Treatment technology of ore dressing alkaline tail water

A technology for treating process and tail water, which is applied in the field of processing alkaline tail water of ore dressing, can solve problems such as difficult operation, high treatment cost, and low safety, and achieve low requirements for operation details, simple process flow, and low process cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

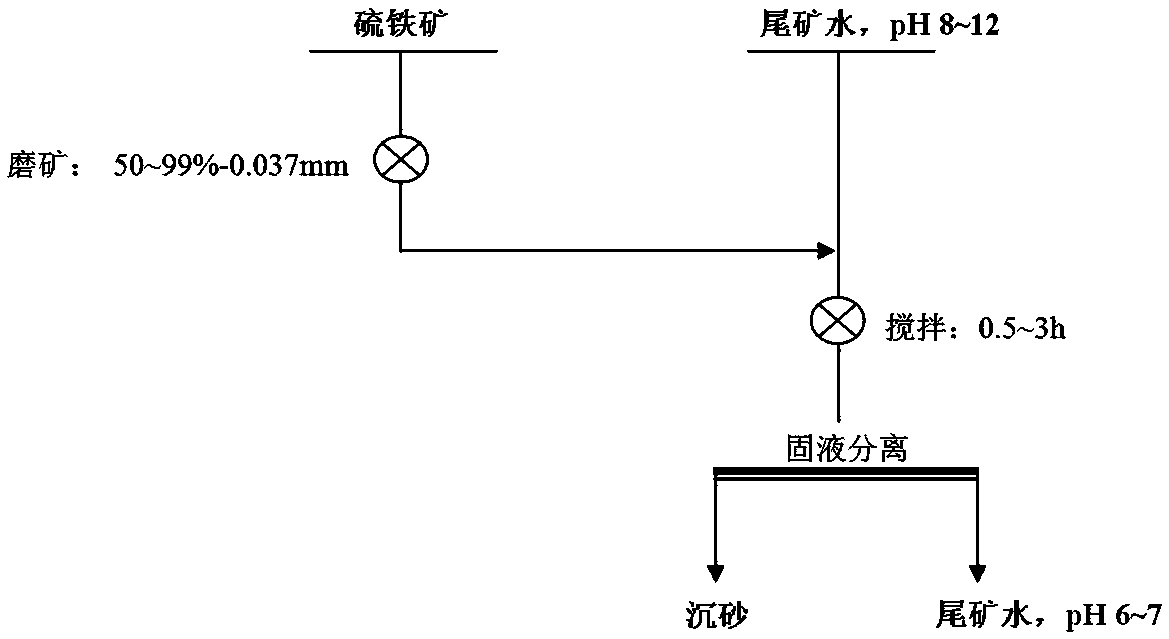

Method used

Image

Examples

Embodiment 1

[0030] The pyrite used is the sulfur concentrate of a concentrator containing 43% S, with a fineness of -0.037mm accounting for 33.84%; the alkaline water to be treated is artificially prepared lime water, with 15g of analytically pure CaO in 2L of water, and a pH value of 12 .

[0031] The above-mentioned alkaline water is passed through the following process steps:

[0032] (1) Grinding 500g of pyrite, the fineness of the grinding product is -0.037mm accounting for 99%, the grinding water is prepared lime water, and the weight ratio of water to mineral is 1:1;

[0033] (2) Pour the finely ground pyrite slurry into a 5L mechanical mixing tank, add the prepared lime water, and the weight ratio of water to mineral is 4:1;

[0034] (3) Stir the pulp, and the pH value of lime water decreases with the increase of stirring time;

[0035] Technical indicators: Lime water with a pH value of 12 is stirred and neutralized by pyrite for 1 hour, and the pH value drops to 7.

Embodiment 2

[0037] The pyrite used is the sulfur concentrate of a concentrator containing 43% S, with a fineness of -0.037mm accounting for 33.84%; the alkaline water to be treated is artificially prepared lime water, with 15g of analytically pure CaO in 2L of water, and a pH value of 12 .

[0038] The above-mentioned alkaline water is passed through the following process steps:

[0039] (1) Grinding 500g of pyrite, the fineness of the grinding product is -0.037mm accounts for 70%, the grinding water is prepared lime water, and the weight ratio of water and mineral is 1:1;

[0040] (2) Pour the finely ground pyrite slurry into a 5L mechanical mixing tank, add the prepared lime water, and the weight ratio of water to mineral is 4:1;

[0041] (3) Stir the pulp, and the pH value of lime water decreases with the increase of stirring time;

[0042] Technical indicators: Lime water with a pH value of 12 is stirred and neutralized by pyrite for 1 hour and 20 minutes, and the pH value drops to ...

Embodiment 3

[0044]The pyrite used is the sulfur concentrate of a concentrator containing 30% S, with a fineness of -0.037mm accounting for 33.84%; the alkaline water to be treated is artificially prepared lime water, and 7.5g of analytically pure CaO is added to 2L of water. pH 9.

[0045] The above-mentioned alkaline water is passed through the following process steps:

[0046] (1) Grinding 500g of pyrite, the fineness of the grinding product is -0.037mm accounts for 70%, the grinding water is prepared lime water, and the weight ratio of water and mineral is 1:1;

[0047] (2) Pour the finely ground pyrite slurry into a 5L mechanical mixing tank, add the prepared lime water, and the weight ratio of water to mineral is 4:1;

[0048] (3) Stir the pulp, and the pH value of lime water decreases with the increase of stirring time;

[0049] Technical indicators: Lime water with a pH value of 12 is stirred and neutralized by pyrite for 40 minutes, and the pH value drops to 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com