Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Biorefining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biorefining is the process of "refining" multiple products from biomass as a feedstock or raw material much like a petroleum refinery that is currently in use. A biorefinery is a facility like a petroleum refinery that comprises the various process steps or unit operations and related equipment to produce various bioproducts including fuels, power, materials and chemicals from biomass. Industrial biorefineries have been identified as the most promising route to the creation of a new domestic biobased industry producing entire spectrum of bioproducts or bio-based products.

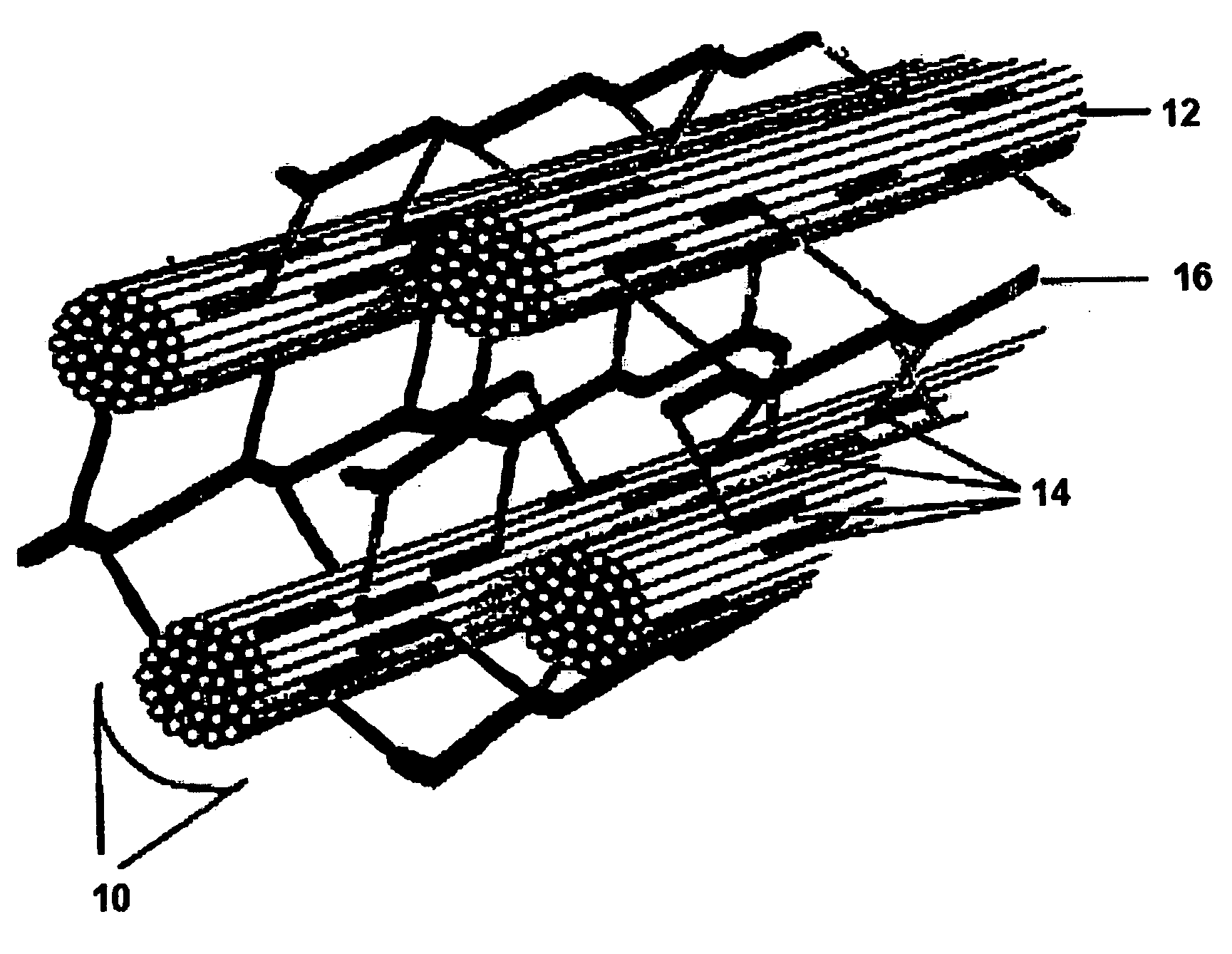

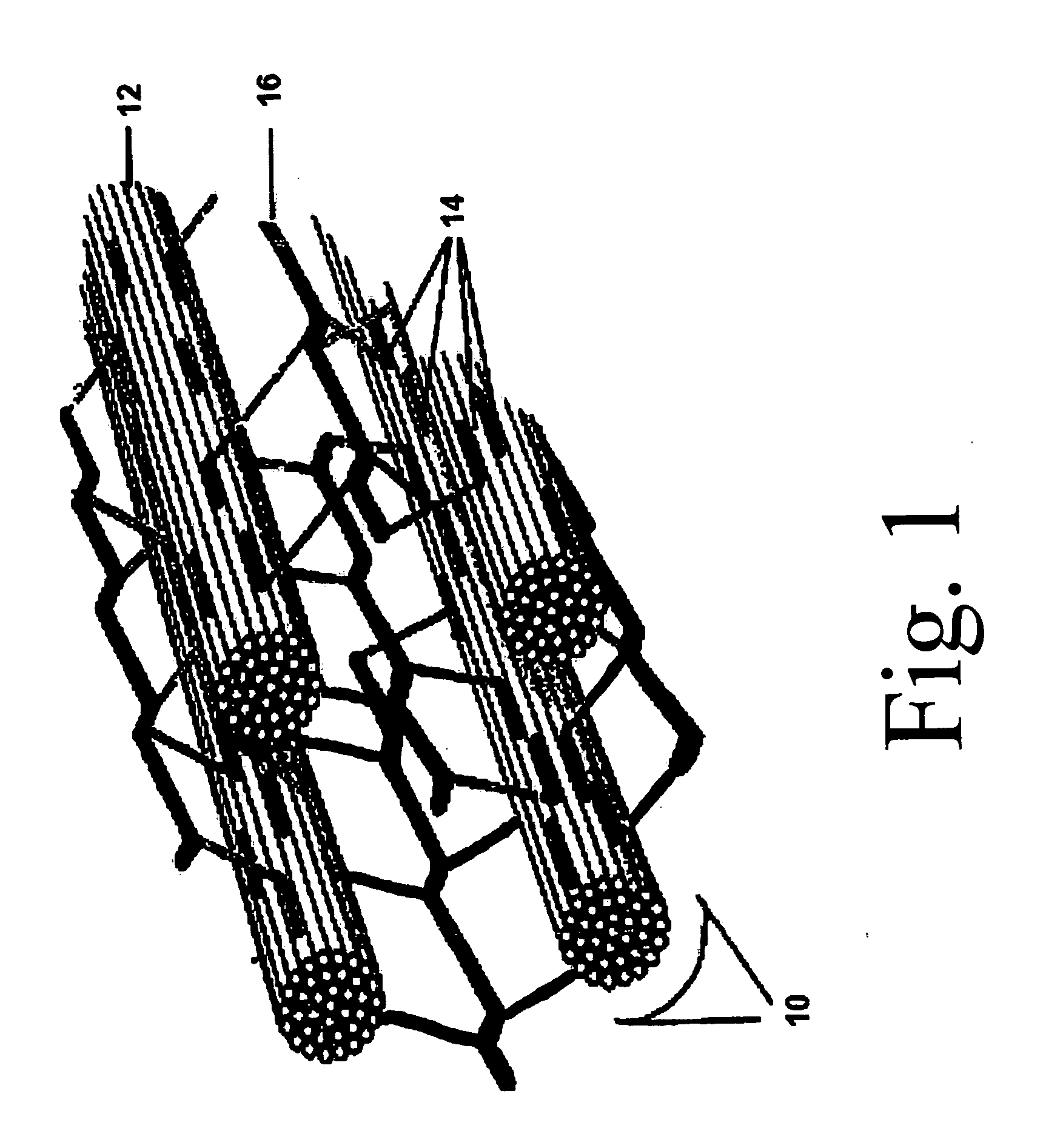

Novel Fungal Enzymes

This invention relates to novel enzymes and novel methods for producing the same. More specifically this invention relates to a variety of fungal enzymes. Nucleic acid molecules encoding such enzymes, compositions, recombinant and genetically modified host cells, and methods of use are described. The invention also relates to a method to convert lignocellulosic biomass to fermentable sugars with enzymes that degrade the lignocellulosic material and novel combinations of enzymes, including those that provide a synergistic release of sugars from plant biomass. The invention also relates to a method to release cellular content by degradation of cell walls. The invention also relates to methods to use the novel enzymes and compositions of such enzymes in a variety of other processes, including washing of clothing, detergent processes, biorefining, deinking and biobleaching of paper and pulp, and treatment of waste streams.

Owner:DANISCO US INC

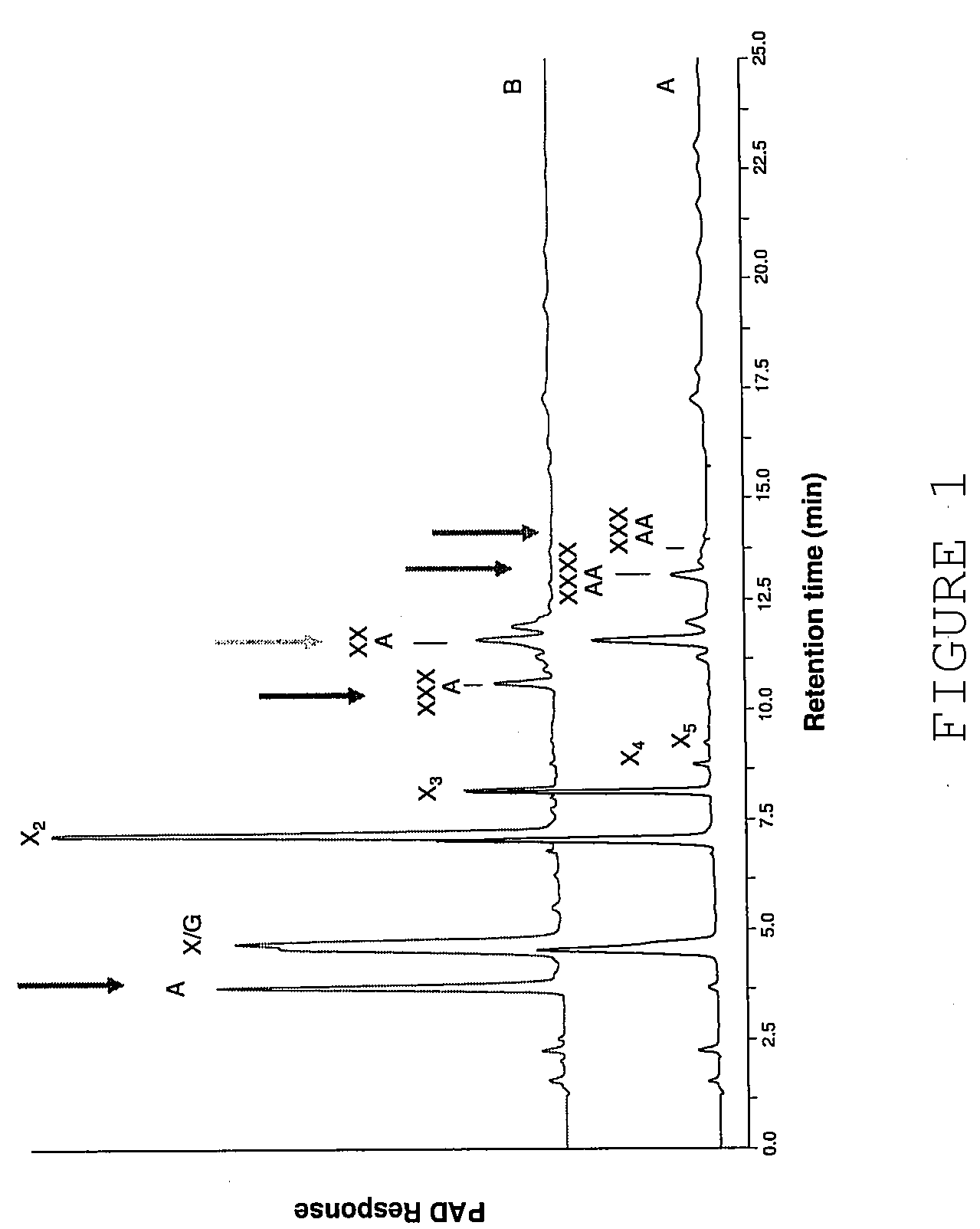

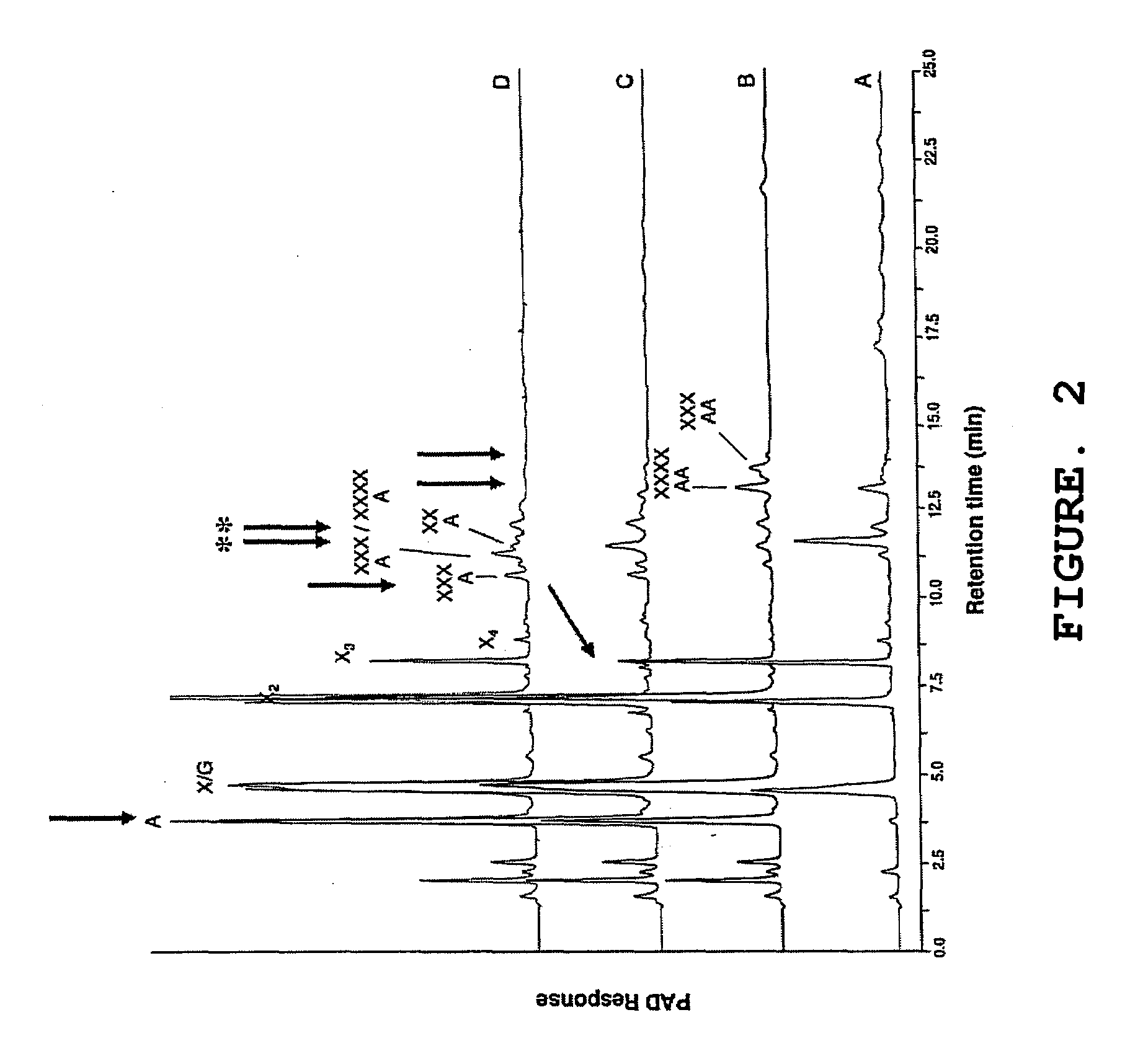

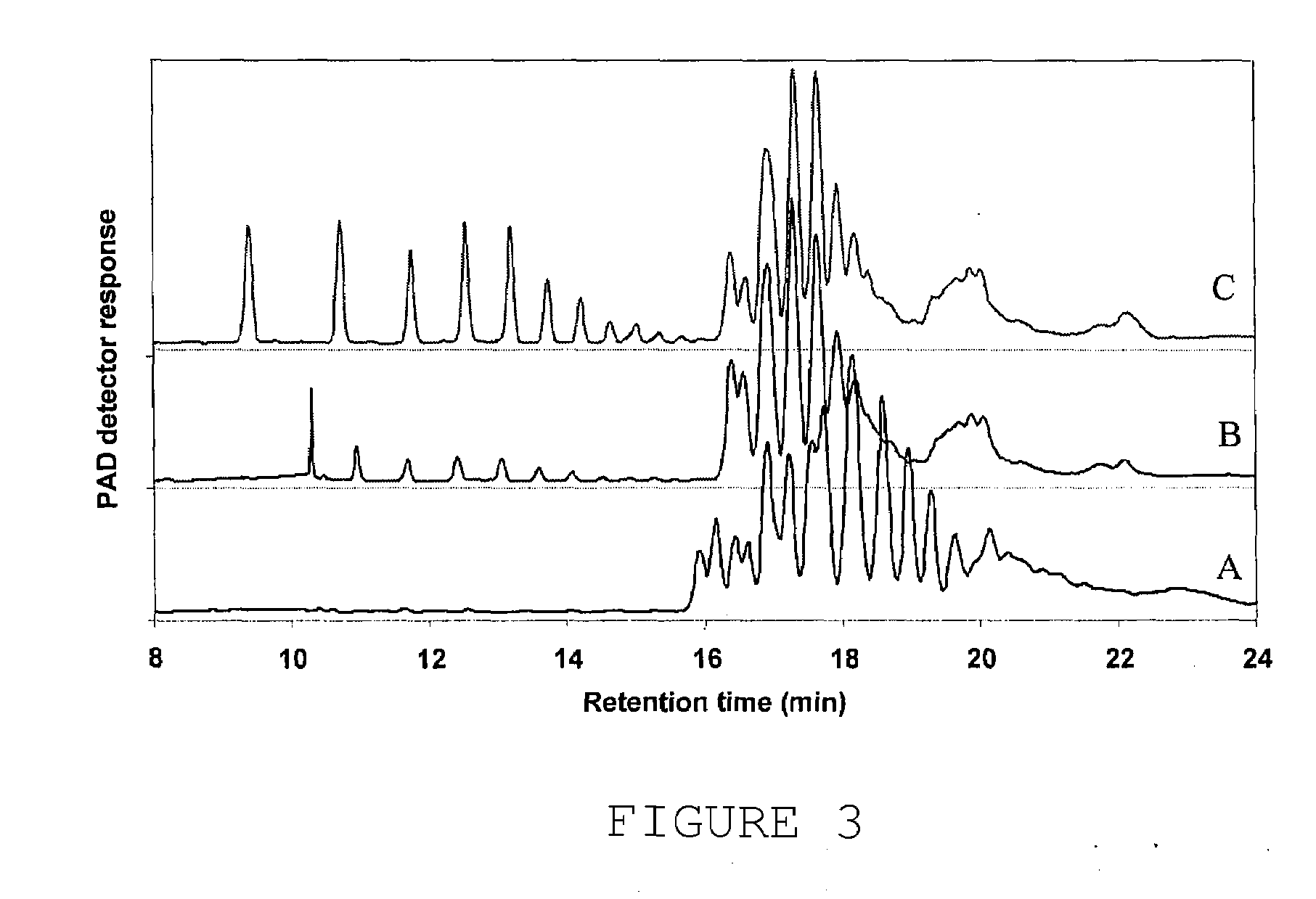

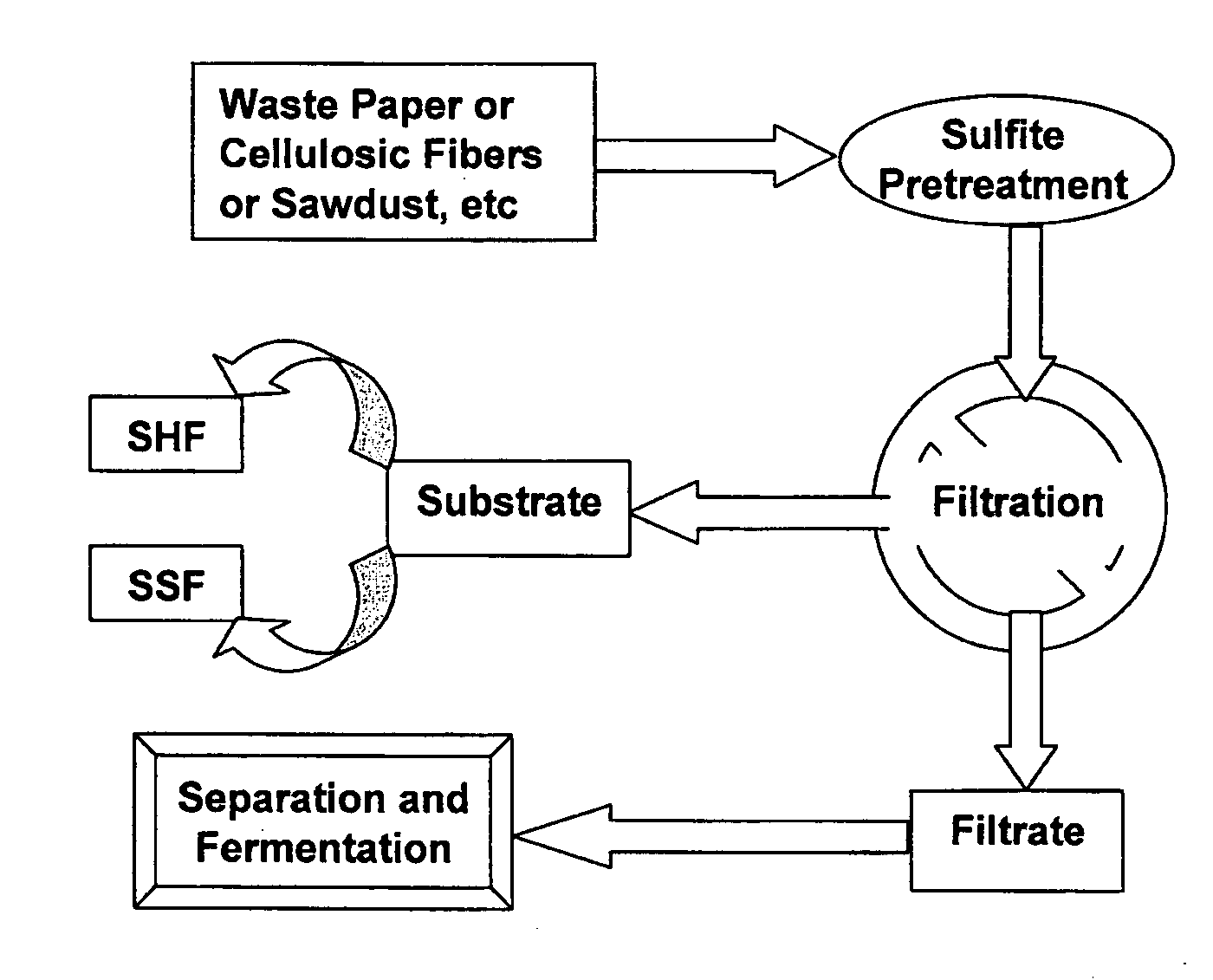

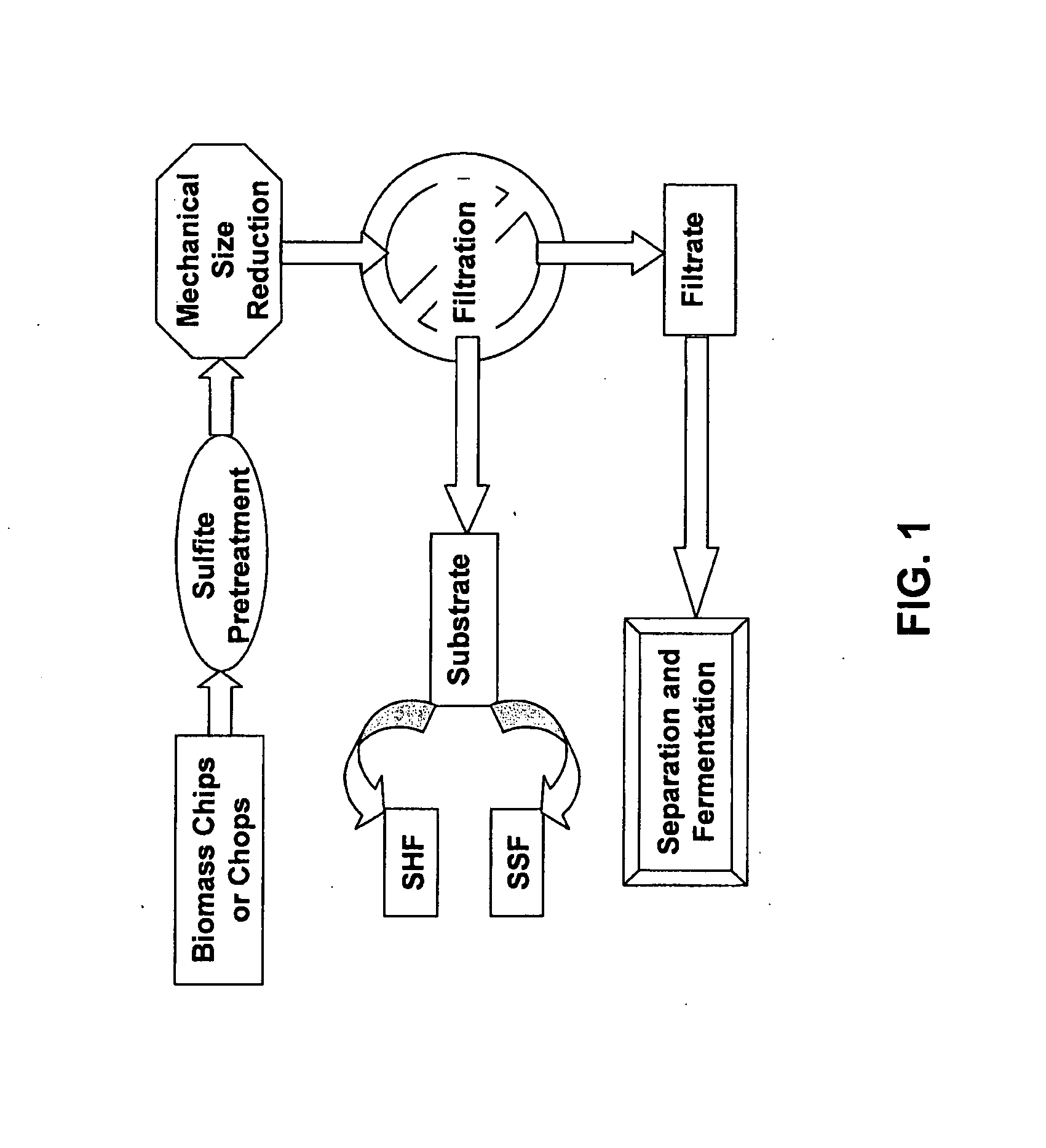

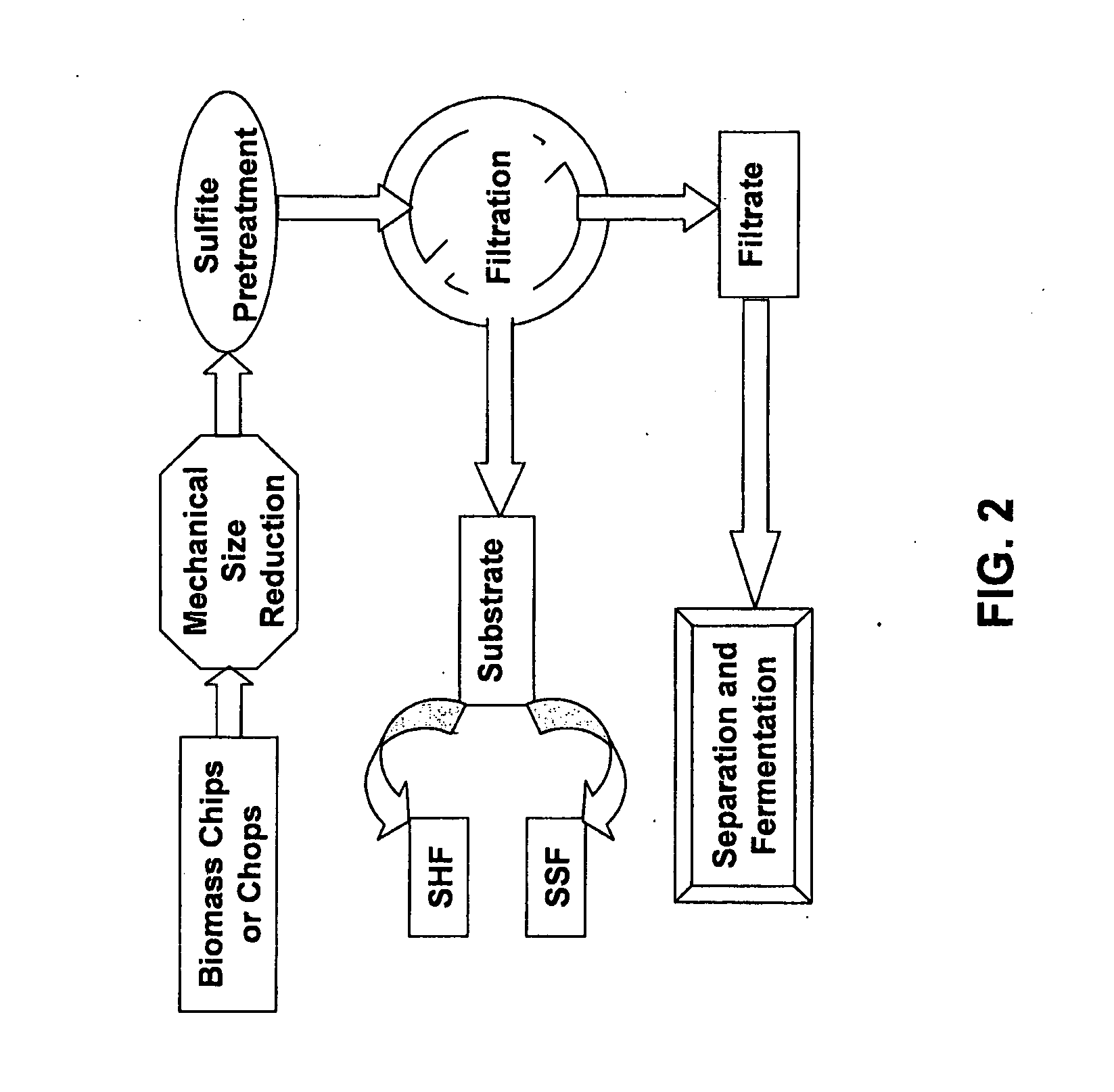

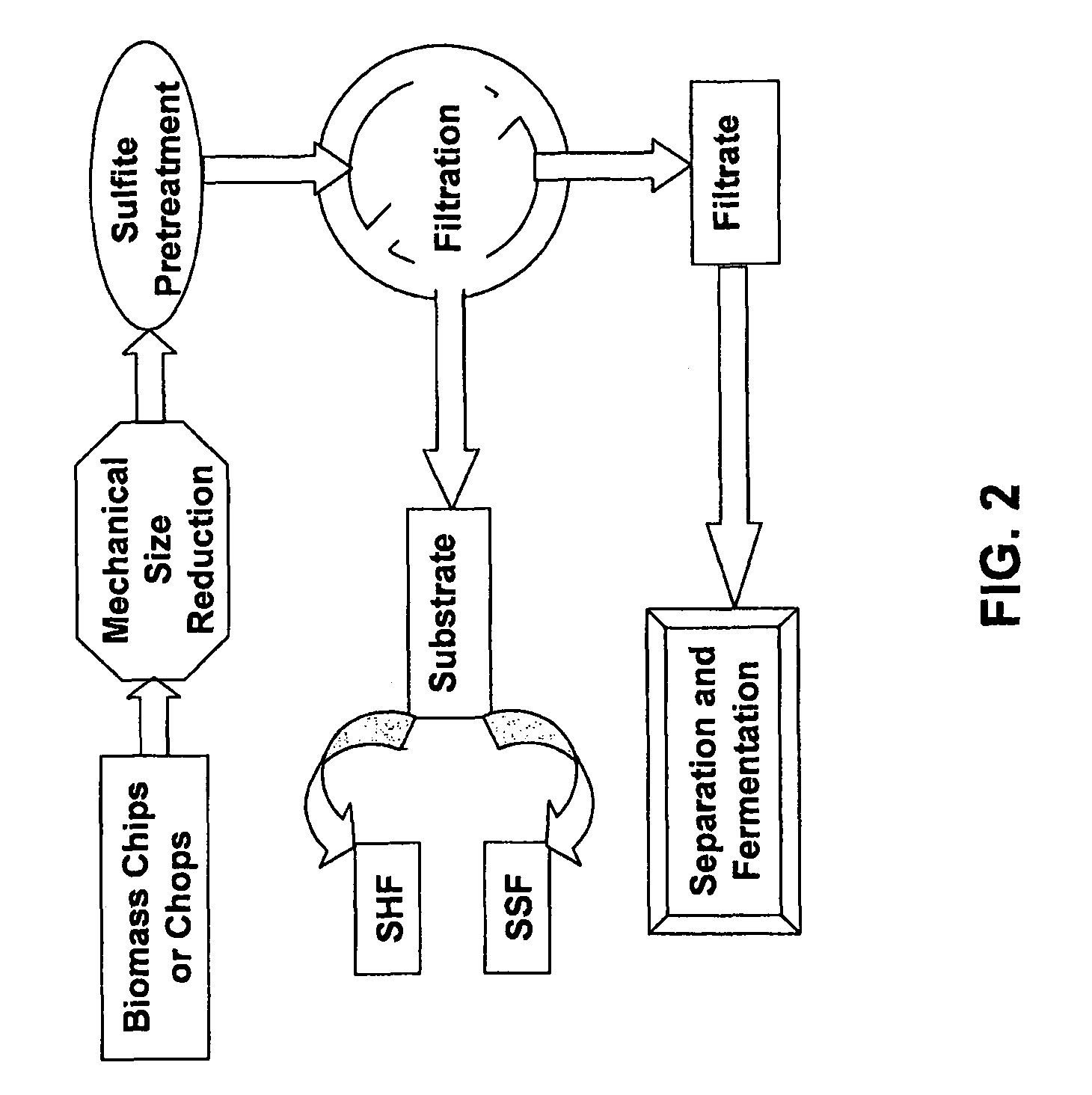

Sulfite Pretreatment For Biorefining Biomass

ActiveUS20090298149A1Save thermal energy consumptionImprove conversion efficiencyBiofuelsPaper recyclingCelluloseSulfite

The present invention relates to a method using sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL). More specifically, it relates to a sulfite-based chemical process for pretreating biomass in solutions to reduce access barriers of enzymes to the lignocellulose, resulting in efficient conversion through enzymatic saccharification.

Owner:US SEC AGRI +1

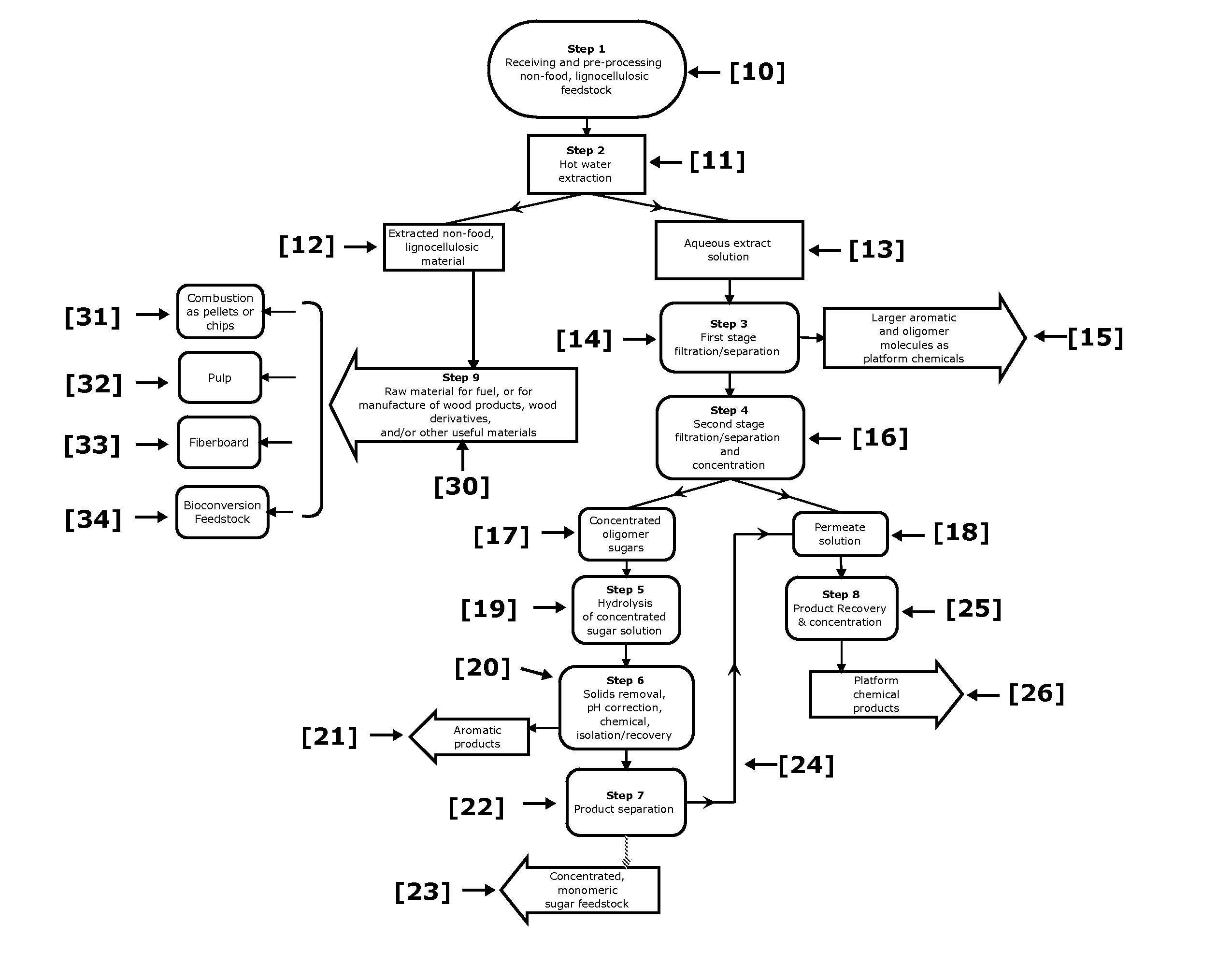

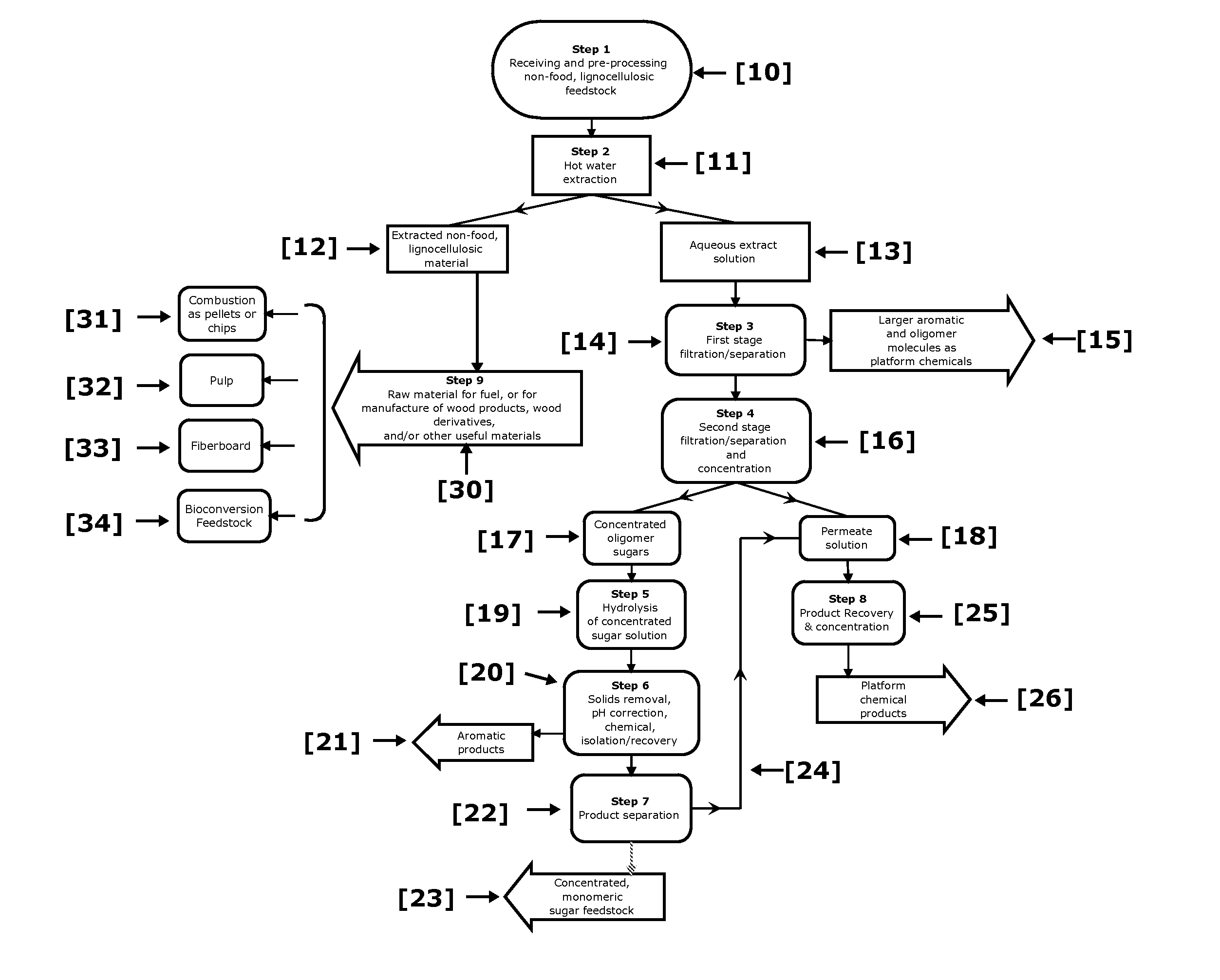

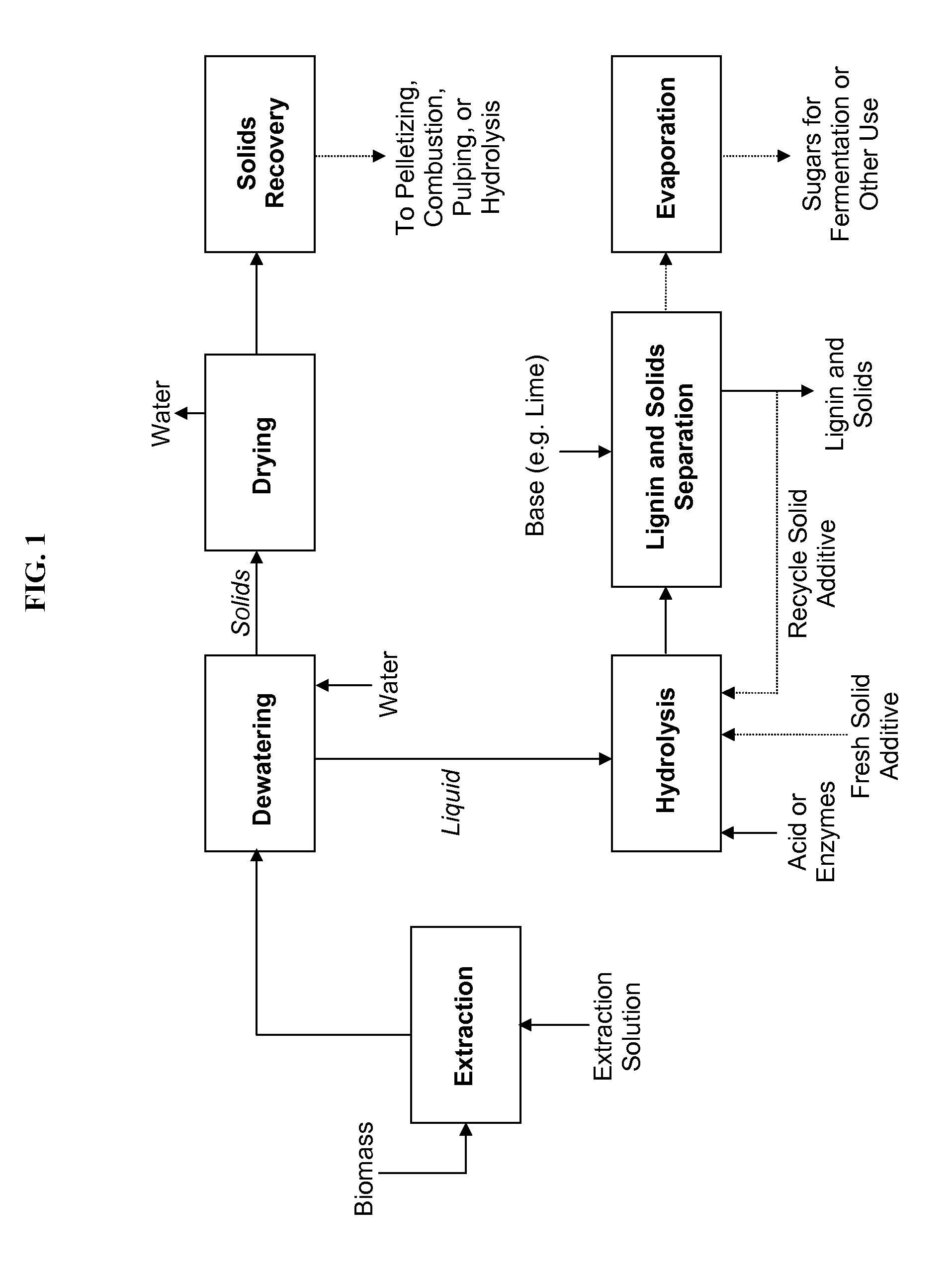

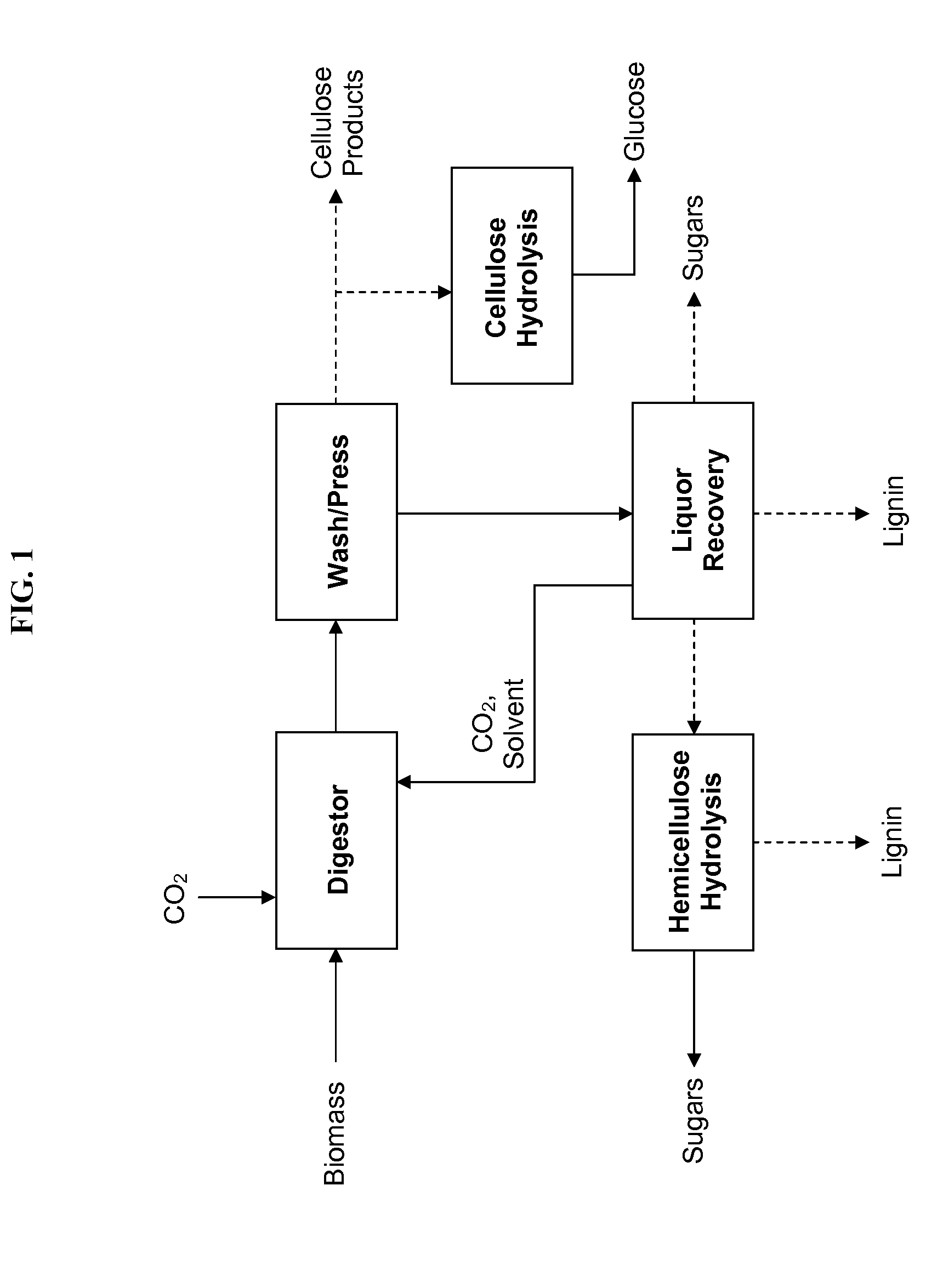

Biorefinery Process for Extraction, Separation, and Recovery of Fermentable Saccharides, other Useful Compounds, and Yield of Improved Lignocellulosic Material from Plant Biomass

ActiveUS20110129886A1Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

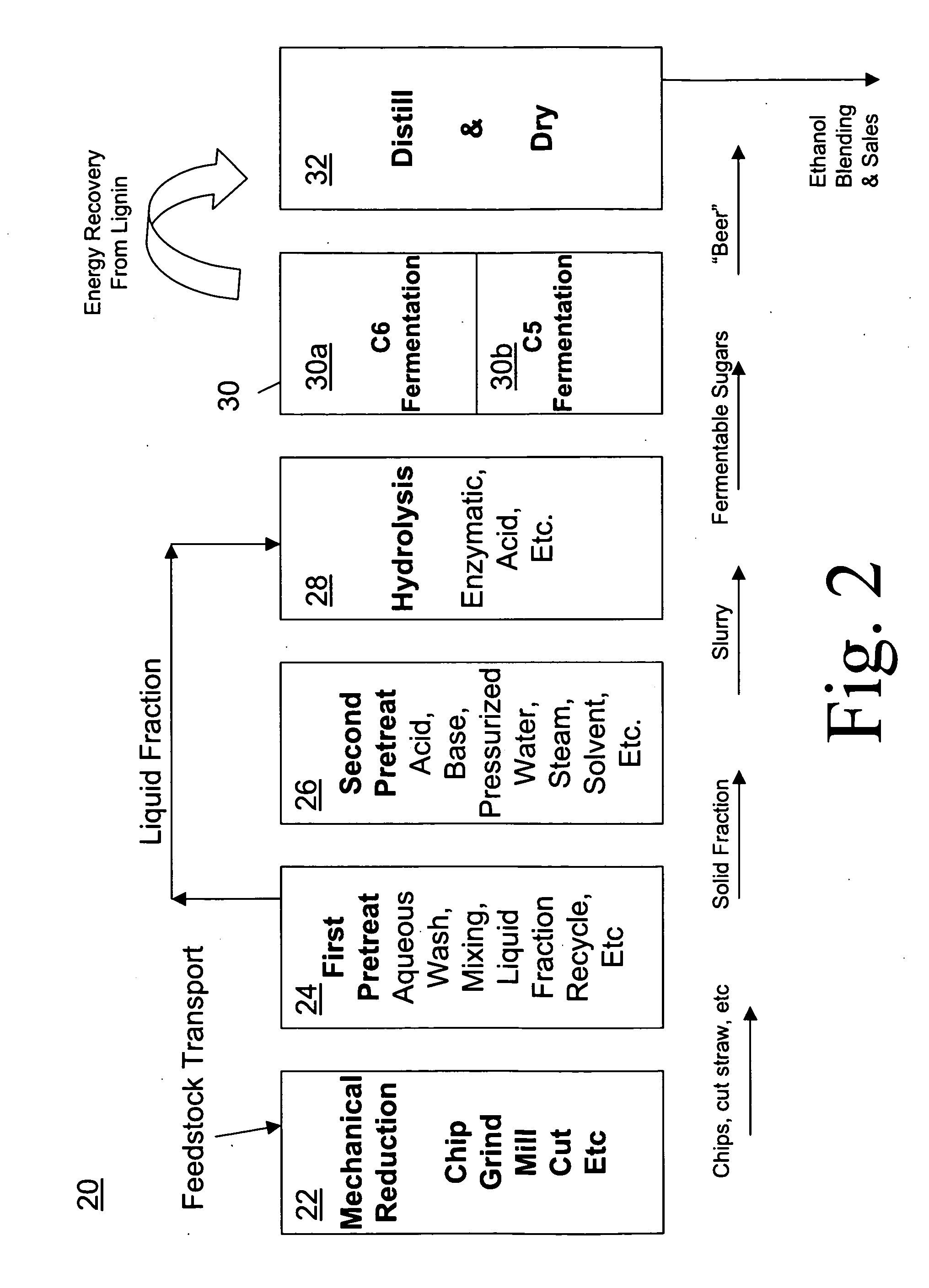

Treatment Systems and Processes for Lignocellulosic Substrates that Contain Soluble Carbohydrates

InactiveUS20090061495A1Lowering capital cost per unit of ethanol producedImprove throughputBiofuelsFermentationDistillationPolymer

A biorefining process used to convert lignocellulosic biomass into ethanol via a fermentation pathway. In a first pretreatment process step, the biomass is mixed with an aqueous wash solution to remove soluble carbohydrates from the biomass structure. Next, the solid fraction is separated from a liquid fraction. In a second pretreatment process, the solid fraction is pre-treated to make the fiber bundles and complex polysaccharides more amenable to enzymatic hydrolysis. Following the second pretreatment process, the pre-treated biomass is subjected to one or more enzymes in a hydrolysis process. The liquid fraction isolated from the first pretreatment process is diverted past the second pretreatment process and is recombined with the solid fraction in the hydrolysis process. The enzyme cocktail in the hydrolysis process breaks down the alpha- and hemicellulose polymers into fermentable sugars. Finally, a fermentation process produces a “beer” that is further processed in a distillation and dehydration process.

Owner:BEATTY CHRIS +2

Systems and Methods for Developing Terrestrial and Algal Biomass Feedstocks and Bio-Refining the Same

InactiveUS20130137154A1Maximize efficiencyMaximize efficacyFatty acid esterificationProductsAlgaePetroleum

Methods and systems for developing and bio-refining or processing biomass feedstocks into a spectrum of bio-based products which can be used as a substitute for fossil oil derivatives in various types of product manufacturing processes and / or the production of bio-energy are disclosed. In addition, methods and systems for identifying, measuring and controlling key parameters in relation to specific biomass developing processes and bio-refining processes so as to maximize the efficiency and efficacy of such processes while standardizing the underlying parameters to facilitate and enhance large-scale production of bio-based products and / or bio-energy are disclosed.

Owner:ORGINOIL INC

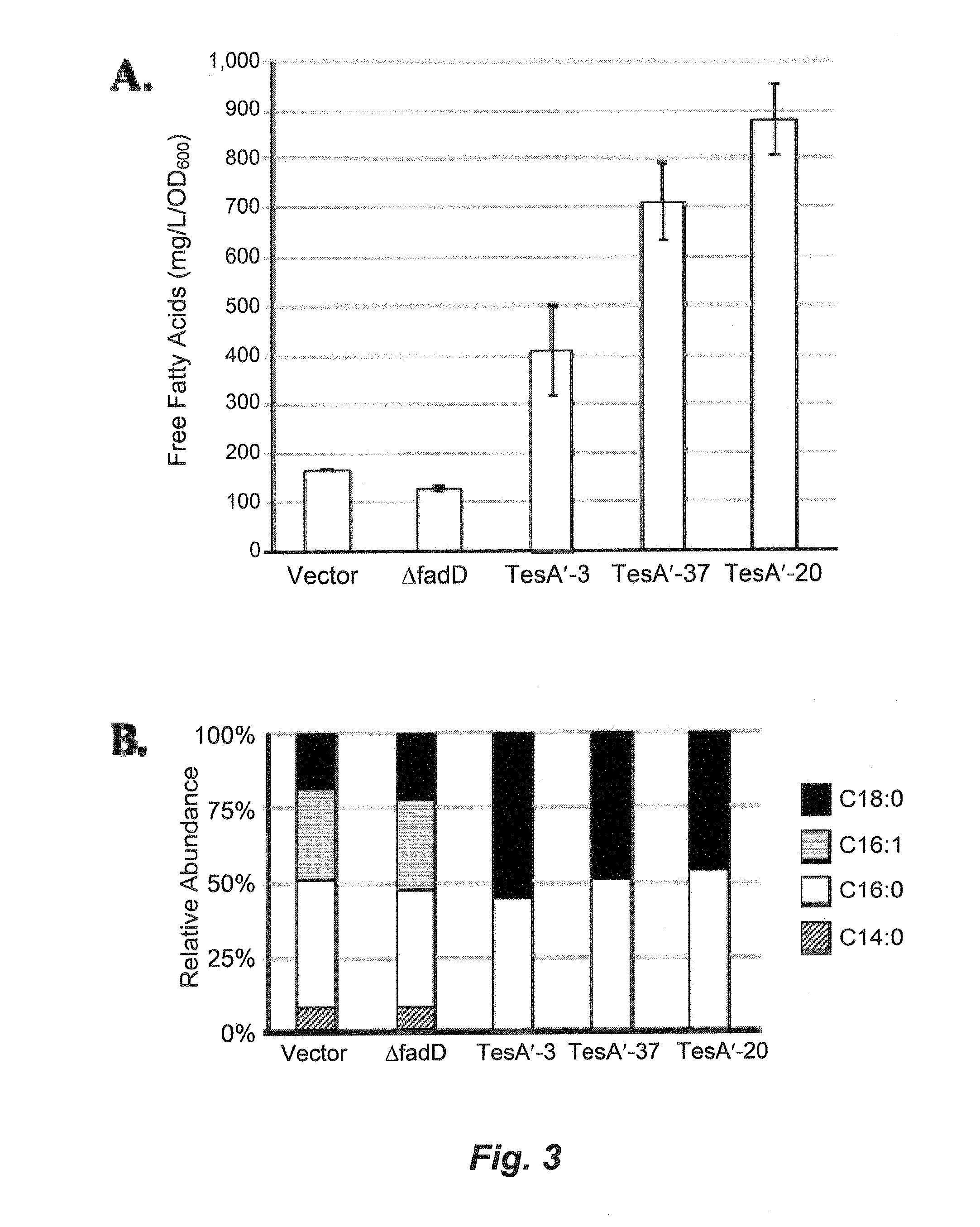

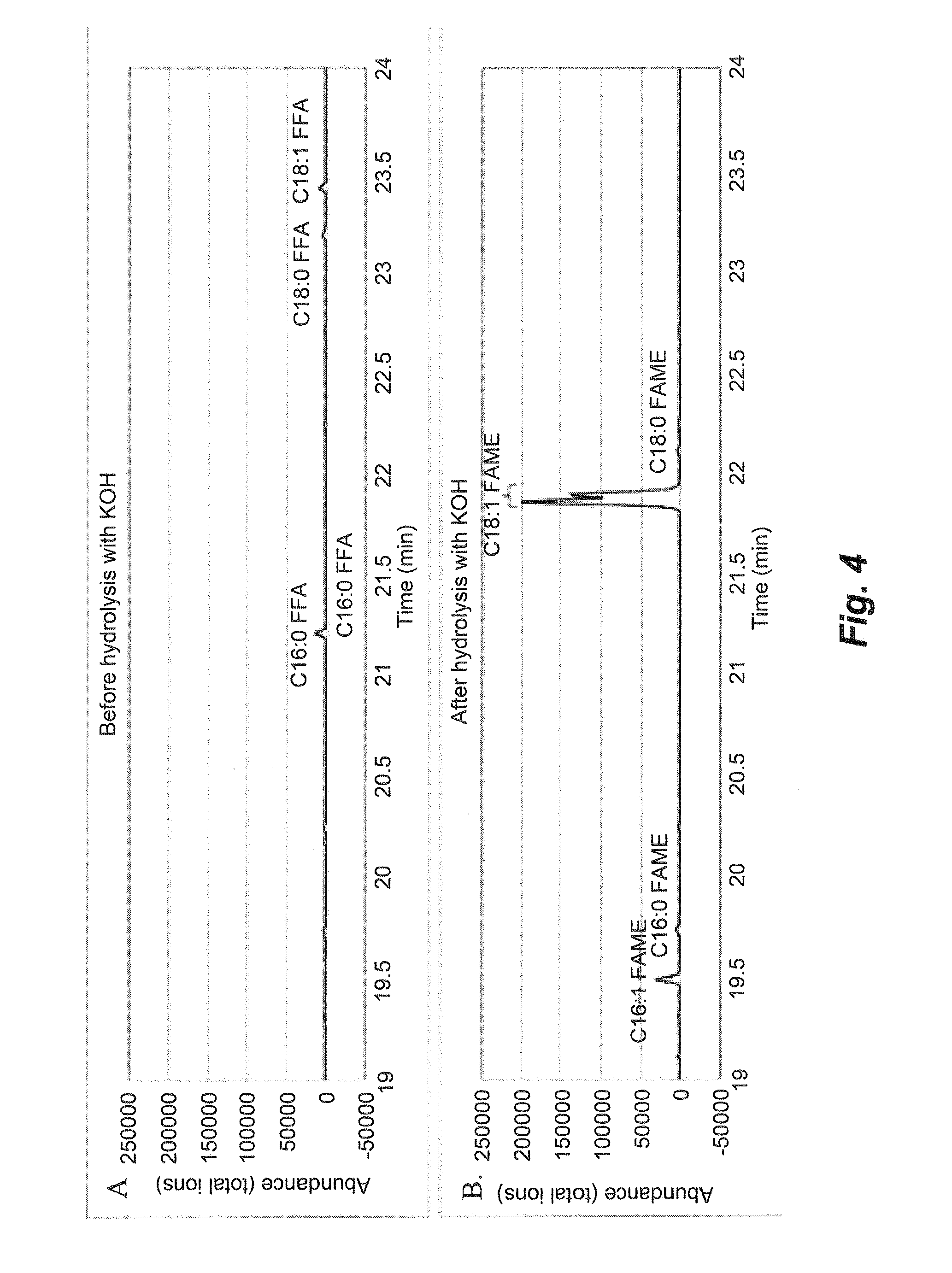

Biorefinery system, methods and compositions thereof

ActiveUS20140013658A1Efficiently and cost-effectively producingTaxing environmentFungiBacteriaBiofuelEngineering

The present disclosure relates to bioengineering approaches for producing biofuel and, in particular, to the use of a C1 metabolizing microorganism reactor system for converting C1 substrates, such as methane or methanol, into biomass and subsequently into biofuels, bioplastics, or the like.

Owner:CALYSTA

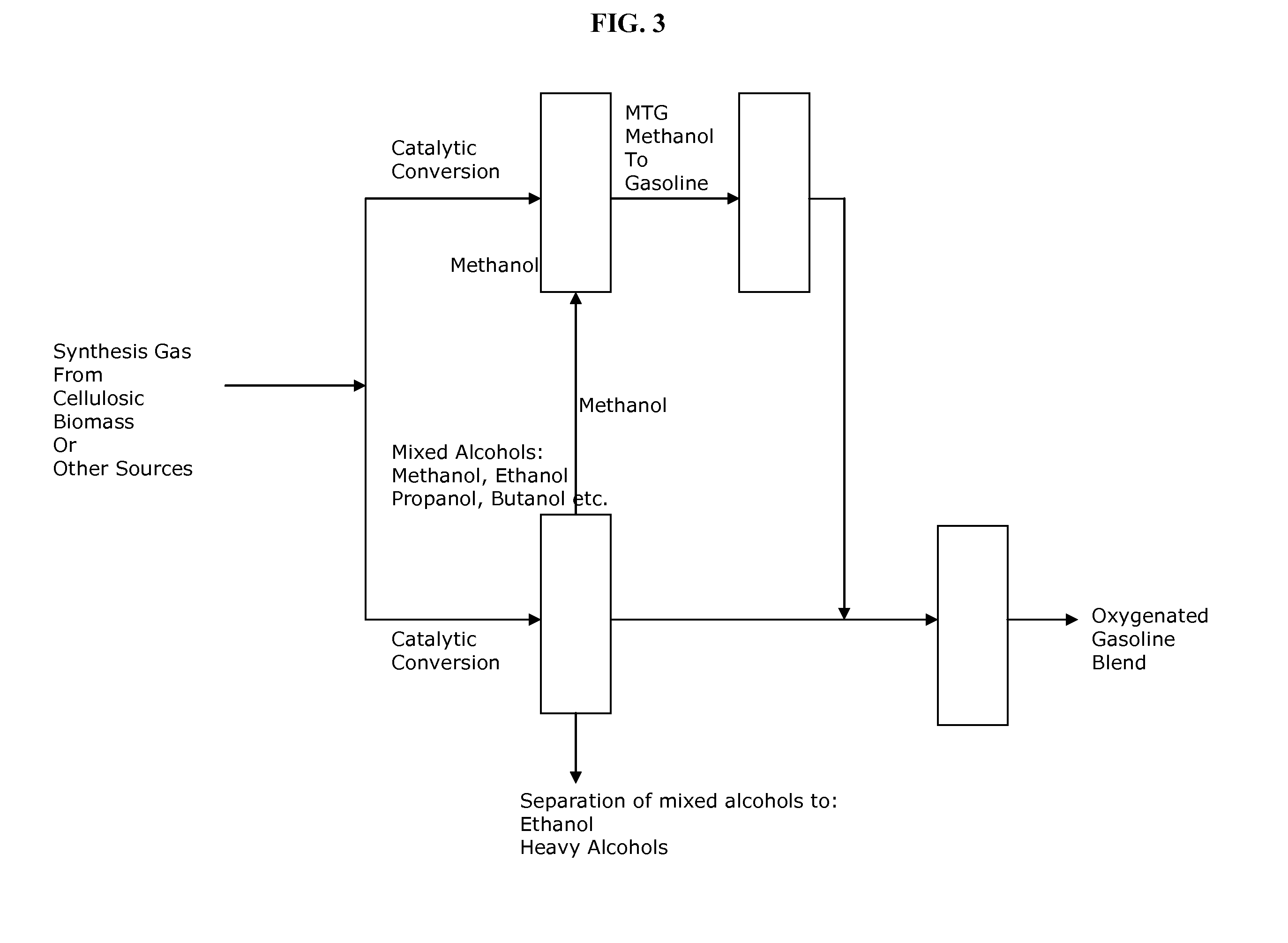

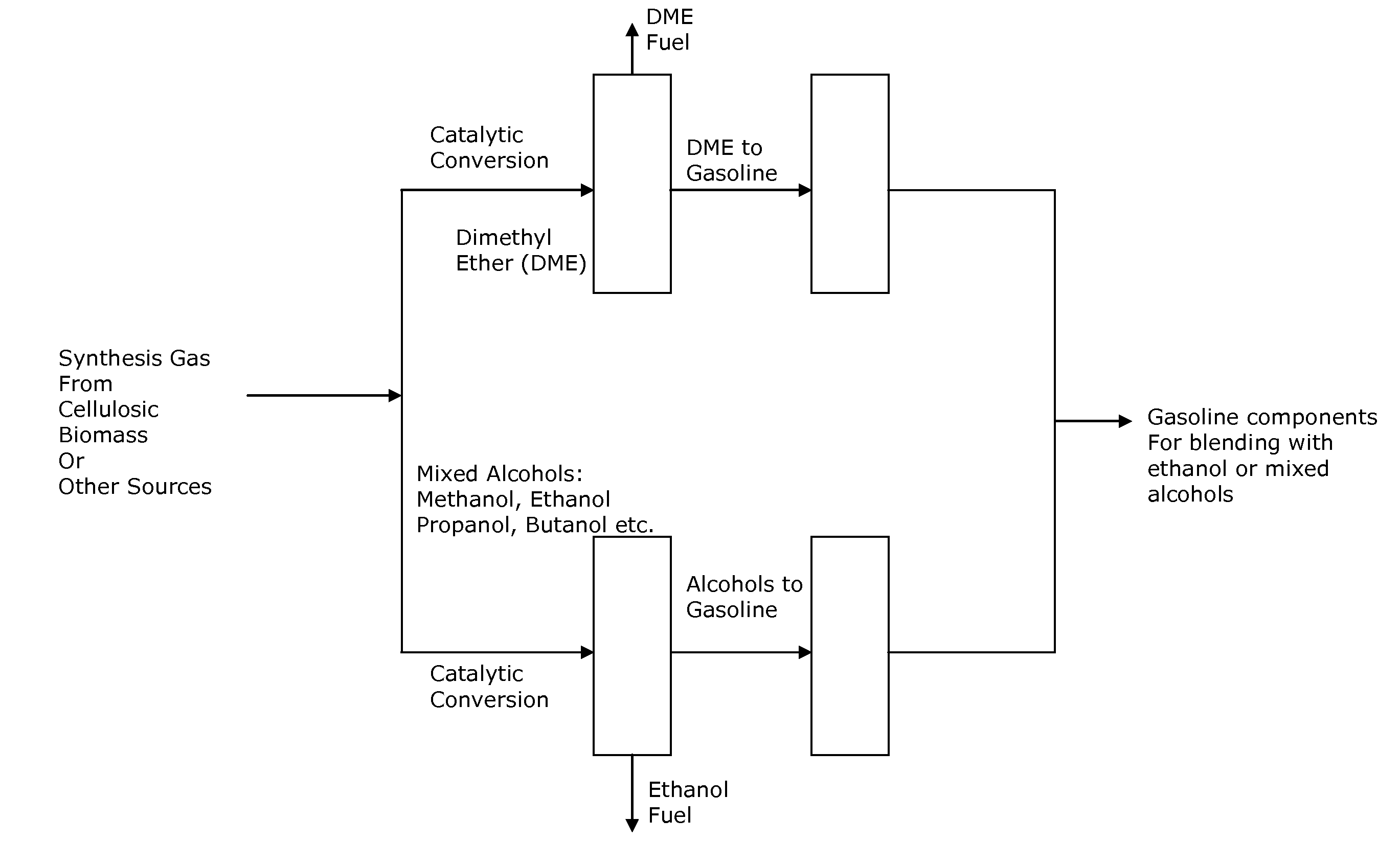

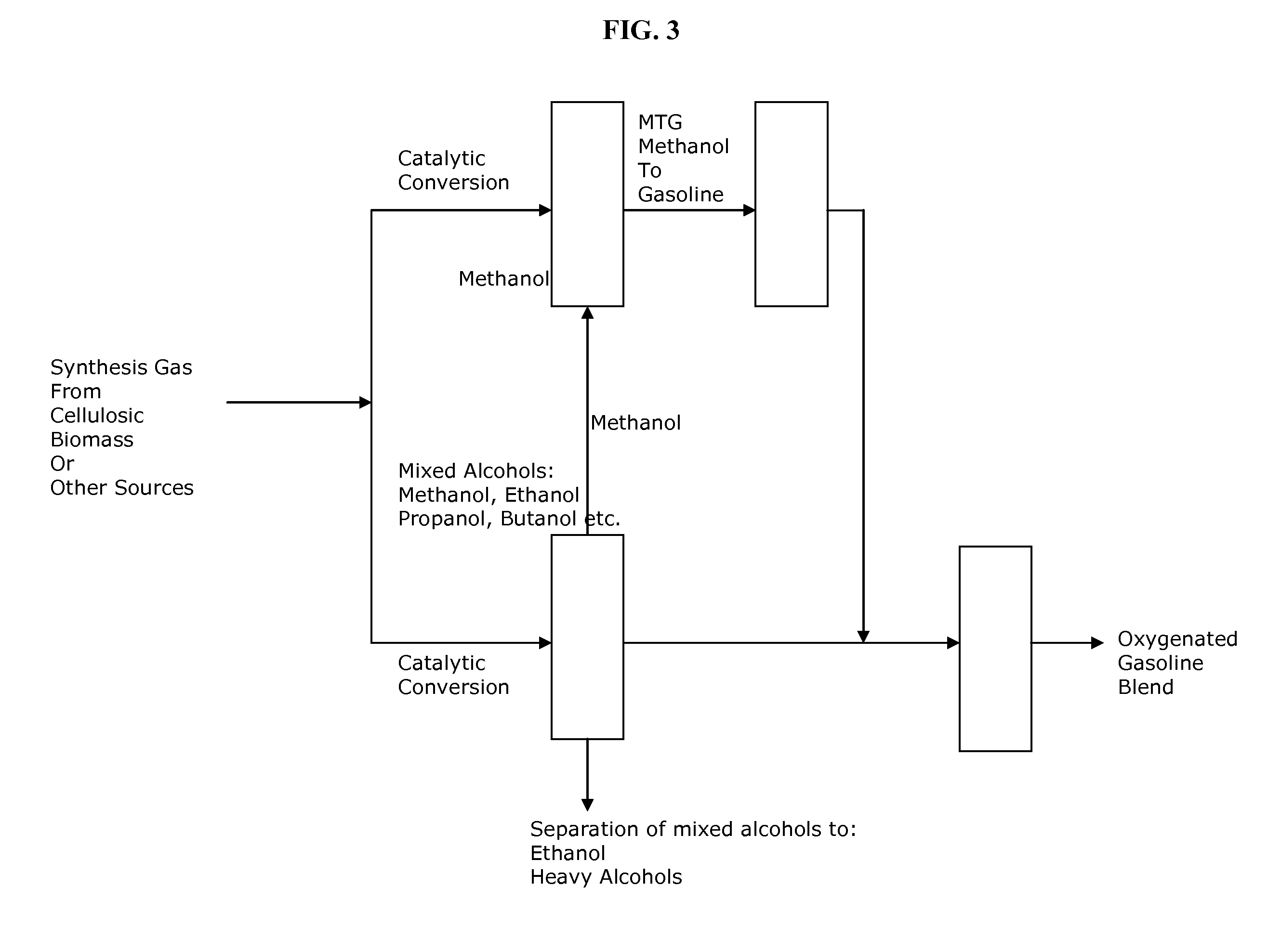

Process for producing renewable gasoline, and fuel compositions produced therefrom

InactiveUS20110107663A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsSyngasAlcohol

The present invention provides a process for producing gasoline components from syngas. Syngas is converted to one or more of methanol, ethanol, mixed alcohols, and dimethyl ether, followed by various combinations of separations and reactions to produce gasoline components with oxygenates, such as alcohols. The syngas is preferably derived from biomass or another renewable carbon-containing feedstock, thereby providing a biorefining process for the production of renewable gasoline.

Owner:RANGE FUELS INC

Process for producing renewable gasoline, and fuel compositions produced therefrom

The present invention provides a process for producing gasoline components from syngas. Syngas is converted to one or more of methanol, ethanol, mixed alcohols, and dimethyl ether, followed by various combinations of separations and reactions to produce gasoline components with oxygenates, such as alcohols. The syngas is preferably derived from biomass or another renewable carbon-containing feedstock, thereby providing a biorefining process for the production of renewable gasoline.

Owner:ALDOUS DAVID C MR

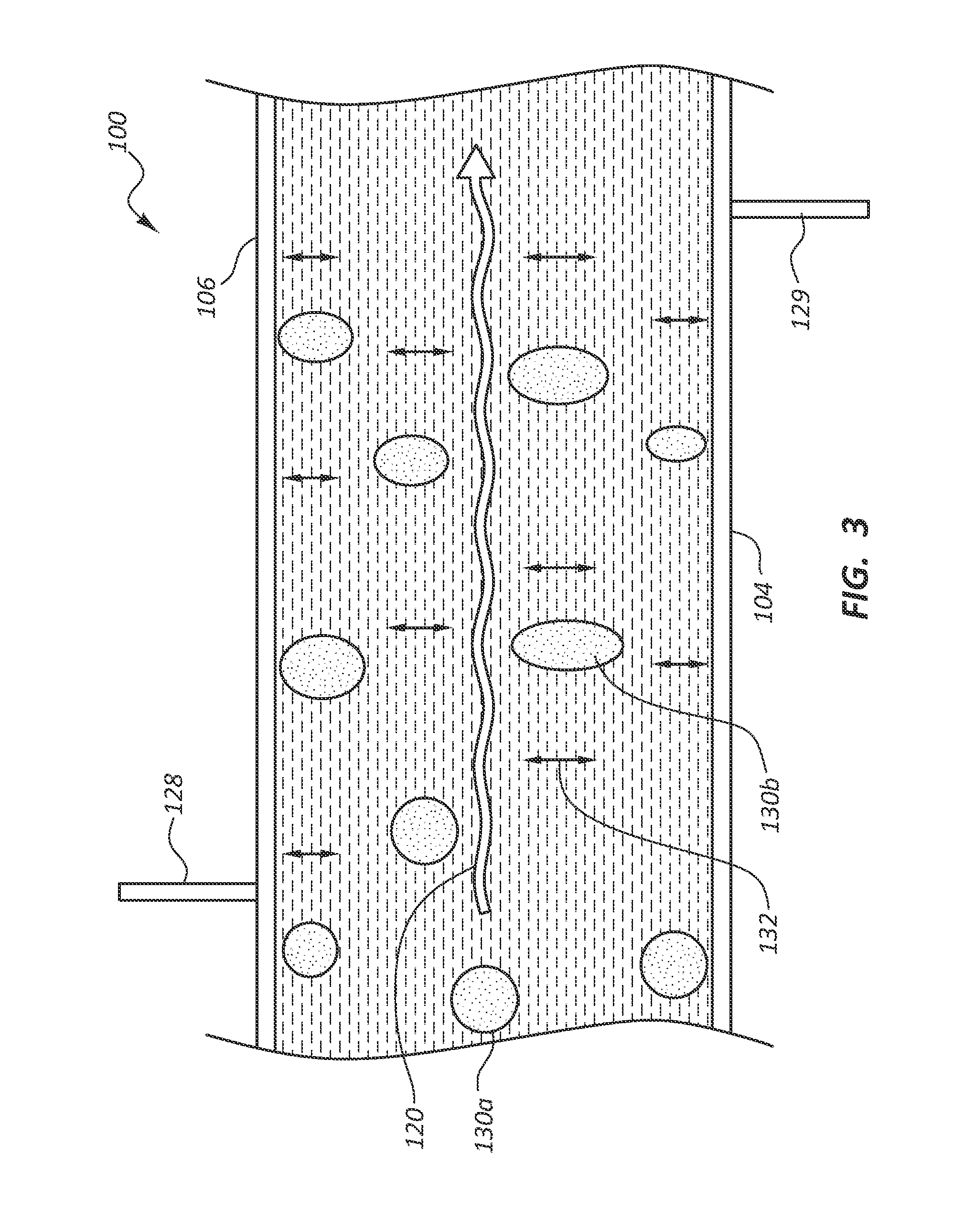

Systems and Methods for Increasing Growth of Biomass Feedstocks

InactiveUS20130164812A1Facilitate large-scale processBroaden applicationBioreactor/fermenter combinationsBiological substance pretreatmentsPetroleumBiomass

Methods and systems for developing and bio-refining or processing biomass feedstocks into a spectrum of bio-based products which can be used as a substitute for fossil oil derivatives in various types of product manufacturing processes and / or the production of bio-energy are disclosed. In addition, methods and systems for identifying, measuring and controlling key parameters in relation to specific biomass developing processes and bio-refining processes so as to maximize the efficiency and efficacy of such processes while standardizing the underlying parameters to facilitate and enhance large-scale production of bio-based products and / or bio-energy are disclosed.

Owner:ORGINOIL INC

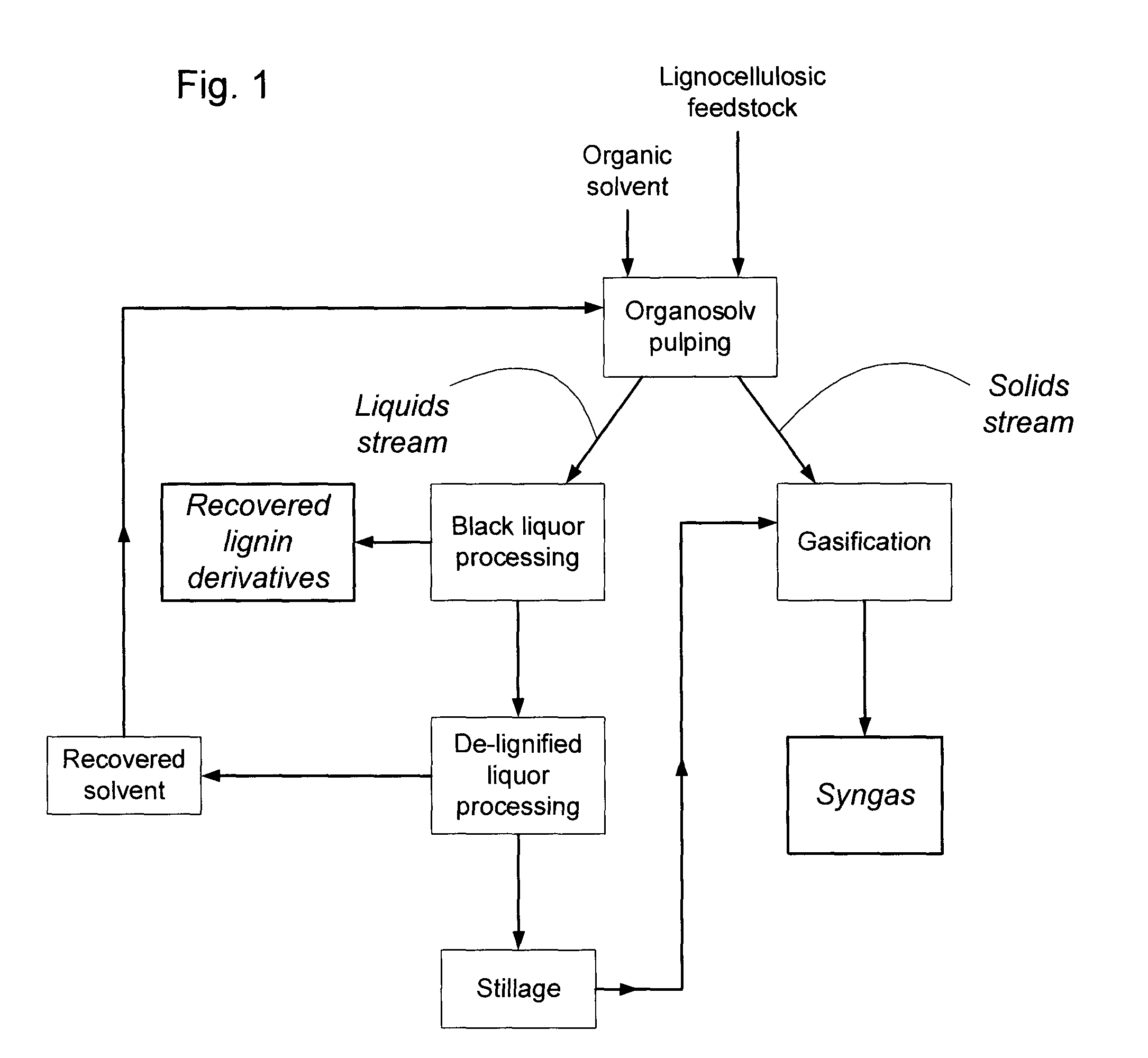

Hybrid biorefining and gasification of lignocellulosic feedstocks

InactiveUS20120202260A1Significant commercial valueProduce energyBiofuelsHydroxy compound preparationCelluloseSyngas

Processes and systems for concurrent recovery of lignin derivatives and syngas from a lignocellulosic feedstock. The processes and systems therefor generally comprise the steps of: (a) perfusing and cooking the lignocellulosic feedstock with a suitable organic solvent for a suitable period of time thereby producing a cellulosic solids output stream and a spent liquid solvent stream, said spent liquid solvent stream comprising solubilized lignin derivatives and other organic compounds; (b) separating said cellulosic solids output stream and said spent liquid solvent stream; (c) recovering lignin derivatives from the spent liquid solvent stream thereby producing at least a partially de-lignified spent liquid solvent stream; (d) recovering a portion of the organic solvent from the at least partially de-lignified spent liquid solvent stream thereby producing a stillage; and (e) gasifying the cellulosic solids output stream thereby producing a combustible syngas.

Owner:LIGNOL INNOVATIONS

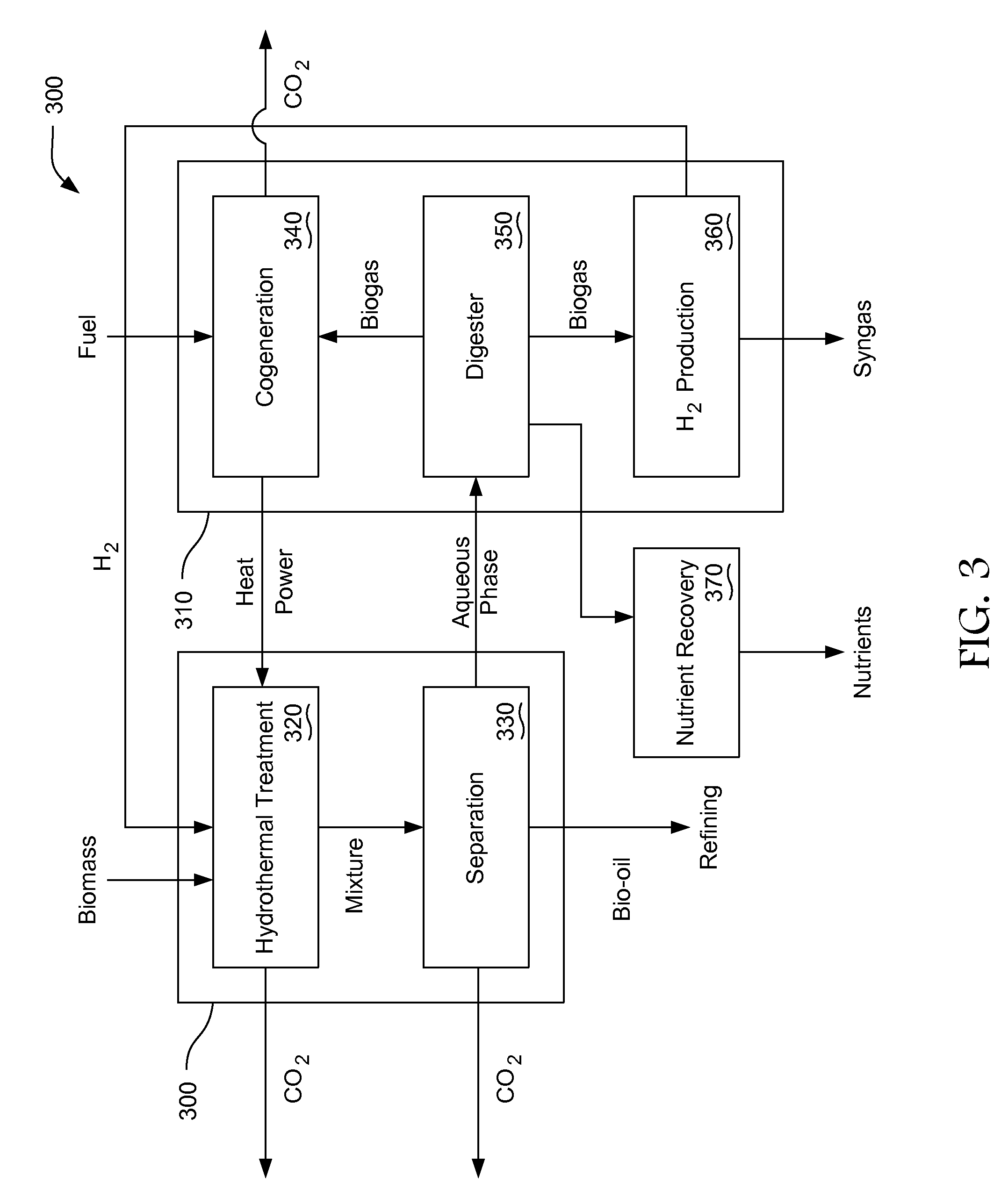

Integrated Biorefinery

InactiveUS20140273141A1Bioreactor/fermenter combinationsBiological substance pretreatmentsElectricityWaste stream

Integrated biorefineries are provided that integrate biomass cultivation with processing to convert cultivated biomass to a fuel, and further integrate carbon recovery from the biomass processing. Biomass processing to fuels begins in a treatment system, such as a hydrothermal treatment system, that produces an organic phase that is suitable for refining to a fuel and also produces a waste stream. The biorefinery optionally includes a dewatering system, a refining system to convert the organic phase to the fuel, and a cogeneration system configured to use at least some of the fuel produced by the treatment system to generate electricity and heat that can be used for biorefinery operations.

Owner:IHI INC

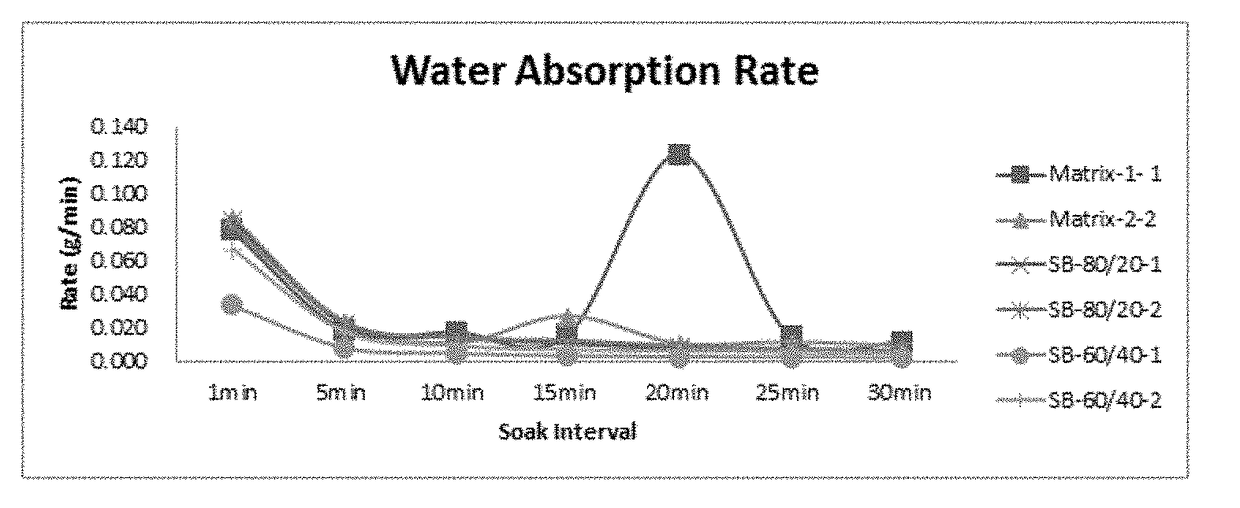

Starch Foams Using Specialized Lignin

This application provides a method of using a highly clarified and clean lignin, derived from a specific biorefinery process to make a starch foam and products of the same. The lignin can be used as a low cost filler substitute for starch and other substrates that are currently employed in foam applications. The lignin has the right mechanical, physical, thermoplastic and barrier properties to enable easy handling and to impart improved properties such as UV resistance, water resistance and other physical parameters to starch foams.

Owner:SWEETWATER ENERGY INC

Sulfite pretreatment for biorefining biomass

Owner:US SEC AGRI +1

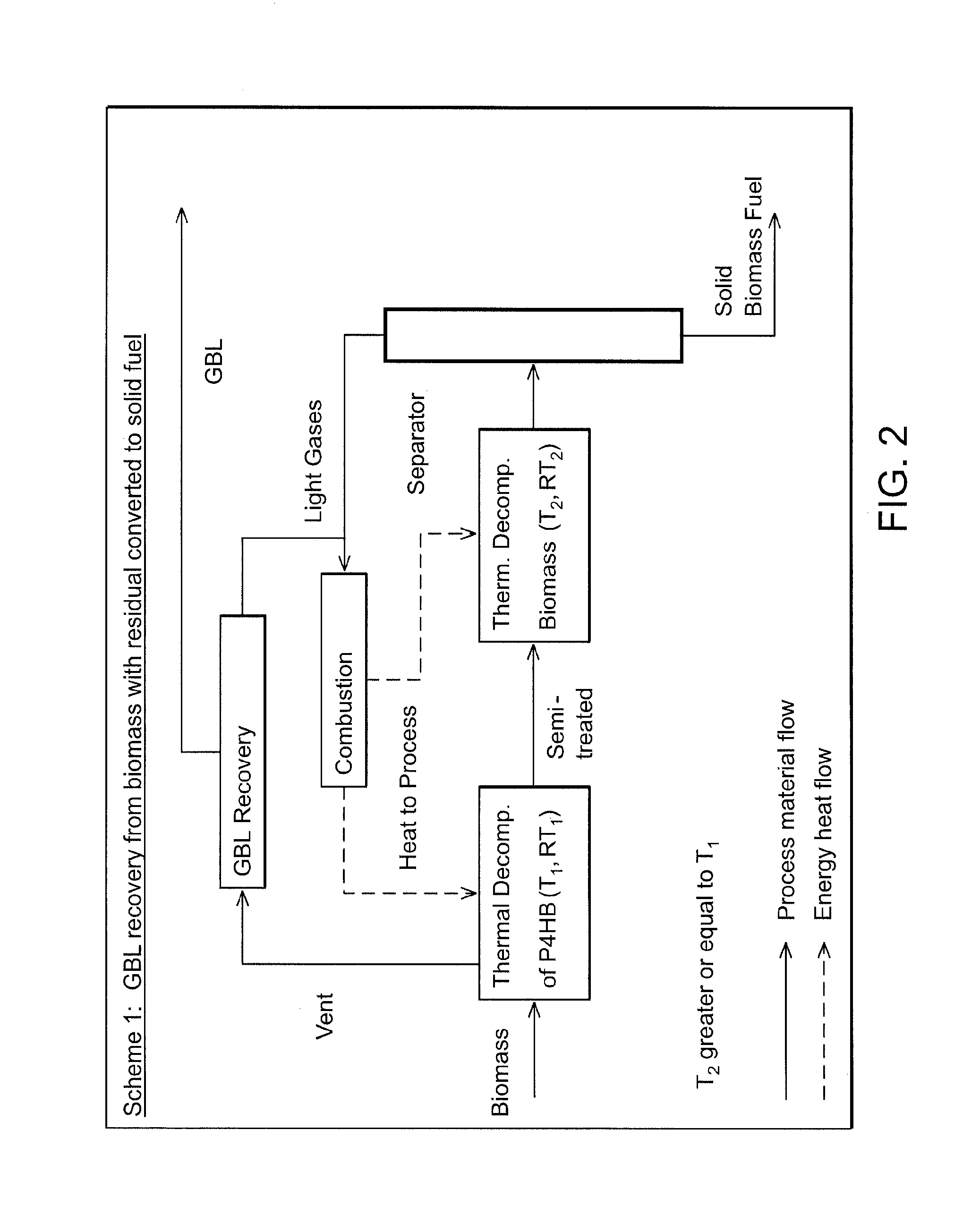

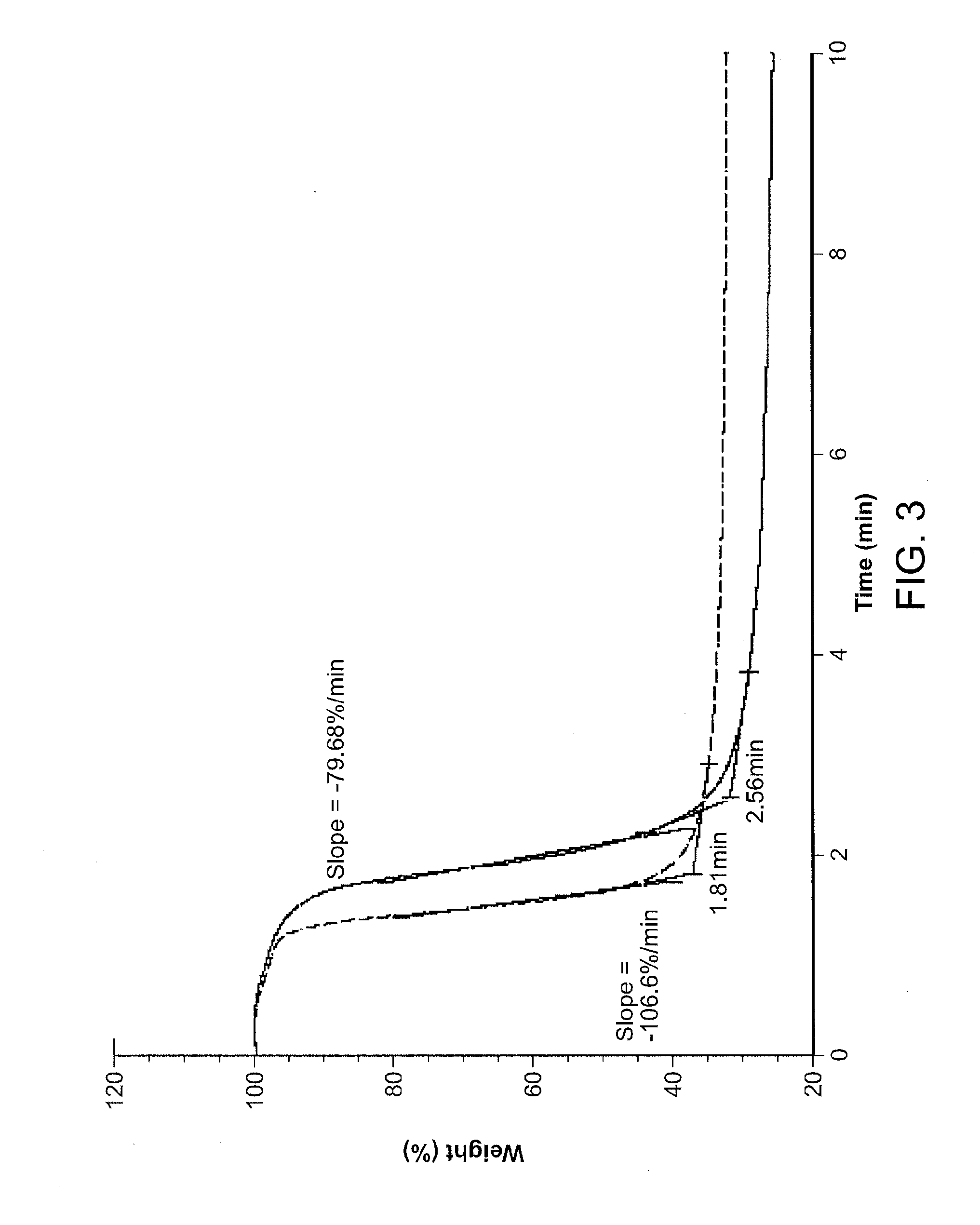

Biorefinery Process For THF Production

Processes and methods for making biobased tetrahydrofuran products from renewable carbon resources are described herein.

Owner:METABOLIX

Processes and apparatus for lignin separation in biorefineries

The present invention generally provides methods of improving lignin separation during lignocellulosic biorefining, comprising the steps of (i) catalyzing fractionation or hydrolysis with an acid to release sugars into an acidified solution containing lignin, (ii) neutralizing the acidified solution with a base to form a salt in a neutralized solution; (iii) in a separation unit, separating the salt and the lignin, each in free or combined form, from the neutralized solution; and then (iv) recycling a portion of the salt and optionally a portion of the lignin to step (i) to combine, physically or chemically, with the lignin, to improve lignin separation in the separation unit. In certain embodiments, the acid is a sulfur-containing acid and the base is lime, forming gypsum which is then recycled, in part, to the hydrolysis reactor.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Process for producing renewable gasoline, and fuel compositions produced therefrom

InactiveUS20110107662A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsSyngasAlcohol

The present invention provides a process for producing gasoline components from syngas. Syngas is converted to one or more of methanol, ethanol, mixed alcohols, and dimethyl ether, followed by various combinations of separations and reactions to produce gasoline components with oxygenates, such as alcohols. The syngas is preferably derived from biomass or another renewable carbon-containing feedstock, thereby providing a biorefining process for the production of renewable gasoline.

Owner:RANGE FUELS INC

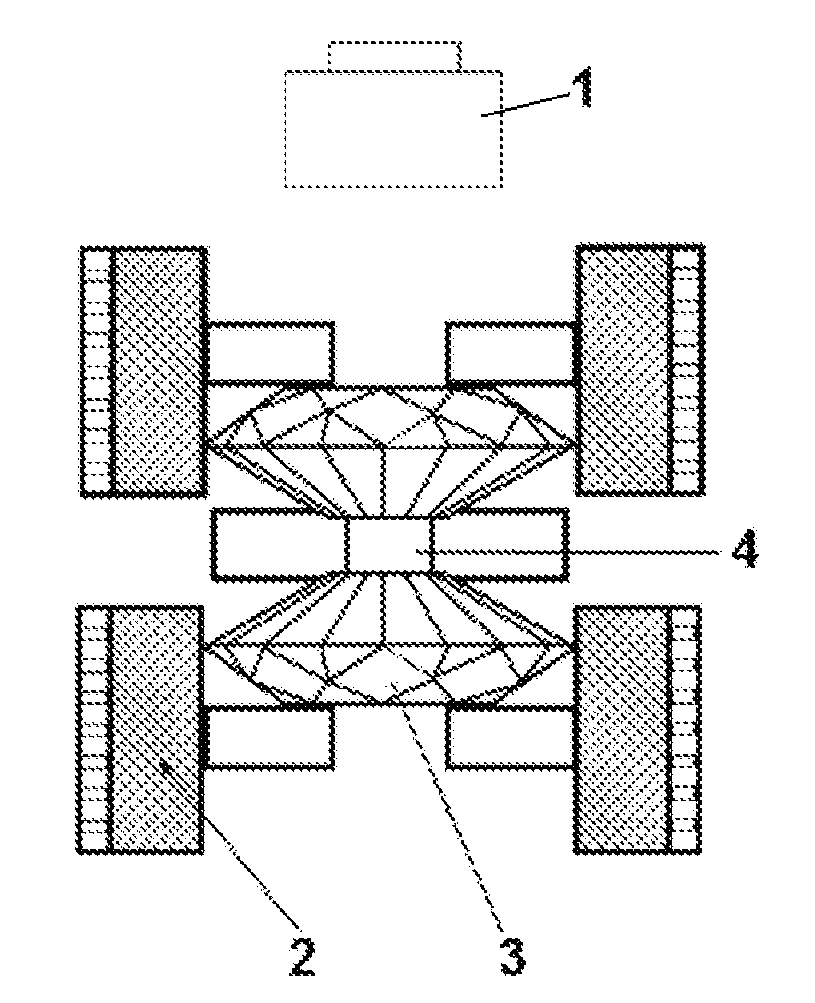

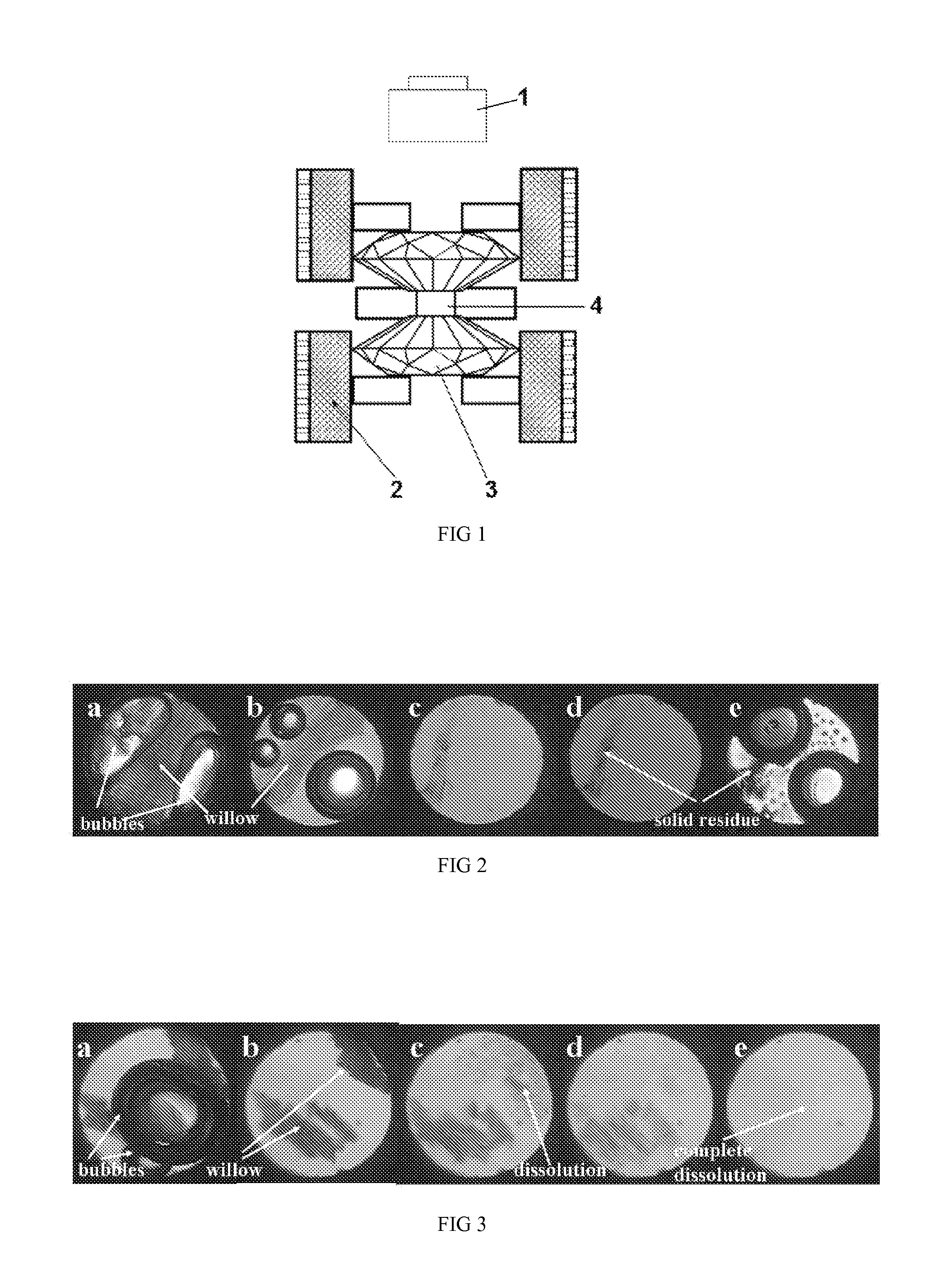

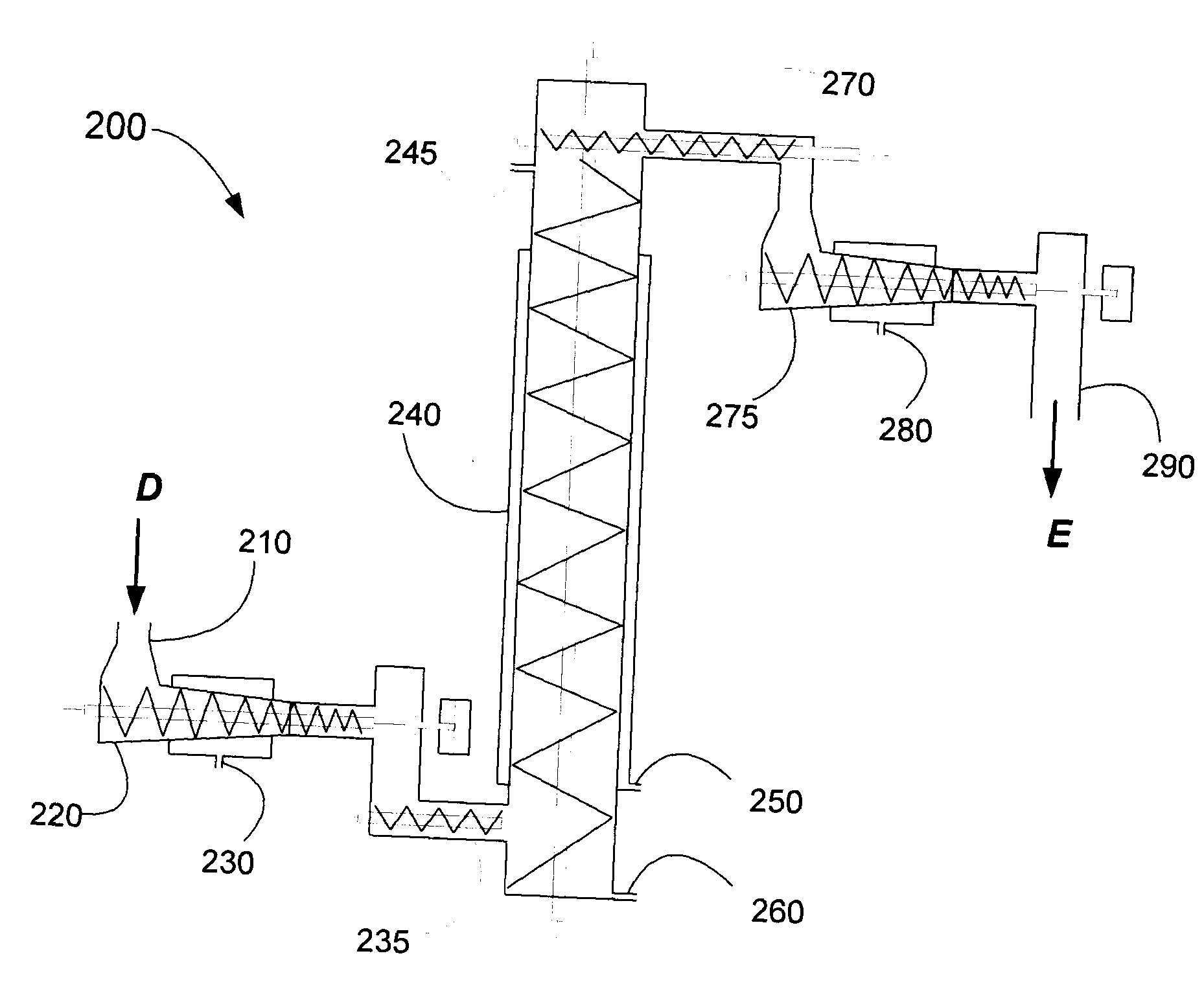

Method, equipment and applications for fast complete dissolution and hydrolysis of lignocellulosic biomass

ActiveUS20100270499A1Quickly and completely dissolve biomassOther chemical processesLiquid hydrocarbon mixture productionCelluloseHydrolysate

The invention herein discloses a method and its equipment for fast and complete dissolution and hydrolysis of lignocellulosic biomass. Lignocellulosic biomass is placed in a dilute alkaline solution and then rapidly heated to a temperature between 329˜367° C. to achieve complete dissolution of the lignocellulosic biomass as biomass solution in 0.7˜2 s. The biomass solution is further hydrolyzed rapidly to hydrolysates at homogeneous conditions. The solubilized biomass solution is easy to rapidly hydrolyze into sugars to produce bio-fuels and other value-added products, and to rapidly quench to produce micron particles in the continuous flow equipment at high pressures and high temperatures. The invention herein provides a simple and low-cost method to quickly dissolve and hydrolyze biomass with great potential for a novel biorefinery.

Owner:FANG ZHEN +1

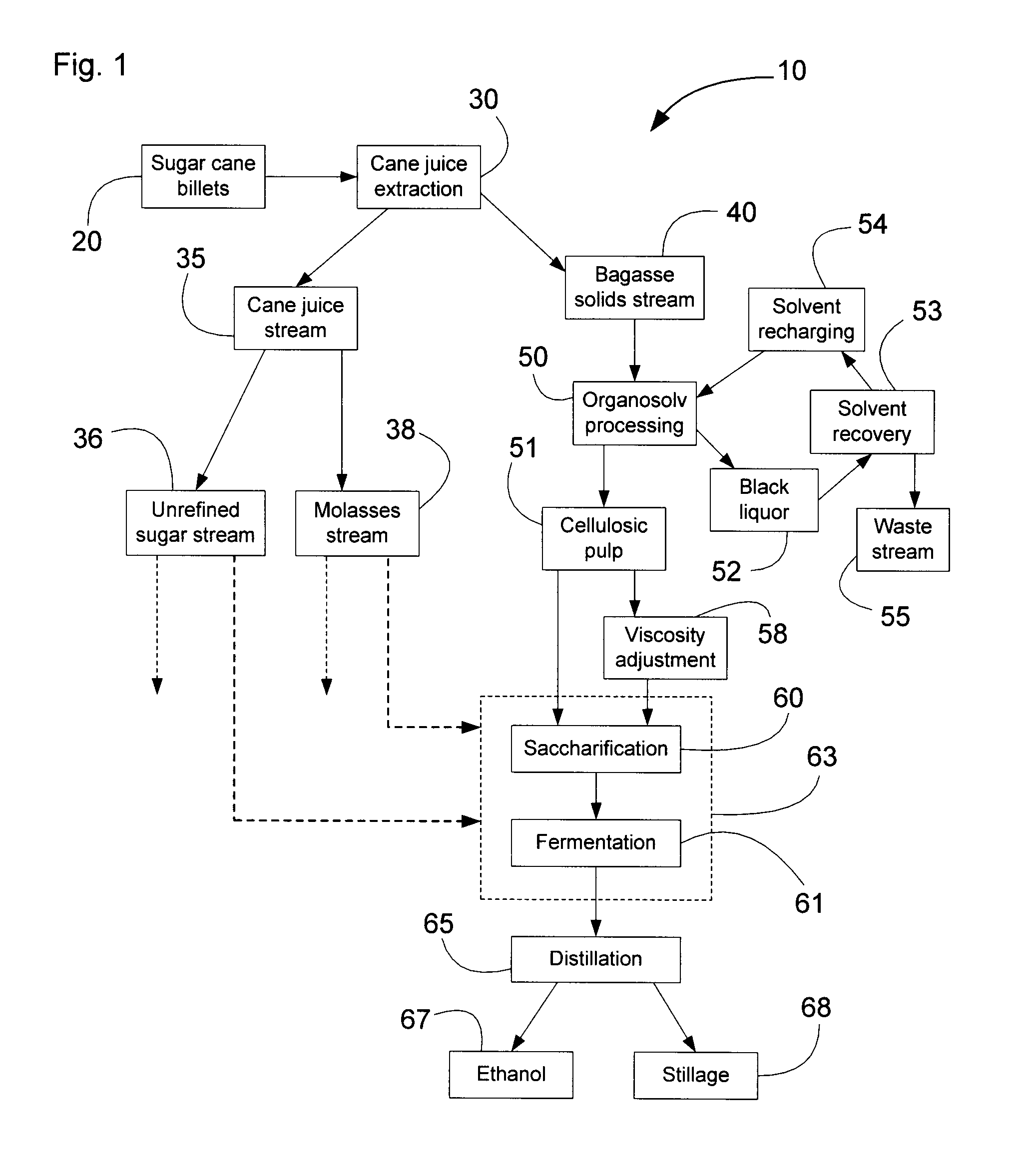

Organosolv biorefining of whole sugar cane

InactiveUS20120094348A1Reduce accumulationBioreactor/fermenter combinationsPressurized chemical processOrganosolvCellulose pulp

An apparatus for processing sugar cane to concurrently produce sugar from cane juice, and ethanol and other co-products from bagasse. The apparatus comprises equipment for separating a cane juice stream and a fibrous bagasse from a sugar cane feed-stock, equipment for refining the cane juice, equipment for processing the fibrous bagasse for recovery therefrom of a cellulosic pulp and a liquor stream, equipment for saccharification and fermentation of the cellulosic pulp to produce a fermentation beer therefrom, and equipment for recovery of an ethanol stream from the fermentation beer. Legacy sugar mills may be retrofitted with a bagasse biorefining apparatus to concurrently produce ethanol and co-products, with existing cane juice extraction and processing operations.

Owner:LIGNOL INNOVATIONS

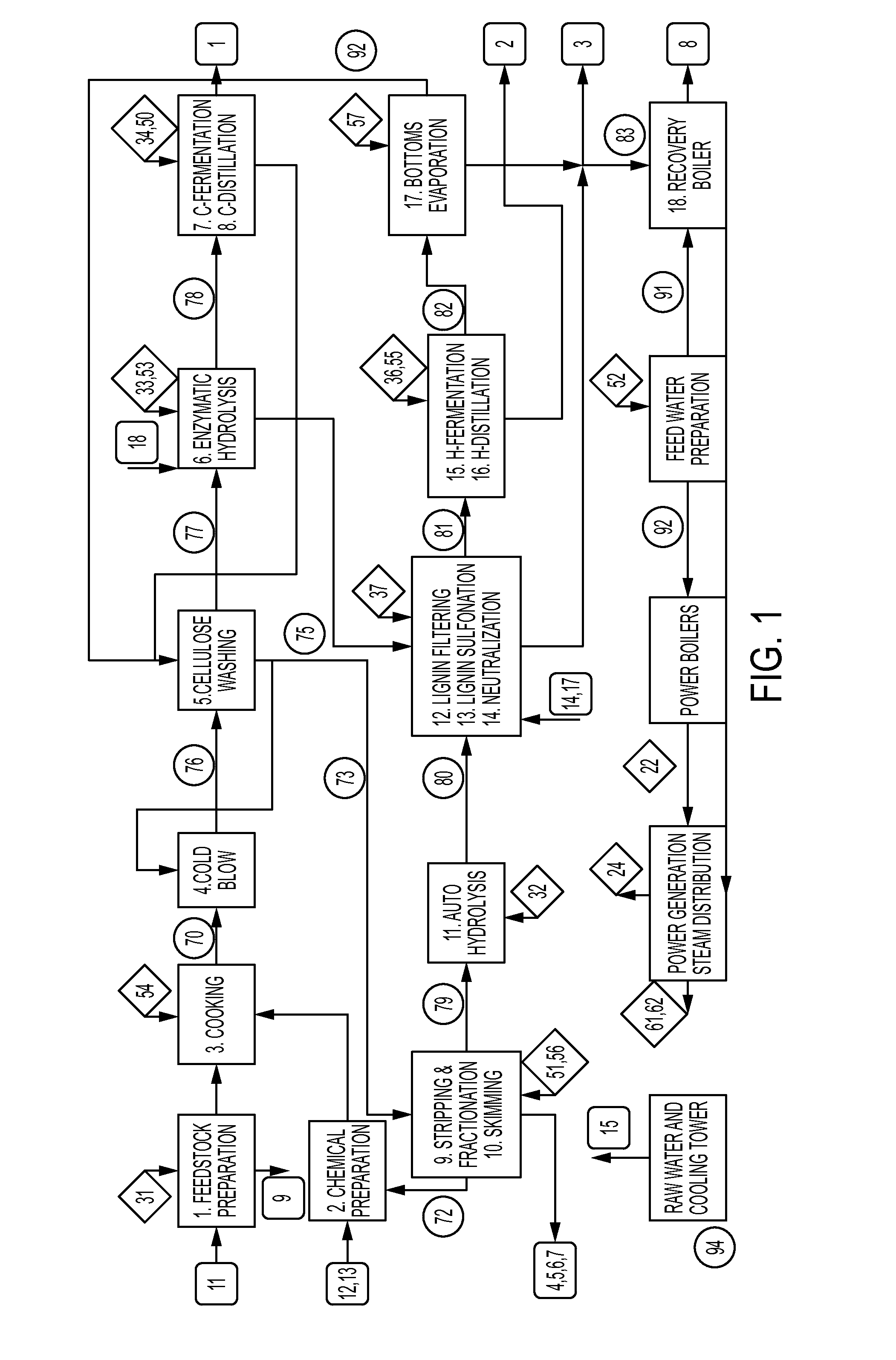

Integration of non-woody biorefining at pulp and paper plants

ActiveUS20150275432A1Enhance the imageBiofuelsPulping with acid salts/anhydridesCelluloseProcess integration

In some variations, a process is provided for producing a pulp product at a biorefinery site, comprising: converting a woody cellulosic material to a first pulp stream; converting a non-woody cellulosic material to a second pulp stream; blending the second pulp stream into the first pulp stream; and recovering or further processing the blended pulp stream as a pulp product. Biorefinery site infrastructure may be shared between the woody and non-woody lines. Also, the process may include process integration of mass and / or energy between the woody and non-woody lines. The process may be a retrofit addition to a pulp plant, or a greenfield biorefinery site. The non-woody line also can generate fermentable sugars, for fermentation to ethanol (or other products). Through allocation of carbon credits from the ethanol to the pulp, the final pulp product life-cycle profile can be improved.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

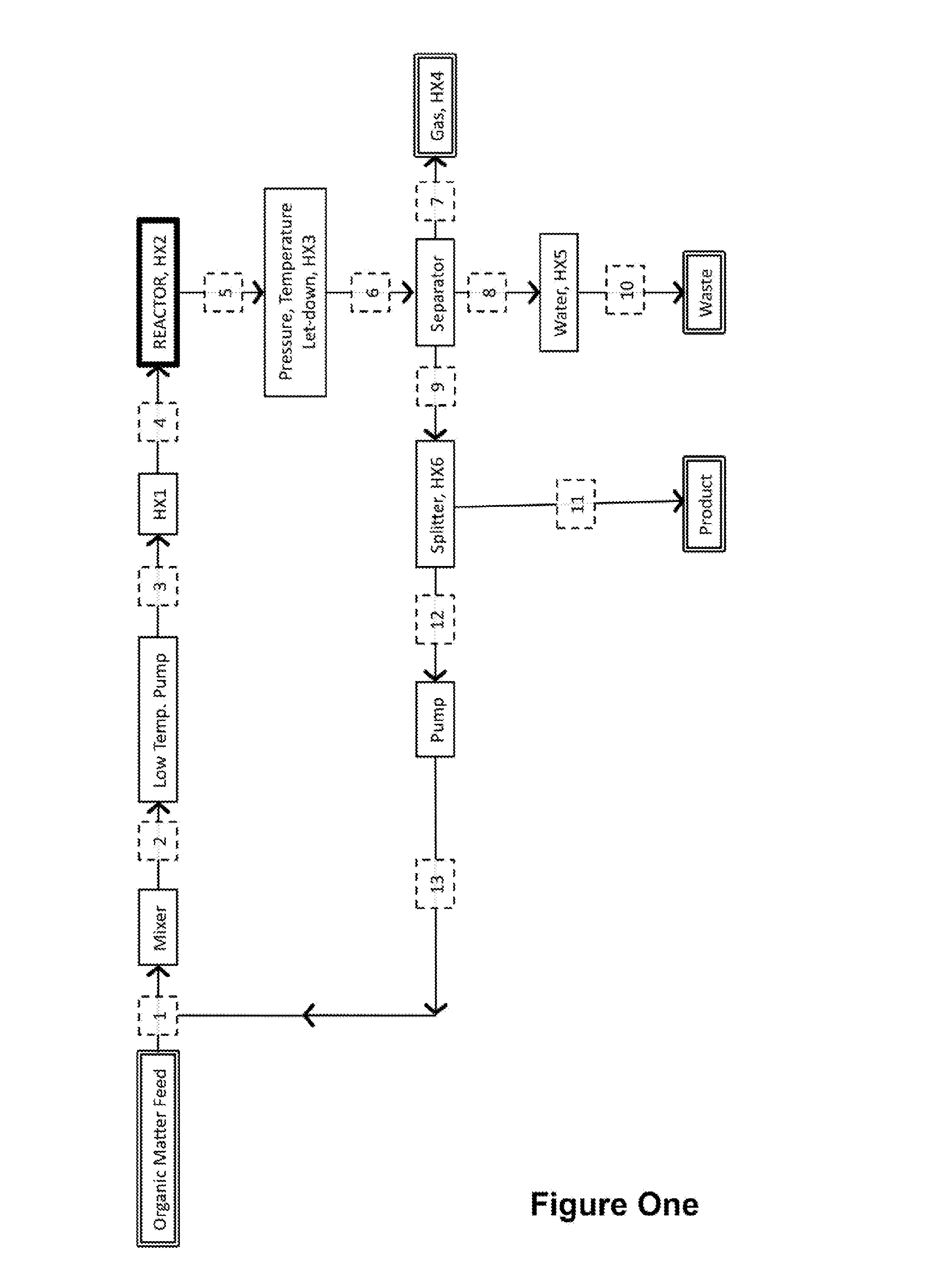

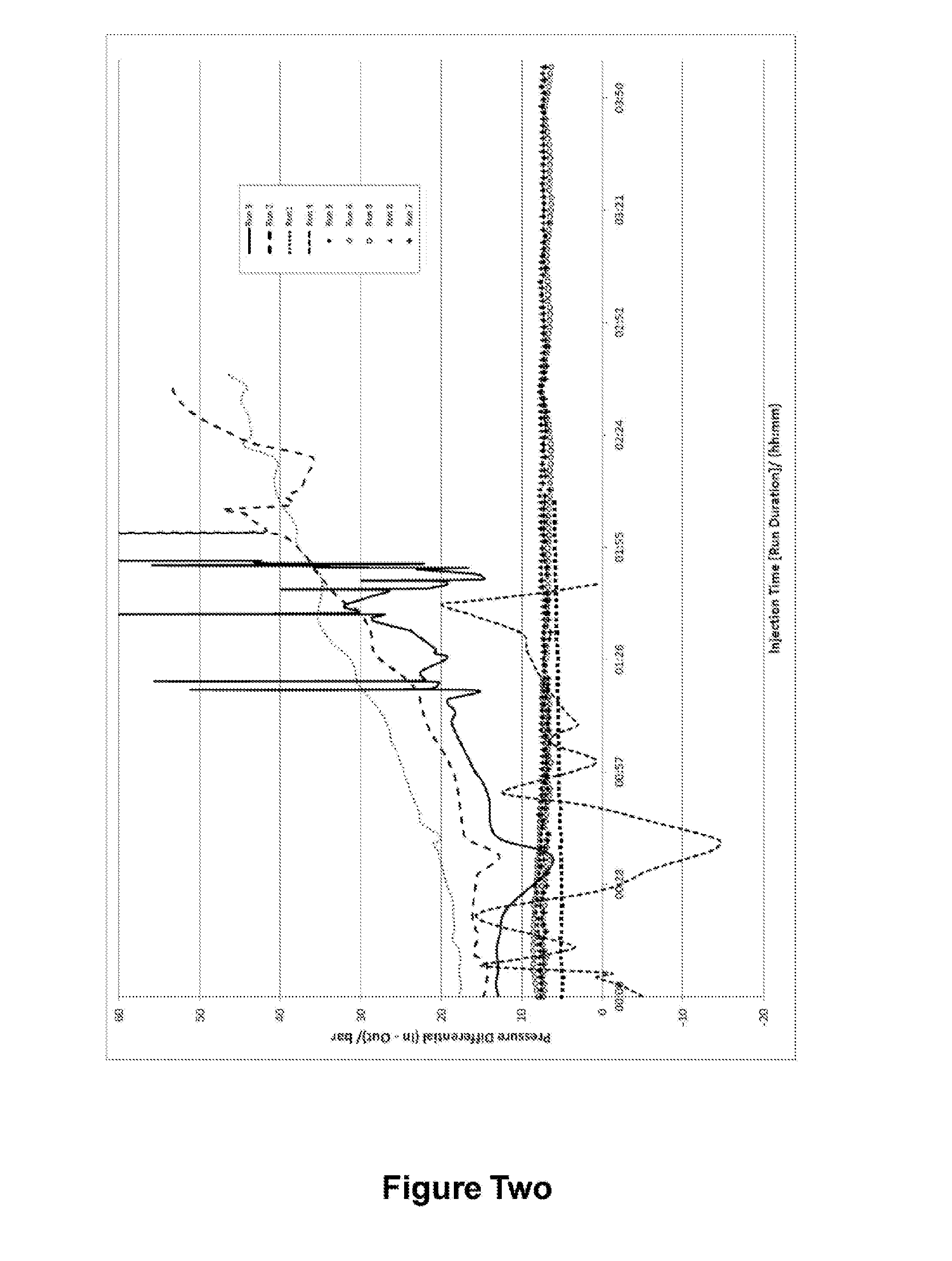

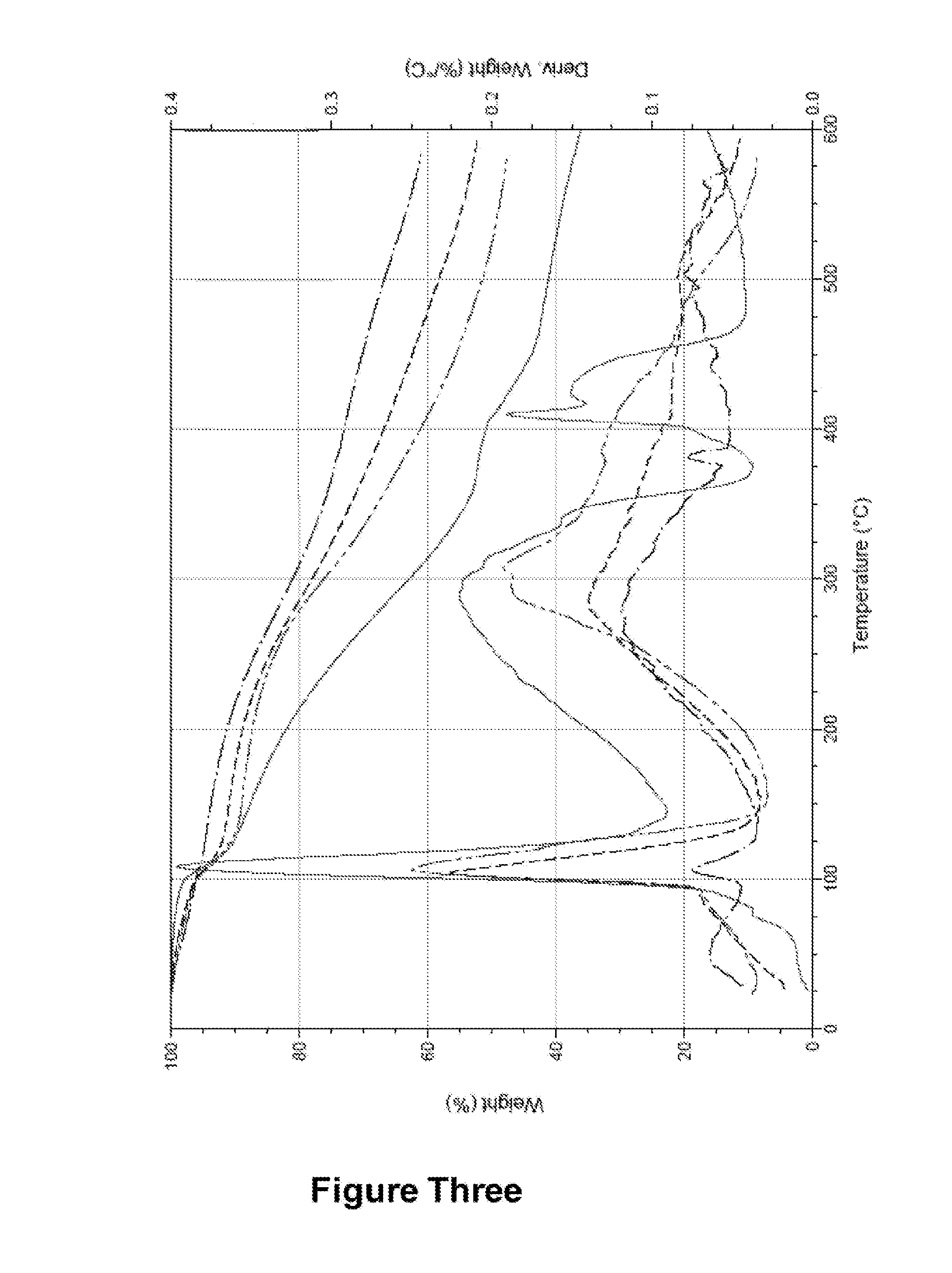

Biorefining Method

ActiveUS20160114307A1Reduce problem sizeReduces development of pressureProcess control/regulationOther chemical processesBio productsBiorefining

The present invention relates generally to the generation of bio-products from organic matter feedstocks. More specifically, the present invention relates to improved methods for the hydrothermal / thermochemical conversion of lignocellulosic and / or fossilised organic feedstocks into biofuels (e.g. bio-oils) and / or chemical products (e.g. platform chemicals).

Owner:LICELLA PTY LTD +2

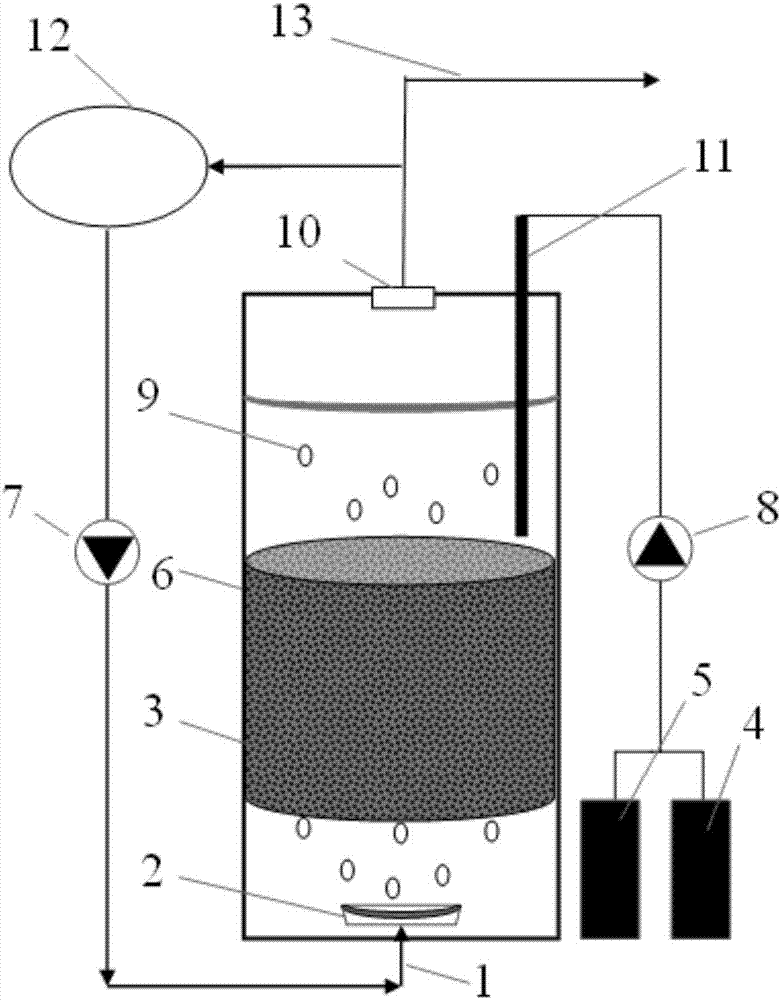

Method for improving anaerobic fermentation effect of synthesis gas by using carbon material

ActiveCN107130003APromote growthTo promote metabolismWaste based fuelFermentationStart timeMicrobial agent

The invention relates to a method for improving anaerobic fermentation of synthesis gas by using a carbon material. The method comprises the following steps: (1) adding the carbon material into an anaerobic reactor which takes anaerobic sludge as a starting microbial agent; (2) carrying out anaerobic fermentation in a way of aeration by taking the synthesis gas as a carbon source. Compared with the prior art, the method takes the carbon material as an additive, thus shortening the starting time of the anaerobic fermentation of the synthesis gas and obviously increasing a carbonic oxide degradation rate and a methane production rate. The method is simple to operate, and a device is simple. The synthesis gas and the carbon material are respectively used as the carbon source and the additive in a microbial anaerobic fermentation process, so that the biological refining and high-value utilization of waste can be realized.

Owner:TONGJI UNIV

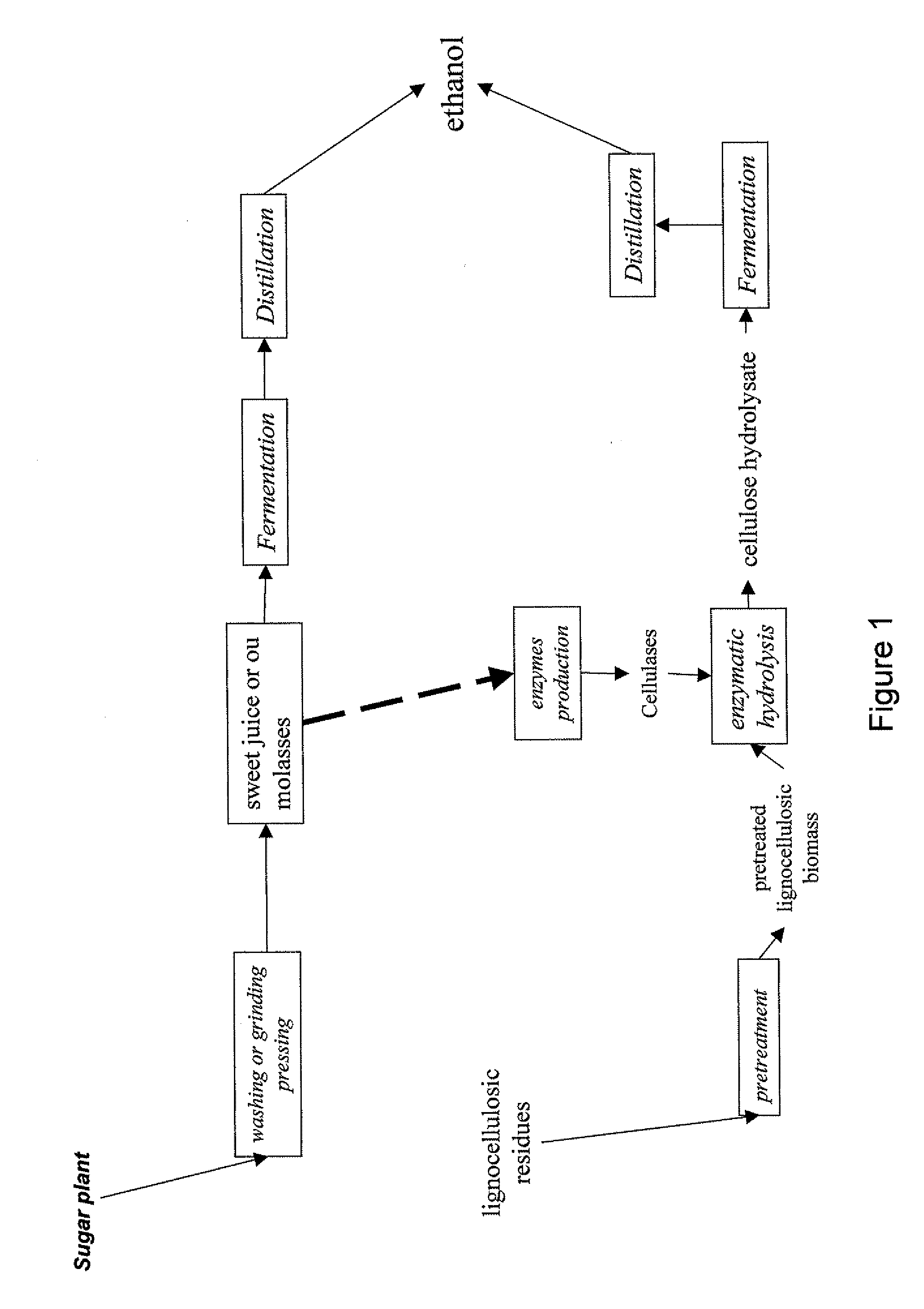

Method of producing alcohol in the biorefinery context

The present invention describes a method of producing alcohol from pretreated lignocellulosic biomass wherein the enzymatic hydrolysis stage is carried out with cellulolytic and / or hemicellulolytic enzymes produced using at least one effluent from another ethanol production process using a sugar plant as the feedstock. This method can be integrated in a method of producing alcohol from cellulosic or lignocellulosic materials, referred to as second-generation method, comprising the following stages:1) chemical and / or physical pretreatment of a cellulosic or lignocellulosic substrate,2) enzymatic hydrolysis of the pretreated substrate using cellulolytic and / or hemicellulolytic enzymes,3) alcoholic fermentation by a suitable alcohol-producing microorganism of the hydrolysate from stage (2) until a fermentation must is obtained, and separation of the alcohol-producing microorganism used in stage (3), separation / purification of the alcohol.

Owner:INST FR DU PETROLE

Preparing method and application of molasses colloid composite alginate immobilizing carrier

ActiveCN106222160AImprove physical strengthIncrease added valueOn/in organic carrierOn/in inorganic carrierFreeze-dryingColloid

The invention discloses a preparing method of a molasses colloid composite alginate immobilizing carrier and application of the carrier in immobilizing microorganism cells and enzymes. According to the preparing method, the molasses colloid composite alginate immobilizing carrier is obtained through the steps of colloid extraction, colloid vacuum freeze drying, colloid esterification, esterified colloid vacuum freeze drying, esterified colloid dry powder smashing, immobilizing carrier preparing and the like. The physical strength of the molasses colloid composite alginate immobilizing carrier is improved by 30-60%, and the colloid substance abandoned in the molasses utilization process is utilized. By implementing the preparing method, comprehensive utilization of inferior biomass molasses is promoted, and a technical base is provided for molasses biorefining.

Owner:NANJING UNIV OF TECH

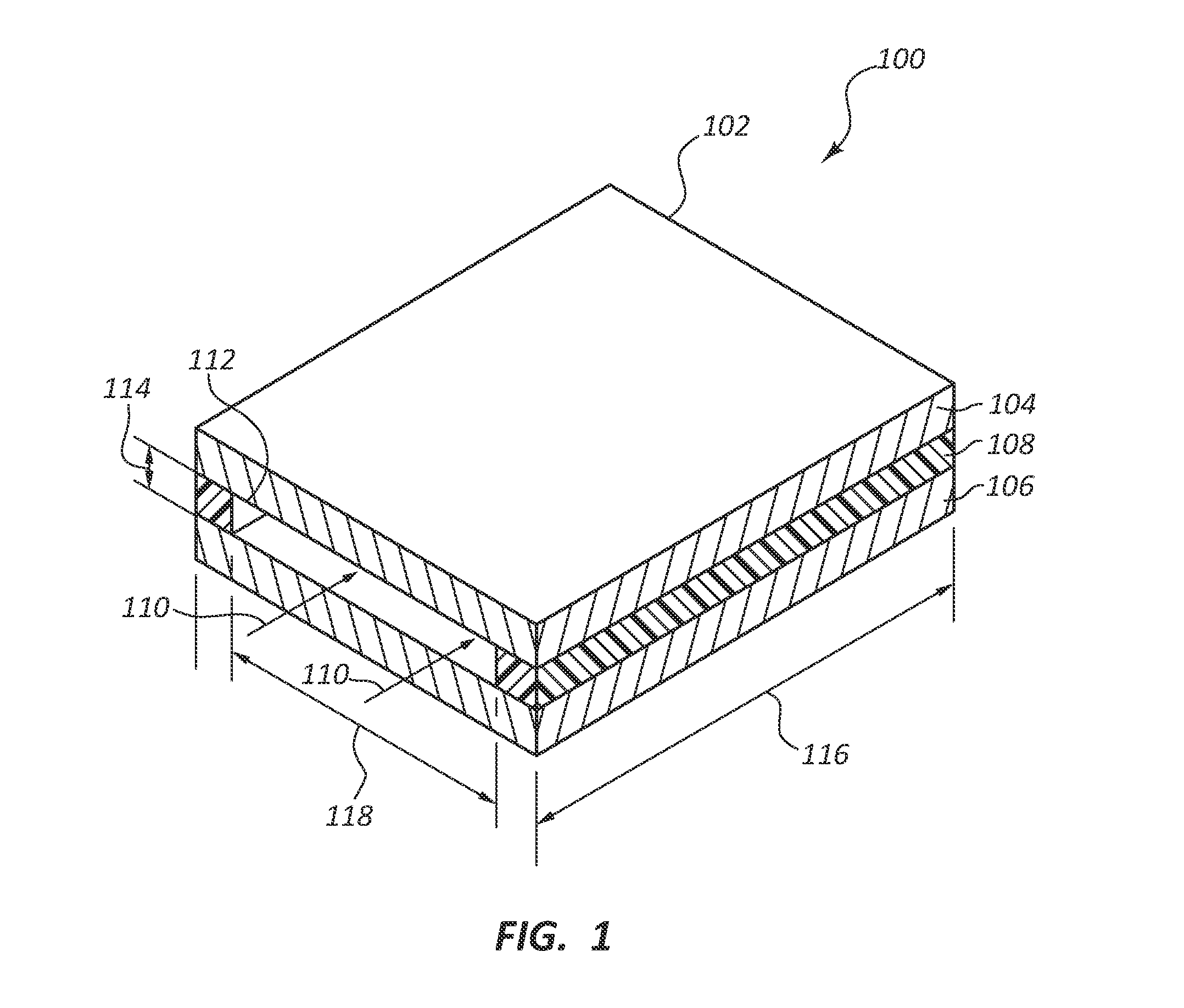

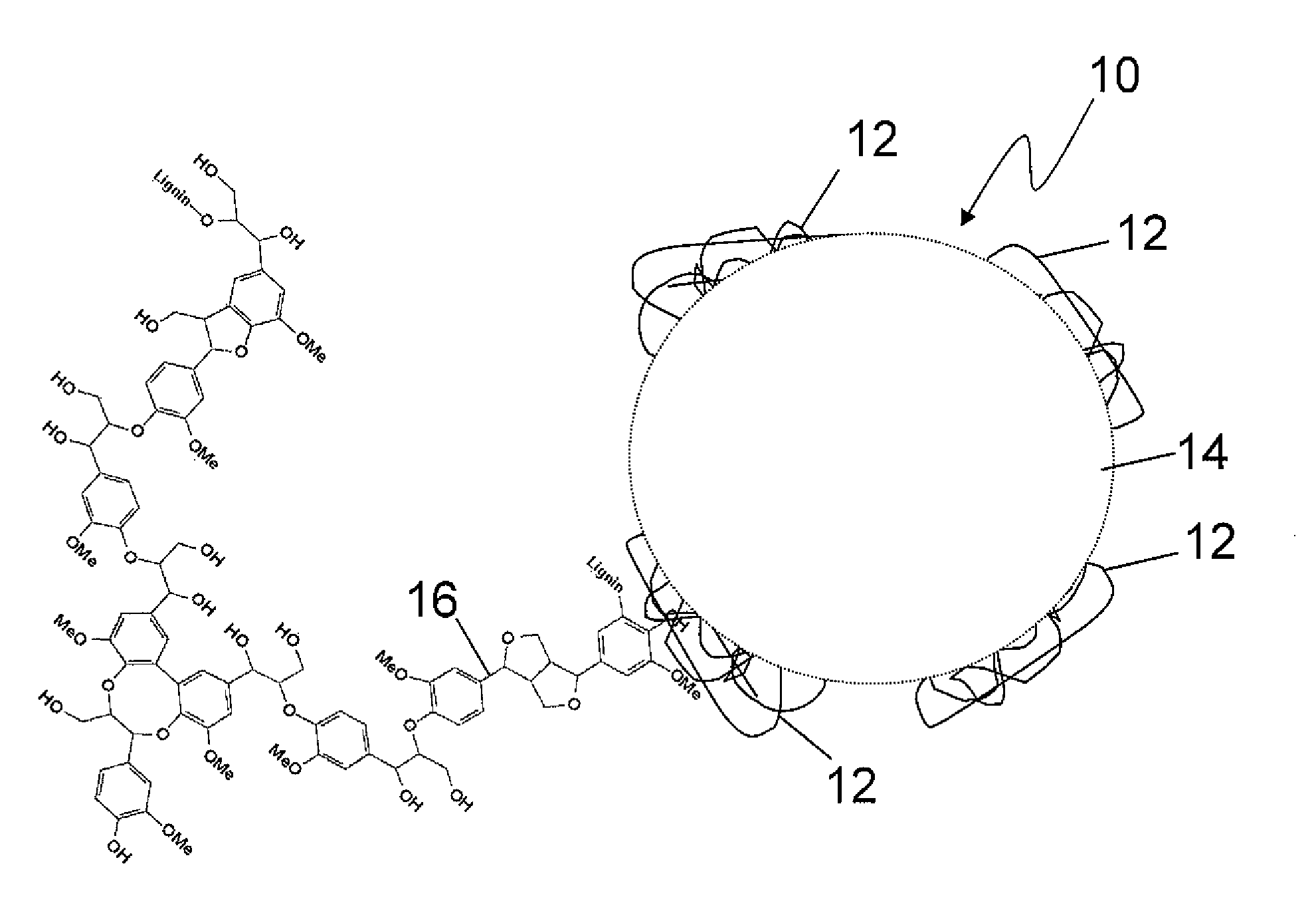

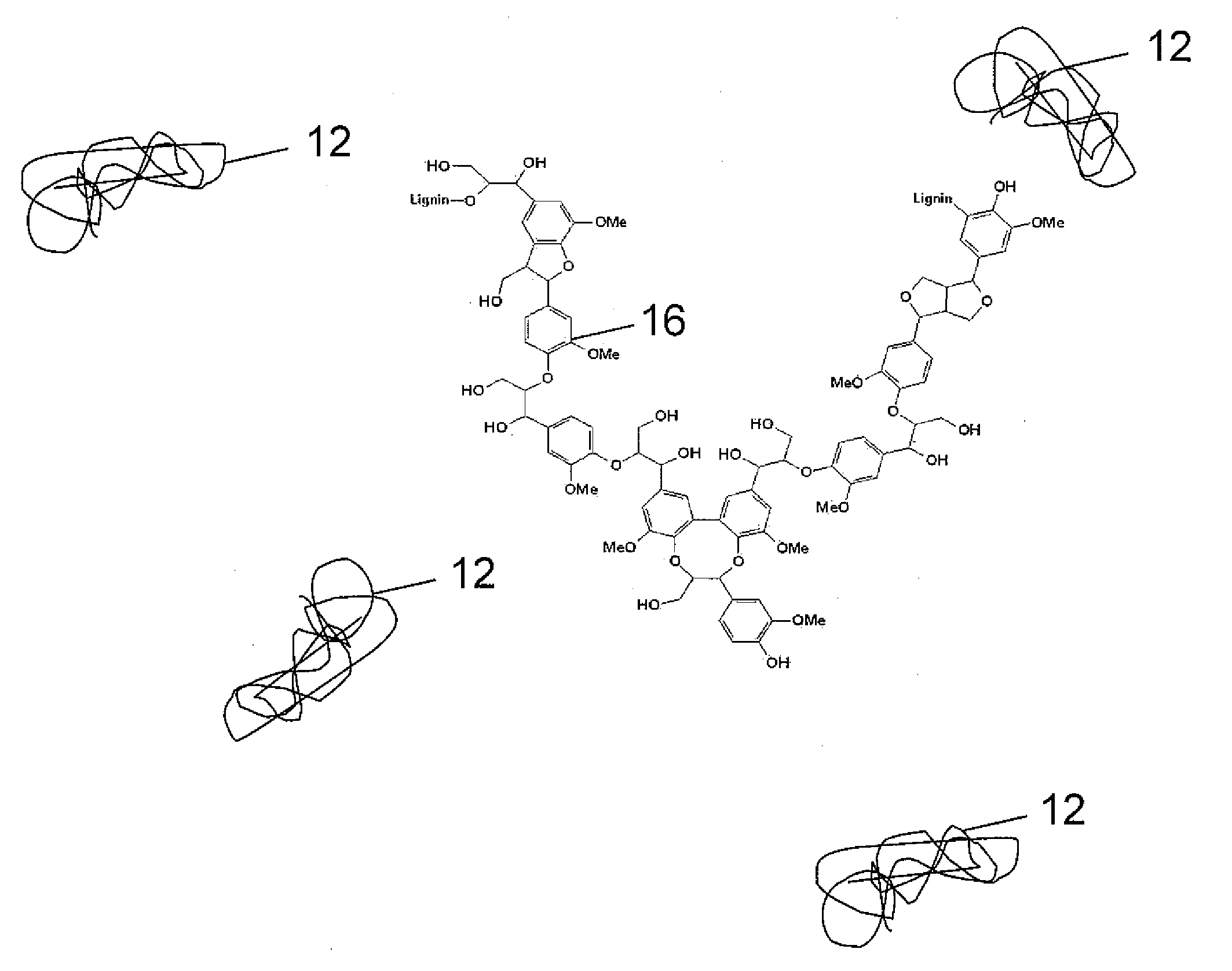

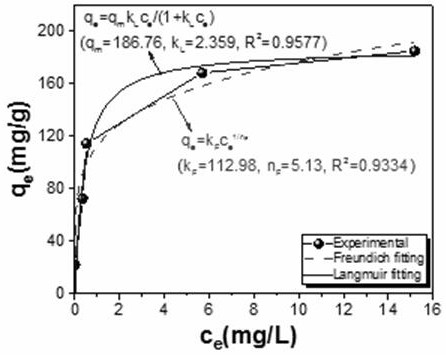

Lignin sorbent, lignin removal unit, biorefinery, process for removing lignin, process for binding lignin and renewable material

InactiveUS8728320B2Reduce enzyme operating cost and production costSolve the high cost of enzymesIon-exchanger regenerationApparatus sterilizationSorbentRenewable materials

This invention relates to a lignin sorbent, a lignin removal unit, a biorefinery, a process for removing lignin, a process for binding lignin, and a renewable material. The lignin sorbent includes a substrate, and a lignin binding material dispersed with respect to the substrate. The lignin binding process includes the step of adding a lignin binding material to an input stream, and the step of converting the input stream into a renewable material.

Owner:BP CORP NORTH AMERICA INC

Lignin sorbent, lignin removal unit, biorefinery, process for removing lignin, process for binding lignin and renewable material

InactiveUS20100331560A1Reduce usage enzyme costReduce operating costsBioreactor/fermenter combinationsBiological substance pretreatmentsSorbentRenewable materials

This invention relates to a lignin sorbent, a lignin removal unit, a biorefinery, a process for removing lignin, a process for binding lignin, and a renewable material. The lignin sorbent includes a substrate, and a lignin binding material dispersed with respect to the substrate. The lignin binding process includes the step of adding a lignin binding material to an input stream, and the step of converting the input stream into a renewable material.

Owner:BP CORP NORTH AMERICA INC

Alcohol sulfite biorefinery process

A biorefinery process to fractionate lignocellulosic materials into cellulose, hemicelluloses and lignin using a pretreatment with mixture of alcohol, sulfur dioxide and water. Further treatment with enzymes, micro-organisms, and optionally bisulfite ion, are used to convert intermediate products to alcohol and lignin derivatives.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Method for preparing porous biochar through waste-free biological refining and application

ActiveCN112221465AHigh feasibilityAchieve governanceOther chemical processesWater contaminantsFiberPtru catalyst

The invention discloses a method for preparing porous biochar through waste-free biological refining and an application. The method comprises the following steps: extracting bagasse pith through alkali liquor, filtering an extracting solution, and washing and drying filter residues; weighing the dried filter residues, and carrying out pre-carbonization in a nitrogen atmosphere; and mixing the pre-carbonized material with alkali, and performing activating in a nitrogen atmosphere to obtain the porous biochar. The biochar is used for purifying simulated chromium wastewater, the adsorption quantity of hexavalent chromium ions reaches up to 185.07 mg / g, the chromium-containing waste biochar is converted into a Cu-Cr / BPR-BC catalyst for further hydrogenation of furfural, and difurfuryl ether isselectively generated to reach 99.99%; According to the method, a waste-free biological refining mode is obtained, and industrial application of the bagasse pith or other similar wood fiber biomass alkali pre-extraction processes is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Biorefining processes and apparatus for separating cellulose hemicellulose, and lignin from biomass

The disclosed invention is a modification of the AVAP® technology, employing CO2 (or derivatives thereof) rather than SO2 in the cooking liquor. In some variations, the invention provides a process for fractionating cellulosic biomass into cellulose, hemicellulose, and lignin, comprising: fractionating the feedstock in the presence of a solvent for lignin, carbon dioxide, and water, to produce a liquor containing hemicellulose, cellulose-rich solids, and lignin; substantially removing the cellulose-rich solids from the liquor; hydrolyzing the hemicellulose contained in the liquor, to produce hemicellulosic monomers; hydrolyzing at least some of the cellulose-rich solids to produce glucose (or recovering the cellulose-rich solids as a cellulose product); recovering the hemicellulosic monomers to produce fermentable sugars; and recovering the lignin which may be in the form of a lignocarbonate.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Method, equipment and applications for fast complete dissolution and hydrolysis of lignocellulosic biomass

ActiveUS8268126B2Quickly and completely dissolve biomassOther chemical processesLiquid hydrocarbon mixture productionCelluloseHydrolysate

The invention herein discloses a method and its equipment for fast and complete dissolution and hydrolysis of lignocellulosic biomass. Lignocellulosic biomass is placed in a dilute alkaline solution and then rapidly heated to a temperature between 329˜367° C. to achieve complete dissolution of the lignocellulosic biomass as biomass solution in 0.7˜2 s. The biomass solution is further hydrolyzed rapidly to hydrolysates at homogeneous conditions. The solubilized biomass solution is easy to rapidly hydrolyze into sugars to produce bio-fuels and other value-added products, and to rapidly quench to produce micron particles in the continuous flow equipment at high pressures and high temperatures. The invention herein provides a simple and low-cost method to quickly dissolve and hydrolyze biomass with great potential for a novel biorefinery.

Owner:FANG ZHEN +1

Biorefinery process for extraction, separation, and recovery of fermentable saccharides, other useful compounds, and yield of improved lignocellulosic material from plant biomass

ActiveUS8618280B2Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com