Formula of high-transmittance zirconia ceramic, preparation method of paste and manufacturing method of dental crown

A technology of zirconia ceramics and a production method, which is applied in the field of denture processing, can solve problems such as poor surface accuracy, prone to subsidence, and reduced overall mechanical properties, and achieve the effects of reducing process costs, controlling manufacturing costs, and easy photocuring molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The embodiment of the present invention provides a composition formula of a high-transparency zirconia ceramic dental crown material for 3D printing, comprising the following raw materials in parts by weight:

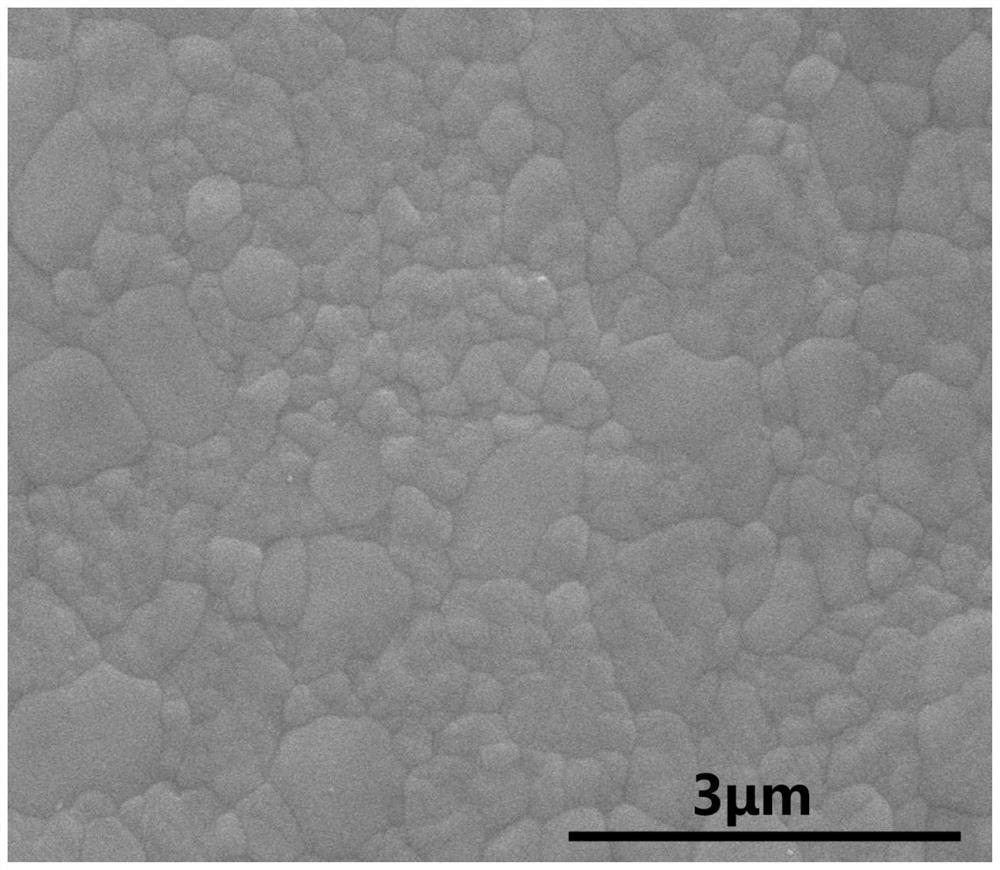

[0035] 81-90 parts of yttria-stabilized zirconia ceramic powder, the yttria content in the yttria-stabilized zirconia ceramic powder is 4mol%-6mol%; the particle size of the yttria-stabilized zirconia ceramic powder is 0.1-1 micron 10-17 parts of photosensitive resin premix; 0.01-0.2 parts of defoamer; 0.01-10 parts of dispersant; 0.01-10 parts of leveling agent; 0.02-4 parts of photoinitiator; 1 -10 parts of rheology modifier.

[0036] Wherein, the photosensitive resin premix is a kind of acrylic resin monomer or a mixture of multiple acrylic resin monomers; for example, 1,6-hexanediol diacrylate, dipentaerythritol hexaacrylate, acryloyl mol Aromatic urethane acrylate, tripropylene glycol diacrylate, ethoxylated pentaerythritol tetraacrylate, cyclotrimethylol...

Embodiment 2

[0040] The technical solution of the present invention also provides the method that the high-transparency zirconia ceramic crown formulation material used for 3D printing involved in embodiment 1 is prepared into a paste, and the preparation method comprises:

[0041] Sa: prepare photosensitive resin premix;

[0042]Sb: First add the dispersant to the photosensitive resin premixed solution in step Sa, mix evenly, and then gradually add the zirconia ceramic powder, the specific addition amount is 50% of the total amount of the zirconia ceramic powder added for the first time , mix evenly; add 20% of the total amount of zirconia ceramic powder for the second time, mix evenly; add 15% of the total amount of zirconia ceramic powder for the third time, mix evenly, and after adding each time, turn / min in a high-speed homogenizer for ball milling for 100 seconds; after mixing evenly, add a defoamer and cooperate with a vacuum defoamer for defoaming treatment, and finally add the re...

Embodiment 3

[0046] The technical solution of the present invention also provides a kind of manufacturing method based on SLA or DLP technology high permeability zirconia crown, it comprises the following steps:

[0047] S1: Intraoral scanning to obtain three-dimensional data of the crown, including personalized design of the crown shape based on the three-dimensional data of the dentition, and preservation of the three-dimensional data of the crown;

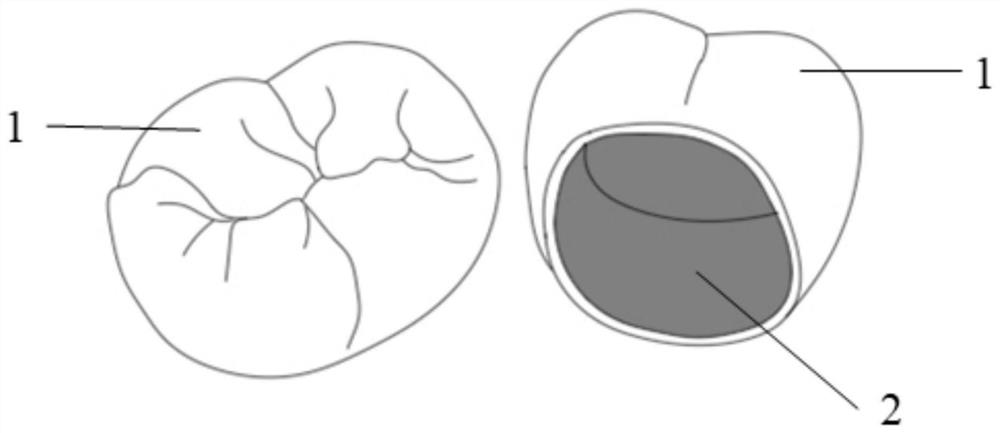

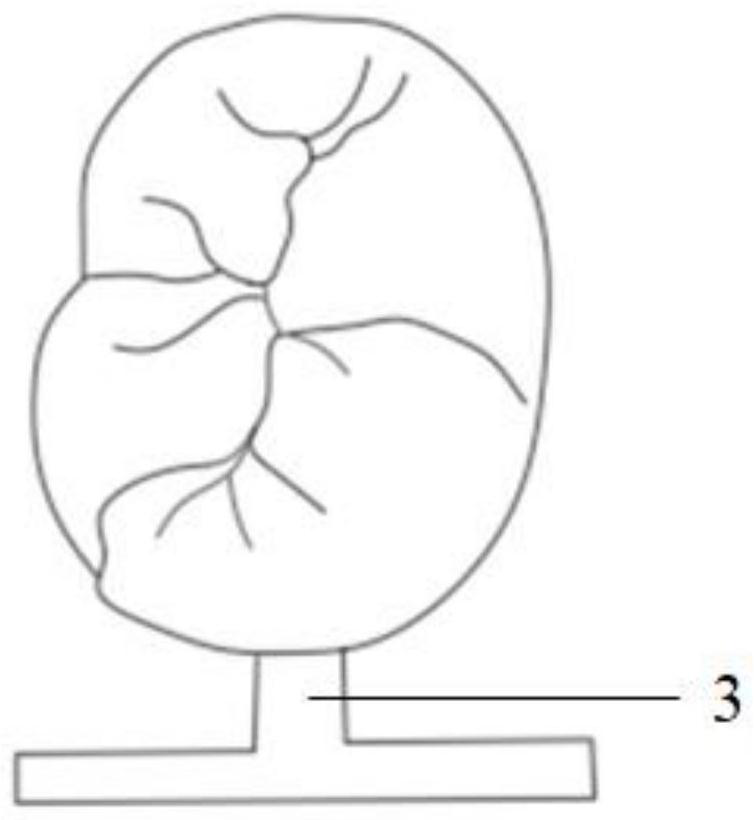

[0048] S2: Import the three-dimensional data of the dental crown into the typesetting software of the SLA or DLP 3D printer, set the corresponding printing parameters to establish the printing method, and set the support structure, and use the SLA or DLP method to form the zirconia ceramic paste prepared according to the above method into Plain embryo; specifically, as shown in Figure 1, the YSZ ceramic paste prepared above was prepared according to the three-dimensional data of the upper part of the structure (including single crown, bridge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com