Recycling treatment method of oil-bearing sludge

A technology for sludge treatment and oil sludge, which is applied in pyrolysis treatment of sludge, cracking, catalytic cracking, etc. It can solve the problems of low quality of recovered oil and poor separation effect of oil and mud and sand, and achieve low production volume and resource utilization. less likely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

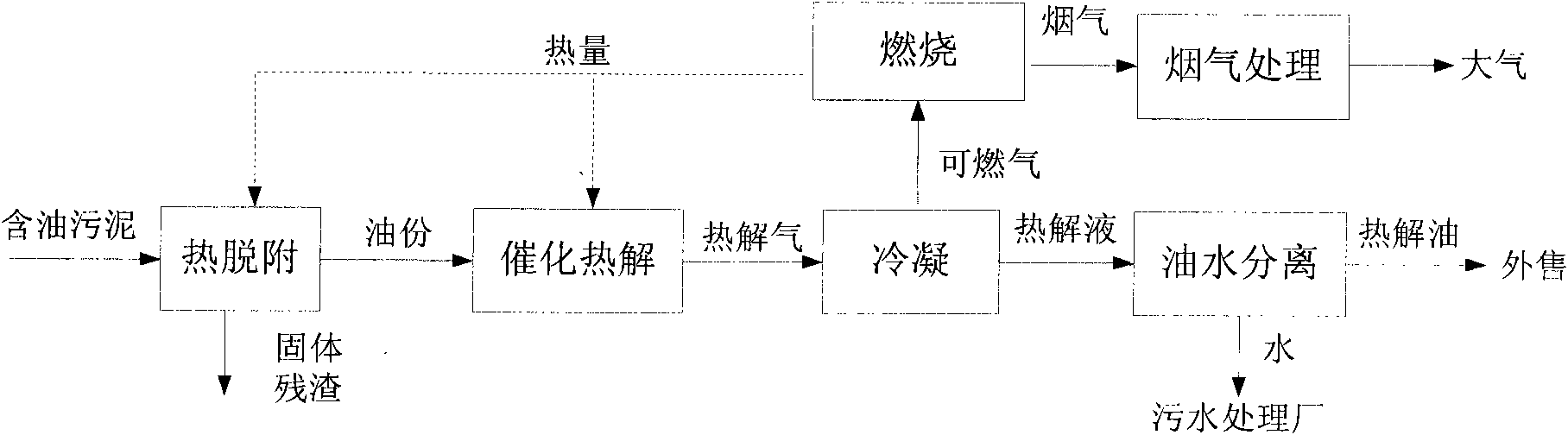

[0033] Embodiment 1, process oily sludge

[0034] The oily sludge from an oilfield is selected, and the mass ratio of mud, sand, oil and water is: 79.69:18.61:1.70.

[0035] The oily sludge is thermally desorbed at a temperature of 500°C and a residence time of 45 minutes; the precipitated pyrolysis gas enters the catalytic pyrolysis device, and is catalytically pyrolyzed with fly ash as a catalyst at a temperature of 450°C and a residence time of 10 seconds. The precipitated gas is condensed to obtain pyrolysis liquid and combustible gas; the pyrolysis liquid is separated from oil and water to obtain recovered oil; the pyrolysis gas is used as fuel, and the combustion provides energy for thermal desorption and catalytic pyrolysis of oil sludge. As a result of the reaction, 0.13 tons of recovered oil, 0.02 tons of combustible gas and 0.85 tons of solid residue can be produced for each ton of oily sludge treated, with a reduction rate of 15%; the ratio of gasoline, diesel and h...

Embodiment 2

[0036] Embodiment 2, processing oily sludge

[0037] The oily sludge from an oilfield is selected, and the mass ratio of mud, sand, oil and water is: 79.69:18.61:1.70.

[0038] The oily sludge is thermally desorbed at a temperature of 550°C and a residence time of 30 minutes; the precipitated pyrolysis gas enters the catalytic pyrolysis device, and is catalytically pyrolyzed with fly ash as a catalyst at a temperature of 500°C and a residence time of 5 seconds. The precipitated gas is condensed to obtain pyrolysis liquid and combustible gas; the pyrolysis liquid is separated from oil and water to obtain recovered oil; the pyrolysis gas is used as fuel, and the combustion provides energy for thermal desorption and catalytic pyrolysis of oil sludge. As a result of the reaction, 0.14 tons of recovered oil, 0.032 tons of combustible gas and 0.811 tons of solid residue can be produced for every ton of oily sludge treated, with a reduction rate of 18.9%; the ratio of gasoline, diesel ...

Embodiment 3

[0039] Embodiment 3, processing oily sludge

[0040] The oily sludge from an oilfield is selected, and the mass ratio of mud, sand, oil and water is: 79.69:18.61:1.70.

[0041] The oily sludge is thermally desorbed at a temperature of 550°C and a residence time of 30 minutes; the precipitated pyrolysis gas enters the catalytic pyrolysis device, and is catalytically pyrolyzed at a temperature of 550°C and a residence time of 2s with fly ash as a catalyst. The precipitated gas is condensed to obtain pyrolysis liquid and combustible gas; the pyrolysis liquid is separated from oil and water to obtain recovered oil; the pyrolysis gas is used as fuel, and the combustion provides energy for thermal desorption and catalytic pyrolysis of oil sludge. As a result of the reaction, 0.14 tons of recovered oil, 0.03 tons of combustible gas and 0.83 tons of solid residue can be produced for each ton of oily sludge treated, with a reduction rate of 17%; the ratio of gasoline, diesel and heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com