Treatment system and treatment process for ink wastewater in packaging industry

A technology of ink waste water and treatment system, which is applied in water/sewage treatment, special compound water treatment, neutralized water/sewage treatment, etc. Simple and convenient, small footprint, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

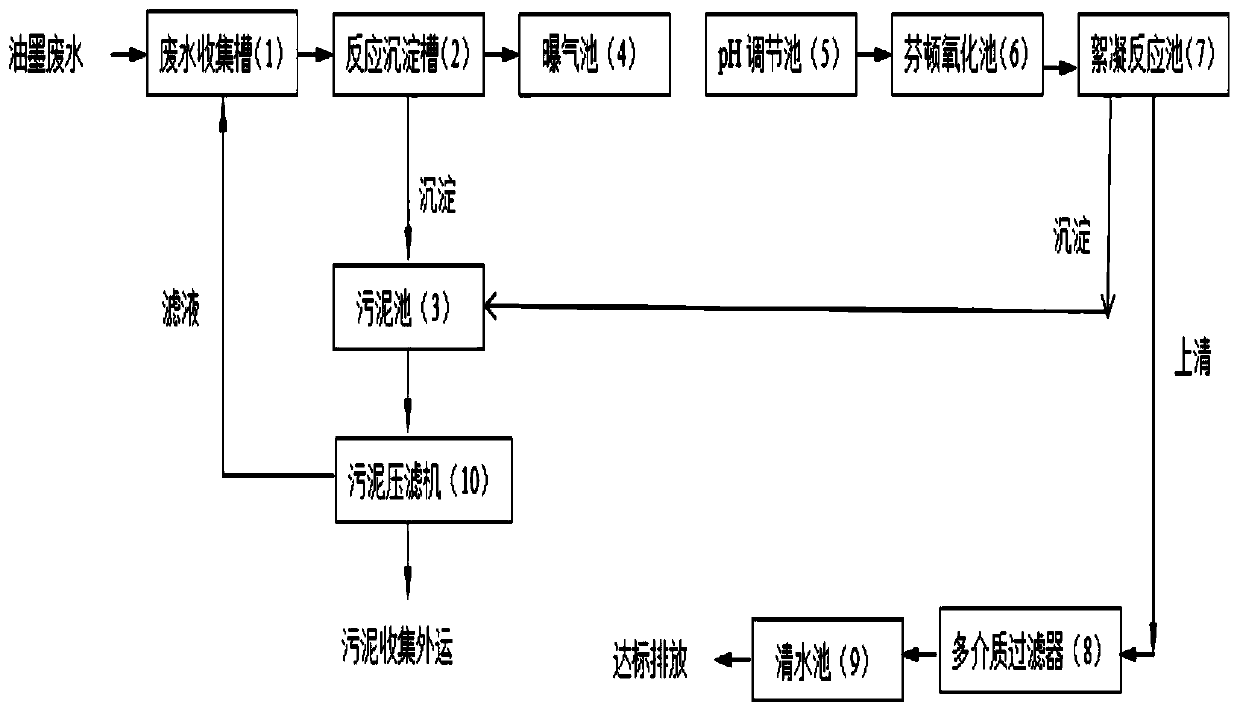

[0028] Such as figure 1 A treatment system for ink wastewater in the packaging industry is shown, including a wastewater collection tank 1, a reaction sedimentation tank 2, a sludge tank 3, an aeration tank 4, a pH adjustment tank 5, a Fenton oxidation tank 6, a flocculation reaction tank 7, Multi-media filter 8, clear water pool 9, sludge filter press 10; the ink waste water flows into the treatment system through the entrance of the waste water collection tank 1, and the waste water in the waste water collection tank 1 is transported into the reaction sedimentation tank 2 by a lift pump The precipitation in the reaction sedimentation tank 2 is drawn into the sludge tank 3 by the sludge extraction machine, and the supernatant in the reaction sedimentation tank 2 flows into the aeration tank 4, and the downstream of the aeration tank 4 is successively Connect the pH adjustment tank 5, the Fenton oxidation tank 6, and the flocculation reaction tank 7; In the multimedia filter ...

Embodiment 2

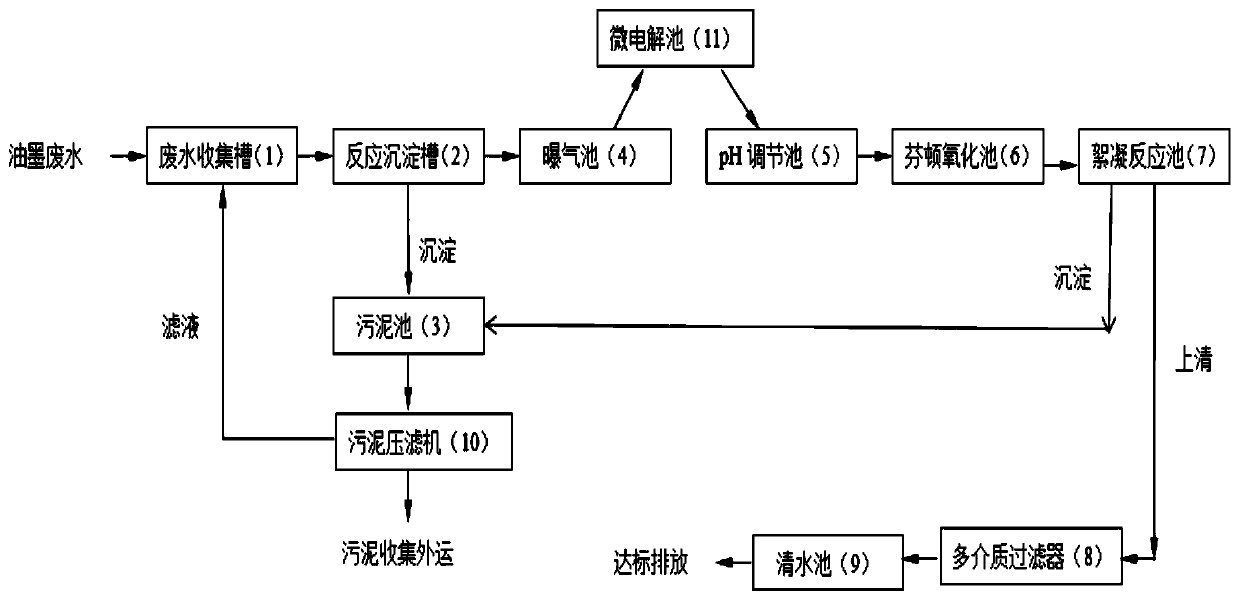

[0041] Such as figure 2 A treatment system for ink wastewater in the packaging industry is shown, including a wastewater collection tank 1, a reaction sedimentation tank 2, a sludge tank 3, an aeration tank 4, a pH adjustment tank 5, a Fenton oxidation tank 6, a flocculation reaction tank 7, Multi-media filter 8, clear water pool 9, sludge filter press 10; the ink waste water flows into the treatment system through the entrance of the waste water collection tank 1, and the waste water in the waste water collection tank 1 is transported into the reaction sedimentation tank 2 by a lift pump The precipitation in the reaction sedimentation tank 2 is drawn into the sludge tank 3 by the sludge extraction machine, and the supernatant in the reaction sedimentation tank 2 flows into the aeration tank 4, and the downstream of the aeration tank 4 is successively Connect the pH adjustment tank 5, the Fenton oxidation tank 6, and the flocculation reaction tank 7; In the multimedia filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com