Green carbon dioxide absorbent

A carbon dioxide, absorbent technology, applied in the direction of absorption, reagents, inorganic chemistry, etc., can solve the problems of difficult industrial process, high cost, and difficulty in fluidity to meet the convective absorption process, to improve absorption performance and reduce process energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The experimental device for synthesizing ionic liquid is a three-neck flask. Tetramethylammonium hydroxide and glycine were dissolved in water at a ratio of 1:1, and stirred mechanically at room temperature for 48 hours until the pH of the solution was between 9 and 10. After the reaction was complete, most of the water was removed by rotary evaporation at 50°C, and then dried in a vacuum oven at 65°C for more than 48 hours, and the product was taken out after constant weight to obtain tetramethylammonium glycine ionic liquid.

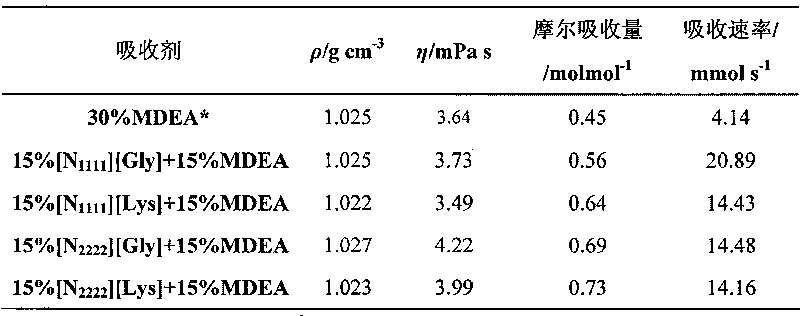

[0028] Tetramethylammonium glycine ionic liquid and N-methyldiehexanolammonium were dissolved in water according to the mass ratio of 0.2:1, 0.5:1, and 1:1, respectively, and three absorbing solutes with a total mass fraction of 30% were formulated. agent.

[0029] Accurately weigh a certain amount of compound absorbent and put it into an absorption chamber, evacuate to a vacuum and maintain it for 5-10min. The absorption chamber is placed in ...

Embodiment 2

[0031] The experimental device for synthesizing ionic liquid is a three-neck flask. Dissolve tetraethylammonium hydroxide and glycine in water at a ratio of 1:1, and react with mechanical stirring at room temperature for 48 hours until the pH of the solution is between 9 and 10. After the reaction was complete, most of the water was removed by rotary evaporation at 50°C, and then dried in a vacuum oven at 65°C for more than 48 hours, and the product was taken out after constant weight to obtain tetraethylammonium glycine ionic liquid.

[0032] Dissolve tetraethylammonium glycine ionic liquid and N-methyldiehexanolammonium in water according to the mass ratio of 0.2:1, 0.5:1, and 1:1 respectively, and prepare three absorbing solutes with a total mass fraction of 30%. agent.

[0033] Accurately weigh a certain amount of compound absorbent and put it into an absorption chamber, evacuate to a vacuum and maintain it for 5-10min. The absorption chamber is placed in a 298K constant...

Embodiment 3

[0035] The experimental device for synthesizing ionic liquid is a three-neck flask. Dissolve tetramethylammonium hydroxide and lysine in water at a ratio of 1:1, and react with mechanical stirring at room temperature for 48 hours until the pH of the solution is between 9 and 10. After the reaction was complete, most of the water was removed by rotary evaporation at 50°C, and then dried in a vacuum oven at 65°C for more than 48 hours, and the product was taken out after constant weight to obtain tetramethylammonium lysine ionic liquid.

[0036] Tetramethylammonium lysine ionic liquid and N-methyldiehexanolammonium were dissolved in water according to the mass ratio of 0.2:1, 0.5:1, and 1:1 respectively, and the total mass fraction of three solutes were all 30%. absorbent.

[0037] Accurately weigh a certain amount of compound absorbent and put it into an absorption chamber, evacuate to a vacuum and maintain it for 5-10min. The absorption chamber is placed in a 298K constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com