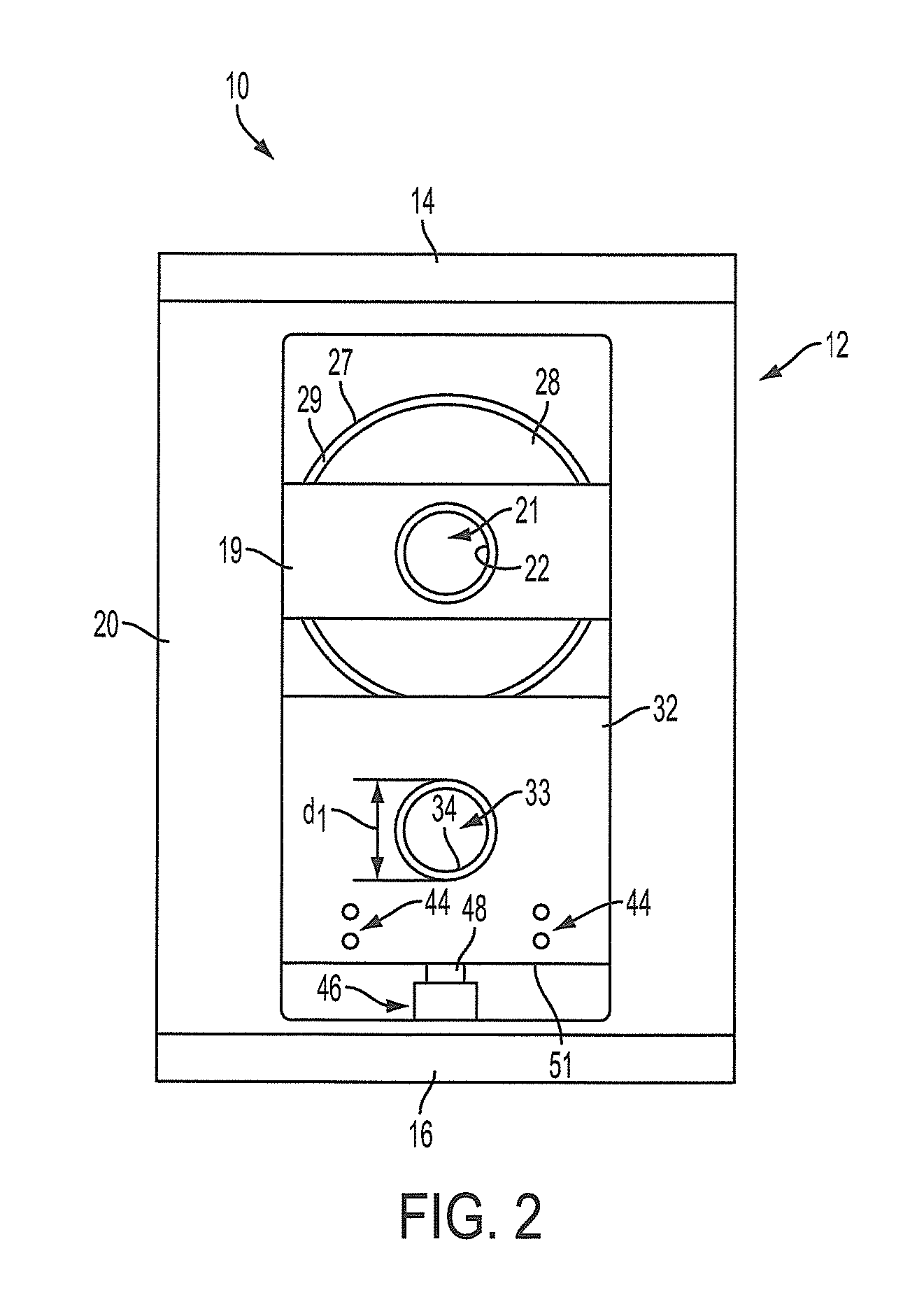

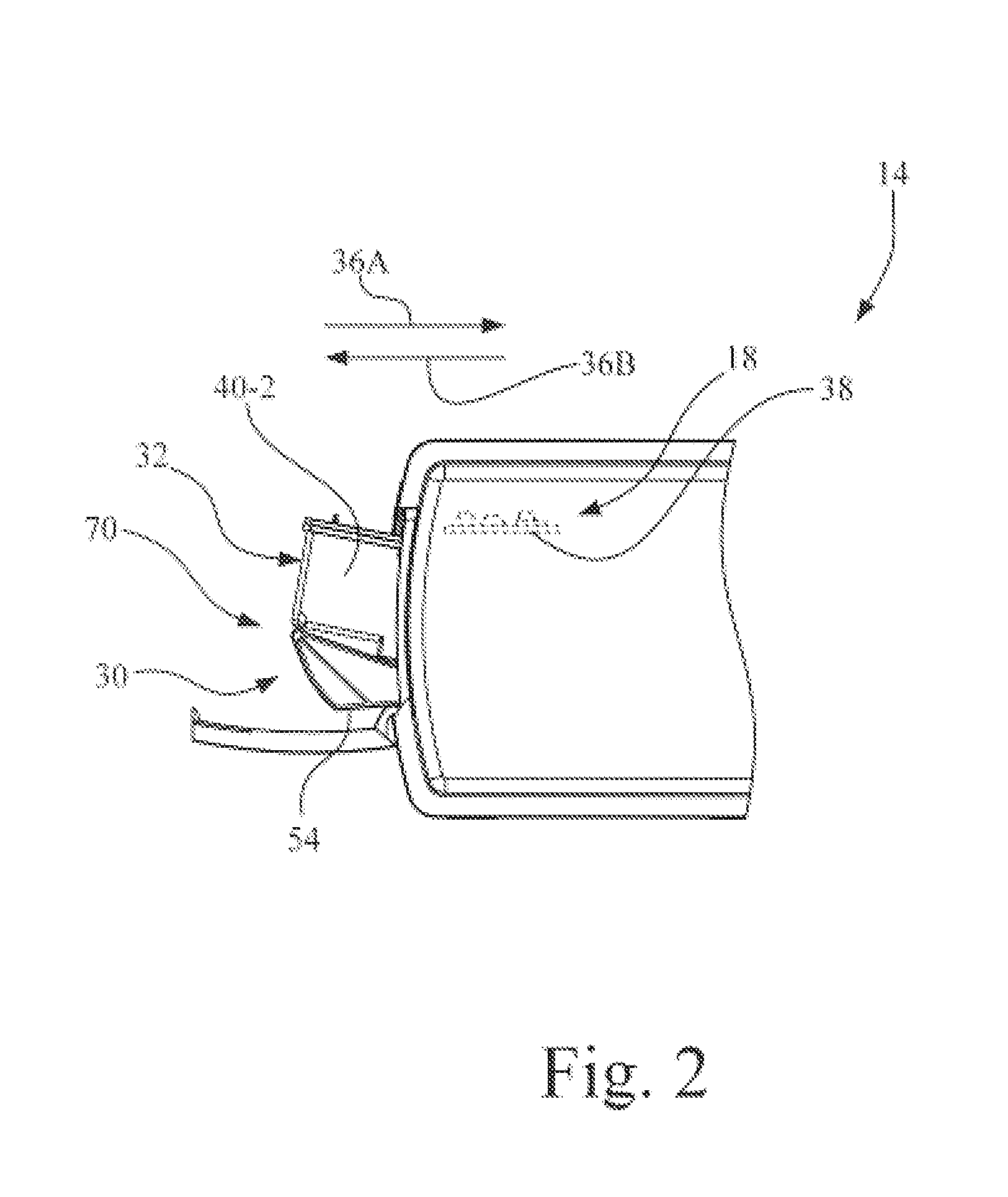

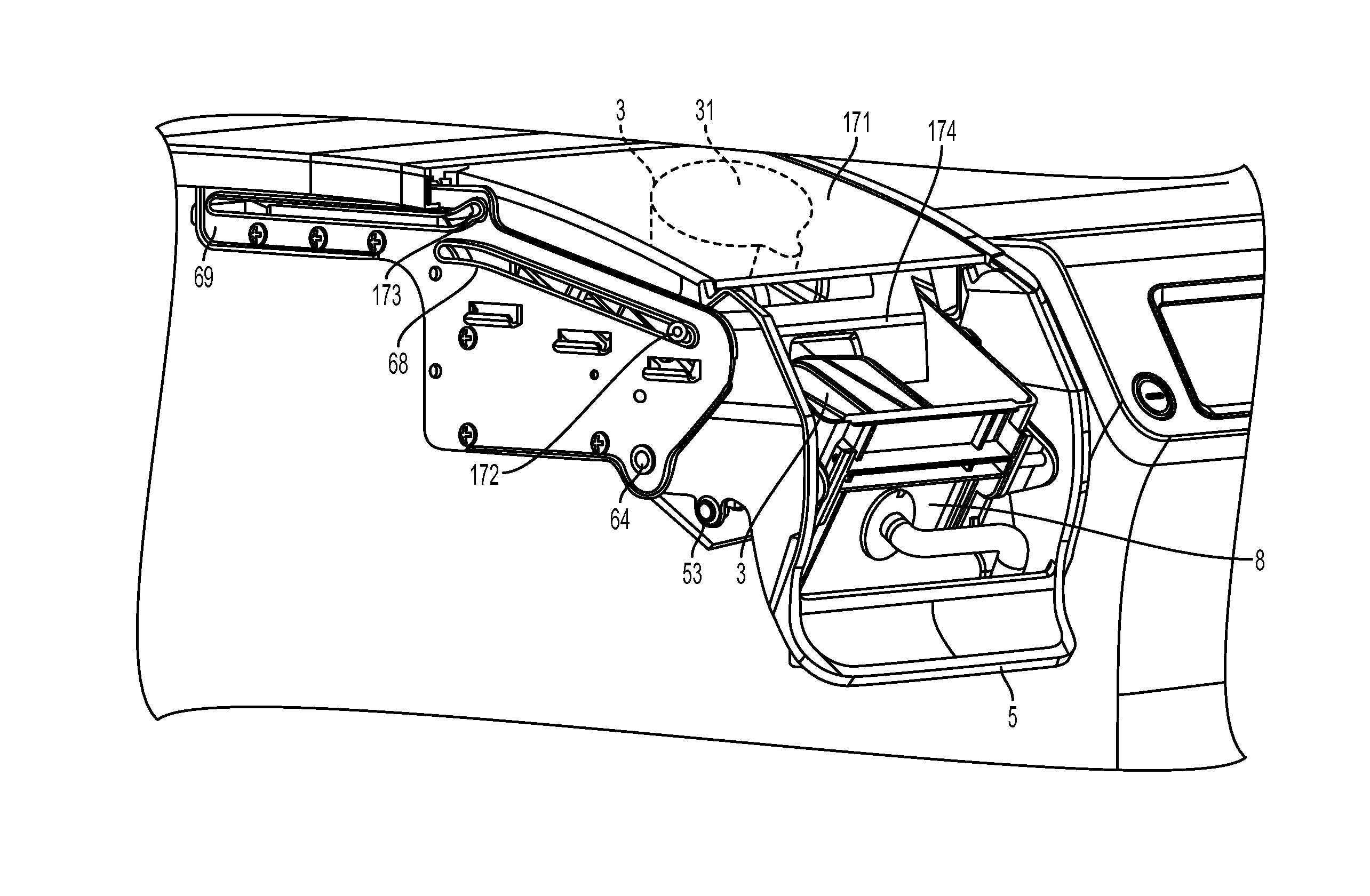

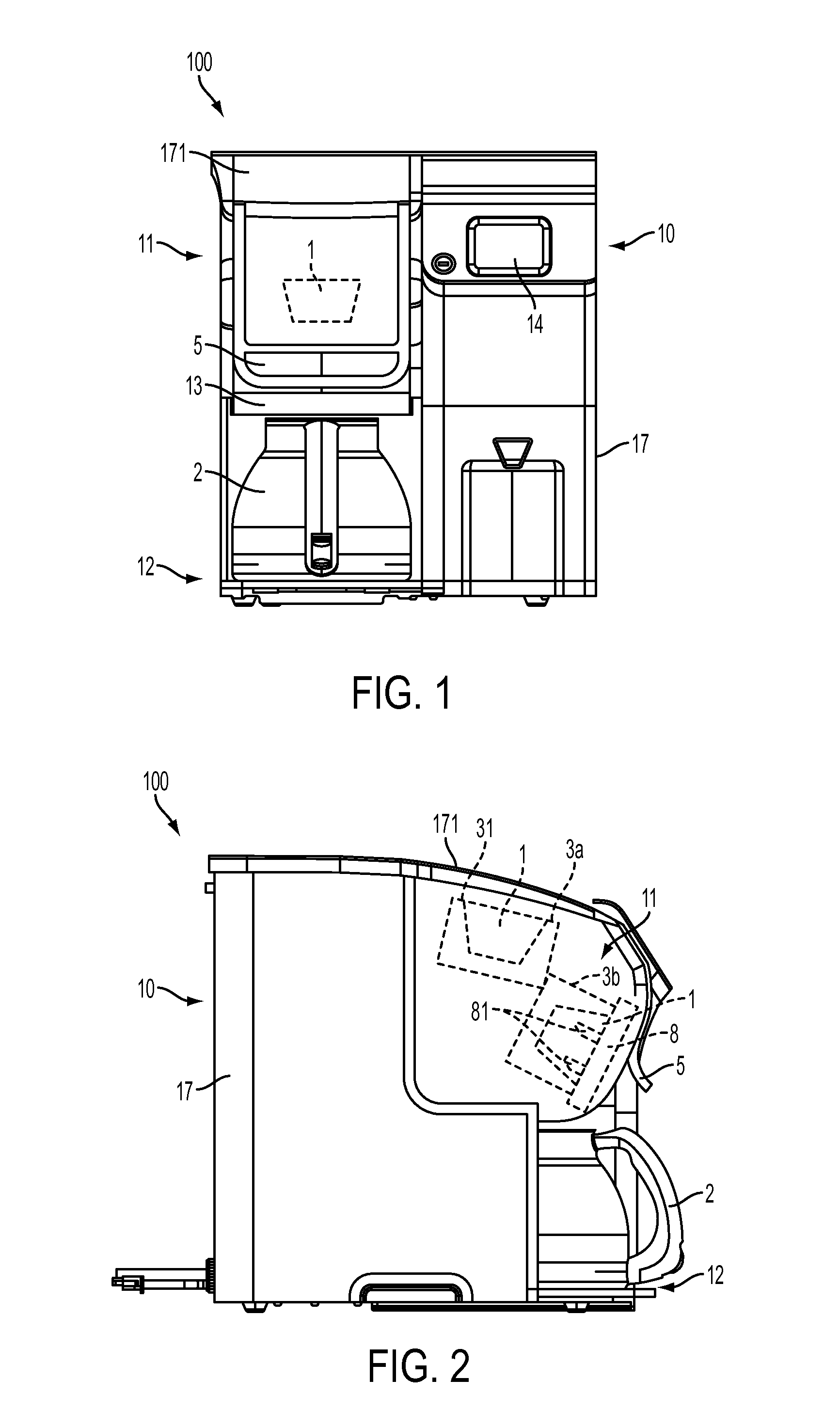

Beverage machine cartridge holder with damped movement

ActiveUS20150013279A1Placement of a cartridge in the holder easy and convenient for a userSecurely holdOpening closed containersBottle/container closureCam follower

A method and apparatus for opening and closing a cartridge holder of a beverage forming machine. The cartridge holder may have an opening arranged to receive and hold a cartridge with the cartridge holder in an open position, e.g., the opening may face a front of the beverage forming machine and be in an upwardly inclined position in the open position. A cam and cam follower may cause the cartridge holder to pivot and move to a closed position, e.g., in which the opening of the cartridge holder is in a downwardly inclined orientation. Rotation of the cartridge holder may be damped in at least a portion of movement between the open and closed positions.

Owner:KEURIG GREEN MOUNTAIN INC

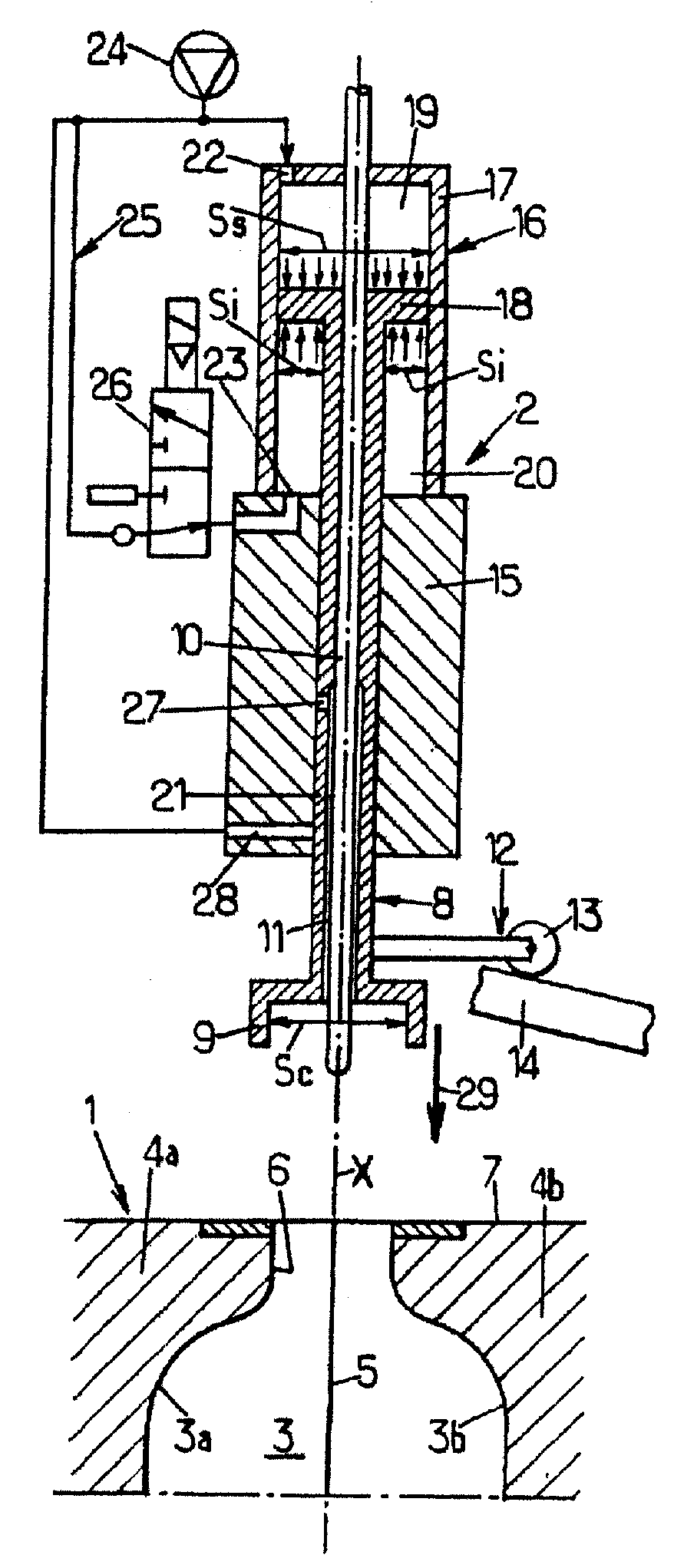

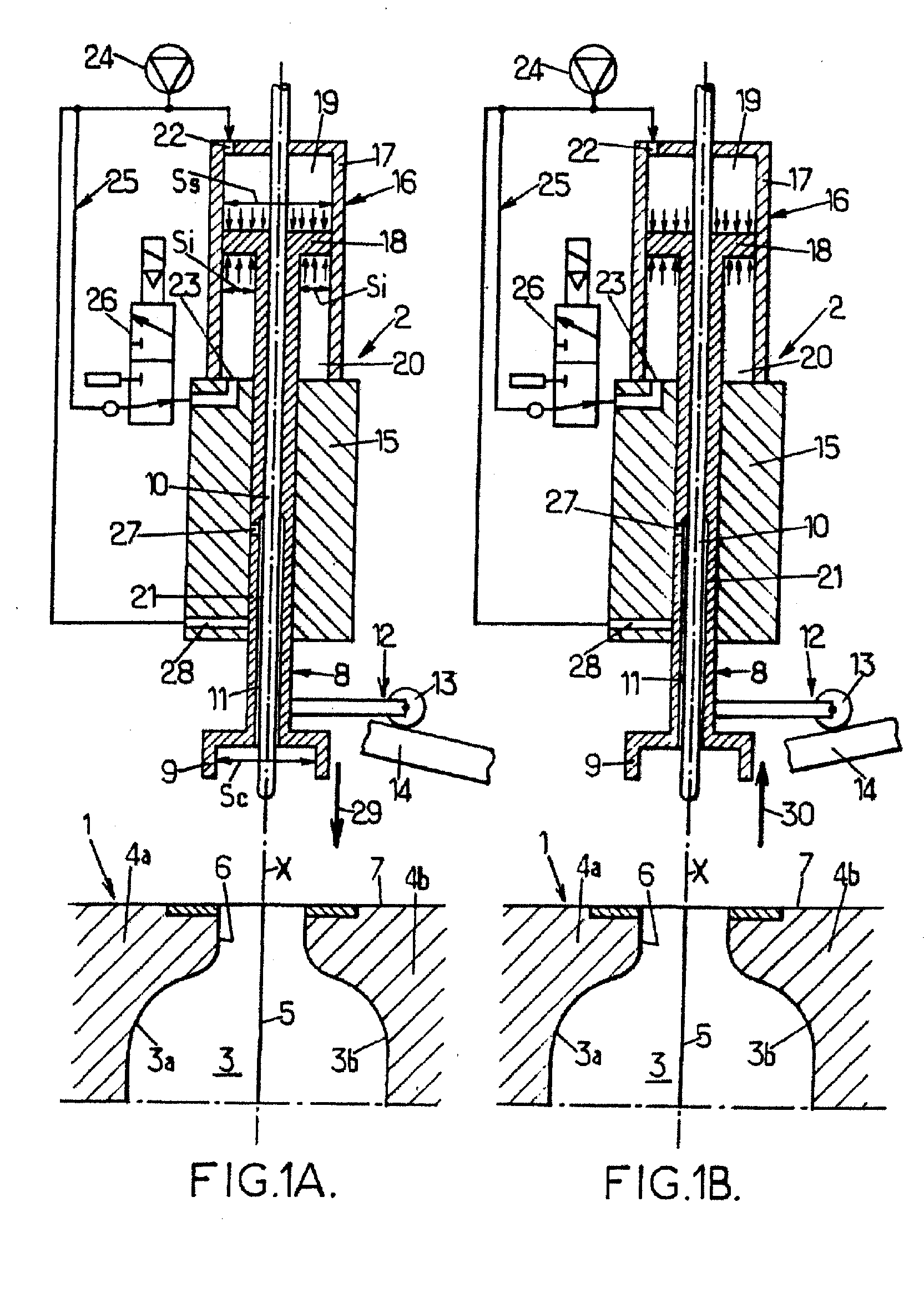

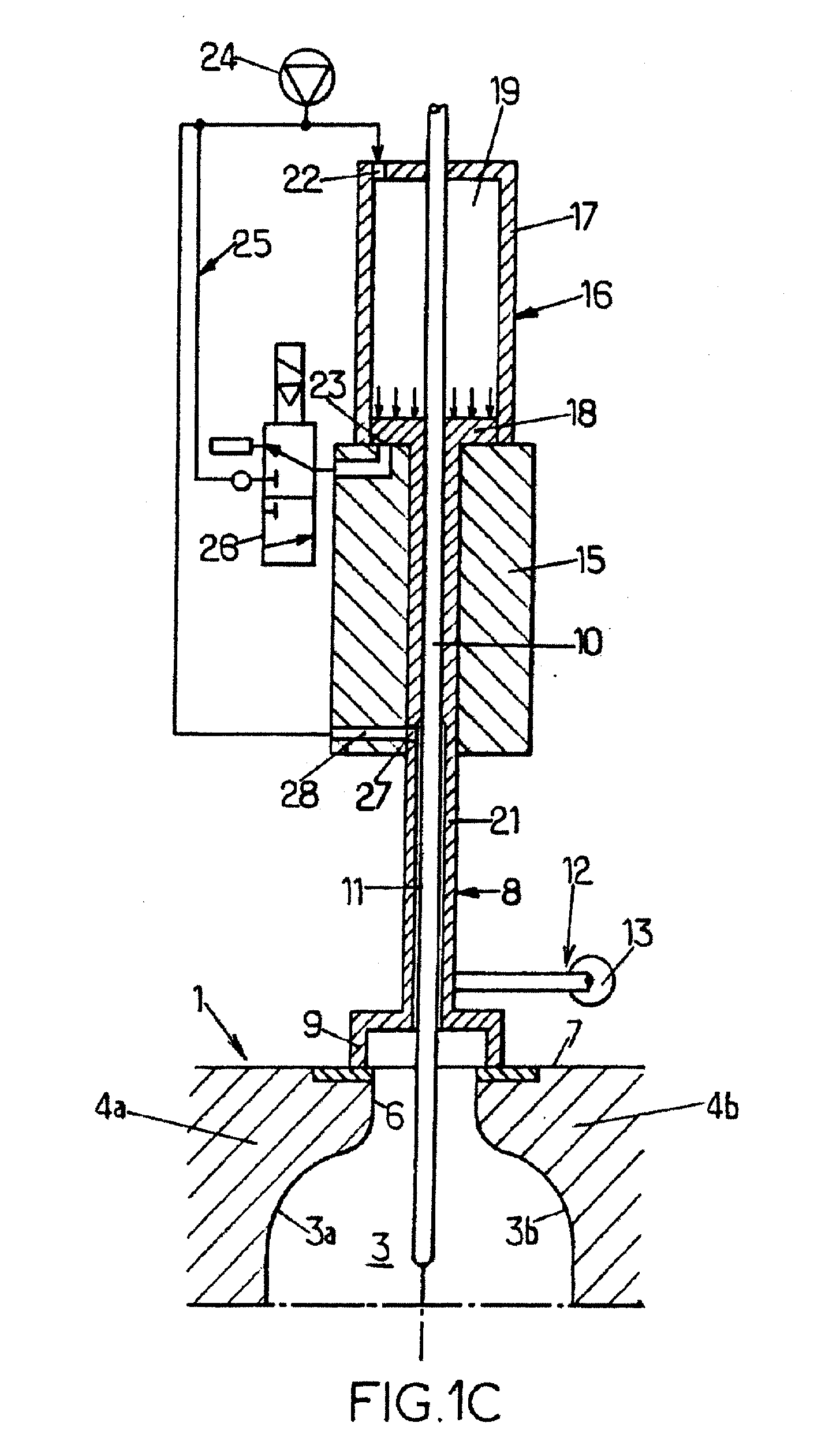

Device for moulding thermoplastic containers by blow-moulding or stretch blow-moulding

Device for moulding thermoplastic containers by blow-moulding hot preforms, comprising a mould (1) and blow-moulding means (2) comprising a bell nozzle (8) which is axially displaceable between a raised position and a blow-moulding position in abutment against the mould; the driving means comprising mechanical means (12) with a cam follower roller (13) / cam (14) and pneumatic means (16) with a piston (18) integral with the upper end of the nozzle and sliding in a fixed enclosure (17), defining therein an upper chamber (19) connected to a source (24) of control fluid and a lower chamber (20) connected to this source and to the upper chamber via a solenoid valve (26); the upper face of the piston has a surface area which is greater than that of its lower face and that of the bell (9) of the nozzle.

Owner:SIDEL PARTICIPATIONS SAS

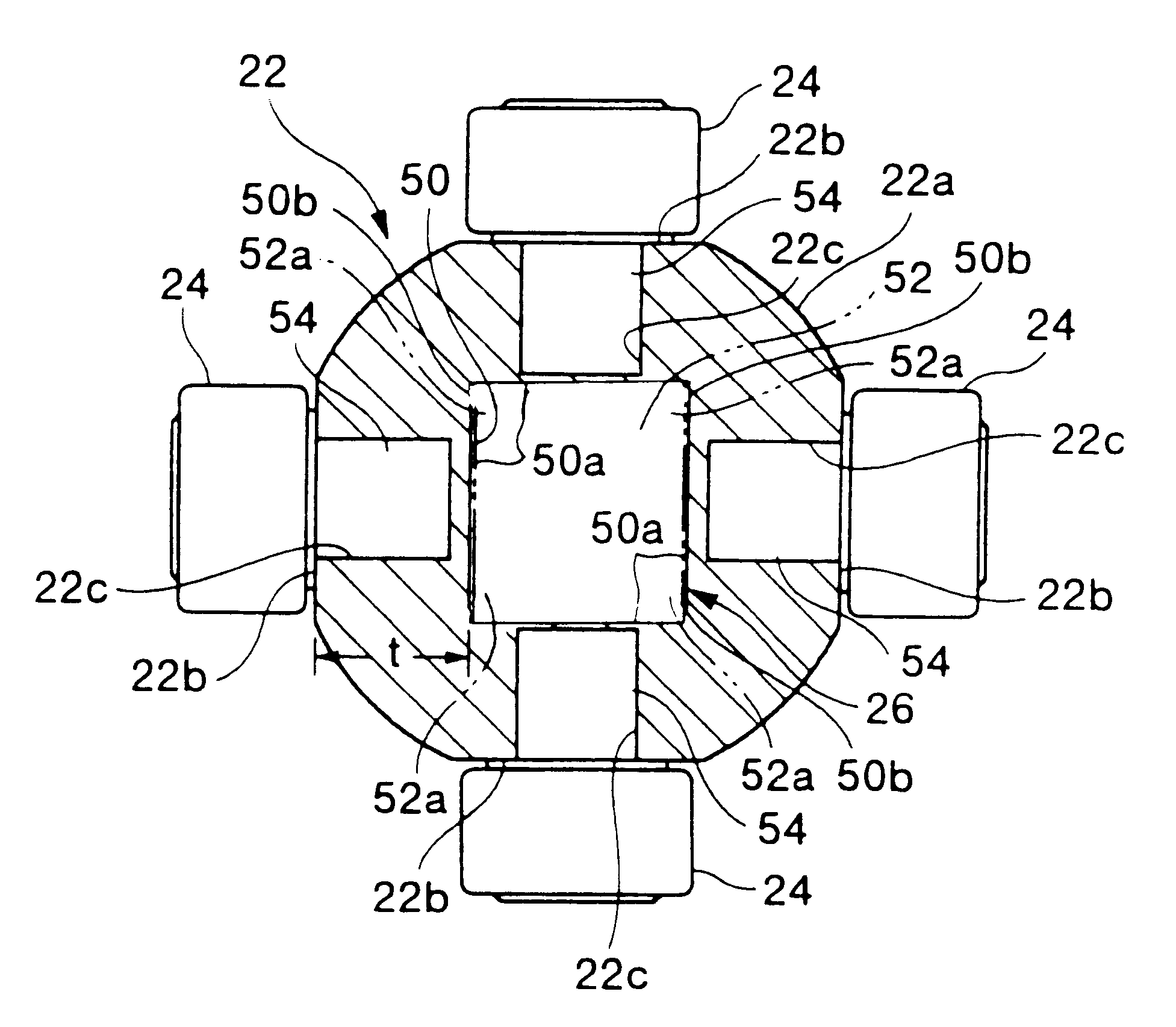

Cam mechanism

A cam powered mechanism which uses two cam forms, a swing arm, and turret to drive an output shaft with a compound radial and axial movement. An arrangement in which a cam follower is positioned opposite each planar surface of the rectangular spline connecting the turret and output shaft acts to increase turret strength and reduces the size of the mechanism.

Owner:SANKYO SEISAKUSHO

Oscillating sorting device for grape berries

A oscillating sorting conveyor is adapted for separating whole berries of wine grapes from undesirable components such as “shot berries” (immature grapes), stems, raisins, leaf material, bugs, pebbles and the like. The sorter deploys a downward tilting trough that is driven to oscillate. A screen is disposed at the bottom of the trough such that whole berries are conveyed over the screen while the undesirable components pass through the screen. The preferred embodiment of the screen has a non-uniform cross-section to improve the efficiency of removal the undesirable components without clogging or requiring constant maintenance. The preferred embodiment of the oscillating conveyor is driven by a cam and cam follower, in which the cam driving shaft is counterweighted to minimize vibration. The more preferred embodiments minimize damage to the grape berries while efficiently removing the undesirable components.

Owner:BARR EDWIN L

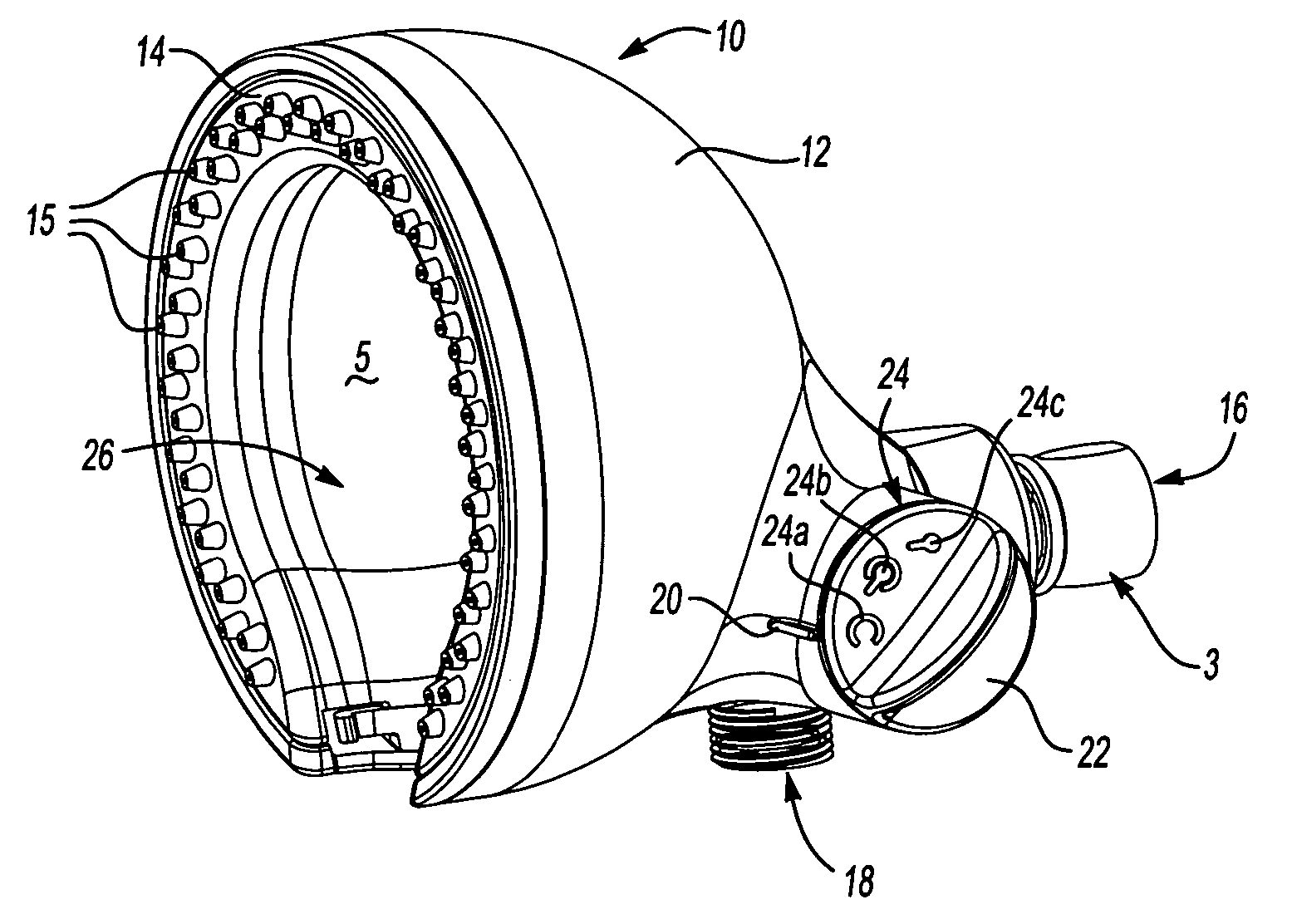

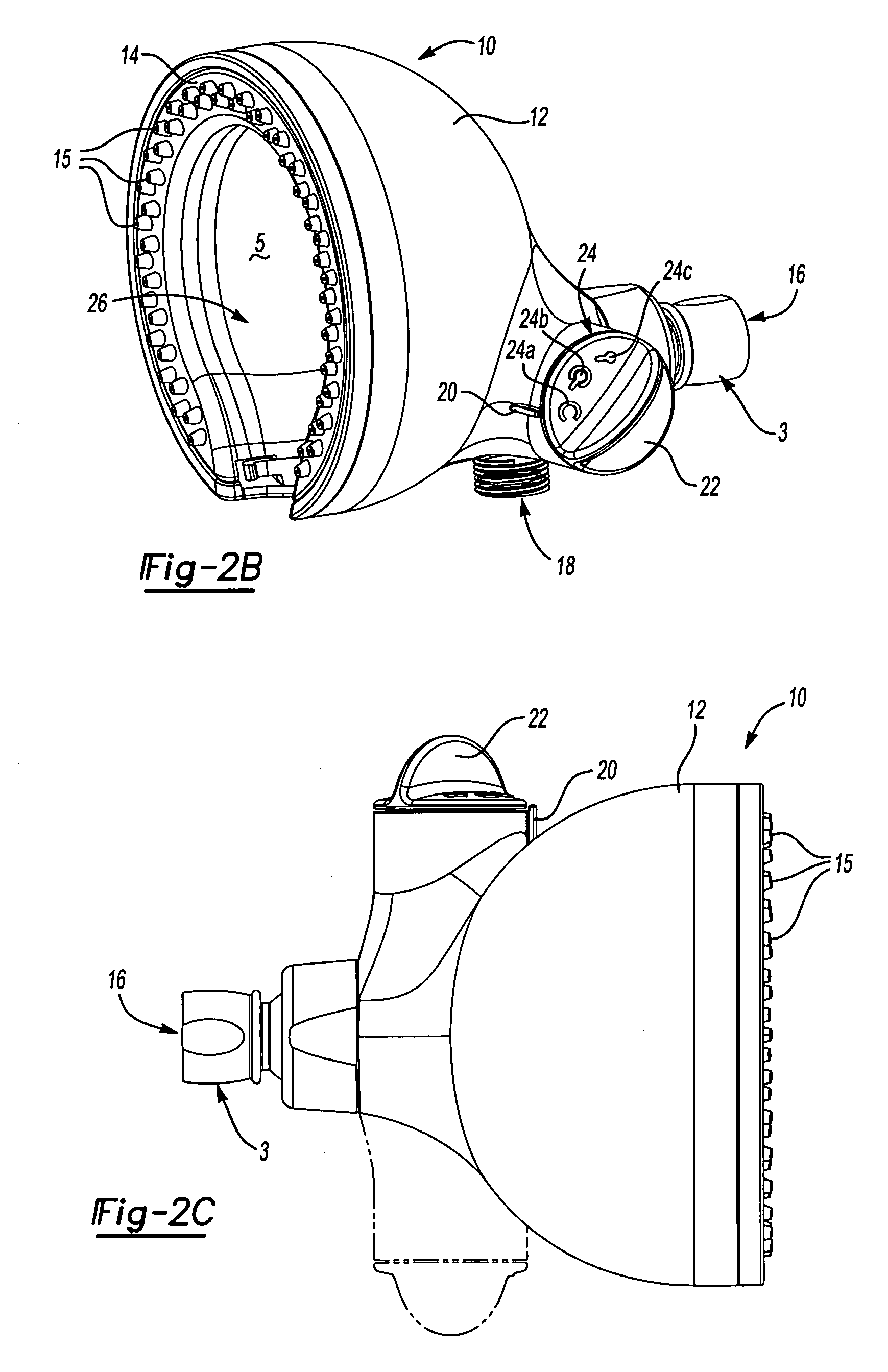

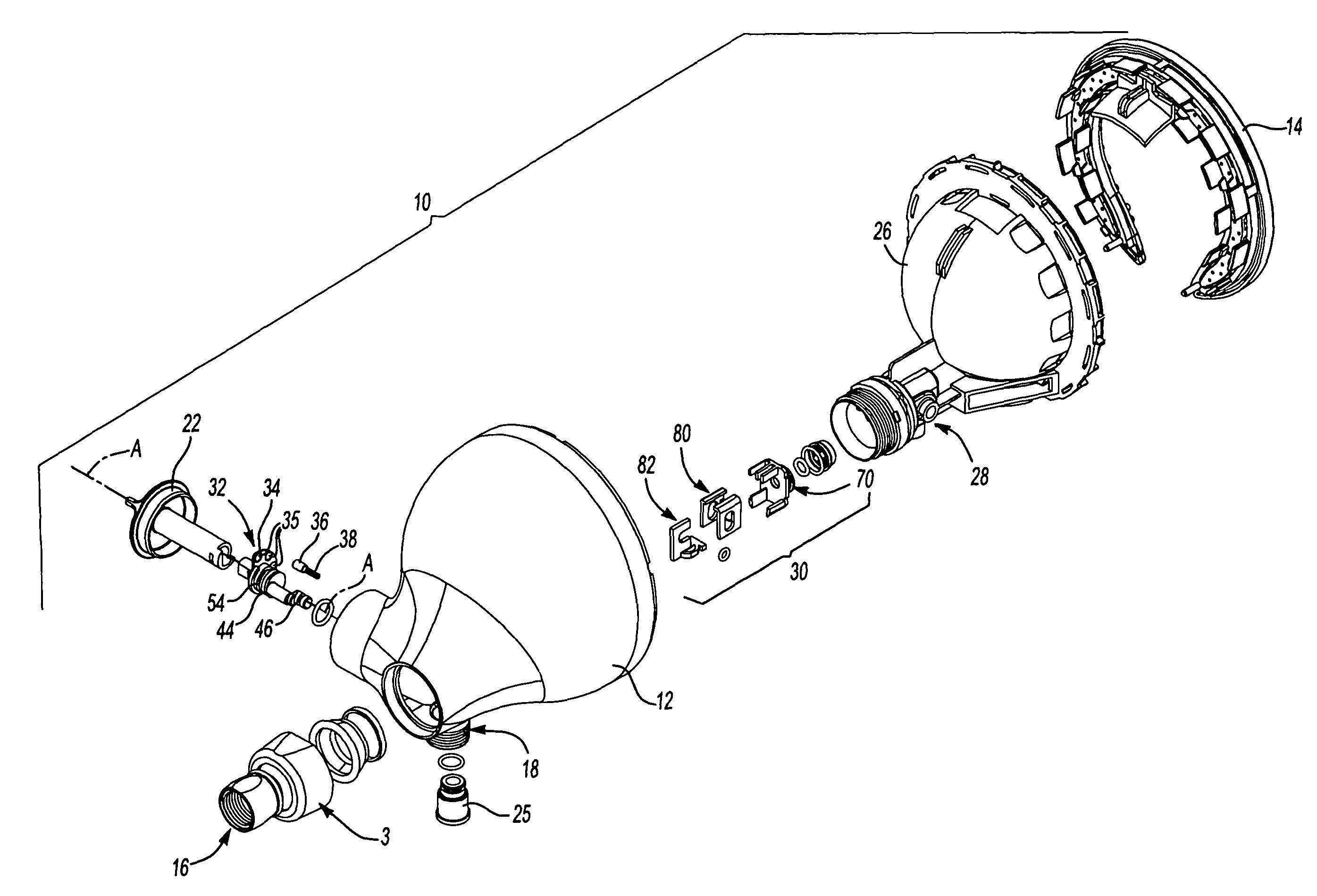

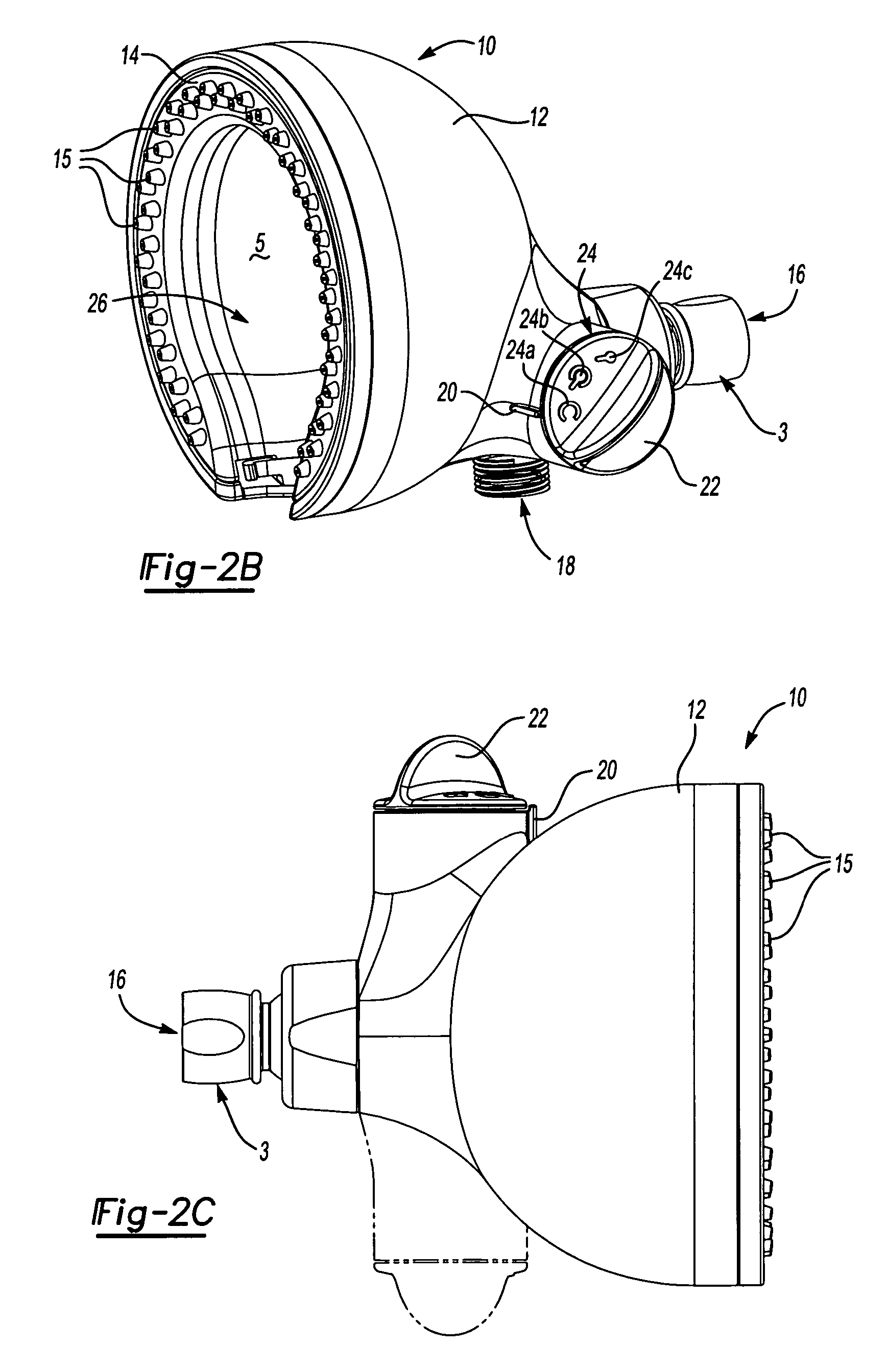

Shower head with integral diverter valve

A shower assembly is provided that includes a shower head having an integrated diverter valve. The shower head receives a detachable hand-held shower wand. The diverter valve is arranged upstream of an adjustable connector so that length is not added to the shower assembly that would interfere with headroom. A cam shaft of the diverter valve is rotated to selectively control fluid flow between the shower head and the hand-held shower wand. Cam followers are moved linearly in response to rotation of the cam shaft to selectively block first and second outlet ports.

Owner:DELTA FAUCET COMPANY

Shower head with integral diverter valve

A shower assembly is provided that includes a shower head having an integrated diverter valve. The shower head receives a detachable hand-held shower wand. The diverter valve is arranged upstream of an adjustable connector so that length is not added to the shower assembly that would interfere with headroom. A cam shaft of the diverter valve is rotated to selectively control fluid flow between the shower head and the hand-held shower wand. Cam followers are moved linearly in response to rotation of the cam shaft to selectively block first and second outlet ports.

Owner:DELTA FAUCET COMPANY

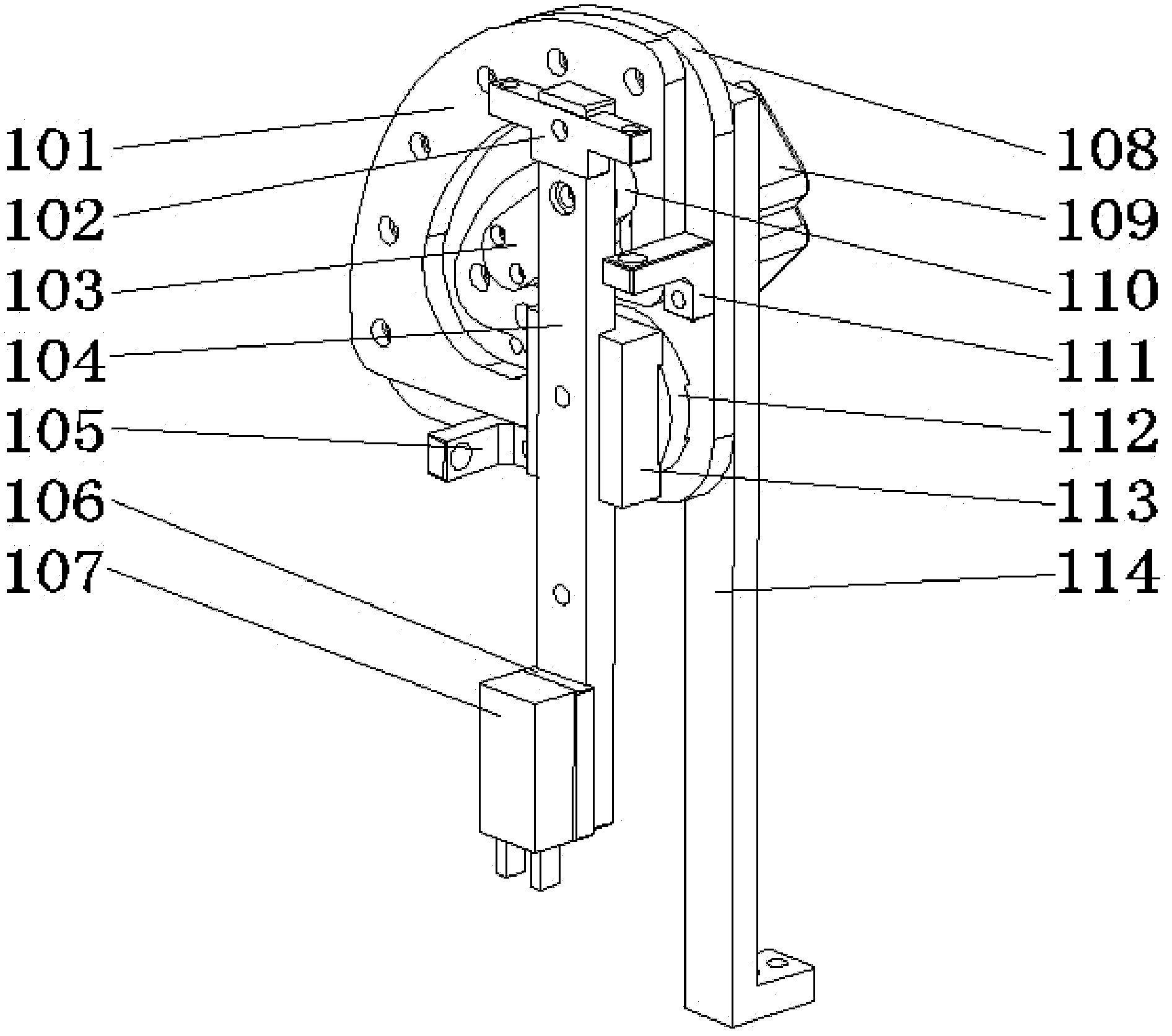

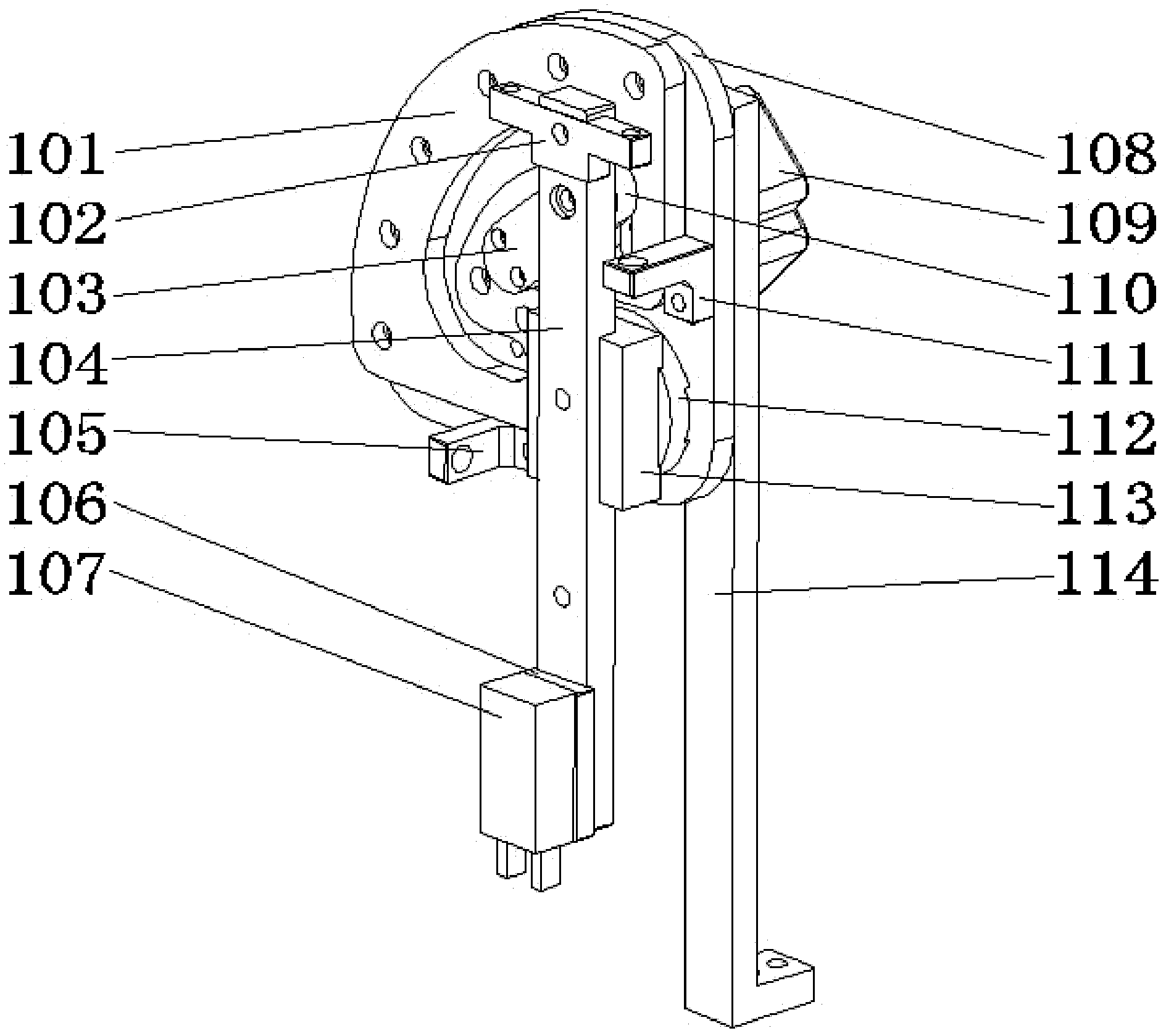

Novel right-angled carrying manipulator

InactiveCN102556655AMeet the requirements of high-speed handlingConveyor partsProduction lineEngineering

The invention discloses a novel right-angled carrying manipulator comprising a manipulator support fixed on a production line, wherein the right lower side of the manipulator support is connected with a sliding rail and a linear slide block sliding back and forth along the sliding rail through bearings, the bottom of the linear slide block is provided with a clamping cylinder, and the top of the linear slide block is connected with a C-shaped track sliding device of which an initial action point is arranged right above a bearing block and the final action point is arranged on a horizontal line of the bearing block. An output shaft of a stepping motor is used for transmitting a rotating force to a cam follower fixing plate and driving the cam follower fixing plate to rotate so that the linear slide block acts along a C-shaped track on a track master plate, the slide rail can only rotate around the bearing block; finally, the tail end of the linear slide block is converted into a marked-out right-angled track, and the action is finished from the beginning to the end without stopping; the clamping cylinder is matched for making corresponding opening and closing actions to finish the right-angled carrying of appointed articles; and the manipulator is enabled to do high-speed point-to-point reciprocated actions to meet the requirement for high-speed carrying.

Owner:邹建炀 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com