Solar battery piece packaging glue structure and preparation method thereof

A technology of solar cells and encapsulation adhesives, which is applied in the direction of chemical instruments and methods, circuits, adhesives, etc., can solve the problems of reducing the reflection effect of reflective materials, increasing the optical path of incident light, and high cost, so as to reduce the water vapor transmission rate and reduce the Material cost, effect of avoiding equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

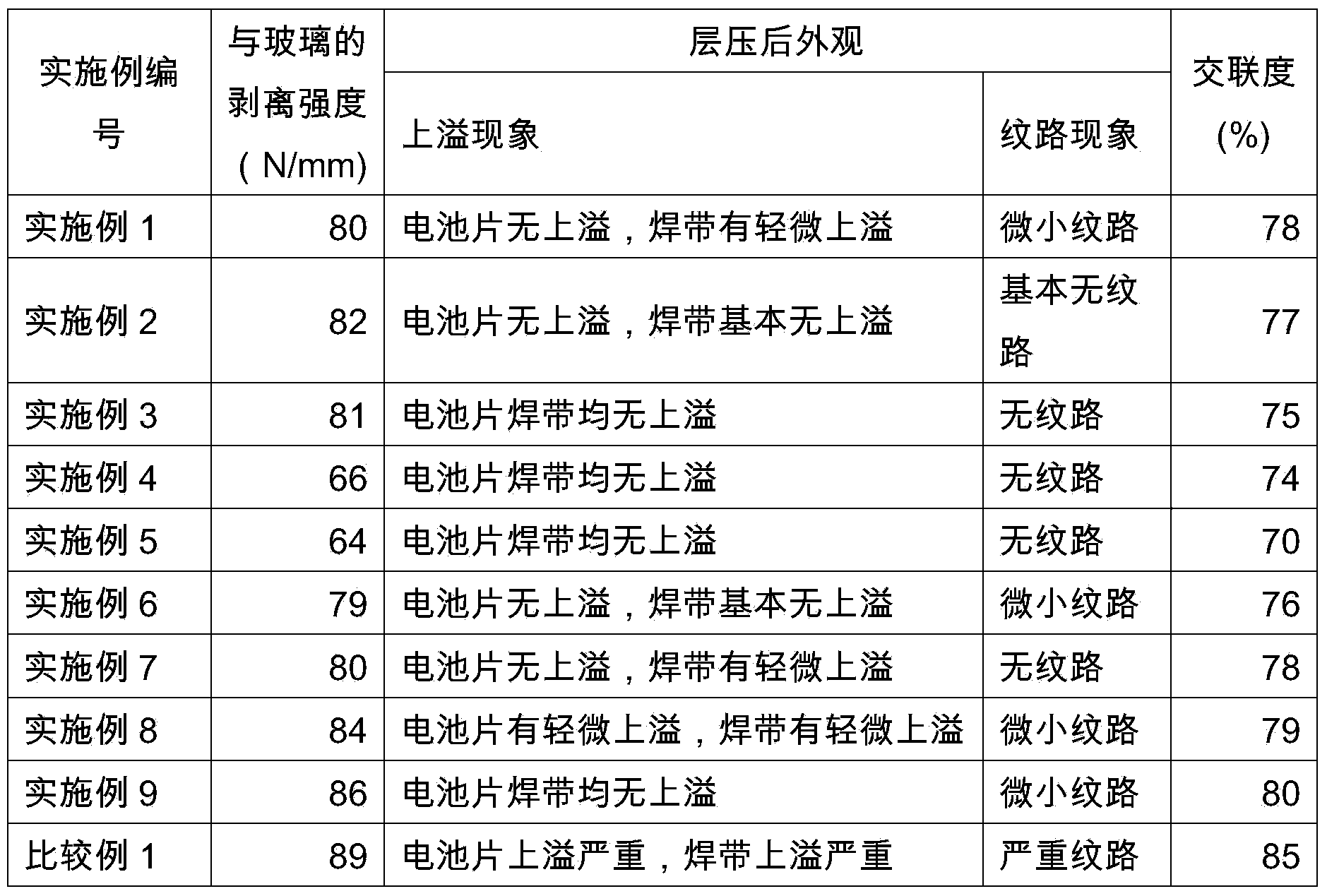

Examples

Embodiment 1

[0038] A solar cell sheet encapsulation adhesive structure sequentially includes an encapsulation adhesive layer and a barrier film layer. The barrier film and the encapsulation adhesive layer are combined together. When laminating, the barrier film surface is close to the battery sheet, and the encapsulation adhesive layer is close to the backplane side. The fluidity of the barrier film is lower than that of the encapsulation adhesive layer, and the encapsulation adhesive layer is made of white EVA, and the entire body composed of the barrier film and the encapsulation adhesive is used as the whole of the back encapsulation adhesive.

[0039] preparation:

[0040] In terms of parts by mass, 100 parts of vinyl acetate content is 32wt%, MI is 40g / 10min of EVA pellets, 6 parts of rutile titanium dioxide (DuPont R105), 0.5 parts of γ-methacryloxypropyl trimethoxy silane, 1.5 parts tert-butyl-(2-ethylhexyl) monoperoxycarbonate, 1 part triallyl isocyanurate, 0.2 parts 2-hydroxy-4-...

Embodiment 2

[0046] A solar cell sheet encapsulation adhesive structure, comprising a layer of barrier film on the side close to the cell sheet and an encapsulation adhesive layer on the side close to the back plate or glass. The barrier film is combined with the encapsulation adhesive layer. The fluidity of the barrier film is less than that of the encapsulation adhesive layer. The encapsulation adhesive layer is made of white EVA. The overall glue is selected from the transparent EVA film on the market, such as Foster F806. The barrier film side is close to the cell sheet during lamination.

[0047] preparation:

[0048] In terms of parts by mass, 100 parts of vinyl acetate content is 32wt%, MI is 40g / 10min of EVA pellets, 6 parts of rutile titanium dioxide, 0.5 parts of γ-methacryloxypropyltrimethoxysilane, 1.5 Parts of tert-butyl-(2-ethylhexyl) monoperoxycarbonate, 1 part of triallyl isocyanurate, 0.2 parts of 2-hydroxy-4-n-octyloxybenzophenone after mixing machine to mix evenly, as...

Embodiment 3

[0054] A solar cell encapsulation adhesive structure, comprising a barrier film on the side of the cell, an encapsulation adhesive layer on the side of the back plate or glass, and an adhesive layer distributed on the side of the barrier film close to the cell. The barrier film is combined with the encapsulation adhesive layer and the adhesive layer. The fluidity of the barrier film is less than that of the encapsulation adhesive layer and the adhesive layer. The encapsulation adhesive layer is made of white EVA. With the barrier film, the adhesive layer and the The package formed by the package is used as the whole of the package on the back, and the package on the light-facing side is made of transparent EVA film on the market, such as Foster F806. The adhesive layer is placed close to the cells during lamination.

[0055] preparation:

[0056] In terms of parts by mass, add 6 parts of rutile titanium dioxide (DuPont R-105) and 0.5 parts of γ-methacryloxypropane to 100 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com