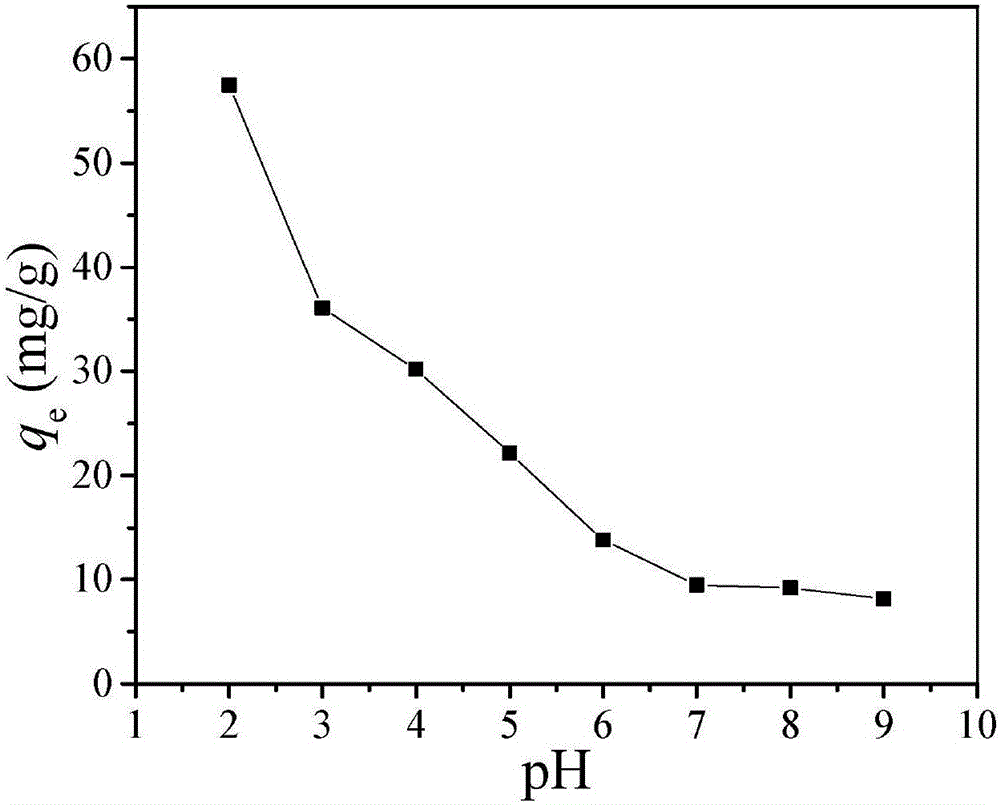

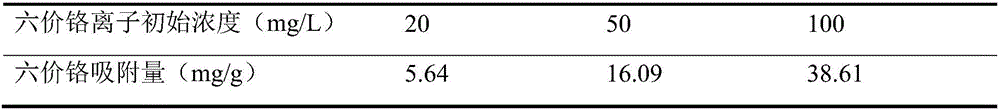

Method for removing hexavalent chrome in wastewater by using sodium humate/biochar magnetic composite material

A magnetic composite material, sodium humate technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., to achieve the effect of wide source of raw materials, low cost of treatment process, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of method utilizing sodium humate / biochar magnetic composite material of the present invention to remove hexavalent chromium in waste water comprises the following steps:

[0031] 1. Preparation of Sodium Humate / Biochar Magnetic Composite

[0032] The peeled stems of ramie were dried at room temperature, pulverized by a pulverizer and then ground, passed through a 100-mesh sieve, and a sodium humate solution with a mass concentration range of 5 g / L was prepared, and filtered after ultrasonication for 20 minutes to remove insoluble matter; 50 g of ramie stems After soaking the powder in 1000mL sodium humate solution with a mass concentration range of 5g / L for 1-5h, dry it at 80°C, put it into a tube furnace for pyrolysis, feed nitrogen at a flow rate of 100mL / min, and Raise the temperature to 500°C at a speed of 1 / min, keep pyrolysis for 2 hours after the temperature rises to 500°C, and cool the obtained product to room temperature under the condition of continuin...

Embodiment 2

[0037] A kind of method utilizing sodium humate / biochar magnetic composite material of the present invention to remove hexavalent chromium in waste water comprises the following steps:

[0038] 1. Preparation of Sodium Humate / Biochar Magnetic Composite

[0039] This step is the same as Step 1 of Example 1.

[0040] 2. Treatment of hexavalent chromium wastewater

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com