Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Low process cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functionalized graphene adsorbent and preparation method and application thereof

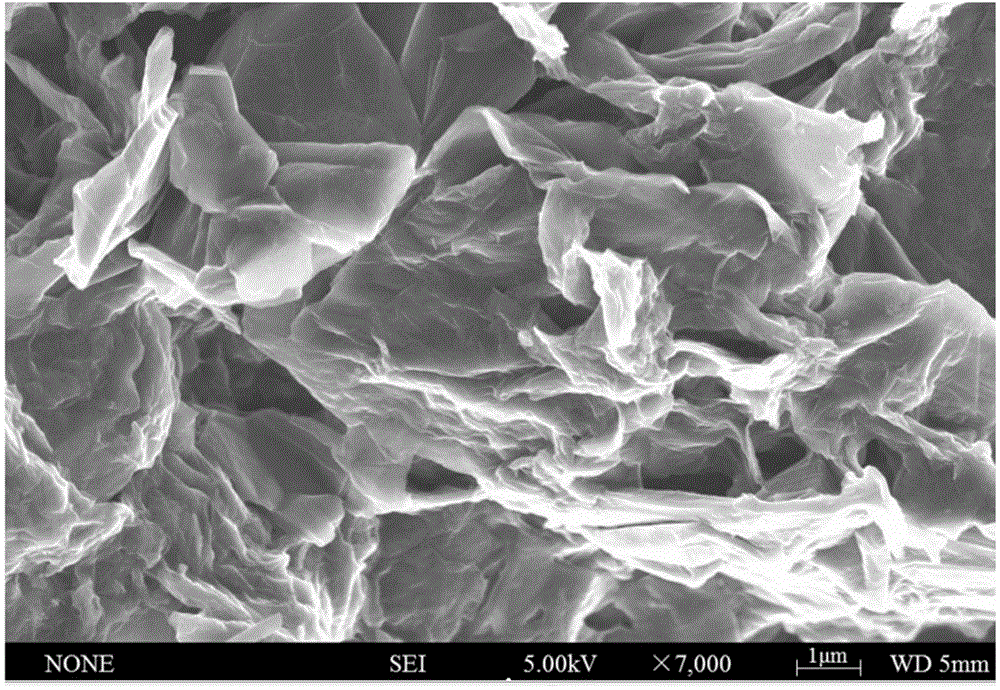

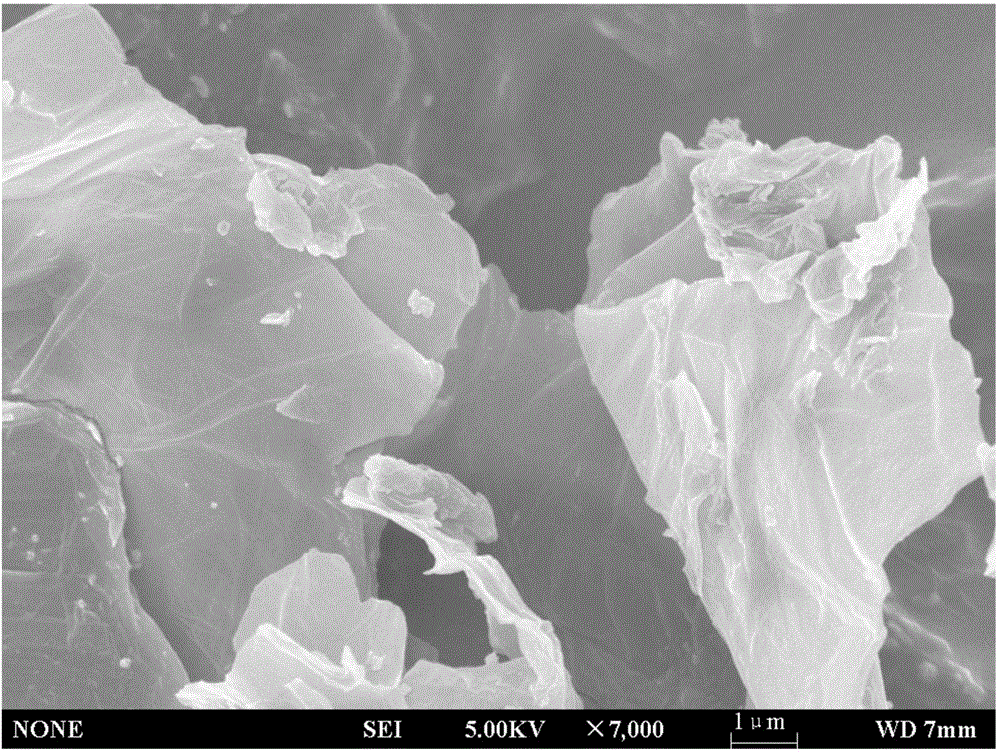

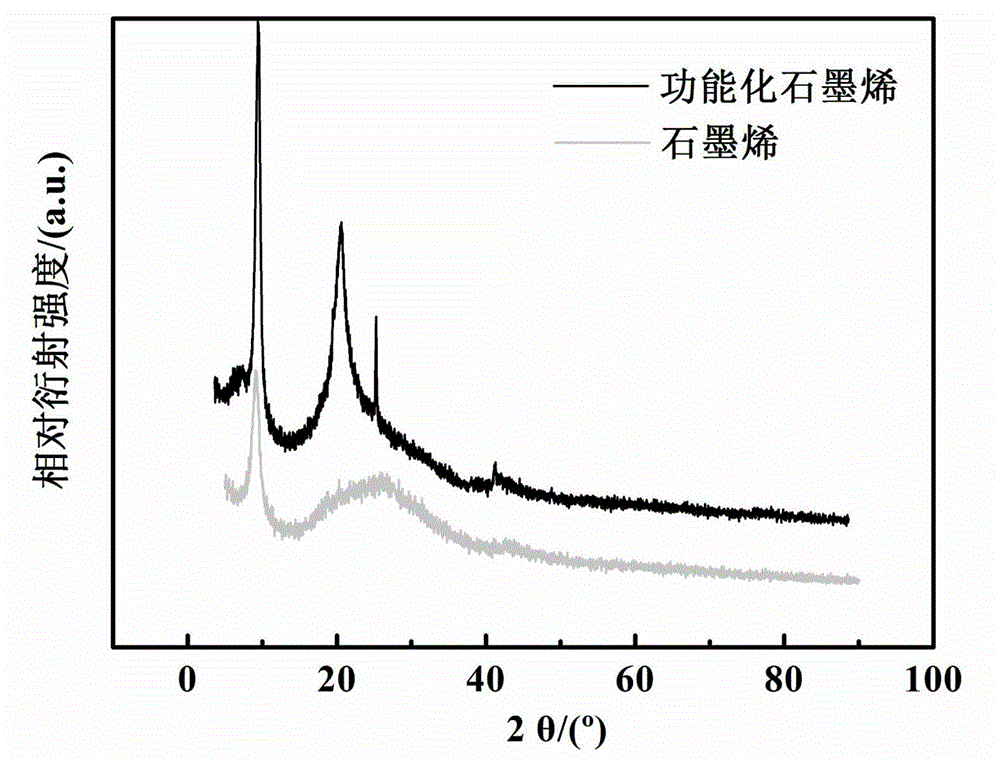

ActiveCN102974307AReduce agglomerationHigh specific surface areaOther chemical processesWater contaminantsEngineeringAmmonium bromide

The invention discloses a functionalized graphene adsorbent and a preparation method and application of the functionalized graphene adsorbent. The adsorbent is mainly composed of grapheme and cetyl trimethyl ammonium bromide. The cetyl trimethyl ammonium bromide inserts into the edge or surface layer of the layered grapheme and or embeds into the edge or surface layer of the layered grapheme through the function of non-covalent bond. The mass fraction of the cetyl trimethyl ammonium bromide in the adsorbent is 40%-50%. The invention discloses the preparation method of the functionalized graphene adsorbent. The method comprises the steps of dispersing the graphene oxide into the water, adding cetyl trimethyl ammonium bromide to the dispersed suspension liquid and stirring to make reaction, then adding suspension liquid to the heated reaction system and conducting suction filtration, washing and drying to the black cotton-shaped precipitate obtained by reduction. The functionalized graphene adsorbent can wipe out the chrome in the waste. The adsorbent is added into the chromate waste water, control the temperature of the waste, then after the full adsorption and complete oscillatory removal of the chromate is completed. The functionalized graphene adsorbent and a preparation method and application of the functionalized graphene adsorbent has the advantages of being simple, high efficient, green, economical and environmental and the like.

Owner:湖南红普创新科技发展有限公司

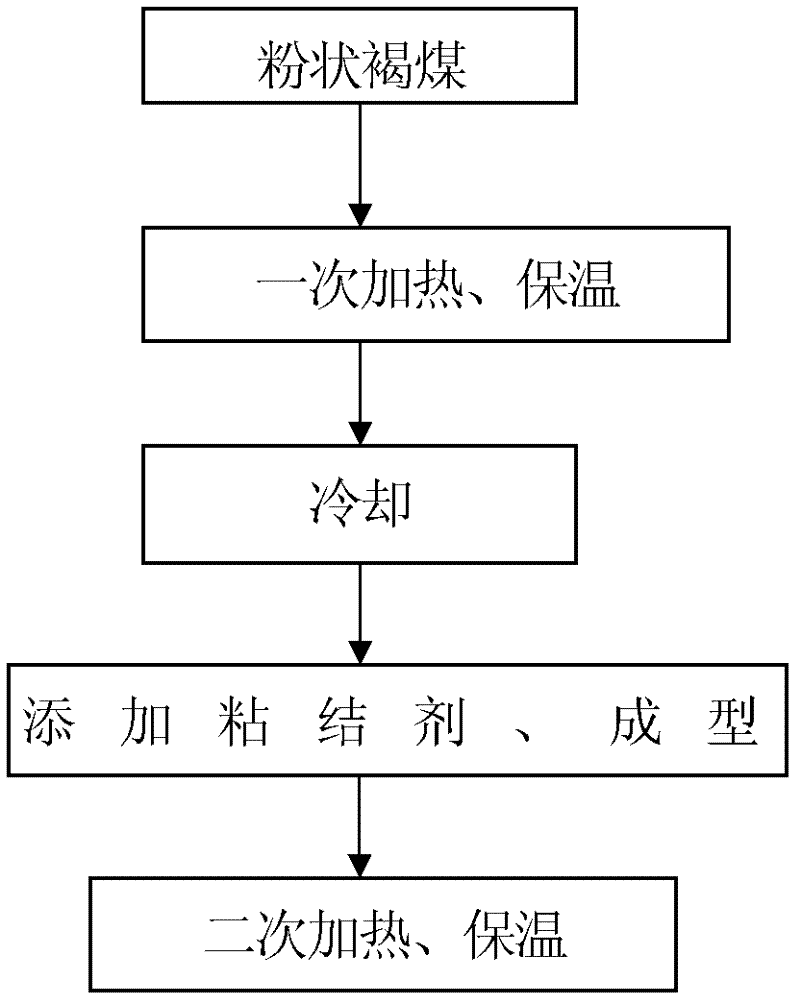

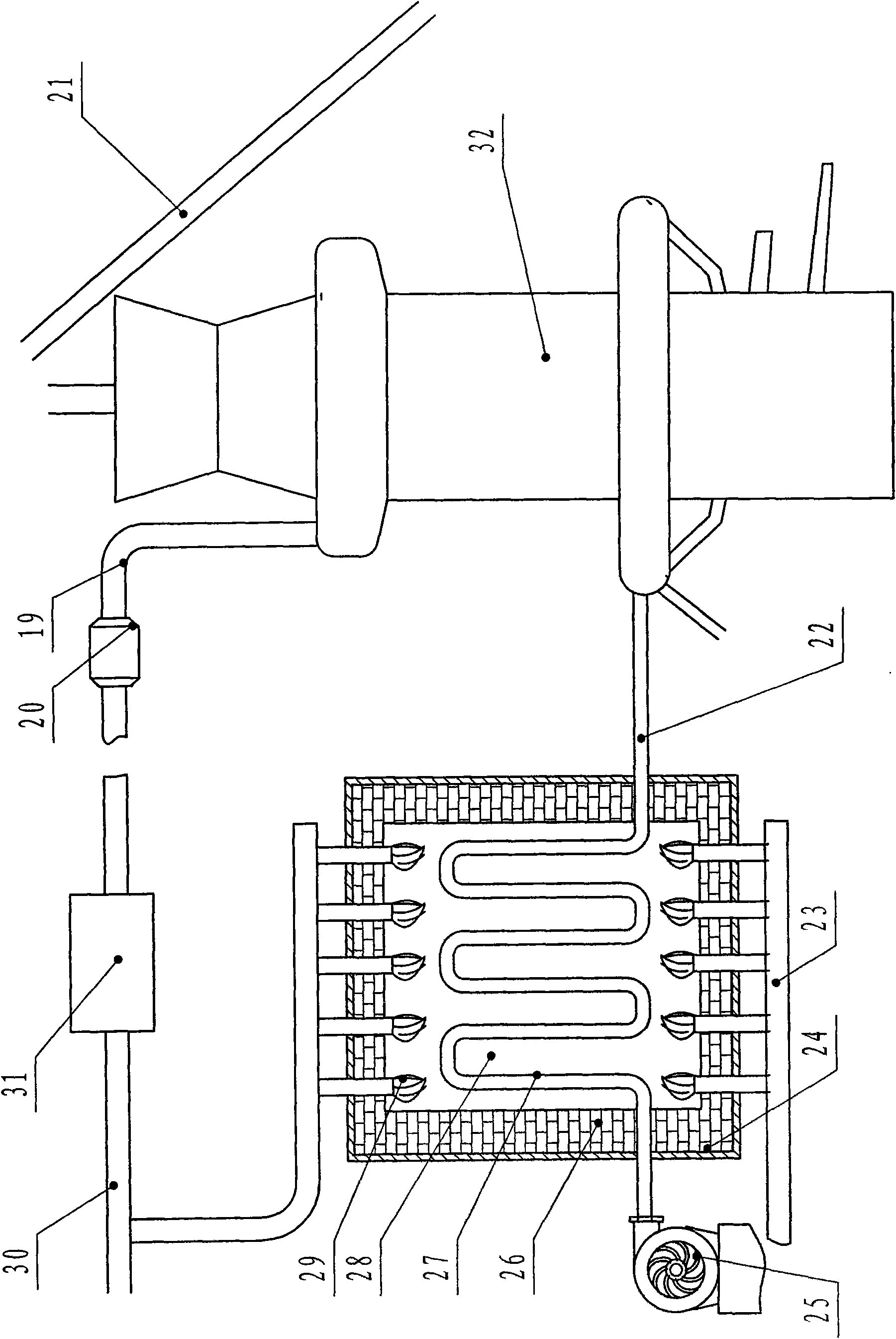

Technology for processing pulverized lignite

The invention discloses a technology for processing pulverized lignite. The technology comprises the followings steps of: firstly, heating pulverized lignite to 100-1000 DEG C, and then heat-preserving for 1-5h; secondly, cooling the lignite processed and obtained in the first step below 100; thirdly, then adding a binding agent, and uniformly stirring to form; fourthly, heating the formed lignite to 100-1000 DEG C and heat-preserving for 1-5h. According to the technology for processing the pulverized lignite disclosed by the invention, the lower calorific value of finally obtained products is greatly increased compared with that of the raw coal and is increased by more than 2 times compared with that of the raw coal before modification; all water is nearly completely removed, volatile components are greatly reduced, the content of solid carbon is greatly improved, and yield of condensed water is greater; and compared with the prior art, the technology for processing the pulverized lignite disclosed by the invention has lower cost, and the obtained products can be convenient to transport and has high calorific value.

Owner:QIANQIU ENERGY SHANGHAI

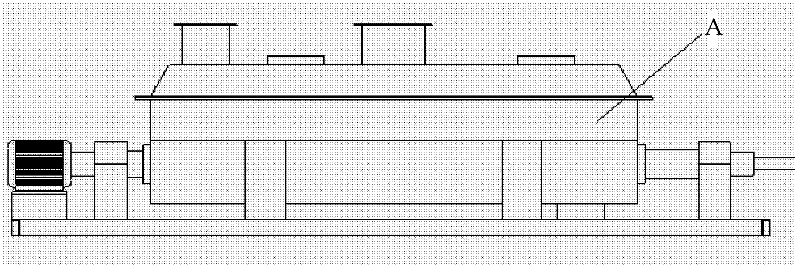

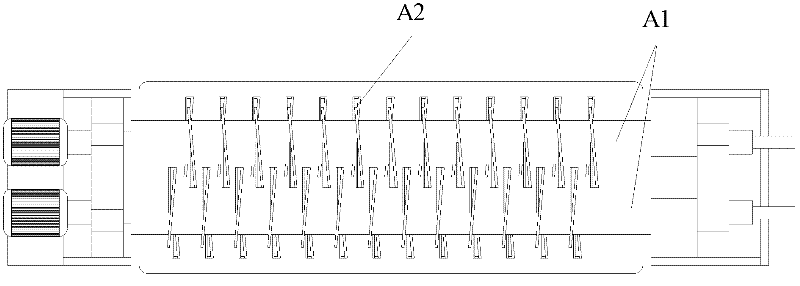

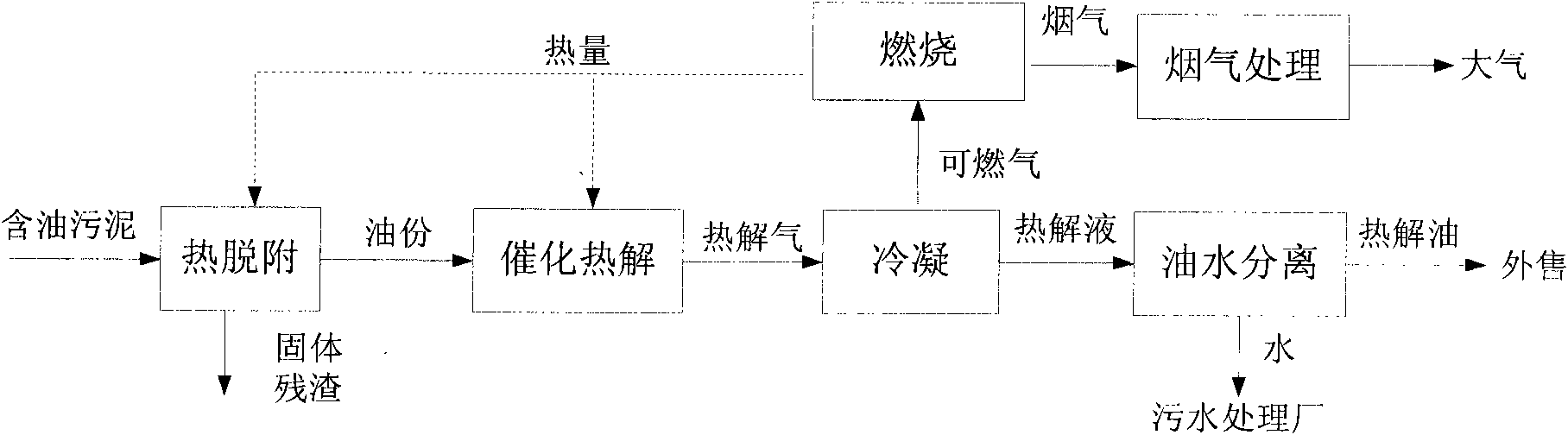

Recycling treatment method of oil-bearing sludge

InactiveCN101774741ARealize resourcesAchieve reductionCatalytic crackingSludge treatment by pyrolysisCatalytic pyrolysisSludge

The invention discloses a treatment method of oil-bearing sludge. The method comprises the following steps of: firstly, carrying out thermal desorption treatment on the oil-bearing sludge to obtain an oil component in the oil-bearing sludge; and then, carrying out catalytic pyrolysis on the oil component, carrying out oil-gas-water separation after condensing the precipitated gas, and collecting recovered oil and combustible gas. The two-stage treatment method for carrying out the thermal desorption and the catalytic pyrolysis on the oil-bearing sludge, which is provided by the invention, can effectively separate oil and sand, also obtains the recovered oil with high added value, generates the combustible gas, can realize recycle at the inside of a system and has high total recycling utilization level and good process economy. Compared with other treatment techniques, the technique has the advantages of high recovery rate of oil resources, good economy, strong adaptability and small secondary pollution and is a recycling treatment technique of the oil-bearing sludge, which can realize the recycle of resources and energy resources simultaneously and is worth popularizing.

Owner:TSINGHUA UNIV

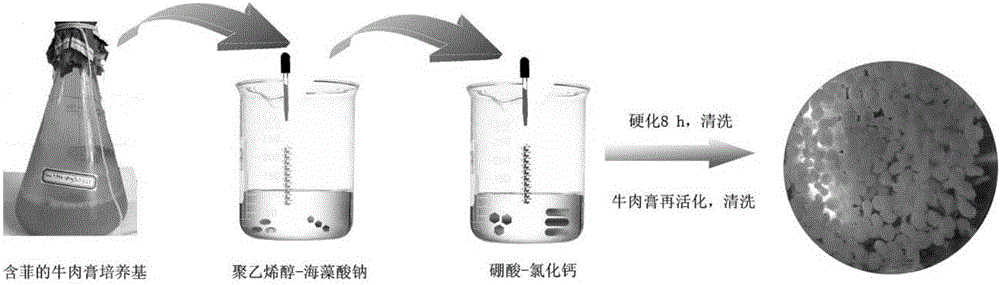

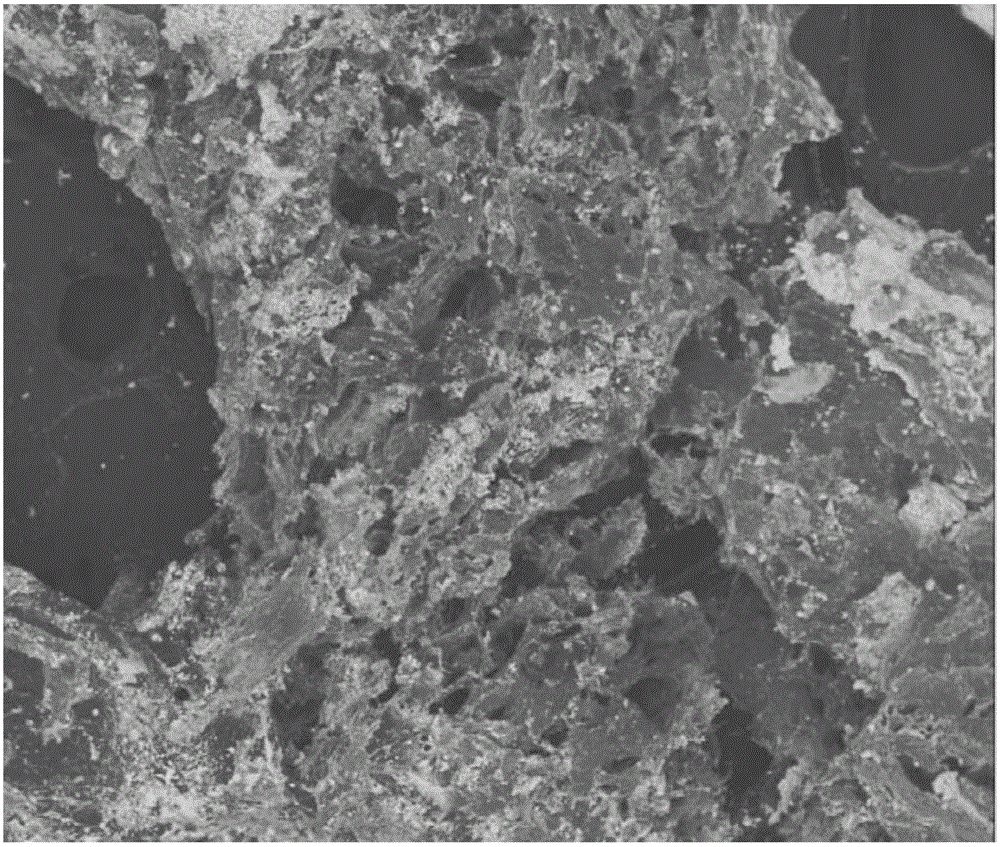

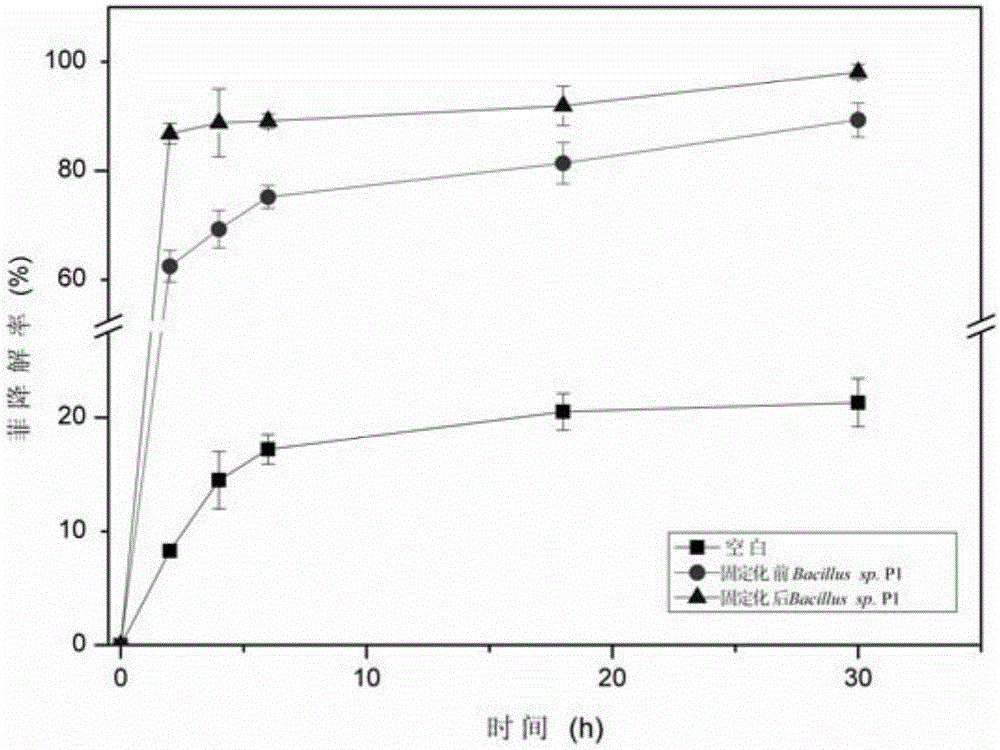

Compound microbial agent as well as preparation method and application thereof

InactiveCN105018458AEfficient degradationStrong processing effectWater contaminantsMicroorganism based processesMicrobial agentChemistry

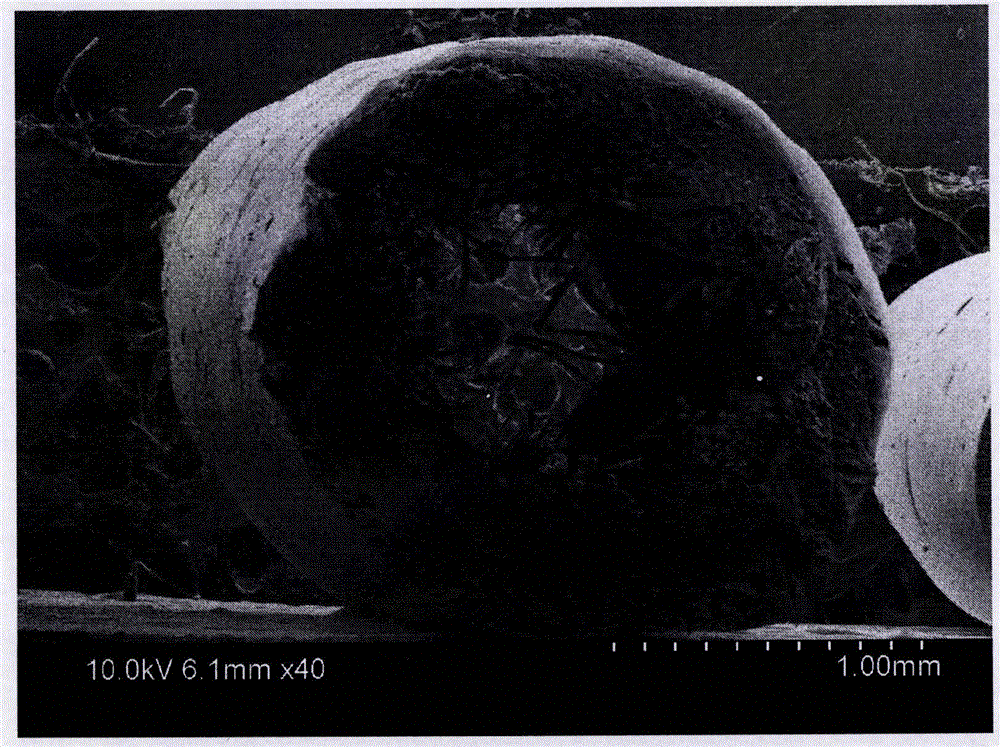

The invention discloses a compound microbial agent as well as a preparation method and application thereof. The compound microbial agent comprises bacillus, an embedding carrier and a cross-linking agent, wherein bacillus is immobilized in the embedding carrier via the cross-linking agent. The preparation method comprises the following steps: inoculating bacillus into a culture medium containing phenanthrene to undergo aerobic culture, thus obtaining a bacterial liquid; concentrating the bacterial liquid, adding the concentrated bacterial liquid to the embedding carrier to obtain a mixed liquid containing the bacterial liquid, and then dropwise adding the mixed liquid containing the bacterial liquid in the cross-linking agent to undergo cross-linking hardening to form a bacillus gel pellet; then carrying out aerobic culture, thus obtaining the compound microbial agent. The compound microbial agent can quickly and efficiently degrade high-concentration phenanthrene in wastewater under the condition that the wastewater contains high-concentration Pb<2+>. The preparation method has the advantages of simple process, low production cost, and the like.

Owner:HUNAN UNIV

Method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material

ActiveCN101654738AMeet production needsLow process costBlast furnace detailsShaft furnaceSodium BentoniteSlag

The invention relates to a method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material, which comprises the steps of mixing, briquetting, dosing, smelting and producing the molten iron; wherein (1) mixing: evenly mixing the dedusting ash, bentonite, cement, solvent, iron scale or scrap iron and water; (2) briquetting: putting the mixed material into a briquetting machine to be briquetted; (3) dosing: 60-80 parts by weight of block mass, 30-50 parts by weight of coke and 3-12 parts by weight of solvent; or 60-80 parts by weightof block mass, 30-50 parts by weight of coke, 3-12 parts by weight of solvent and 6-20 parts by weight of slag-metal; (4) smelting: adding the prepared raw materials into a novel shaft furnace or a minitype blast furnace provided with a single iron notch and a single air inlet to be smelted; and (5) producing the molten iron: sending the smelted molten iron into steel plants or casting into iron ingots. Or in step (3), 6-20 parts by weight of slag-metal can be added into the material. The smelting method is low in production cost and high in content of chromium and nickel of the product.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

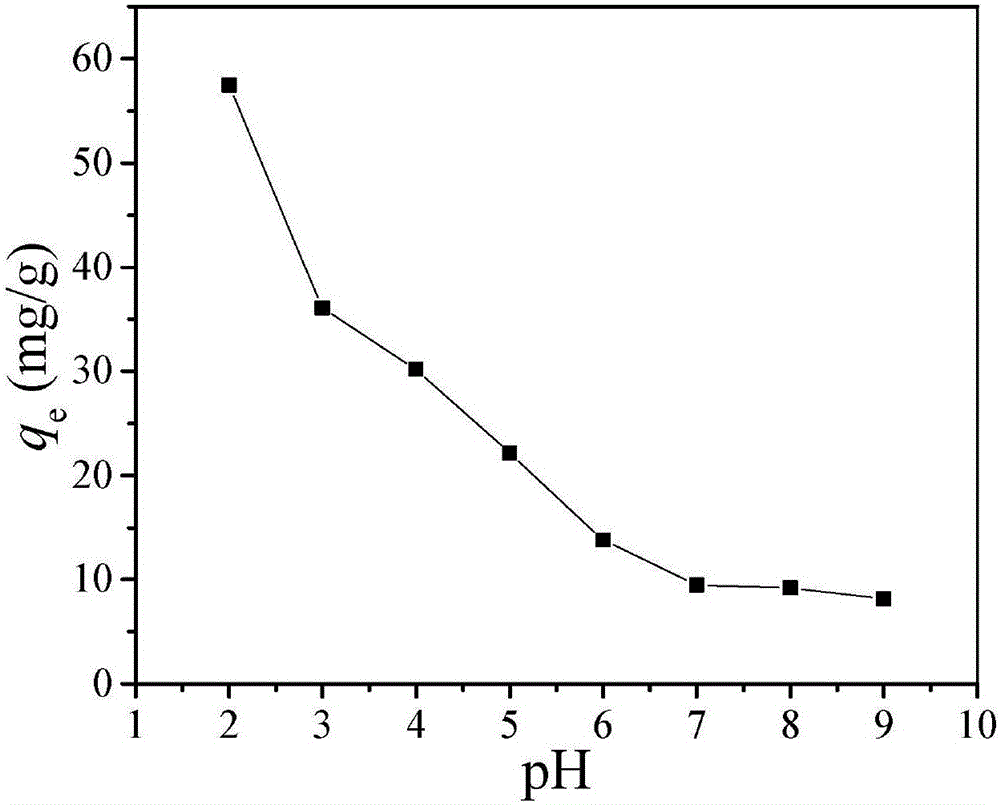

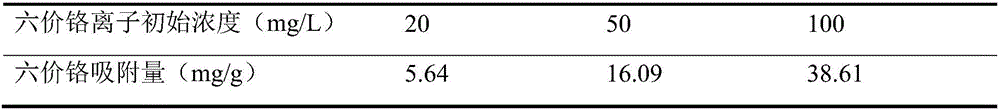

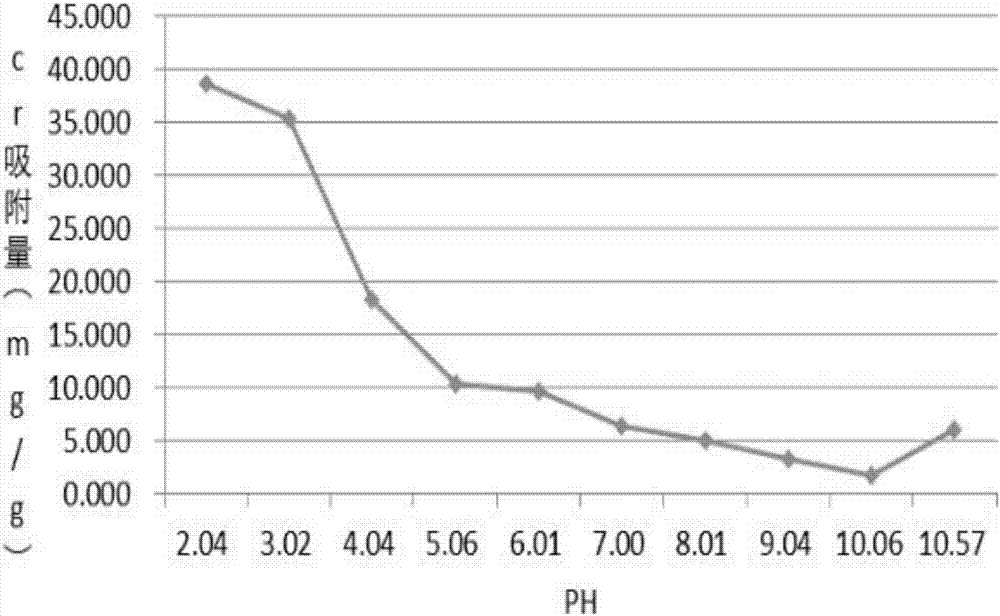

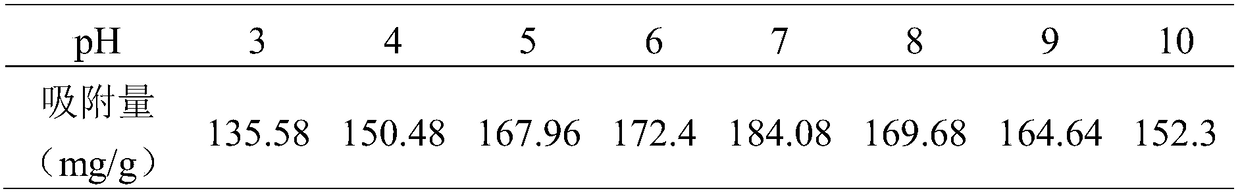

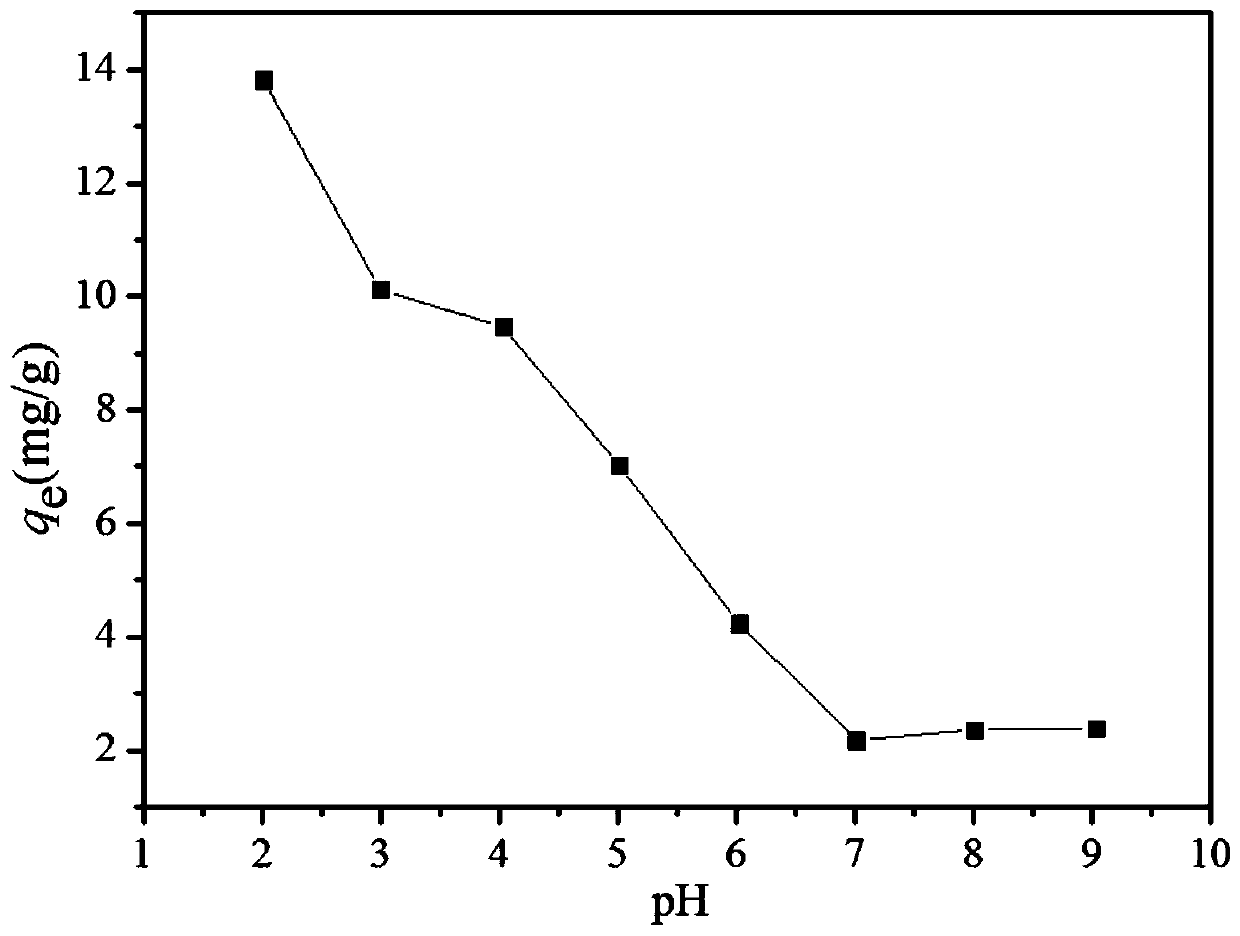

Method for removing hexavalent chrome in wastewater by using sodium humate/biochar magnetic composite material

ActiveCN106315742AExtensive sources of raw materialsWide variety of sourcesWater treatment parameter controlOther chemical processesDry weightWastewater

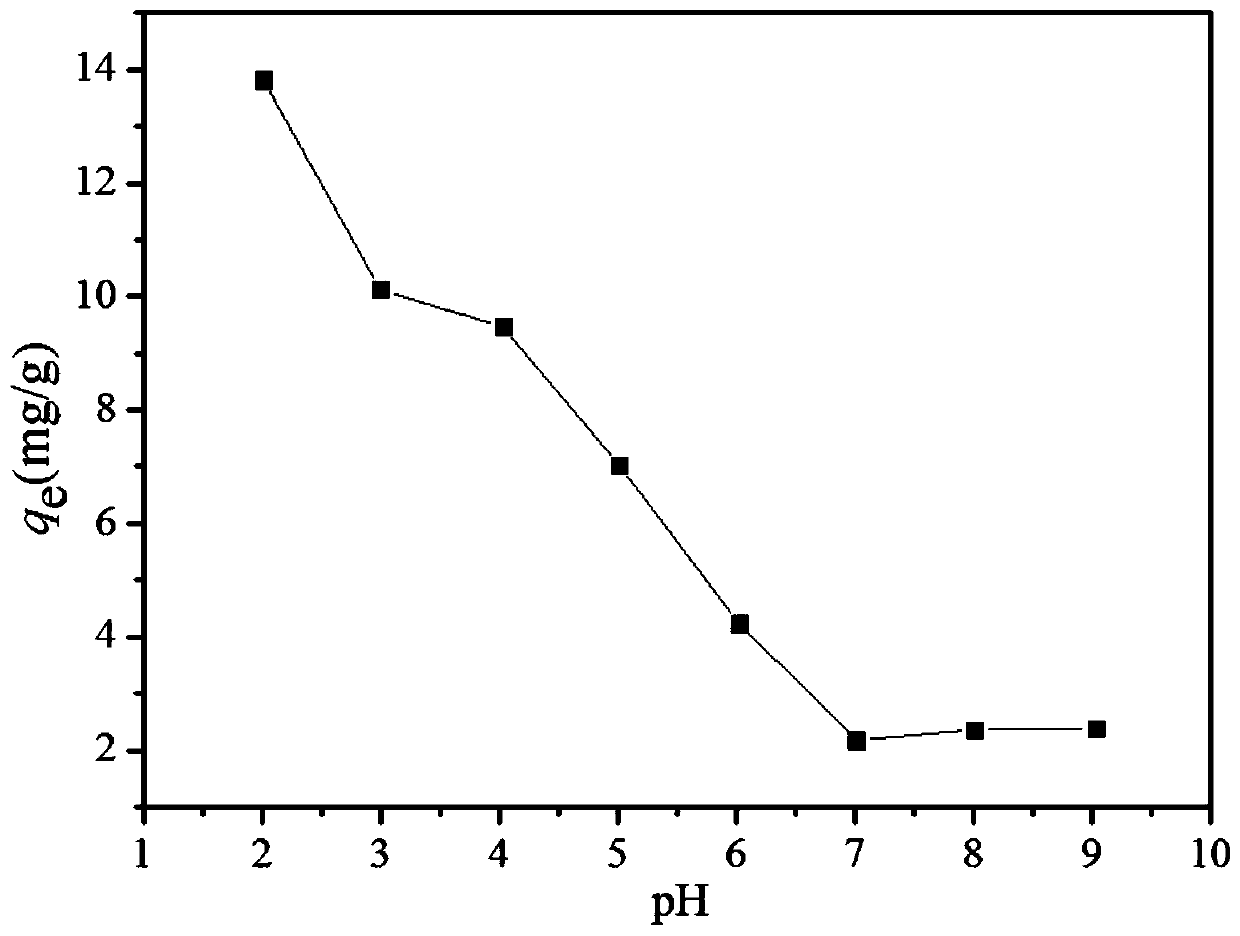

The invention discloses a method for removing hexavalent chrome in wastewater by using a sodium humate / biochar magnetic composite material. The method comprises the following steps: taking a certain amount of hexavalent chrome wastewater, regulating the pH value to 2.0-10.0 (preferably 2.0-6.0, and most preferably 2.0), and adding a certain amount of the sodium humate / biochar magnetic composite material into the wastewater, wherein the dry weight of the sodium humate / biochar magnetic composite material for every liter of wastewater is 0.5-10g; reacting in a constant-temperature oscillator at the speed of 100-300 rpm for 0-24 hours (most preferably 1-6 hours) while controlling the reaction temperature at 10-50 DEG C (most preferably 30-40 DEG C); and after the reaction finishes, separating the sodium humate / biochar magnetic composite material from the solution, thereby removing the hexavalent chrome from the wastewater. The method has the advantages of low cost, high treatment efficiency and the like, and is convenient to operate. The method can be used for treating hexavalent-chrome-containing wastewater in electroplating factories, smelteries, electronic factories and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

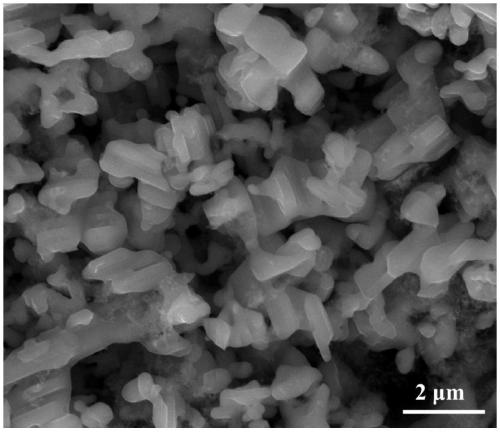

Lamellar MXene material and preparation method thereof and energy storage material

PendingCN110304632ALow costLow process costMaterial nanotechnologyCell electrodesMaterials preparationMolten salt

The invention provides a lamellar MXene material preparation method and a battery material thereof. The method includes: directly forming a raw material mixture according to a stoichiometric ratio, wherein a structural formula of a multi-element conductive ceramic material is (M1-xYx)n+1ACn, n is equal to 1, 2 or 3, x is greater than or equal to 0 and less than or equal to 1, M and Y are transition metal elements, A refers to an IIIA or IVA element with an atomic number greater than 13, and C refers to carbon; in an inert atmosphere, subjecting the raw material mixture to reaction in molten salt, and cooling after reaction is finished; removing the molten salt from a product mixture to obtain the multi-element conductive ceramic material; subjecting A atoms in the conductive ceramic material to corrosion to obtain a lamellar MXene material. At least one of problems including high synthesis temperature, complexity in preparation process and equipment, high cost and the like of an existing MXene material can be solved, and the method has advantages of quickness, high efficiency, energy saving, environmental friendliness, low cost, easiness in implementation of large-scale productionand the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

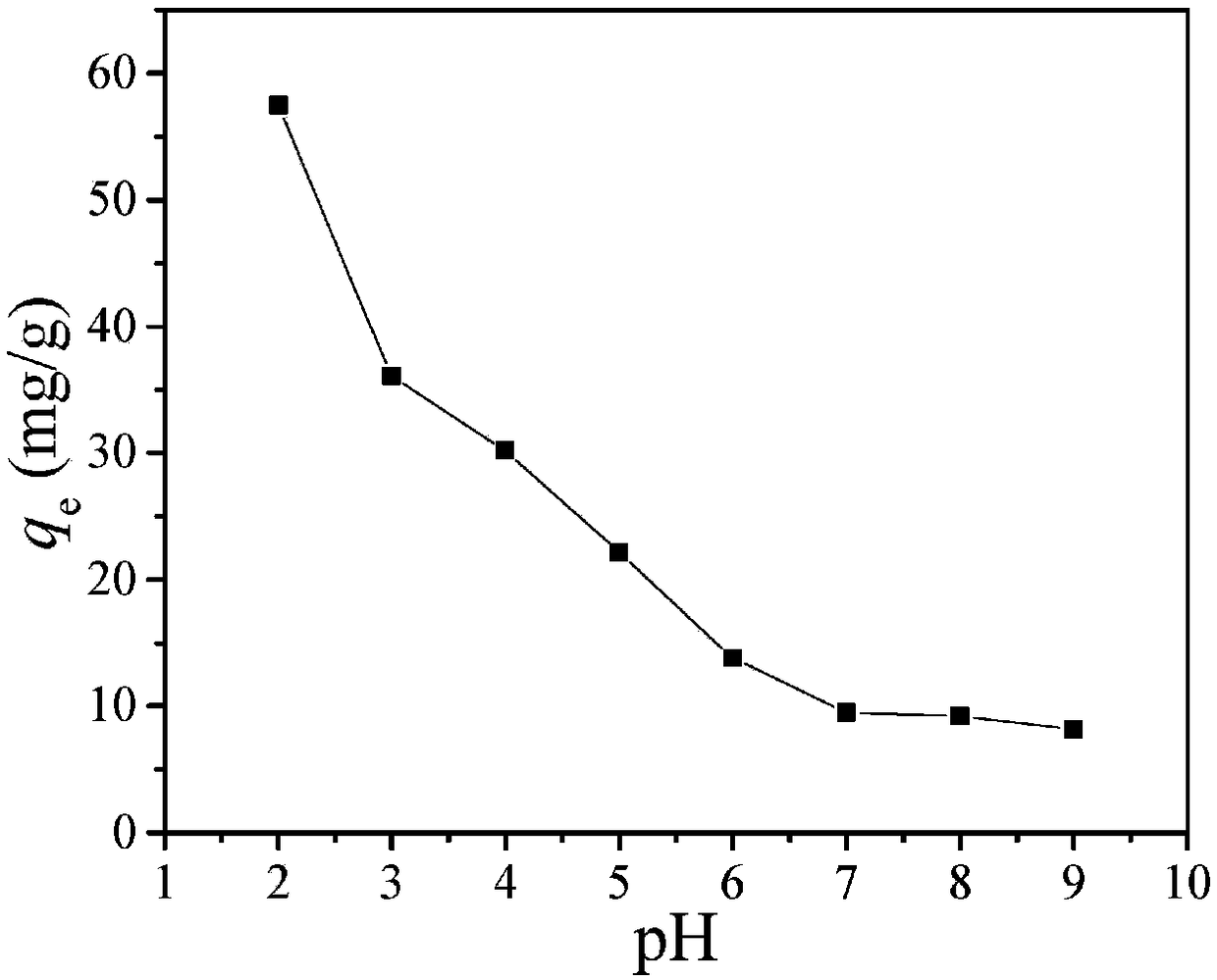

Method for removing divalent cadmium in wastewater by using carboxylated magnetic graphene oxide

InactiveCN104045123AWide variety of sourcesLow priceWater/sewage treatment by sorptionDry weightWastewater

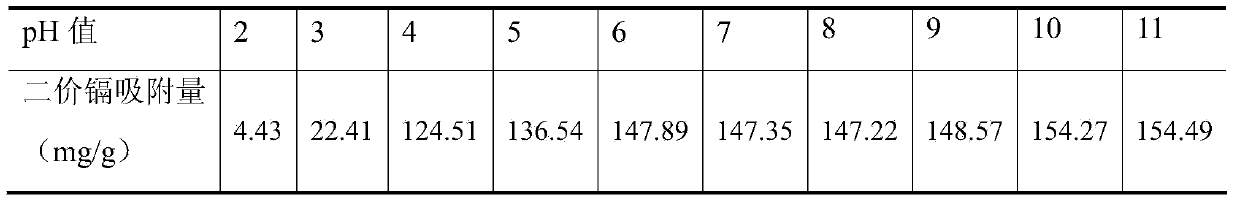

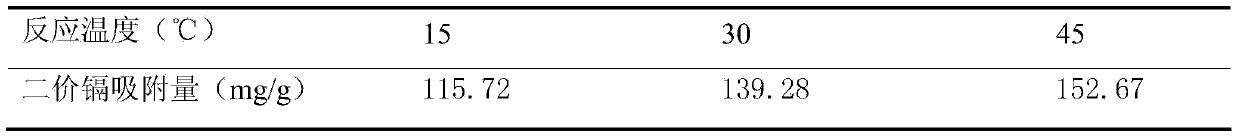

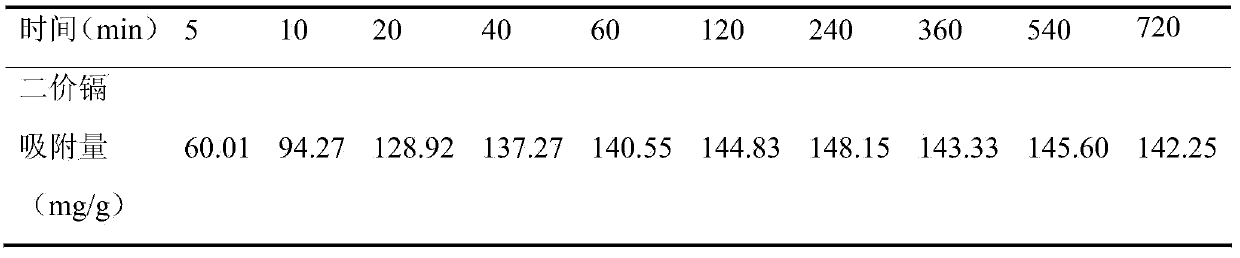

The invention discloses a method for removing divalent cadmium in wastewater by using carboxylated magnetic graphene oxide. The method comprises the following steps of taking a certain quantity of divalent cadmium wastewater, and regulating the pH value of the divalent cadmium wastewater to 2.0-11.0 (preferably 5.0-7.0, most preferably 6); adding a certain quantity of carboxylated magnetic graphene oxide into the wastewater, wherein the dry weight of carboxylated magnetic graphene oxide added in every liter of wastewater is 0.02-5g; reacting in a constant-temperature oscillator with the rotating speed of 50-300rpm for 0-24h (most preferably 1-6h) while controlling the reaction temperature at 10-50 DEG C (most preferably 20-40 DEG C); separating carboxylated magnetic graphene oxide from the solution after the reaction is ended to finish the removal of divalent cadmium in wastewater. The method has the advantages of low cost, convenience in operation, high treatment efficiency, easiness for separation and recovery and the like.

Owner:HUNAN UNIV

Formula of high-transmittance zirconia ceramic, preparation method of paste and manufacturing method of dental crown

PendingCN113336542AHigh viscosityHigh strengthImpression capsAdditive manufacturing apparatusPhotoinitiatorYttria-stabilized zirconia

The invention provides a high-permeability zirconia ceramic dental crown material and a preparation method thereof and a manufacturing method of a high-permeability zirconia dental crown. The high-permeability zirconia ceramic dental crown material is prepared from the following raw materials in parts by weight: 81-90 parts of yttria-stabilized zirconia ceramic powder, wherein the content of yttrium oxide in the yttria-stabilized zirconia ceramic powder is 4 mol%-6 mol%; 10-19 parts of a photosensitive resin premixed liquid; 0.01-0.2 part of a defoaming agent; 0.01-10 parts of a dispersant; 0.01-10 parts of a leveling agent; 0.02-4 parts of a photoinitiator; and 1-10 parts of a rheological additive. The method has the advantages of high raw material utilization rate, low process cost and high surface precision, and the prepared molded dental crown is good in quality, high in strength and good in aesthetic effect.

Owner:江苏京科智镕新材料科技有限公司

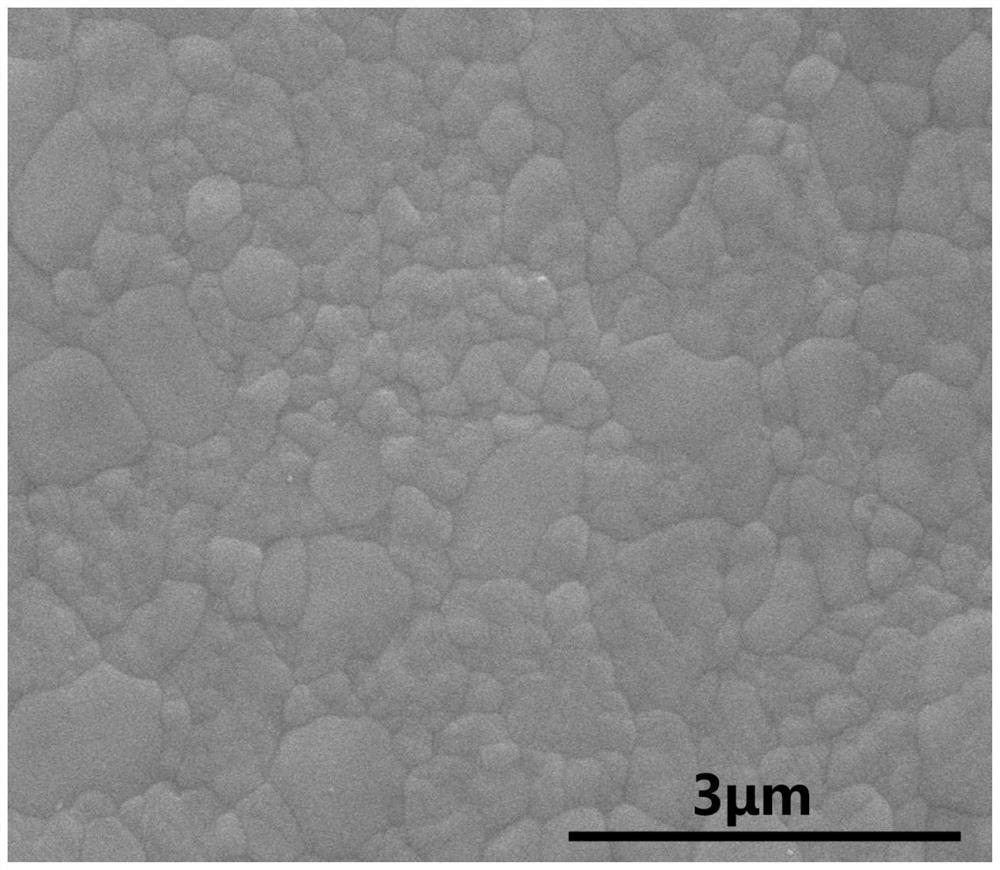

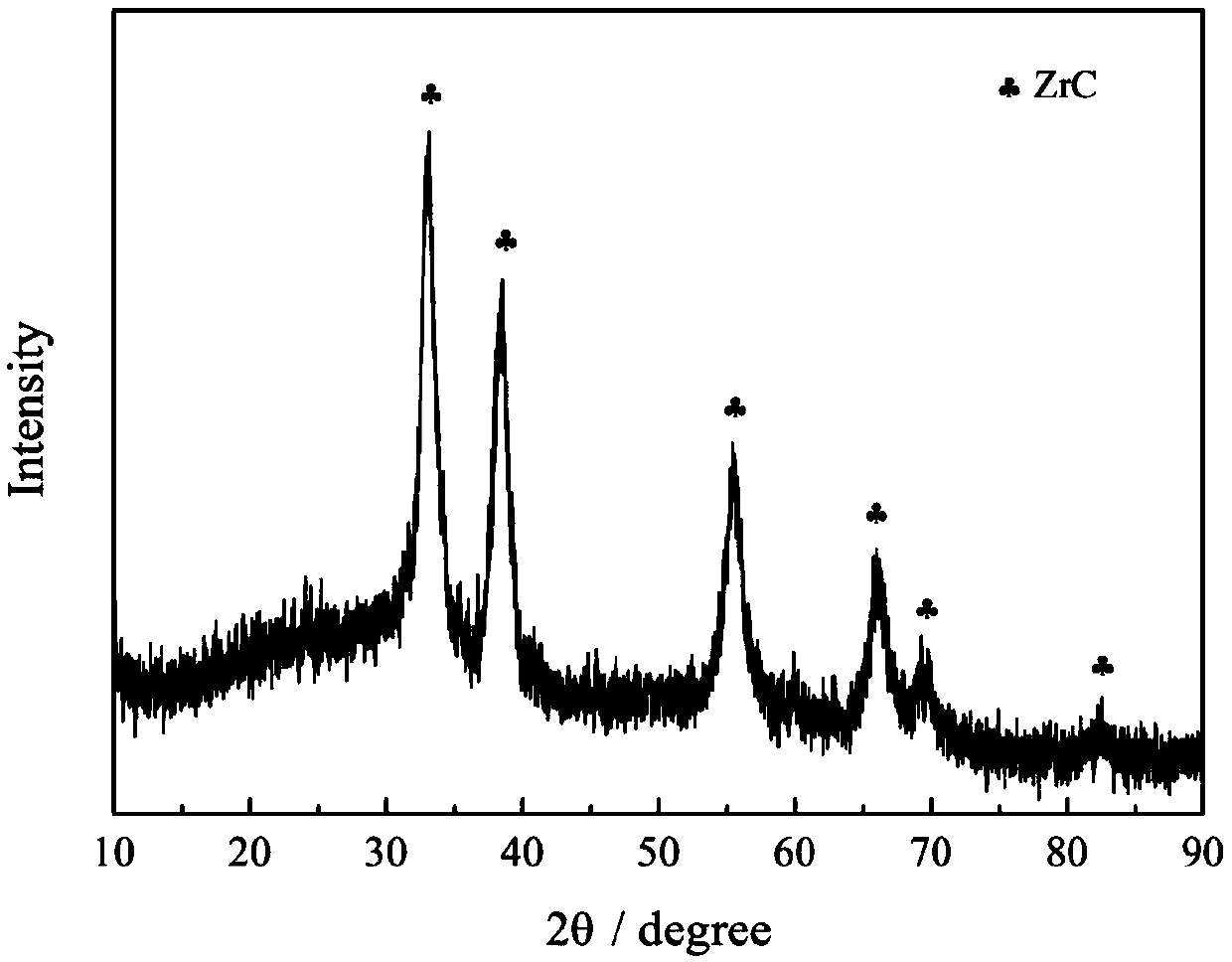

Method for in-situ preparation of zirconium, hafnium or vanadium carbide powder by molten salt disproportionation reaction

The invention relates to the technical field of preparation of transition metal carbide powder materials, in particular to a method for in-situ preparation of ZrC, HfC or VC powder in situ through molten salt disproportionation reaction. The method comprises directly forming a raw material mixture according to the stoichiometric ratio, with the structural formula of transition metal carbide beingMC, M being a transition metal element zirconium or hafnium or vanadium, and C being a carbon element; reacting the raw material mixture in molten salt in an inert atmosphere, and cooling after the reaction is finished to obtain a product mixture; and removing the molten salt in the product mixture to obtain ZrC, HfC or VC powder. The method can solve one or more of the problems of high ZrC, HfC or VC powder synthesis temperatures, complex preparation processes and equipment, high costs, uncontrollable morphology and sizes and the like in the prior art, and has the advantages of rapidness, high efficiency, energy saving, environmental protection, a low cost, easy realization of large-scale production and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of low-As-content tree moss absolute oil

ActiveCN106318617AReduce processing costsWill not affect the qualityEvaporator accessoriesFatty-oils/fats refiningFlavorAlcohol

A preparation method of low-As-content tree moss absolute oil comprises the following specific steps that 1, a tree moss raw material is soaked with water of 15-30 times of the amount of the tree moss raw material for 0.5 -2 hours, the soaked tree moss raw material is naturally air-dried, 100-mesh screening is performed after smashing, extraction is performed by using 65%-95% ethyl alcohol or petroleum ether, an extract is concentrated till no solvent is evaporated after extraction, and tree moss extract is obtained; 2, 95% ethyl alcohol 3-6 times of the mass of the extract is added to the tree moss extract for redissolution, freezing is performed at the temperature of 10-30 DEG C for 8-24 hours after full stirring and dissolution, insoluble substances are filtered out, the solution is concentrated till no solvent is dissolved, and the low-As-content tree moss absolute oil is obtained. The preparation method has the advantages that the operation is simple, the As content in the tree moss absolute oil is reduced under the coordinating effect of two treatment processes, no adverse influence is produced on the perfume quality of the final tree moss extract, the fragrance is purer, and the product quality is better. In addition, a preparation method is low in cost and suitable for large-scale industrial production.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method of enhanced chlorinated polyvinyl chloride hollow fiber membrane

InactiveCN106693725AImprove mechanical propertiesSolve the problem of high brittleness and easy wire breakageSemi-permeable membranesPolymer scienceFoaming agent

The invention discloses a preparation method of a chlorinated polyvinyl chloride (CPVC) hollow fiber membrane. The preparation method comprises the following process steps: (1) preparing fibers into a hollow braided tube by adopting a two-dimensional braiding technology, and taking the hollow braided tube as a hollow fiber membrane enhancement body; (2) preparing a CPVC casting solution from the following components in percentage by weight: 15 to 35 percent of CPVC, 5 to 20 percent of pore-foaming agent, 2 to 10 percent of processing aid and 40 to 70 percent of organic solvent, totaling 100 percent; (3) coextruding the hollow braided tube obtained in the step (1) and the CPVC casting solution obtained in the step (2) through an annular spinning nozzle by adopting a co-extrusion compound spinning process, uniformly coating the surface of the hollow braided tube with the casting solution, and fully curing to obtain the enhanced CPVC hollow fiber membrane. The enhanced CPVC hollow fiber membrane prepared by the method has high toughness, is low in production cost, and has a wide practical application prospect; the problem of insufficient mechanical strength of an elemental CPVC hollow fiber membrane can be solved effectively.

Owner:康泽源(天津)科技发展有限公司

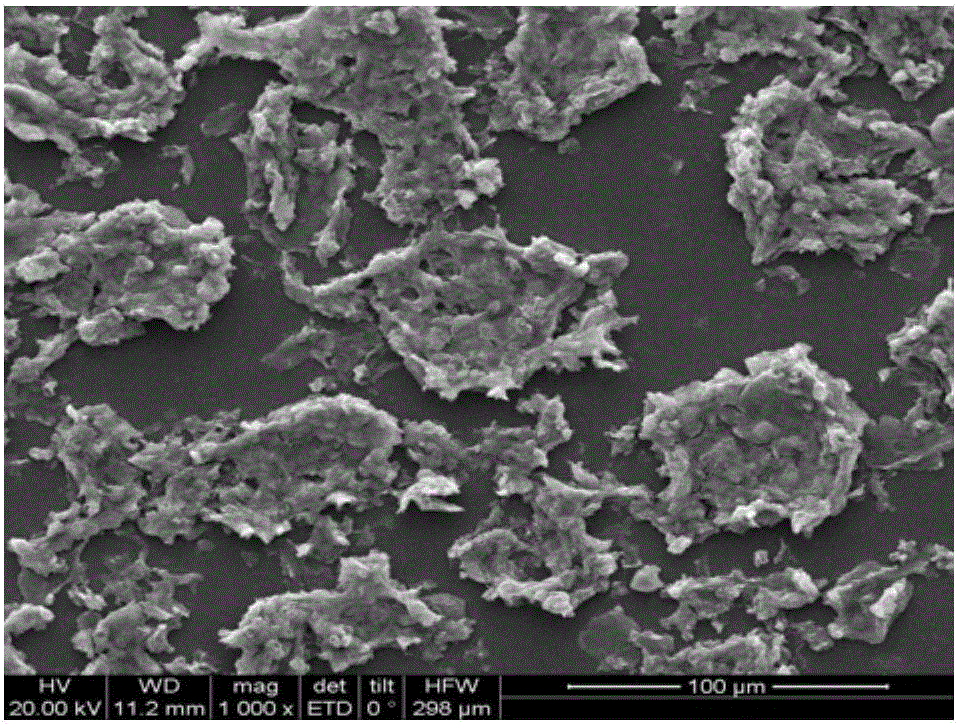

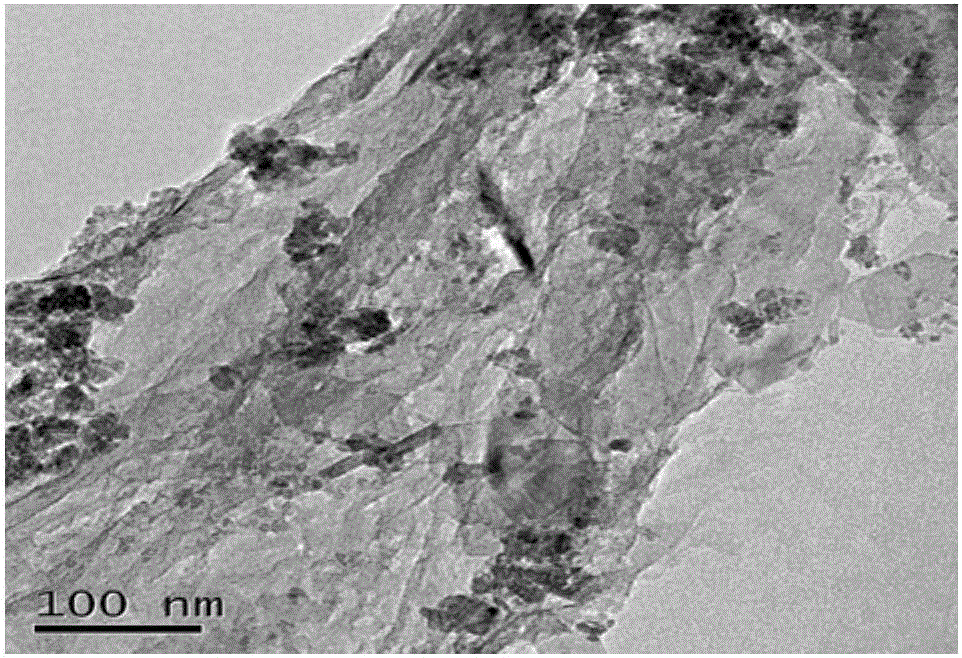

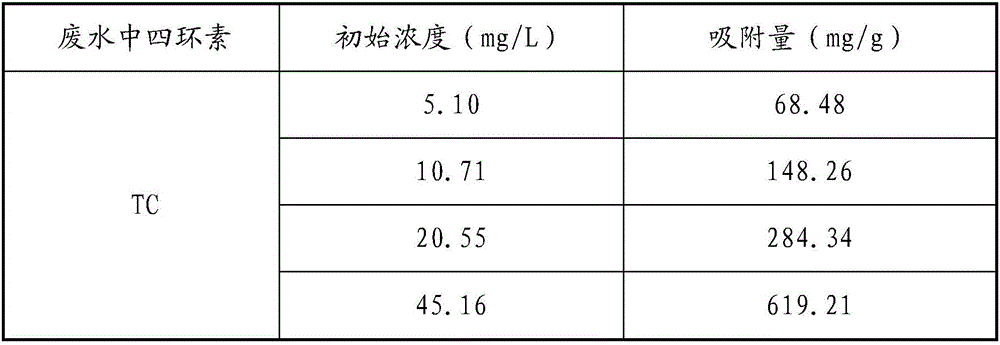

Thiourea dioxide reduced magnetic graphene oxide as well as preparation method and application of thiourea dioxide reduced magnetic graphene oxide

InactiveCN106824142AWide variety of sourcesLow priceOther chemical processesWater contaminantsFerrite nanoparticlesOxide matrix

The invention relates to thiourea dioxide reduced magnetic graphene oxide as well as a preparation method and application of the thiourea dioxide reduced magnetic graphene oxide. An adsorbent comprises a graphene oxide matrix; magnetic ferrite nanoparticles are loaded on the matrix. A preparation sequence is that graphite powder is pre-oxidized, graphene oxide and magnetic graphene oxide are prepared, and finally, the magnetic graphene oxide is reduced through thiourea dioxide. A product provided by the invention has a relatively good removing capability on tetracycline in a water body and has a high solid-liquid separation capability. The product can be used for treating tetracycline-containing wastewater in the fields of pharmacy, medical treatment, livestock and poultry breeding and the like.

Owner:SOUTH CHINA AGRI UNIV

Ethylenediamine-grafted magnetic graphene oxide, and preparation method and application thereof

InactiveCN107308913AExtensive sources of raw materialsLow priceOther chemical processesWater treatment compoundsNanometreFerrite nanoparticles

The invention discloses an ethylenediamine-grafted magnetic graphene oxide adsorbent which can be used for adsorption of hexavalent chromium in wastewater and has the advantages of low cost, a large specific surface area, high efficiency and easy separation, and a preparation method and application thereof. According to the invention, magnetic ferrite nanoparticles are assembled on the surface of graphene oxide, and then ethylenediamine is used for graft modification of the graphene oxide; and the prepared adsorbent can be rapidly separated through an external magnetic field and has more adsorption sites, which is beneficial for improvement of adsorption capacity. The whole process is low in cost, simple to operate and easy to implement, and ethylenediamine-grafted magnetic graphene oxide can be easily separated from a treated solution and be reused, so a novel approach is provided for treatment of pollution caused by heavy metals in wastewater.

Owner:SOUTH CHINA AGRI UNIV

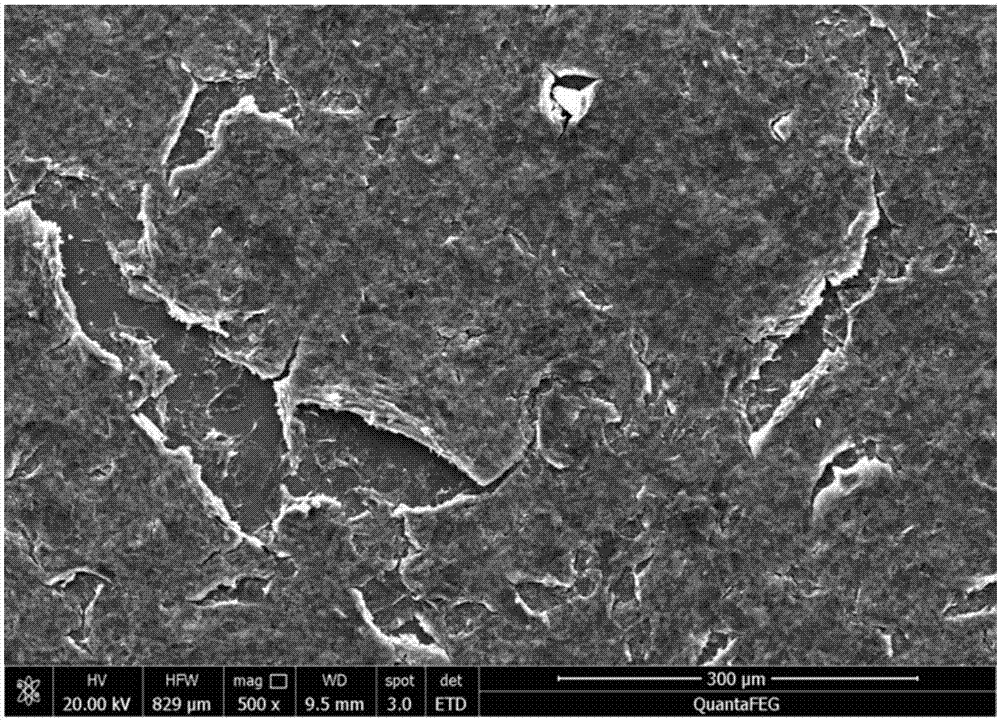

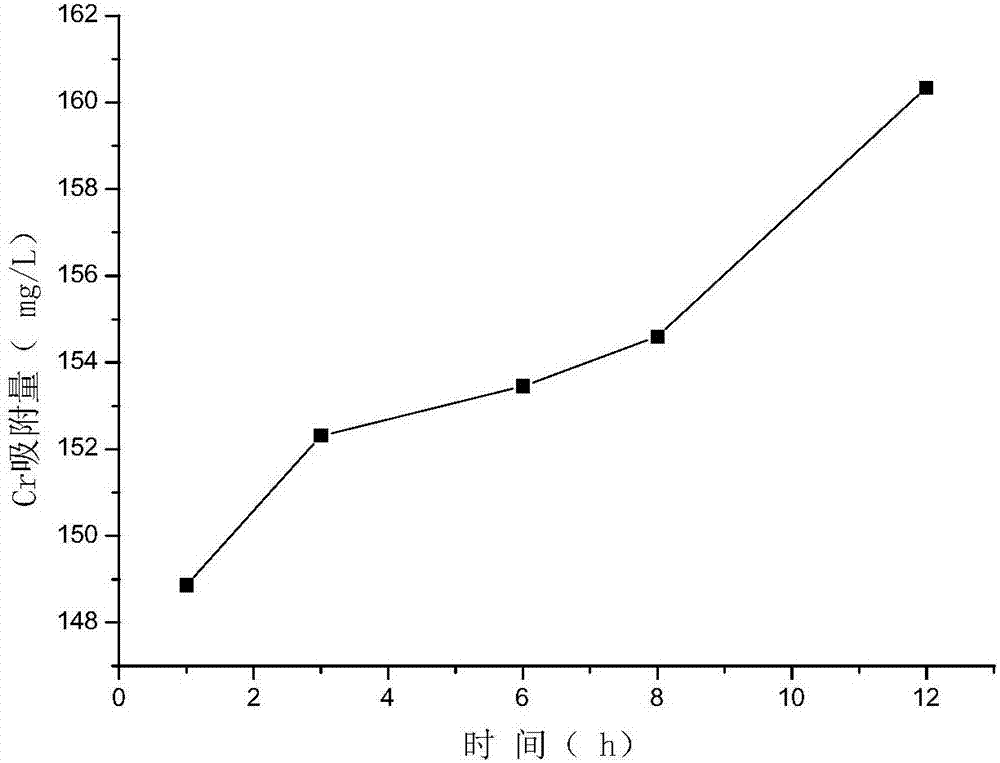

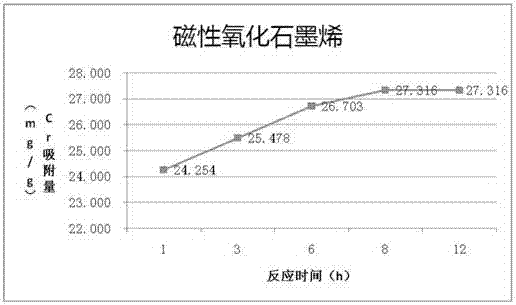

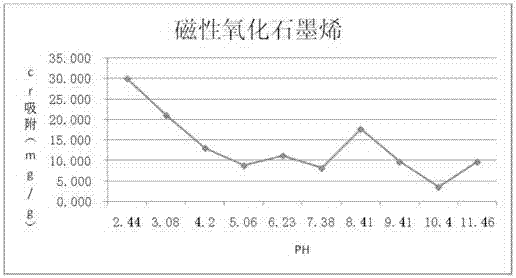

Preparation method for magnetic graphene oxide and application

ActiveCN107051411AWide variety of sourcesLow priceWater treatment parameter controlOther chemical processesReaction temperatureWastewater

The invention provides a method for preparing magnetic graphene oxide and removing hexavalent chromium from wastewater. The application method comprises the following steps: taking a certain amount of chromate wastewater and regulating the pH value to 2.0-11.0 (optimally 2.0-5.0); adding a certain amount of magnetic graphene oxide into the wastewater; reacting for 1-12h (optimally 8-12h) in a constant temperature oscillator at a rotation speed of 180 rpm; controlling the reaction temperature to 15 DEG C-45 DEG C (optimally 35-45 DEG C); and separating the magnetic graphene oxide from the solution after the ending of the reaction, thereby completing the removal of chromium ions from the wastewater. The method provided by the invention can effectively treat the wastewater containing chromium ions and can provide a new path for treating heavy metal pollutants in the wastewater.

Owner:SOUTH CHINA AGRI UNIV

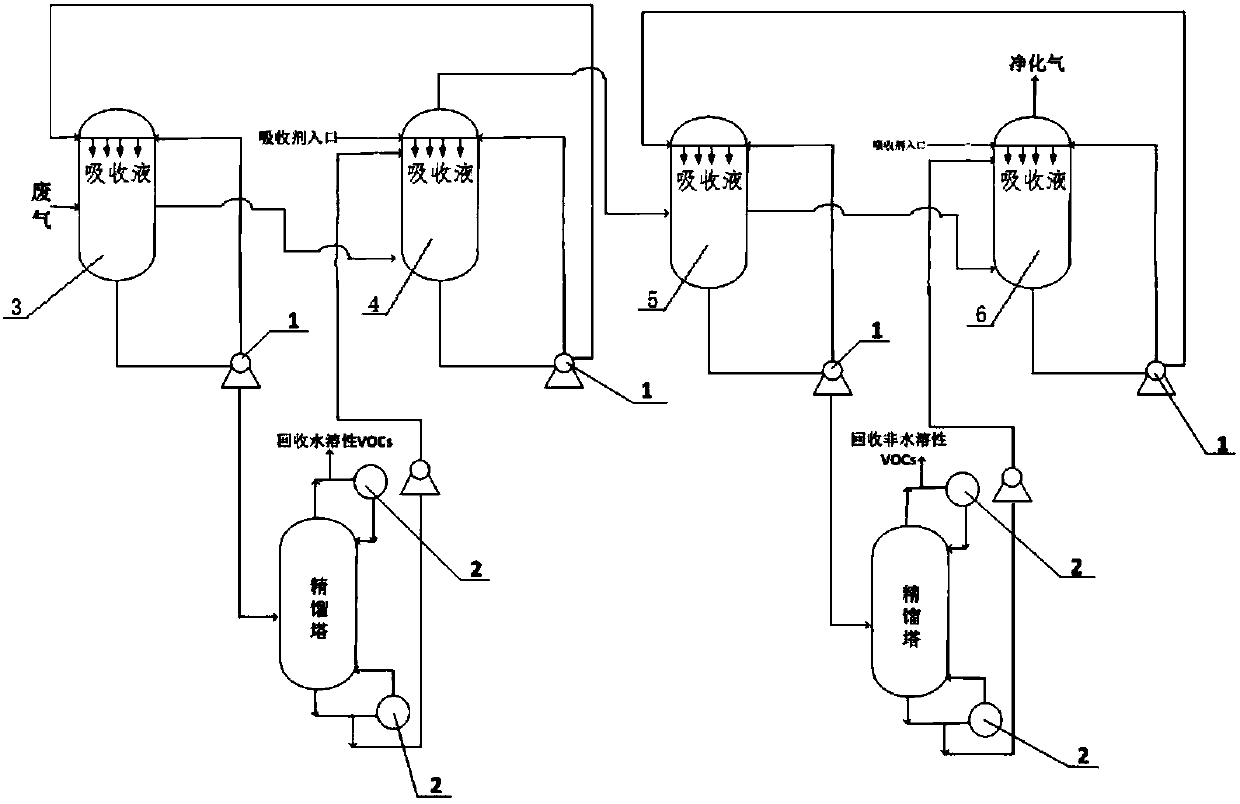

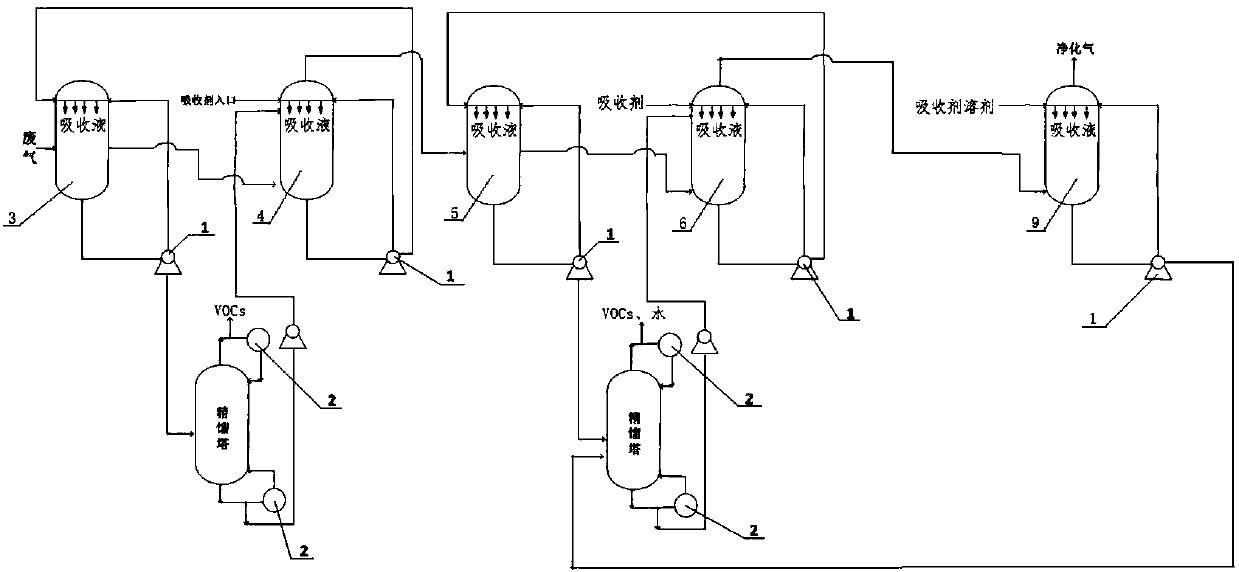

Treatment process of VOCs (volatile organic chemicals) waste gas

InactiveCN107774097AImprove purification efficiencyReduce exhaustGas treatmentDispersed particle separationWater insolubleEnvironmental engineering

The invention discloses a treatment process of VOCs (volatile organic chemicals) waste gas. The treatment process includes the steps: removing water-soluble VOCs; removing water-insoluble VOCs. Two steps adopt at least two serially connected waste gas absorption units. In the same removal step, absorbing agents enter from a tail end waste gas absorption unit, waste gas enters the waste gas absorption unit and contacts with the absorbing agents, one part of generated absorption liquid absorbing the VOCs cycles to the waste gas absorption unit and serves as the absorbing agents to be used, and the rest absorption liquid cycles to the front waste gas absorption unit and serves as absorbing agents of the front waste gas absorption unit to be used. The process has the advantages that the purification efficiency of the VOCs is improved, the consumption of the absorbing agents is reduced, energy consumption is reduced, and the height of an absorption tower is reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Manufacturing method of nickel-plated natural garnet anti-abrasion material

The invention discloses a manufacturing method of a nickel-plated natural garnet anti-abrasion material, comprising the following steps: by taking the weight of natural garnet matrix powder as a reference, weighing 0.05-0.3% of nickel nitrate and 0.05-0.3% of borax, dissolving borax in water firstly, then adding nickel nitrate under a stirring condition to prepare into plating solution; putting the natural garnet matrix powder into a stirring pan, adding the plating solution and stirring; putting the natural garnet matrix powder mixed with the plating solution into a baking oven, and drying; and placing the dried natural garnet matrix powder into a kiln, raising the temperature to 700-850 DEG C, keeping the temperature for 10-30 min, cooling naturally and screening the cooled matrix powder. The invention has the advantages of simple working procedure, uniform plating, low cost of treatment technology, low energy consumption and little environmental pollution, the particle strength and the wear-resisting property of natural garnet matrix powder after being plated with nickel are both improved greatly, and the nickel-plated natural garnet anti-abrasion material can partially replace artificial abrasive under controllable cost.

Owner:蒋盛川 +3

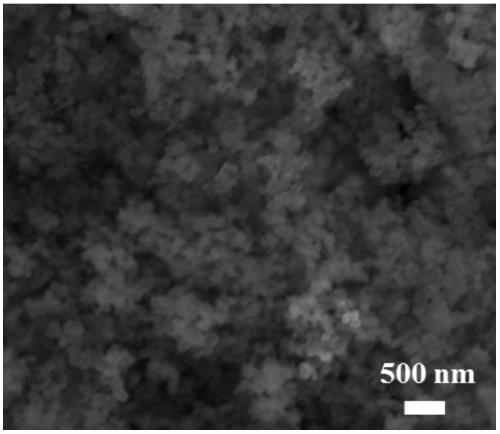

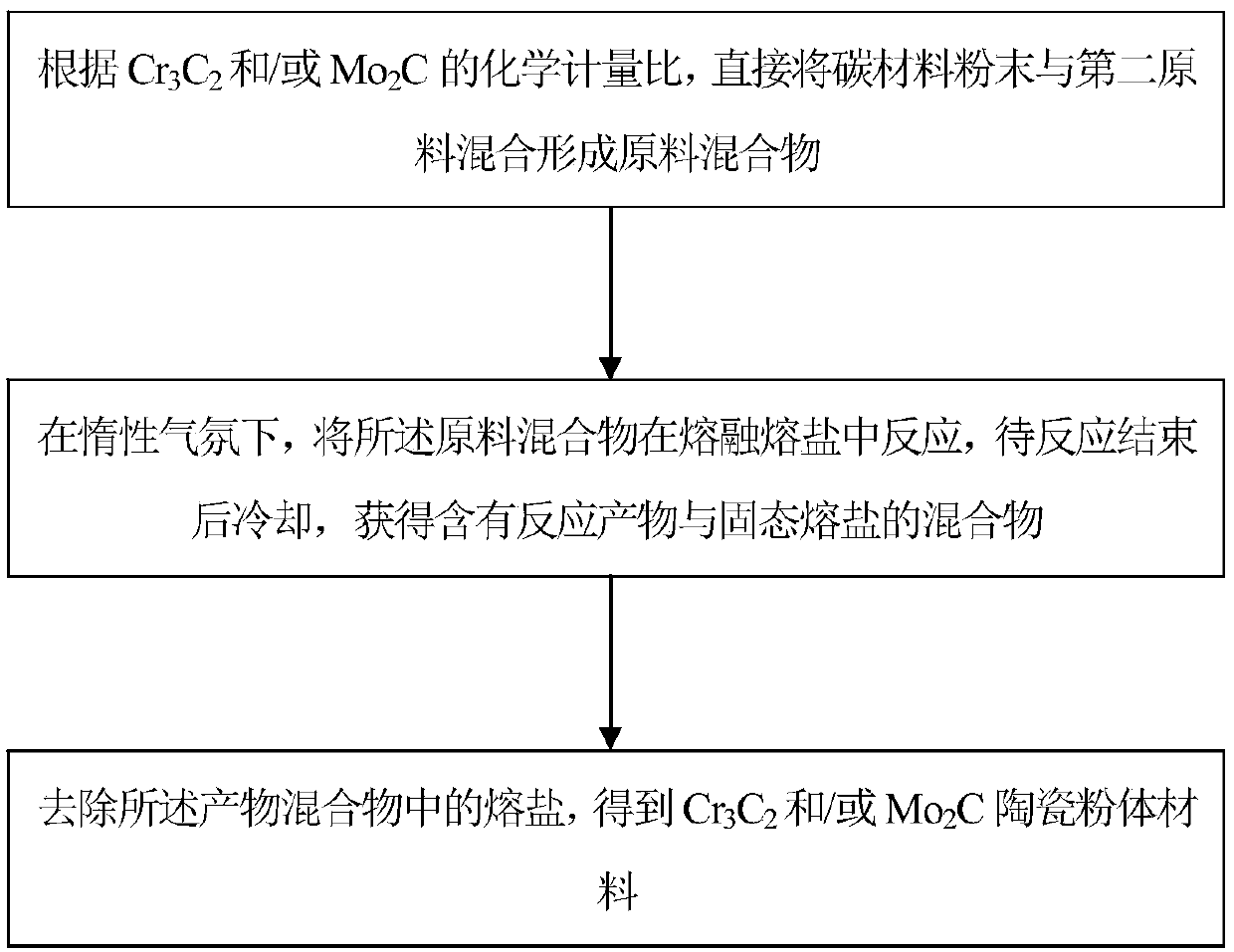

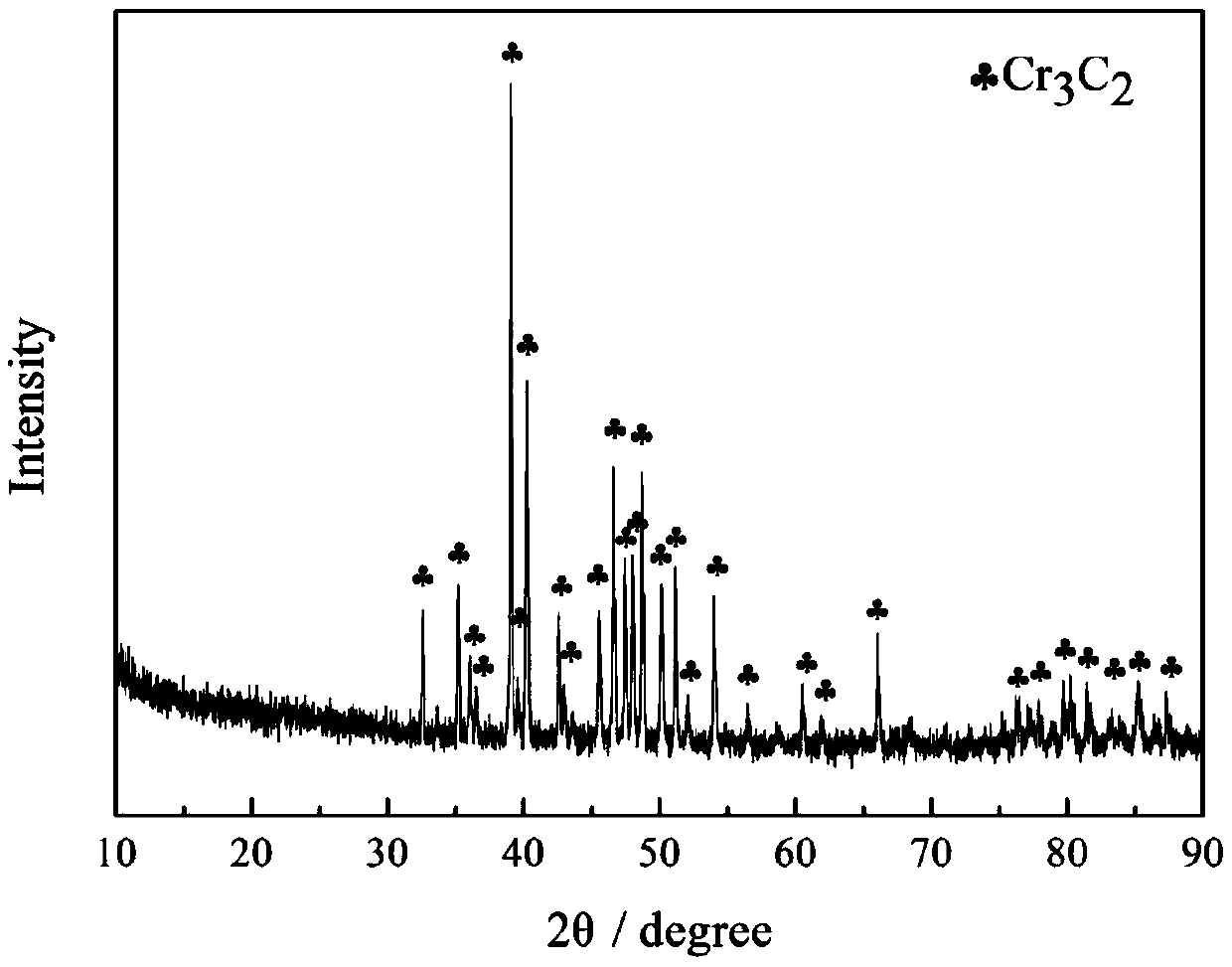

Method for in-situ preparation of Cr3C2 and/or Mo2C powder by using molten salt

The invention relates to the technical field of preparation of transition metal carbide powder materials, in particular to a method for in-situ preparation of Cr3C2 and / or Mo2C powder in through molten salt disproportionation reaction. The method comprises directly forming a raw material mixture according to the stoichiometric ratio, with the structural formula of transition metal carbide being MxCy, M being a transition metal element Cr and / or Mo, and C being carbon; reacting the raw material mixture in molten salt in an inert atmosphere, and cooling after the reaction is finished to obtain aproduct mixture; and removing the molten salt in the product mixture to obtain the Cr3C2 and / or Mo2C powder material. The method can solve one or more of the problems of high synthesis temperature, complex preparation process and equipment, high cost, uncontrollable morphology and size and the like of the existing transition metal carbide, and has the advantages of rapidness, high efficiency, energy conservation, environmental protection, low cost, easiness in realizing large-scale production and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

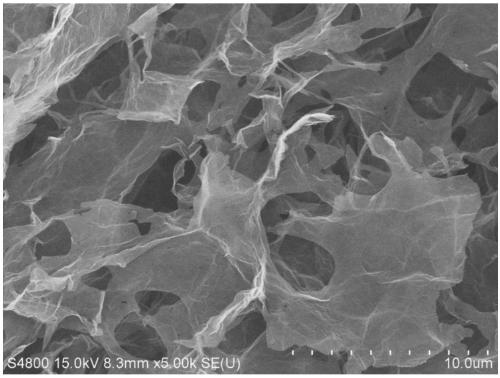

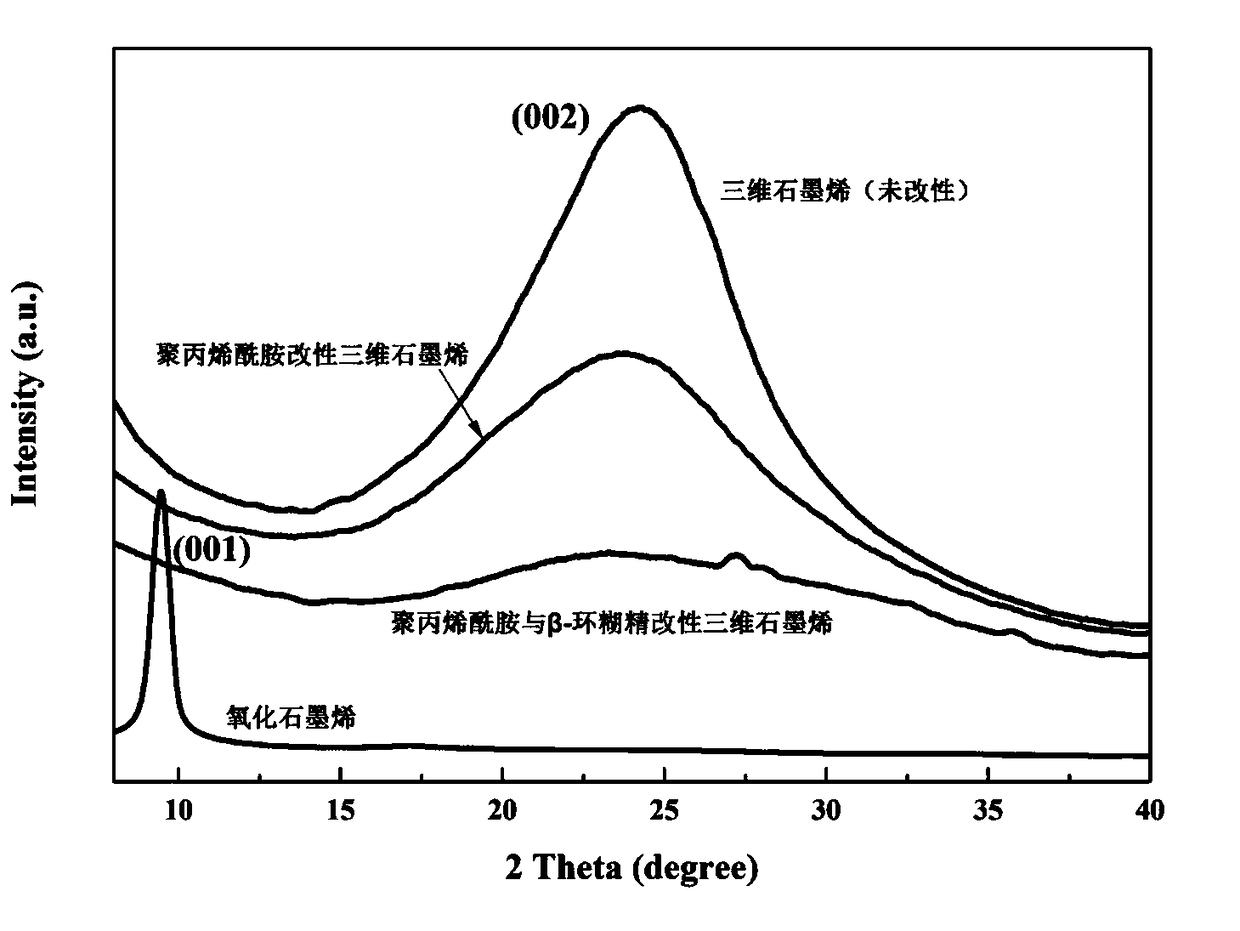

Modified three-dimensional graphene composite material, and preparation method and application thereof

InactiveCN109395695ASolve reunionImprove adsorption capacityOther chemical processesWater contaminantsSorbentAntibiotic Y

The invention belongs to the technical fields of environmental functional materials and water treatment and particularly relates to a modified three-dimensional graphene composite material, and a preparation method and an application thereof. The method includes: mixing polyacrylamide, beta-cyclodextrin and graphene oxide, and performing one-step chemical reduction to synthesize the composite material. The material has a three-dimensional pore structure and abundant functional groups, so that a problem of agglomeration of two-dimensional graphene is avoided and adsorption effect of an adsorbent to antibiotics in water is significantly enhanced. The preparation method is simple and is gentle in conditions, wherein all the modification materials are green chemical reagents, so that the wholemethod is free of secondary pollution, and the adsorbent is free of toxicity on environment. When being applied to removal of ciprofloxacin in water, the material is low in cost and can reach up to 73.63% in removal rate. The three-dimensional graphene can be separated from the solution easily and rapidly and is easy to recycle.

Owner:SOUTH CHINA UNIV OF TECH +1

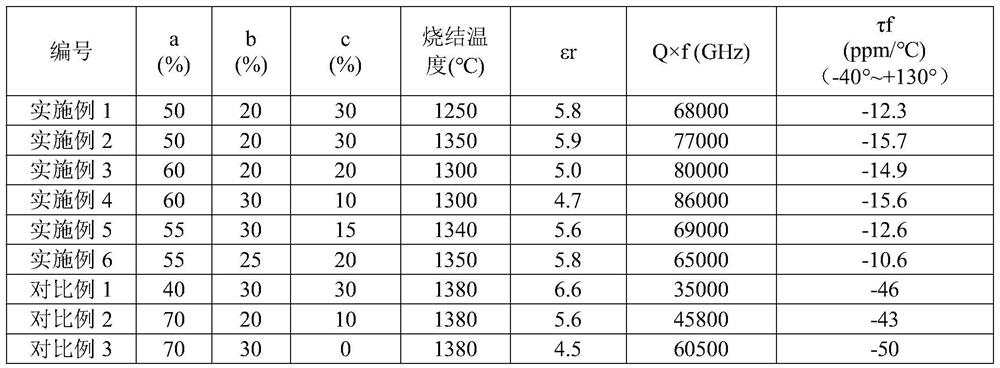

Microwave dielectric ceramic material with low dielectric constant and preparation method thereof

The invention relates to the technical field of electronic information materials, in particular to a microwave dielectric ceramic material with a low dielectric constant and a preparation method thereof, and aims to solve the problems of over-high sintering temperature and large dielectric constant in the prior art. The microwave dielectric ceramic material with the low dielectric constant is characterized in that the microwave dielectric ceramic material with the low dielectric constant is a composition represented by a chemical formula aMgSiO3-b cordierite-cCaSiO3, a, b and c independently represent molar ratios and meet the following conditions that a+b+c is equal to 100%, a is larger than or equal to 50% mol and smaller than or equal to 60% mol, b is larger than or equal to 20% mol andsmaller than or equal to 30% mol and smaller than 10% mol. The microwave dielectric ceramic material with the low dielectric constant, provided by the invention, can keep Er=4.0-6.0, Qf>15000 and anadjustable temperature coefficient tau f<+ / -30ppm / DEG C under the condition of medium-temperature sintering, and the powder does not contain toxic elements such as lead, cadmium and arsenic. Raw materials and process cost are low, and the technical requirements in the fields of microwave mobile communication, satellite communication, radar systems and the like can be met.

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

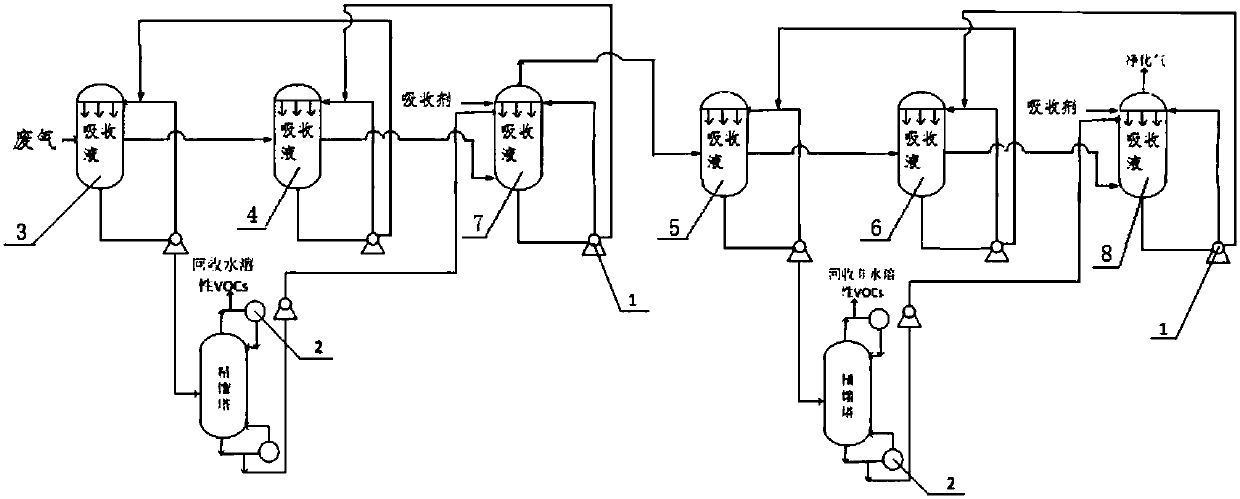

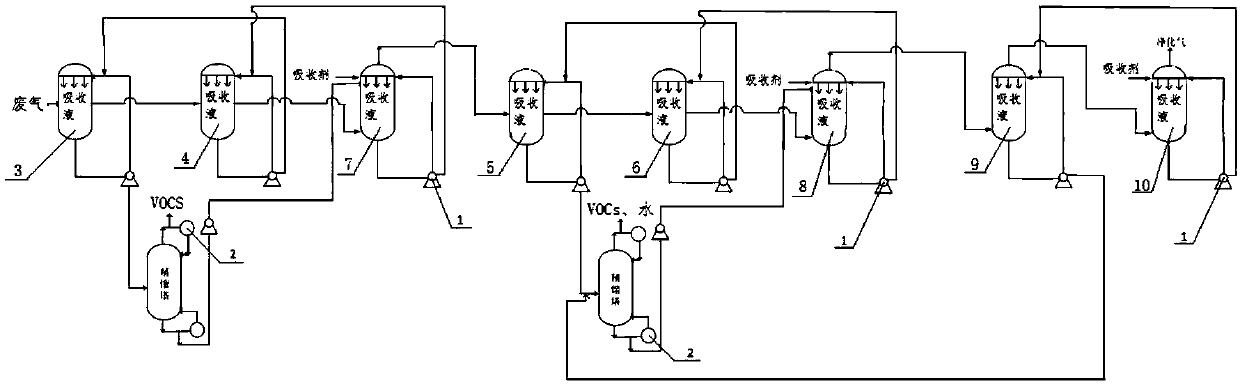

Treatment process of VOCs exhaust gas

InactiveCN107670465AReduce exhaustImprove purification efficiencyGas treatmentDispersed particle separationExhaust fumesWater soluble

The invention discloses a treatment process of VOCs exhaust gas. The treatment process comprises the steps of water-soluble VOCs removal, non-water-soluble VOCs removal and exhaust gas treatment. In the removal steps, at least two serially connected exhaust gas absorbing units are adopted, an absorbent enters the tail end exhaust gas absorbing unit in the same removal step, the exhaust gas entersthe exhaust gas absorbing units and is in contact with the absorbent, then a part of produced absorption liquid absorbing VOCs is circulated back to the exhaust gas absorbing units to serve as the absorbent, and the rest is circulated back to the previous exhaust gas absorbing unit to serve as the absorbent of the previous exhaust gas absorbing unit. The process has the advantages of improving theVOCs purifying efficiency, decreasing the use amount of the absorbent, reducing energy consumption and reducing the height of an absorption tower. In addition, absorbent in exhaust gas is recycled byadopting the process, and the use amount of the absorbent is decreased to the greatest degree.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

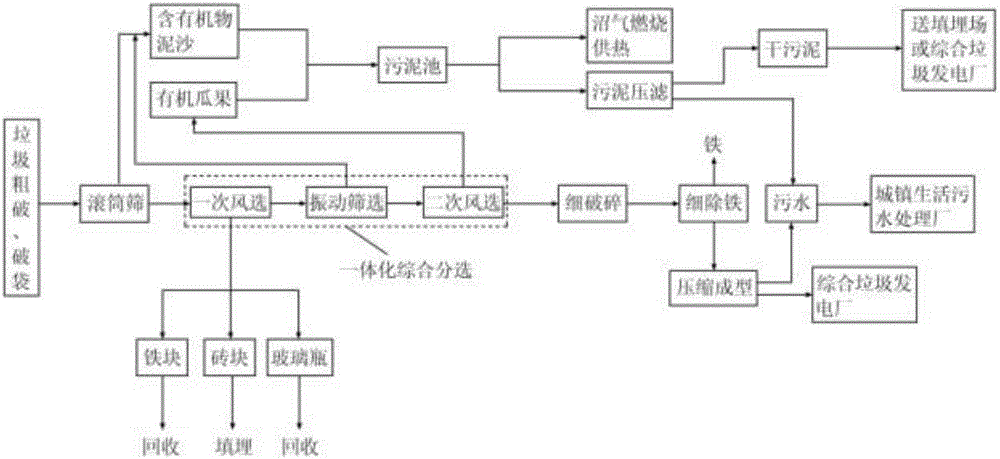

Comprehensive treatment technique for town domestic waste

InactiveCN106623350AIncrease profitLow process costSolid waste disposalEnvironmental resistanceBrick

The invention discloses a comprehensive treatment technique for town domestic waste. The technique comprises the following steps that (1), the municipal solid waste is sent into a trommel sieve after being subjected to coarse breaking and bag breaking, and sand containing organics and waste are subjected to preliminary separation; (2), the preliminarily separated domestic waste obtained in the step (1) is sent to an integration comprehensive sorting machine, firstly, first air sorting is conducted to separate iron blocks, bricks and glass bottles from the domestic waste, then vibration screening is conducted, residual sand containing organics in the domestic waste is screened out, and then second air sorting is conducted to separate the organic fruits from the domestic waste, the domestic waste subjected to integration comprehensive sorting is obtained; and (3), the domestic waste subjected to integration comprehensive sorting and obtained in the step (2) is sent to a fine crusher to be crushed, then second iron removing is conducted, and fine domestic waste is obtained and subjected to compression forming. The treatment technique is low in treatment cost, high in resource using efficiency, economical and environmentally friendly.

Owner:高细平

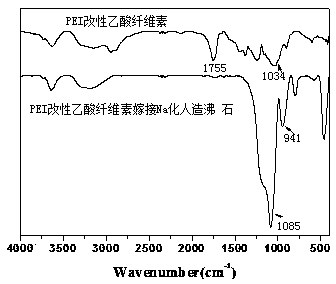

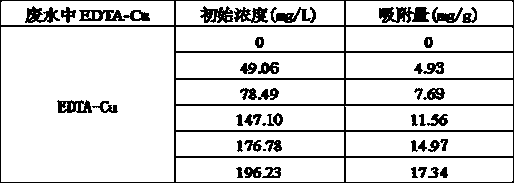

Method for grafting functional cellulose onto zeolite and waste water treatment method

ActiveCN107715853AWide variety of sourcesThe grafting process is simple and easyOther chemical processesWater contaminantsCelluloseSludge

The invention discloses a method for grafting functional cellulose onto zeolite and a waste water treatment method. According to the zeolite grafted with the functional cellulose, moisture and inorganic impurities in original porous channels can be removed, the porous channels of the artificial zeolite can be broadened, and the pore diameter can be increased, so that the steric hindrance is reduced, internal diffusion is accelerated, and the ion-exchange capacity is increased; by grafting the cellulose functionally modified by polyethyleneimine onto the artificial zeolite, an adsorbing agent with the surface containing a large number of carboxyl and amidogen can be obtained, wherein a large number of adsorbing functional groups are introduced. According to the method for grafting the functional cellulose onto the zeolite, the resources of the cellulose and the artificial zeolite used in the method are wide, the cellulose and the artificial zeolite are cheap and easy to obtain, the whole grafting process of the artificial zeolite is simple and easy to implement, and large-scale application can be achieved; the adsorbing agent can be directly put into an adsorption reaction for stirring, and solid-liquid separation can be achieved after standing; in industrial application, separation of heavy metal from a water body can be achieved by discharging supernatant and recycling sludge,the whole treatment process is low in cost, simple in operation, easy to implement and high in efficiency.

Owner:SOUTH CHINA AGRI UNIV

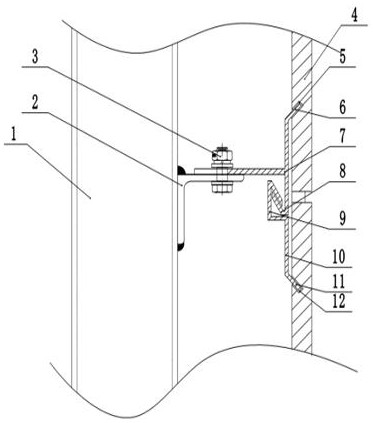

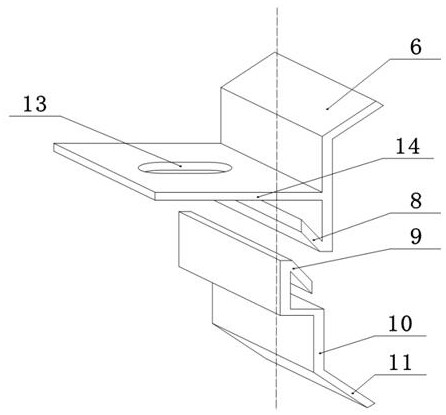

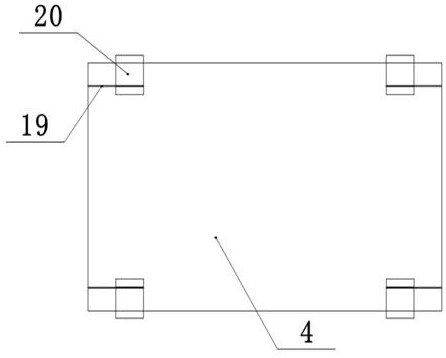

A kind of dry-hanging wall brick structure and construction method thereof

The invention discloses a dry-hanging wall brick structure, which includes a wall body and wall bricks, and also includes a column connected to the outer wall of the wall. A side of the column away from the wall body is distributed with a plurality of horizontally arranged connectors from top to bottom. , the connecting piece includes a vertical plate and a horizontal plate, wherein the vertical plate is fixedly connected to the column; a number of anchor kits are arranged on the horizontal plate, the anchor kit includes a connecting support plate, an upper hanger and a lower hanger, and the upper hanger includes a vertically arranged upper Hanging arm, the upper end of the upper hanging arm is bent in a direction away from the column and extended to form an upper hanging part, and its lower end is bent in a direction close to the column and tilted upward to form a hook; the lower hanging part includes a vertically arranged lower hanging arm, the lower hanging arm The upper end is bent to form a barb, and the lower end of the lower hanging arm is bent in a direction away from the column and extended to form a lower hanging part. A construction method for a dry-hanging wall brick structure, comprising the following steps: base treatment; measurement and setting-out; wall brick slotting; wall brick installation; glue pointing; finished product protection. Strong shock resistance.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

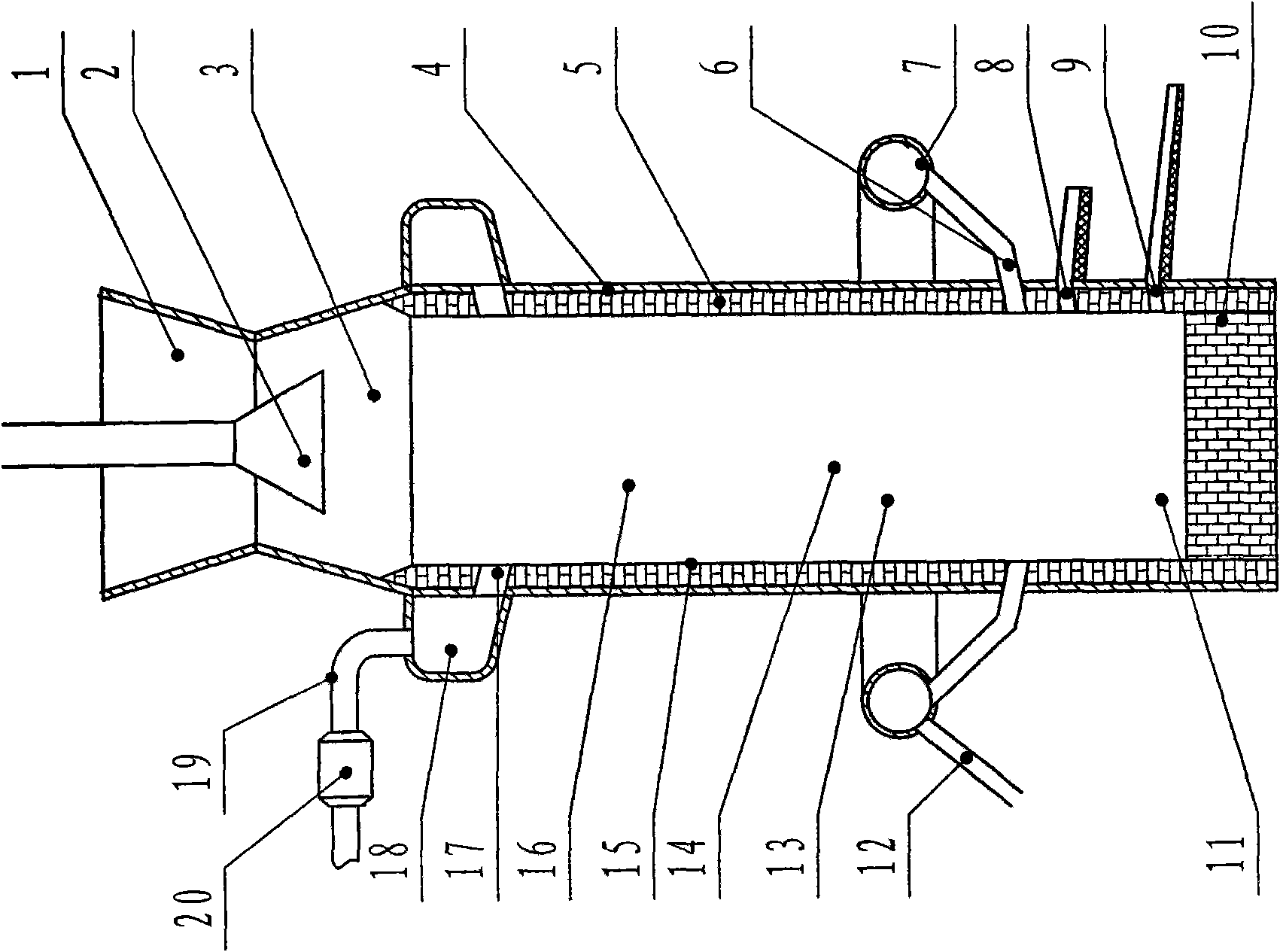

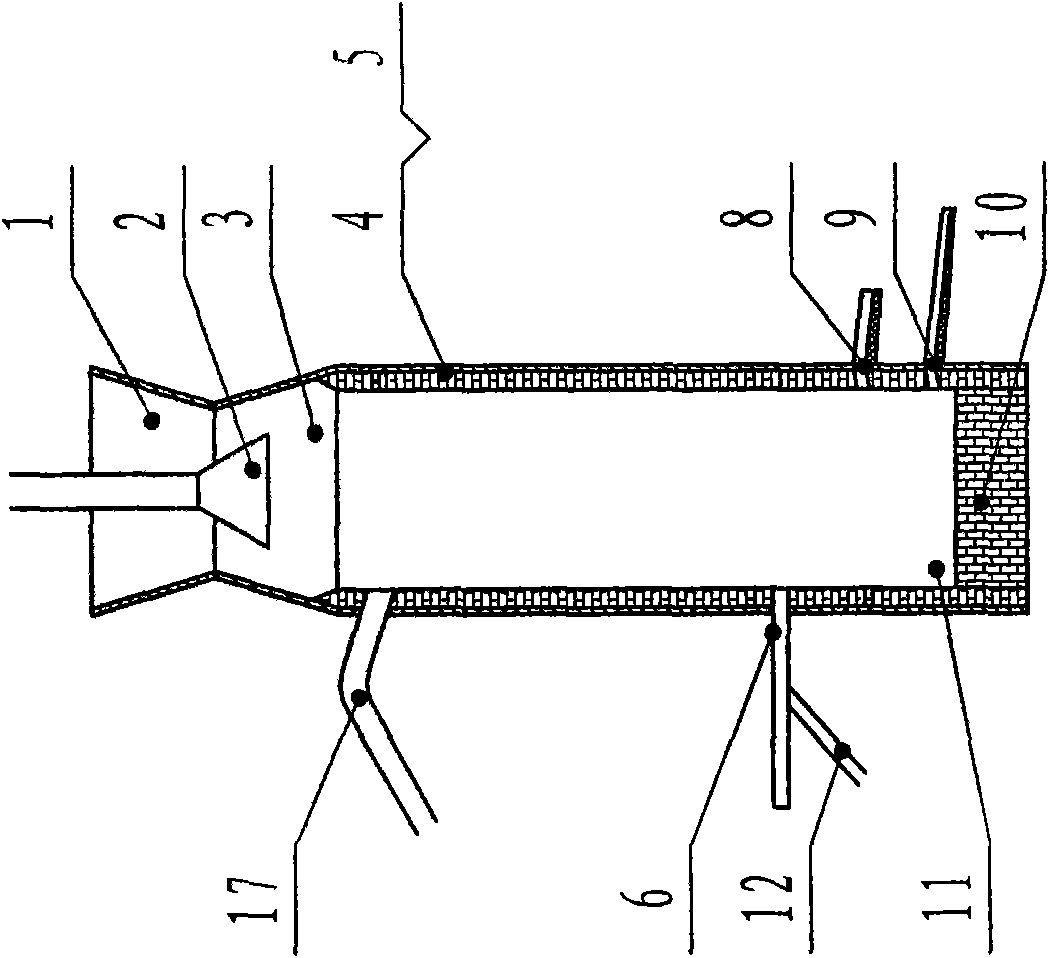

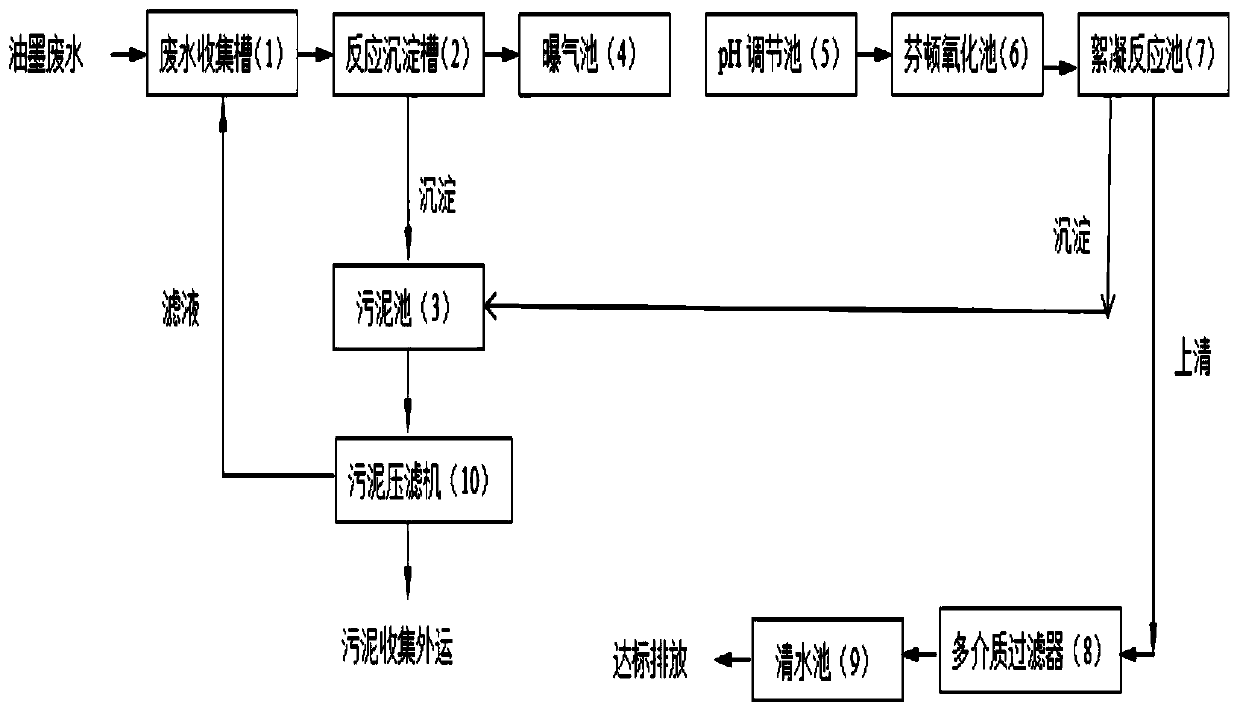

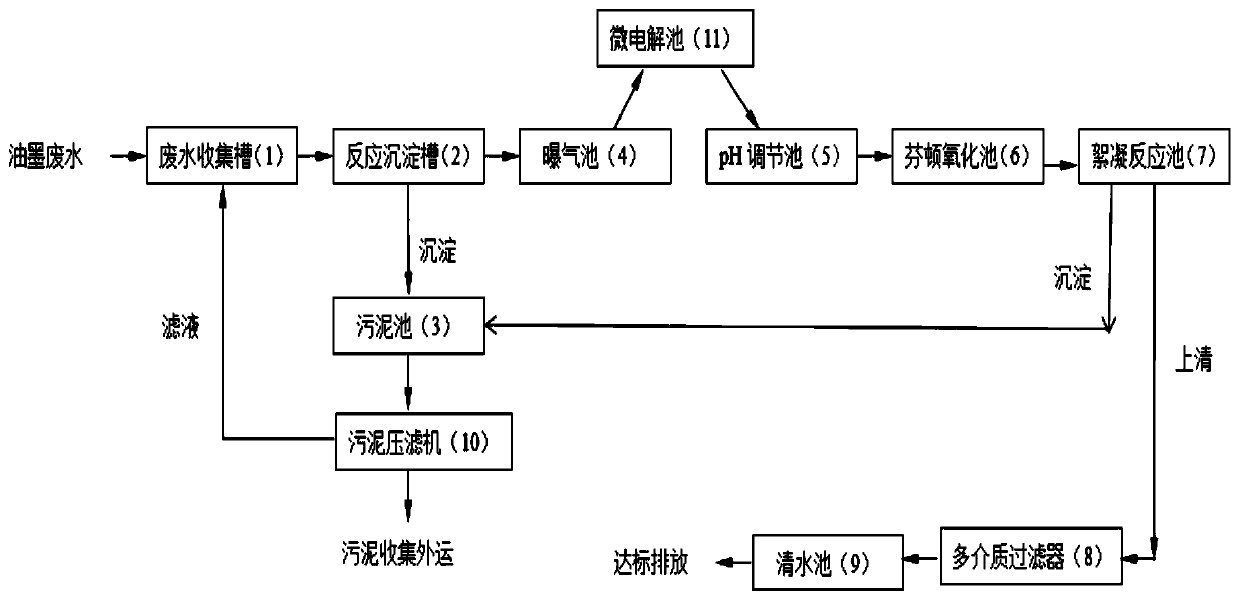

Treatment system and treatment process for ink wastewater in packaging industry

InactiveCN110697951AZero emissionLow process costSludge treatmentWater treatment compoundsSludgeProcess engineering

The invention belongs to the field of sewage treatment, and more specifically discloses a treatment system and treatment process thereof for ink wastewater in packaging industry. The treatment systemcomprises a wastewater collecting tank (1), a reaction settling tank (2), a sludge tank (3), an aeration tank (4), a pH regulating tank (5), a Fenton oxidation tank (6), a flocculation reaction tank (7), a multi-medium filter (8), a clean water tank (9), and a sludge filter press (10). The treatment process disclosed by the invention overcomes the difficulties of high COD and chromaticity and difficulty in treatment of ink wastewater, so that the quality of the treated water reaches the first-grade discharge standard, and zero discharge of pollution is realized.

Owner:SUZHOU TASHANSHI ENVIRONMENTAL PROTECTION TECH CO LTD

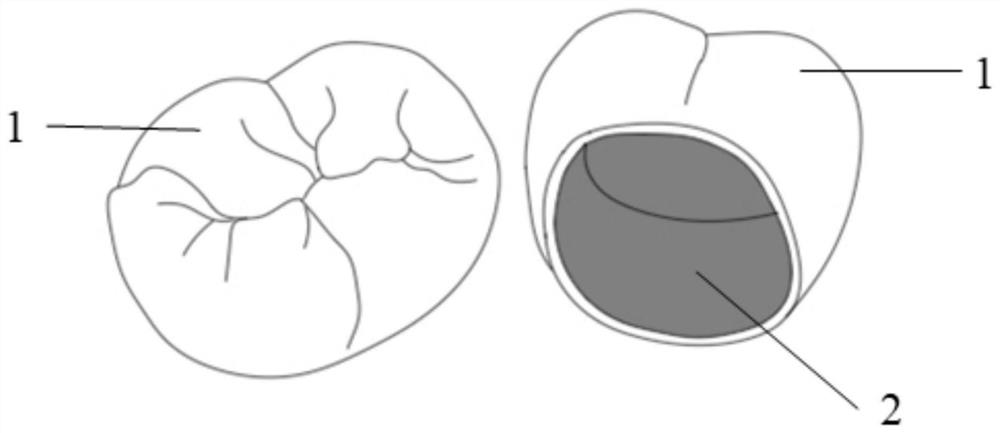

Method for removing divalent cadmium in wastewater by utilization of microcystis aeruginosa gel beads

InactiveCN103318986BWide variety of sourcesLow priceWater/sewage treatment by sorptionWastewaterReaction temperature

The invention discloses a method for removing divalent cadmium in wastewater by the utilization of microcystis aeruginosa gel beads. The method provided by the invention comprises the following steps: taking a certain amount of divalent cadmium wastewater and adjusting pH value to 2.0-10.0, adding a certain amount of microcystis aeruginosa gel beads into wastewater with the addition amount of the microcystis aeruginosa gel beads in a liter of wastewater being 10-100g (by wet weight), reacting in a thermostatic oscillator at the rotating speed of 50rpm-300rpm for 0-24h, controlling the reaction temperature to 10-50 DEG C, and separating the small microcystis aeruginosa gel beads from a solution after the reaction so as to remove divalent cadmium in wastewater. The method provided by the invention has advantages of low cost, convenient operation, high processing efficiency and the like. The method provided by the invention can be applied in processing wastewater from an electroplate factory, a smelting plant, an electronics factory and the like.

Owner:HUNAN UNIV

Method for removing hexavalent chromium in wastewater by magnetic cellulose/polyglutamic acid coupling material

ActiveCN107265552BExtensive sources of raw materialsWide variety of sourcesOther chemical processesWater contaminantsCelluloseHydrogen

The invention discloses a method for adsorbing and removing hexavalent chromium in wastewater by the aid of magnetic cellulose / polyglutamic acid coupling materials. The method includes steps of acquiring a certain quantity of hexavalent chromium wastewater and regulating a pH (potential of hydrogen) value of the hexavalent chromium wastewater until the pH value reaches 2.0-7.0 (preferably 2.0-6.0 and optimally 2.0); adding, by dry weight, 0.2-10 g of magnetic cellulose / polyglutamic acid coupling materials into each liter of wastewater to obtain mixtures; carrying out reaction on the mixtures in a constant-temperature vibrator at the rotational speed of 100-300 rpm and the reaction temperature of 10-50 DEG C under the control for 0-24 h (optimally 1-8 h); separating the magnetic cellulose / polyglutamic acid coupling materials from solution after the reaction is completely carried out so as to remove the hexavalent chromium in the wastewater. The method has the advantages of low cost, convenience in operation, high treatment efficiency and the like. Besides, the method can be applied to treating hexavalent-chromium-containing wastewater from electroplating factories, smelting plants, electronics factories and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

A kind of preparation method of moss absolute oil with low as content

ActiveCN106318617BReduce processing costsWill not affect the qualityEvaporator accessoriesFatty-oils/fats refiningFlavorAlcohol

A preparation method of low-As-content tree moss absolute oil comprises the following specific steps that 1, a tree moss raw material is soaked with water of 15-30 times of the amount of the tree moss raw material for 0.5 -2 hours, the soaked tree moss raw material is naturally air-dried, 100-mesh screening is performed after smashing, extraction is performed by using 65%-95% ethyl alcohol or petroleum ether, an extract is concentrated till no solvent is evaporated after extraction, and tree moss extract is obtained; 2, 95% ethyl alcohol 3-6 times of the mass of the extract is added to the tree moss extract for redissolution, freezing is performed at the temperature of 10-30 DEG C for 8-24 hours after full stirring and dissolution, insoluble substances are filtered out, the solution is concentrated till no solvent is dissolved, and the low-As-content tree moss absolute oil is obtained. The preparation method has the advantages that the operation is simple, the As content in the tree moss absolute oil is reduced under the coordinating effect of two treatment processes, no adverse influence is produced on the perfume quality of the final tree moss extract, the fragrance is purer, and the product quality is better. In addition, a preparation method is low in cost and suitable for large-scale industrial production.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

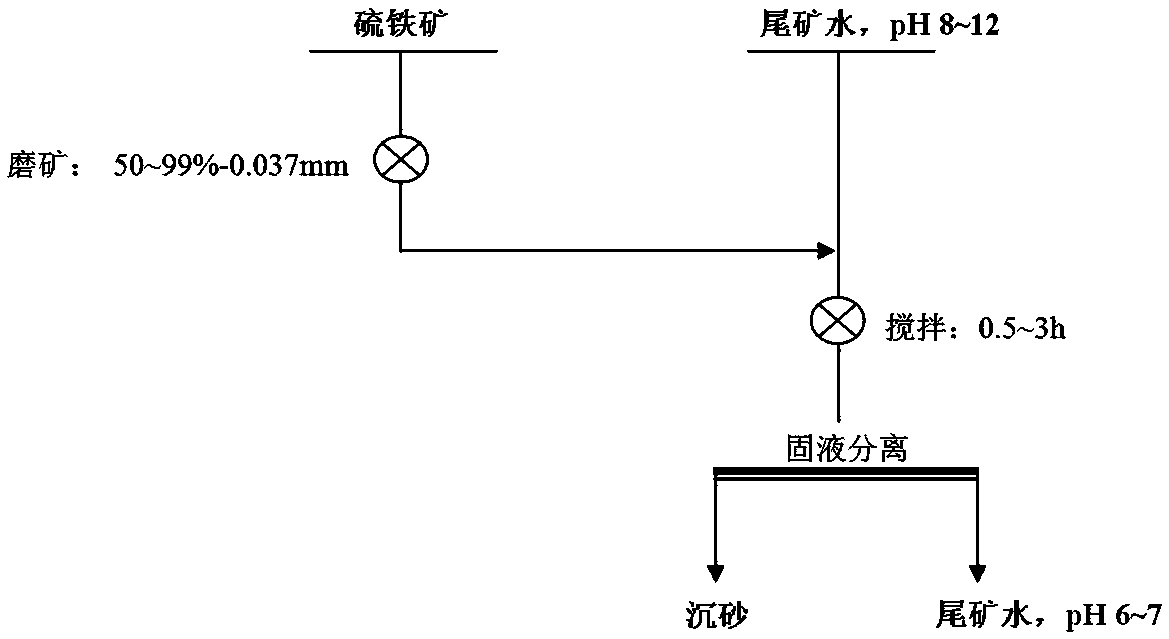

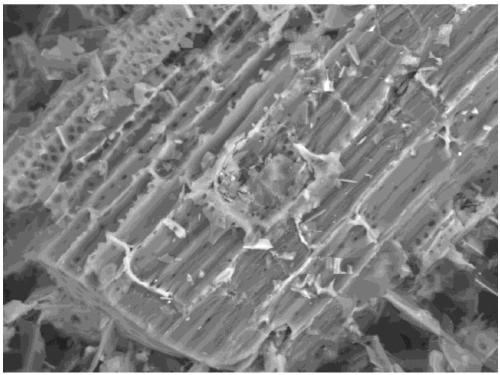

Treatment technology of ore dressing alkaline tail water

InactiveCN109231402ALow process costImprove securityWater/sewage treatment by neutralisationPyriteSulfur

The invention discloses a treatment technology of ore dressing alkaline tail water. The treatment technology of the ore dressing alkaline tail water is used for treating the ore dressing alkaline tailwater by utilizing cheap pyrite and specifically comprises the following steps: carrying out ore grinding on the pyrite until the pyrite with the fineness of -0.037mm accounts for 50 percent or more,so as to obtain a material a; adding the material a into the ore dressing alkaline tail water needing to be treated, stirring at 5 to 50 DEG C and reacting for 0.5 to 3h to obtain a reaction solutionb; carrying out solid-liquid separation on the reaction solution b to obtain settled sand c and reclaimed water capable of being circularly utilized. The treatment technology of the ore dressing alkaline tail water, provided by the invention, has the advantages of low cost, high safety and easiness for operation; the requirements on operational details of technical staff are low and the treatmenttechnology is suitable for large-scale popularization and application, so that the possibility of large-scale implementation is solved radically. Aiming at the alkaline tailing water of a current oredressing factory, the treatment technology adopting the technical scheme has a simple technological flow; the pyrite with the low price is adopted and any medicament does not need to be added; national clean production and circular economy policies are met and the aim of comprehensive utilization of resources is realized.

Owner:KUNMING METALLURGY INST

Method for removing hexavalent chromium in wastewater by sodium humate/biochar magnetic composite material

ActiveCN106315742BExtensive sources of raw materialsWide variety of sourcesWater treatment parameter controlOther chemical processesDry weightWastewater

The invention discloses a method for removing hexavalent chrome in wastewater by using a sodium humate / biochar magnetic composite material. The method comprises the following steps: taking a certain amount of hexavalent chrome wastewater, regulating the pH value to 2.0-10.0 (preferably 2.0-6.0, and most preferably 2.0), and adding a certain amount of the sodium humate / biochar magnetic composite material into the wastewater, wherein the dry weight of the sodium humate / biochar magnetic composite material for every liter of wastewater is 0.5-10g; reacting in a constant-temperature oscillator at the speed of 100-300 rpm for 0-24 hours (most preferably 1-6 hours) while controlling the reaction temperature at 10-50 DEG C (most preferably 30-40 DEG C); and after the reaction finishes, separating the sodium humate / biochar magnetic composite material from the solution, thereby removing the hexavalent chrome from the wastewater. The method has the advantages of low cost, high treatment efficiency and the like, and is convenient to operate. The method can be used for treating hexavalent-chrome-containing wastewater in electroplating factories, smelteries, electronic factories and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com