Method for in-situ preparation of Cr3C2 and/or Mo2C powder by using molten salt

A technology for in-situ preparation and molten salt, applied in the field of preparing Cr3C2 and/or Mo2C powder, can solve the problems of high synthesis temperature, difficult control of morphology and size, complicated preparation process and equipment, etc. The effect of low mass production, raw material cost and process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

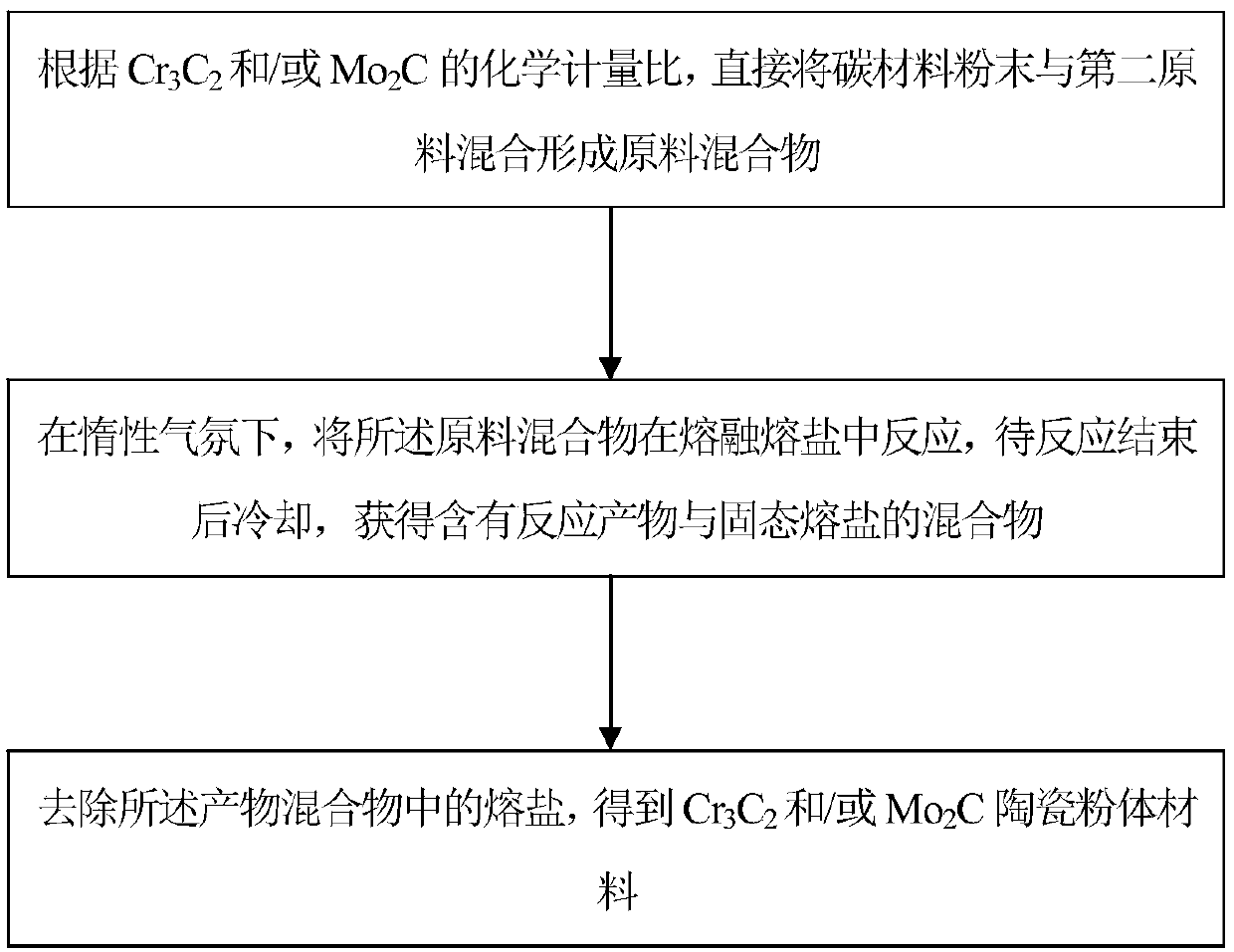

Method used

Image

Examples

Embodiment 1

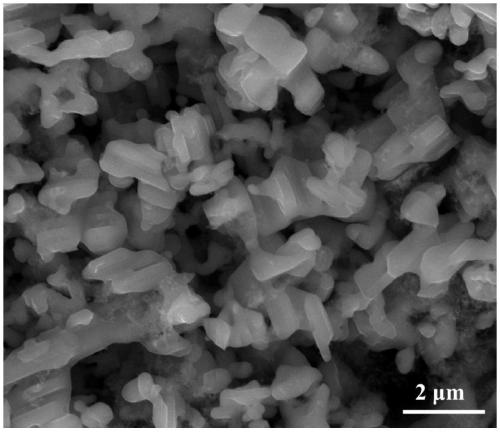

[0049] In this embodiment, weigh 20 units of LiCl-KCl eutectic salt, and mix with 1.3 units of Cr powder (325 mesh), 0.34 units of NH 4 Cl and 0.2 unit weight of graphite (average particle size 1 μm) were mixed, and the mixture was placed in a corundum crucible. The above crucible was placed in a stainless steel reactor, sealed and protected by Ar gas. Use a temperature controller to raise the temperature to 920°C at a rate of 8°C / min, keep at this temperature for 3 hours, then turn off the power and cool down to room temperature with the furnace. The obtained product is taken out, soaked and rinsed with deionized water to remove residual molten salt, and then dried at 80°C to obtain Cr 3 C 2 , Cr in the resulting product 3 C 2 The particle size of the powder is 1-2 μm, and the purity is 98wt%.

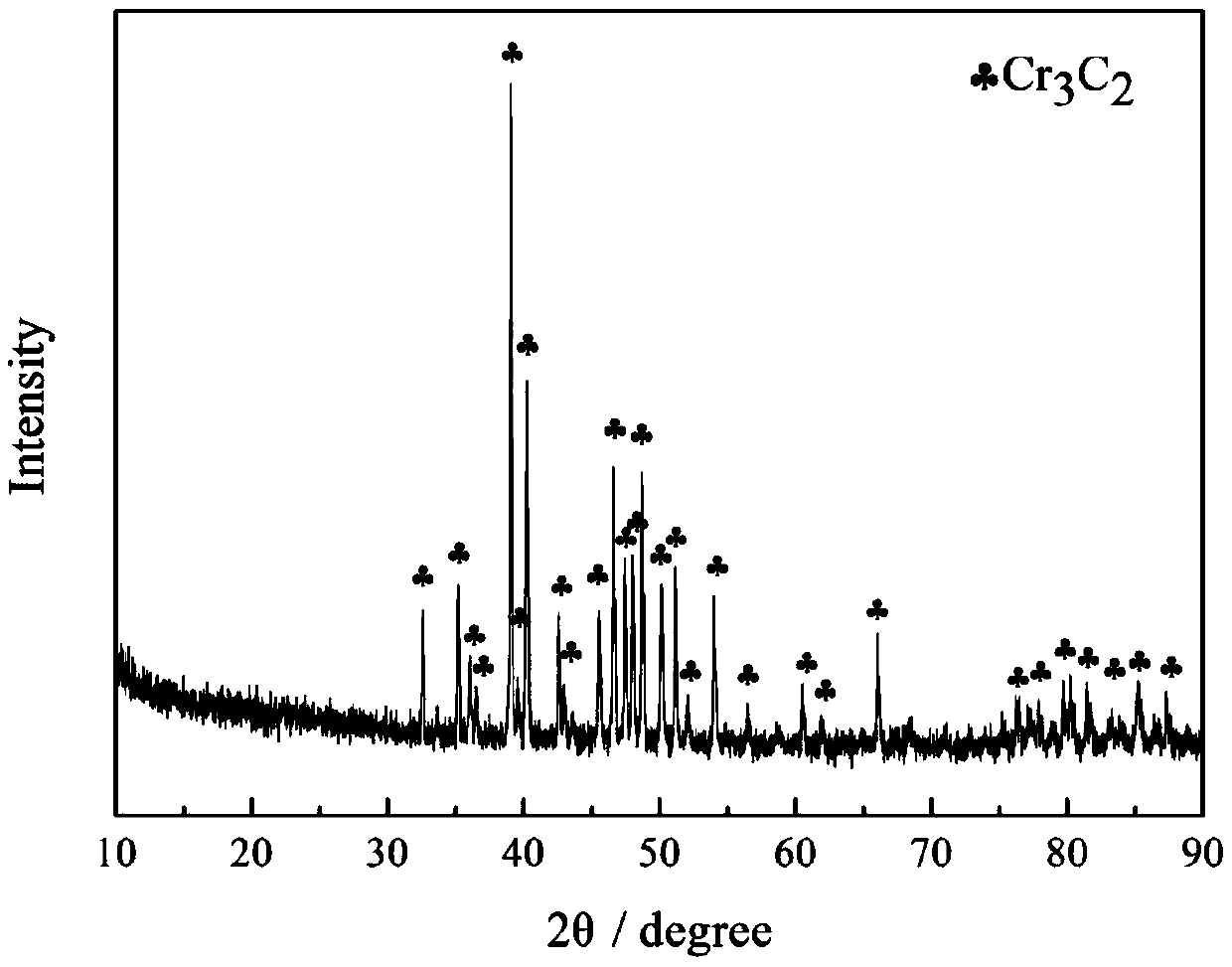

[0050] As detected by XRD figure 2 As shown, the target product is Cr 3 C 2 . The obtained target product is characterized by SEM, and its SEM is as follows image 3 shown....

Embodiment 2

[0052] In the present embodiment, weigh 30 unit weights of NaCl-KCl eutectic salt, and mix with 2.6 unit weights of Cr powder (325 mesh), 2.1 unit weights of CrCl 3 , 0.4 unit weight of carbon black (average particle size 200nm) was mixed, and the mixture was placed in a corundum crucible. The above crucible was placed in a stainless steel reactor, sealed and protected by Ar gas. Use a temperature controller to raise the temperature to 860°C at a rate of 8°C / min, keep it at this temperature for 5 hours, then turn off the power and cool down to room temperature with the furnace. The obtained product is taken out, soaked and rinsed with deionized water to remove residual molten salt, and then dried at 120°C to obtain Cr 3 C 2 , Cr in the resulting product 3 C 2 The particle size of the powder is 300-500nm, and the purity is 99wt%.

Embodiment 3

[0054] In the present embodiment, weigh 40 unit weight of KF-KCl eutectic salt, and mix with 2.6 unit weight of Cr powder (325 mesh), 1.08 unit weight of Cr powder 2 o 3 , 0.25 unit weight flake graphite (average particle size 500nm) was mixed, and the mixture was placed in a corundum crucible. The above crucible was placed in a stainless steel reactor, sealed and protected by Ar gas. Use a temperature controller to raise the temperature to 980°C at a rate of 10°C / min, keep it at this temperature for 2 hours, then turn off the power and cool down to room temperature with the furnace. The obtained product is taken out, soaked and rinsed with deionized water to remove residual molten salt, and then dried at 80°C to obtain Cr 3 C 2 , Cr in the resulting product 3 C 2 The particle size of the powder is 1-2 μm, and the purity is 99.5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com